Structural-Integrated Electrothermal Anti-Icing Components for UAVs: Interfacial Mechanisms and Performance Enhancement

Abstract

1. Introduction

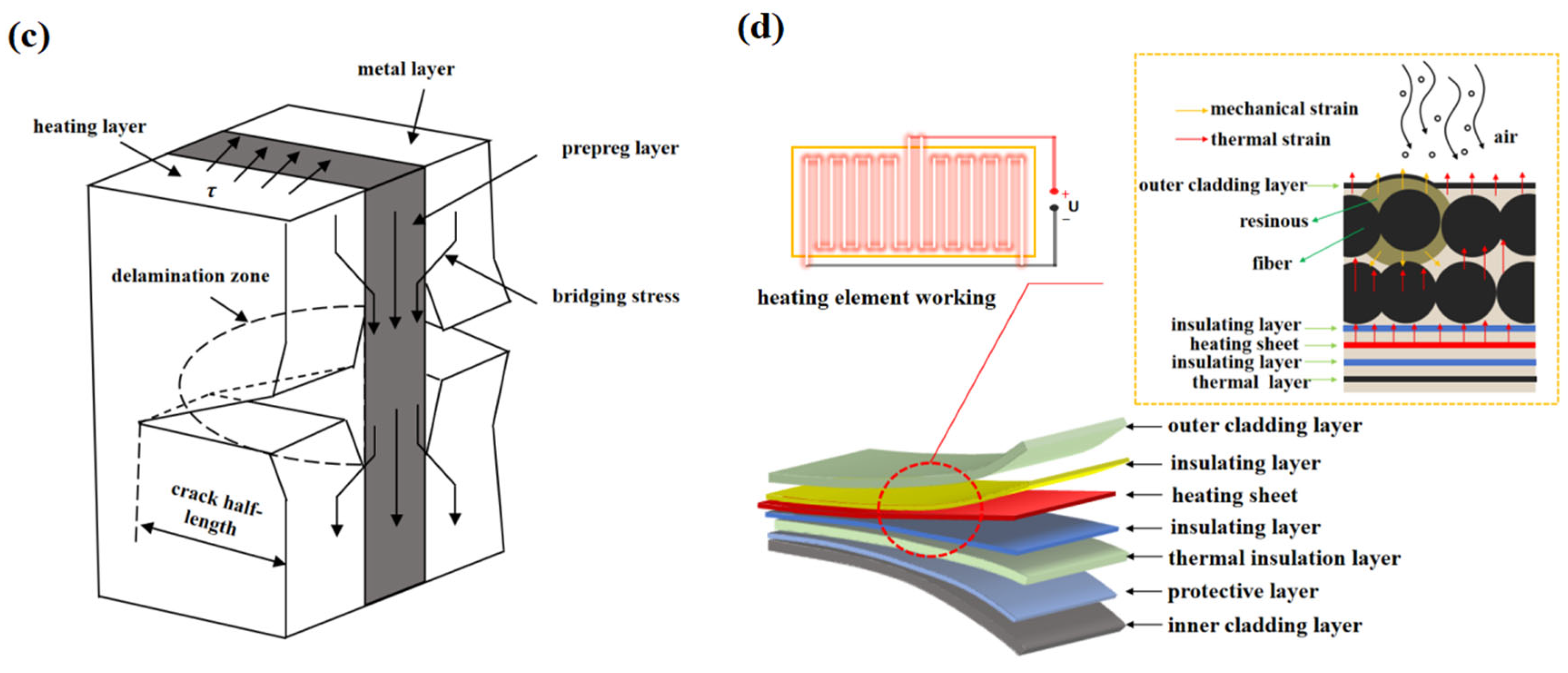

2. Materials and Methods

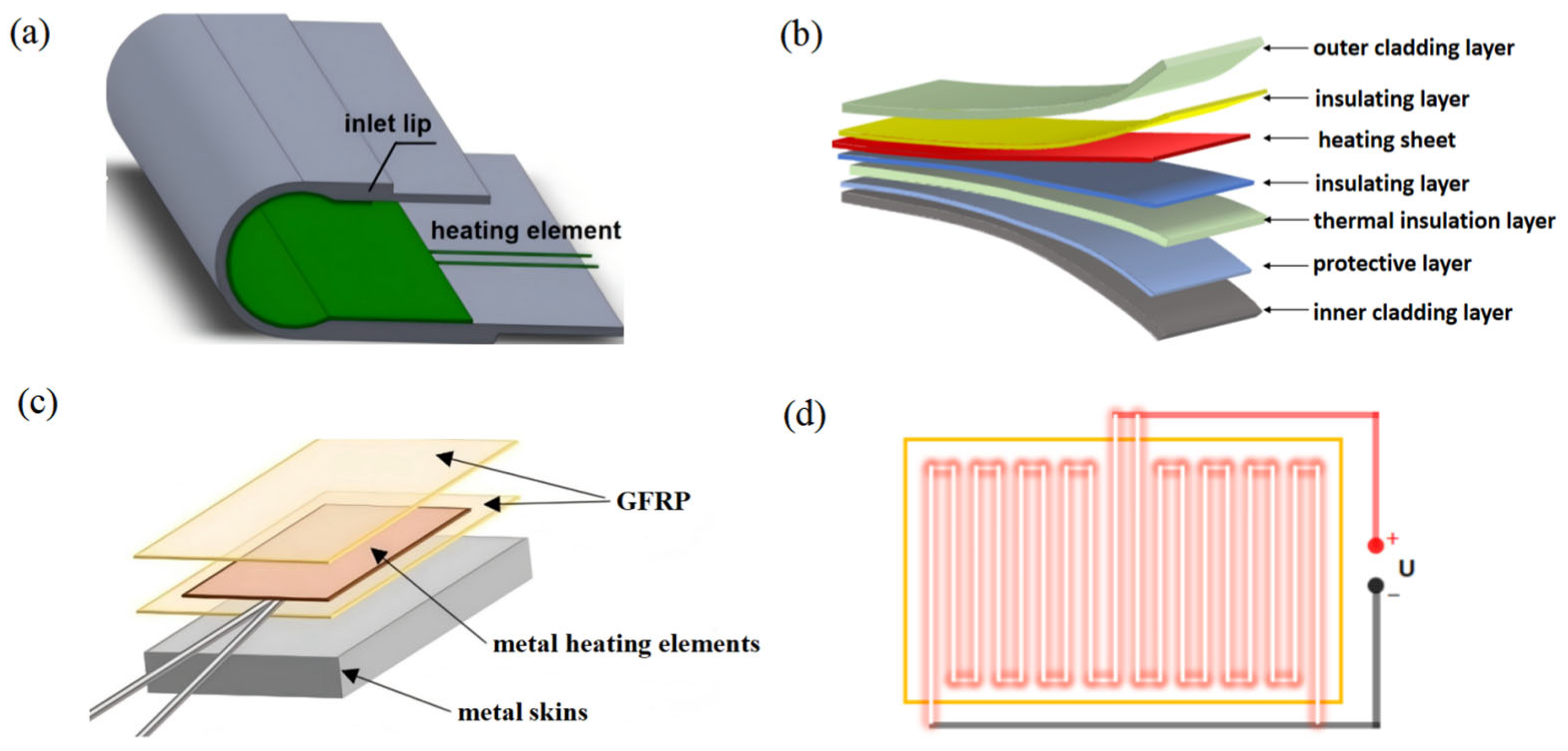

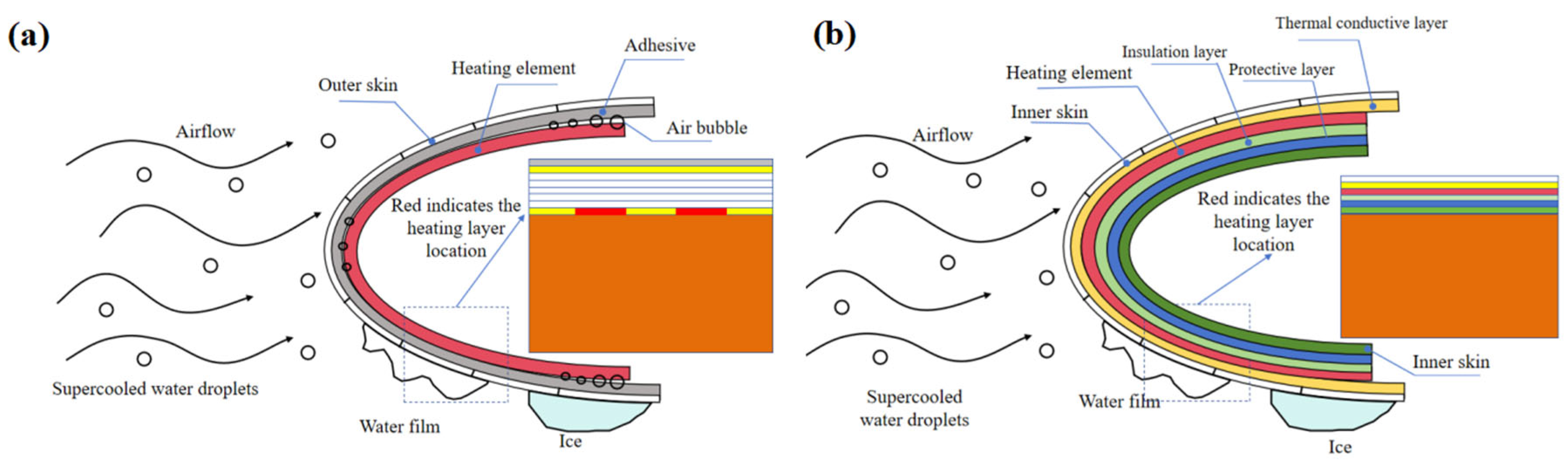

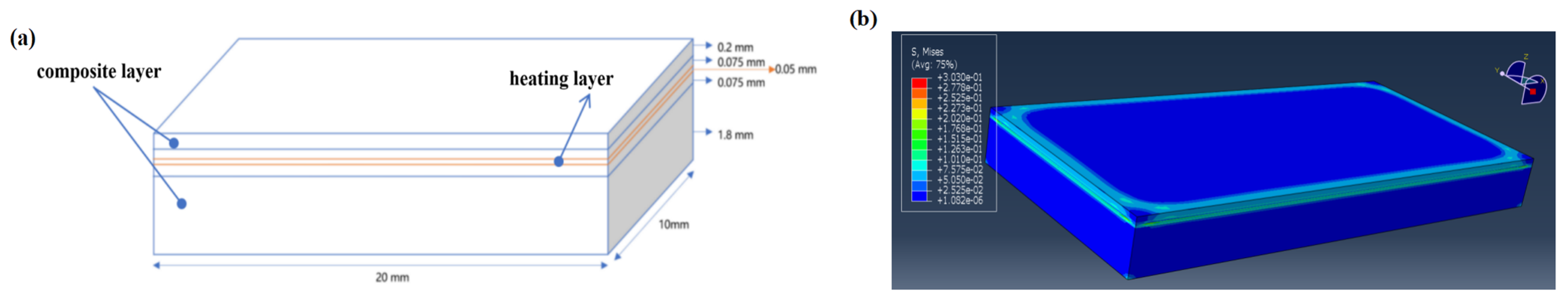

2.1. Anti-Icing/De-Icing Structure Design

2.2. Experimental Materials

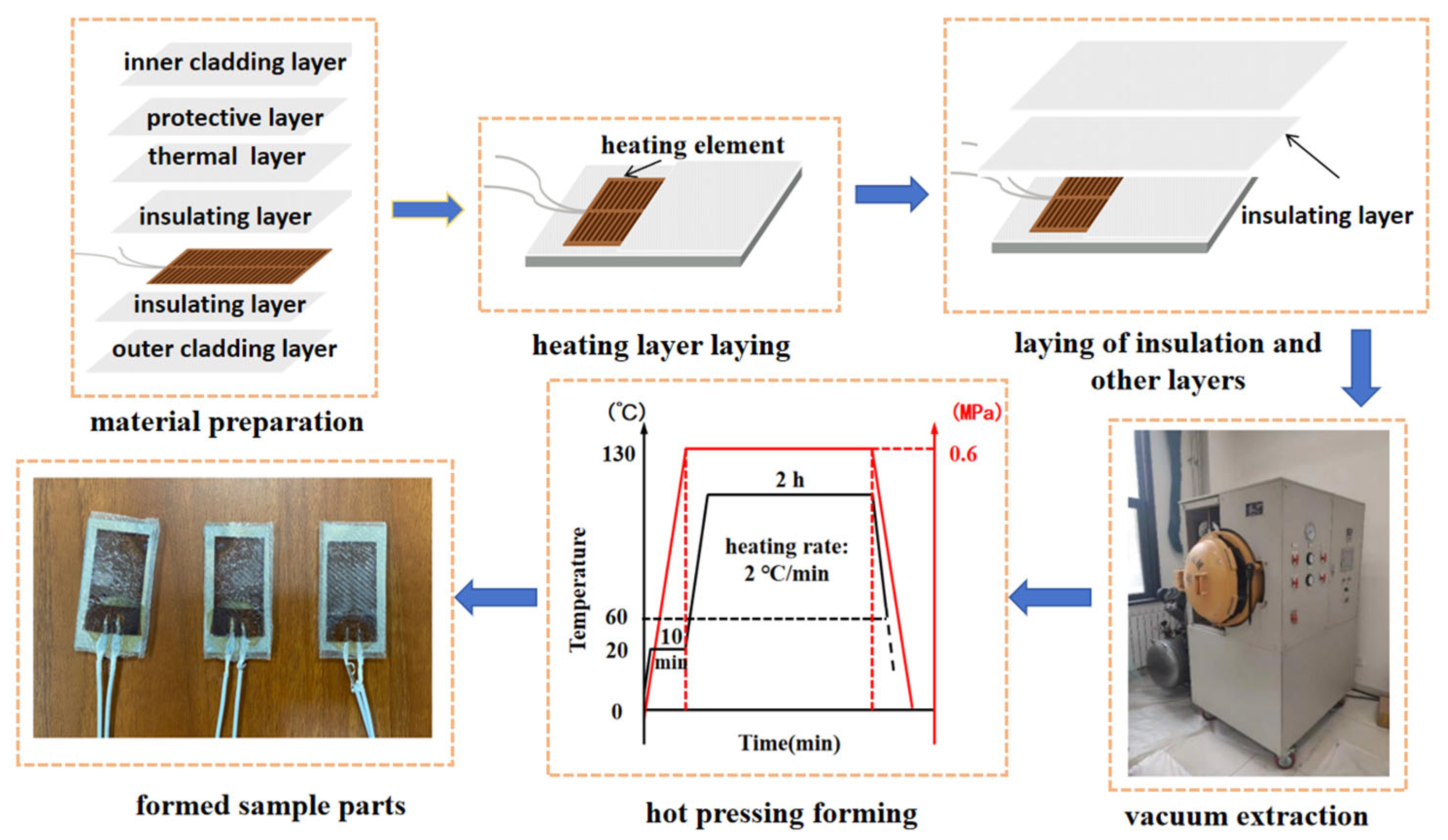

2.3. Preparation Process

- (1)

- Pretreatment Stage

- (2)

- Lay-Up Process Stage

- (3)

- Curing Formation Stage

2.4. Characterization Methods

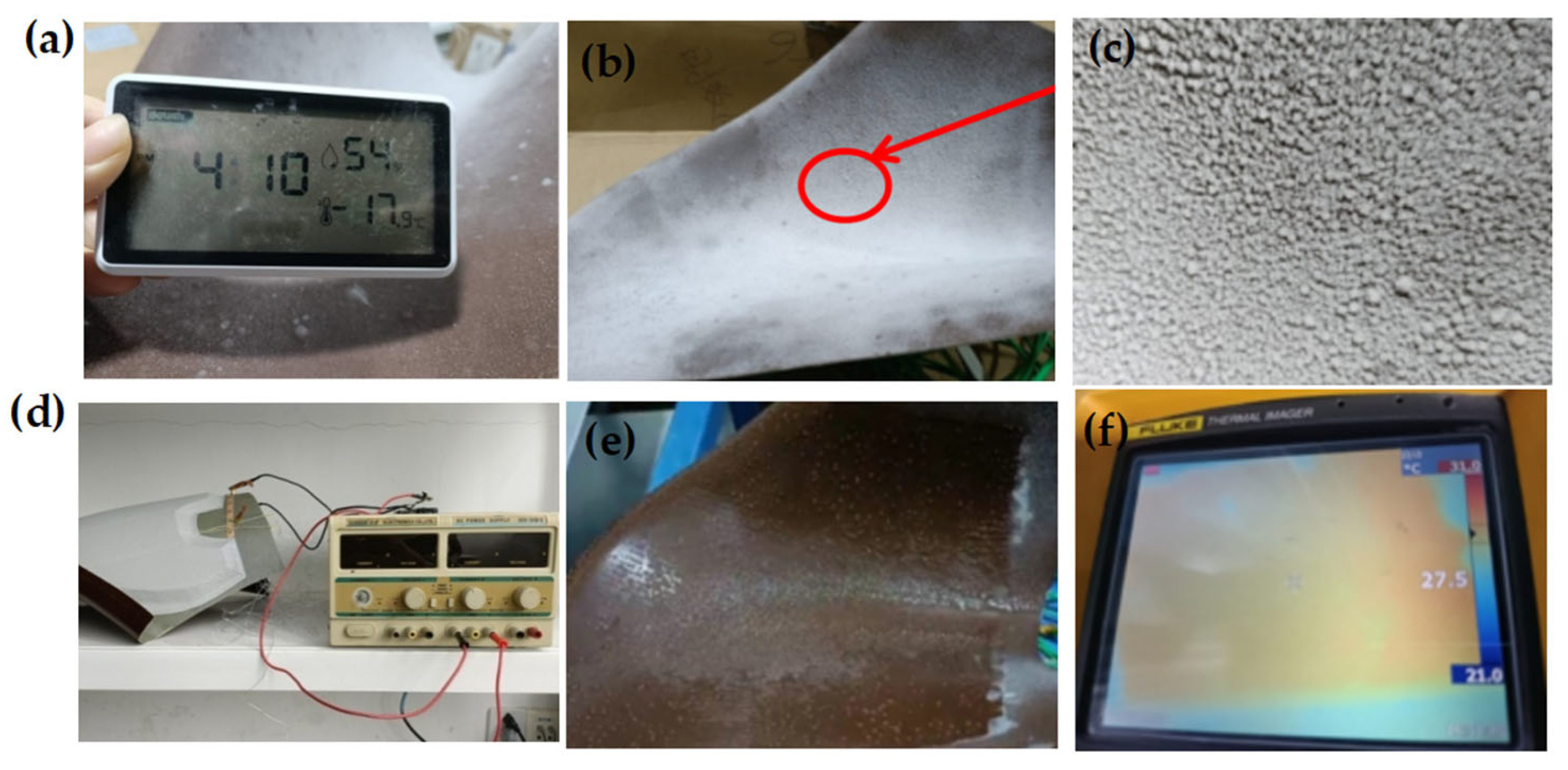

2.4.1. Electrothermal Test Method

- (1)

- Experimental Equipment System

- (2)

- Test Protocol

- (3)

- Evaluation Metrics

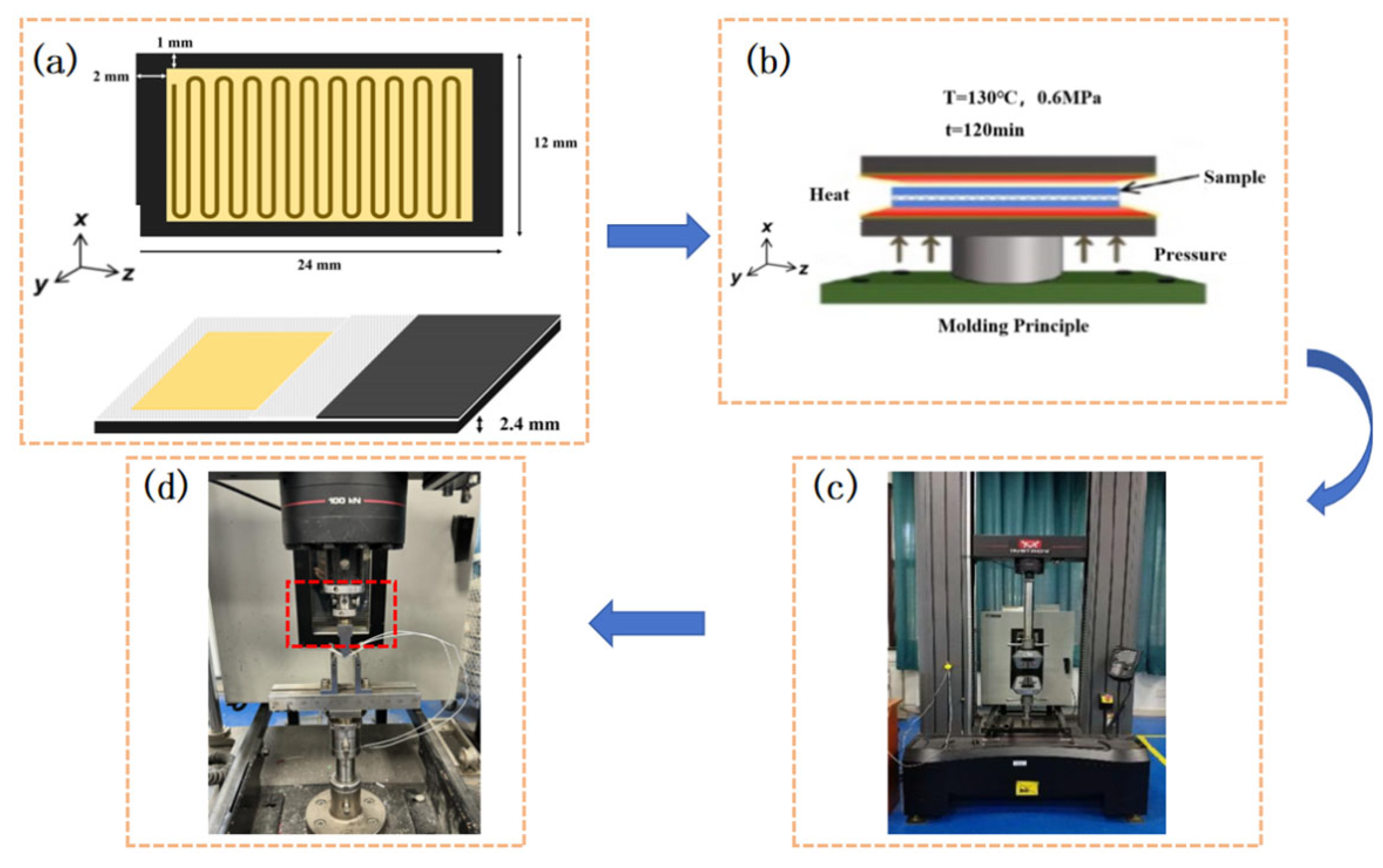

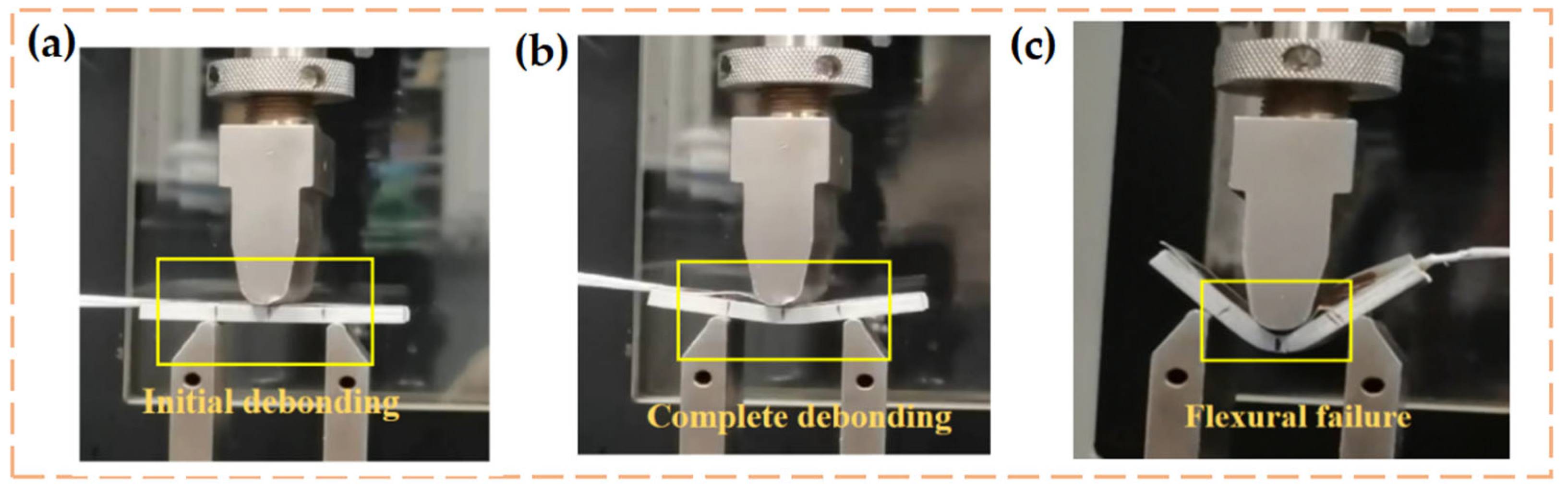

2.4.2. Interlaminar Strength Test Methodology

- (1)

- Testing Method

- (2)

- Experimental Equipment and Parameters

- (3)

- Testing Equipment

3. Results and Discussion

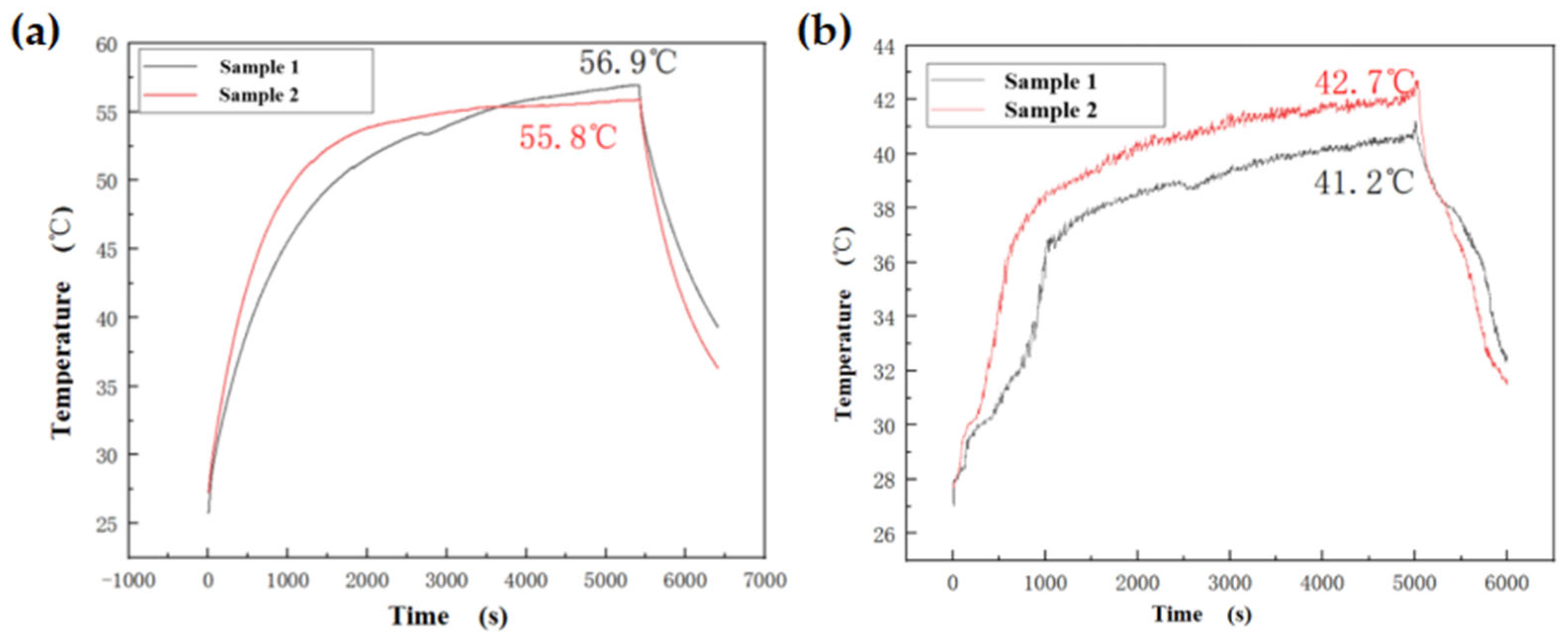

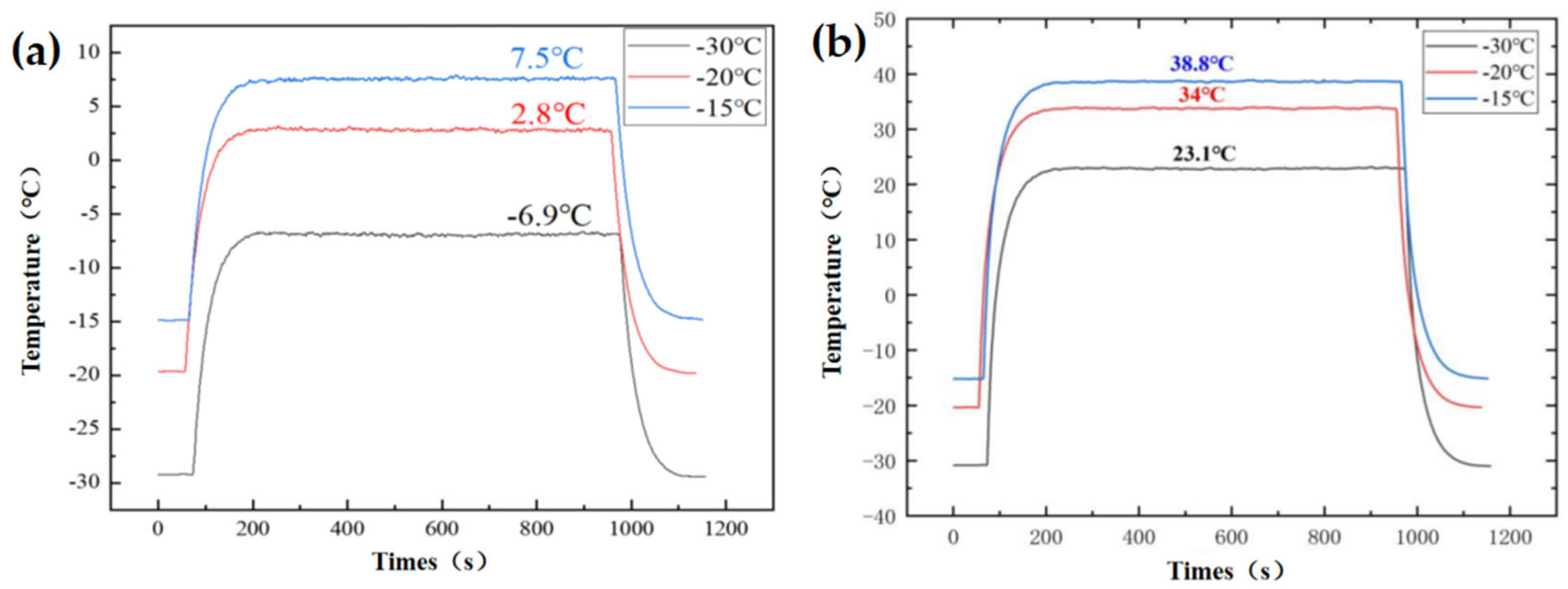

3.1. Electrothermal Modeling and Performance Analysis

- (1)

- Static conditions

- (2)

- Low-temperature dynamic conditions

- (3)

- De-icing Effectiveness Evaluation

3.2. Heat Transfer Path Analysis

3.3. Interlaminar Mechanical Performance Evaluation

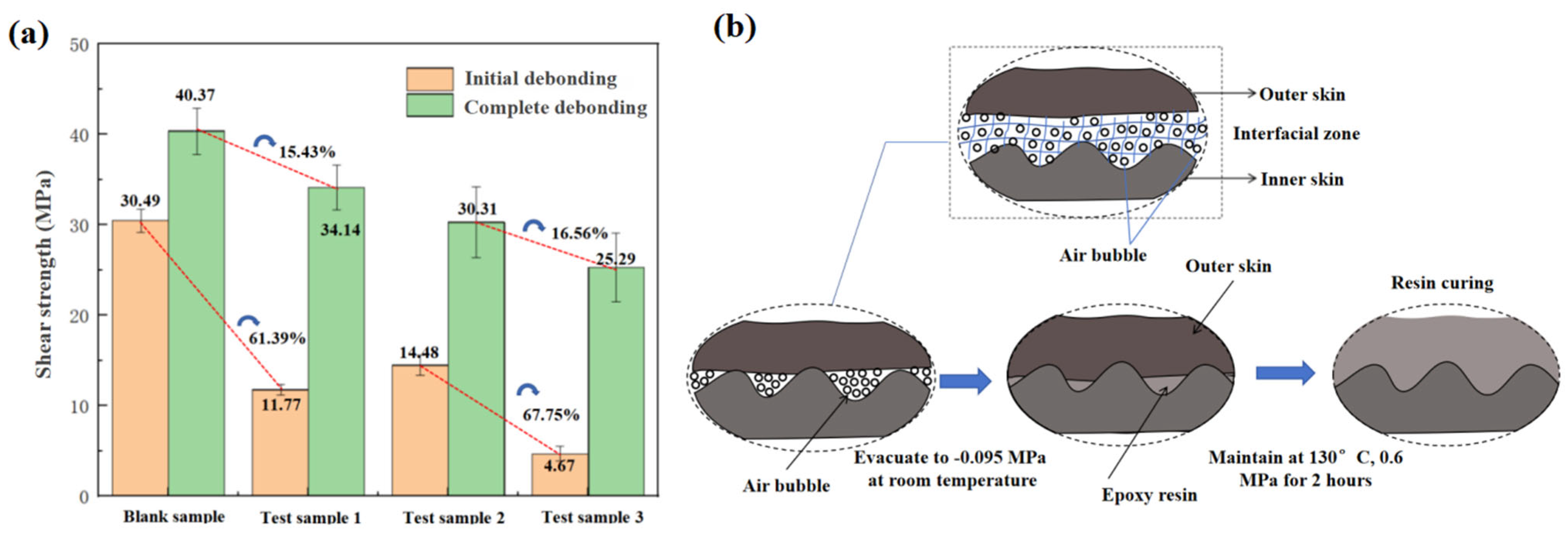

3.3.1. Interlaminar Mechanical Test Methods

3.3.2. Interlaminar Mechanical Testing Results and Discussion

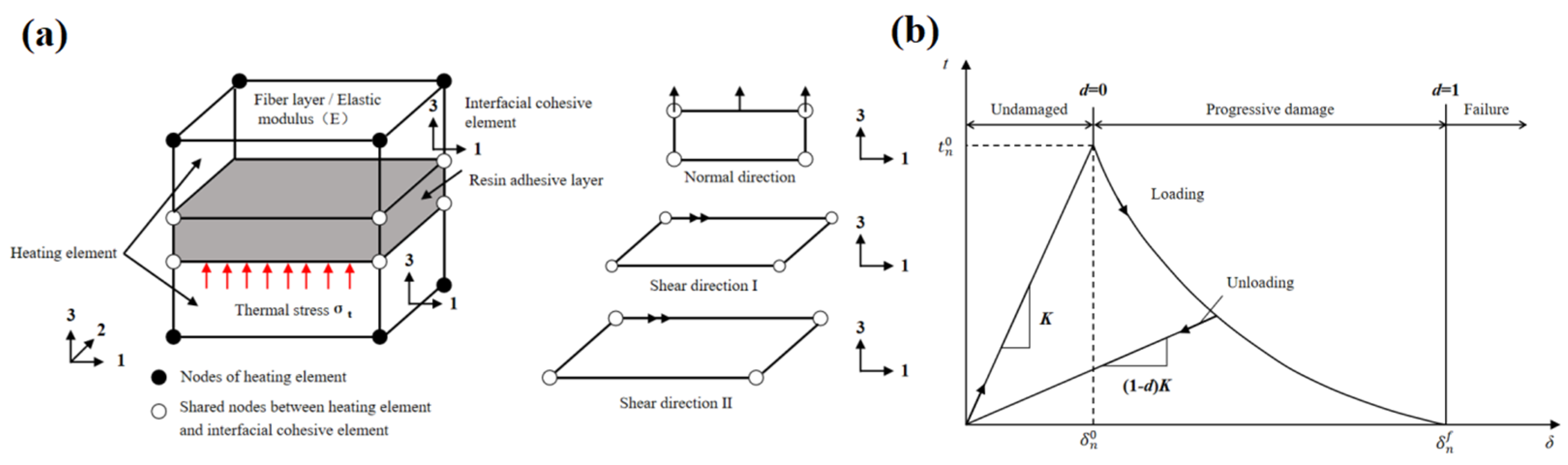

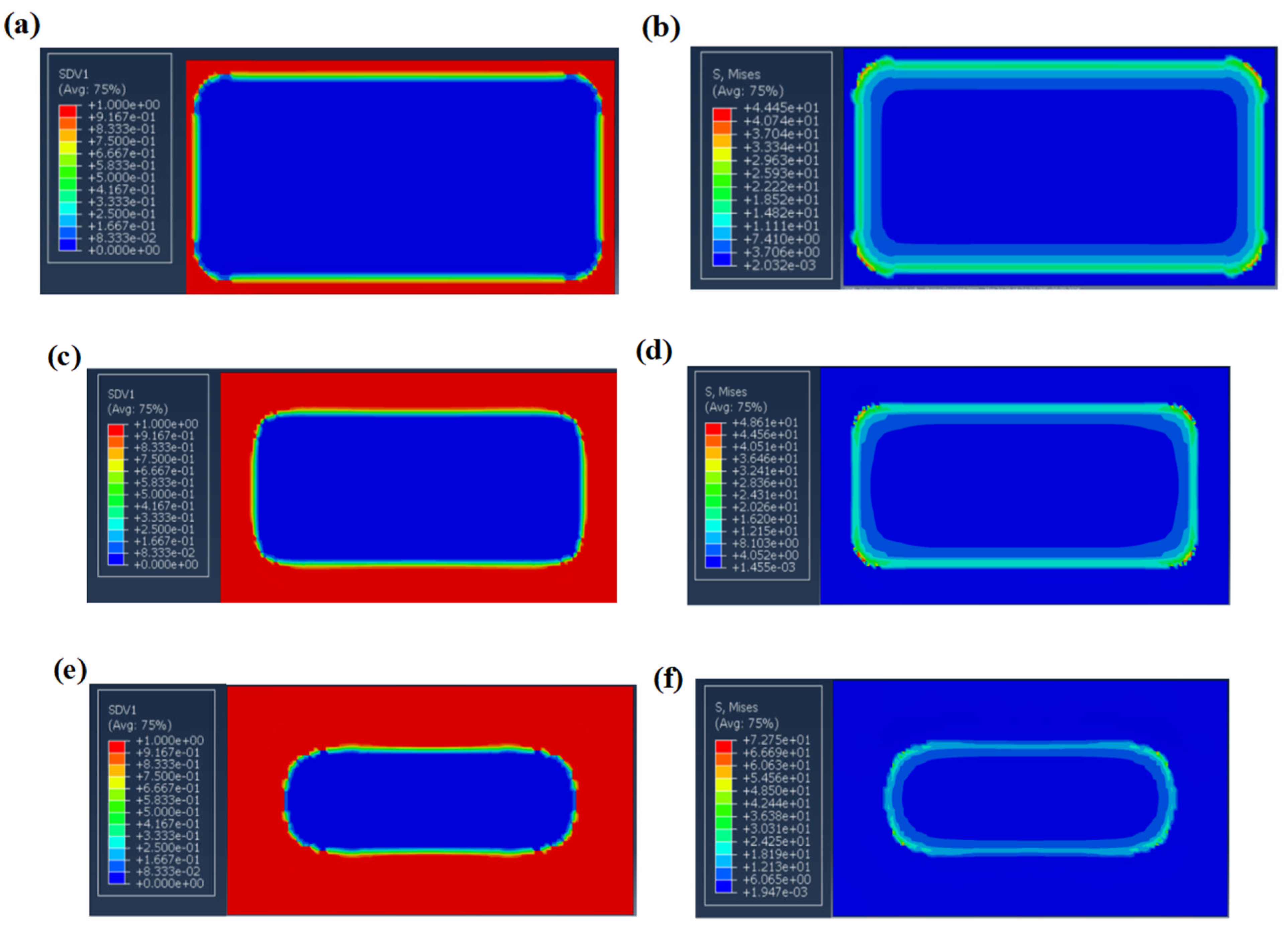

3.4. Thermo-Electro–Mechanical Coupling Analysis

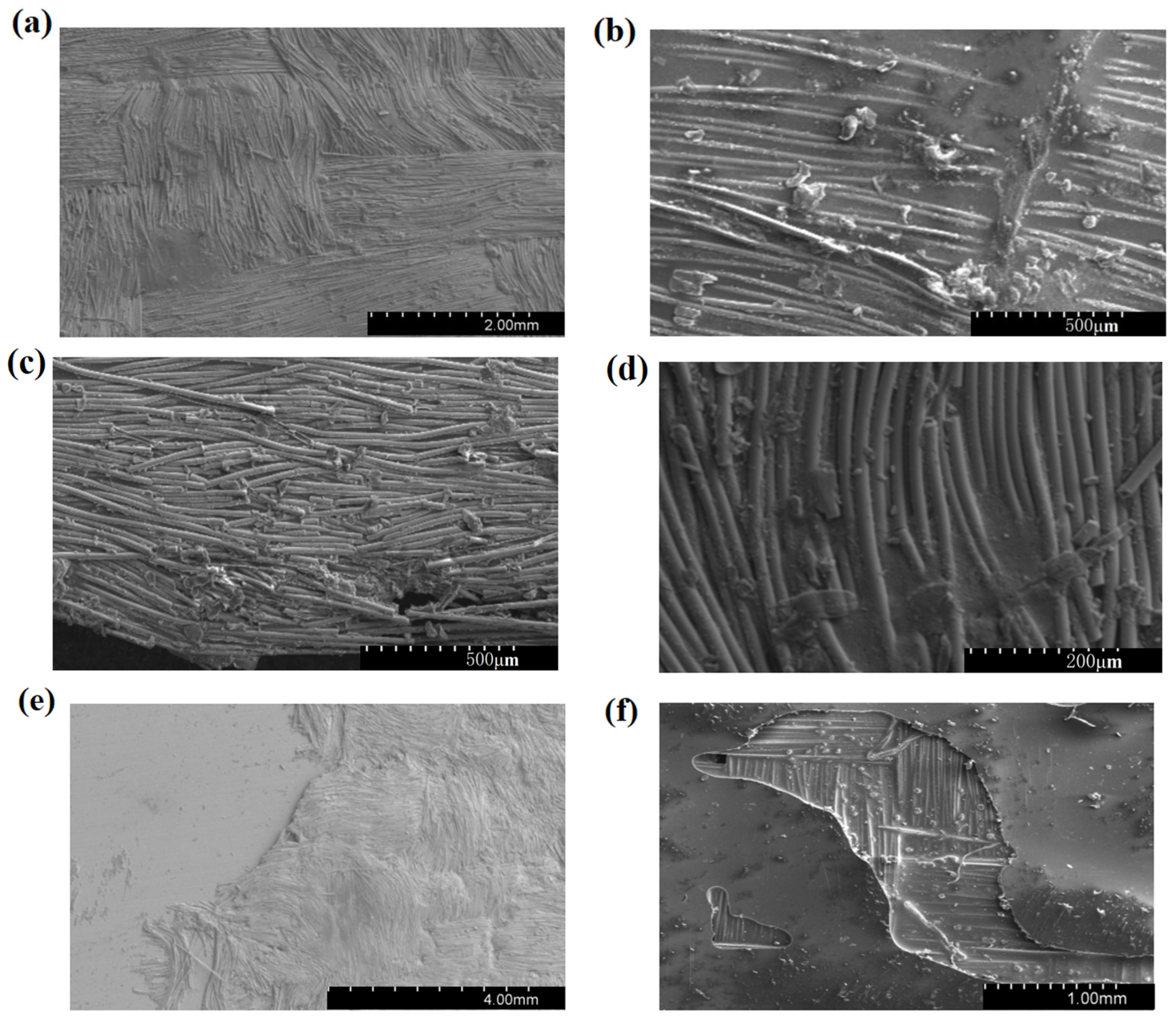

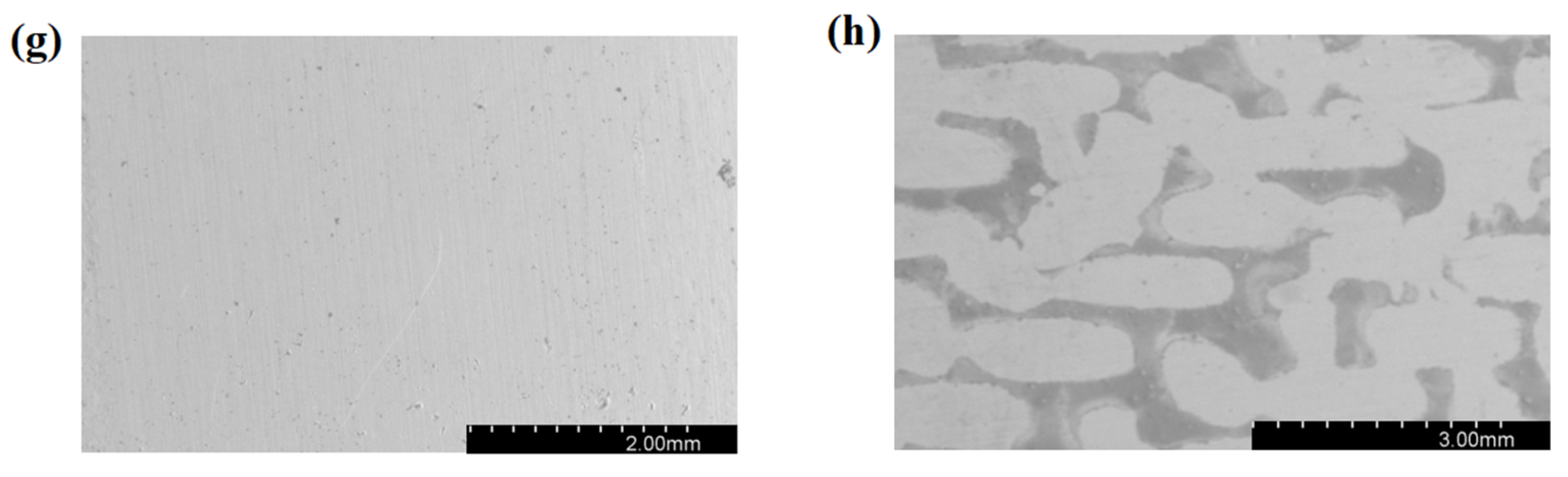

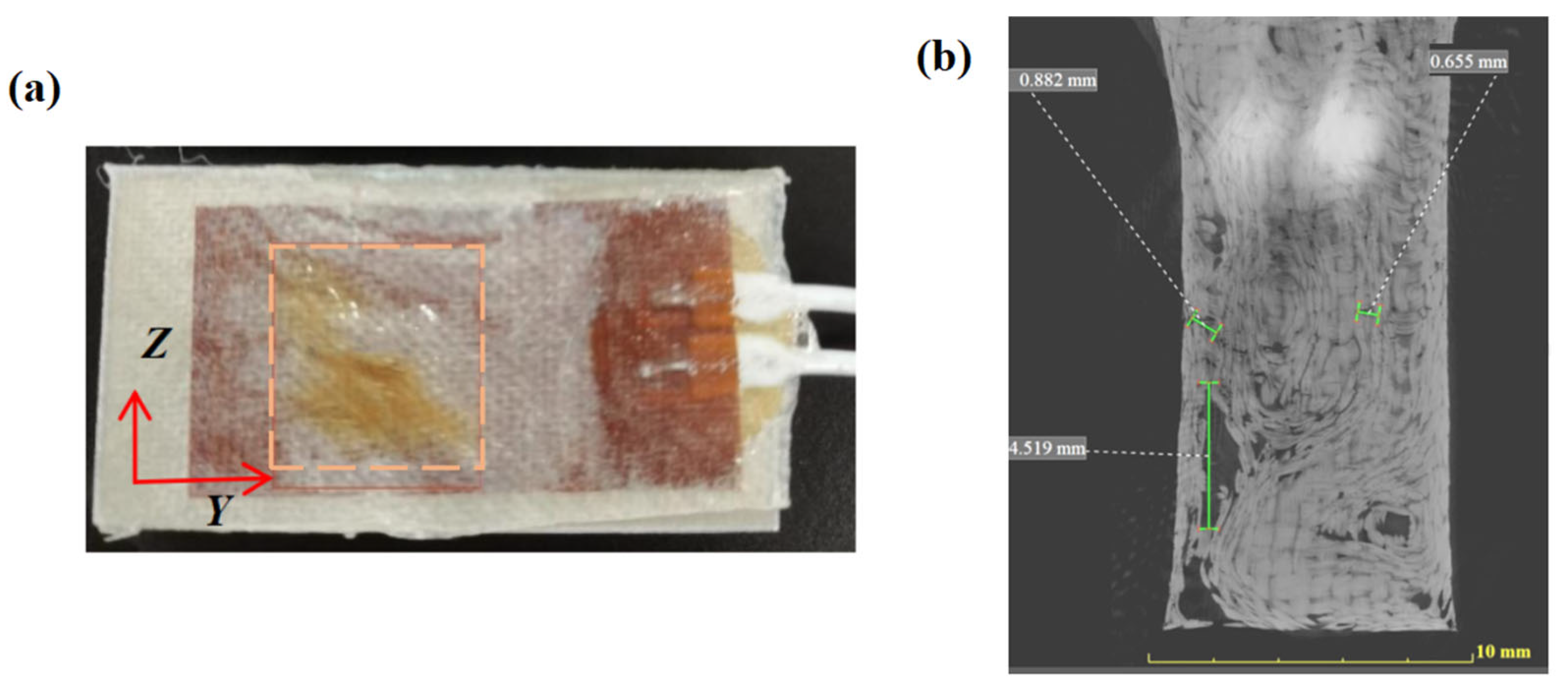

3.4.1. Microstructural Characterization

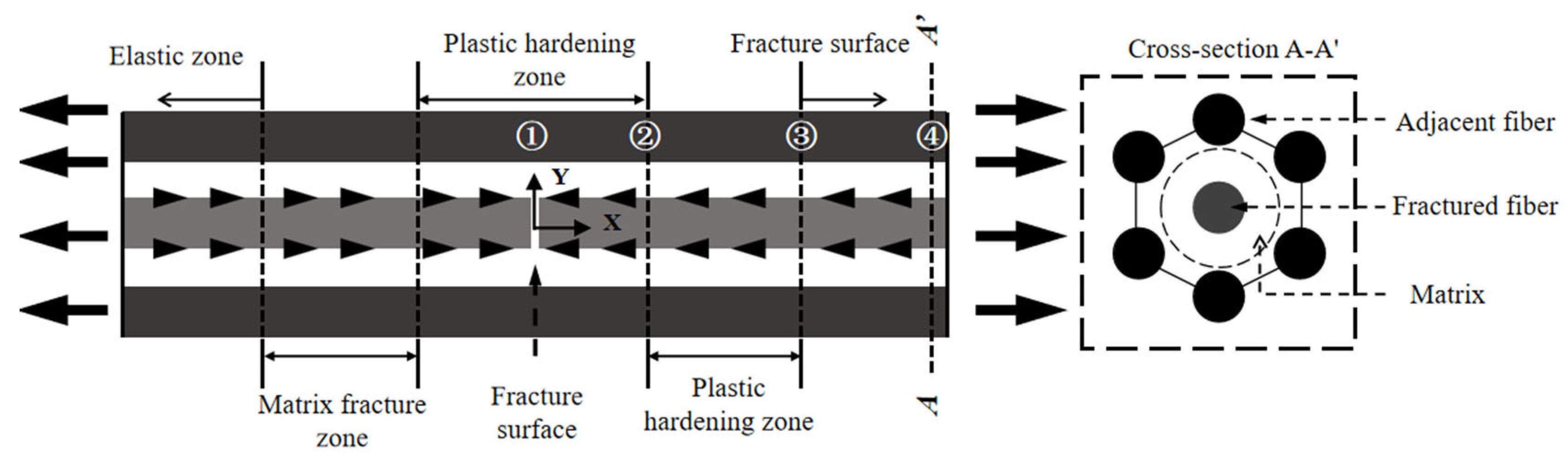

3.4.2. Interfacial Constitutive Modeling

3.4.3. Interfacial Degradation Mechanisms

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, Y.; Tan, W.; Wu, Z. Aircraft icing: An ongoing threat to aviation safety. Aerosp. Sci. Technol. 2018, 75, 353–385. [Google Scholar] [CrossRef]

- Lynch, F.T.; Khodadoust, A. Effects of ice accretions on aircraft aerodynamics. Prog. Aerosp. Sci. 2001, 37, 669–767. [Google Scholar] [CrossRef]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- Farzaneh, M.; Charles; Ryerson, C. Anti-icing and deicing techniques. Cold Reg. Sci. Technol. 2011, 65, 1–4. [Google Scholar] [CrossRef]

- Cui, Y.; Chen, W.; Dai, N.; Han, C. Integrated Technologies for Anti-Deicing Functions and Structures of Aircraft: Current Status and Development Trends. Aerospace 2024, 11, 821. [Google Scholar] [CrossRef]

- da Costa, A.A.; da Silva, D.F.N.R.; Travessa, D.N.; Botelho, E.C. The effect of thermal cycles on the mechanical properties of fiber–metal laminates. Mater. Des. 2012, 42, 434–440. [Google Scholar] [CrossRef]

- NASA Technology Taxonomy 2020; NASA Technical Reports Server (NTRS); National Aeronautics and Space Administration: Washington, DC, USA, 2019; pp. 1–239.

- Mohseni, M.; Amirfazli, A. A novel electro-thermal anti-icing system for fiber-reinforced polymer composite airfoils. Cold Reg. Sci. Technol. 2013, 87, 47–58. [Google Scholar] [CrossRef]

- Niu, Y.; Su, J.; Yao, J.; Qin, Z.; Yang, L. Flexible hybrid nanomaterial film with the electro-thermal and reliabilityproperties for active anti/de-icing application in static and dynamic icing environment. Compos. Commun. 2025, 53, 102228. [Google Scholar] [CrossRef]

- Wróblewski, G.; Kielbasinski, K.; Swatowska, B.; Jaglarz, J.; Marszalek, K.; Stapinski, T.; Jakubowska, M. Carbon nanomaterials dedicated to heating systems. Circuit World 2015, 41, 102–106. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Kempers, R.; Amirfazli, A. 3D printed electro-thermal anti- or de-icing system for composite panels. Cold Reg. Sci. Technol. 2019, 166, 102844. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Ding, Y.; Zhou, J.; Kong, X.; Harper, L.T.; Blackman, B.R.K.; Falzon, B.G.; Dear, J.P. Modelling damage in fibre-reinforced thermoplastic composite laminates subjected to three-point bend loading. Compos. Struct. 2020, 236, 111889. [Google Scholar] [CrossRef]

- Shiverskii, A.V.; Owais, M.; Mahato, B.; Abaimov, S.G. Electrical Heaters for Anti/De-Icing of Polymer Structures. Polymers 2023, 15, 1573. [Google Scholar] [CrossRef] [PubMed]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Müller, B.; Hagenbeek, M.; Sinke, J. Thermal cycling of (heated) fibre metal laminates. Compos. Struct. 2016, 152, 106–116. [Google Scholar] [CrossRef]

- Hagenbeek, M.; Sinke, J. Effect of long-term thermal cycling and moisture on heated Fibre Metal Laminates and glass-fibre epoxy composites. Compos. Struct. 2019, 210, 500–508. [Google Scholar] [CrossRef]

- Li, R.; Xu, W.; Zhang, D. Impacts of Thermal and Mechanical Cycles on Electro-Thermal Anti-Icing System of CFRP Laminates Embedding Sprayable Metal Film. Materials 2021, 14, 1589. [Google Scholar] [CrossRef]

- Wu, T.; Zhou, G.; Cai, D.; Mao, D. Electro-thermal functional fatigue properties of deicing composite laminates: Internal thermal and compression cycle tests. Aerosp. Sci. Technol. 2024, 146, 108978. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, J.; Wang, H.; Wu, L. Improving the interlaminar shear strength and thermal conductivity of carbon fiber/epoxy laminates by utilizing the graphene-coated carbon fiber. J. Appl. Polym. Sci. 2019, 136, 47061. [Google Scholar] [CrossRef]

- ISO 14130; Fibre-Reinforced Plastic Composites—Determination of Apparent Interlaminar Shear Strength by Short-Beam Method. ISO: Geneva, Switzerland, 1997.

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Geng, S.; Sha, Y. Cohesion model applied in the interface layer of composite materials. Shandong Ind. Technol. 2019, 3, 41–42. [Google Scholar]

- Hagenbeek, M.; Müller, B.; Sinke, J. Effect of Thermal Cycling and Aging on Heated Fiber Metal Laminates and Glass-Fiber Epoxy Composites. Adv. Eng. Mater. 2019, 21, 1800084. [Google Scholar] [CrossRef]

- Zheng, J. Research on Interface Properties and Forming Processs of TA1/Al5083 Composite Based on an Improved Cohesion Zone Model. Master’s Thesis, Central South University, Changsha, China, 2023. [Google Scholar]

- Zhang, X.; Duan, Q.; Cao, D.; Chen, C.; Hu, H.; Wang, J.; Li, S. Decoupling cohesion method based on Mode I delamination damage mechanism of composite materials. Acta Mater. Compos. Sin. 2024, 41, 4942–4955. (In Chinese) [Google Scholar]

- Deng, D. Research on Crack Propagation of Composite Materials Based on Cohesive Zone Model. Master’s Thesis, Civil Aviation University of China, Tianjin, China, 2021. [Google Scholar]

- Yao, L.; Zhang, S.; Cao, X.; Gu, Z.; Wang, C.; He, W. Tensile mechanical behavior and failure mechanisms of fiber metal laminates under various temperature environments. Compos. Struct. 2022, 284, 115142. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, B.; Chen, M.; Cai, D.; Zhou, G. Flexural properties of electrothermal deicing composite laminates: Experimental and numerical study. Thin-Walled Struct. 2022, 170, 108527. [Google Scholar] [CrossRef]

- Wu, T.; Zhou, G.; Cai, D.; Zhou, F.; Cai, L. Effect of internal heating on delamination properties of deicing composite curved beams under four-point bending. Compos. Struct. 2021, 256, 113084. [Google Scholar] [CrossRef]

- Donadon, M.V.; Iannucci, L.; Falzon, B.G.; Hodgkinson, J.M.; de Almeida, S.F.M. A progressive failure model for composite laminates subjected to low velocity impact damage. Comput. Struct. 2008, 86, 1232–1252. [Google Scholar] [CrossRef]

- Ramanujam, N.; Vaddadi, P.; Nakamura, T.; Singh, R.P. Interlaminar fatigue crack growth of cross-ply composites under thermal cycles. Compos. Struct. 2008, 85, 175–187. [Google Scholar] [CrossRef]

- Zhang, B.Y. Interface Technology of Advanced Composite; Aviation Industry Press: Beijing, China, 2017; pp. 133–145. [Google Scholar]

- Tao, J.; Li, H.G.; Hu, Y.B. Mechanical Properties and Forming Technologies of Fiber Metal Laminates; Science Press: Beijing, China, 2017; pp. 85–120. [Google Scholar]

| Structure | Number of Layers | Thickness (mm) | Grade | Manufacturer |

|---|---|---|---|---|

| Outer cladding layer | 1 layer | 2 | 3A21 | Guangdong Xingfa Aluminium Co., Ltd. (Foshan, Guangdong Province, China) |

| Insulating layer | 2 layers | 0.5 | E-7202 | Tianjin Hanshuo Advanced Materials Co., Ltd. (Tianjin, China) |

| Heating sheet | 1 layer | 0.3 | HL-368-E | Jiangsu Huilong Electric Heating Appliance Co., Ltd. (Jiangyin, Jiangsu Province, China) |

| Thermal insulation layer | 1 layer | 0.15 | E-7202 | Tianjin Hanshuo Advanced Materials Co., Ltd. (Tianjin, China) |

| Protective layer | 1 layer | 0.75 | SPC-1 | Hangzhou Huaju Composite Materials Co., Ltd. (Hangzhou, Zhejiang Province, China) |

| Inner cladding layer | 1 layer | 0.15 | E-7202 | Tianjin Hanshuo Advanced Materials Co., Ltd. (Tianjin, China) |

| Test Item | Voltage (V) | Current (A) | Power (W) | Heating Rate (°C/min) | Electrothermal Efficiency | Heat Flux Density (W/m2) |

|---|---|---|---|---|---|---|

| Sample 1 | 15 V | 0.66 A | 9.9 W | 0.51 | 63.13% | 515.63 |

| Sample 2 | 0.61 A | 9.2 W | 0.76 | 67.93% | 464.65 |

| Test Item | Temperature (°C) | Wind Speed (m/s) | Current (A) | Power (W) | Heating Rate (°C/min) | Electrothermal Efficiency | Heat Flux Density (W/m2) |

|---|---|---|---|---|---|---|---|

| Sample 1 | −15 | 20 | 3.37 | 270.1 | 3.00 | 67.24% | 13,743.6 |

| −20 | 3.37 A | 270.3 | 2.76 | 66.76% | 13,842.4 | ||

| −30 | 3.40 A | 272.2 | 2.96 | 66.16% | 13,967.1 | ||

| Sample 2 | −15 | 3.37 A | 270.1 | 9.02 | 75.82% | 13,666.95 | |

| −20 | 3.37 A | 270.3 | 9.08 | 75.77% | 13,577.07 | ||

| −30 | 3.40 A | 272.2 | 8.95 | 75.31% | 13,773.21 |

| No. | Parameter | Sample 1 (−30 °C) | Sample 2 (−30 °C) | Index Improvement Range | Remarks |

|---|---|---|---|---|---|

| 1 | Heating rate | 2.96 (°C/min) | 8.95 (°C/min) | +202% | (Sample 2 − Sample 1)/(Sample 1) |

| 2 | Electrothermal efficiency | 66.16% | 75.31% | +13.8% | (Sample 2 − Sample 1)/(Sample 1) |

| 3 | Minimum surface temperature | −6.9 (°C) | 23.1 (°C) | +30.0 (°C) | Sample 2 − Sample 1 |

| Experimental Scheme | Initial Debonding | Complete Debonding | ||||||

|---|---|---|---|---|---|---|---|---|

| Displacement (mm) | Load (N) | Shear Strength τ (MPa) | Error (MPa) | Displacement (mm) | Load (N) | Shear Strength τ (MPa) | Error (MPa) | |

| Virgin Specimen | 0.86 | 5122.17 | 30.49 | 1.3 | 1.63 | 6781.94 | 40.37 | 2.59 |

| After 10,000 Cycles | 0.28 | 1976.64 | 11.77 | 0.59 | 0.71 | 5734.69 | 34.14 | 2.47 |

| After 15,000 Cycles | 0.37 | 2432.80 | 14.48 | 1.12 | 1.16 | 5091.54 | 30.31 | 3.94 |

| After 20,000 Cycles | 0.21 | 785.15 | 4.67 | 0.83 | 0.63 | 4249.48 | 25.29 | 3.82 |

| Encapsulation Method | Initial Debonding | Complete Debonding | ||||

|---|---|---|---|---|---|---|

| Displacement (mm) | Load (N) | Shear Strength τ (MPa) | Displacement (mm) | Load (N) | Shear Strength τ (MPa) | |

| Sample 1 | 0.57 | 3329.41 | 23.36 | 1.05 | 5196.87 | 30.93 |

| Sample 2 | 0.86 | 5122.17 | 30.49 | 1.63 | 6781.94 | 40.37 |

| Material Name | Density (kg/m3) | Thermal Conductivity Coefficient (W/(m·K)) | Elastic Modulus (GPa) | Poisson’s Ratio | Coefficient of Thermal Expansion (1/°C) |

|---|---|---|---|---|---|

| GFRP | 1800 | 0.8 | 30 | 0.25 | 8 × 10−6 |

| Polyimide | 1400 | 0.2 | 2.5 | 0.35 | 50 × 10−6 |

| Nichrome alloy (Cr20Ni80) | 8400 | 15 | 200 | 0.3 | 16 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Dai, N.; Han, C. Structural-Integrated Electrothermal Anti-Icing Components for UAVs: Interfacial Mechanisms and Performance Enhancement. Aerospace 2025, 12, 719. https://doi.org/10.3390/aerospace12080719

Cui Y, Dai N, Han C. Structural-Integrated Electrothermal Anti-Icing Components for UAVs: Interfacial Mechanisms and Performance Enhancement. Aerospace. 2025; 12(8):719. https://doi.org/10.3390/aerospace12080719

Chicago/Turabian StyleCui, Yanchao, Ning Dai, and Chuang Han. 2025. "Structural-Integrated Electrothermal Anti-Icing Components for UAVs: Interfacial Mechanisms and Performance Enhancement" Aerospace 12, no. 8: 719. https://doi.org/10.3390/aerospace12080719

APA StyleCui, Y., Dai, N., & Han, C. (2025). Structural-Integrated Electrothermal Anti-Icing Components for UAVs: Interfacial Mechanisms and Performance Enhancement. Aerospace, 12(8), 719. https://doi.org/10.3390/aerospace12080719