1. Introduction

Improving aircraft flight operation methods can reduce fuel consumption. Reducing fuel consumption is financially beneficial for airlines because fuel costs increased from 24% to 32% of their expenditures between 2019 and 2024 [

1]. Although aviation has many environmental impacts, such as contrails [

2] and black carbon [

3], lower fuel consumption leads to reduced carbon dioxide emissions, which comprise approximately one-third of radiative forcing by the aviation industry [

4], contributing to a decrease in the overall environmental impact of the aviation industry. Aircraft flight operations involve various phases. During the ascent phase, the aircraft is heavy and consumes a significant amount of fuel.

Given this background, this study focused on climbing methods. Under a continuous climb operation (CCO), considering fuel consumption [

5], it has been proposed that an airplane should climb to its cruising altitude without leveling. The optimization of climb trajectories must consider various factors, such as greenhouse gas emissions, noise, flight time, and fuel consumption, which are often interrelated and may involve trade-offs. Wan et al. optimized climbing trajectory using the required time-of-arrival constraints [

6]. Zeh et al. balanced these factors [

7]. In [

8], the authors successfully reduced both noise and fuel consumption. CCO has the potential to reduce fuel consumption by more than 10%, as estimated using Quick Access Recorder data [

9] and by solving a mathematical model [

10]. In one study, new procedures for the end of the climb were proposed [

11]. In another study [

12], the climb trajectory was optimized sufficiently quickly for onboard computing.

Despite the merits of damping fuel consumption, it is difficult to conduct CCO around a congested airport, as the optimal trajectory may change owing to weather conditions, which requires trajectory flexibility [

13]. In [

14], the characteristics of flight level-offs in current operations were examined. Considering airport capacity, CCO should be employed entirely or not at all [

15], as it leads to an increased workload for air traffic controllers [

16]. Research on managing conflicts with arrival traffic is advancing. Data links enable the automation of trajectory prediction and other processes. This improves the accuracy of collision prediction and significantly reduces the frequency of climb interruptions [

17]. Considering these previous studies, trajectory optimization with a flight envelope and customizable restrictions is useful.

An accurate fuel-consumption model is an important and necessary technology that enables effective trajectory management. Numerous studies have been conducted to predict fuel consumption. These studies can be categorized as physically based or data-driven based on the nature of the fuel-consumption-prediction models. Traditionally, as in [

18], thrust is calculated using an equation based on energy, and the fuel-flow rate is calculated by multiplying the thrust by an engine-specific constant. Some studies, such as OpenAP [

19], have improved accuracy by adding correction terms to the physical model. Although physical knowledge has been used to explore important parameters in the fuel-flow rate [

20,

21], energy-based calculations suffer from low accuracy, despite their low computational cost. Meanwhile, machine learning techniques have enabled high-accuracy predictions at the cost of increased computational load, and recent studies have reported improved accuracy by introducing the latest neural networks (NNs) [

22]. Moreover, highly accurate predictions can be achieved by incorporating physical properties [

23] and selecting appropriate learning methods for each flight phase [

24]. Fuel consumption has also been estimated using radar track data [

25] and ADS-B data [

26]. In addition, fuel consumption over the entire terminal area [

27] and on the airport surface [

28] has been estimated to optimize fuel efficiency in overall operations. Moreover, the relationship between takeoff weight and fuel consumption has been estimated by calculating the sensitivity of machine learning models [

29].

Based on the above research, this paper proposes a method to create a fuel-optimal CCO profile for an aircraft using a novel approach combining machine learning fuel-consumption models and a genetic algorithm (GA).

Recently, the integration of machine learning models and optimization algorithms has gained significant attention across various fields. In the aerospace domain in particular, this integration has been applied to several design-related problems, such as unmanned aerial vehicle (UAV) design [

30], thin-walled stiffened structures [

31], and low-Reynolds-number airfoil optimization [

32]. These studies typically employ NNs as surrogate models to approximate complex physical phenomena, enabling a more efficient exploration of high-dimensional design spaces and facilitating the identification of optimal configurations. However, this approach has not yet been applied to the trajectory design of civil aircraft around airports.

While previous studies have applied either machine learning techniques for fuel estimation or optimization algorithms for trajectory planning, few have explored the integration of high-fidelity data-driven fuel models with trajectory optimization using evolutionary algorithms. To the best of our knowledge, the combination of an NN-based fuel-consumption model and GA for continuous climb trajectory optimization has not been comprehensively investigated. This novel integration enables flexible trajectory design under realistic operational constraints, thereby achieving improved fuel efficiency while maintaining operational feasibility. This data-driven framework leverages an NN-based fuel-consumption model and GA, enabling the efficient and flexible optimization of vertical profiles for any aircraft type if the data are accessible. The contributions of this study are twofold. First, we propose a data-driven approach to determine the fuel-optimum profile with a flight envelope and restrictions, which is versatile and applicable to cruise or descent optimization. Second, the results indicate a new operation strategy for airlines from the perspective of fuel reduction.

The remainder of this paper is organized as follows.

Section 2 explains the problem setting and optimization method used in this study.

Section 3 illustrates the results of the fuel-consumption prediction and optimized climb path in terms of fuel consumption.

Section 4 discusses the proposed method and operational feasibility of the optimized vertical profile. Finally,

Section 5 presents the conclusions and future prospects.

5. Conclusions and Future Work

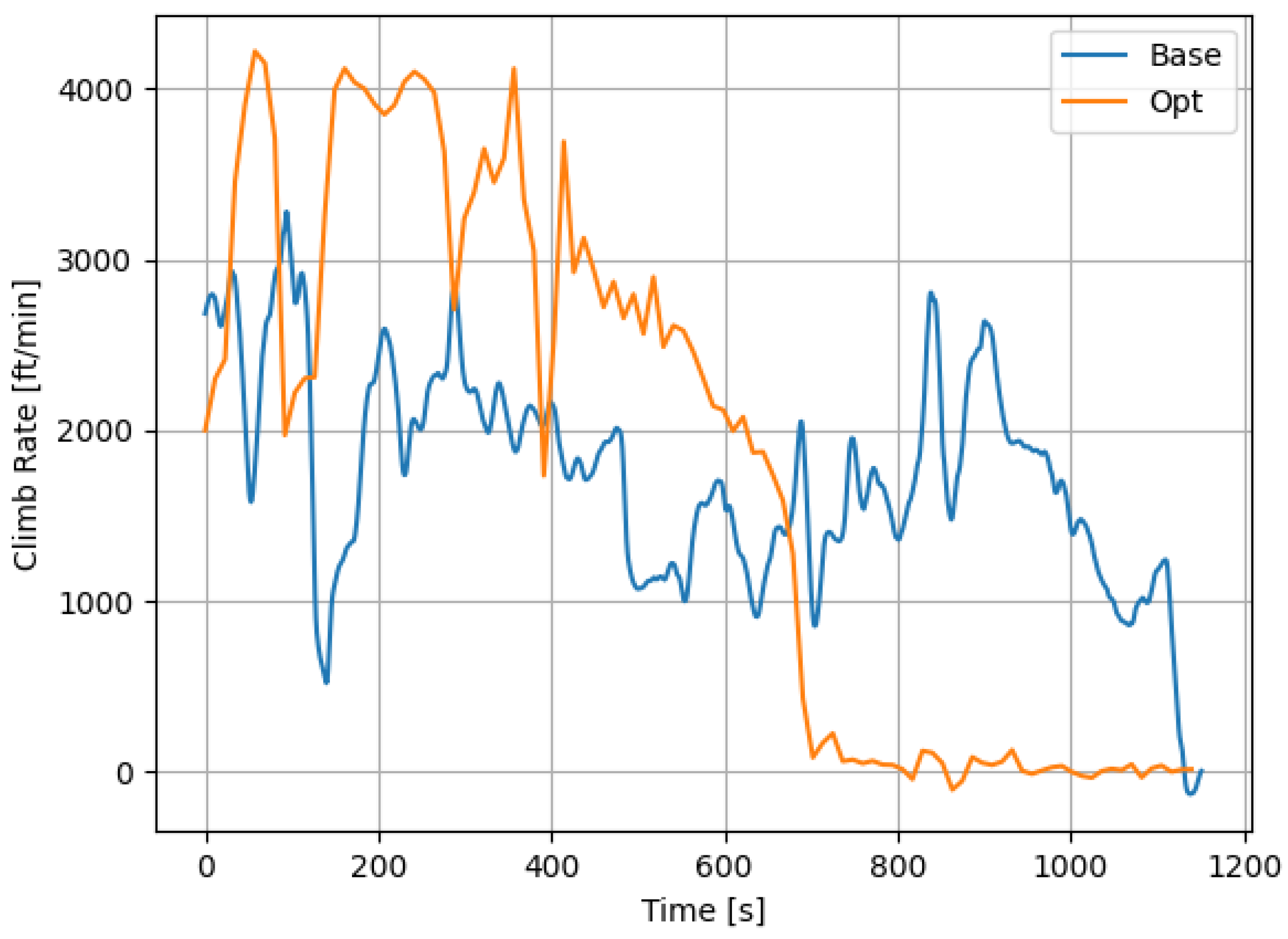

In this paper, we proposed a novel trajectory-optimization method that combines an artificial NN and GA. This approach enables optimization of the trajectory with any restrictions and flight envelope based on a precise fuel-consumption model of the trajectory. We utilized this method for the climbing phase of a Boeing 787. The optimization results indicated that it is desirable to climb continuously and rapidly to the cruise altitude at a faster rate of approximately 3000 ft/min compared to current practice, which could reduce fuel consumption by approximately 15%. Additionally, the trajectory plot showed that a vertical profile is possible under current airport operations, although it is difficult to handle overflight.

However, this method has some limitations that need to be considered. First, without constraints, the result goes out of the flight envelope, and the profile is impossible. This problem can be solved by improving the fuel-flow model. Second, the output solution is sometimes only locally optimal.

Our future research directions are as follows: First, we will incorporate weather conditions and arriving traffic into the simulation, verify the feasibility of safe implementation, and apply the optimized trajectory in practice. Second, we will use the optimized trajectory identified in this study to reduce overall fuel consumption at the airport. Finally, we will compare the convergence properties of different optimization algorithms while exploring the influence of various data sources, human factors, controllability, and passenger comfort.