Research and Experimental Verification of the Static and Dynamic Pressure Characteristics of Aerospace Porous Media Gas Bearings

Abstract

1. Introduction

2. Model and Verification of the Porous Medium Gas Bearing

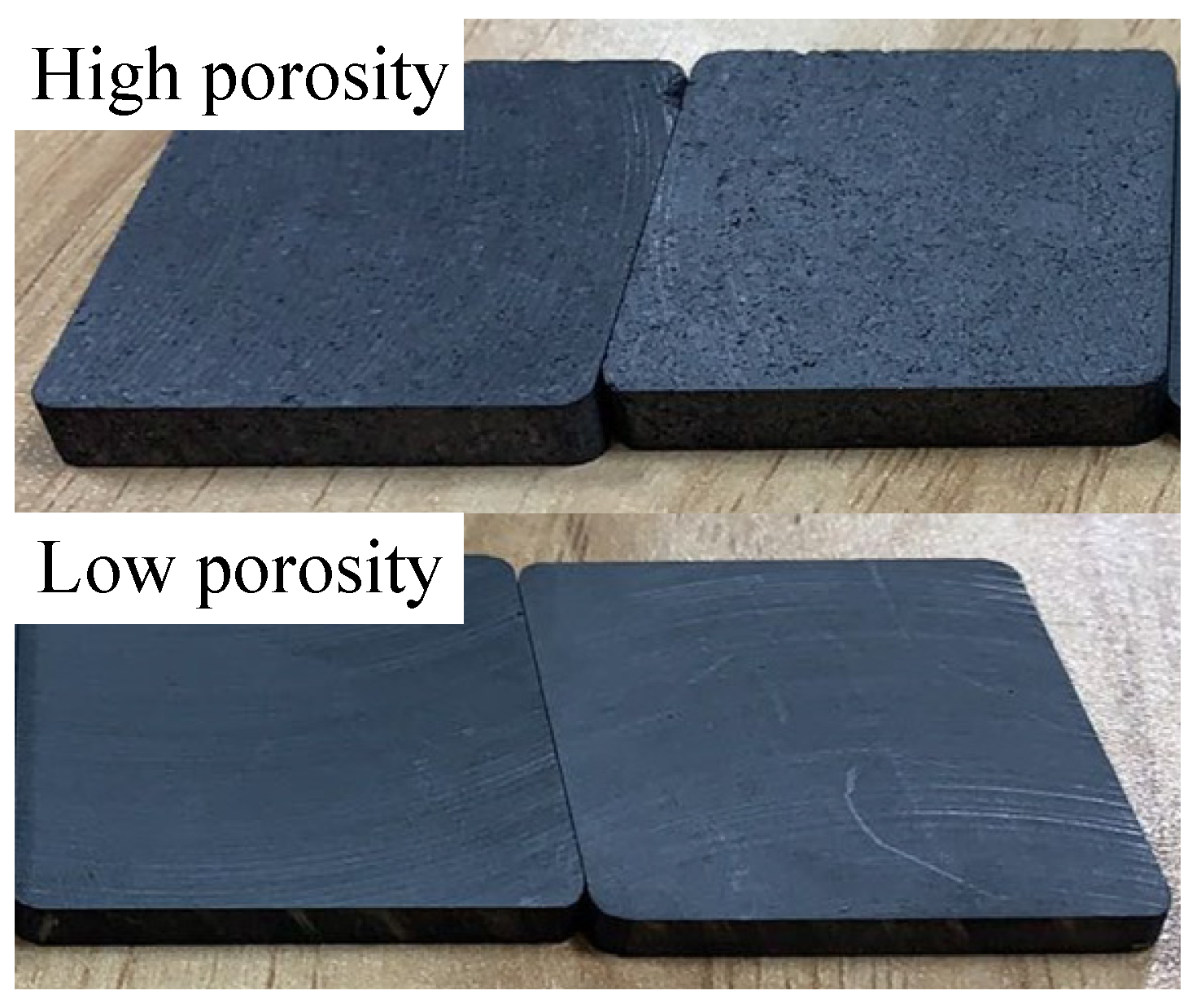

2.1. Porous Medium Materials

2.1.1. Porosity of Porous Medium Materials

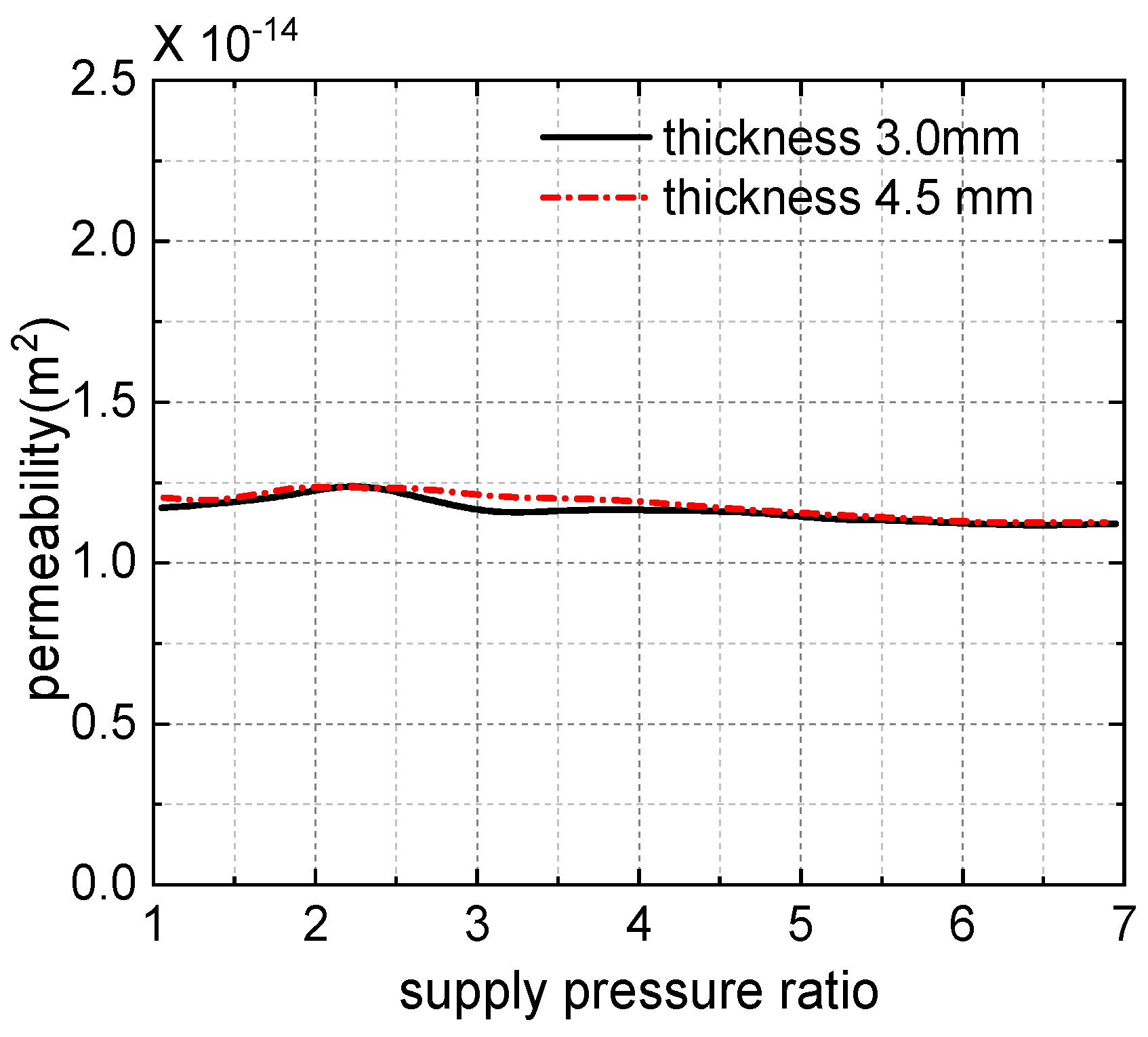

2.1.2. Permeability of Porous Media Materials

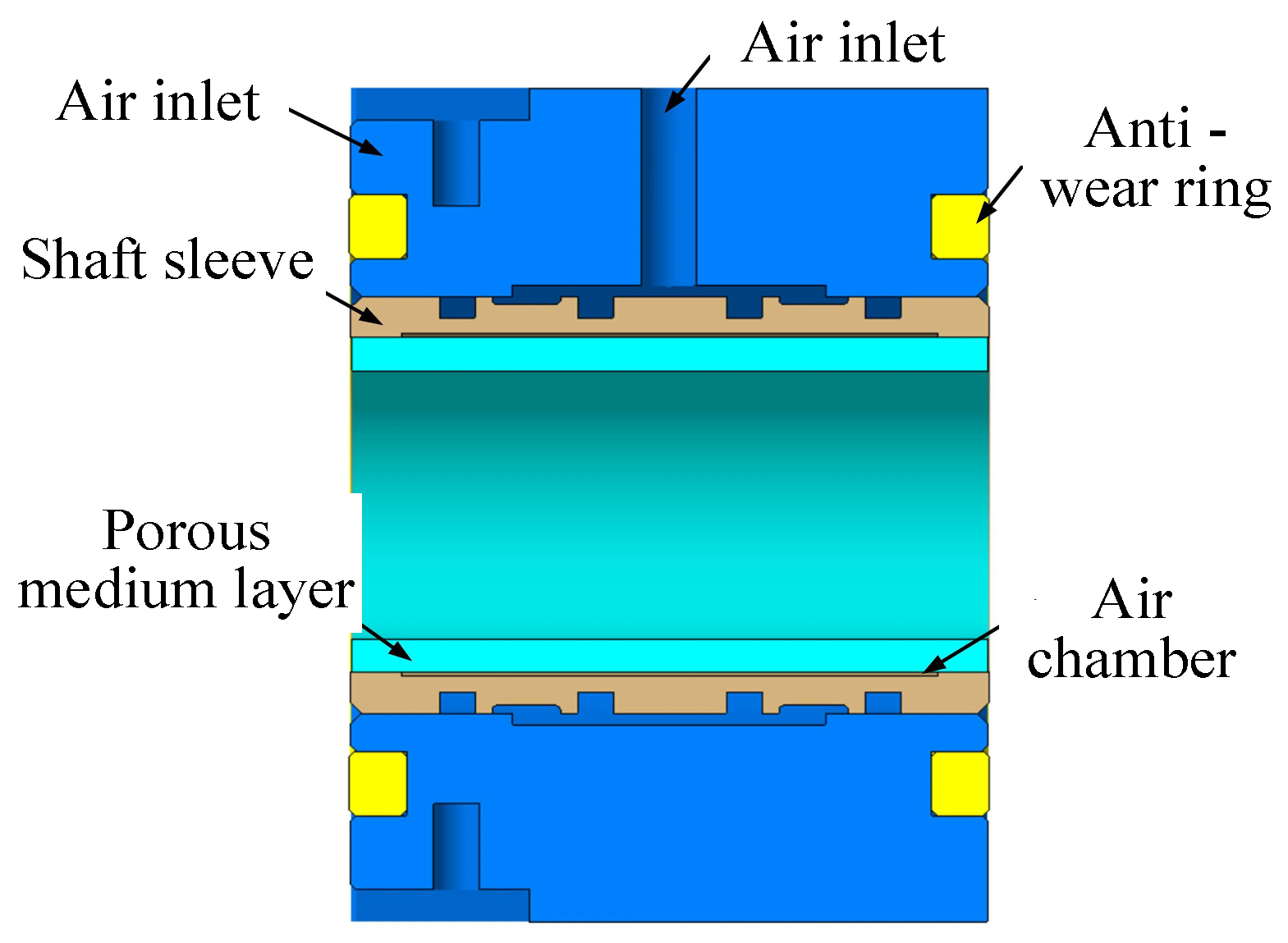

2.2. Airflow of the Porous Medium Gas Bearing

2.3. Simulation Model of the Porous Medium Gas Bearing

2.4. The Mesh Model and Mesh Independence of the Porous Medium Gas Bearing

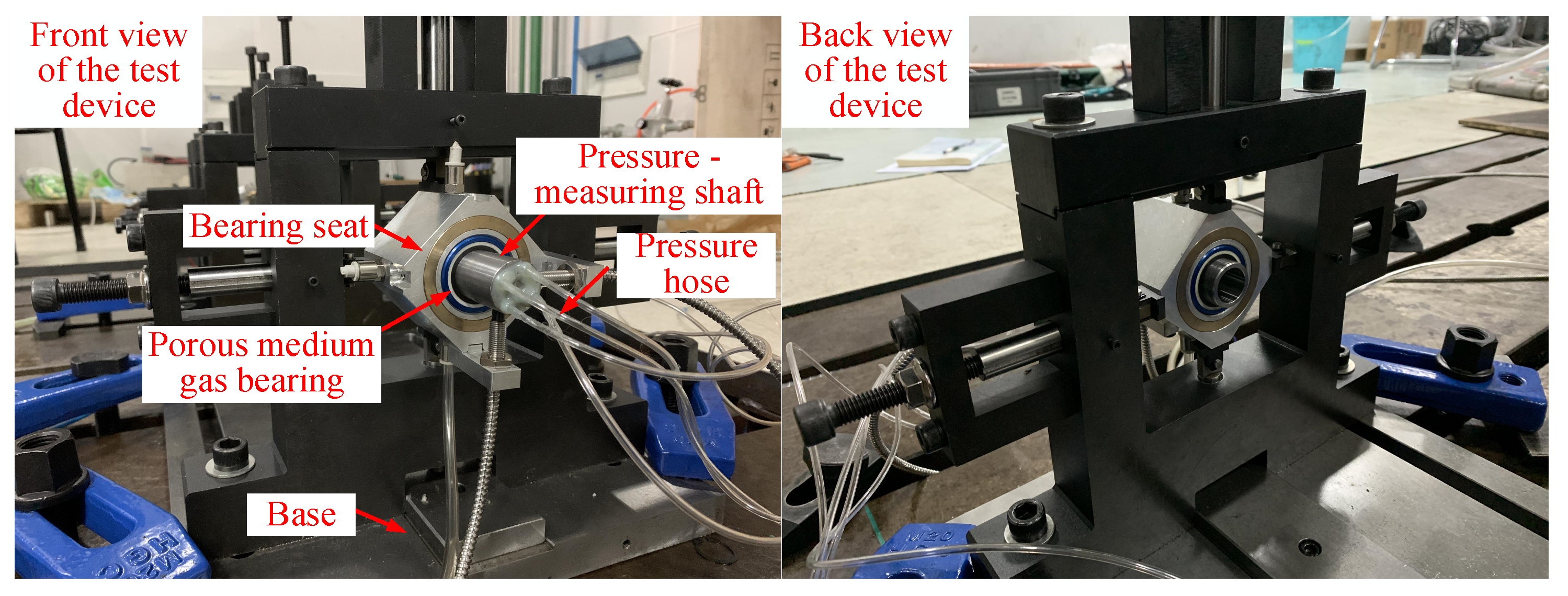

2.5. Solution of the Steady-State Characteristics of the Porous Medium Gas Bearing

3. Static Characteristics of the Porous Medium Gas Bearing

4. Steady-State Characteristics of Porous Medium Gas Bearings

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ICAO: Environmental Report–Aviavtion and Environment; ICAO: Montreal, QC, Canada, 2024; 2016 Environmental Report.

- Gao, Q.; Chen, W.; Lu, L.; Huo, D.; Cheng, K. Aerostatic Bearings Design and Analysis with the Application to Precision Engineering: State-of-the-art and Future Perspectives. Tribol. Int. 2019, 135, 1–17. [Google Scholar] [CrossRef]

- Majumdar, B.C.K.A. Analysis of two-layered gas-lubricated porous bearings. Appl. Mech. Eng. 2002, 7, 653–664. [Google Scholar]

- Lee, C.-C.; You, H.-I. Geometrical Design Considerations on Externally Pressurized Porous Gas Bearings. Tribol. Trans. 2010, 53, 386–391. [Google Scholar] [CrossRef]

- Lee, C.-C.; You, H.-I. Characteristics of Externally Pressurized Porous Gas Bearings Considering Structure Permeability. Tribol. Trans. 2009, 52, 768–776. [Google Scholar] [CrossRef]

- Sharma, S.; Siginer, D.A. Permeability Measurement Methods in Porous Media: A Review. In Proceedings of the ASME 2008 International Mechanical Engineering Congress and Exposition, Boston, MA, USA, 31 October–6 November 2008; pp. 179–200. [Google Scholar]

- Nicoletti, R.; Silveira, Z.C.; Purquerio, B.M. Modified reynolds equation for aerostatic porous radial bearings with quadratic forchheimer pressure flow assumption. J. Tribol. 2008, 130, 031701. [Google Scholar] [CrossRef]

- Cui, H.; Wang, Y.; Yue, X.; Huang, M.; Wang, W. Effects of manufacturing errors on the static characteristics of aerostatic journal bearings with porous restrictor. Tribol. Int. 2017, 115, 246–260. [Google Scholar] [CrossRef]

- Rao, T.V.V.L.N.; Rani, A.M.A.; Awang, M.; Nagarajan, T.; Hashim, F.M. Stability analysis of double porous and surface porous layer journal bearing. Tribol. Mater. Surf. Interfaces 2016, 10, 19–25. [Google Scholar] [CrossRef]

- Xu, Z.; Fan, Y.; Zheng, Y.; Ding, S.; Zhu, M.; Li, G.; Wang, M.; Yu, Z.; Song, Y.; Chang, L.; et al. Emission reduction characteristics of heavy-fuel aircraft piston engine fueled with 100% HEFA sustainable aviation fuel. Environ. Pollut. 2025, 368, 125661. [Google Scholar] [CrossRef] [PubMed]

- Le, N.T.P.; Roohi, E.; Tran, T.N. Comprehensive assessment of newly-developed slip-jump boundary conditions in high-speed rarefied gas flow simulations. Aerosp. Sci. Technol. 2019, 91, 656–668. [Google Scholar] [CrossRef]

- Cui, H.; Wang, Y.; Yue, X.; Huang, M.; Wang, W.; Jiang, Z. Numerical analysis and experimental investigation into the effects of manufacturing errors on the running accuracy of the aerostatic porous spindle. Tribol. Int. 2018, 118, 20–36. [Google Scholar] [CrossRef]

- Gad-el-Hak, M. MEMS: Introduction and Fundamentals; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Kudenatti, R.B.; Madalli, V.S.; Basti, D.P. Non-Newtonian Fluid Model for Pressure-Driven Flow Between Porous and Rough Surfaces in Journal Bearing. J. Porous Media 2017, 20, 881–898. [Google Scholar] [CrossRef]

- Gururajan, K.; Prakash, J. Roughness effects in a narrow porous journal bearing with arbitrary porous wall thickness. Int. J. Mech. Sci. 2002, 44, 1003–1016. [Google Scholar] [CrossRef]

- Kalavathi, G.K.; Dinesh, P.A.; Gururajan, K. Influence of roughness on porous finite journal bearing with heterogeneous slip/no-slip surface. Tribol. Int. 2016, 102, 174–181. [Google Scholar] [CrossRef]

- Bailey, N.Y.; Hibberd, S.; Power, H. Dynamics of a small gap gas lubricated bearing with Navier slip boundary conditions. J. Fluid Mech. 2017, 818, 68–99. [Google Scholar] [CrossRef]

- Cui, H.; Wang, Y.; Yang, H.; Zhou, L.; Li, H.; Wang, W.; Zhao, C. Numerical analysis and experimental research on the angular stiffness of aerostatic bearings. Tribol. Int. 2018, 120, 166–178. [Google Scholar] [CrossRef]

- Su, J.C.; You, H.-I.; Lai, J.-X. Numerical analysis on externally pressurized high-speed gas-lubricated porous journal bearings. Ind. Lubr. Tribol. 2003, 55, 244–250. [Google Scholar] [CrossRef]

- Saha, N.; Majumdar, B. Study of externally-pressurized gas-lubricated two-layered porous journal bearings: A steady state analysis. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 2002, 216, 151–158. [Google Scholar] [CrossRef]

- Ji, F.; Bao, Y.; Zhou, Y.; Du, F.; Zhu, H.; Zhao, S.; Li, G.; Zhu, X.; Ding, S. Investigation on performance and implementation of Tesla turbine in engine waste heat recovery. Energy Convers. Manag. 2019, 179, 326–338. [Google Scholar] [CrossRef]

- Jebauer, S.; Czerwińska, J. Implementation of Velocity Slip and Ttemperature Jump Boundary Conditions for Microfluidic Devices. Prace Instytutu Podstawowych Problemów Techniki PAN 2007, 1–50. Available online: https://www.semanticscholar.org/paper/Implementation-of-velocity-slip-and-temperature-for-JeaueCzerwi%C5%84ska/e75c811b80d1833eb562a292f97dc68037a80264 (accessed on 26 July 2025).

- Zhou, Y.; Li, X.; Geng, T.; Shao, L.; Xu, Z.; Zhong, Z.; Zhu, K.; Song, Y.; Ding, S. Piston engine energy utilization for variable-altitude applications: A review of two-stage turbo-charging technologies. Renew. Sustain. Energy Rev. 2025, 223, 116036. [Google Scholar] [CrossRef]

- Khaghani, A.; Cheng, K. CFD-based design and analysis of air-bearing-supported paint spray spindle. Nanotechnol. Precis. Eng. 2018, 1, 226–235. [Google Scholar] [CrossRef]

- Ji, F.; Zhang, X.; Du, F.; Ding, S.; Zhao, Y.; Xu, Z.; Wang, Y.; Zhou, Y. Experimental and Numerical Investigation on Micro Gas Turbine as a Range Extender for Electric Vehicle. Appl. Therm. Eng. 2020, 173, 115236. [Google Scholar] [CrossRef]

- Wu, L. A slip model for rarefied gas flows at arbitrary Knudsen number. Appl. Phys. Lett. 2008, 93, 253103. [Google Scholar] [CrossRef]

- Liang, H.; Guo, D.; Luo, J. Film forming behavior in thin film lubrication at high speeds. Friction 2018, 6, 156–163. [Google Scholar] [CrossRef]

- Zhang, S.; Qiao, Y.; Liu, Y.; Ma, L.; Luo, J. Molecular behaviors in thin film lubrication—Part one: Film formation for different polarities of molecules. Friction 2019, 7, 372–387. [Google Scholar] [CrossRef]

- Tang, Z.; Zhou, D.; Jia, T.; Pan, D.; Zhang, C. Investigation of lubricant transfer and distribution at head/disk interface in air-helium gas mixtures. Friction 2019, 7, 564–571. [Google Scholar] [CrossRef]

- Ma, L.; Luo, J. Thin film lubrication in the past 20 years. Friction 2016, 4, 280–302. [Google Scholar] [CrossRef]

- Gao, M.; Li, H.; Ma, L.; Gao, Y.; Ma, L.; Luo, J. Molecular behaviors in thin film lubrication—Part two: Direct observation of the molecular orientation near the solid surface. Friction 2019, 7, 479–488. [Google Scholar] [CrossRef]

- Beskok, A.; Karniadakis, G.E.; Trimmer, W. Rarefaction and compressibility effects in gas microflows. J. Fluids Eng. 1996, 118, 448–456. [Google Scholar] [CrossRef]

- Maxwell, J. On stresses in rarefied gases arising from inequalities of temperature Philos. Trans R. Soc. 1879, 170, 231–256. [Google Scholar]

- Singh, K.C.; Rao, N.S.; Majumdar, B.C. Hybrid Porous Gas Journal Bearings: Steady State Solution Incorporating the Effect of Velocity Slip. J. Tribol. 1984, 106, 322–328. [Google Scholar] [CrossRef]

- Ji, F.; Pan, Y.; Zhou, Y.; Du, F.; Zhang, Q.; Li, G. Energy recovery based on pedal situation for regenerative braking system of electric vehicle. Veh. Syst. Dyn. 2020, 58, 144–173. [Google Scholar] [CrossRef]

- ISO/IEC GUIDE 98-3:2008(E); Uncertainty of Measurement-Part 3: Guide to the Expression of Uncertainty in Measurement (GUM: 1995). ISO: Geneva, Switzerland, 2008.

| Gas Bearing | Dimension | Dimensionless Bearing Capacity | Rotational Speed (r/min) |

Stiffness Coefficient | Damping Coefficient | |

|---|---|---|---|---|---|---|

| metal mesh foil bearing [12] | 31.4 × 30 | 20 | 0.16 | 40,000 | 1.2 | 0.4 |

| double-layered foil bearing [13] | 30 × 30 | 15 | 0.56 | 50,000 | 3.1 | 3.4 |

| tilting pad bearing [14] | 28 × 33 | 20 | 0.56 | 50,000 | 1.5 | 0.05 |

| porous medium bearing [15] | 40 × 40 | 20 | 0.625 | 25,000 | 20 | - |

| porous medium bearing [16] | 30 × 40 | 15 | 0.92 | 20,000 | 19 | 38 |

| Scheme | Total Number of Meshes | Load-Carrying Capacity (N) | Deviation |

|---|---|---|---|

| Scheme A | 1,064,100 | 68.58 | −5.21% |

| Scheme B | 1,641,600 | 71.20 | −1.58% |

| Scheme C | 2,395,800 | 72.35 | - |

| Location | Boundary Definition |

|---|---|

| Outer cylindrical surface of the porous layer | Pressure Inlet |

| Inner cylindrical surface of the porous layer | Slip |

| Axial end face of the porous layer | Wall |

| Outer cylindrical surface of the gas film layer | Slip |

| Inner cylindrical surface of the gas film layer | Wall |

| Axial end face of the gas film layer: | Pressure Outlet |

| Component | Parameter | Value |

|---|---|---|

| Porous medium gas bearing | inner diameter/mm | 12.5 |

| outer diameter/mm | 19.5 | |

| bearing length/mm | 57 | |

| thickness of porous medium layer/mm | 3 | |

| length of porous medium layer/mm | 57 | |

| Pressure measuring shaft | outer diameter/mm | 12.5 |

| length/mm | 91.5 | |

| diameter of pressure collection hole/mm | 0.2 | |

| diameter of axial pressure channel/mm | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Tu, Y.; Jiang, N.; Jin, W.; Liang, Y.; Guo, X.; Liu, X.; Xu, Z.; Shao, L. Research and Experimental Verification of the Static and Dynamic Pressure Characteristics of Aerospace Porous Media Gas Bearings. Aerospace 2025, 12, 788. https://doi.org/10.3390/aerospace12090788

Zhang X, Tu Y, Jiang N, Jin W, Liang Y, Guo X, Liu X, Xu Z, Shao L. Research and Experimental Verification of the Static and Dynamic Pressure Characteristics of Aerospace Porous Media Gas Bearings. Aerospace. 2025; 12(9):788. https://doi.org/10.3390/aerospace12090788

Chicago/Turabian StyleZhang, Xiangbo, Yi Tu, Nan Jiang, Wei Jin, Yongsheng Liang, Xiao Guo, Xuefei Liu, Zheng Xu, and Longtao Shao. 2025. "Research and Experimental Verification of the Static and Dynamic Pressure Characteristics of Aerospace Porous Media Gas Bearings" Aerospace 12, no. 9: 788. https://doi.org/10.3390/aerospace12090788

APA StyleZhang, X., Tu, Y., Jiang, N., Jin, W., Liang, Y., Guo, X., Liu, X., Xu, Z., & Shao, L. (2025). Research and Experimental Verification of the Static and Dynamic Pressure Characteristics of Aerospace Porous Media Gas Bearings. Aerospace, 12(9), 788. https://doi.org/10.3390/aerospace12090788