Design and Analysis of a Cushioning Airbag System for Heavy Airdropped Equipment in High-Altitude Environments

Abstract

1. Introduction

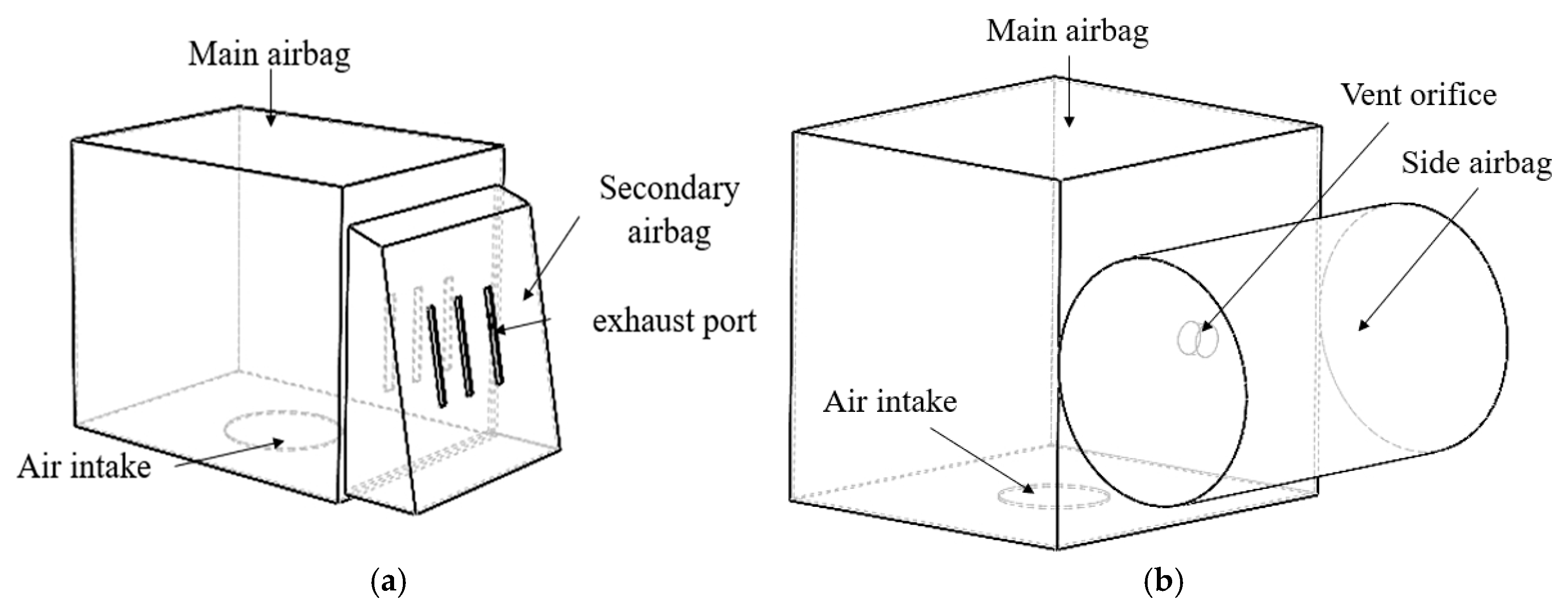

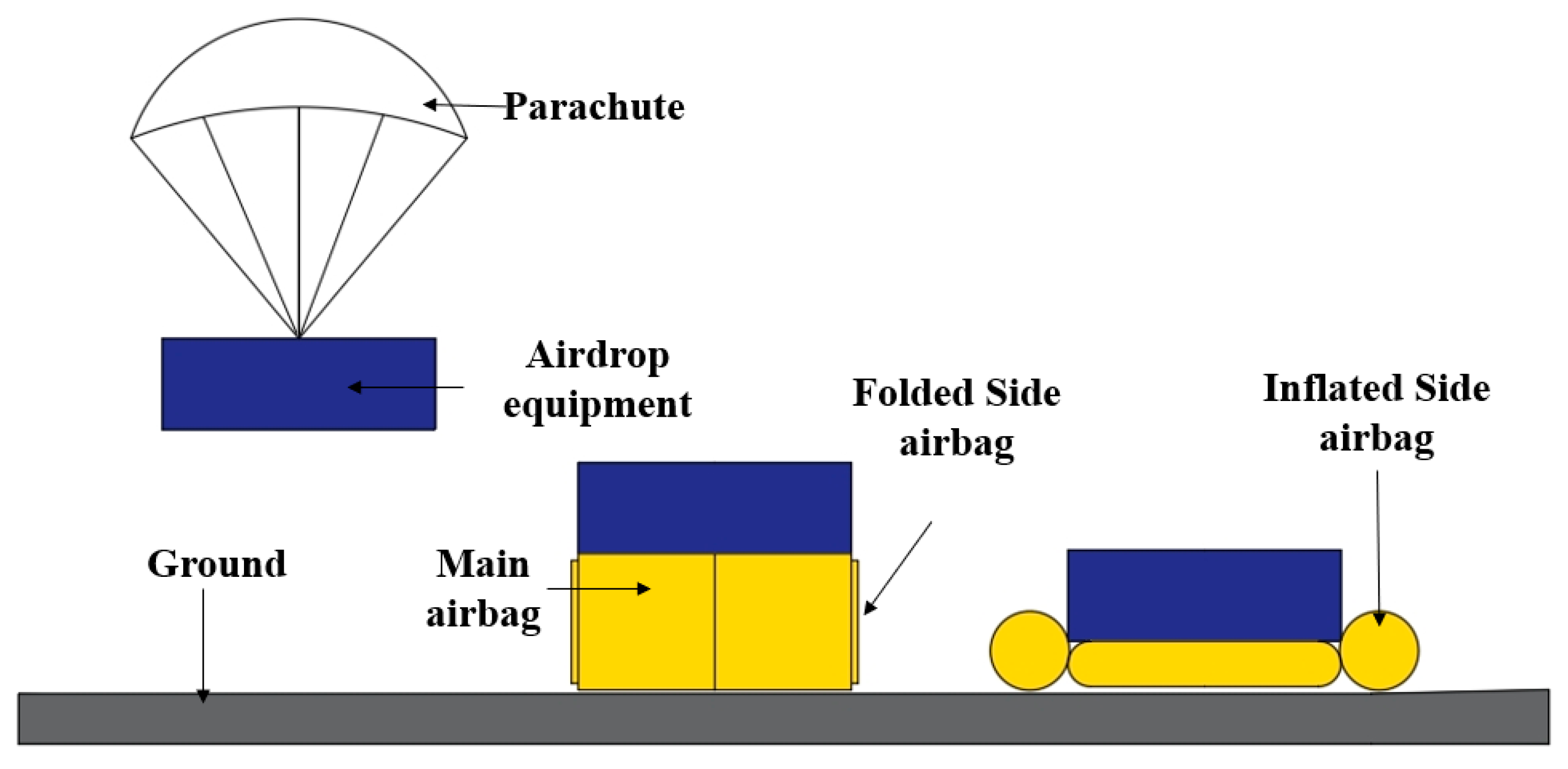

2. Airbag Cushioning System Configuration Design

2.1. Airbag Cushioning System Configuration

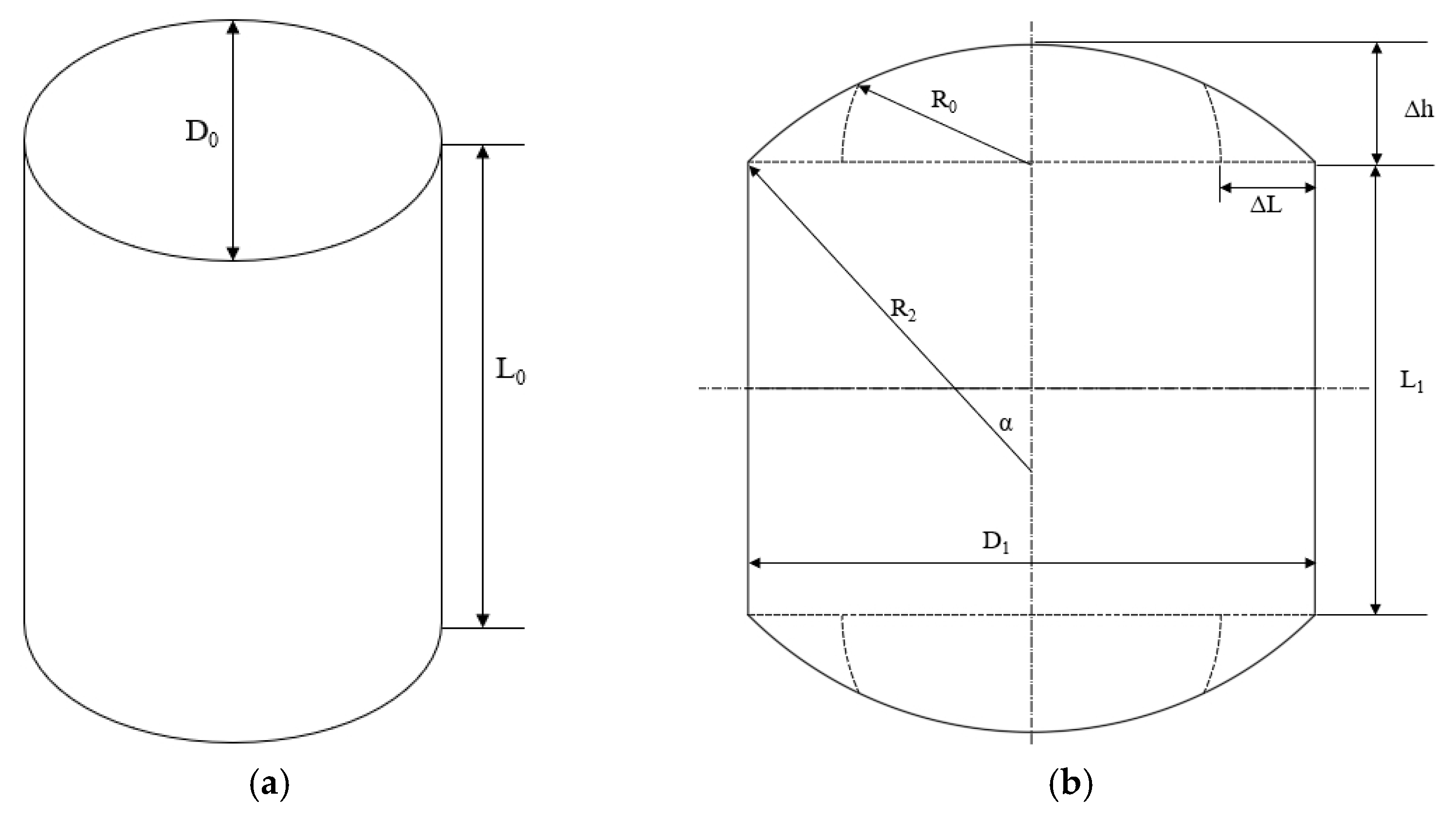

2.2. Airbag Design

3. Analysis of the Cushioning Performance of the Airdrop System in High-Altitude Environments

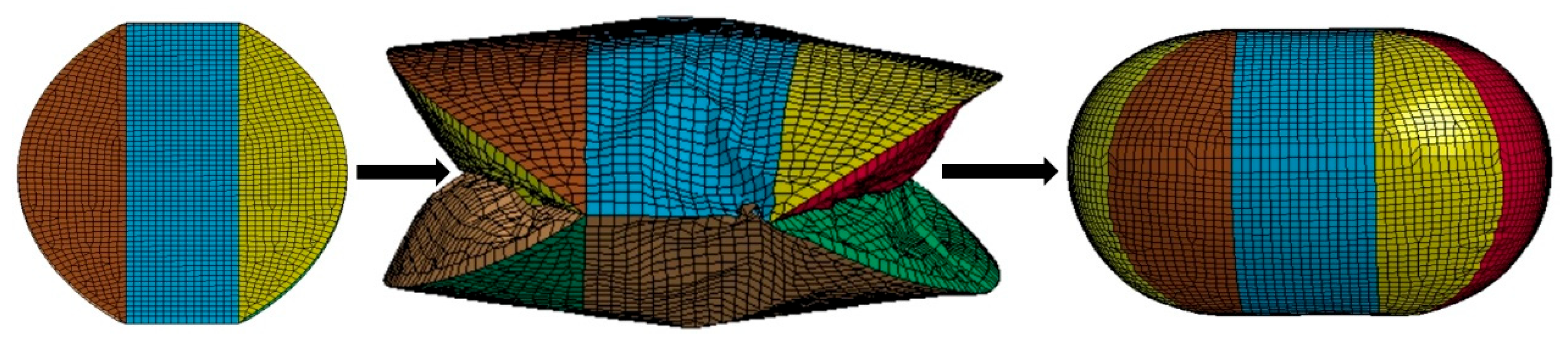

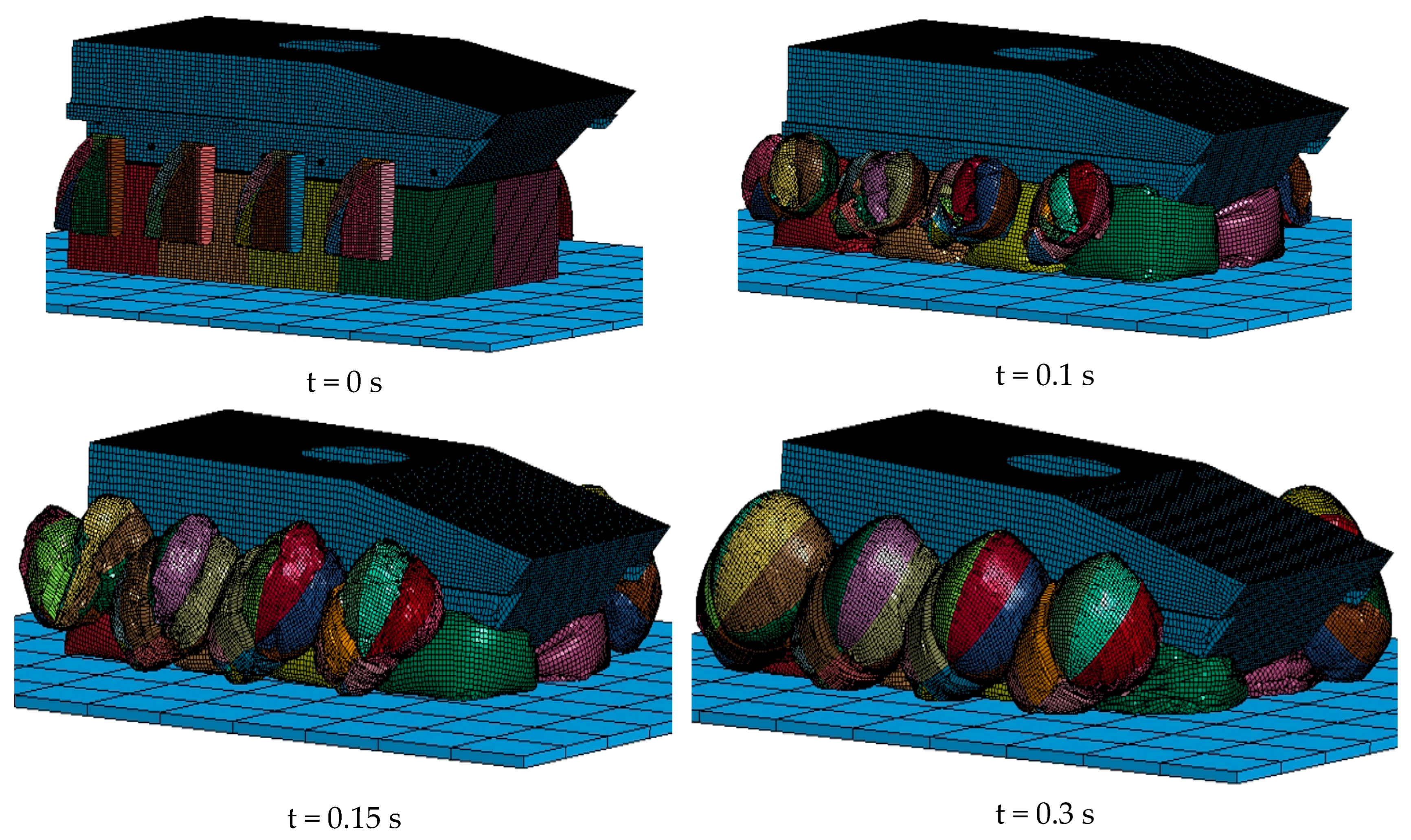

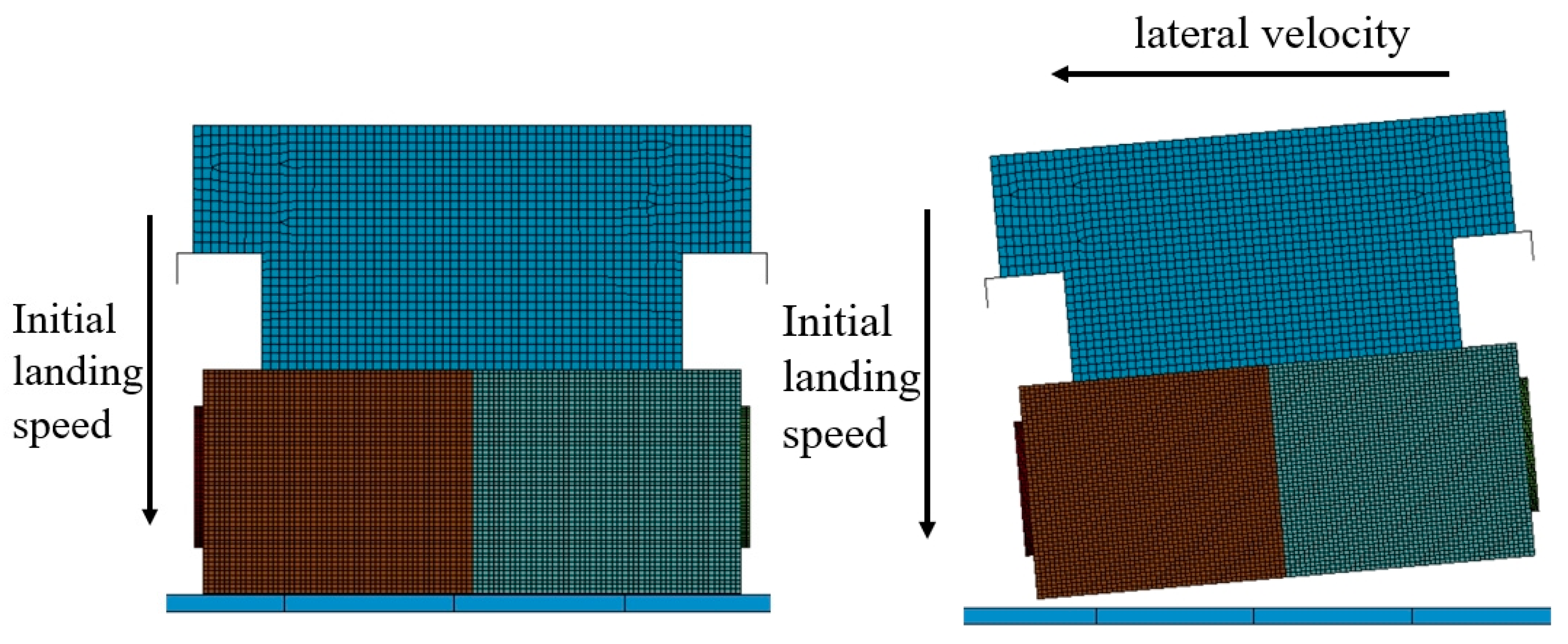

3.1. Finite Element Modeling and Mesh Independence Verification

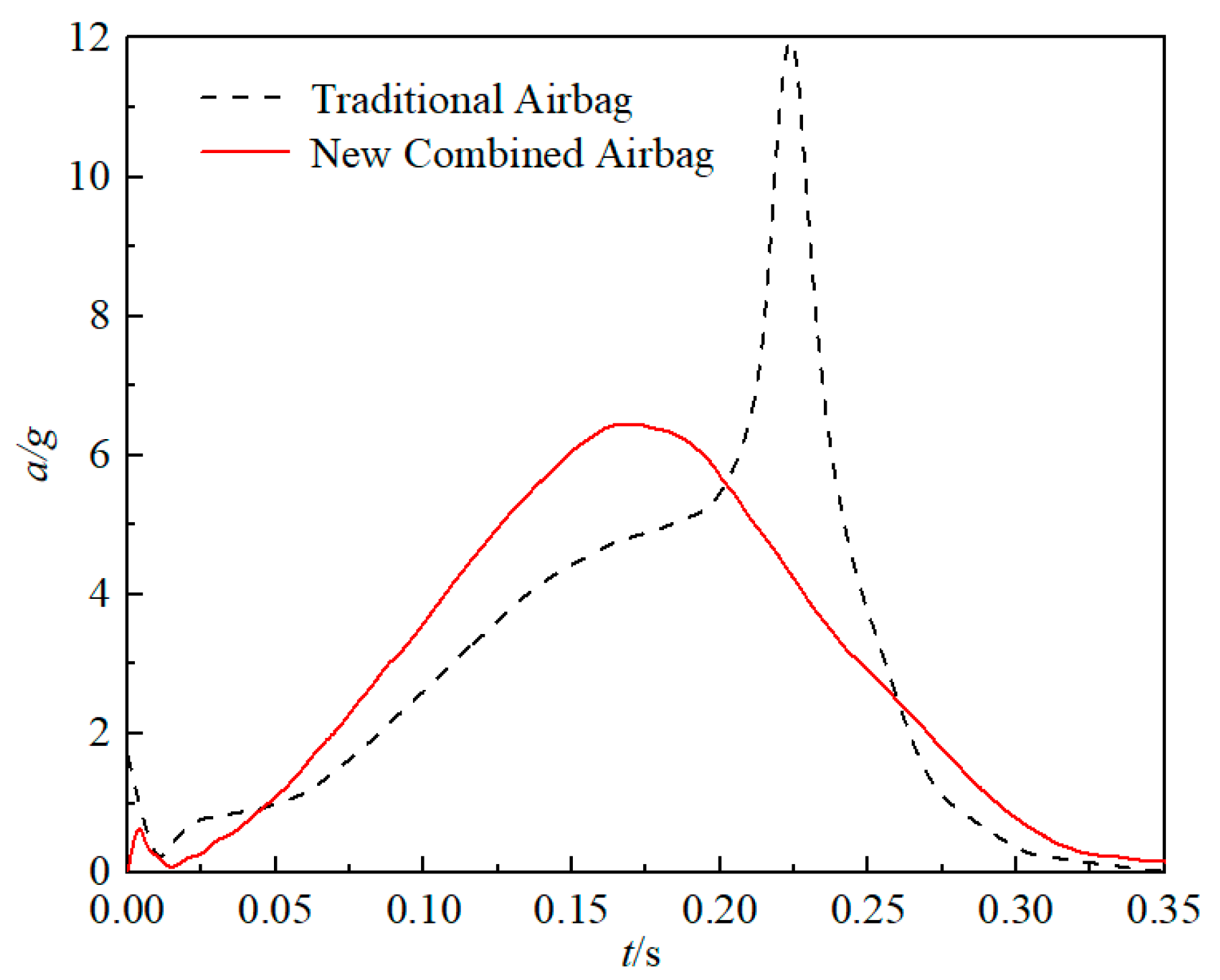

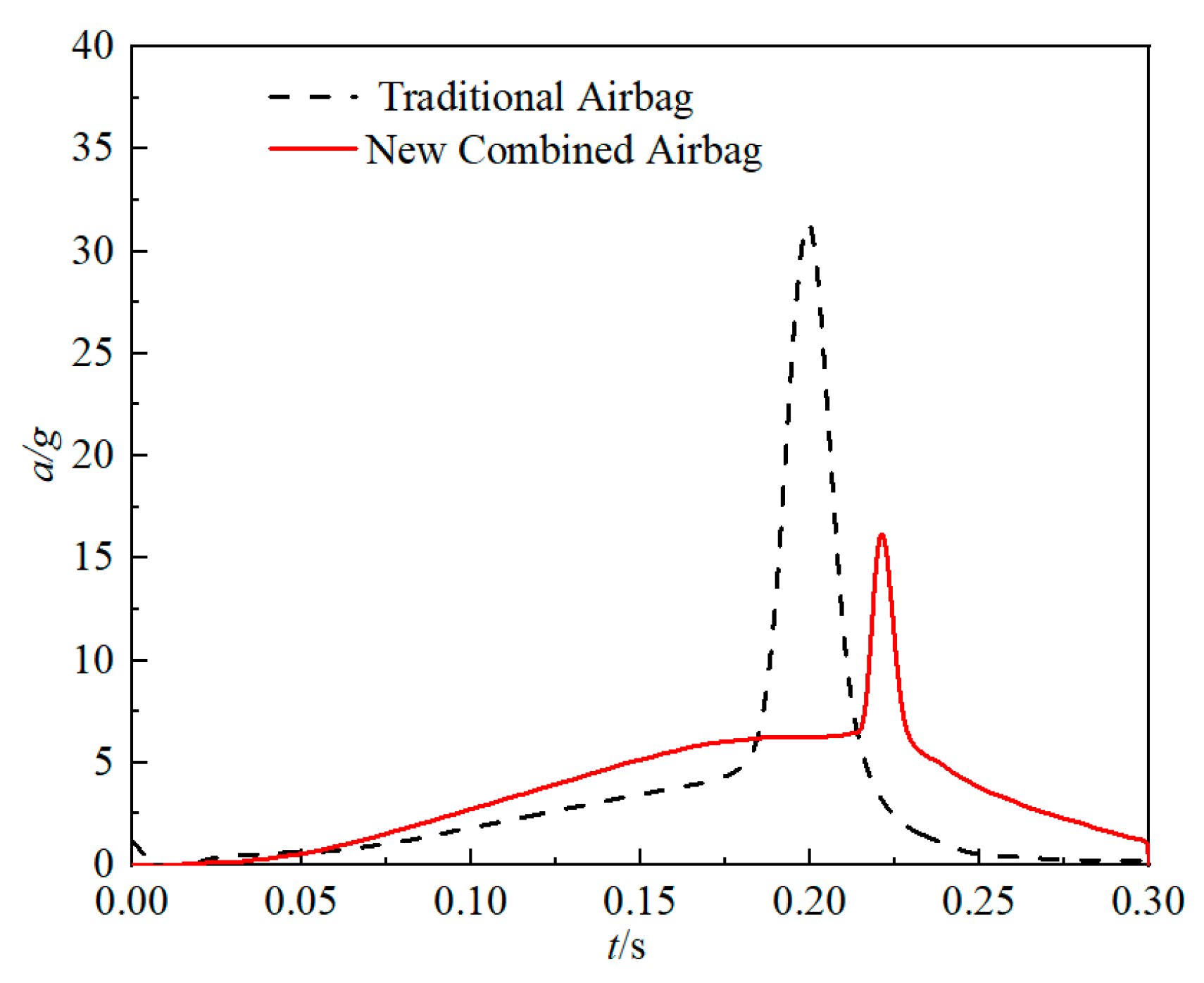

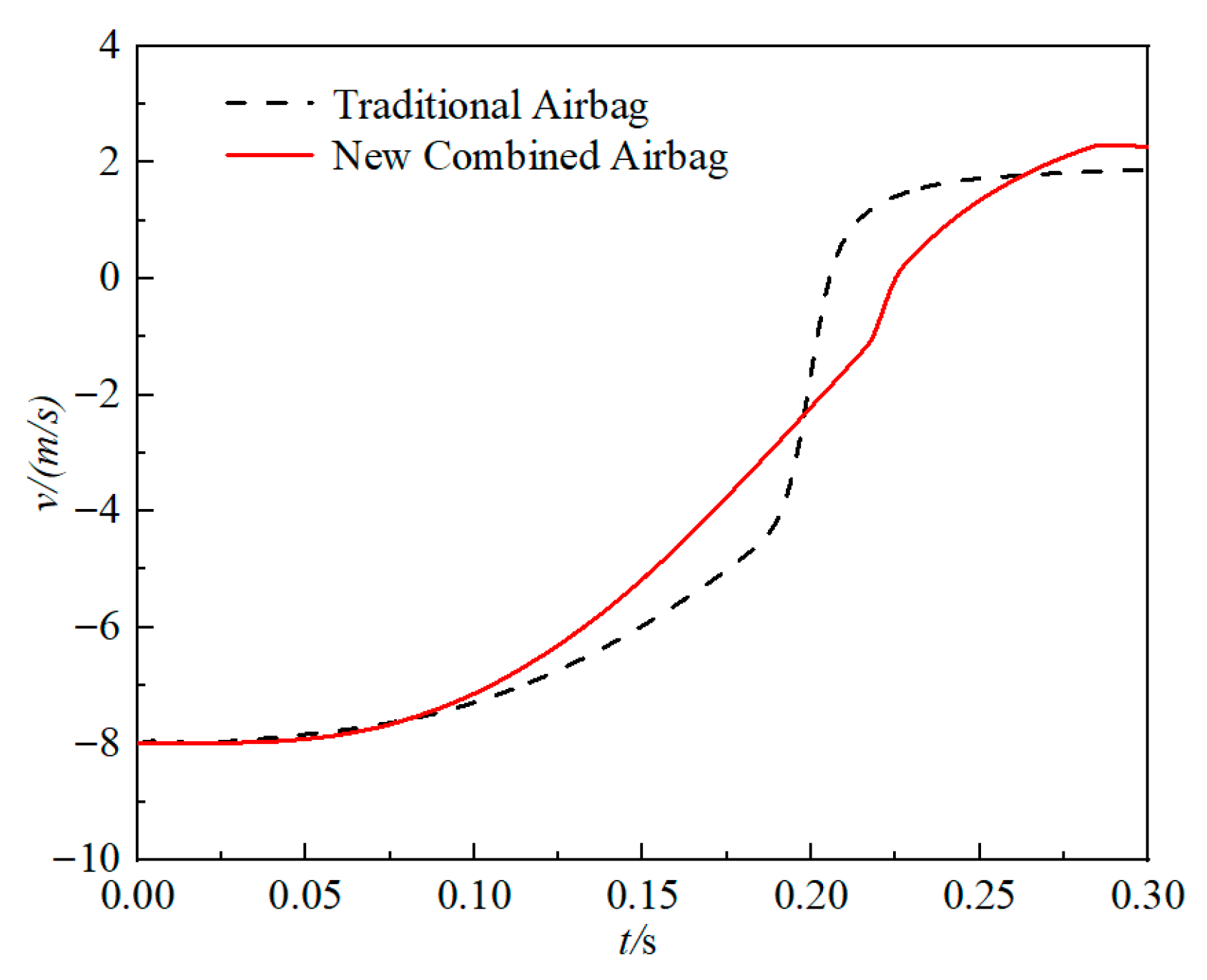

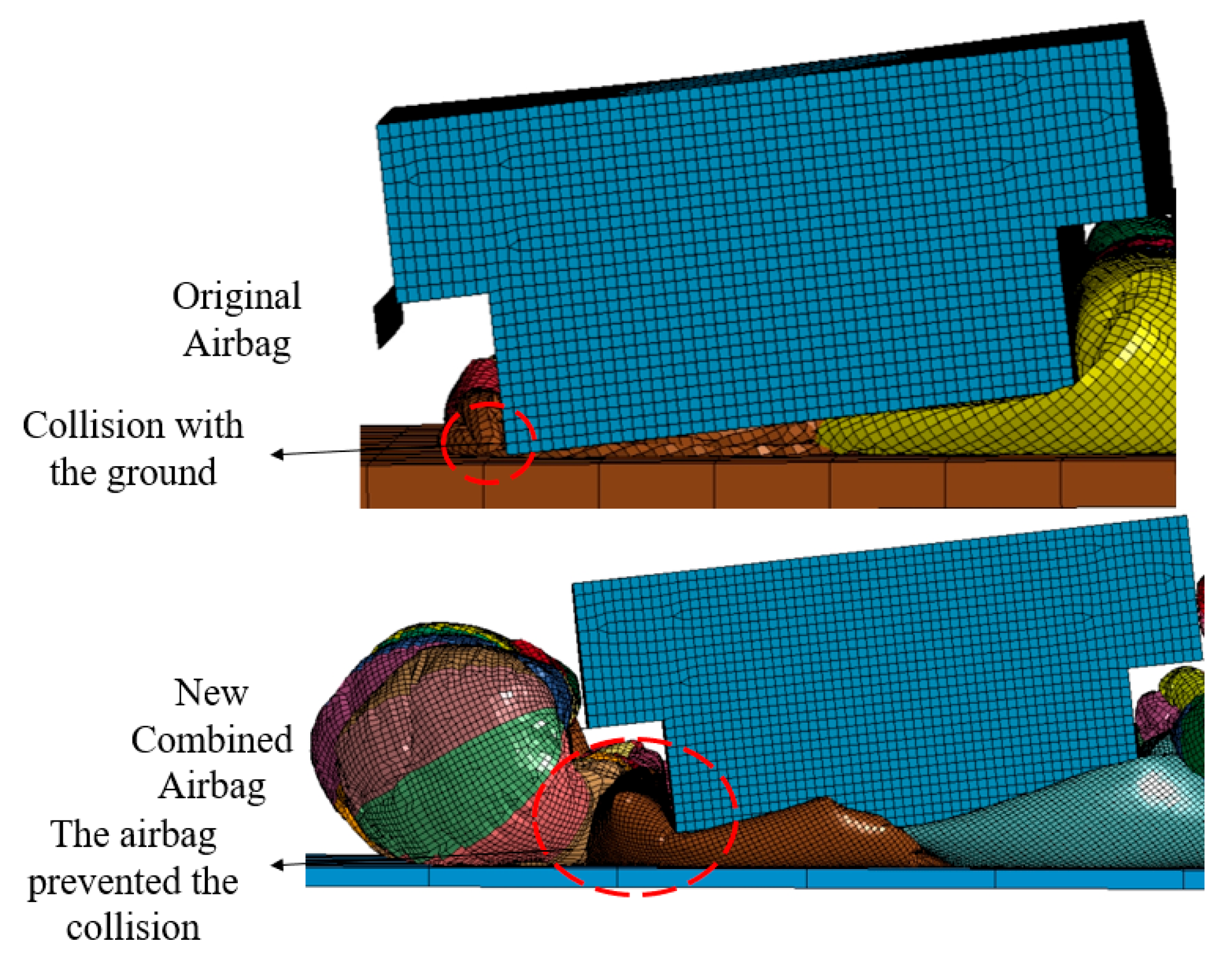

3.2. Analysis of the Cushioning Performance of the New Combined Airbag

4. The Impact of New Combined Airbag Parameters on the Cushioning Effect

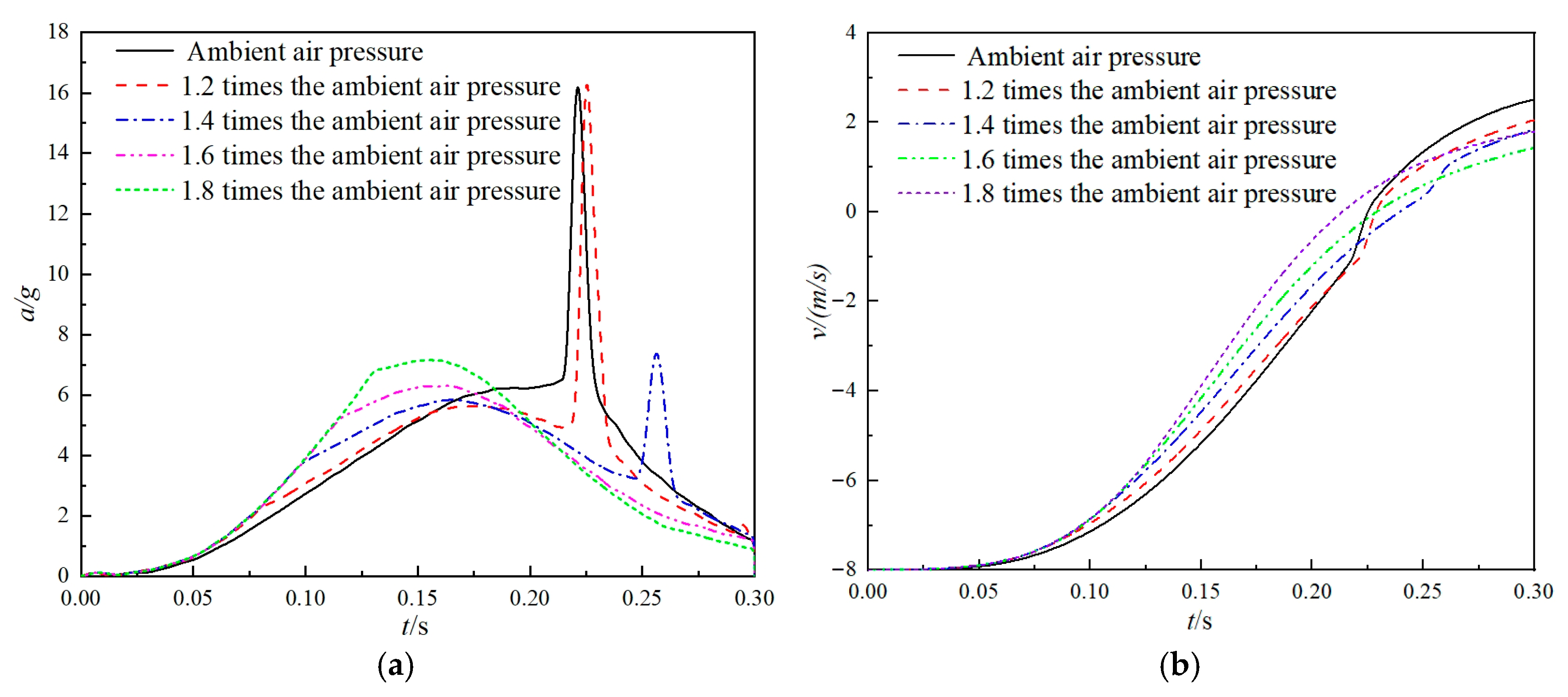

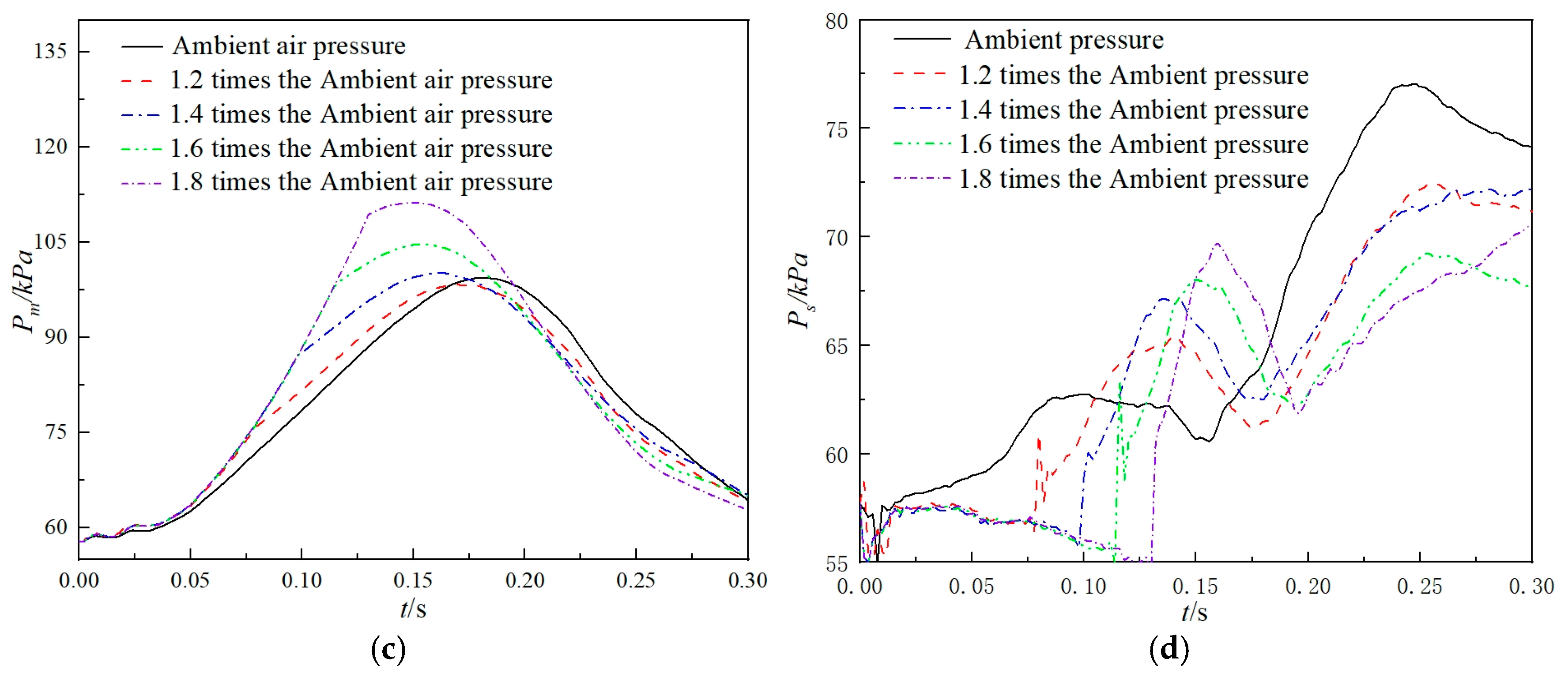

4.1. Effect of Vent Orifice Exhaust Pressure on Airbag Cushioning Performance

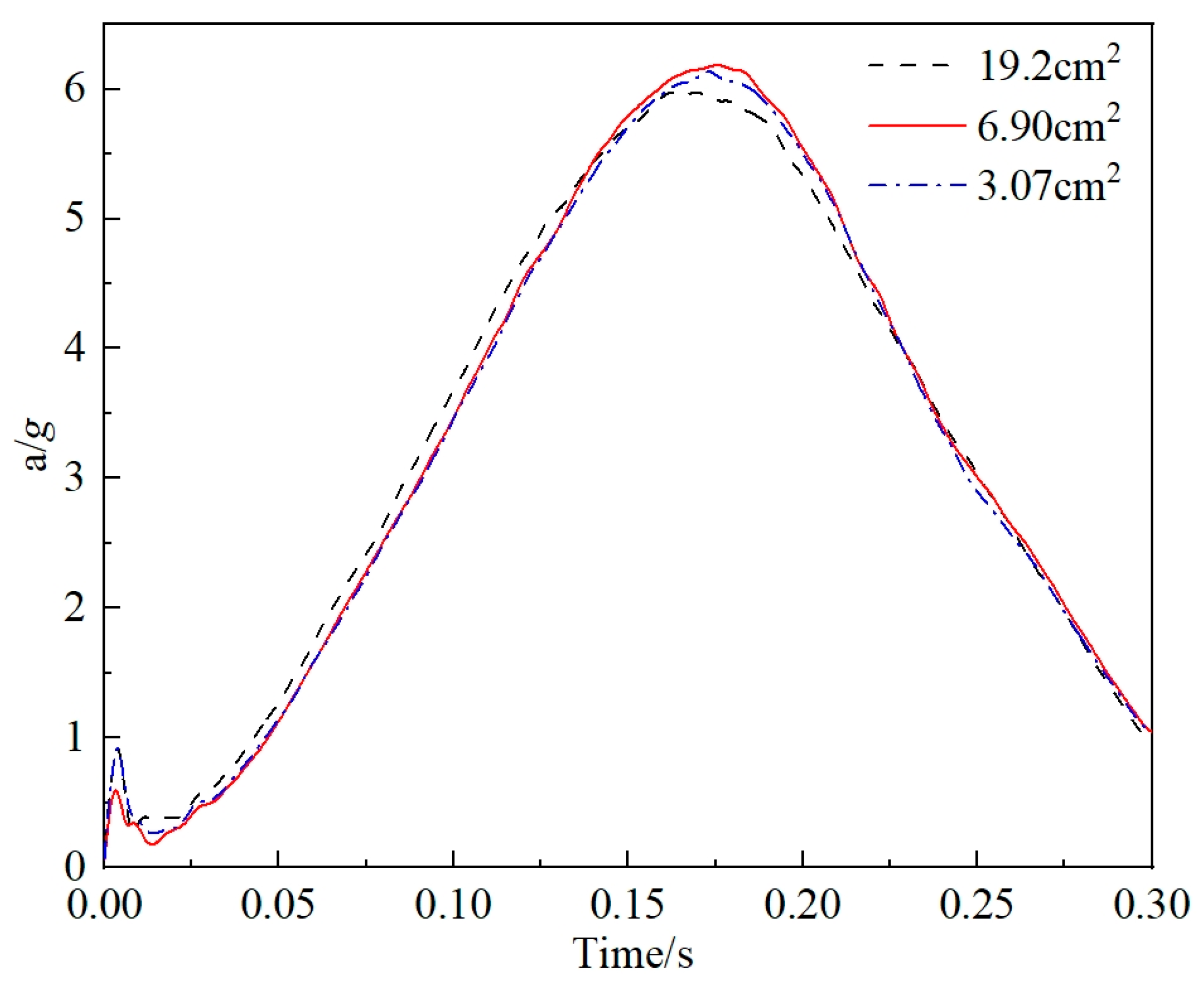

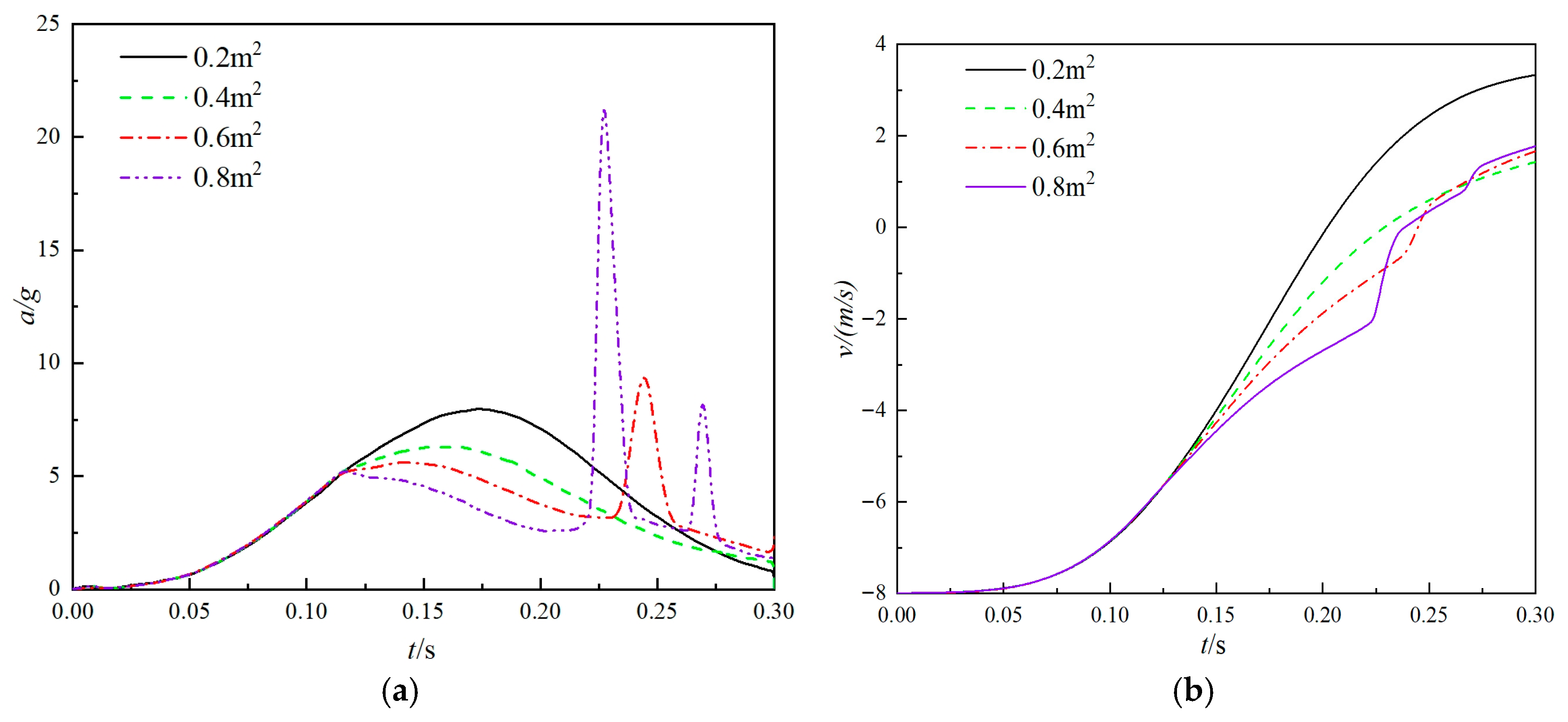

4.2. Effect of Vent Orifice Area on Airbag Cushioning Performance

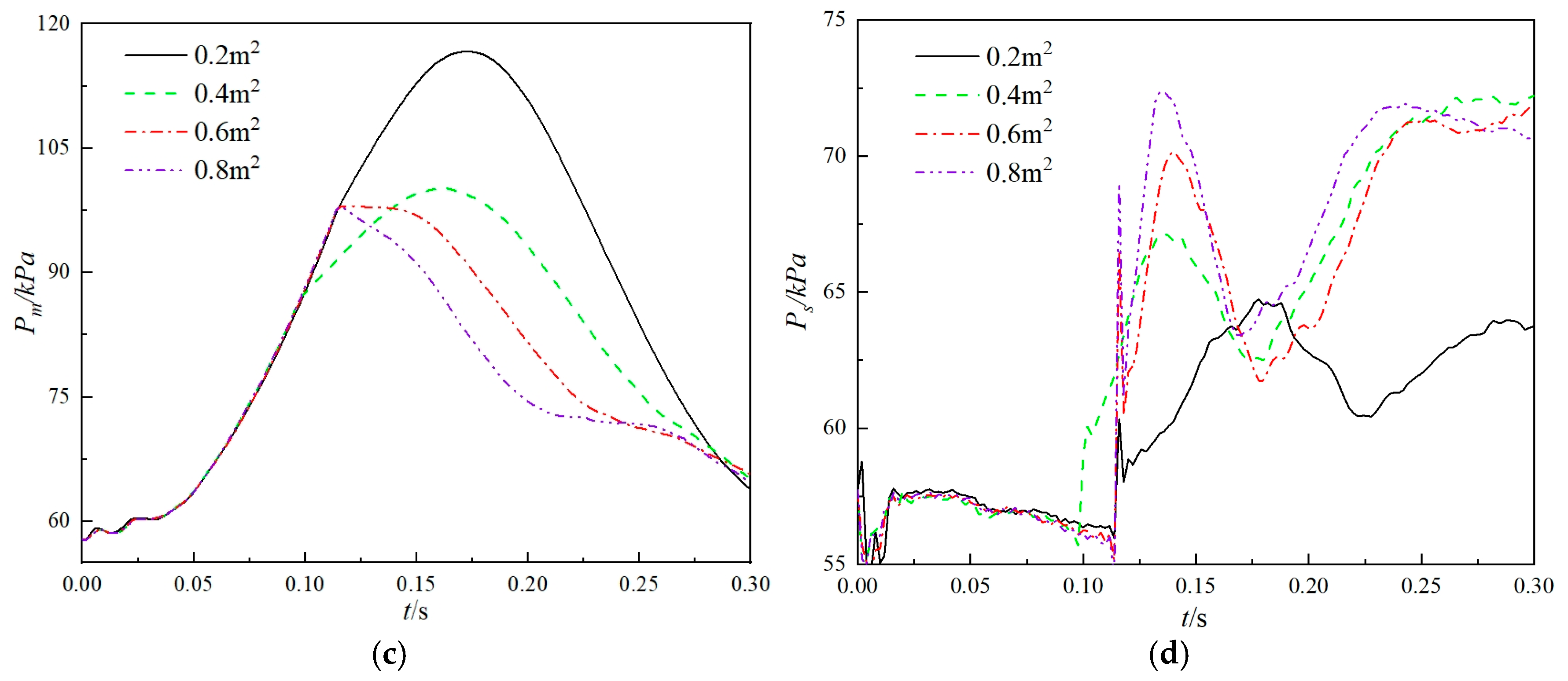

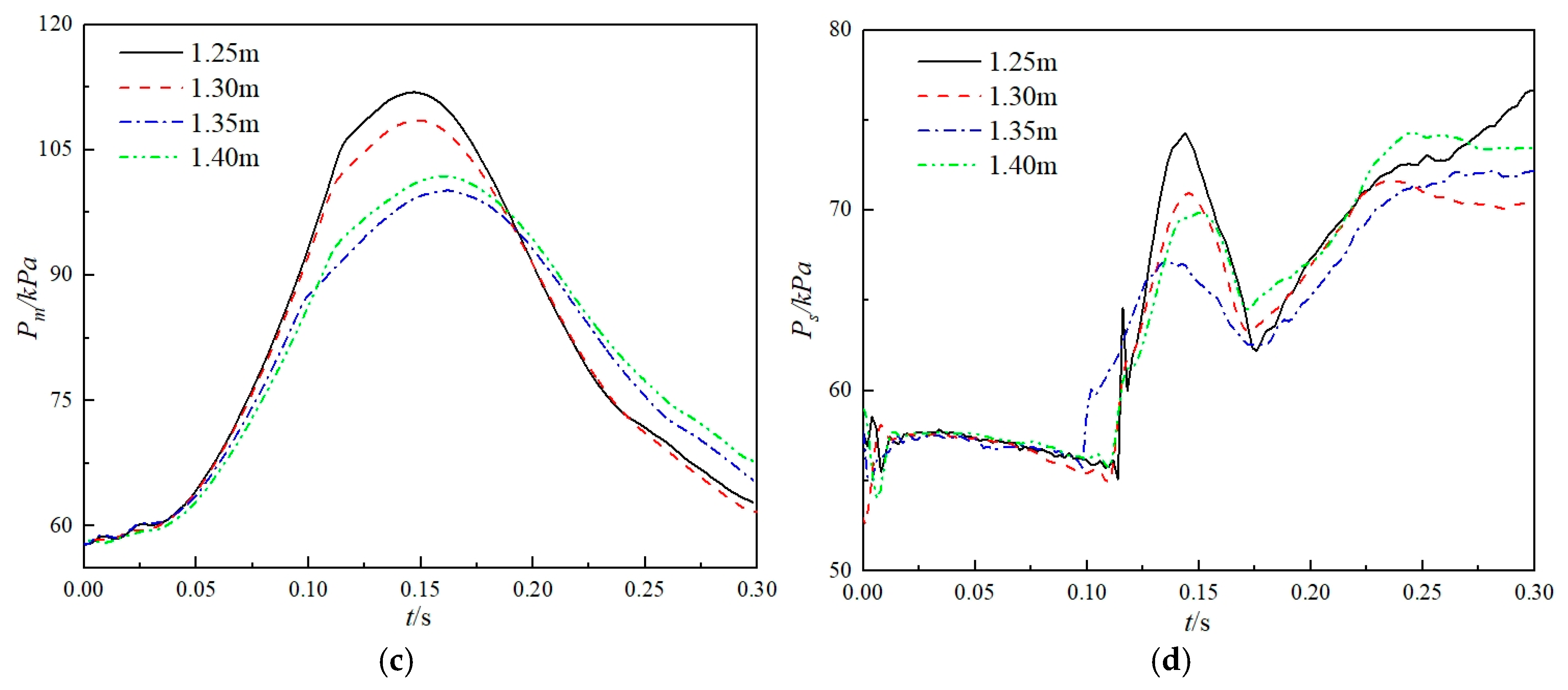

4.3. Effect of Main Airbag Height on Airbag Cushioning Performance

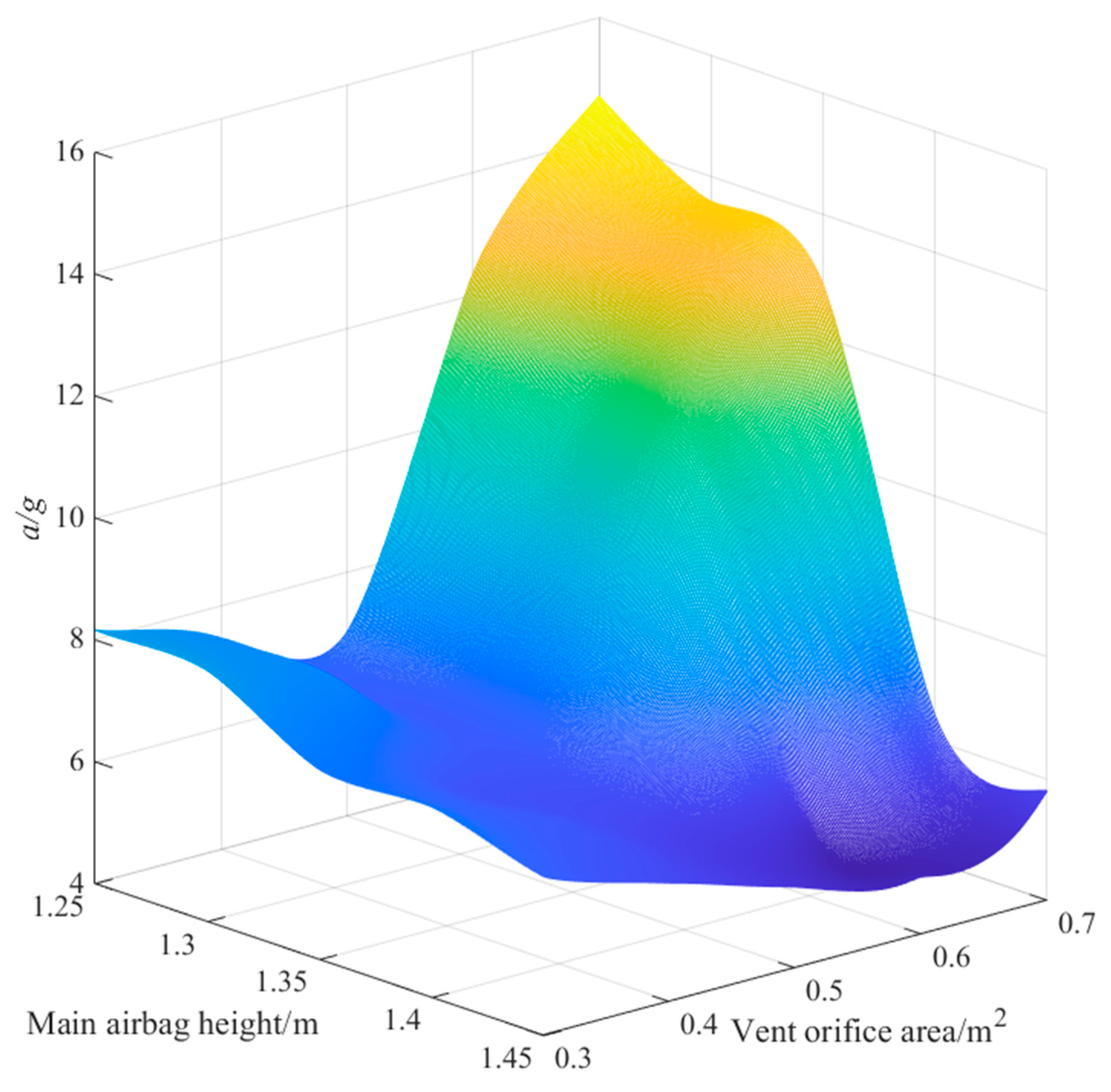

4.4. The Influence Trends of Airbag Parameters on the Cushioning Performance

5. Evaluation of the Environmental Adaptability of the New Combined Airbag

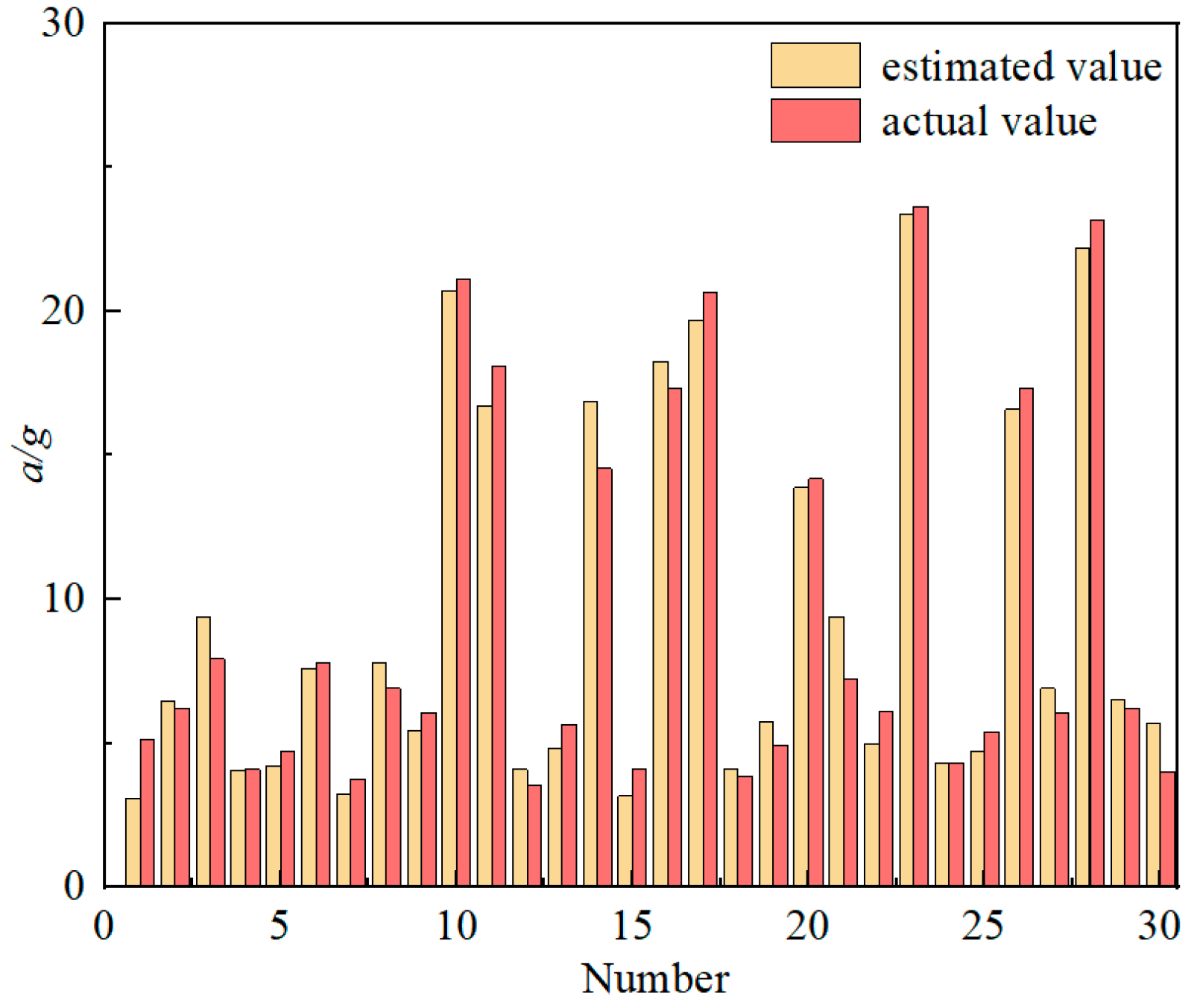

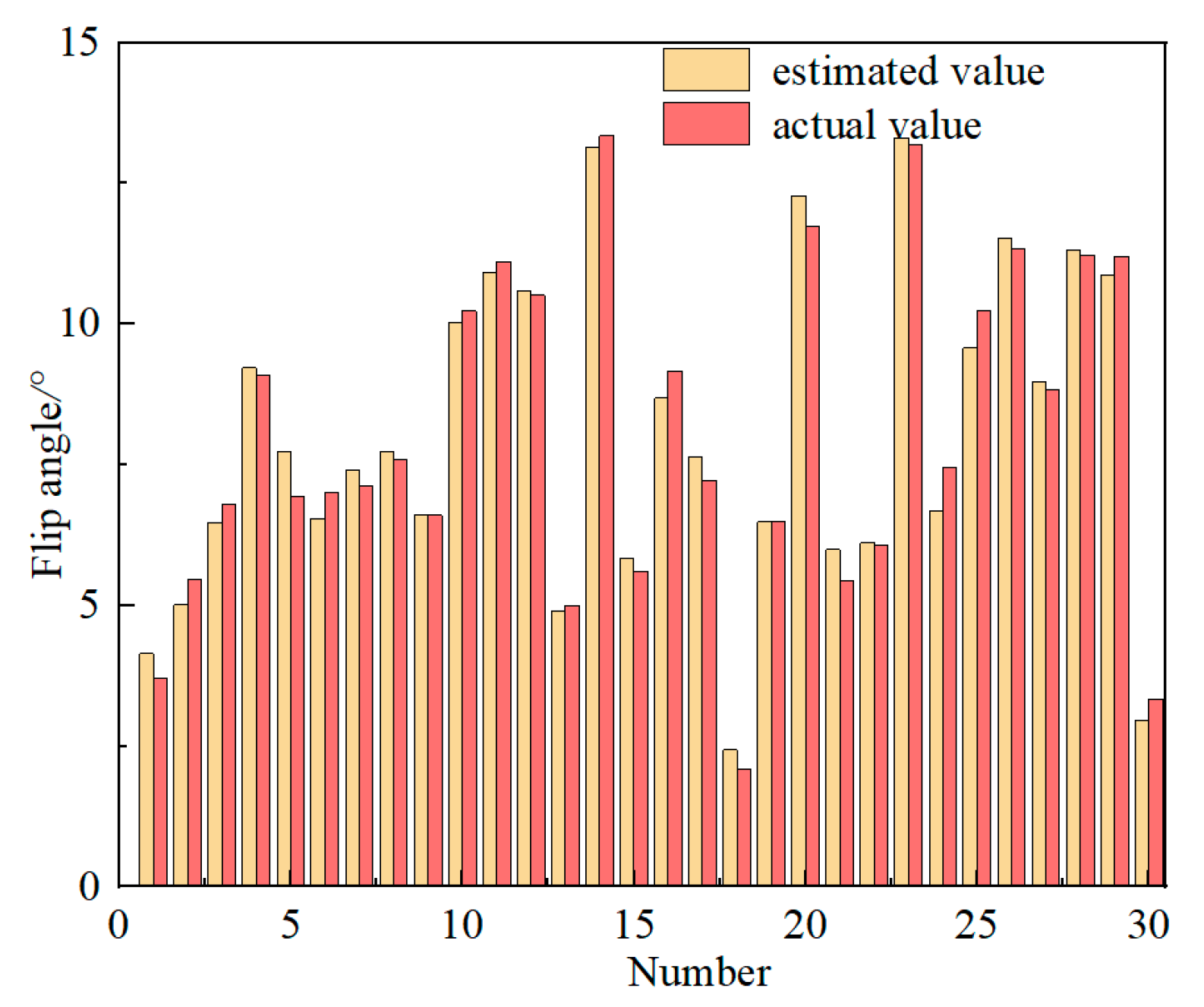

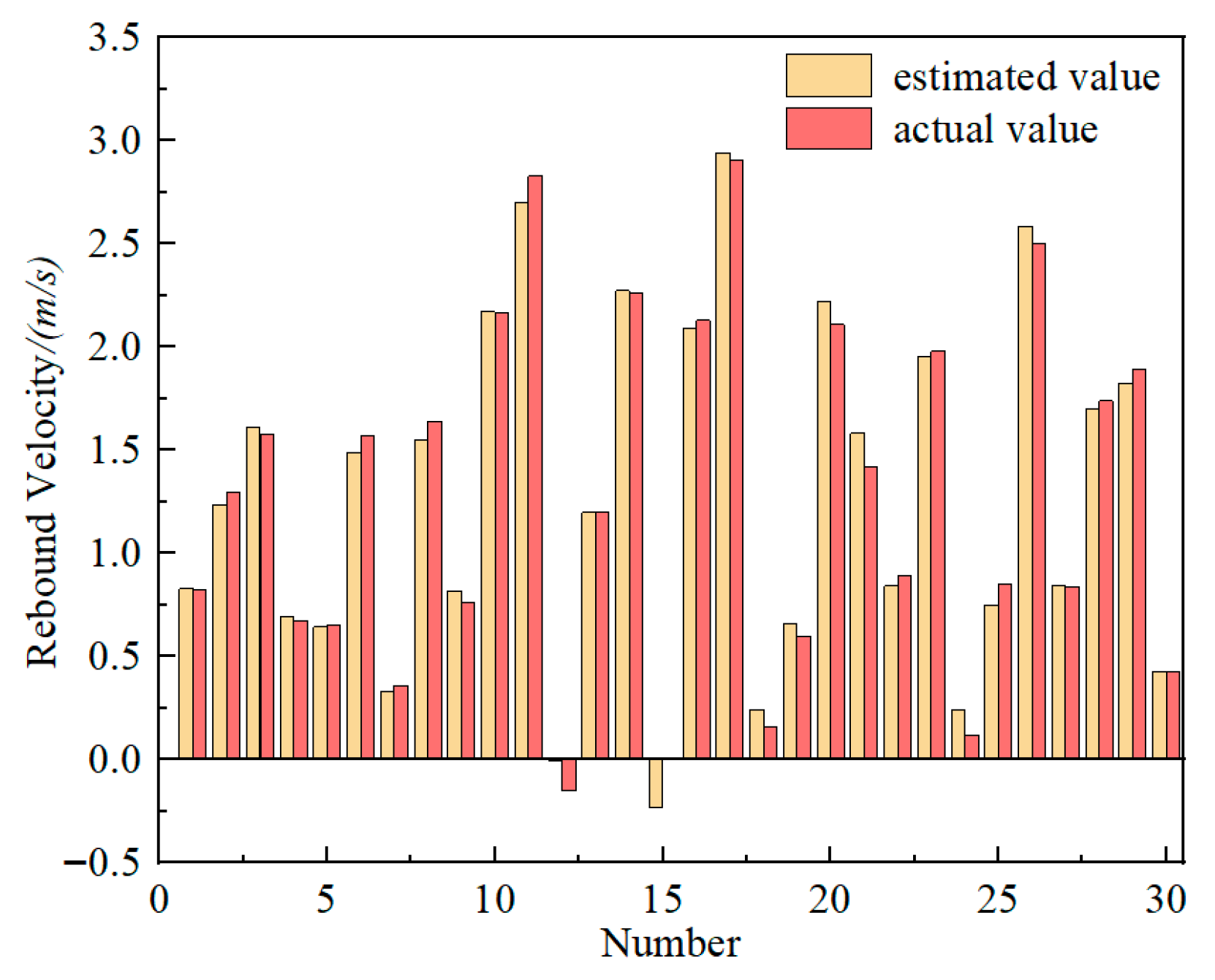

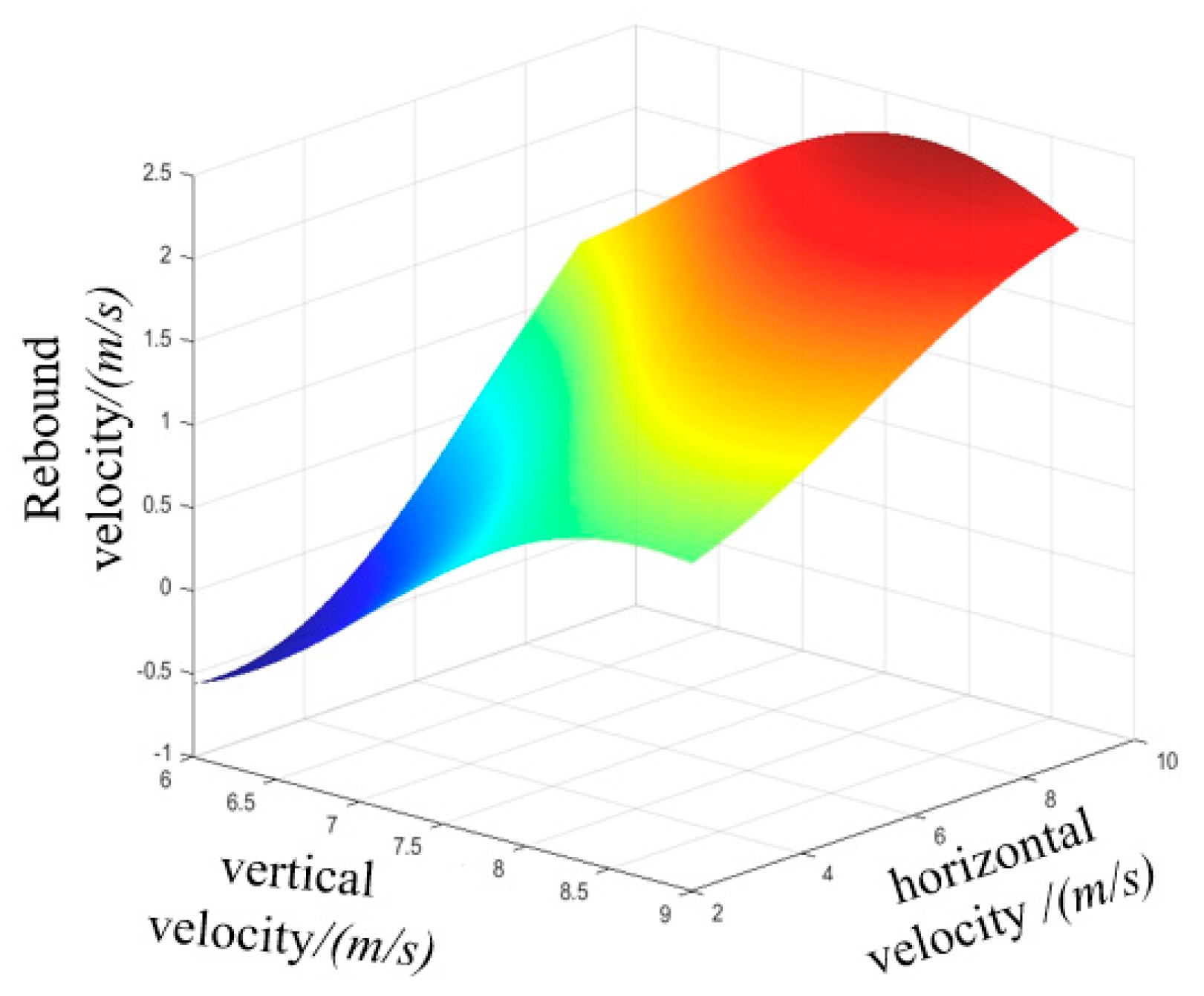

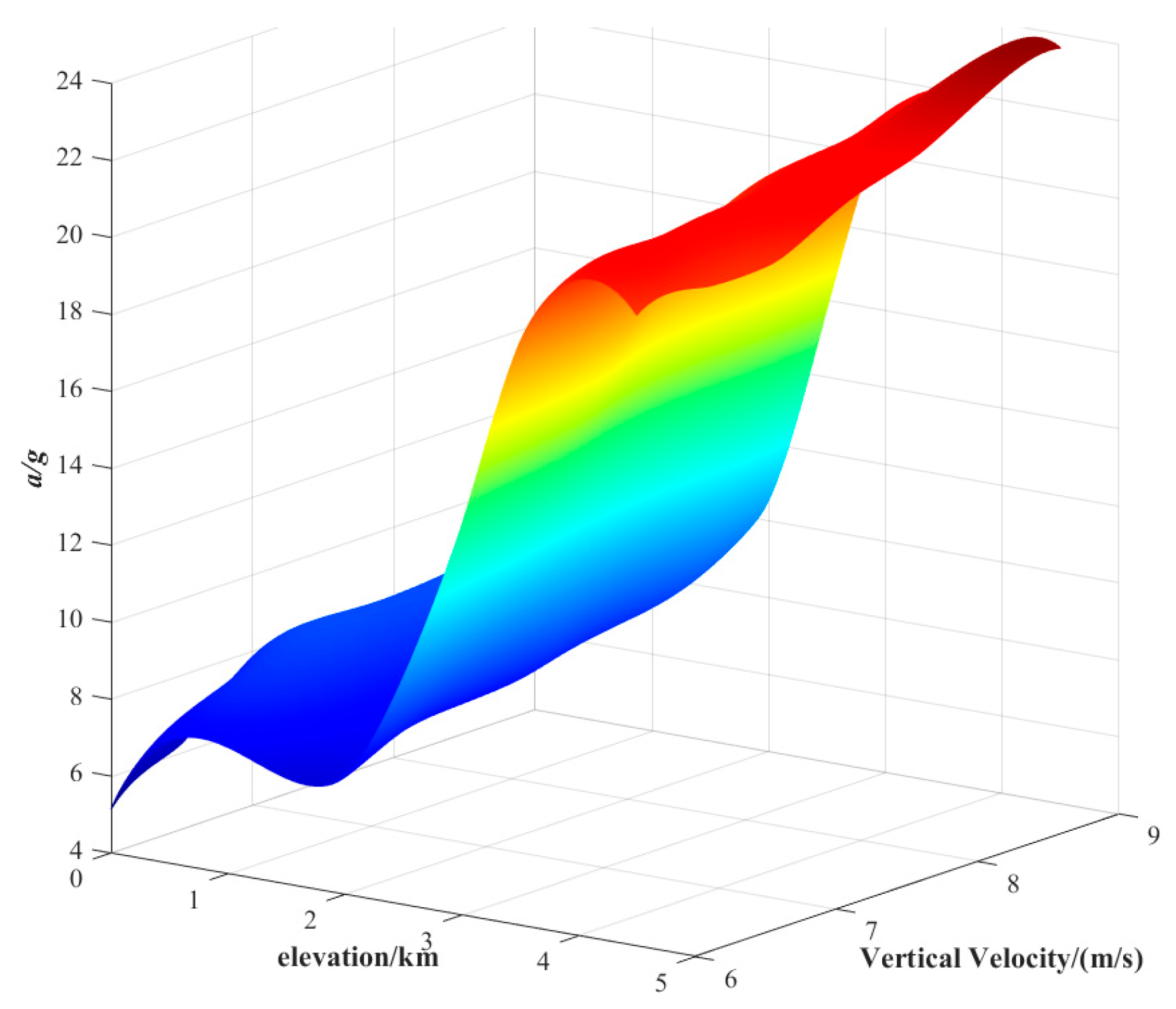

5.1. Surrogate Model Construction

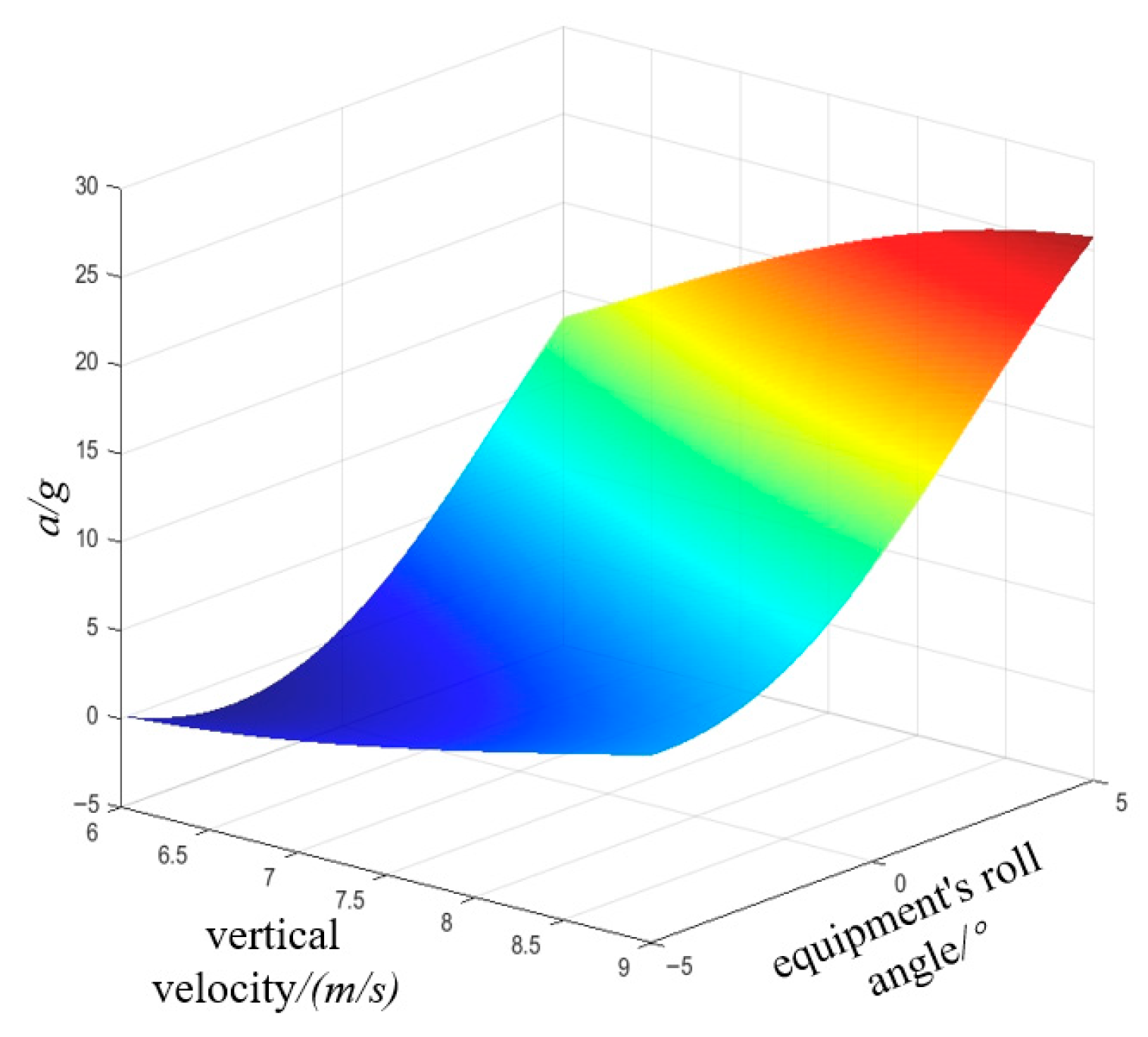

5.2. Analysis of Airdrop Success Rate and Environmental Adaptability in Complex Environments

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, X.; Zhang, Z.; Zhao, Z. The uncertain optimisation of buffering characteristics of landing airbag in manned airdrop. Int. J. Crashworthiness 2013, 18, 225–236. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, X.; Li, D.K. Influence of lunar soil parameters on the lunar landing airbag cushioning performance. J. Natl. Univ. Def. Technol. 2022, 44, 69–80. [Google Scholar] [CrossRef]

- Lu, C.; Chen, J.; Wang, C.; Song, Z. Landing cushioning analysis of new generation heavy airborne armored vehicles. Aircr. Eng. Aerosp. Technol. 2024, 96, 621–630. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, Y.; Huang, H.; Chen, G.; Li, G.; Chen, H. Multi-Objective Optimization Design of an Origami-Inspired Combined Cushion Airbag. Aerospace 2024, 11, 169. [Google Scholar] [CrossRef]

- Holnicki-Szulc, J.; Faraj, R.; Graczykowski, C.; Mikułowski, G.; Sekuła, K.; Wiącek, D. Adaptive Airbag Systems for Protection of General Aviation. In Proceedings of the ECCOMAS Thematic Conference on Multidisciplinary Design Optimization of Aerospace Systems, Lisbon, Portugal, 19–21 July 2023. [Google Scholar]

- Cole, J.K.; Waye, D.E. A Code for Predicting the Performance of a Gas Bag Impact Attenuation System for the Pathfinder Lander; Sandia National Lab: Albuquerque, NM, USA, 1993. [Google Scholar] [CrossRef][Green Version]

- Esgar, J.B.; Morgan, W.C. Analytical Study of Soft Landing on Gasfilled Bags; Lewis Research Center: Cleveland, OH, USA, 1960. [Google Scholar][Green Version]

- Zhou, X.; Zhou, S.M.; Li, D.K. Research on design and cushioning performance of combined lunar landing airbag. Acta Astronaut. 2022, 191, 55–78. [Google Scholar] [CrossRef]

- Cao, P.; Hou, X.Y.; Wang, Y.B. Flexible airbag cushioning for Martian landing based on discrete element method. Adv. Space Res. 2019, 63, 2566–2583. [Google Scholar] [CrossRef]

- Yin, H.; Wen, G. Multi-objective optimisation design of a double-chamber airbag landing system with structure-selection techniques. Int. J. Crashworthiness 2012, 17, 529–539. [Google Scholar] [CrossRef]

- Hong, H.J.; Wang, H.Y.; Li, J.Y. Research on assessment method of airbag cushion system for airdropping equipment. J. Mech. Eng. 2015, 51, 148–154. [Google Scholar] [CrossRef]

- Fu, X.H.; Wang, J.; Chen, Y. A study on soft landing buffering process of manned armored vehicle airdrop. J. Vib. Shock 2021, 40, 57–64. [Google Scholar] [CrossRef]

- Dai, J.C.; Zhou, Y.B.; Zhang, J.C. Effects of different postures on crew damage under the impact of manned airdrop landing. Explos. Shock Waves 2021, 41, 122–134. [Google Scholar] [CrossRef]

- Tang, X.H.; Qin, L.F.; Tang, J.H. Stability analysis of a soft landing system for heavy cargo airdrop. J. Vib. Shock 2015, 34, 122–126. [Google Scholar] [CrossRef]

- Li, J. Exhaust Area Matching Method of Self-Inflating Airbag Dropped at High Altitude. J. Ordnance Equip. Eng. 2019, 40, 21–24. [Google Scholar] [CrossRef]

- Lee, C.; Rosato, N.; Lai, F. An investigation of improved airbag performance by vent control and gas injection. In Proceedings of the 11th Aerodynamic Decelerator Systems Technology Conference, San Diego, CA, USA, 9–11 April 1991; Available online: https://arc.aiaa.org/doi/pdf/10.2514/6.1991-892 (accessed on 2 July 2025).[Green Version]

- Timmers, R.; Hardy, R.; Welch, J. Modeling and simulation of the second generation Orion Crew Module air bag landing system. In Proceedings of the 20th AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Seattle, WA, USA, 4–7 May 2009; Available online: https://arc.aiaa.org/doi/pdf/10.2514/6.2009-2921 (accessed on 1 July 2025).[Green Version]

- Tutt, B.; Sandy, C.; Corliss, J. Status of the Development of an Airbag Landing System for the Orion Crew Module. In Proceedings of the 20th AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Seattle, WA, USA, 4–7 May 2009; Available online: https://arc.aiaa.org/doi/pdf/10.2514/6.2009-2923 (accessed on 6 July 2025).[Green Version]

- Wang, H.Y.; Hong, H.J.; Li, J.Y.; Rui, Q. Study on multi-objective optimization of airbag landing attenuation system for heavy airdrop. Def. Technol. 2013, 9, 237–241. [Google Scholar] [CrossRef]

- Do, S.; De Weck, O. A personal airbag system for the orion crew exploration Vehicle. Acta Astronaut. 2012, 81, 239–255. [Google Scholar] [CrossRef]

- Alizadeh, M.; Sedaghat, A.; Kargar, E. Shape and orifice optimization of airbag systems for UAV parachute landing. Int. J. Aeronaut. Space Sci. 2014, 15, 335–343. [Google Scholar] [CrossRef]

- Wang, H.Y.; Wang, C.; Lu, C.Y. Multi Objective Optimization and Design of Reinstalling Airdrop Buffer System. Spacecr. Recovery Remote Sens. 2025, 46, 1–10. [Google Scholar]

- Xiao, X.; Long, A.; Lin, H. Large deformation modelling of tight woven fabric under high air pressure. J. Eng. Fibers Fabr. 2015, 10, 10–11. [Google Scholar] [CrossRef]

- Wang, H.Y. Optimization and Environmental Adaptability Evaluation of Airbag Landing Attenuation System for Airdrop; National Defense Industry Press: Arlington, VA, USA, 2016; ISBN 9787118106398. [Google Scholar][Green Version]

| Number | Parameters | Values |

|---|---|---|

| 1 | Equipment mass | 15 t |

| 2 | Initial pressure | 5.7715 × 104 Pa |

| 3 | Landing velocity | 8 m/s |

| 4 | Main airbag height | 1.35 m |

| 5 | Vent orifice area | 0.04 m2 |

| 6 | Airbag fabric elastic modulus | 4 × 108 Pa |

| 7 | Airbag fabric density | 850 Kg/m3 |

| 8 | Airbag fabric Poisson’s ratio | 0.3 |

| 9 | Equipment and airbag element | Shell |

| 10 | Equipment material density | 7850 Kg/m3 |

| 11 | Number of nodes | 194,073 |

| 12 | Number of elements | 195,177 |

| 13 | Software of finite element analysis | lsdyna_R11 |

| Condition | Vertical Velocity (m/s) | Lateral Velocity (m/s) | Tilt Angle/° | Ambient Atmospheric Pressure/Pa |

|---|---|---|---|---|

| 1 | 8 | 0 | 0 | 57,715 |

| 2 | 8 | 5 | 5 | 57,715 |

| Number | Airbag Height/m | Vent Orifice Area/m2 | a/g |

|---|---|---|---|

| 1 | 1.25 | 0.3 | 8.163 |

| 2 | 1.25 | 0.4 | 7.475 |

| 3 | 1.25 | 0.5 | 7.022 |

| 4 | 1.25 | 0.6 | 12.34 |

| 5 | 1.25 | 0.7 | 14.7 |

| 6 | 1.30 | 0.3 | 8.120 |

| 7 | 1.30 | 0.4 | 7.440 |

| 8 | 1.30 | 0.5 | 6.674 |

| 9 | 1.30 | 0.6 | 10.612 |

| 10 | 1.30 | 0.7 | 13.21 |

| 11 | 1.35 | 0.3 | 7.122 |

| 12 | 1.35 | 0.4 | 6.314 |

| 13 | 1.35 | 0.5 | 6.7 |

| 14 | 1.35 | 0.6 | 10.5 |

| 15 | 1.35 | 0.7 | 12.85 |

| 16 | 1.40 | 0.3 | 7.130 |

| 17 | 1.40 | 0.4 | 6.35 |

| 18 | 1.40 | 0.5 | 5.755 |

| 19 | 1.40 | 0.6 | 5.32 |

| 20 | 1.40 | 0.7 | 6.4 |

| 21 | 1.45 | 0.3 | 6.610 |

| 22 | 1.45 | 0.4 | 5.95 |

| 23 | 1.45 | 0.5 | 5.33 |

| 24 | 1.45 | 0.6 | 4.94 |

| 25 | 1.45 | 0.7 | 5.8 |

| Number | Parameter | Data Range |

|---|---|---|

| 1 | Horizontal velocity/(m·s−1) | [2, 9] |

| 2 | Vertical velocity/(m·s−1) | [6, 9] |

| 3 | Elevation/m | [0, 4500] |

| 4 | Roll angle/° | [−5, 5] |

| 5 | Ground slope/° | [−5, 5] |

| Number | Parameter | Distribution Function | Data |

|---|---|---|---|

| 1 | Lateral velocity | Weibull distribution α = 2.9 | β = 6.3 |

| 2 | Vertical velocity | Normal distribution μ = 7.1 | = 0.6 |

| 3 | Roll angle | Normal distribution μ = 7.1 | = 2.33 |

| 4 | Ground slope | Uniform distribution | a = −5, b = 5 |

| Response Evaluation Indicators of Airdrop Equipment | Failure Threshold Value |

|---|---|

| Maximum overload acceleration of equipment/g | 20 |

| Maximum flip angle of equipment/° | 25 |

| Maximum rebound velocity of equipment/(m·s−1) | 3 |

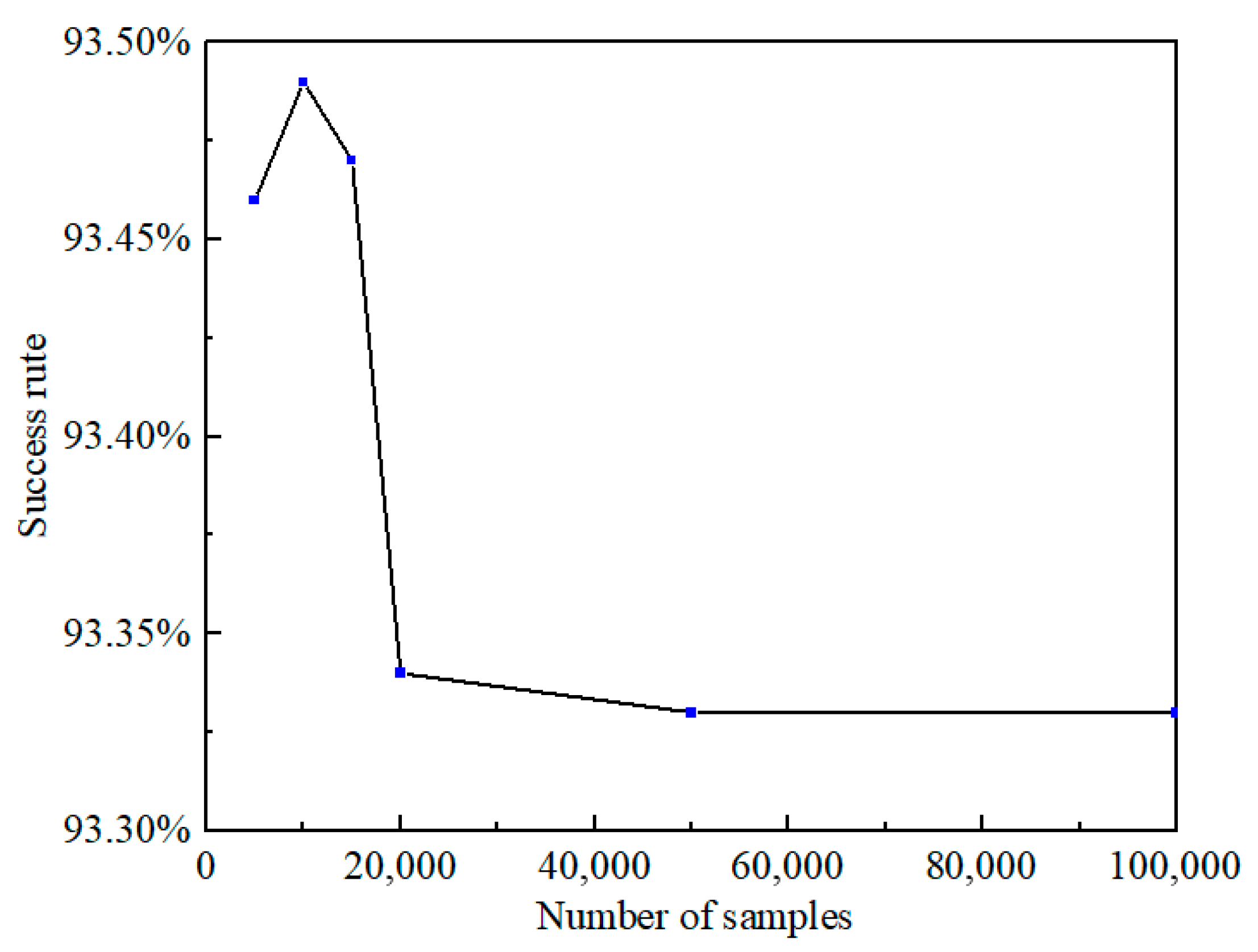

| Number of Failures | |||||

|---|---|---|---|---|---|

| Number of Samples | Number of Failures | Number of Failures | Success Rate Statistics | ||

| Maximum Overload Acceleration/g | Maximum Flip Angle/° | Maximum Rebound Velocity of Equipment/(m·s−1) | |||

| 5000 | 232 | 5 | 130 | 327 | 93.46% |

| 10,000 | 459 | 6 | 257 | 651 | 93.49% |

| 15,000 | 686 | 14 | 374 | 979 | 93.47% |

| 20,000 | 960 | 12 | 482 | 1332 | 93.34% |

| 50,000 | 2342 | 30 | 1261 | 3335 | 93.33% |

| 100,000 | 4735 | 84 | 2513 | 6670 | 93.33% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Wang, H.; Lu, C.; Wang, C.; Chen, J. Design and Analysis of a Cushioning Airbag System for Heavy Airdropped Equipment in High-Altitude Environments. Aerospace 2025, 12, 768. https://doi.org/10.3390/aerospace12090768

Zhao Q, Wang H, Lu C, Wang C, Chen J. Design and Analysis of a Cushioning Airbag System for Heavy Airdropped Equipment in High-Altitude Environments. Aerospace. 2025; 12(9):768. https://doi.org/10.3390/aerospace12090768

Chicago/Turabian StyleZhao, Qilong, Haoyang Wang, Chaoyu Lu, Chen Wang, and Jinbao Chen. 2025. "Design and Analysis of a Cushioning Airbag System for Heavy Airdropped Equipment in High-Altitude Environments" Aerospace 12, no. 9: 768. https://doi.org/10.3390/aerospace12090768

APA StyleZhao, Q., Wang, H., Lu, C., Wang, C., & Chen, J. (2025). Design and Analysis of a Cushioning Airbag System for Heavy Airdropped Equipment in High-Altitude Environments. Aerospace, 12(9), 768. https://doi.org/10.3390/aerospace12090768