1. Introduction

With the advancement of the times and the continuous improvement in social productivity, the demand for electricity driven by various human activities has been steadily increasing. In order to reduce the reliance on fossil fuel combustion for power generation and to mitigate the associated greenhouse gas emissions, the utilization of renewable energy sources—such as wind, biomass, and hydropower—has emerged as a crucial solution. Both terrestrial environments and the vast expanses of the ocean contain abundant hydropower resources. For hydropower extraction, turbines are generally used, with efficiencies typically exceeding 40% [

1]. In some cases, the integration of auxiliary components—such as inlet nozzles—can provide additional pressure energy to the turbine, enabling the efficiency to surpass the Betz limit [

2]. However, turbines also present certain limitations, including large spatial requirements and challenges in maintaining the operational stability of their rotating mechanisms.

Flapping foils can be employed for both propulsion and energy harvesting from the surrounding fluid environment. These foils typically feature simple structures, low noise levels, and strong adaptability to diverse environmental conditions. Wu [

3] first proposed the concept of harnessing wave energy using oscillating foils in 1971. Since then, the application of oscillating foils for energy harvesting and propulsion in uniform flows has attracted considerable attention. Since the initial proposal and experimental demonstration by McKinney et al. [

4], the development of flapping foil energy harvesting systems has progressed rapidly. In 2006, Kinsey and Dumas [

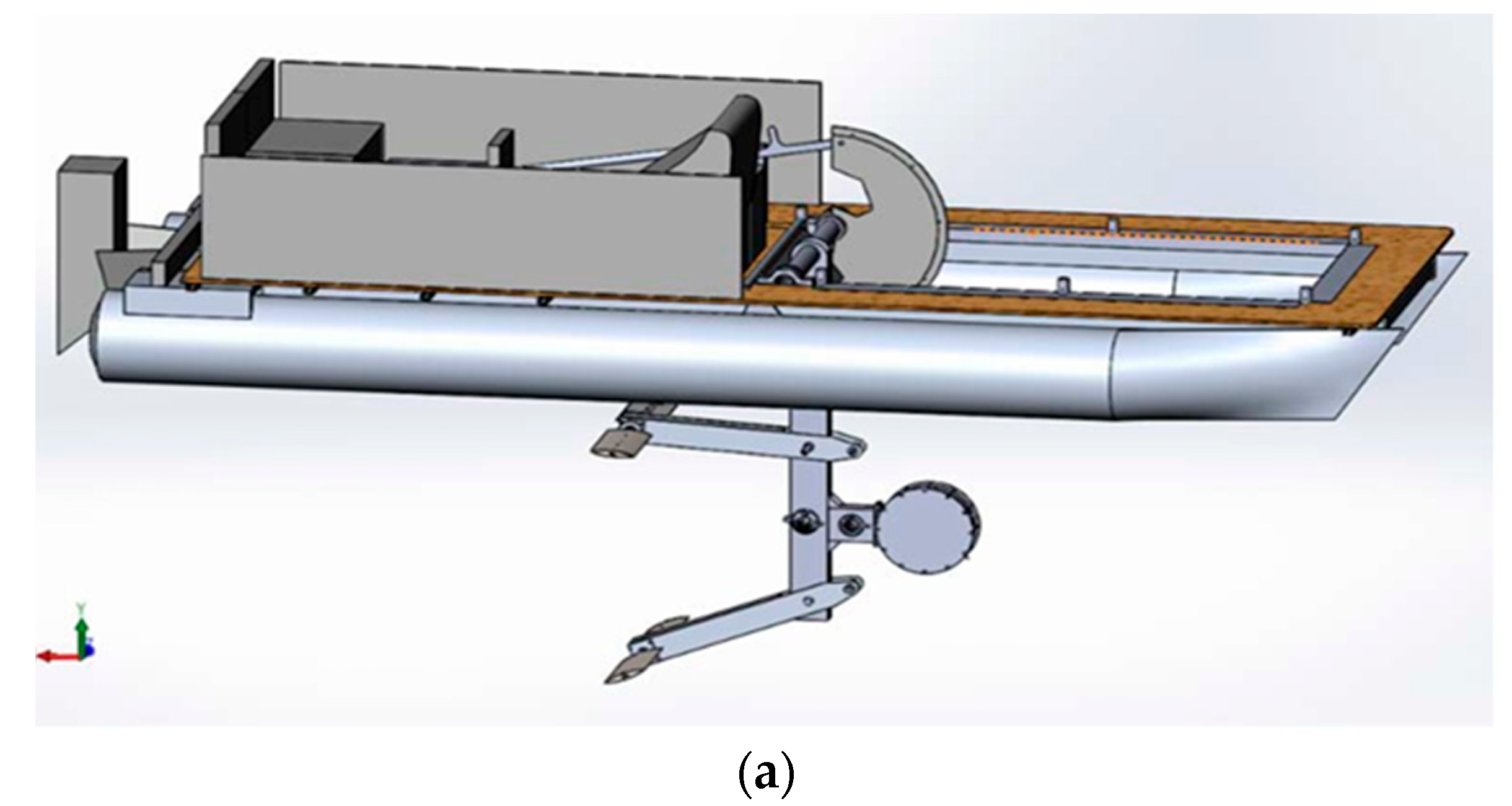

5] discovered that energy could be extracted from oncoming flow using foils undergoing simultaneous heaving and pitching motions; under a Reynolds number of 1100, they achieved a maximum energy harvesting efficiency of 33.7%. The first commercial prototype of a flapping-based hydropower device was developed in 2002 by an engineering firm and was named “Stingray,” as shown in

Figure 1. The entire system consists of a support frame, flapping foil, actuating arms, and hydraulic cylinders. The foil performs both pitching and heaving motions and is capable of generating 122 kW of power [

6]. The Leading Edge research group at Brown University developed dual-foil energy harvesting systems with output capacities of 1.0 kW and 2.0 kW, as shown in

Figure 2, achieving an energy harvesting efficiency of 28% [

7]. Therefore, flapping foil energy harvesters can be installed in tidal current regions with large flow variability to generate electricity from water resources. However, the energy harvesting efficiency of flapping foils is generally not superior to that of traditional turbine-based systems, making the enhancement of flapping foil efficiency a key area of ongoing research.

In the pursuit of improving energy harvesting efficiency, researchers have extensively studied the motion trajectories of flapping foils. These foils typically undergo periodic coupled pitching and heaving motions. Various trajectories have been explored, including sinusoidal motion [

8,

9], non-sinusoidal motion [

10,

11], elliptical motion [

12], and asymmetric sinusoidal motion [

13]. Studies on motion parameters have revealed that the heaving amplitude significantly influences efficiency; as the amplitude increases, the efficiency initially rises and then declines [

14]. Under different trajectory types, the pitching amplitude also exhibits an optimal value for maximizing efficiency. The pitching amplitude affects the formation of leading-edge vortices on the foil surface, which in turn impacts energy harvesting performance [

14,

15]. Kinsey et al. [

15] and Zhu et al. [

16] found that under sinusoidal motion at a Reynolds number of 1100, the reduced frequency plays a critical role in wake stability. The optimal energy harvesting efficiency occurs when the wake is most unstable, corresponding to a reduced frequency in the range of 0.1 to 0.15. The rotational axis of the pitching motion also plays a significant role in flapping foil performance. Variations in the axis location affect the flow velocity over the foil surface, thereby altering the pressure distribution and ultimately influencing the energy harvesting efficiency. When the rotational axis is positioned at one-third of the chord length, the synchronization between the generated lift and the heaving motion is enhanced, leading to improved energy harvesting performance [

17]. In addition to rigid hydrofoils, researchers have investigated the use of flexible foils to further enhance energy harvesting efficiency. Leveraging the deformability of flexible foils, fluid–structure interaction (FSI) enables a combination of active and passive deformation modes. This coupling improves lift generation and reduces drag, thereby enhancing the overall energy harvesting performance of the flapping foil system [

18,

19,

20].

Similarly to the approach of enhancing turbine performance through the addition of auxiliary devices, control mechanisms can be integrated into flapping foils to improve energy extraction efficiency. These mechanisms are generally categorized into passive and active control strategies. Traditional passive flow control methods require no external energy input and primarily involve additive or subtractive modifications to the foil surface to enhance flow characteristics. Such methods include surface protrusions, grooves, splitter plates, upstream rods, bleed, and dimpled surfaces, among others [

21].

Active flow control methods require external energy input to manipulate the flow field. Low-power, high-efficiency active flow control strategies are particularly beneficial for enhancing the energy harvesting performance of flapping foils. These methods aim to mitigate periodic vortex shedding, reduce drag, and suppress fluctuations in lift forces [

22]. For example, placing a bluff body upstream of the flapping foil can alter the direction of incoming flow, promote the formation of leading-edge vortices, and thereby improve foil performance—resulting in up to a 30% increase in efficiency [

23]. In another strategy, two auxiliary foils are positioned on the upper and lower surfaces of the main flapping foil. When the main foil and auxiliary foils approach each other during motion, their respective induced vortices interact, leading to a redistribution of surface pressure and an enhancement in lift, thereby improving energy extraction [

24]. Trailing-edge flaps have also been implemented on flapping foils to optimize energy harvesting performance [

25,

26]. Additionally, vortex generators mounted on the foil surface can generate secondary vortices that interact with those induced by the flapping motion, promoting energy exchange within the boundary layer and enhancing both lift and the synchronization between pitching and heaving motions [

27]. Furthermore, jet slots installed at the trailing edge of the foil have been shown to increase energy harvesting efficiency by 21.6%, as reported in the literature [

28].

Chen et al. [

29] proposed the use of steady suction to modify boundary layer flow over a circular cylinder. Control strategies based on suction and blowing have been widely adopted for manipulating flow around cylinders. These steady suction and blowing control (SBC) devices can be easily installed on bluff bodies of various shapes and configurations [

30,

31]. The SBC approach has been demonstrated to be effective and energy efficient. Delaunay and Kaiktsis [

32] conducted numerical simulations and stability analyses to investigate the effects of base suction and blowing on the flow around a cylinder at low Reynolds numbers. Their results indicated that for Re > 47, even mild blowing or sufficiently strong suction could stabilize the wake and reduce absolute instability in the near-wake region. Suction and blowing techniques have also been applied in aircraft slat design. For instance, a dual-slotted blown airfoil based on the NACA 23015 [

33] profile was shown to achieve a significant increase in lift coefficient through optimization of configuration parameters [

34]. Gao et al. [

35] carried out an experimental study on the control effects and mechanisms of a bluff body subjected to windward-side suction combined with leeward-side blowing, as illustrated in

Figure 3. Through active control, leeward-side blowing generated a pair of vortices in the cylinder’s wake, altering the conventional vortex shedding process. As these blowing-induced vortices shifted downstream, they facilitated the detachment of the unstable shear layers from the cylinder surface. The study demonstrated that steady and symmetric disturbances imposed on periodic flow over a circular cylinder could induce a symmetric mode of wake vortex shedding. Additionally, their research showed that when a circular cylinder exposed to transverse flow is allowed to oscillate, vortex-induced vibrations (VIVs) occur when the vortex shedding frequency matches the structural natural frequency. In engineering applications, effective control strategies are essential to mitigate the adverse effects caused by vortex shedding around bluff bodies.

The SBC method employed in this study differs from that used by Gao et al. [

35]. Unlike their configuration, the present study adopts a reversed approach: suction is applied on the leeward side and blowing on the windward side, aiming to enhance the wake strength of the flapping foil. By synchronizing the timing of suction and blowing with different phases of the flapping motion, the control is coordinated as follows: at t/T = 0–0.5, when the foil moves downward, suction and blowing are applied on the lower surface; at t/T = 0.5–1, when the foil moves upward, they are applied on the upper surface. The generation and shedding of leading-edge vortices (LEVs) play a critical role in determining the energy harvesting efficiency of flapping foils. Therefore, the periodicity and spatial characteristics of vortex shedding must be carefully considered. In this study, the placement of SBC devices is aligned with the vortex formation regions induced by foil motion. This includes optimizing the slot position of SBC devices, as well as their slot length and depth and the angle of the blowing openings. The objective is to investigate the optimal installation positions and design parameters of SBC devices that can maximize energy harvesting efficiency and improve the overall performance of the flapping foil system.

It is well known that tidal flows are inherently slow. Due to the relatively low energy harvesting efficiency of flapping foils, their large-scale deployment has remained a challenge. This study introduces a suction and blowing control (SBC) strategy to enhance the energy harvesting performance of flapping foils. Compared with other flow control techniques, SBC offers distinct advantages, including strong environmental adaptability and low noise emission. This research quantitatively compares the energy harvesting efficiency of flapping foils equipped with SBC devices to that of baseline (uncontrolled) foils, aiming to overcome the efficiency bottleneck in low-speed flow conditions and enable the broader application of flapping foil technology. Through systematic numerical simulations, the effects of different SBC configurations—including installation positions and design parameters—on the energy harvesting performance of flapping foils are investigated. The study identifies the optimal SBC placement and geometry that maximize energy harvesting efficiency. Additionally, the influence of varying Reynolds numbers and pitching amplitudes on the effectiveness of SBC-enhanced energy harvesting is examined. The findings provide a valuable parametric basis for the optimized design and practical implementation of flapping foils integrated with SBC.