Experiment and Numerical Investigation of a Forebody Design Method for Inward-Turning Inlet

Abstract

1. Introduction

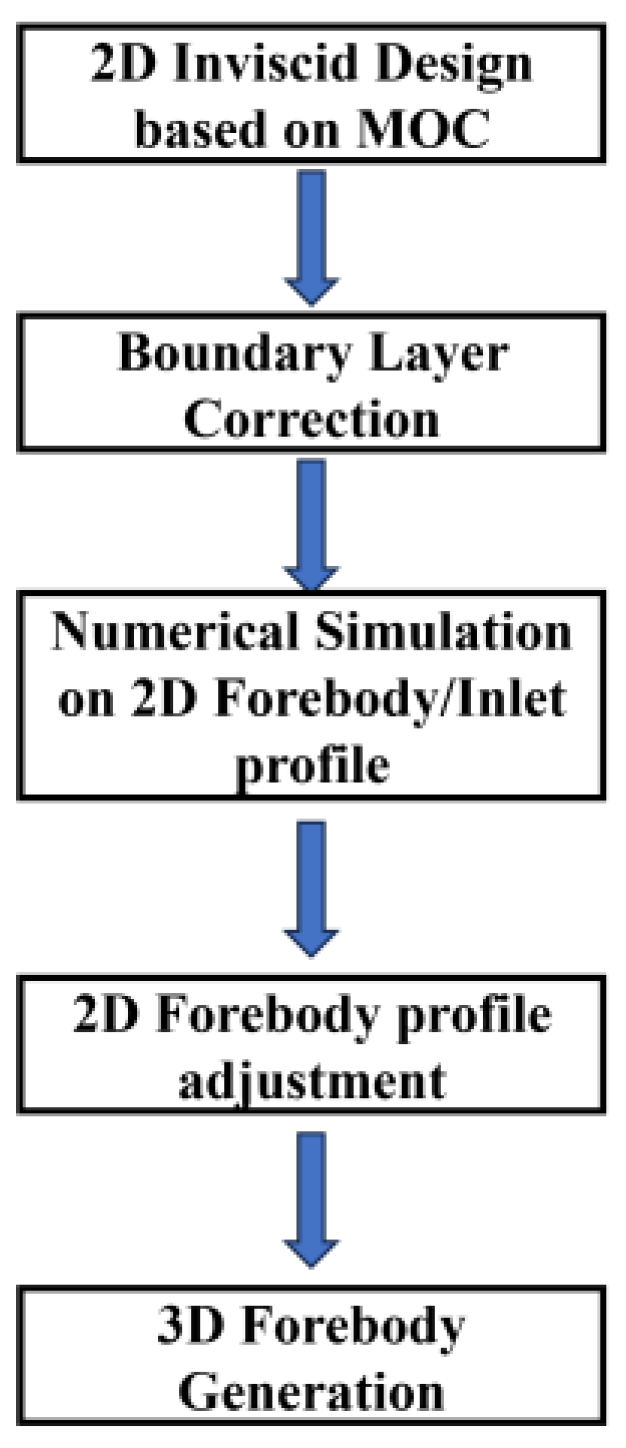

2. Forebody Design Method Matching with Inlet

2.1. Method of Characteristic

- (1)

- Characteristic equation:

- (2)

- Consistency equation:

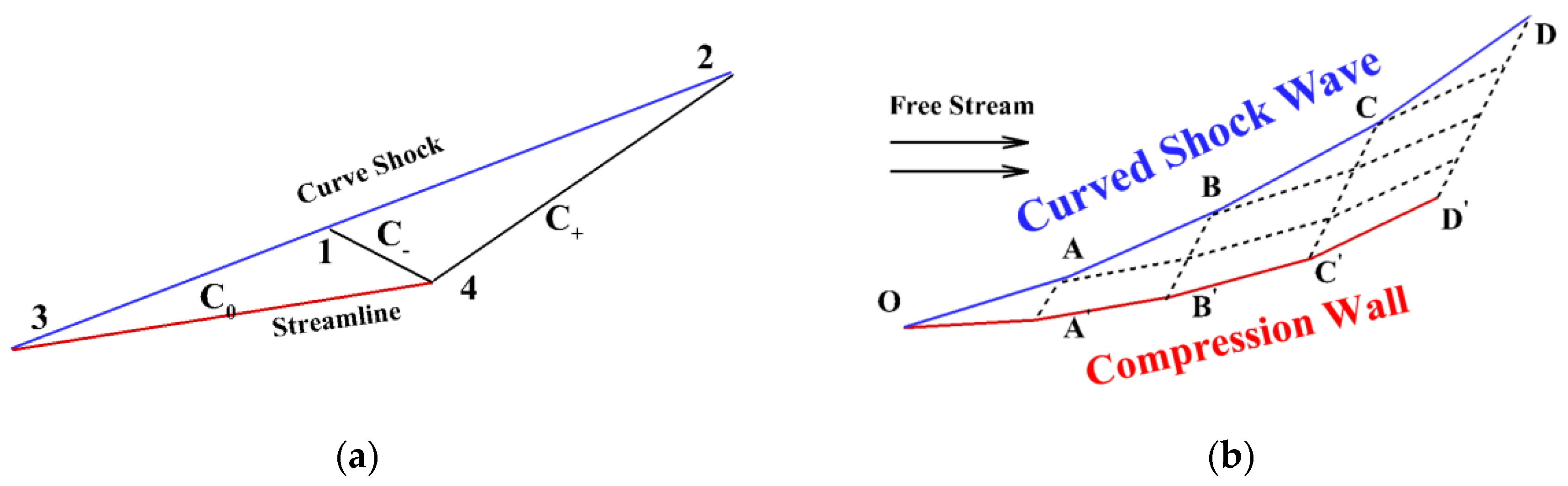

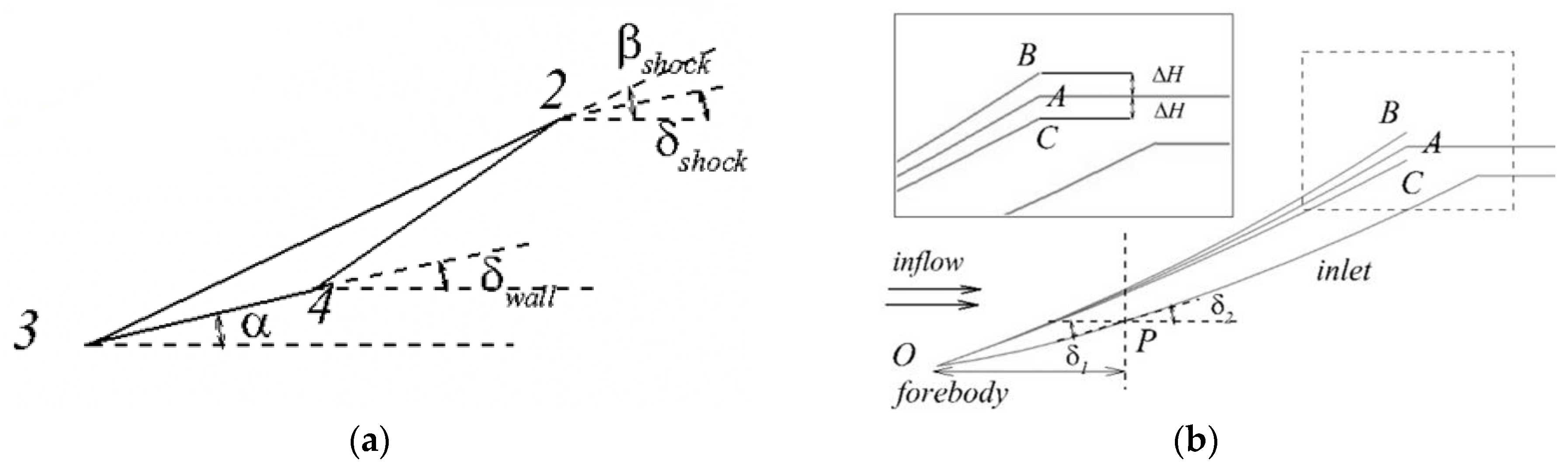

2.2. Introduction of the Inverse Characteristic Line Method Based on Shock Wave Shape

2.2.1. Inviscid Design

2.2.2. Boundary Layer Correction

2.3. Design of Forebody Profile on Symmetrical Plane

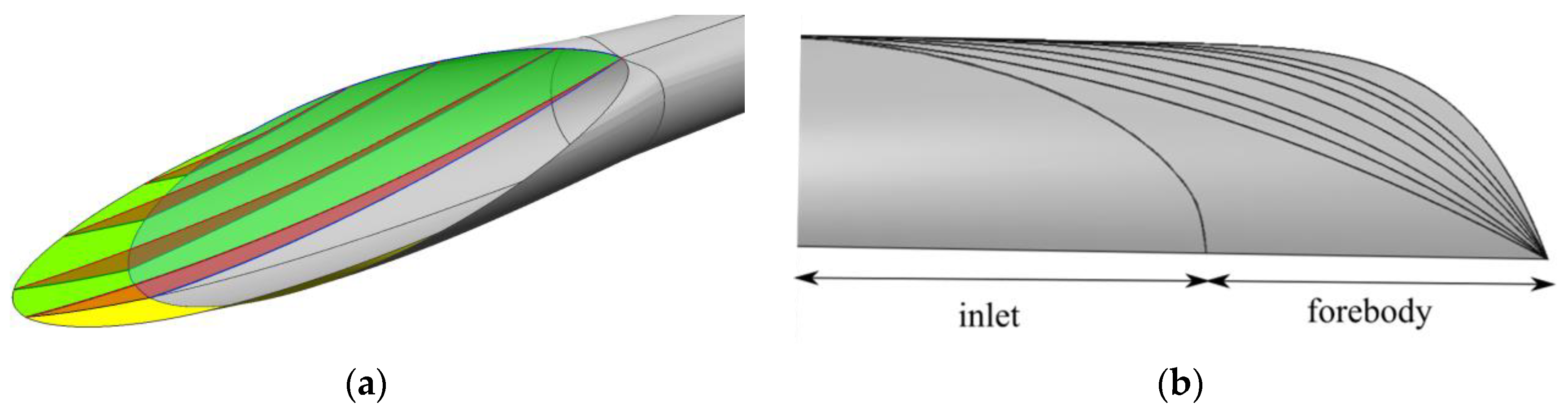

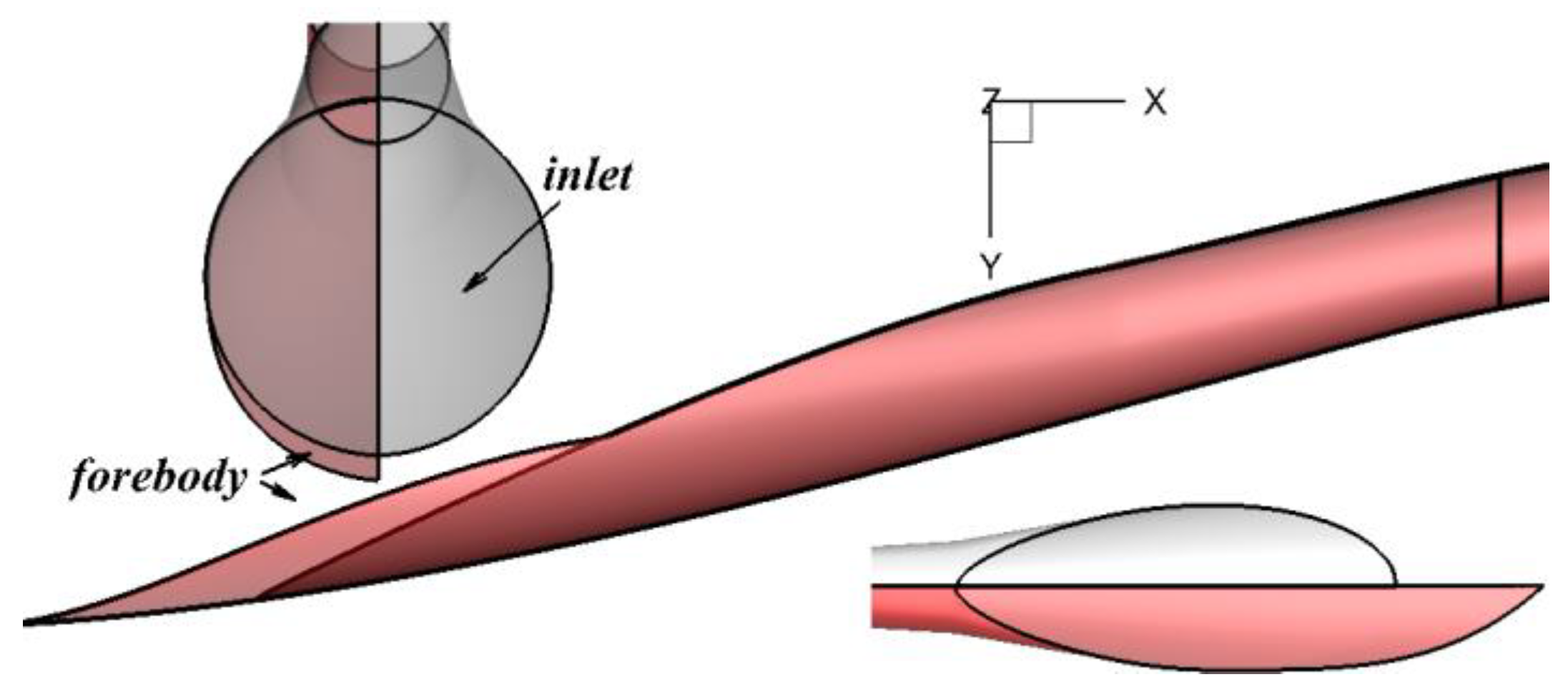

2.4. Three-Dimensional Forebody Generation Scheme

3. Introduction to Numerical Simulation and Wind Tunnel Experiment

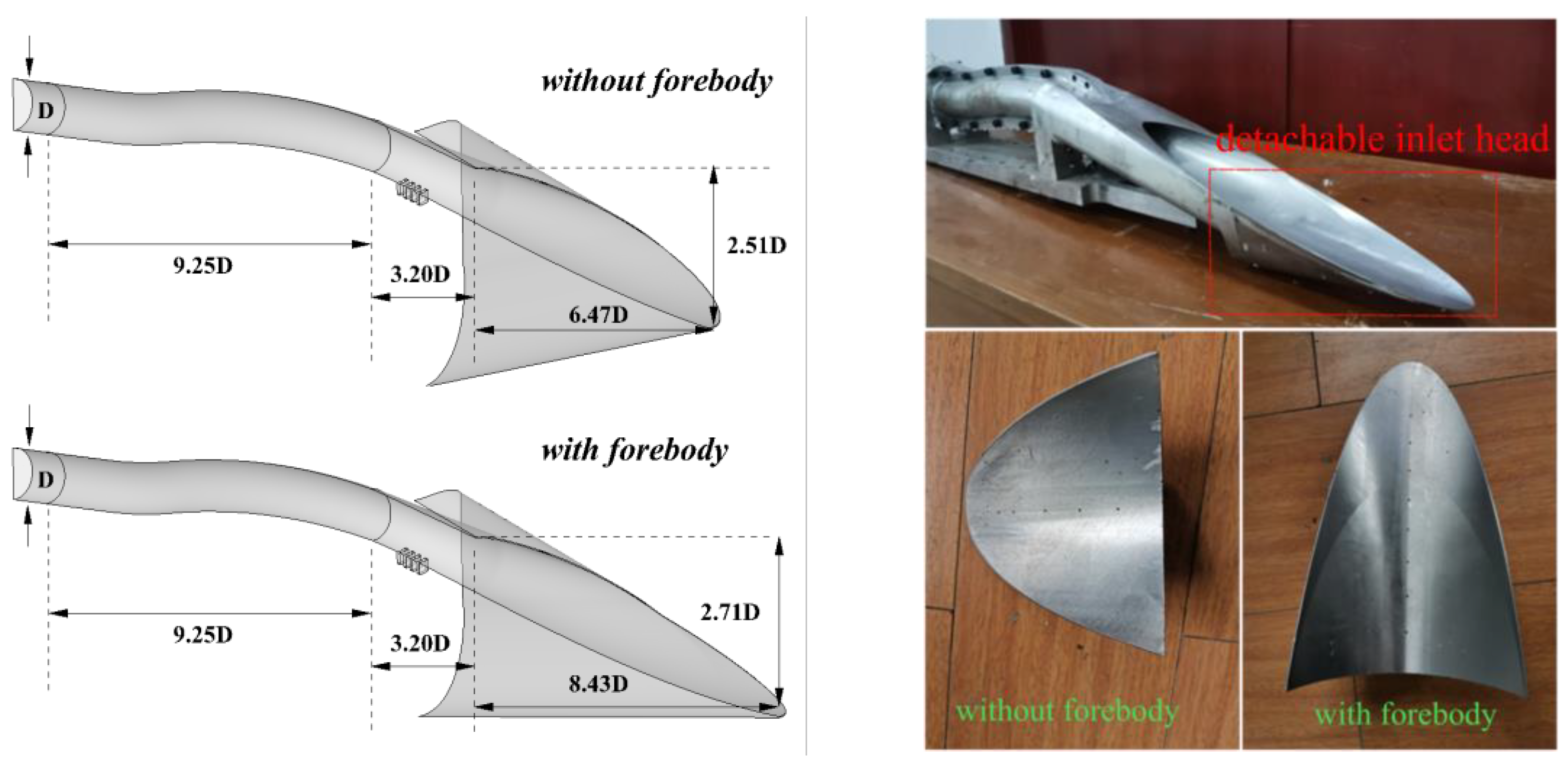

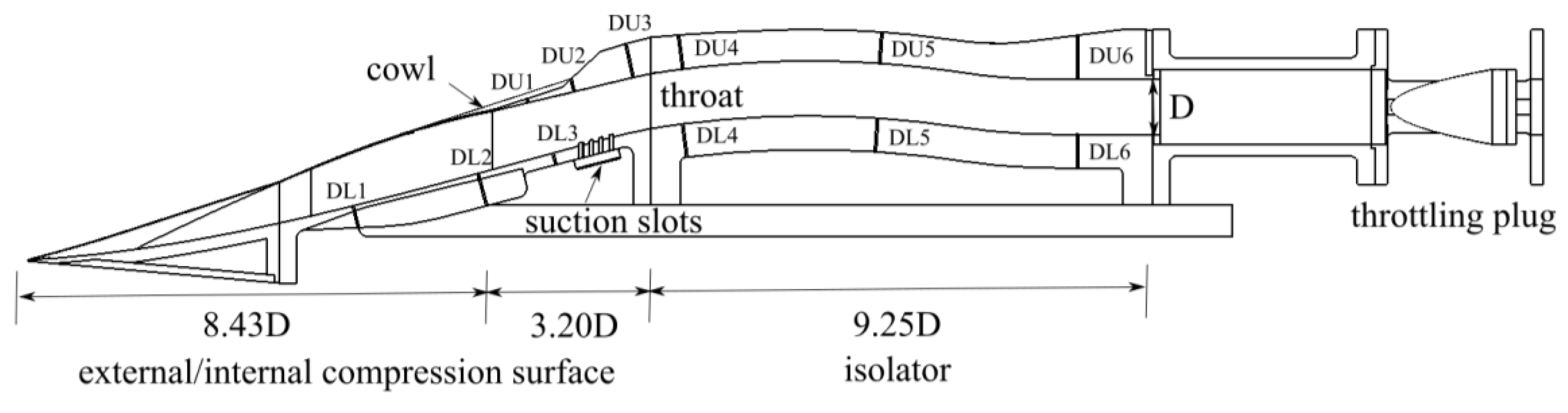

3.1. Wind Tunnel Experiment

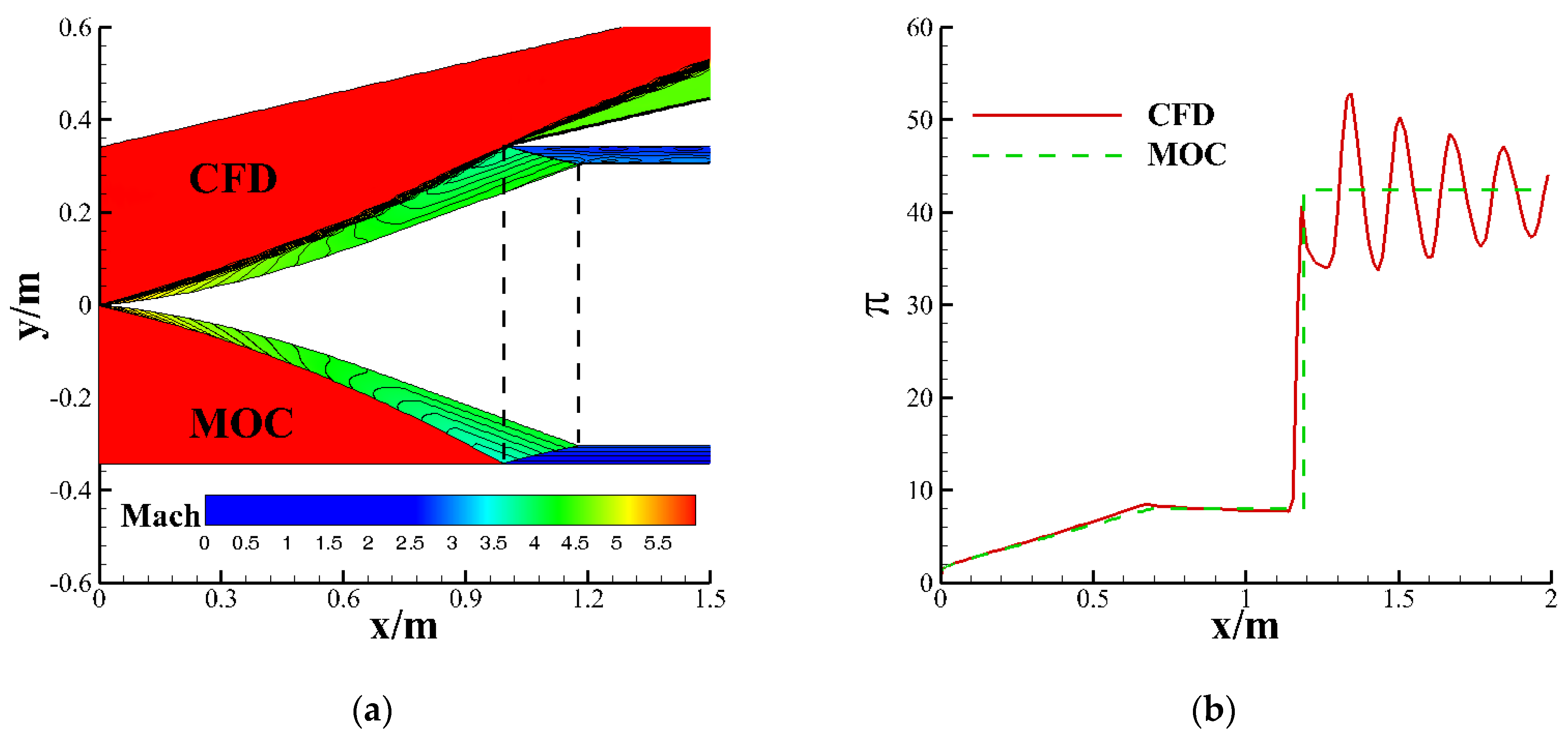

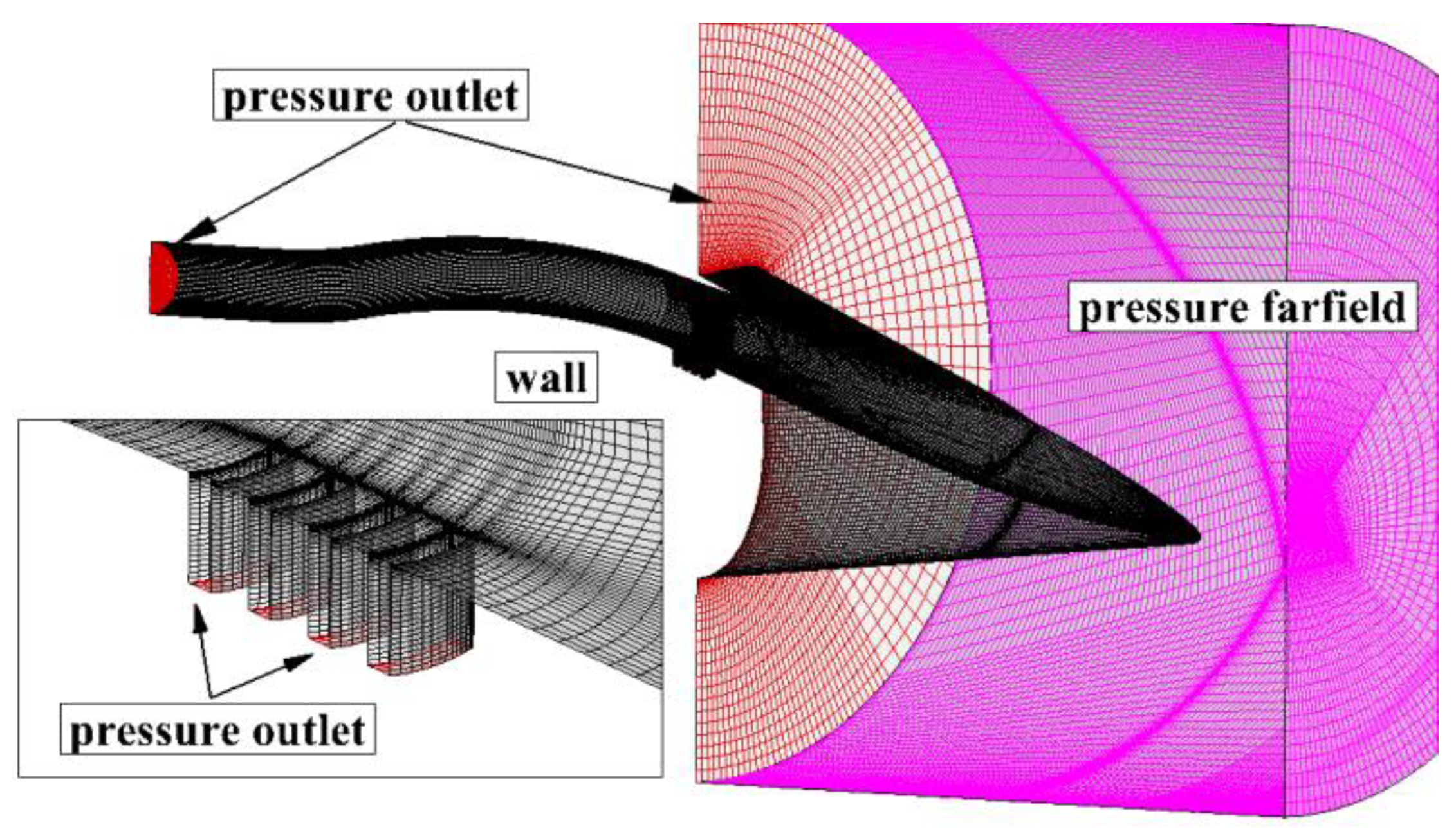

3.2. Numerical Simulation

4. Results and Discussion

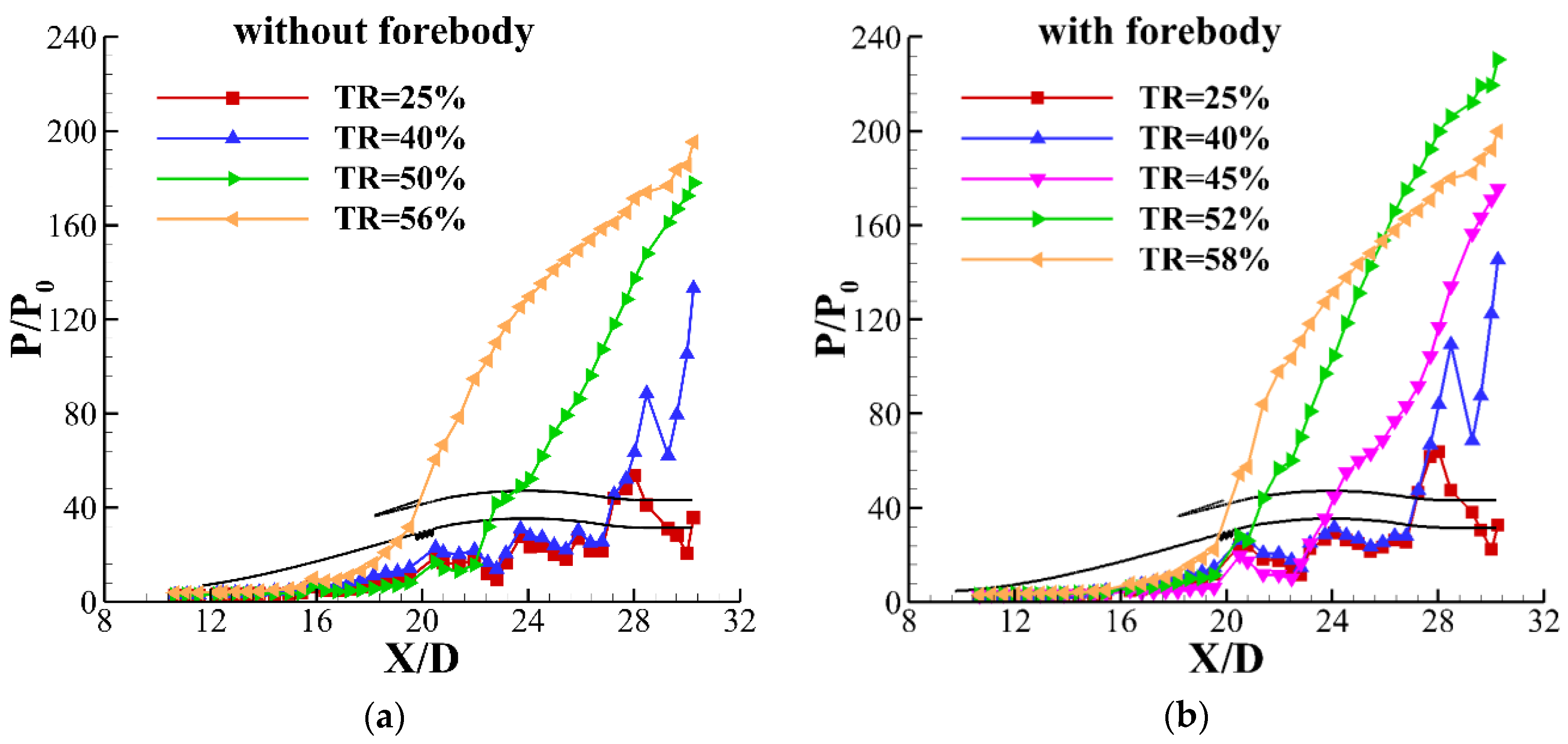

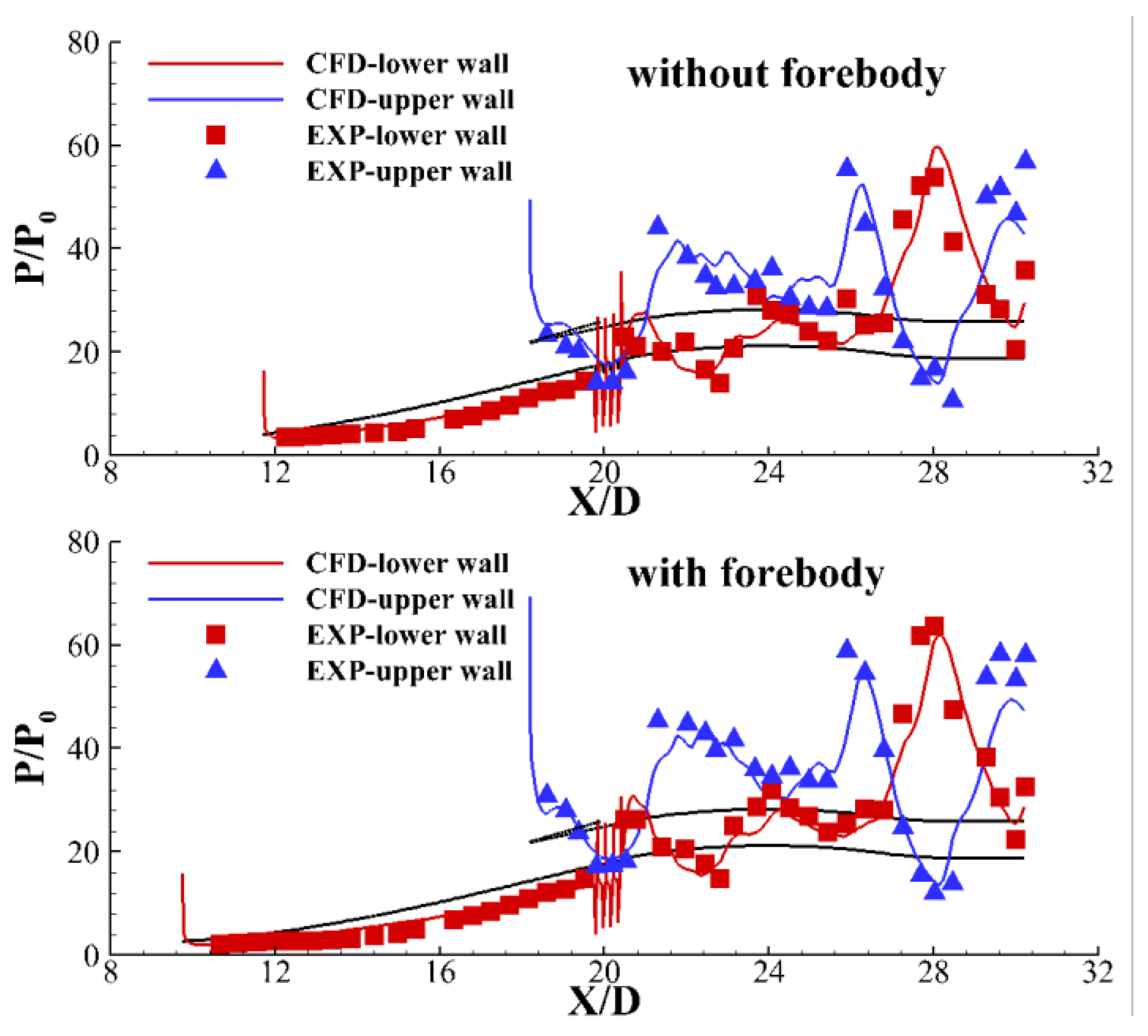

4.1. Result of the Wind Tunnel Experiment

4.2. Numerical Simulation Validation

4.3. Numerical Simulation Results

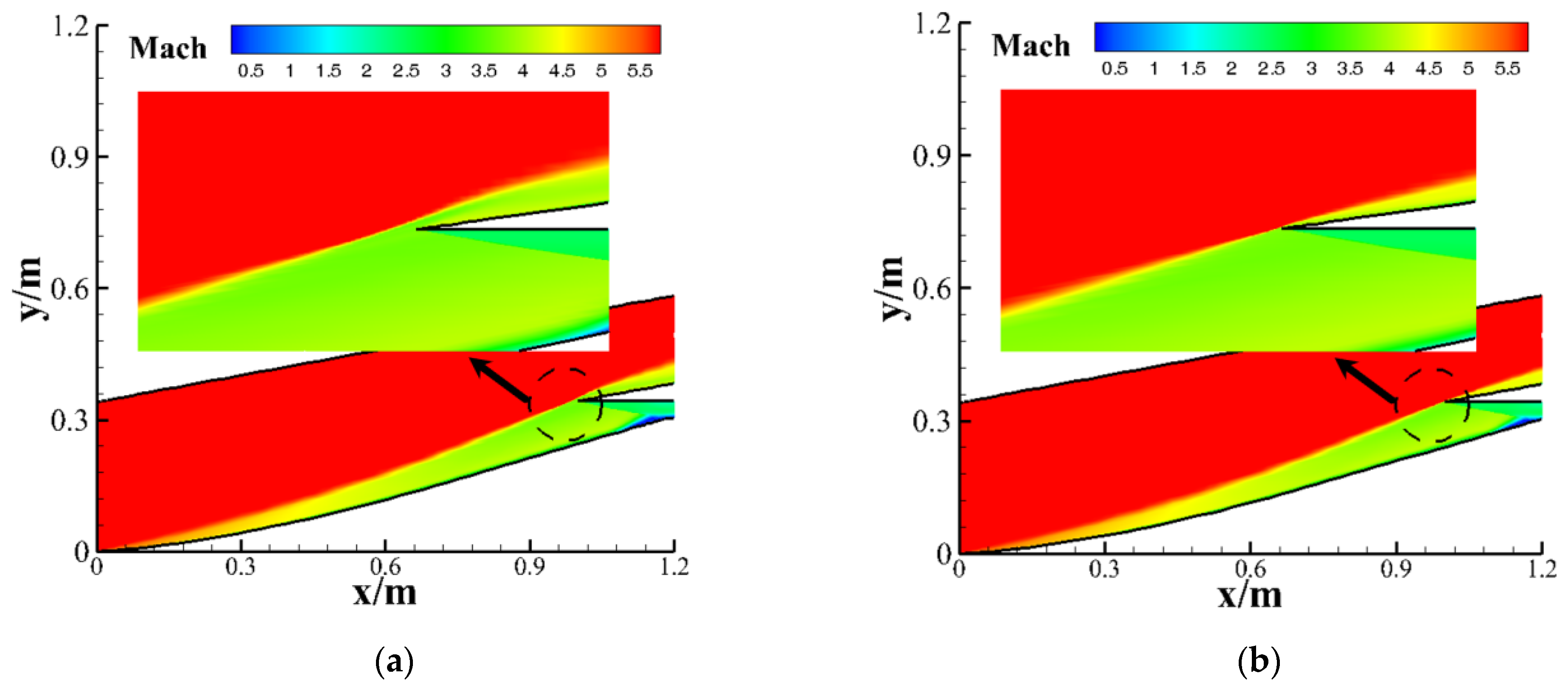

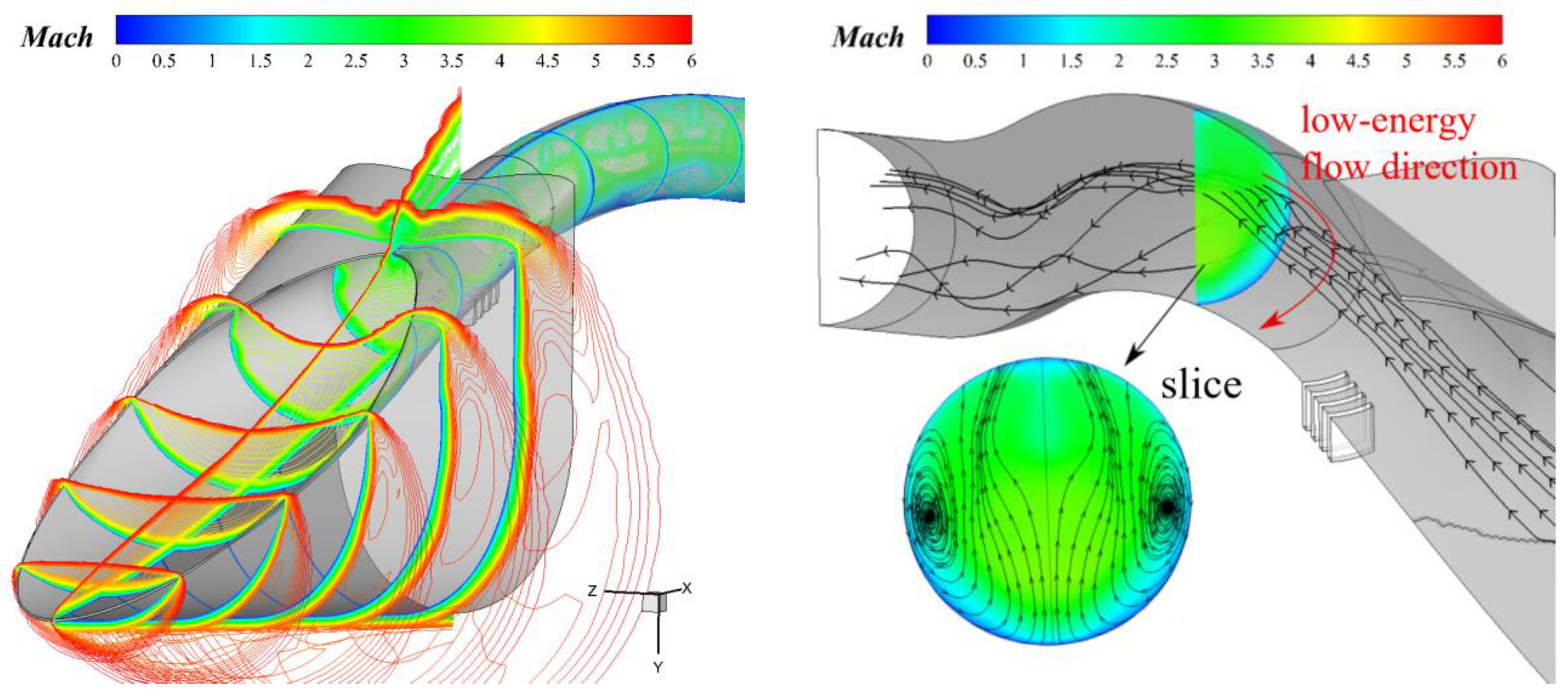

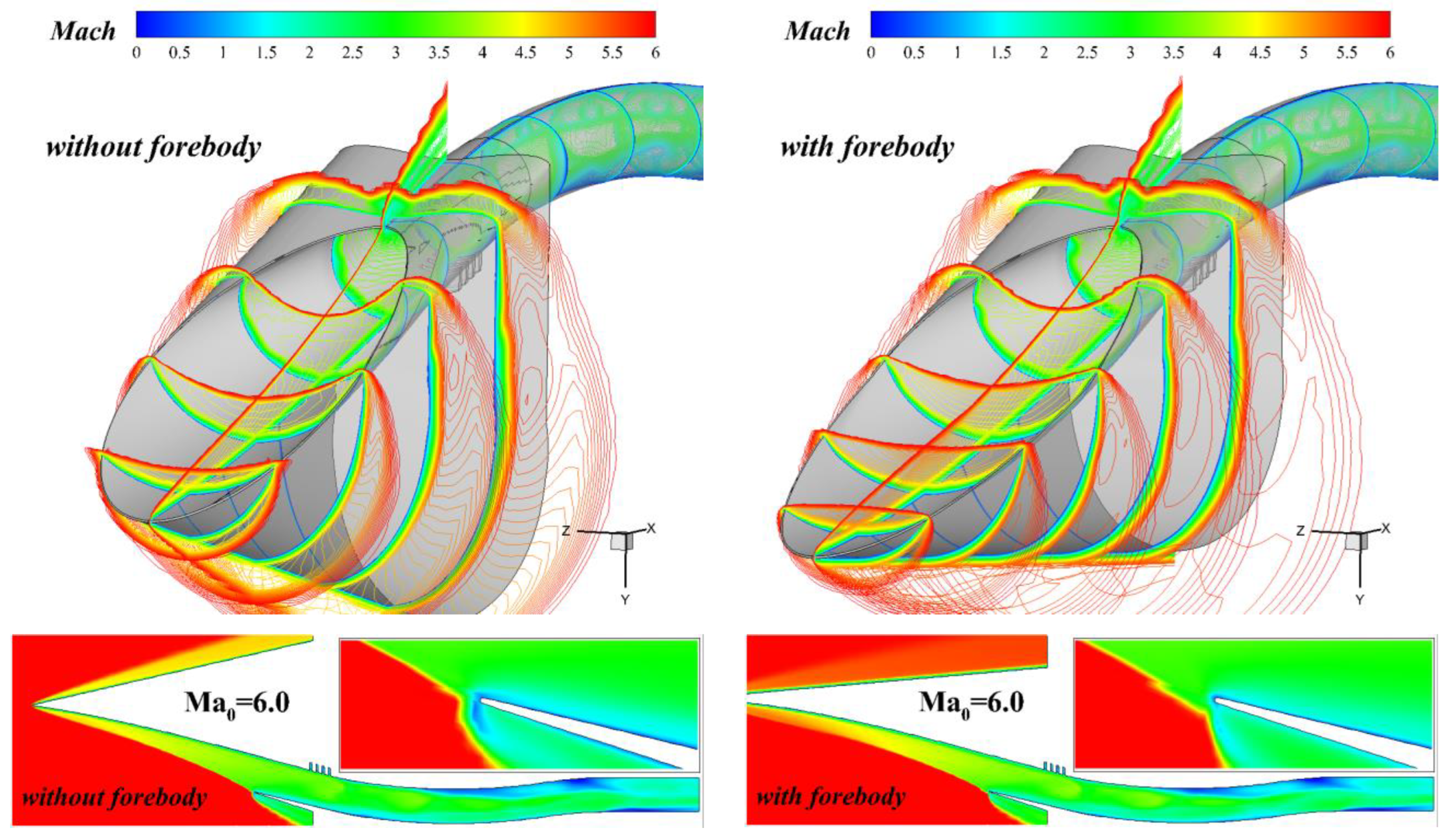

4.3.1. Analysis of Flow Field Characteristics in Three-Dimensional Inward-Turning Inlet

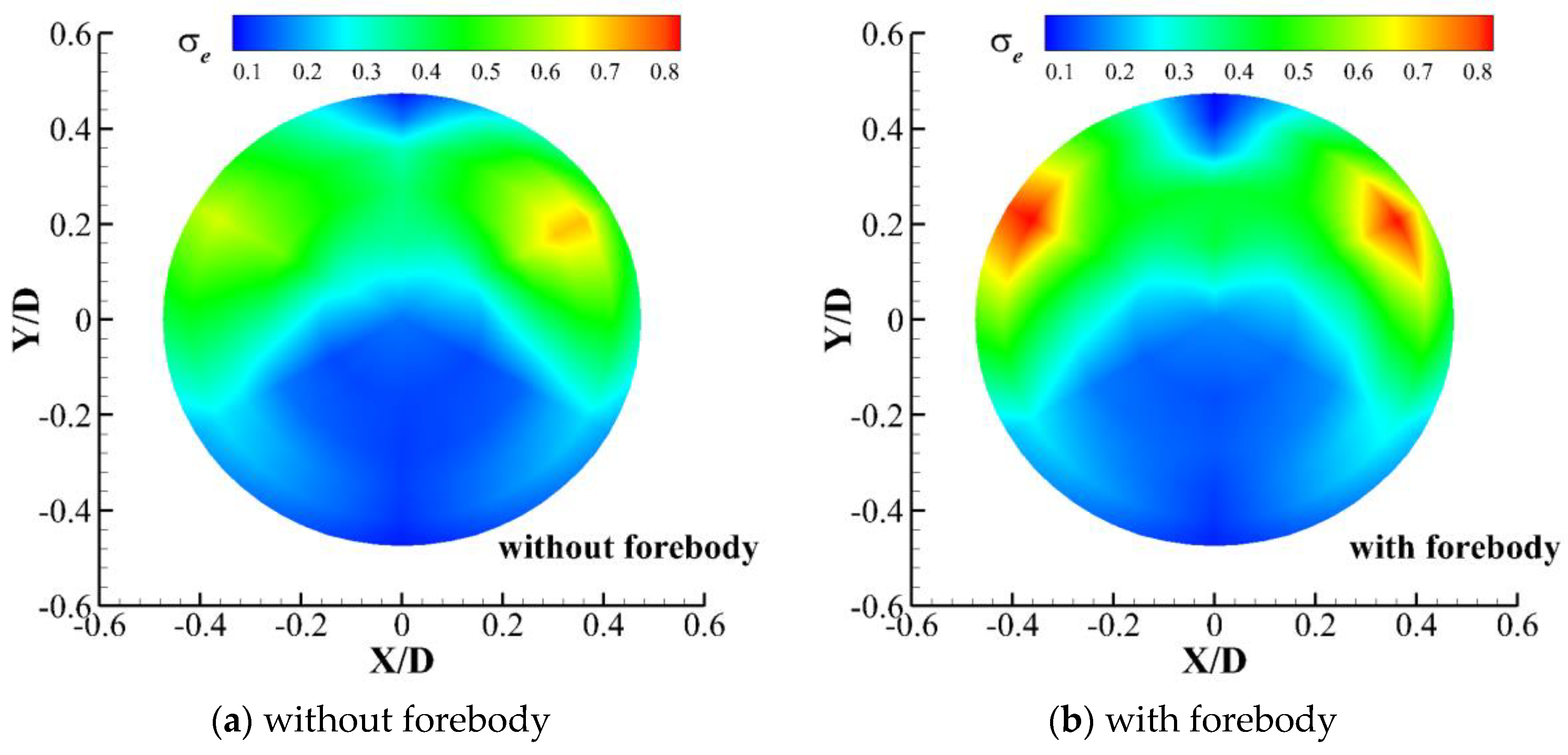

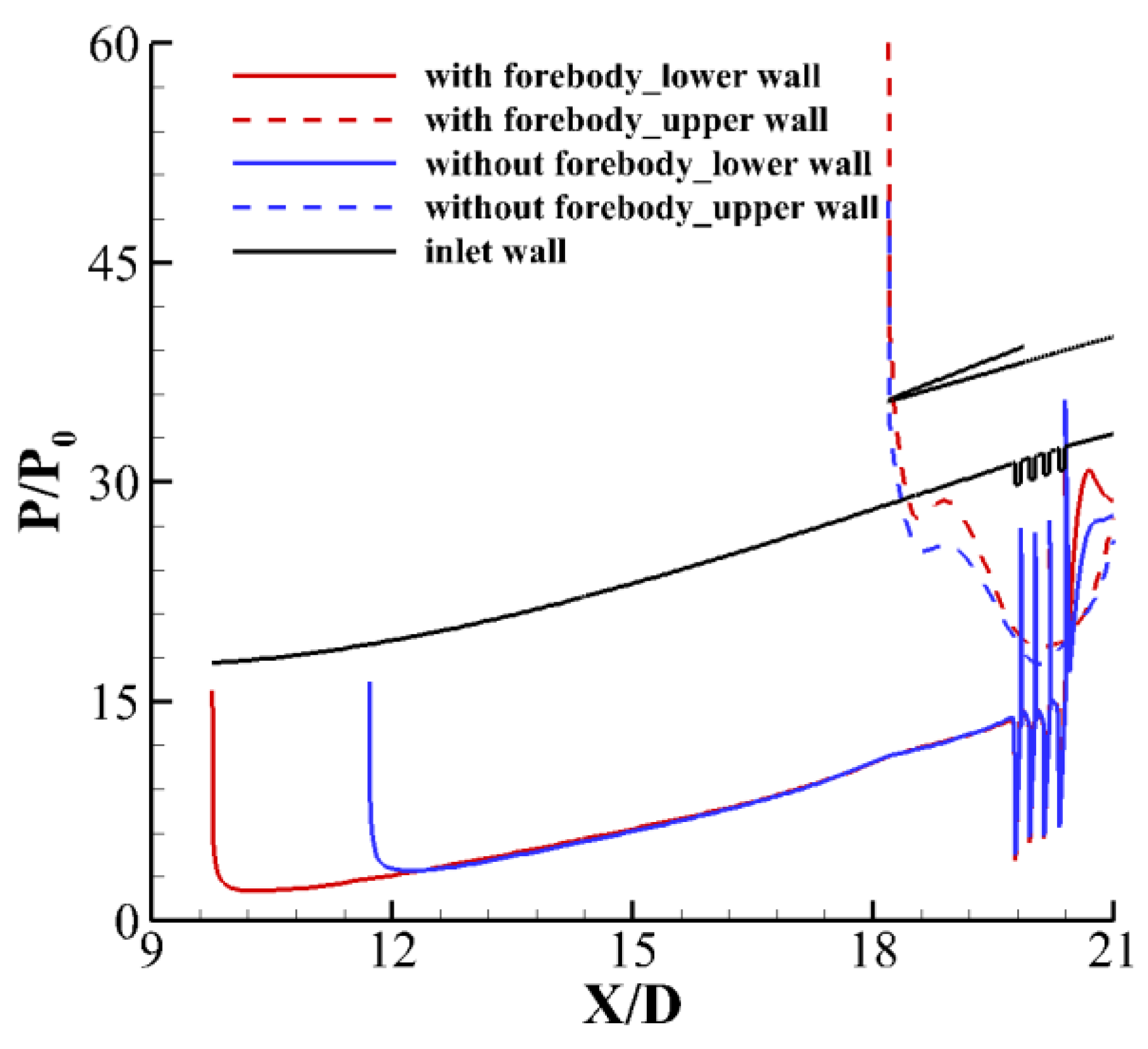

4.3.2. Performance Comparison of Inlet with and Without Forebody on Design Point

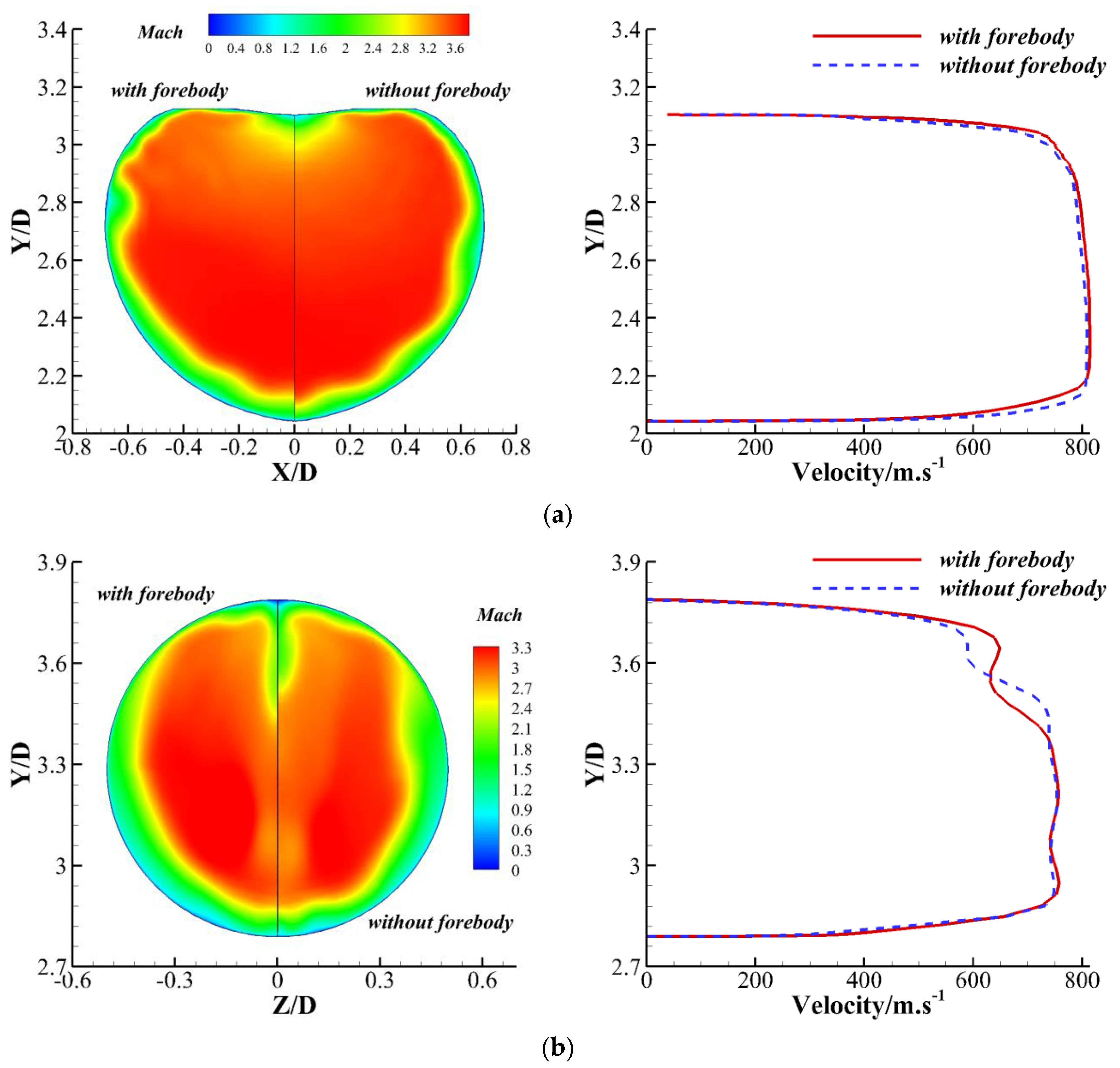

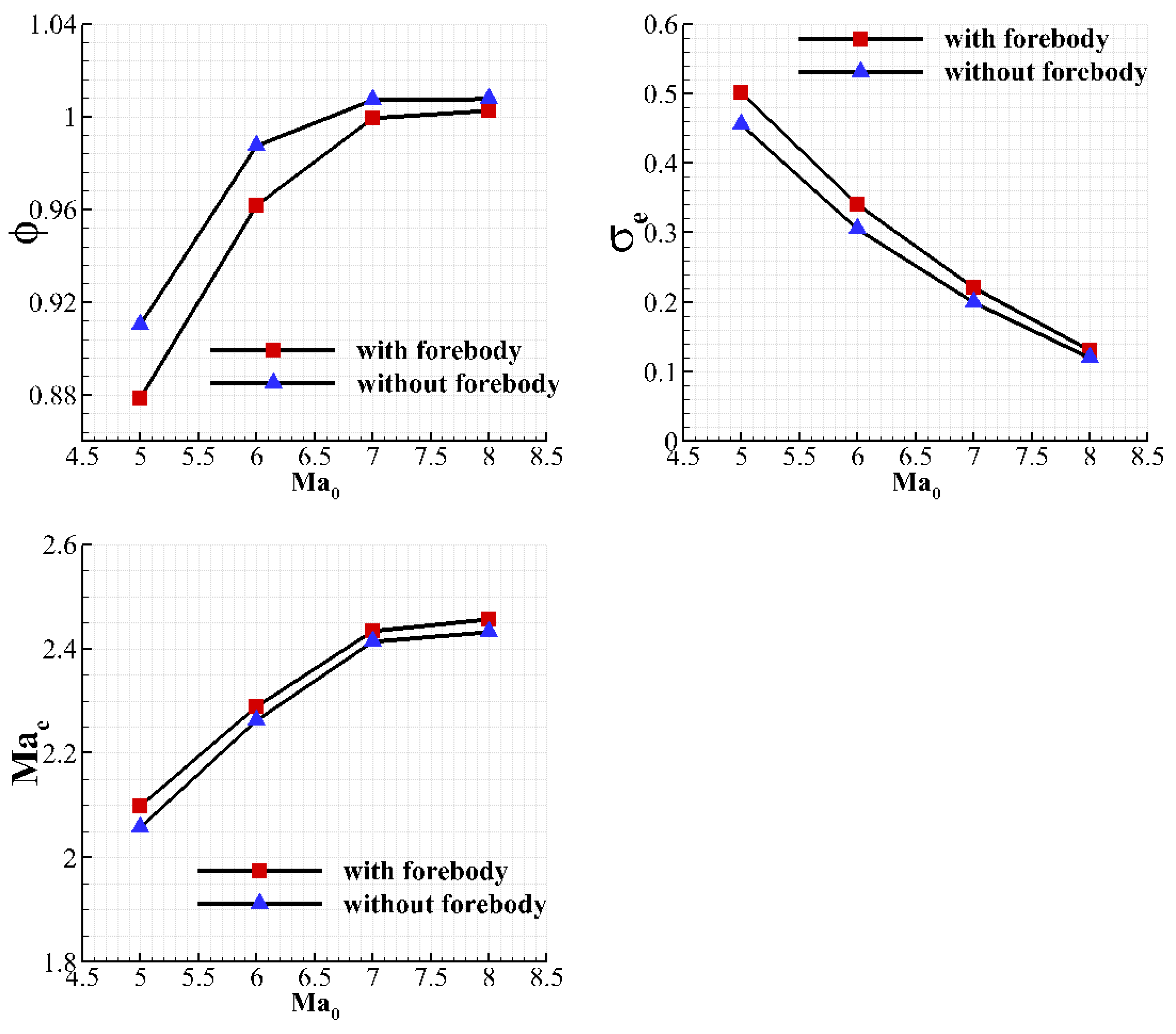

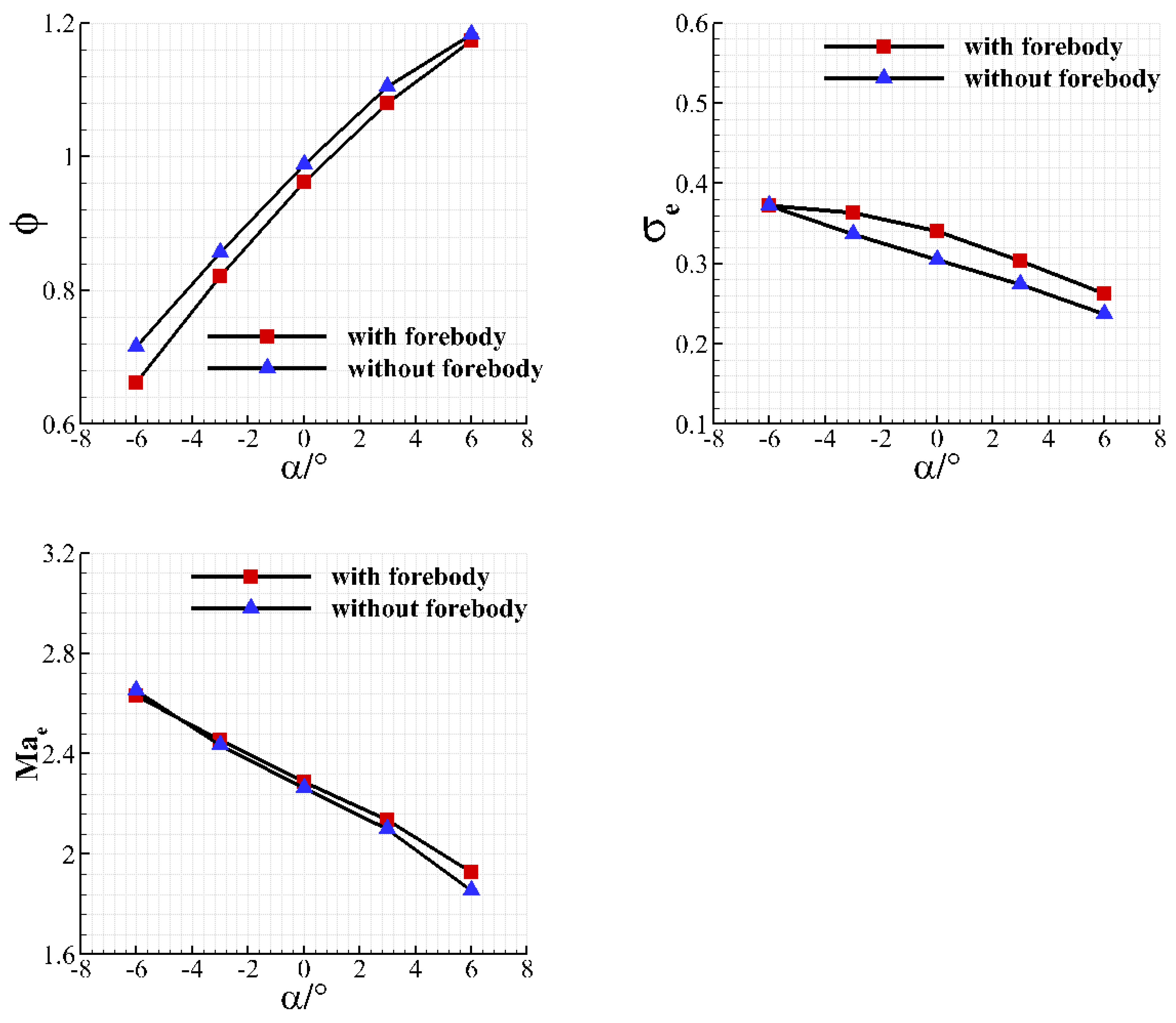

4.3.3. Analysis of Velocity Characteristics and Angle of Attack Characteristics of Inlet with and Without Forebody

5. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Smart, M.K. Experimental testing of a hypersonic inlet with rectangular-to-elliptical shape transition. J. Propuls. Power 1999, 17, 276–283. [Google Scholar] [CrossRef]

- Ren, H.; Yuan, H.; Zhang, J.; Zhang, B. Experimental and numerical investigation of isolator in three-dimensional inward turning inlet. Aerosp. Sci. Technol. 2019, 95, 105435. [Google Scholar] [CrossRef]

- Lewis, M. A Hypersonic Propulsion Airframe Integration Overview. In Proceedings of the 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 20–23 July 2003. [Google Scholar]

- Xiang, X.; Qian, Z. An Overview and Development Analysis of Air-Breathing Hypersonic Airframe/Propulsion Integrative Design Technology. Tuijin Jishu/J. Propuls. Technol. 2018, 39, 2207–2218. (In Chinese) [Google Scholar]

- Kothari, A.P. Designs of and Methodology for Inward or Outward, and Partially Inward or Outward Turning Flow Hypersonic Air-Breathing and Rocket-Based- Combined- Cycle Vehicles. U.S. Patent 6164596A, 26 December 2000. [Google Scholar]

- Li, Y.; You, Y.; Han, W.; Teng, J. An Innovative Integration Concept for Forebody and Two-Dimensional Hypersonic Inlet with Controllable Wall Pressure Distribution. In Proceedings of the 20th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, Glasgow, Scotland, 6–9 July 2015. [Google Scholar]

- Qiao, W.; Yu, A.; Yang, D.; Le, J. Integration design of inward-turning inlets based on forebody shock wave. Acta Aeronaut. Astronaut. Sin. 2018, 39, 65–76. (In Chinese) [Google Scholar]

- Nonweiler, T. Aerodynamic Problems of Manned Space Vehicles. J. R. Aeronaut. Soc. 1959, 63, 521–528. [Google Scholar] [CrossRef]

- Nonweiler, T. Delta Wing of Shape Amenable to Exact Shock-Wave Theory. J. R. Aeronaut. Soc. 1963, 67, 39–40. [Google Scholar] [CrossRef]

- Rasmussen, M.L.; Jischke, M.C.; Daniel, D.C. Experimental Forces and Moments on Cone-Derived Waveriders for M = 3 to 5. J. Spacecr. Rocket. 1982, 19, 592–598. [Google Scholar] [CrossRef]

- Sobieczky, H.; Zores, B.; Wang, Z.; Qian, Y.J. High speed flow design using the theory of osculating cone and axisymmetric flows. Chin. J. Aeronaut. 1999, 12, 3–10. [Google Scholar]

- He, X.; Ni, H. Osculating inward turning cone (OIC) wave rider-design methods and performace analysis. Chin. J. Theor. Appl. Mech. 2011, 43, 803–808. (In Chinese) [Google Scholar]

- Starkey, R.; Lewis, M. Design of an engine-airframe integrated hypersonic missile within fixed box constraints. In Proceedings of the 37th Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 11–14 January 1999. [Google Scholar]

- Zucrow, M.J.; Hoffman, J.D. Gas Dynamics; John Wiley & Sons, Inc.: New York, NY, USA, 1976; pp. 191–192. [Google Scholar]

- Li, Y.; Zhang, K.; Nan, X. Design of hypersonic inward turning inlets base on concept of controllable Mach number distribution. J. Aerosp. Power 2012, 27, 2484–2491. (In Chinese) [Google Scholar]

- Nan, X.; Zhang, K.; Jin, Z. Investigation on hypersonic inward turning inlets with controlled pressure gradient. J. Aerosp. Power 2011, 26, 518–523. (In Chinese) [Google Scholar]

- Qian, Y. Computer program of supersonic axisymmetric rotaional characteristic method. J. Beijing Univ. Aeronaut. Astronaut. 1996, 4, 70–75. (In Chinese) [Google Scholar]

- Qiao, W.; Huang, G.; Xia, C.; Wang, M. Development of inverse characteristic method for matching design of high-speed aircraft forebody/inlet. J. Aerosp. Power. 2014, 29, 1444–1452. (In Chinese) [Google Scholar]

- Guo, S.; Wang, Z.; Zhao, Y. Inverse Design of the Fore-body Curved Shock Wave of the Hypersonic Planar Inlet. Acta Aeronaut. Astronaut. Sin. 2014, 35, 1246–1256. (In Chinese) [Google Scholar]

- Han, W.; Zhu, C.; You, Y.; Li, Y. An inverse method for supersonic flowfield with given downstream boundary. Acta Aeronaut. Astronaut. Sin. 2016, 37, 624–631. (In Chinese) [Google Scholar]

- Yuan, H.; Li, Z.; Zhang, J.; Wang, X. Experimental and Numerical Research on a Three-Dimensional Inward-Turning Inlet. J. Aerosp. Eng. 2023, 36, 04023008. [Google Scholar] [CrossRef]

| Ma0 | P*/MPa | T*/K | P/Pa |

|---|---|---|---|

| 5 | 0.6 | 440 | 380 |

| 6 | 0.6 | 350 | 1134 |

| With Forebody | Without Forebody | |||||

|---|---|---|---|---|---|---|

| σ | π | Mae | σ | π | Mae | |

| EXP | 0.31 | 37.80 | 2.32 | 0.29 | 33.73 | 2.35 |

| CFD | 0.33 | 36.56 | 2.29 | 0.30 | 34.63 | 2.26 |

| error | 6.45% | 3.28% | 1.29% | 3.45% | 2.67% | 3.83% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Liu, J.; Gu, T.; Yuan, H. Experiment and Numerical Investigation of a Forebody Design Method for Inward-Turning Inlet. Aerospace 2025, 12, 763. https://doi.org/10.3390/aerospace12090763

Yang D, Liu J, Gu T, Yuan H. Experiment and Numerical Investigation of a Forebody Design Method for Inward-Turning Inlet. Aerospace. 2025; 12(9):763. https://doi.org/10.3390/aerospace12090763

Chicago/Turabian StyleYang, Dezhuang, Jun Liu, Tianlai Gu, and Huacheng Yuan. 2025. "Experiment and Numerical Investigation of a Forebody Design Method for Inward-Turning Inlet" Aerospace 12, no. 9: 763. https://doi.org/10.3390/aerospace12090763

APA StyleYang, D., Liu, J., Gu, T., & Yuan, H. (2025). Experiment and Numerical Investigation of a Forebody Design Method for Inward-Turning Inlet. Aerospace, 12(9), 763. https://doi.org/10.3390/aerospace12090763