Dynamic Modeling and Safety Analysis of Whole Three-Winch Traction System of Shipboard Aircraft

Abstract

1. Introduction

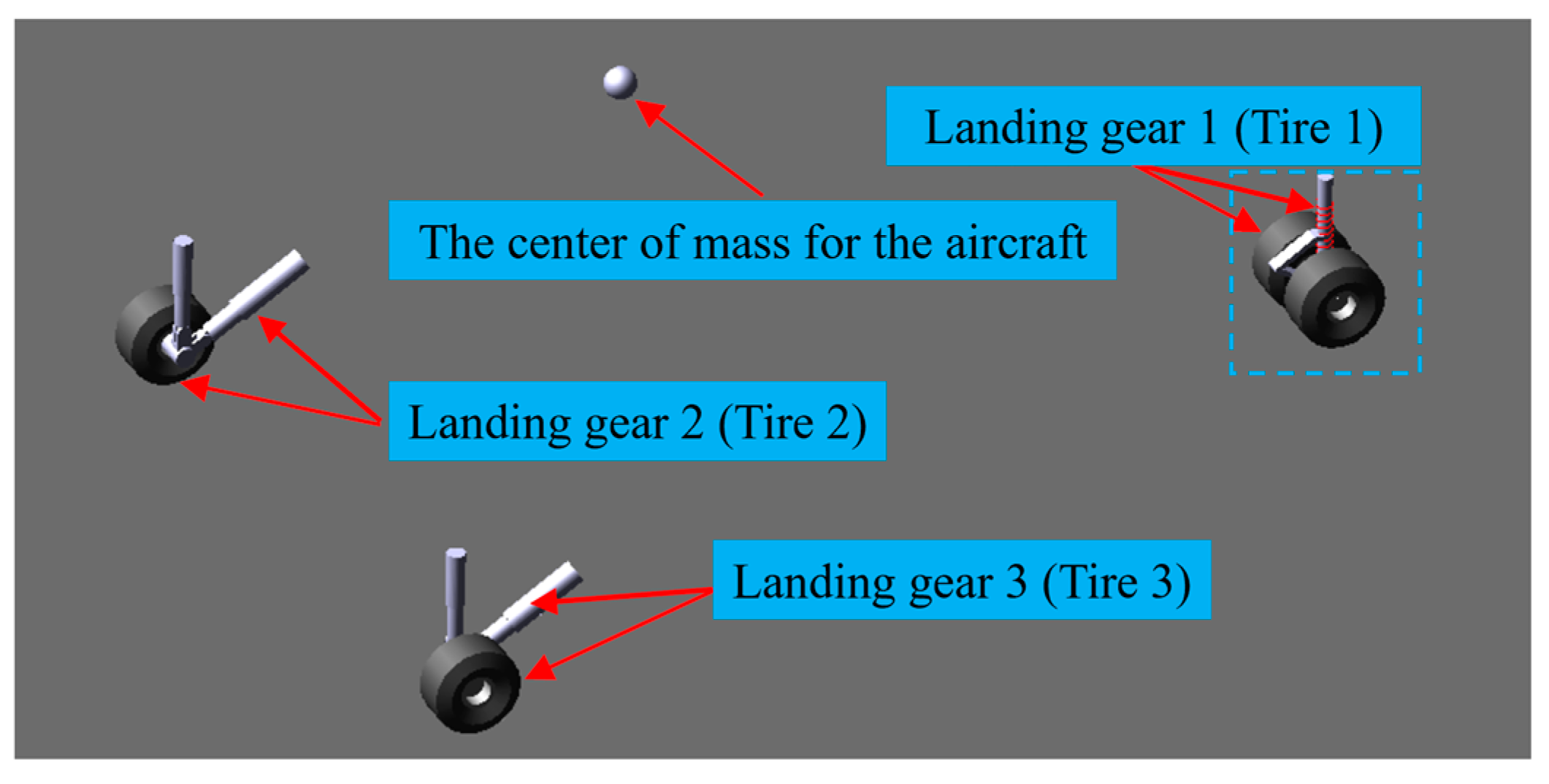

2. Modeling of the Traction Dynamics of the Shipboard Aircraft with Three Winches

2.1. Modeling of Three-Winch Traction Dynamics of Shipboard Aircraft

2.1.1. Fuselage Model

2.1.2. The Winch Model

- (1)

- The capstan

- (2)

- Rope model

2.1.3. Landing Gear and Tire Models

- (1)

- Force analysis of the landing gear in the vertical direction

- (2)

- Force analysis of the tire in the vertical direction

2.1.4. Ship Motions

2.1.5. Wind Load

2.2. Establishment and Transformation of the Coordinate System

2.2.1. Establishment of the Coordinate System

- (1)

- Inertial coordinate system. The origin oi is located at sea level and remains relatively fixed with respect to the Earth. The oixi axis aligns with the direction of the ship’s velocity and points forward, while the oizi axis is directed vertically upward. The oiyi axis points to the larboard, as illustrated in Figure 7.

- (2)

- Ship coordinate system. The origin os is positioned at the ship’s center of mass. The osxs axis aligns with the ship’s longitudinal axis and points forward, while the oszs axis is perpendicular to the ship reference surface, pointing vertically upward. The osys axis extends to the larboard, as illustrated in Figure 7.

- (3)

- Fuselage coordinate system. The origin op is located at the aircraft’s center of mass. The opxp axis is aligned with the fuselage’s longitudinal axis, extending forward. The opyp axis represents the pitch axis, pointing to the left of the fuselage. The opzp axis, or yaw axis, is perpendicular to the horizontal plane of the fuselage and points vertically upward, as shown in Figure 7.

2.2.2. Transformation of the Coordinate System

2.3. PID Control of Speed

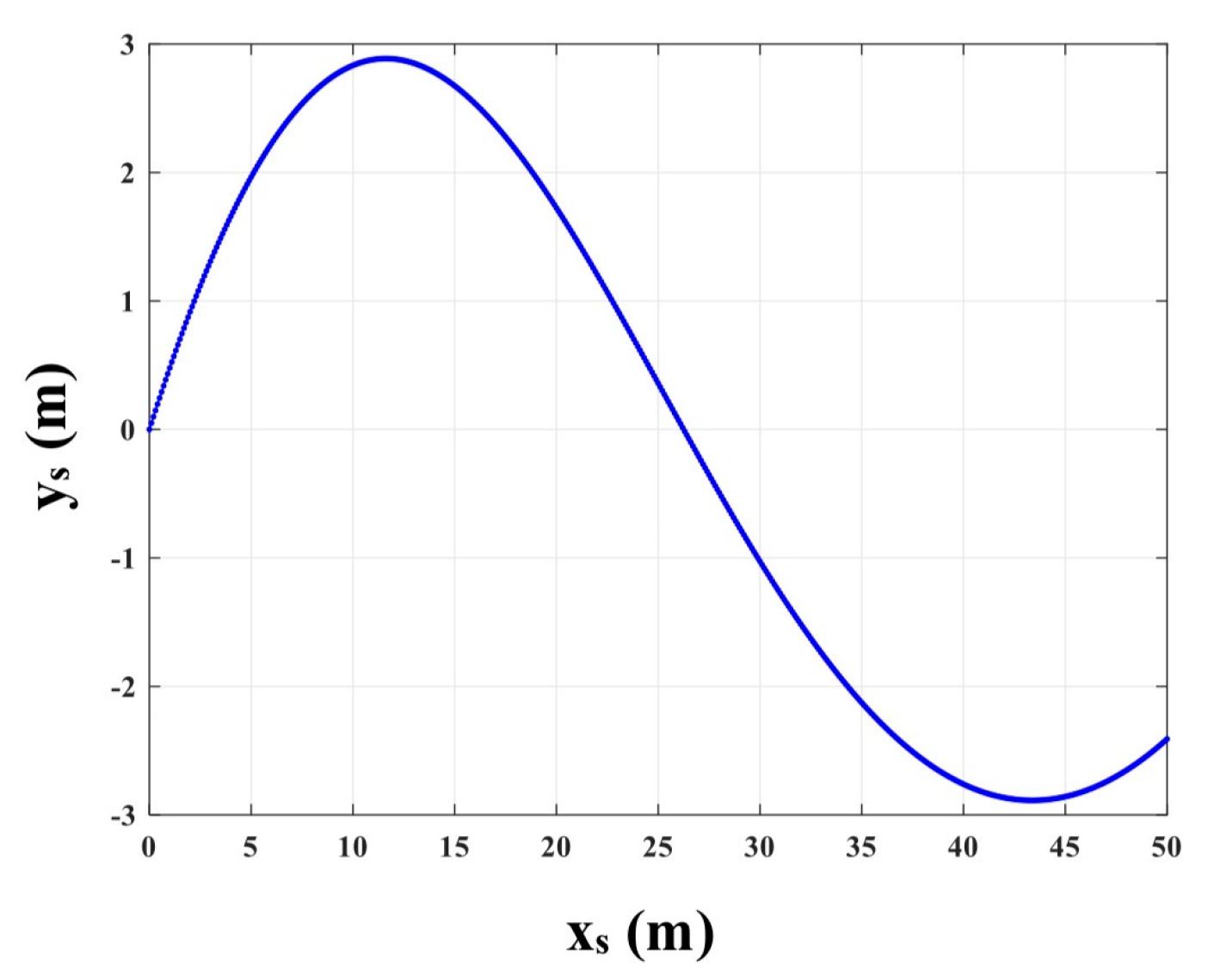

2.4. Bezier Curve

3. Calculating Results and Analyses

3.1. Effect of the Rear Winch Position

3.2. Effect of Towing Trajectory for Shipboard Aircraft

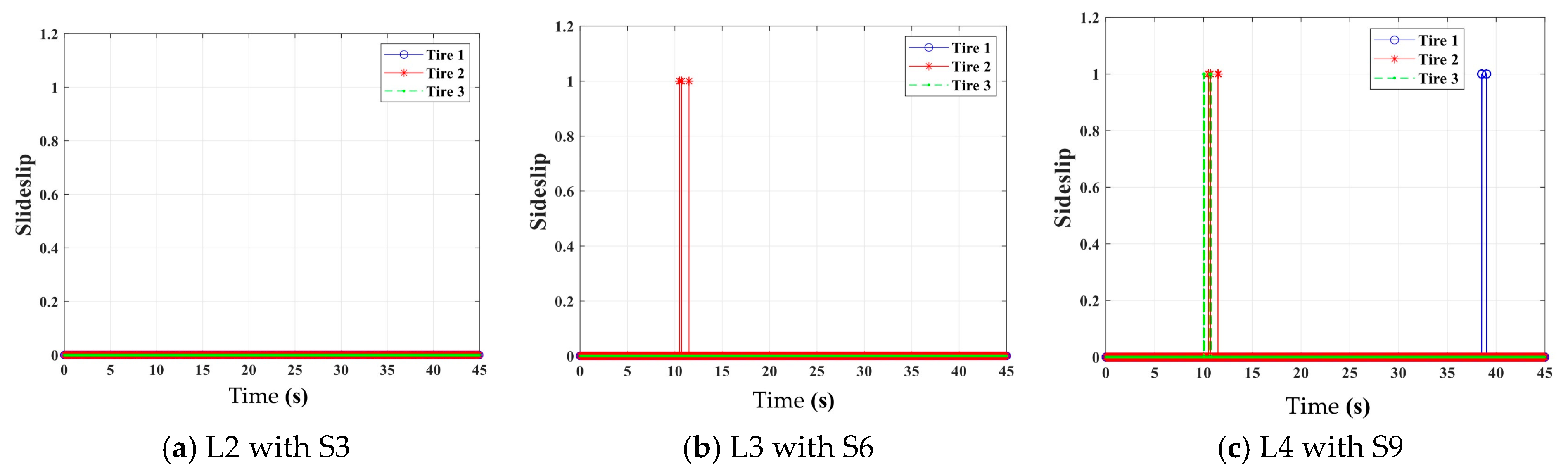

3.3. Effect of SEA Condition Level and Wind Scale

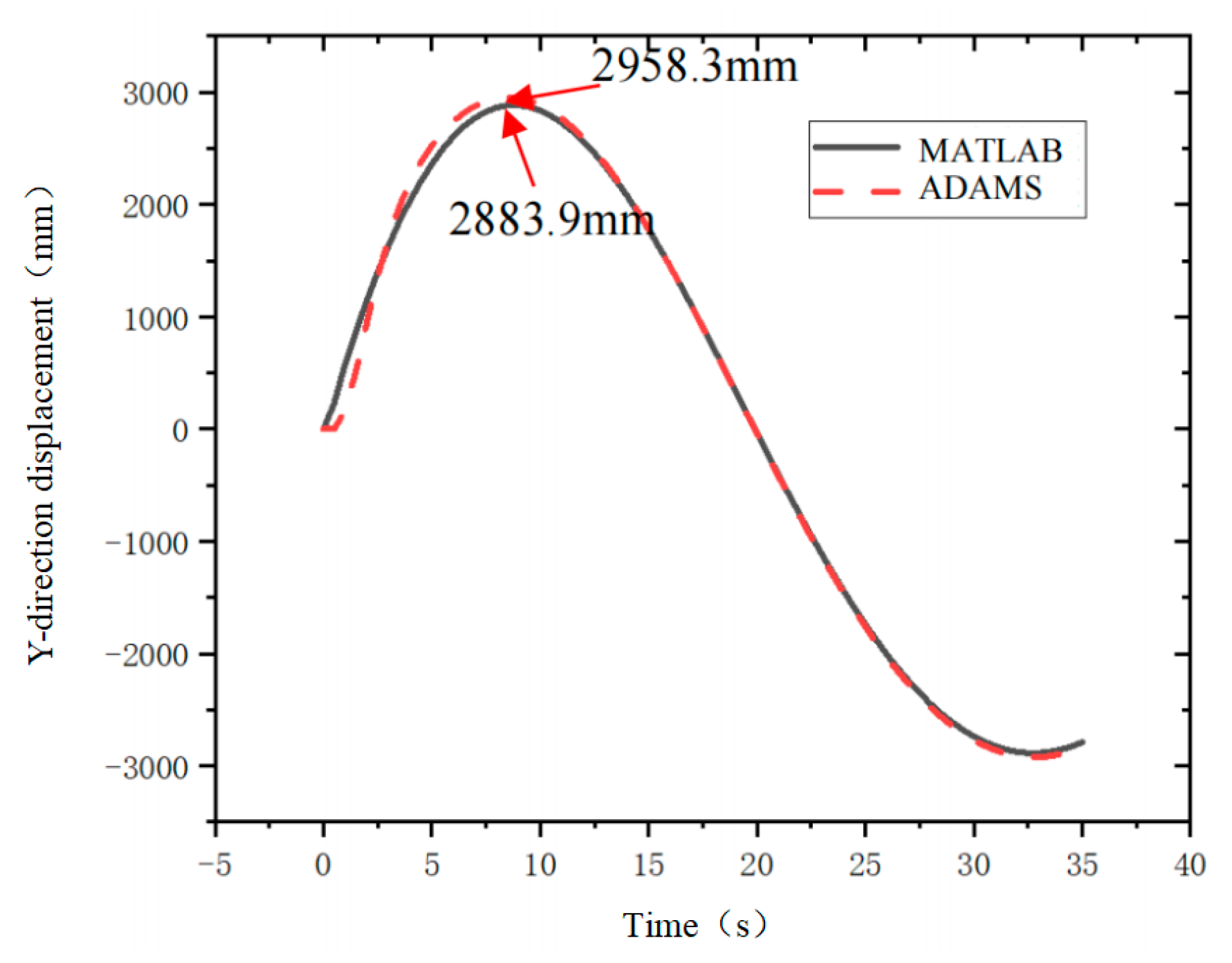

4. Verification of the Calculation Results

5. Conclusions

- (1)

- The effects of rear winch position on tire forces are examined. As the distance between the two rear winches increases, the lateral force on the tire decreases. Designing a reasonable winch position in engineering practice is crucial for improving tire lifespan and enhancing the safety and stability of aircraft traction.

- (2)

- The influence of the aircraft’s towing trajectory on rope force is analyzed. A Bezier curve is employed to define the towing path. As the aircraft’s turning angle increases, the front winch rope force also increases. Therefore, sharp turns should be avoided as much as possible, and a well-planned towing trajectory can help reduce cyclic fatigue in the rope, thereby extending the service life of the winch–rope system. These findings provide valuable insights for traction route planning and barrier avoidance strategies.

- (3)

- The effects of sea condition levels and wind scales on the traction dynamics of shipboard aircraft are investigated. With increasing sea conditions and wind scales, the front winch rope force becomes more complex, the maximum lateral deformation and force in the tires increase, and the differences in average lateral deformation and force among the tires increase. The stability and safety of winch traction for shipboard aircraft are significantly reduced, particularly when the sea condition level exceeds 3 and the wind scale exceeds 6, leading to a higher risk of tire sideslip or off-ground events.

- (4)

- The accuracy of the theoretical calculation method for the winch traction system in this study was verified by conducting multibody dynamics simulations using ADAMS software, with simulation parameters consistent with the theoretical model. The results show that the aircraft towing trajectory and the front winch rope force closely match the MATLAB theoretical calculations, with a maximum error of about 7%. The error in the lateral tire forces is also within acceptable limits. The consistency between simulation and theoretical results confirms the reliability and engineering applicability of the established model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Yang, X.; Li, Y.; Guo, H. Adaptive Backstepping Controller to Improve Handling Stability of Tractor-Aircraft System on Deck. In Proceedings of the 2018 15th International Conference on Ubiquitous Robots (UR), Honolulu, HI, USA, 26–30 June 2018; IEEE: Honolulu, HI, USA, 2018; pp. 839–846. [Google Scholar] [CrossRef]

- Wang, N.; Liu, H.; Yang, W. Path-tracking control of a tractor-aircraft system. J. Mar. Sci. Appl. 2012, 11, 512–517. [Google Scholar] [CrossRef]

- Zhao, D.X.; Zhao, Y.; Li, Y.J. Modeling and Simulation of Tractor and Aircraft Multibody System. Adv. Mater. Res. 2012, 466–467, 640–644. [Google Scholar] [CrossRef]

- Wang, N.J.; Zhou, L.J.; Song, Q.; Zhang, D.F. Simulation Research on Braking Safety Properties of Aircraft Traction System. Key Eng. Mater. 2009, 419–420, 705–708. [Google Scholar] [CrossRef]

- Jiang, Y.; Feng, G.; Liu, P.; Yuan, L.; Ding, J.; Jiang, B. Influence of Nose Landing Gear Torsional Damping on the Stability of Aircraft Taxiing Direction. Aerospace 2022, 9, 729. [Google Scholar] [CrossRef]

- Linn, D.R.; Langlois, R.G. Development and Experimental Validation of a Shipboard Helicopter On-Deck Maneuvering Simulation. J. Aircr. 2006, 43, 895–906. [Google Scholar] [CrossRef]

- Huang, M. Research on loads applied on powered wheels and struts of civil aircraft at touchdown. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 840–851. [Google Scholar] [CrossRef]

- He, B.; Wang, W.; Zhang, Y.; Liu, L. A Simulation Model of a Helicopter Landing on a Ship. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 5.1–5.7. [Google Scholar] [CrossRef]

- Thota, P.; Krauskopf, B.; Lowenberg, M.; Coetzee, E. Nonlinear Analysis of the Influence of Tire Inflation Pressure on Nose Landing Gear Shimmy. In Proceedings of the AIAA Modeling and Simulation Technologies Conference, American Institute of Aeronautics and Astronautics, Chicago, IL, USA, 10–13 August 2009. [Google Scholar] [CrossRef]

- Daniels, N. A Method for Landing Gear Modeling and Simulation with Experimental Validation; NASA: Hampton, VA, USA, 1996.

- Zhou, C.; Liu, H.; Yang, X.; Han, W. Driving stability control of the carrier-borne aircraft traction system. In Proceedings of the 2022 IEEE International Conference on Real-Time Computing and Robotics (RCAR), Guiyang, China, 17–22 July 2022; IEEE: Guiyang, China, 2022; pp. 355–359. [Google Scholar] [CrossRef]

- Qi, J.; Xu, H.; Su, M. Study on lateral stability control of carrier-based aircraft towbarless tractor system. Syst. Sci. Control. Eng. 2024, 12, 2343306. [Google Scholar] [CrossRef]

- Yoo, B.-W.; Park, K.-P.; Oh, J. Dynamics simulation model for the analysis of aircraft movement characteristics on an aircraft carrier deck. Int. J. Nav. Arch. Ocean Eng. 2024, 16, 100591. [Google Scholar] [CrossRef]

- Liu, J.; Han, W.; Peng, H.; Wang, X. Trajectory planning and tracking control for towed carrier aircraft system. Aerosp. Sci. Technol. 2019, 84, 830–838. [Google Scholar] [CrossRef]

- Yu, M.; Gong, X.; Fan, G.; Zhang, Y. Trajectory Planning and Tracking for Carrier Aircraft-Tractor System Based on Autonomous and Cooperative Movement. Math. Probl. Eng. 2020, 2020, 1–24. [Google Scholar] [CrossRef]

- Wang, X.-W.; Peng, H.-J.; Liu, J.; Dong, X.-Z.; Zhao, X.-D.; Lu, C. Optimal control based coordinated taxiing path planning and tracking for multiple carrier aircraft on flight deck. Def. Technol. 2022, 18, 238–248. [Google Scholar] [CrossRef]

- Su, X.; Li, Z.; Song, J.; Wang, L. A Path Planning Method for Carrier Aircraft on Deck Combining Artificial Experience and Intelligent Search. In Proceedings of the 4th Annual International Workshop on Materials Science and Engineering (IWMSE2018), Xi’an, China, 18–20 May 2018; Volume 381, p. 012194. [Google Scholar] [CrossRef]

- Marantos, P.; Bechlioulis, C.P.; Kyriakopoulos, K.J. Robust Trajectory Tracking Control for Small-Scale Unmanned Helicopters with Model Uncertainties. IEEE Trans. Control. Syst. Technol. 2017, 25, 2010–2021. [Google Scholar] [CrossRef]

- Raptis, I.A.; Valavanis, K.P.; Vachtsevanos, G.J. Linear Tracking Control for Small-Scale Unmanned Helicopters. IEEE Trans. Control. Syst. Technol. 2012, 20, 995–1010. [Google Scholar] [CrossRef]

- Wu, Y.; Qu, X. Obstacle avoidance and path planning for carrier aircraft launching. Chin. J. Aeronaut. 2015, 28, 695–703. [Google Scholar] [CrossRef]

- Wang, N.; Liu, H. Research on trajectory tracking behavior in traction task for tractor-aircraft system. In Proceedings of the 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 4–7 August 2013; IEEE: Takamatsu, Japan, 2013; pp. 1251–1255. [Google Scholar] [CrossRef]

- Yu, L.; Huang, M.M.; Jiang, S.; Wang, C.; Wu, M. Unmanned aircraft path planning for construction safety inspections. Autom. Constr. 2023, 154, 105005. [Google Scholar] [CrossRef]

- Woo, J.W.; An, J.-Y.; Cho, M.G.; Kim, C.-J. Integration of path planning, trajectory generation and trajectory tracking control for aircraft mission autonomy. Aerosp. Sci. Technol. 2021, 118, 107014. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Su, X.; Peng, H.; Zhao, X.; Lu, C. A review on carrier aircraft dispatch path planning and control on deck. Chin. J. Aeronaut. 2020, 33, 3039–3057. [Google Scholar] [CrossRef]

- Pritchard, J. Overview of Landing Gear Dynamics. J. Aircr. 2001, 38, 130–137. [Google Scholar] [CrossRef]

- Yang, H.; Ni, T.; Wang, Z.; Wang, Z.; Zhao, D. Dynamic modeling and analysis of traction operation process for the shipboard helicopter. Aerosp. Sci. Technol. 2023, 142, 108661. [Google Scholar] [CrossRef]

- Hu, G.; Wu, J.; Qin, X. A novel extension of the Bézier model and its applications to surface modeling. Adv. Eng. Softw. 2018, 125, 27–54. [Google Scholar] [CrossRef]

- The MathWorks, MATLAB, Version R2021a; The MathWorks Inc.: Natick, MA, USA, 2021. Available online: https://www.mathworks.com (accessed on 1 January 2021).

- MSC Software, ADAMS, Version 2020; MSC Software Corporation: Newport Beach, CA, USA, 2020. Available online: https://www.mscsoftware.com/product/adams (accessed on 1 January 2020).

| The Names of the Parameters | The Meanings of the Parameters | Values |

|---|---|---|

| Aircraft mass | Maximum take-off mass of the aircraft (kg) | 13,000 |

| Wheel mass | The mass of each tire of the aircraft (kg) | 150 |

| Position of center of aircraft mass | The vertical distance between centroid and deck (m) | 2.8 |

| The horizontal distance from the center of mass to the shaft between landing gears 2 and 3 (m) | 2 | |

| Moment of inertia | Moment of inertia for the center of mass around the X-axis (kg·m2) | 18,000 |

| Moment of inertia for the center of mass around the Y-axis (kg·m2) | 32,666.7 | |

| Moment of inertia for the center of mass around the Z-axis (kg·m2) | 50,666.7 | |

| The distance of landing gears 2 and 3 | The horizontal distance between the centerlines of the two main landing gears, 2 and 3 (m) | 4 |

| The distance between landing gears 1 and 2, 3 | The horizontal distance between the axle of landing gear 1 and the axle of landing gears 2, 3 (m) | 6.6 |

| Landing gears 2, 3 | Stiffness (N/m) | 3.7 × 105 |

| Damping (N·s/m) | 4.9 × 104 | |

| Landing gear 1 | Stiffness (N/m) | 8.8 × 105 |

| Damping (N·s/m) | 1.5 × 104 |

| Names | Values |

|---|---|

| Tire mass (kg) | 150 |

| Tire radius (m) | 0.28 |

| Vertical stiffness of tire (N/m) | 2.8 × 106 |

| Vertical damping of tire (N·s/m) | 2.8 × 104 |

| Lateral/longitudinal stiffness of tire (N/m) | 1.0 × 106 |

| Lateral/longitudinal damping of tire (N·s/m) | 1.0 × 104 |

| Names | Coordinates |

|---|---|

| Front winch traction point | (89.00, 0.00, 0.00) |

| Traction point of rear winch 1 | (−21.00, 15.00, 0.00) |

| Traction point of rear winch 2 | (−21.00, −15.00, 0.00) |

| Traction point of landing gear 1 | (4.60, 0.00, 1.00) |

| Traction point of landing gear 2 | (−1.95, 1.95, 1.00) |

| Traction point of landing gear 3 | (−1.95, −1.95, 1.00) |

| Names | Coordinates |

|---|---|

| Traction point of rear winch 1 at position A | (−21, 2, 0) |

| Traction point of rear winch 2 at position A | (−21, −2, 0) |

| Traction point of rear winch 1 at position B | (−21, 12, 0) |

| Traction point of rear winch 2 at position B | (−21, −12, 0) |

| Traction point of rear winch 1 at position C | (−21, 22, 0) |

| Traction point of rear winch 2 at position C | (−21, −22, 0) |

| Names | Coordinates |

|---|---|

| The control points of Bezier curve 1 | (0, 0), (20, 4), (30, −4), (60, 0) |

| The control points of Bezier curve 2 | (0, 0), (20, 8), (30, −8), (60, 0) |

| The control points of Bezier curve 3 | (0, 0), (20, 12), (30, −12), (60, 0) |

| Sea Condition Level | Level 1 (L1) | Level 2 (L2) | Level 3 (L3) | Level 4 (L4) |

|---|---|---|---|---|

| φ0 (°) | 3.25 | 6.33 | 9.10 | 13.52 |

| T1 (s) | 10 | 8 | 6 | 6 |

| θ0 (°) | 1.15 | 2.10 | 3.25 | 4.09 |

| T2 (s) | 14 | 12 | 10 | 10 |

| Z0 (m) | 0.19 | 0.29 | 0.30 | 0.42 |

| T3 (s) | 14 | 12 | 10 | 10 |

| Wind Scale | Wind Speed (m/s) |

|---|---|

| Scale 1 (S1) | 0.3~1.5 |

| Scale 2 (S2) | 1.6~3.3 |

| Scale 3 (S3) | 3.4~5.4 |

| Scale 4 (S4) | 5.5~7.9 |

| Scale 5 (S5) | 8.0~10.7 |

| Scale 6 (S6) | 10.8~13.8 |

| Scale 7 (S7) | 13.9~17.1 |

| Scale 8 (S8) | 17.2~20.7 |

| Scale 9 (S9) | 20.8~24.4 |

| Scale 10 (S10) | 24.5~28.4 |

| Physical Quantity | Theoretical Calculation (MATLAB) | Simulation Calculation (ADAMS) | Relative Error (%) |

|---|---|---|---|

| The maximum rope force (N) | 30,089.3 | 27,946.0 | 7.12 |

| Lateral force range of left and right tires (N) | −5639.8 N~5291.5 N | −5221.22~5353.463 | 1.16~7.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nan, G.; Wang, Y.; Zhou, Y.; Wang, H.; Li, Y. Dynamic Modeling and Safety Analysis of Whole Three-Winch Traction System of Shipboard Aircraft. Aerospace 2025, 12, 579. https://doi.org/10.3390/aerospace12070579

Nan G, Wang Y, Zhou Y, Wang H, Li Y. Dynamic Modeling and Safety Analysis of Whole Three-Winch Traction System of Shipboard Aircraft. Aerospace. 2025; 12(7):579. https://doi.org/10.3390/aerospace12070579

Chicago/Turabian StyleNan, Guofang, Ying Wang, Yihui Zhou, Haoyu Wang, and Yao Li. 2025. "Dynamic Modeling and Safety Analysis of Whole Three-Winch Traction System of Shipboard Aircraft" Aerospace 12, no. 7: 579. https://doi.org/10.3390/aerospace12070579

APA StyleNan, G., Wang, Y., Zhou, Y., Wang, H., & Li, Y. (2025). Dynamic Modeling and Safety Analysis of Whole Three-Winch Traction System of Shipboard Aircraft. Aerospace, 12(7), 579. https://doi.org/10.3390/aerospace12070579