Analysis of Influencing Factors on the Feasible Operating Range of a Triple-Bypass Adaptive Variable Cycle Engine Compression System

Abstract

1. Introduction

2. Research Methodology

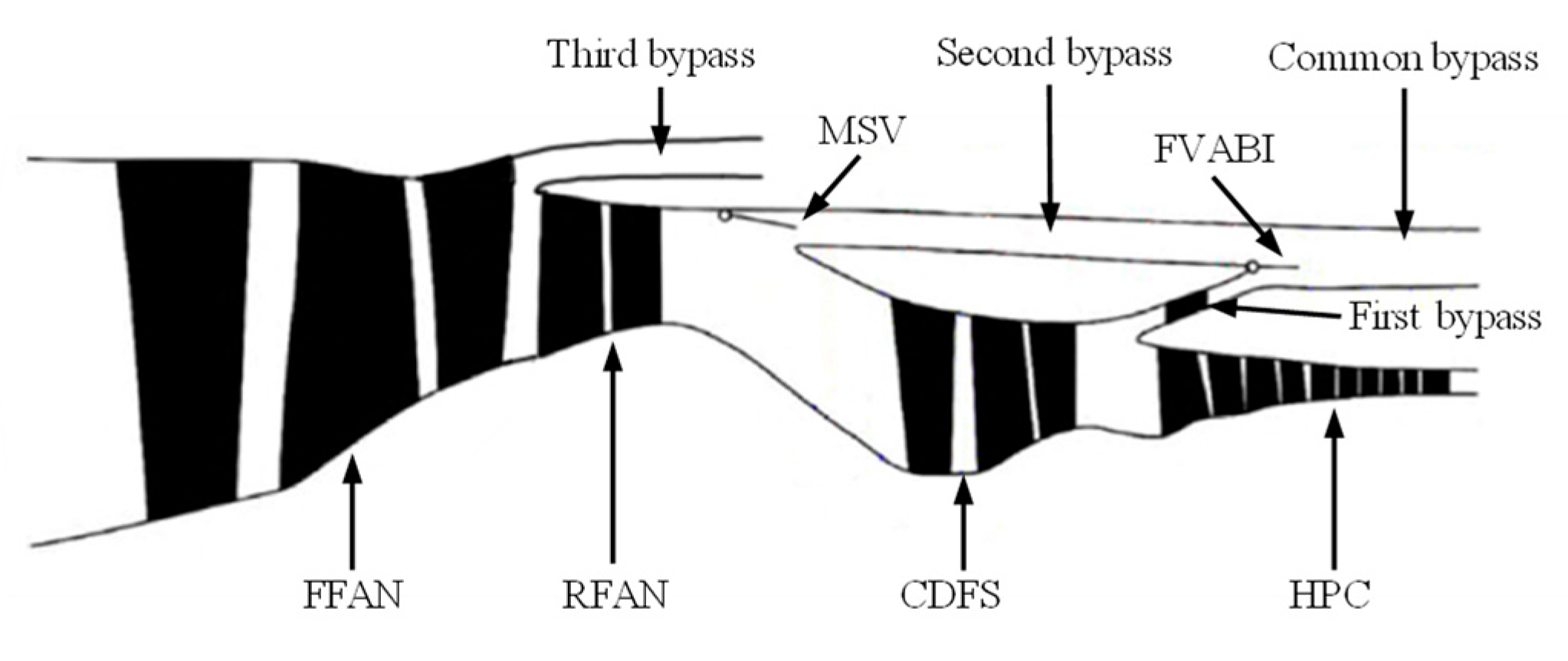

2.1. Research Object

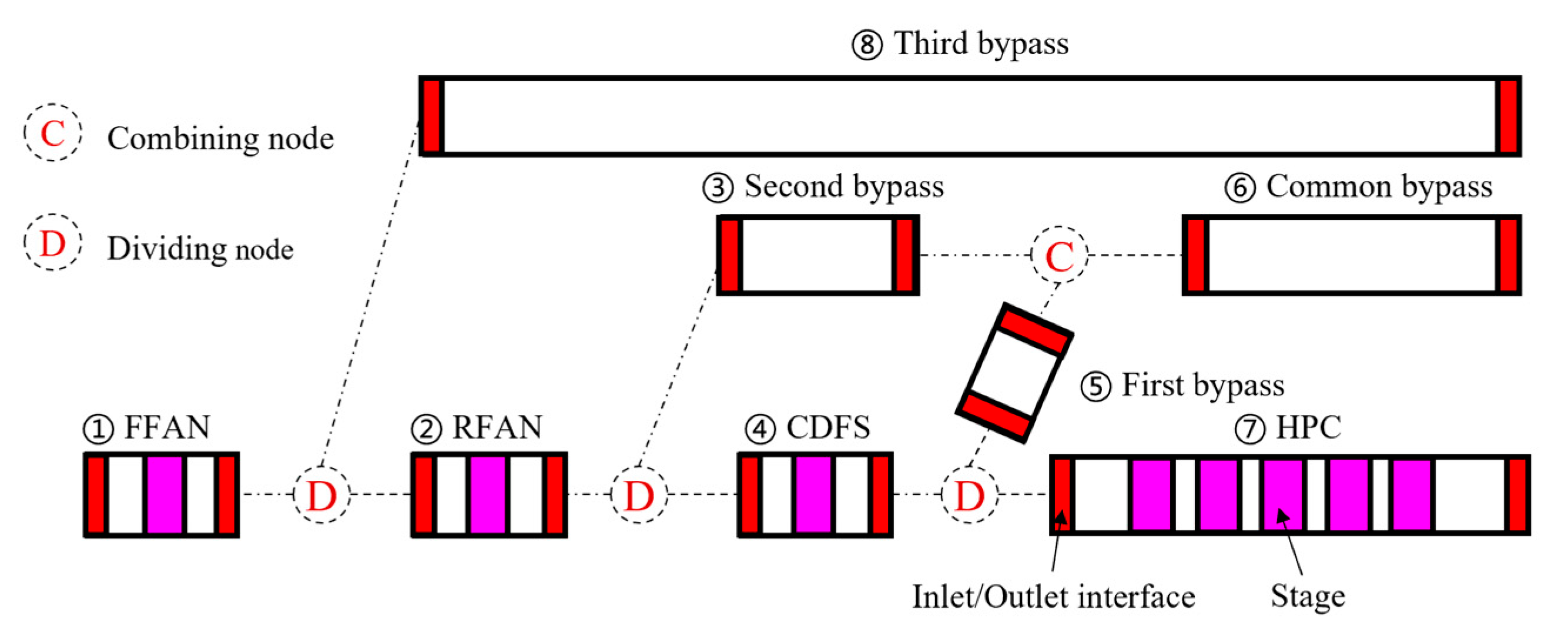

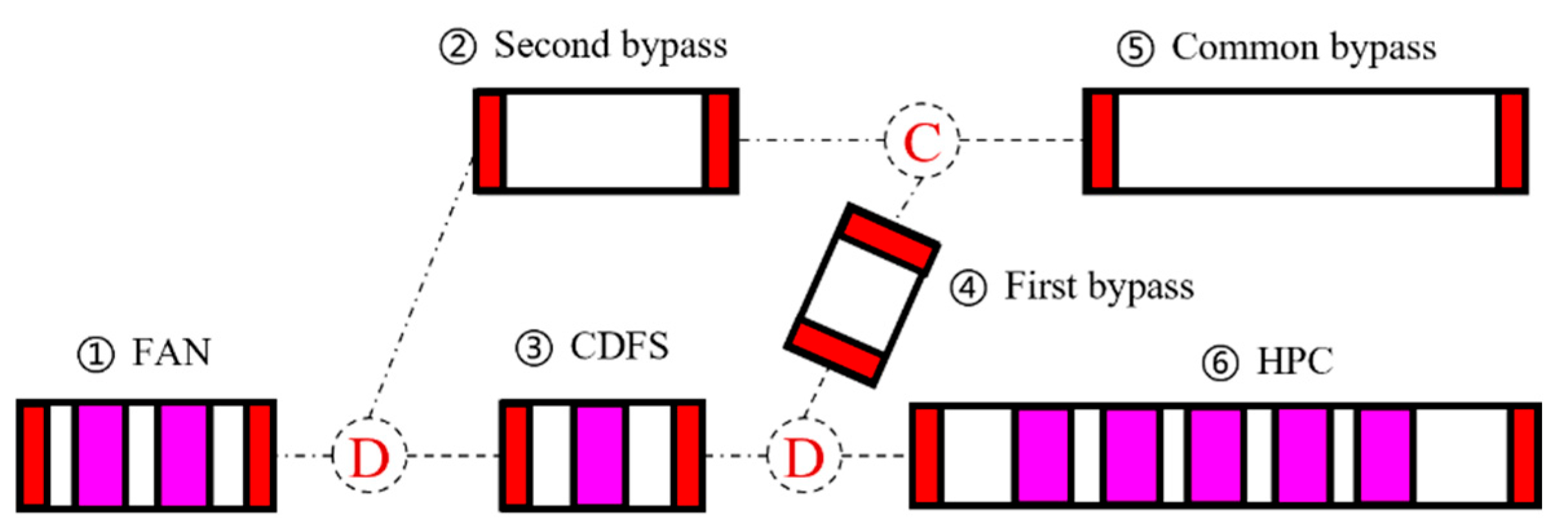

2.2. Integrated Analysis Methodology for ACE Compression Systems

2.2.1. Overall Framework

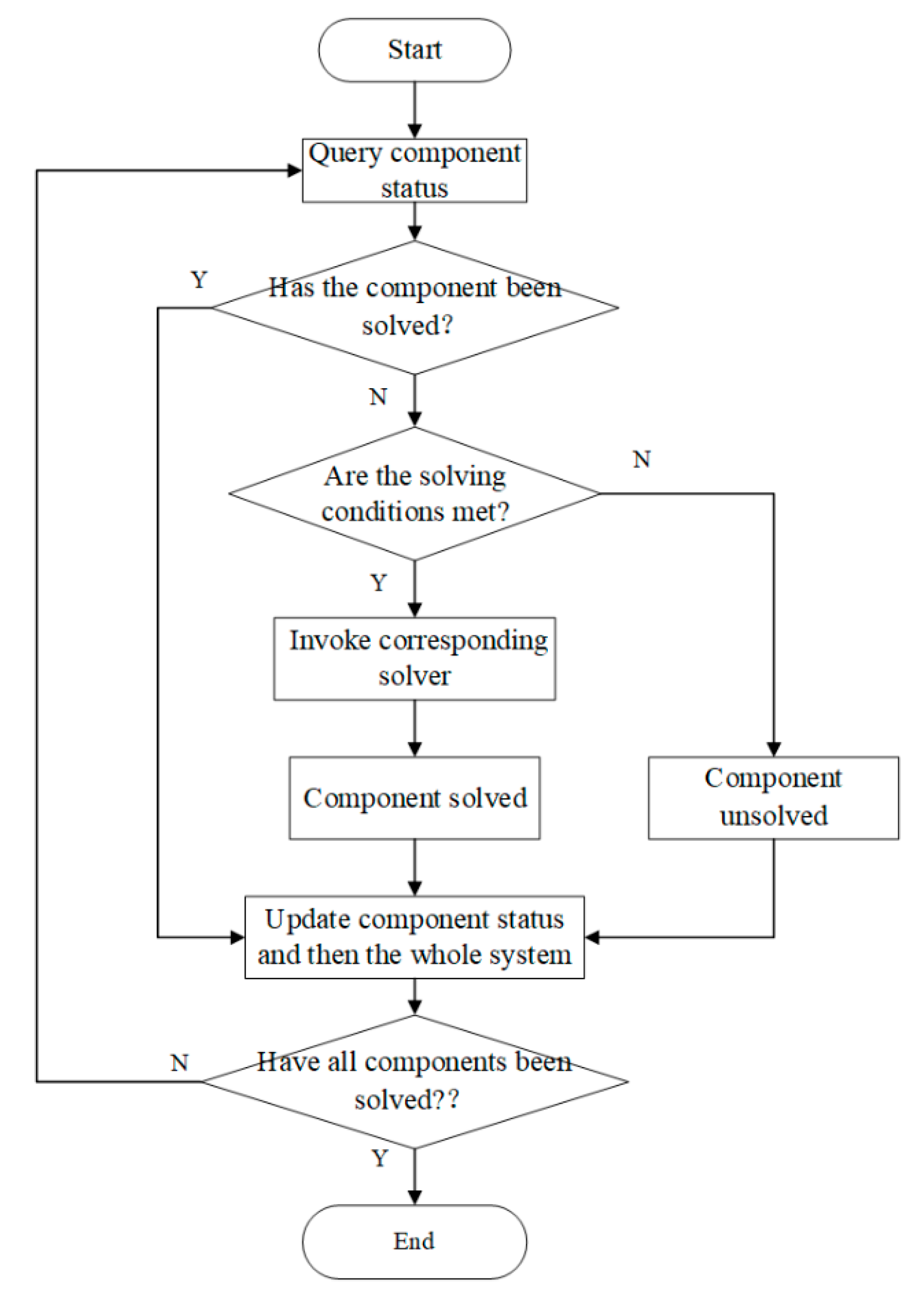

2.2.2. State-Driven Adaptive Solving Method for the Duct-Level

2.2.3. Component Models

- (a)

- One-dimensional mean-line model

- (b)

- Quasi-two-dimensional model

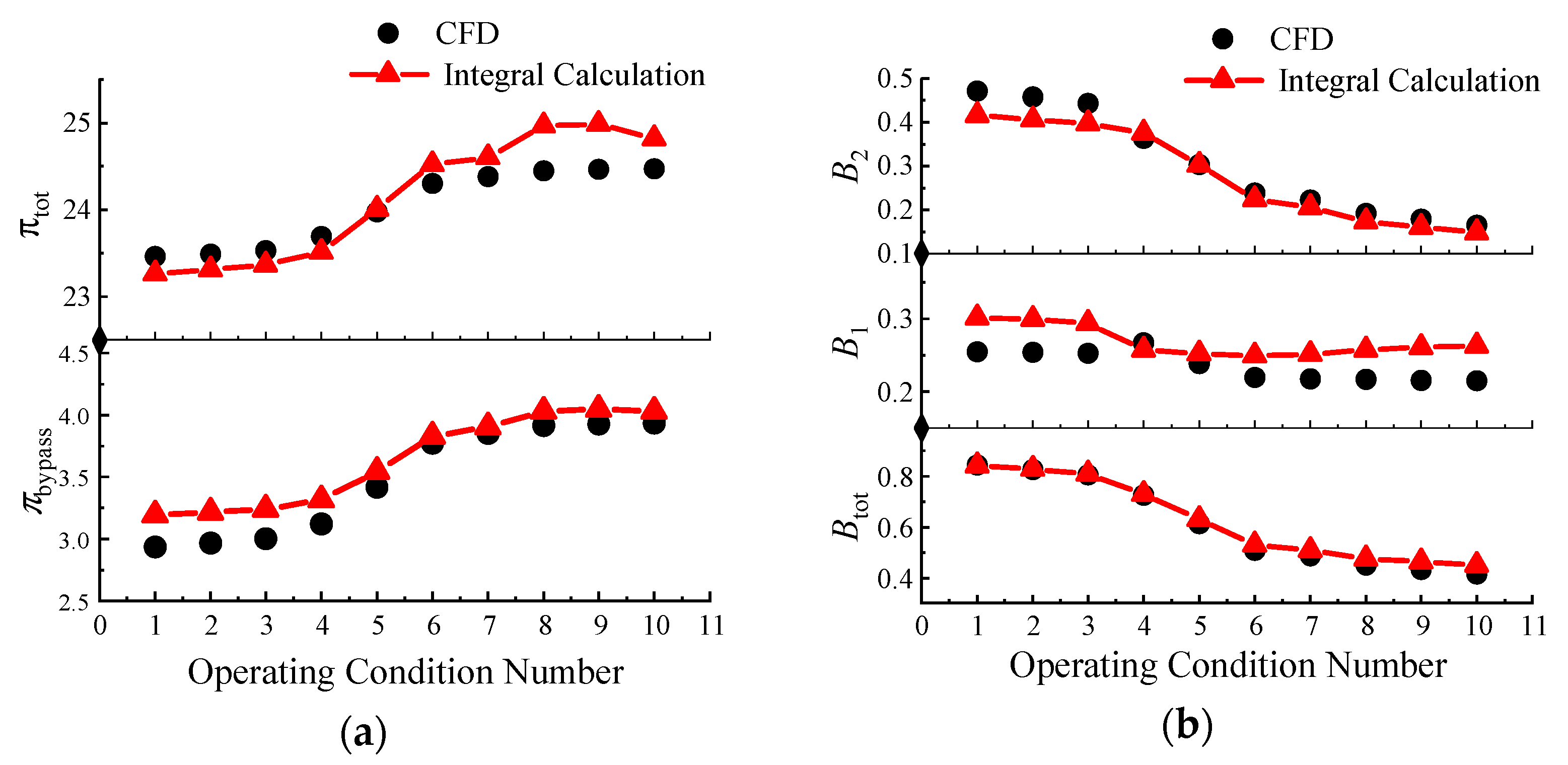

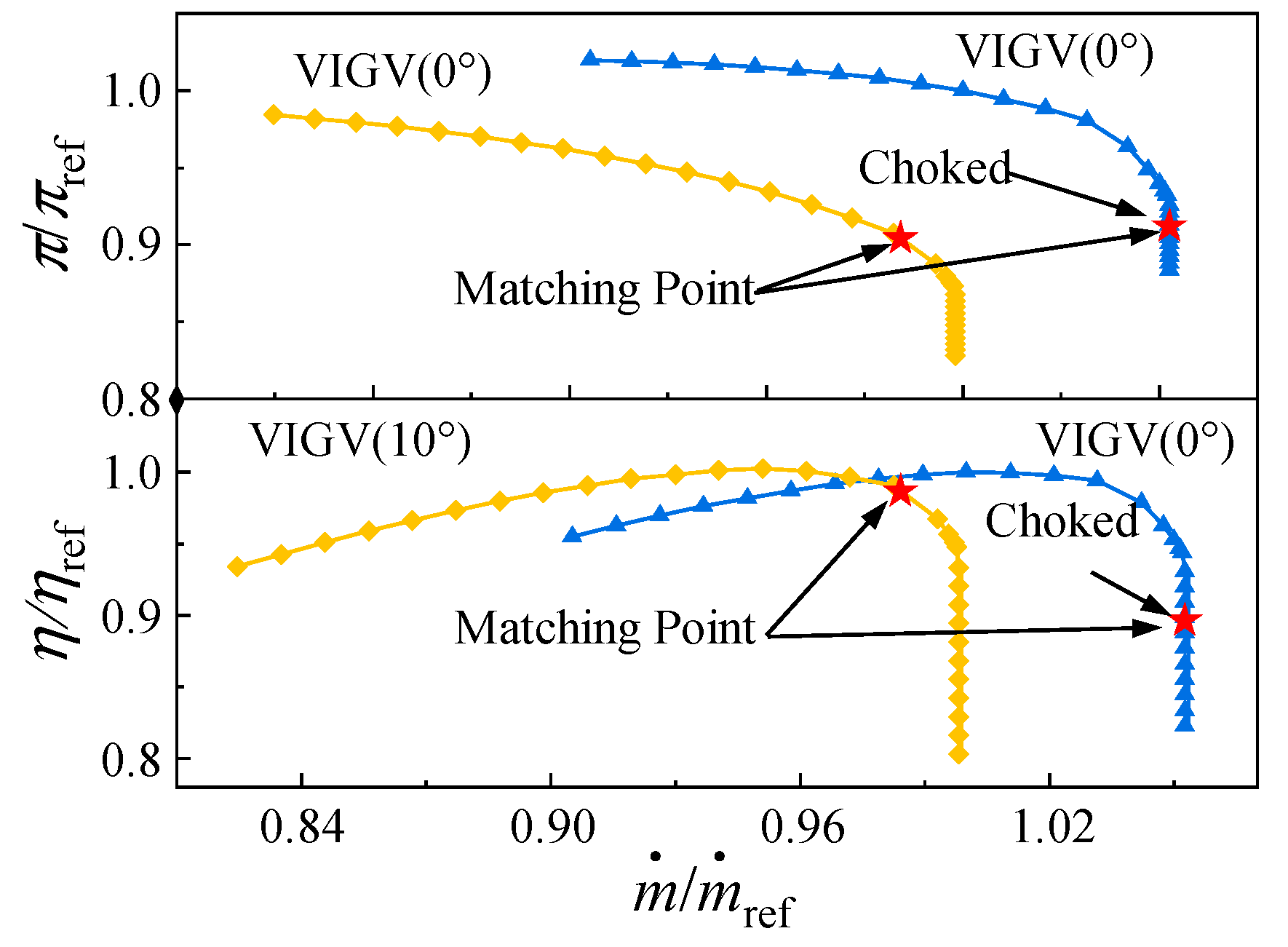

2.2.4. Validation of the Integrated Analysis Methodology

3. The Influence of Component Matching States on Bypass Ratio Regulation Range

3.1. Analysis of Influencing Factors on the Bypass Ratio

- (a)

- Third bypass ratio

- (b)

- Second bypass ratio

- (c)

- First bypass ratio

- (d)

- Total bypass ratio

3.2. Influence of Component Matching State on the Bypass Ratio

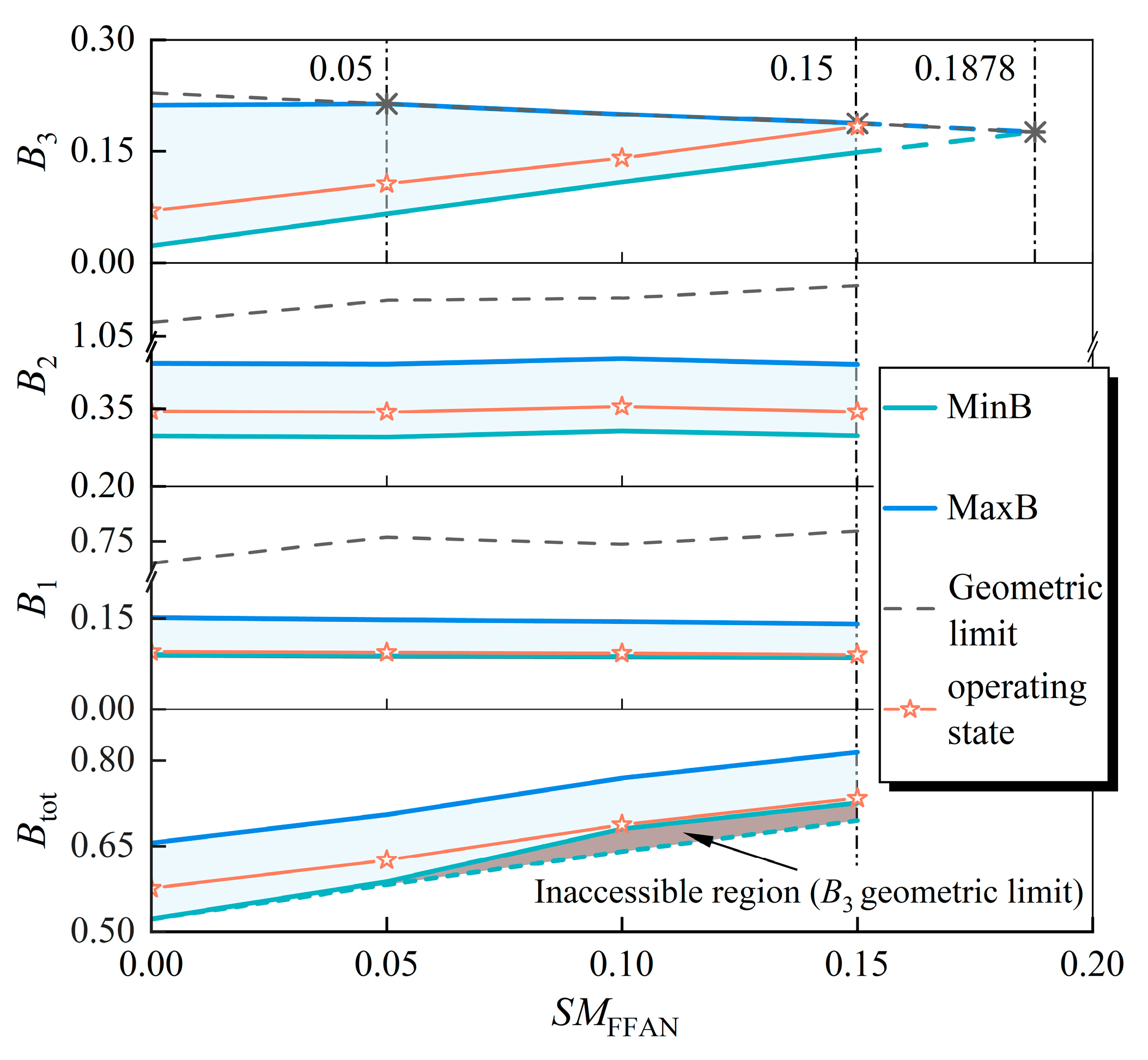

3.2.1. FFAN Matching State

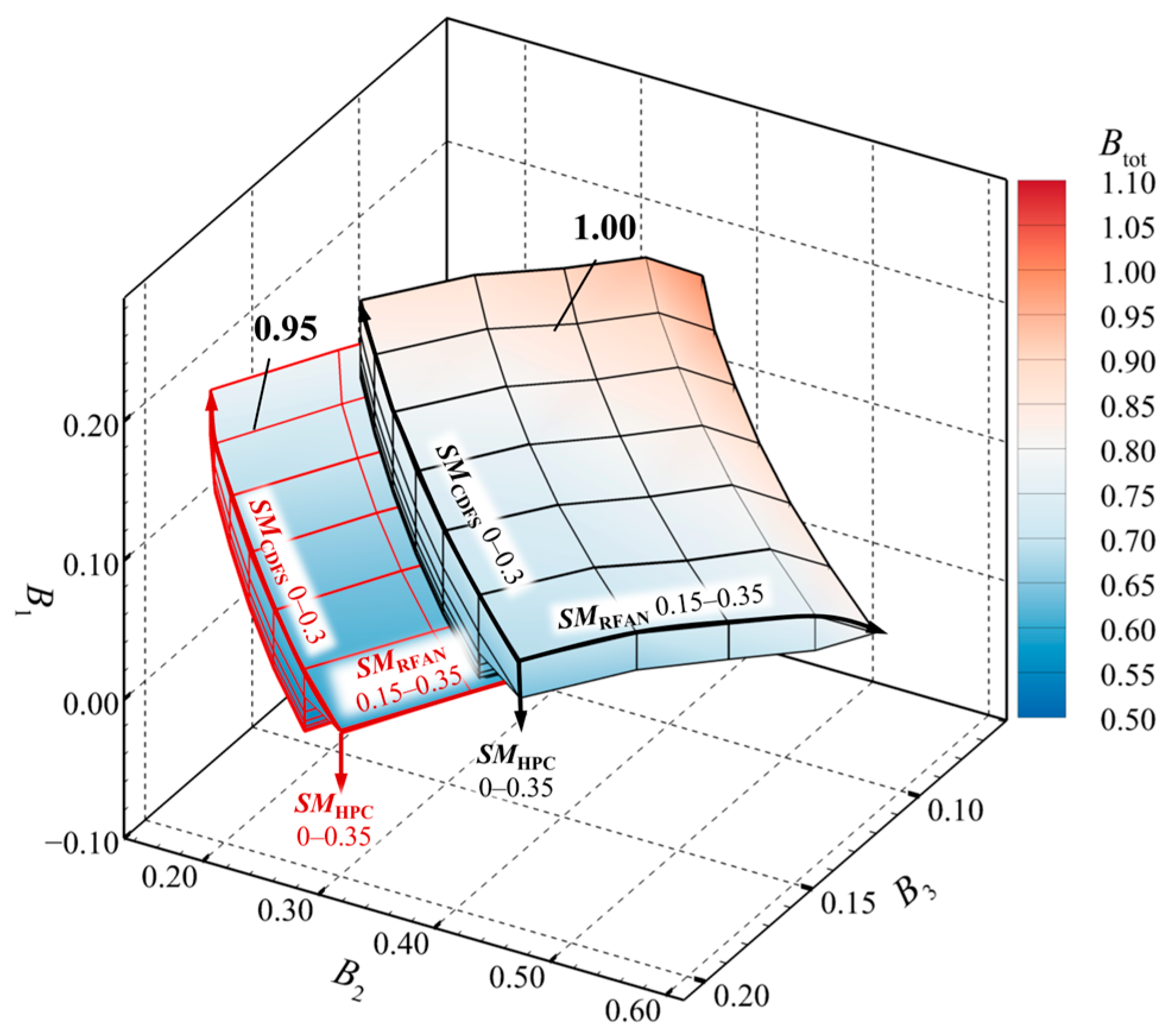

3.2.2. RFAN Matching State

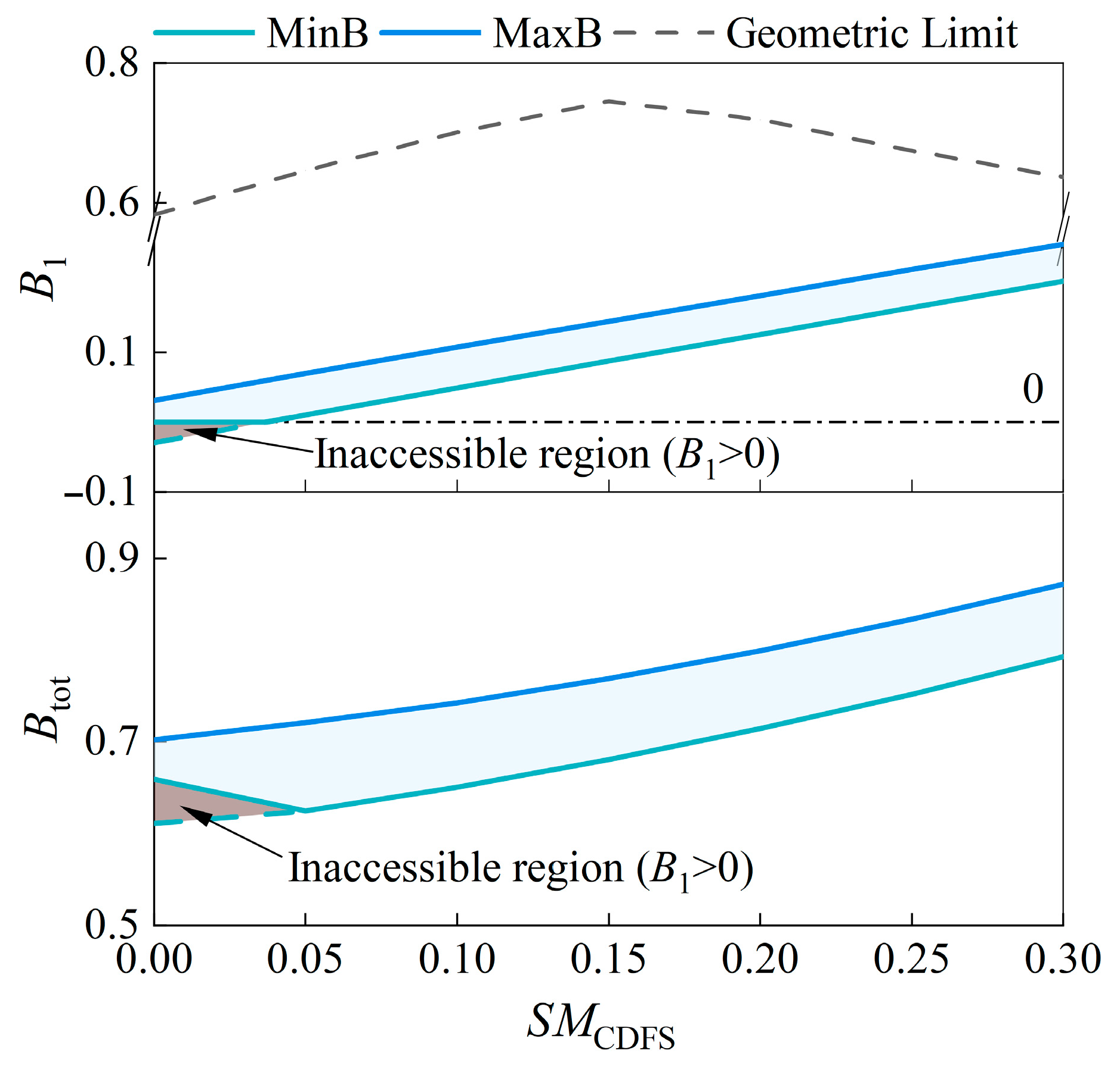

3.2.3. CDFS Matching State

3.3. Influence of Rotational Speed on the Bypass Ratio

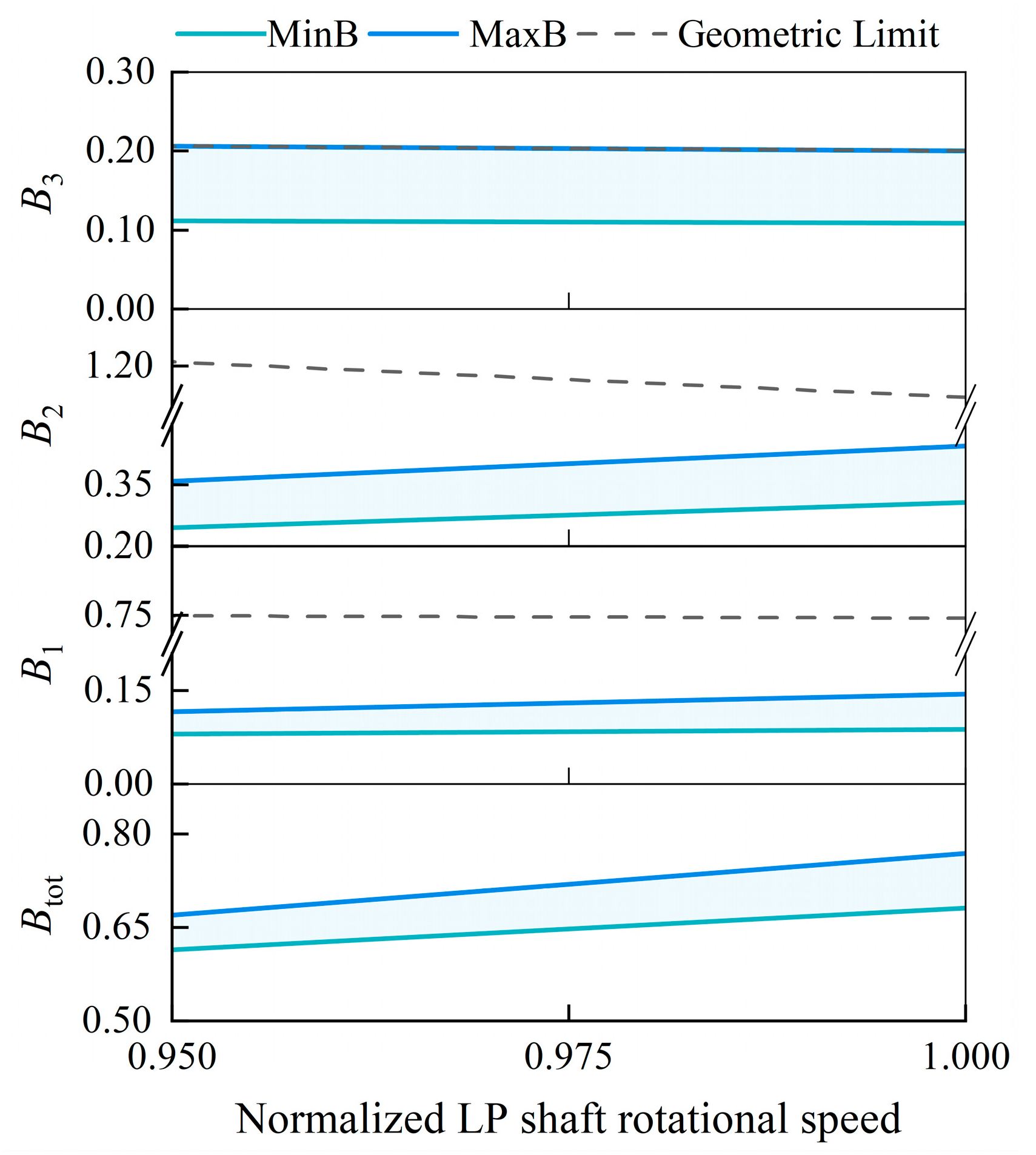

3.3.1. LP Shaft Speed

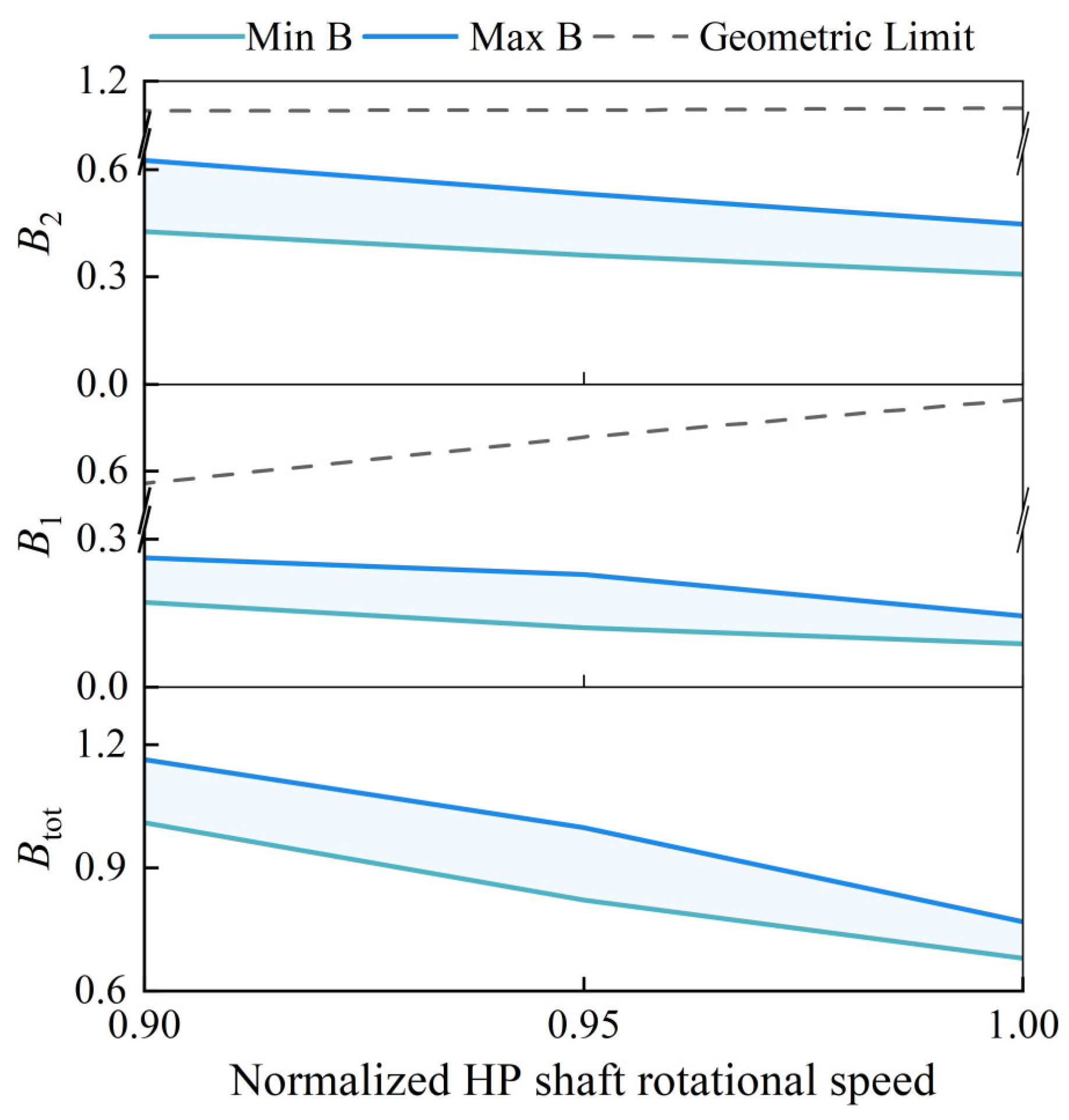

3.3.2. HP Shaft Speed

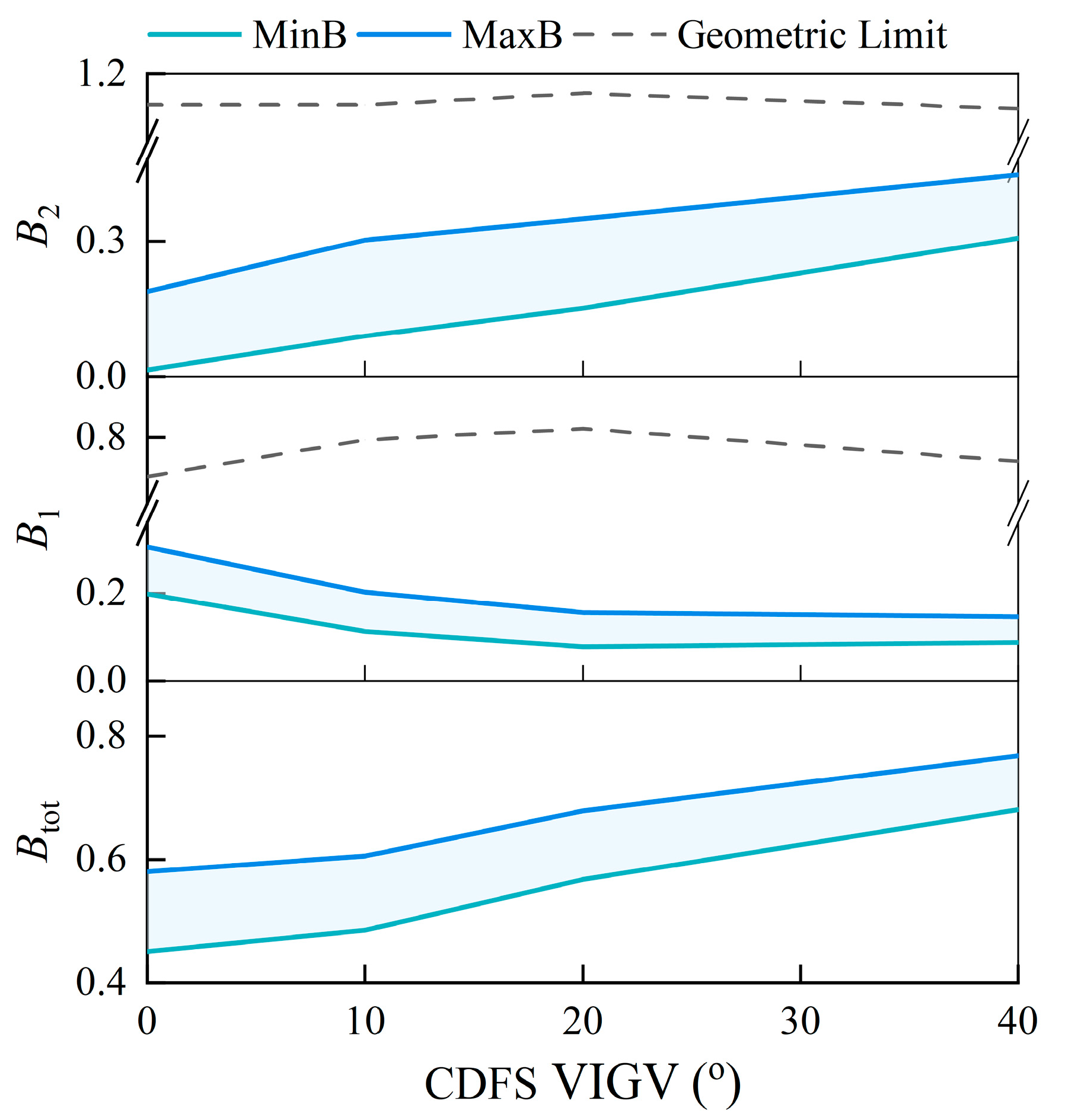

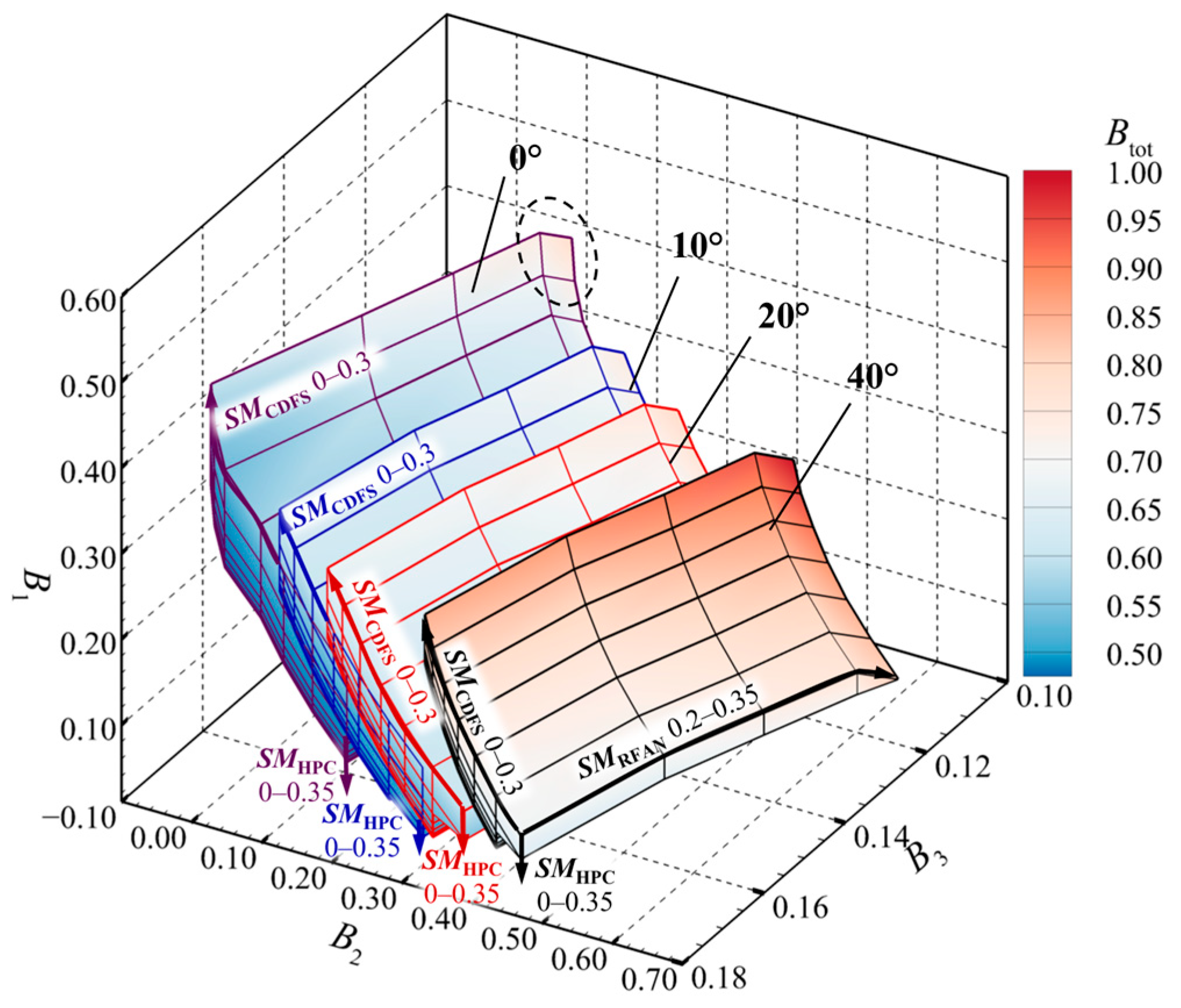

3.4. Influence of CDFS VIGV Angle on the Bypass Ratio

- Increasing SMFFAN enhances the upper limit of the engine bypass ratio by increasing B3. However, its impact on the bypass ratio regulation range is limited. Care must be taken to ensure that the geometry of the third bypass is compatible with the increase in B3.

- Increasing SMRFAN or SMCDFS helps raise the upper limit of the engine bypass ratio regulation range. However, this also leads to an increase in the lower limit of the Btot regulation range. Consequently, the overall regulation range of Btot experiences minimal net change.

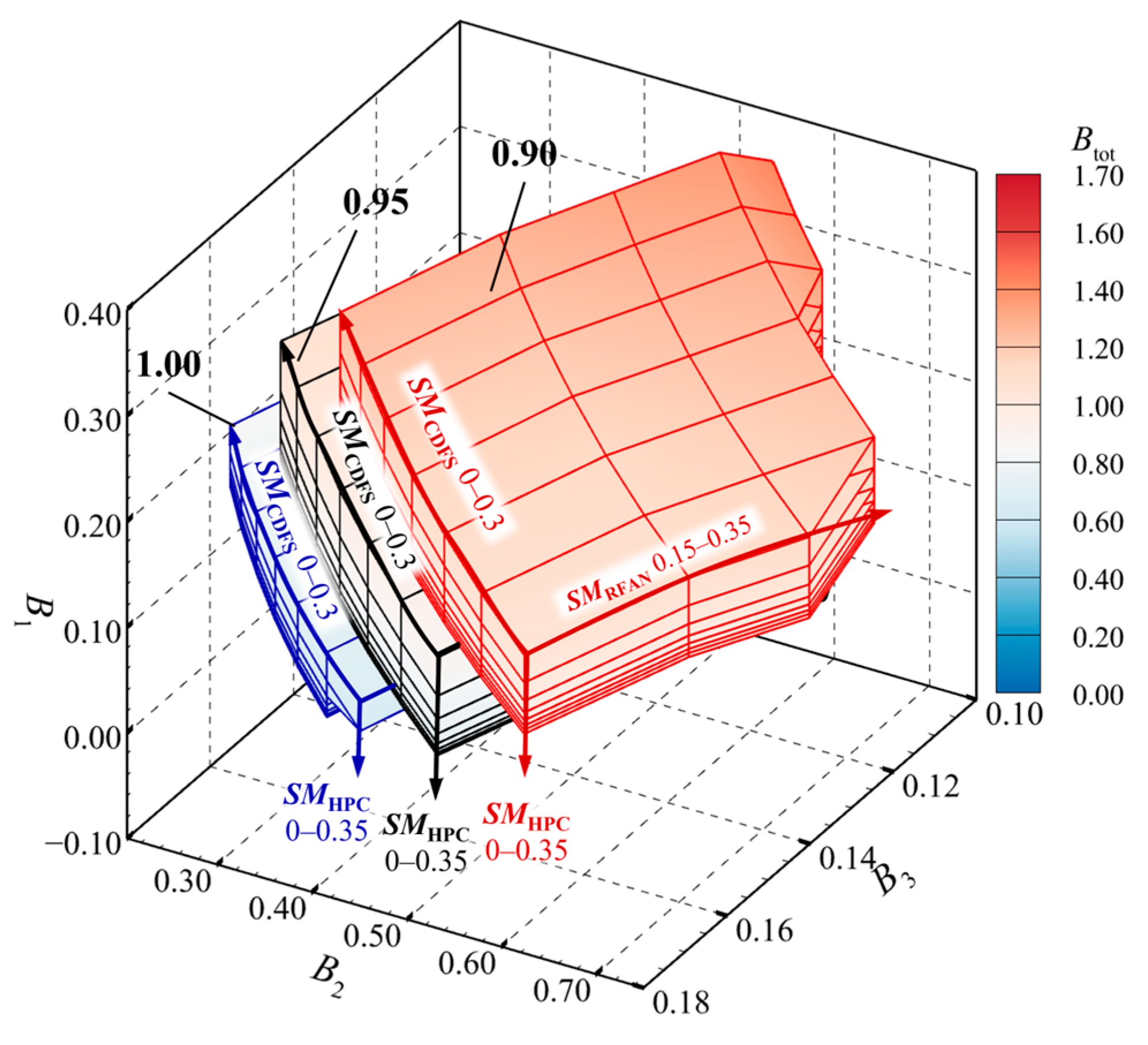

- Changes in the matching rotational speeds of the LP and HP shafts have opposite effects on both the bypass ratio regulation range and the overall bypass ratio. Reducing the LP shaft speed decreases both Btot and its regulation range. Conversely, reducing the HP shaft speed enhances both. Furthermore, changes in the HP shaft speed exhibit higher sensitivity to bypass ratio regulation.

- The CDFS VIGV angle also significantly affects Btot and its regulation range. A larger positive VIGV angle increases the bypass ratio, whereas a larger negative VIGV angle has the opposite effect. Adjustments to the VIGV angle demonstrate low sensitivity to the regulation range of the bypass ratio.

- The bypass ratio regulation range is primarily constrained by the intrinsic characteristics of the compression components and the flow capacity limits of the bypass ducts. For a given compression component, its inherent bypass ratio regulation range is relatively fixed. However, the overall bypass ratio level (whether increased or decreased) can be achieved by adjusting the matching parameters mentioned above.

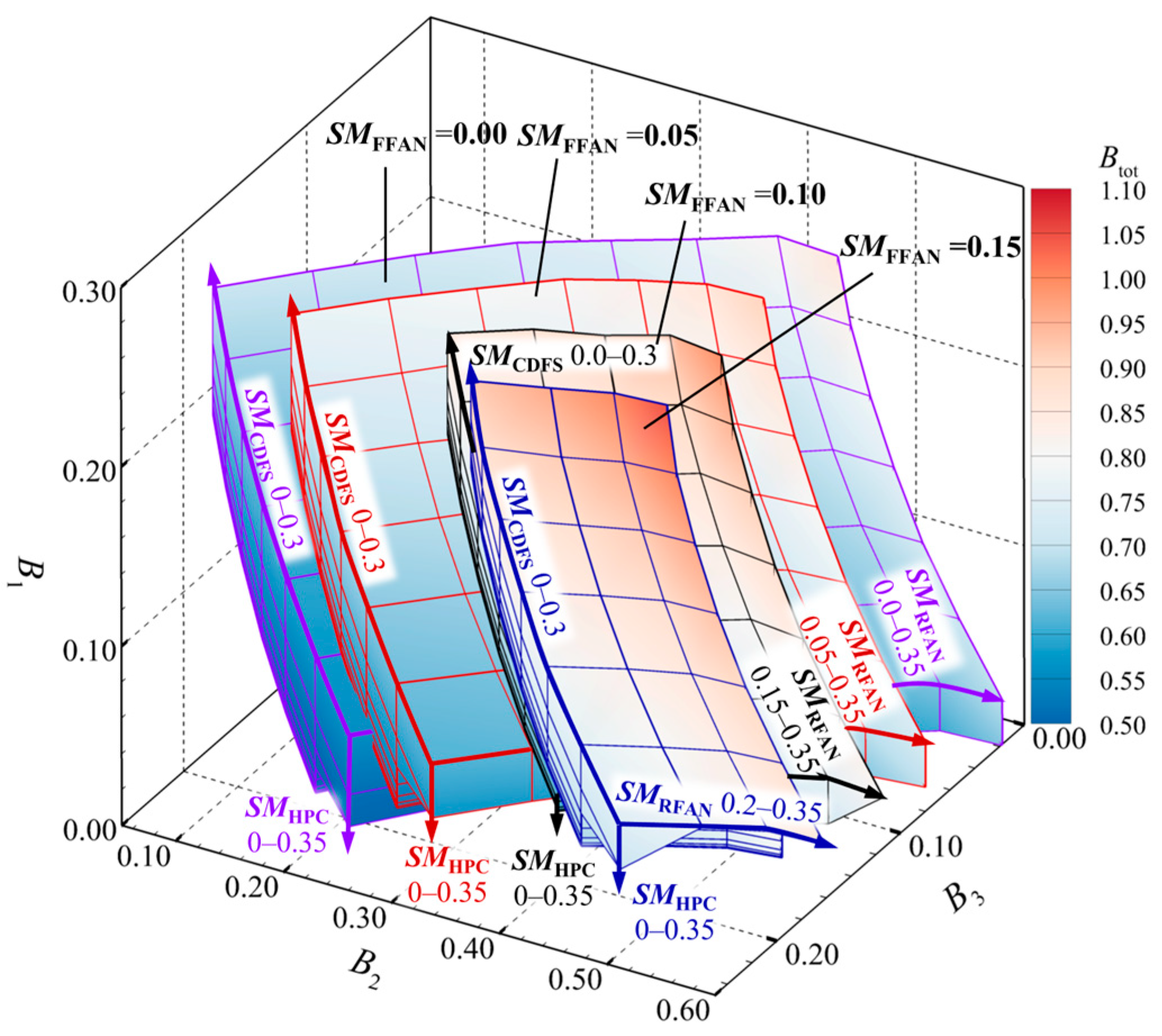

4. Influence of Component Coupling Adjustment on the System’s Feasible Operating Zone

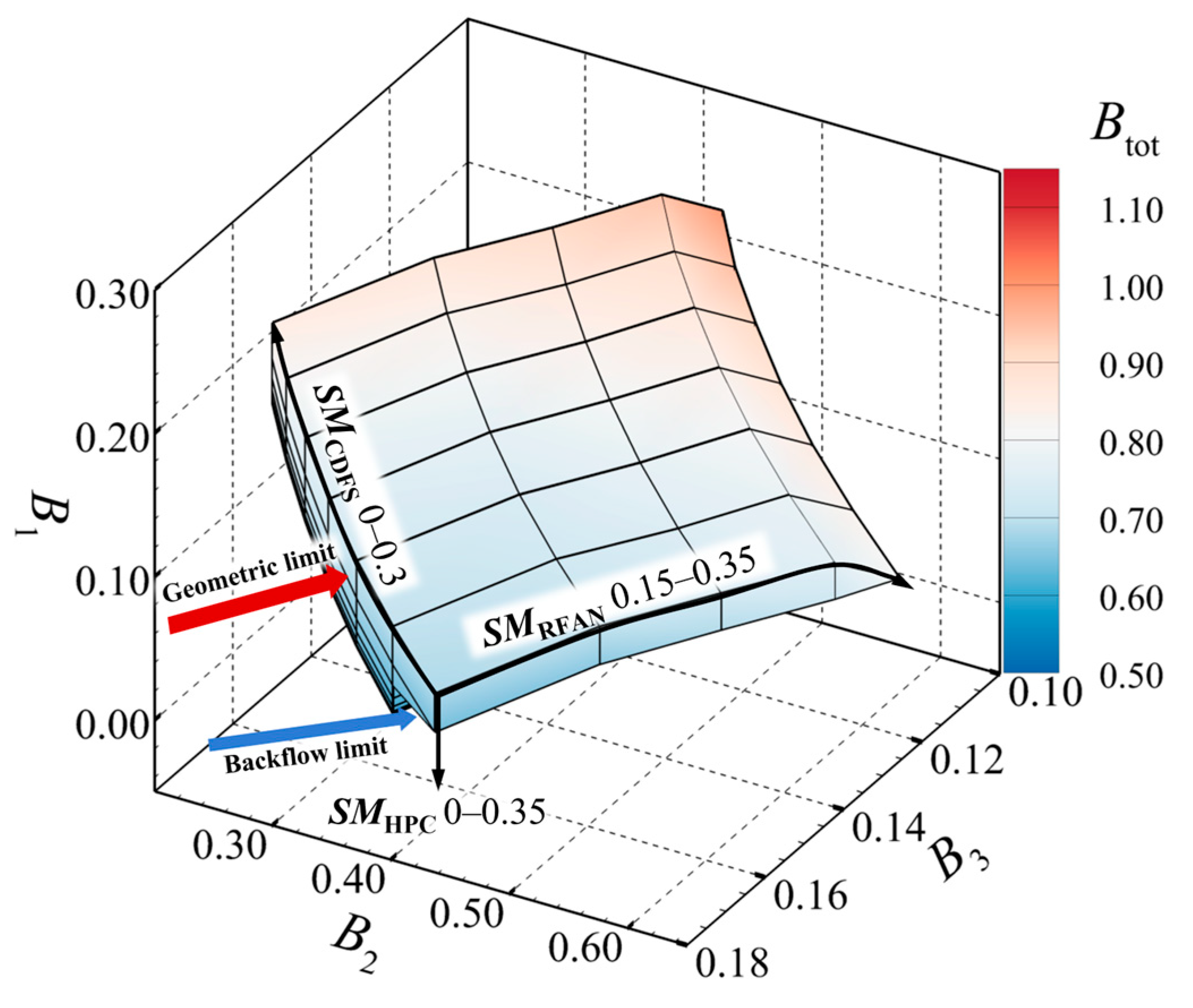

4.1. Definition of Feasible Operating Zone for the Triple-Bypass ACE Compression System

4.2. Influence of Compression System State Adjustment on the Feasible Operating Zone

4.2.1. FFAN Matching State

4.2.2. LP Shaft Speed

4.2.3. HP Shaft Speed

4.2.4. CDFS VIGV Angle

5. Conclusions

- The matching state of each compression system component (FFAN, RFAN, CDFS, HPC) primarily affects the bypass ratio of the adjacent downstream bypass, with a minor impact on the bypass ratios of other bypasses.

- The rotational speeds of the HP and LP shafts and the CDFS VIGV angle mainly influence B1 and B2, albeit through different mechanisms. The LP shaft speed directly affects B2 by influencing the flow capacity of the FFAN and RFAN. Simultaneously, changes in the flow capacity of these fans alter the inlet conditions of the CDFS, thereby affecting the operating state of HP shaft components and indirectly influencing B1. The HP shaft speed directly affects B1 and B2 by influencing the flow capacity of the CDFS and the HPC. The CDFS VIGV angle primarily affects B1 and B2 by altering the flow capacity of the CDFS.

- To increase the Btot of the compression system, SMFFAN should be increased, the LP shaft speed should be raised, the HP shaft speed should be reduced, and the CDFS VIGV should be appropriately closed (increasing positive pre-swirl). However, it should be noted that adjusting the HP shaft speed is the most effective measure, while attention must be paid to avoiding HP shaft overspeed during the LP shaft adjustment process.

- The influence of matching control parameters on the feasible operating zone of the compression system results from the superposition of their effects on each of the bypass ratios. Results obtained by analyzing the influence of each matching control parameter on the bypass ratios using the control variable method align in trend with those obtained through the feasible operating zone analysis. Therefore, the control variable method can be used for the qualitative analysis of the influence laws of matching control parameters on the bypass ratios.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |

| VCE | Variable cycle engine |

| ACE | Adaptive cycle engine |

| MSV | Mode Selector Valve |

| FVABI | Forward Variable Area Bypass Injector |

| VIGV | Variable inlet guide vane |

| FFAN | Front fan |

| RFAN | Rear fan |

| CDFS | Core-driven fan stage |

| HPC | High-pressure compressor |

| LP shaft | Low-pressure shaft |

| HP shaft | High-pressure shaft |

| SM | Stall margin |

| MaxB | Max bypass ratio |

| MinB | Min bypass ratio |

| Symbols | |

| B | Bypass ratio |

| B1 | First bypass ratio |

| B2 | Second bypass ratio |

| B3 | Third bypass ratio |

| Btot | Total bypass ratio |

| Bmax | Maximum bypass ratio under bypass geometric limit |

| ṁ | mass flow |

| N | Rotational speed |

| P* | Total pressure |

| T* | Total temperature |

| P0 | Standard atmospheric pressure |

| T0 | Standard atmospheric temperature |

| Mao | Mach number at the throat of the bypass |

| π | Total pressure ratio |

| τ | Total temperature ratio |

| η | Adiabatic efficiency |

| δ | Corrected flow scaling factor, ratio of inlet corrected mass flow rate to outlet corrected mass flow rate for a compressor |

| Sπ | Pressure ratio sensitivity of corrected flow scaling factor |

| Sη | Efficiency ratio sensitivity of corrected flow scaling factor |

| k | Specific heat ratio |

| Subscripts | |

| FFAN | Pertaining to the front fan |

| RFAN | Pertaining to the rear fan |

| CDFS | Pertaining to the core-driven fan stage |

| HPC | Pertaining to the high-pressure compressor |

| bypass | Pertaining to the common bypass of the double-bypass compression system |

| phy | Physical condition |

| cor | Corrected condition (standard atmosphere) |

| in | Inlet of compression component |

| out | Outlet of compression component |

References

- Murthy, S.N.B.; Curran, E.T. Variable Cycle Engine Developments At General Electric-1955-1995. In Developments in High-Speed Vehicle Propulsion Systems; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1996; pp. 105–158. [Google Scholar] [CrossRef]

- Kurzke, J. The Mission Defines the Cycle: Turbojet, Turbofan and Variable Cycle Engines for High Speed Propulsion; RTO Educational Notes; EN-AVT-185 Lecture: Dachau, Germany, 2010; Available online: https://www.sto.nato.int/document/the-mission-defines-the-cycle-turbojet-turbofan-and-variable-cycle-engines-for-high-speed-propulsion/ (accessed on 9 July 2025).

- Chen, M.; Deng, L.; Zhang, J.; Tang, H. Review on the development status and performance deign of adaptive cycle engines. Propul. Power Res. 2025, 14, 35–63. [Google Scholar] [CrossRef]

- Jafaripanah, S.; Ommi, F.; Saboohi, Z. Off-Design Performance Simulation of Non-mixed Twin-Spool Aero Turbine Engine. J. Inst. Eng. India Ser. C 2024, 105, 101–114. [Google Scholar] [CrossRef]

- Wagenknecht, C.D.; Faust, G.K. Individual Bypass Injector Valves for a Double Bypass Variable Cycle Turbofan Engine. U.S. Patent 4,175,384, 27 November 1979. [Google Scholar]

- Vdoviak, J.W.; Ebacher, J.A. VCE test bed engine for supersonic cruise research. NASA Langley Res. Cent. Supersonic Cruise Res. 1979, Pt 1, 1980. Available online: https://ntrs.nasa.gov/citations/19810009472 (accessed on 9 July 2025).

- Bachelder, K.A.; Welty, D.J. Methods and Apparatus for Supporting Variable Bypass Valve Systems. U.S. Patent US6742324B2, 1 June 2004. [Google Scholar]

- Berton, J.J.; Haller, W.J.; Senick, P.F.; Jones, S.M.; Seidel, J.A. A Comparative Propulsion System Analysis for the High-Speed Civil Transport; NASA/TM-2005-213414; NASA: Washington, DC, USA, 2005. Available online: https://ntrs.nasa.gov/citations/20050123580 (accessed on 9 July 2025).

- Simmons, R.J. Design and Control of a Variable Geometry Turbofan with an Independently Modulated Third Stream. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2009. [Google Scholar]

- Aygun, H.; Cilgin, M.E.; Ekmekci, I.; Turan, O. Energy and performance optimization of an adaptive cycle engine for next generation combat aircraft. Energy 2020, 209, 118261. [Google Scholar] [CrossRef]

- Denney, R.K.; Tai, J.C.; Kestner, B.K.; Mavris, D.N. Variable Cycle Optimization for Supersonic Commercial Applications. SAE Trans. 2005, 114, 1354–1361. [Google Scholar]

- Lyu, Y.; Tang, H.; Chen, M. A Study on Combined Variable Geometries Regulation of Adaptive Cycle Engine during Throttling. Appl. Sci. 2016, 6, 374. [Google Scholar] [CrossRef]

- Zheng, J.; Chen, M.; Tang, H. Matching mechanism analysis on an adaptive cycle engine. Chin. J. Aeronaut. 2017, 30, 706–718. [Google Scholar] [CrossRef]

- Yue, X.; Min, C.; Tang, H. Preliminary Design Analysis of Core Driven Fan Stage in Adaptive Cycle Engine. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Guo, H.; Zhang, Y.; Yu, B. Research on Optimization Technology of Minimum Specific Fuel Consumption for Triple-Bypass Variable Cycle Engine. Aerospace 2025, 12, 10. [Google Scholar] [CrossRef]

- Wang, R.; Yu, X.; Zhao, K.; Liu, B.; An, G. Development and Validation of a Novel Control-Volume Model for the Injection Flow in a Variable Cycle Engine. Aerospace 2022, 9, 431. [Google Scholar] [CrossRef]

- Lu, S.; Zhou, W.; Huang, J.; Wang, B. Research on a component characteristic adaptive correction method for variable cycle engines. Int. J. Turbo Jet-Engines 2023, 40, 399–410. [Google Scholar] [CrossRef]

- Liu, B.; Jia, S.; Yu, X. An Integrated Throughflow Method for the Performance Analysis of Variable Cycle Compression Systems. Int. J. Turbo Jet Engines 2021, 38, 245–261. [Google Scholar] [CrossRef]

- Wang, R.; Yu, X.; Liang, C.; Meng, D.; An, G.; Liu, B. Integrated performance evaluation method for variable cycle engine compression system considering influence of complex bypass. Hangkong Dongli Xuebao/J. Aerosp. Power 2022, 37, 2090–2103. [Google Scholar] [CrossRef]

- Wang, R.; Yu, X.; Liu, B.; An, G. New insights into component matching mechanism in the compression system of double bypass engine. Propul. Power Res. 2024, 13, 118–131. [Google Scholar] [CrossRef]

- Kidikian, J.; Reggio, M. Off-Design Prediction of Transonic Axial Compressors, Part 1: Mean-Line Code and Tuning Factors. In Proceedings of the Asme Turbo Expo: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Kidikian, J.; Reggio, M. Off-Design Prediction of Transonic Axial Compressors, Part 2: Generalized Mean-Line Loss Modelling Methodology. In Proceedings of the Asme Turbo Expo: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Zhang, Y.Y.; Zhang, S.J. Performance prediction of transonic axial multistage compressor based on one-dimensional meanline method. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 235, 1355–1369. [Google Scholar] [CrossRef]

- Mohammadian, P.K.; Saidi, M.H. Mean-line model development for off-design performance prediction of transonic axial compressor of an industrial gas turbine based on computational fluid dynamics database. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 236, 1449–1471. [Google Scholar] [CrossRef]

- Wang, R.; Liu, B.; Yu, X.; An, G. The exploration of bypass matching limitation and mechanisms in a double bypass engine compression system. Aerosp. Sci. Technol. 2021, 119, 107225. [Google Scholar] [CrossRef]

- Zheng, J.; Tang, H.; Chen, M.; Yin, F.-J. Equilibrium running principle analysis on an adaptive cycle engine. Appl. Therm. Eng. 2018, 132, 393–409. [Google Scholar] [CrossRef]

- Miller, A.S. Compressor Conceptual Design Optimization. Master’s Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2015. [Google Scholar]

- Hosseini, S.E.; Jafaripanah, S.; Saboohi, Z. CFD simulation and aerodynamic optimization of two-stage axial high-pressure turbine blades. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 666. [Google Scholar] [CrossRef]

- Howell, A.R. Fluid Dynamics of Axial Compressors. Proc. Inst. Mech. Eng. 1945, 153, 441–452. [Google Scholar] [CrossRef]

- Madadi, A.; Hajilouy Benisi, A. Performance Predicting Modeling of Axial-Flow Compressor at Design and Off-Design Conditions. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; pp. 317–324. [Google Scholar]

- Yan, W.; Zheng, Q.; Chi, Z.; Jiang, B. Improving the accuracy of one-dimensional analysis in axial compressor performance prediction. Phys. Fluids 2025, 37, 037150. [Google Scholar] [CrossRef]

- Szuch, J.R.; Seldner, K. Real-Time Simulation of F100-PW-100 Turbofan Engine Using the Hybrid Computer; E-8136; NASA: Washington, DC, USA, 1975. [Google Scholar]

- Szuch, J.R.; Bruton, W.M. Real-Time Simulation of the TF30-P-3 Turbofan Engine Using a Hybrid Computer; E-7904; NASA: Washington, DC, USA, 1974. [Google Scholar]

- Liu, B.; Wang, R.; Yu, X. On the mode transition of a double bypass variable cycle compression system. Aerosp. Sci. Technol. 2020, 98, 105743. [Google Scholar] [CrossRef]

- Wang, R.; Yu, X.; Liu, B.; An, G. Exploration of acceptable operating range for a compression system in a double bypass engine. Chin. J. Aeronaut. 2023, 36, 111–122. [Google Scholar] [CrossRef]

| Component | Solving Requirements |

|---|---|

| Split node | Inlet total temperature/pressure + Flow distribution |

| Combine node | Inlet total temperature/pressure (Two inlets) + Flow distribution |

| Compressor duct | Inlet total temperature/pressure + Arbitrary state indicator (e.g., Stall Margin, mass flow Rate, Pressure Ratio...) |

| Bypass duct | Inlet Total Temperature/Pressure + mass Flow |

| Matching Parameter | Datum Point | Range |

|---|---|---|

| SMFFAN | 10% | 0–25% |

| SMRFAN | 20% | 0–35% |

| SMCDFS | 15% | 0–30% |

| SMHPC | 20% | 0–35% |

| CDFS VIGV angle | 40° | 0–40° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, X.; Hao, D.; Wang, R.; Miao, S.; Liu, B. Analysis of Influencing Factors on the Feasible Operating Range of a Triple-Bypass Adaptive Variable Cycle Engine Compression System. Aerospace 2025, 12, 775. https://doi.org/10.3390/aerospace12090775

Yu X, Hao D, Wang R, Miao S, Liu B. Analysis of Influencing Factors on the Feasible Operating Range of a Triple-Bypass Adaptive Variable Cycle Engine Compression System. Aerospace. 2025; 12(9):775. https://doi.org/10.3390/aerospace12090775

Chicago/Turabian StyleYu, Xianjun, Dongbo Hao, Ruoyu Wang, Songlin Miao, and Baojie Liu. 2025. "Analysis of Influencing Factors on the Feasible Operating Range of a Triple-Bypass Adaptive Variable Cycle Engine Compression System" Aerospace 12, no. 9: 775. https://doi.org/10.3390/aerospace12090775

APA StyleYu, X., Hao, D., Wang, R., Miao, S., & Liu, B. (2025). Analysis of Influencing Factors on the Feasible Operating Range of a Triple-Bypass Adaptive Variable Cycle Engine Compression System. Aerospace, 12(9), 775. https://doi.org/10.3390/aerospace12090775