1. Introduction

Hypersonic vehicles, as next-generation aircraft capable of achieving speeds above Mach 5 within the atmosphere, demonstrate tremendous application potential. In civilian domains, they enable rapid material delivery and logistics replenishment, while militarily, they facilitate high-altitude reconnaissance and strategic strike missions [

1]. However, two critical challenges emerge in hypersonic vehicle design: thermal management and electrical power deficiency.

Hypersonic vehicles typically need to manage thermal loads from three primary sources: the aerodynamic leading edges, the scramjet combustion chamber walls, and the avionics bay. External aerodynamic heat loads are concentrated at the leading edges, such as the wing leading edges, the nose cone, and the lip of the scramjet inlet [

2]. For the aerodynamic leading edges, Japan’s JAXA simulated the heat load on the vehicle surface at Mach 5 and found that the heat flux at the leading edges of the fuselage and wings could reach 40 kW/m

2 [

3]. Liu [

4], in studying the thermal management of the nose cone using heat pipes at Mach 8, reported that even with thermal conduction via heat pipes, the maximum temperature at the nose cone could reach 1313 K, with a corresponding heat flux of up to 1 MW/m

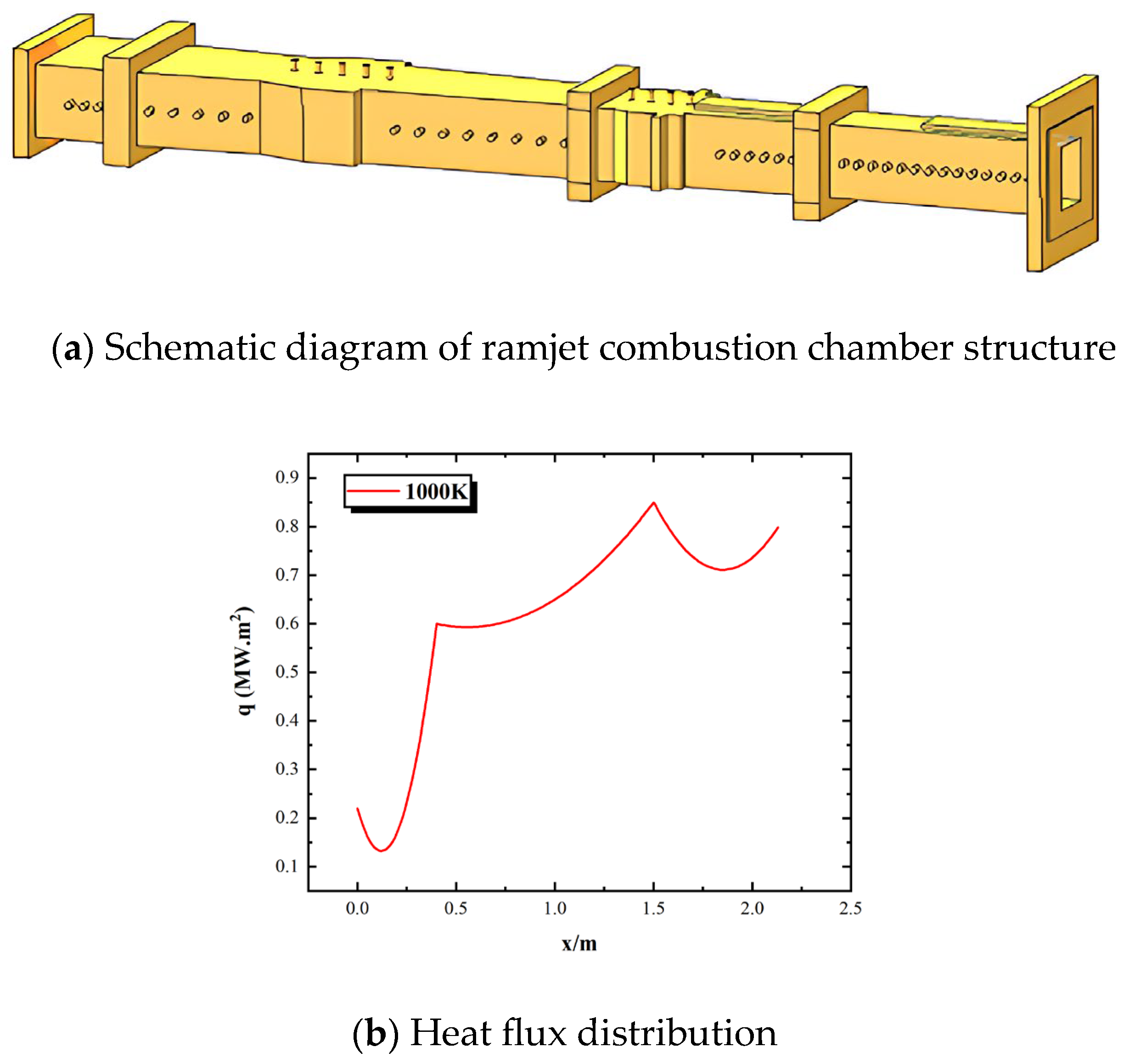

2. Currently, thermal protection methods for aerodynamic leading edges are either passive or semi-active (ablative protection), which are only suitable for short-duration high heat flux conditions and are inadequate for long-duration missions with sustained thermal loads. Combined-cycle engines are considered the most promising propulsion systems for hypersonic vehicles. Due to their superior performance, the walls of scramjet combustion chambers are subject to extremely high thermal loads, far exceeding the limits of current materials. Jason et al. [

5] used direct-write temperature sensors to measure the heat flux within the combustion chamber and found it could reach 780 kW/m

2 under a dynamic pressure of 1000 psf. Existing cooling solutions, such as film cooling, evaporative cooling, and regenerative cooling, all have drawbacks: they either require additional coolant or may lead to coking and cracking of the fuel (kerosene) [

6]. As such, wall thermal protection technology represents a critical bottleneck that must be overcome for scramjet engine applications. The thermal load in the avionics bay is relatively low and determined by the number and power of onboard electronic devices. This heat comes entirely from electrical power consumption and typically does not exceed 125 kW [

7]. Given its low energy quality, this heat is usually dissipated using high-pressure bleed air for expansion cooling. The duration of high-Mach flight generally depends on the mission. According to limited flight data from the European Space Agency’s European Space Research and Technology Centre (ESA-ESTEC) under the LAPCAT2 program, the A2 and MR2 vehicles (with cruise Mach numbers of 5 and 8, respectively) demonstrated that Mach 5 flight could last up to 169 min [

8]. In summary, it can be seen that the thermal load on the aerodynamic leading edge and the combustion chamber wall is very large and has a high thermal quality, which requires special attention. Hypersonic vehicles must manage at least two high-temperature (T > 1200 K), high-energy-density heat sources for extended periods.

Simultaneously, hypersonic vehicles face critical electrical power deficits during high-Mach-number operations. These aircraft require substantial electrical power for control and sensing systems during hypersonic flight, yet encounter fundamental energy conversion constraints: Ramjet engines typically lack rotating components for shaft work-to-electricity conversion, while conventional power solutions prove inadequate: chemical batteries exhibit low energy density, and auxiliary power units (APUs) [

9]/ram air turbines (RATs) [

10] suffer compromised mechanical efficiency due to extreme incoming airflow temperatures (>1000 K) [

11].

Recent years have witnessed the emergence of thermoelectric conversion-based thermal management concepts, aiming to achieve both thermal protection and energy reuse for hot-end components like scramjet combustors [

12,

13]. Technologies including magnetohydrodynamic (MHD) power generation, thermoelectric generators (TEGs), and thermodynamic cycles have attracted significant research attention. During the 1990s, the United States and Russia proposed the energy-bypass hypersonic vehicle concept based on MHD technology [

14]. This method generates electricity by creating gaseous plasma through interactions between high-temperature incoming flow/combustion gases and low-ionization-potential compounds, subsequently extracting power via superconducting magnetic fields. While demonstrating advantages such as rapid response and huge power output [

15], MHD systems still face critical challenges, including magnetic/thermal instability issues. The stringent cryogenic requirements for superconductors limit their application exclusively to hydrogen-fueled vehicles, rendering them incompatible with kerosene-based systems [

16]. TEG technology, operating through the Seebeck effect for direct thermoelectric conversion, offers distinct benefits such as the absence of rotating parts, structural simplicity, and high reliability. Cheng et al. [

17] implemented TEGs in multi-stage energy utilization for hypersonic environments, developing a variable-stage TEG model that considers flow directions of heat/cold sources, along with performance evaluation and stage-number optimization [

18]. Some research has also been conducted on TEG technology in the field of thermoelectric conversion for exhaust gas reuse in ground vehicles. Using TEG generators to replace alternators can provide electricity at the 1 kW level and reduce fuel consumption by 12–30% [

19]. However, the thermoelectric conversion efficiency of TEG is only 5–10% [

20], with additional challenges in hypersonic applications: thermoelectric materials struggle to withstand extreme temperature gradients, resulting in insufficient power density. Current technological constraints position TEGs primarily as auxiliary power units in hypersonic vehicles.

Additionally, thermodynamic cycle-based thermoelectric conversion systems have garnered researchers’ attention due to their more mature technological foundation. Sforza [

21] proposed a Rankine cycle thermoelectric conversion scheme suitable for hypersonic vehicles. However, this approach exhibited low thermoelectric efficiency, and using fuel as the working medium caused heat transfer degradation, posing risks of structural damage to heat exchangers. Bao [

22] introduced a hydrogen-fueled re-cooling cycle, but this solution is only compatible with hydrogen fuel possessing substantial thermal sink capacity. Zhang [

23] developed a fuel vapor turbine power generation system. Nevertheless, these thermodynamic cycle-based solutions suffer from low energy conversion efficiency, limiting their potential for higher electrical power generation. Consequently, hypersonic vehicles demand thermoelectric conversion solutions with higher efficiency and more compact configurations.

In recent years, the supercritical carbon dioxide (sCO

2) Brayton cycle has found applications across multiple domains, including nuclear power generation [

24], solar energy [

25], geothermal energy [

26], and waste heat recovery [

27]. The sCO

2 Brayton cycle is renowned for its compactness and high efficiency, owing to the unique thermophysical properties of sCO

2 near its critical point, which significantly improve the power-to-weight ratio of compressors. Advancements in printed circuit heat exchangers (PCHEs) have further enhanced the compactness and lightweight characteristics of Brayton cycle systems [

28,

29], thereby enhancing their potential applicability for hypersonic vehicles. Cheng [

30] investigated sCO

2 Brayton cycles under fuel-limited cold source conditions in hypersonic vehicles, where the fuel (acting as the cold source) is constrained by combustion mass flow rate limitations. Using a scramjet engine as the heat source, their study compared simple recuperative and recompression cycle configurations. The results indicated that while the recompression cycle achieves higher thermal efficiency, the simple recuperative configuration exhibits enhanced utilization of the fuel’s thermal sink capacity. Thus, the simple recuperative cycle demonstrates greater applicability for hypersonic vehicle power generation systems under fuel-constrained operating conditions. To prevent blockage of the wall channels in the ramjet combustor caused by fuel cracking, Guo [

31] introduced a SCO

2 Brayton cycle into the original fuel-turbine system. A comparison between the original and the modified systems showed that the new system achieved higher power output and thermoelectric conversion efficiency, while requiring less fuel for cooling. The additional mass introduced by the new system was offset by the reduced fuel consumption after 3025 s of flight. In further research, Guo [

32] developed a two-stage optimization approach for this system: first, conducting a dual-objective optimization at the cycle level to minimize system weight and coolant mass flow rate, followed by a component-level dual-objective optimization of the PCHE to reduce mass and entropy generation. Ma [

33] investigated the application potential of two cycles—simple recuperative and recompression recuperative cycles—in an integrated hypersonic vehicle engine cooling and power generation system. The study analyzed the thermal performance of both systems and the working fluid mass flow rate under given heat source conditions. The results demonstrated that the recompression cycle achieved 16.6% higher efficiency than the simple recuperative cycle but required 27.53% more working fluid flow. Under the specified heat source power, the recuperator heat transfer in the recompression cycle exceeded that of the simple recuperative cycle by 726.81 kW. Additionally, recuperator effectiveness and pressure drop were found to significantly influence cycle performance. Furthermore, numerous thermoelectric conversion studies focus on utilizing the ramjet combustor as the heat source for hypersonic flight applications [

34,

35,

36], while other investigations explore inlet precooling as an alternative heat source. Ma [

11] proposed a turbofan precooling system based on the sCO

2 Brayton cycle, establishing coupling between the Brayton cycle and turbofan engines, and conducted dynamic analysis of this configuration [

37]. Further research led to the design of an sCO

2 Brayton cycle-based integrated system applicable to all operational phases of TBCC engines [

38], providing both thermal protection and electrical power generation during precooling and ramjet phases.

Most previous studies have focused on thermal protection and thermoelectric conversion for ramjet engines, with limited consideration of multiple heat sources, such as the aerodynamic leading edge and the combustor. In the onboard environment of hypersonic vehicles, hydrocarbon fuel serves both as a coolant and a propellant, making its consumption a critical concern. Furthermore, vehicles exhibit high sensitivity to the mass of onboard thermoelectric conversion systems. This necessitates the development of a multi-heat-source thermoelectric conversion system tailored for hypersonic vehicles, requiring concurrent optimization of conversion efficiency, coolant flow requirements, and system mass.

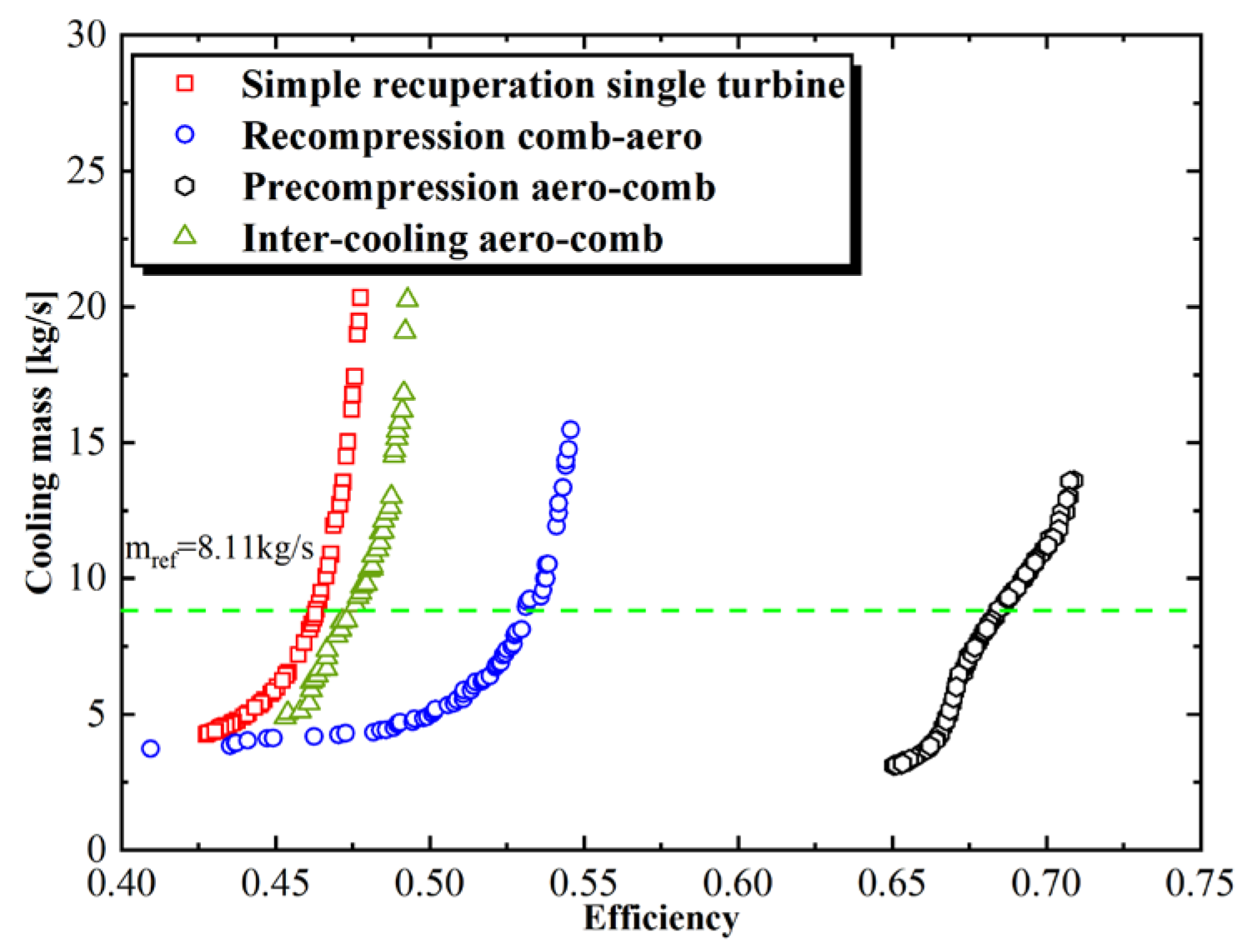

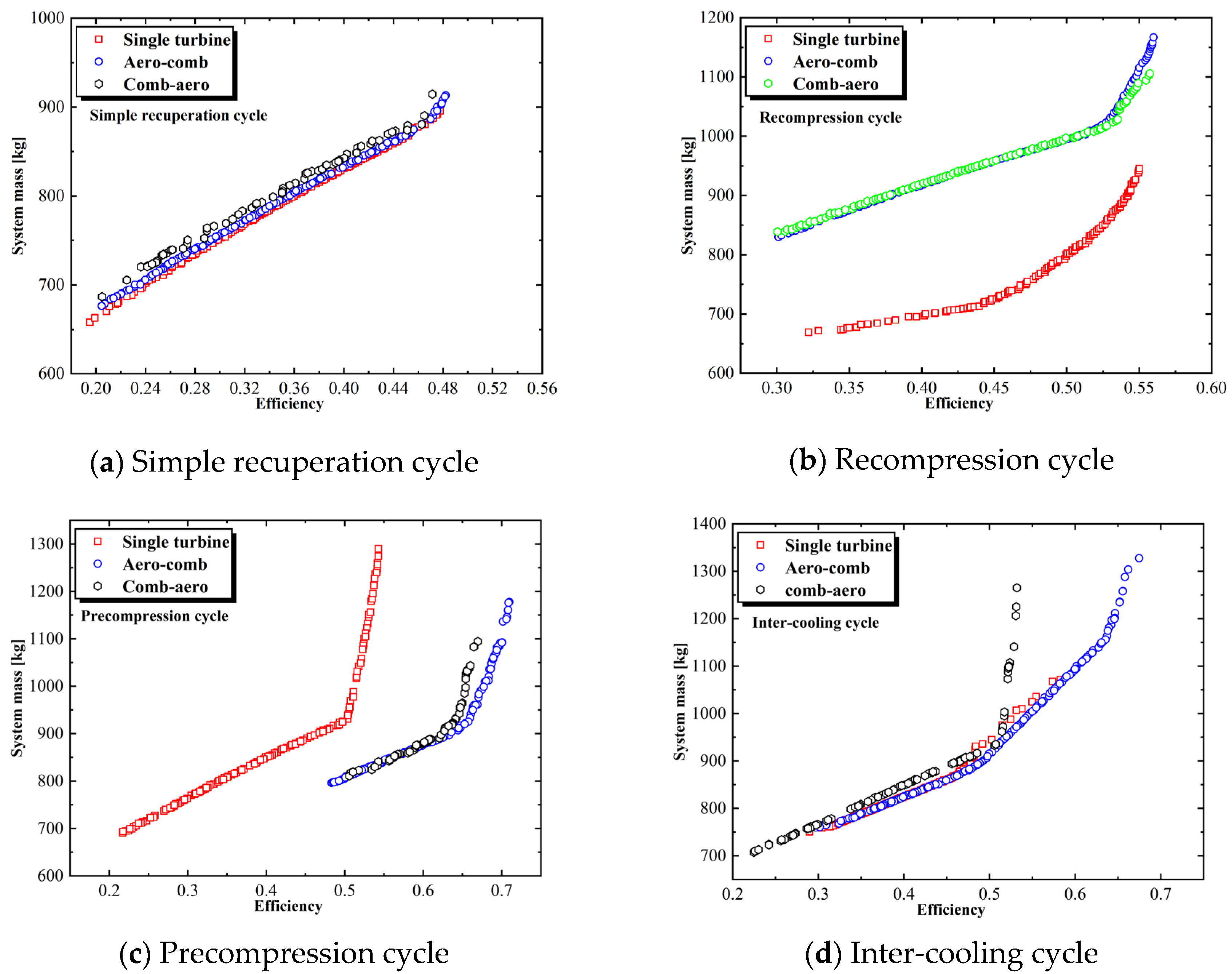

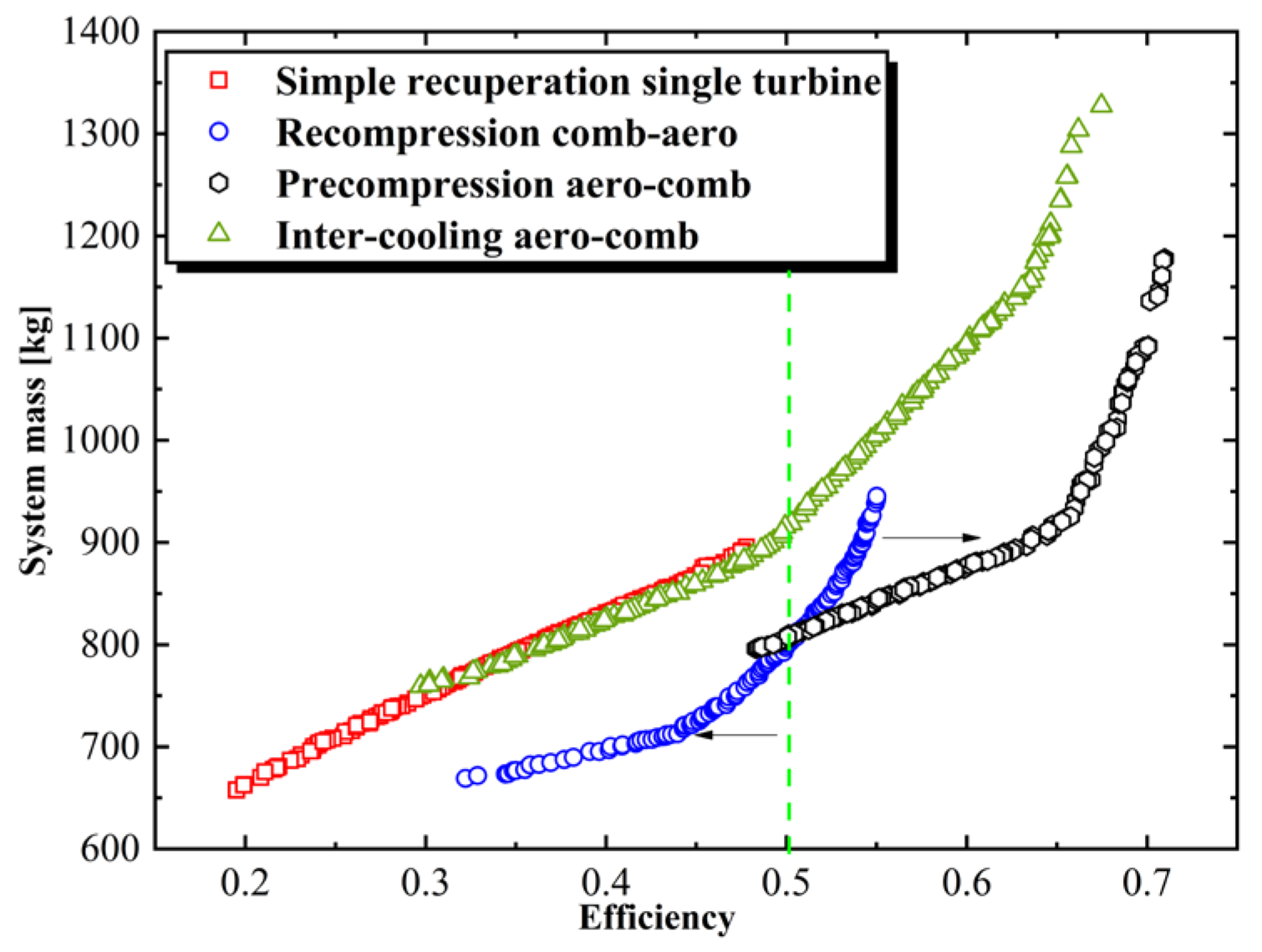

This paper establishes multiple sCO2 Brayton cycle configurations targeting two heat sources: aerodynamic leading edges and ramjet combustor walls. The evaluation criteria include cycle efficiency, coolant mass flow rate, and system mass. Parametric sensitivity analysis is conducted to reveal the impacts of key parameters on thermodynamic performance and system mass. Subsequently, the Non-dominated Sorting Genetic Algorithm II (NSGA-II) method is employed for bi-objective optimization, targeting efficiency-coolant mass flow rate, efficiency-mass, and coolant mass flow rate-mass as optimization objectives. The Pareto fronts of each cycle configuration under different optimization goals are obtained, and the superiority of cycle configurations is evaluated based on the positions of these Pareto fronts. Designers can select cycle solutions based on specific onboard system requirements or design specifications.

2. System Description

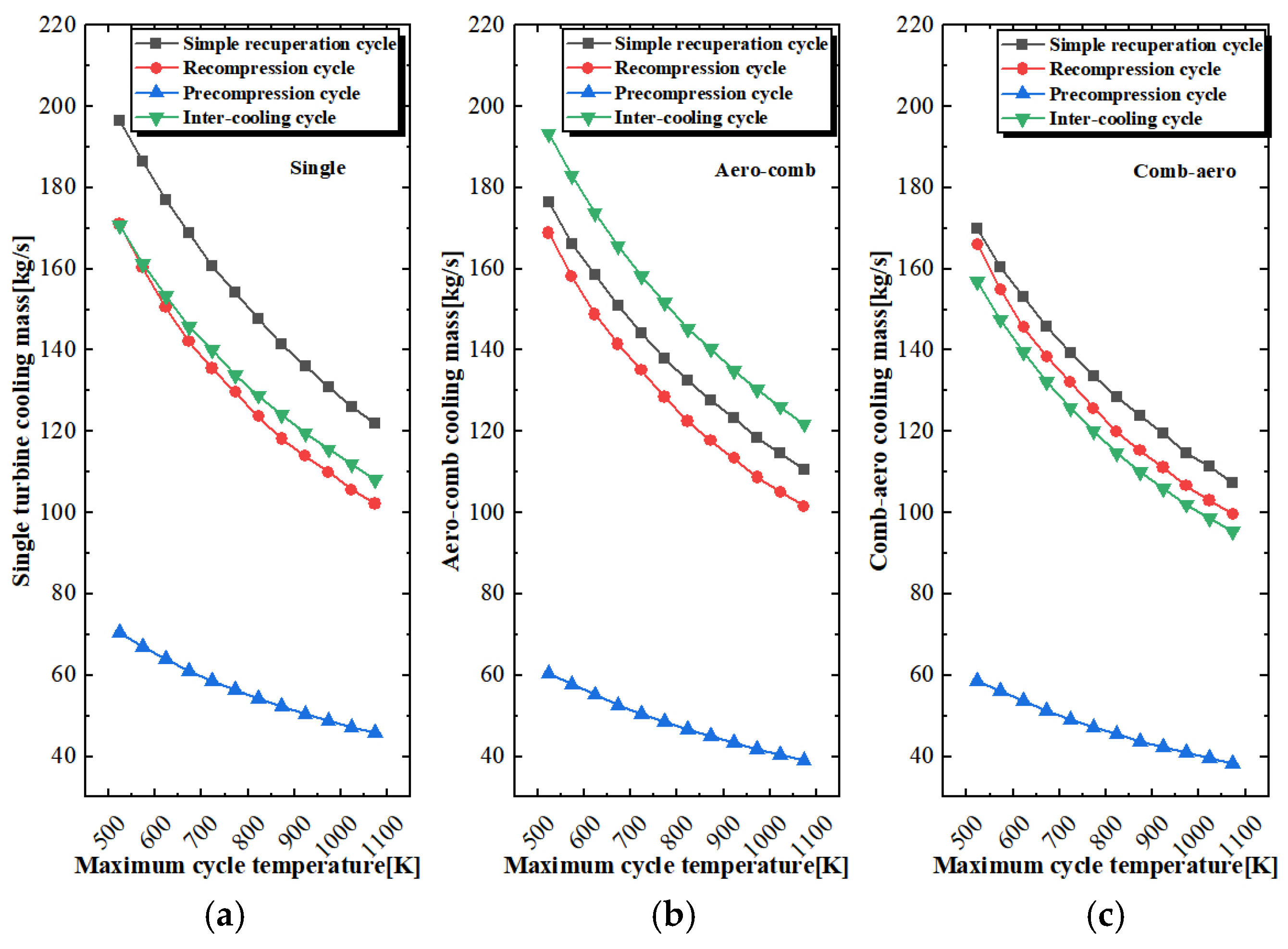

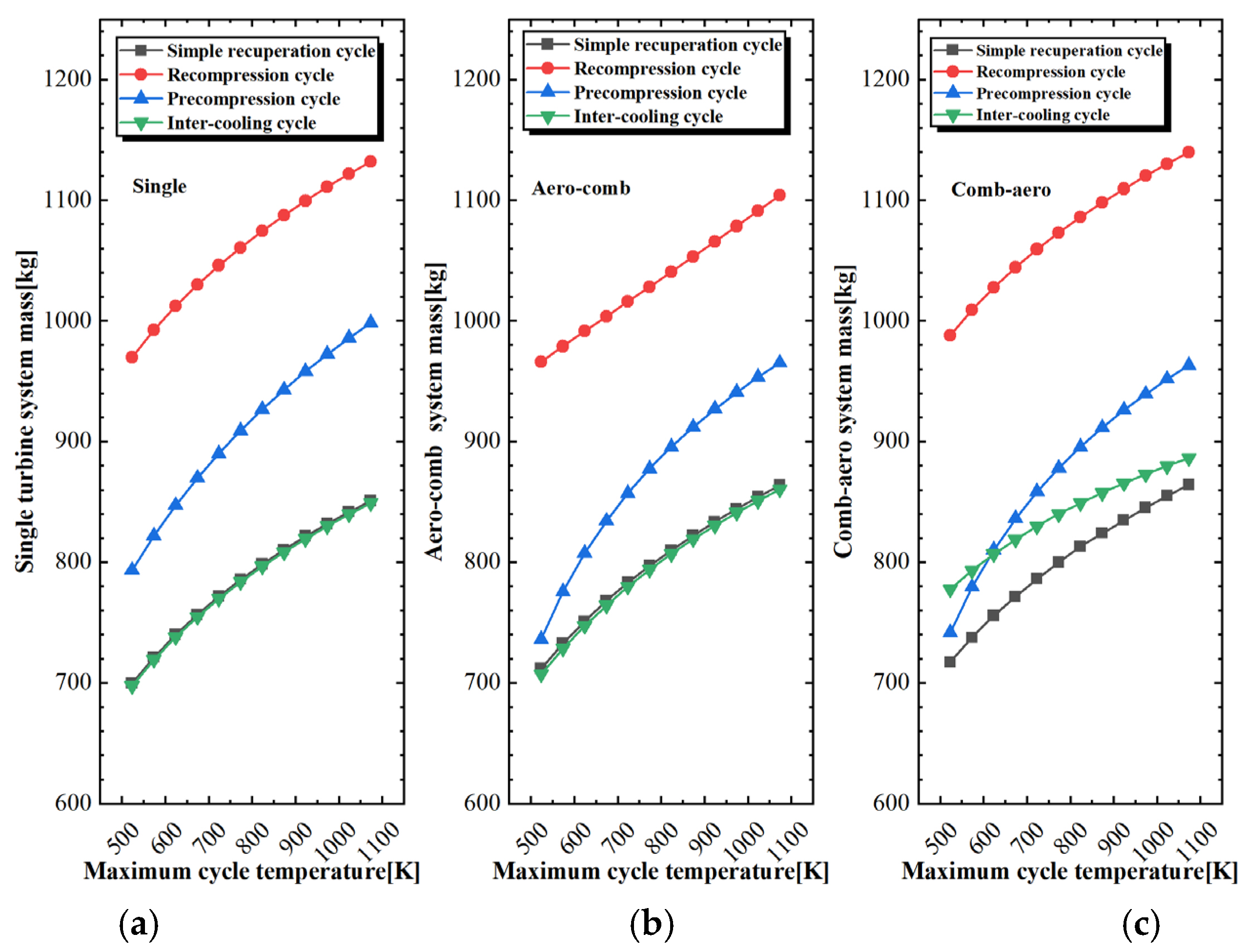

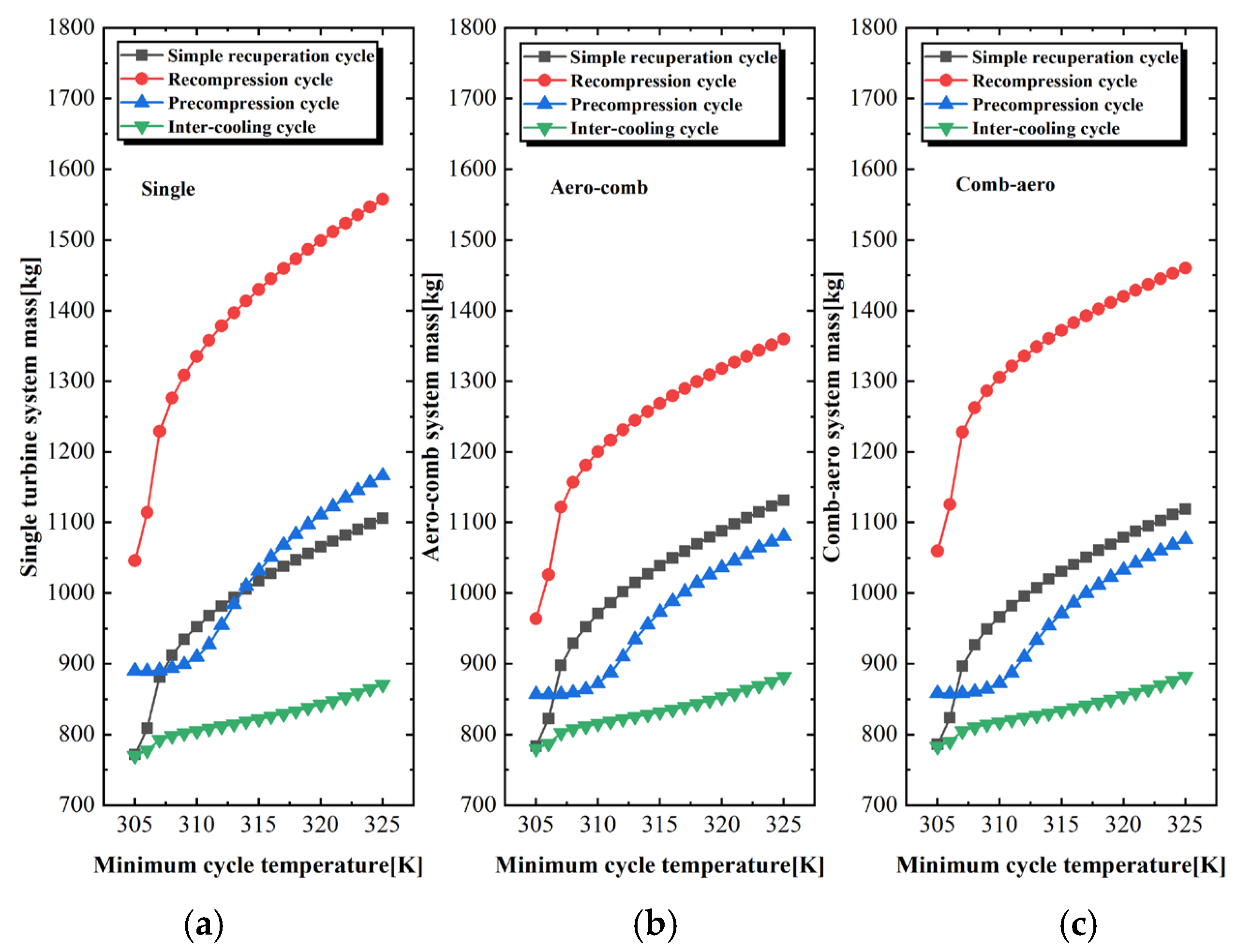

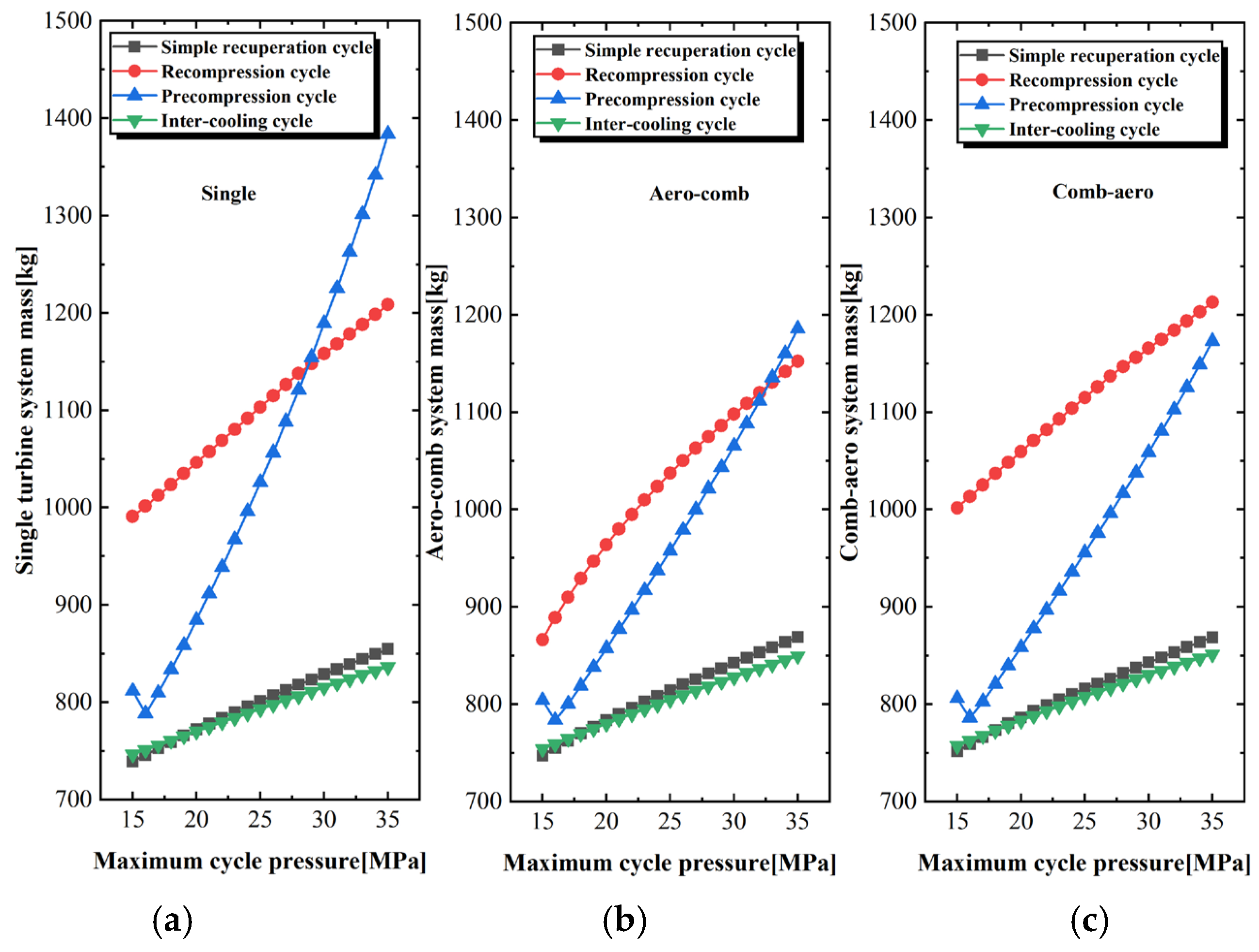

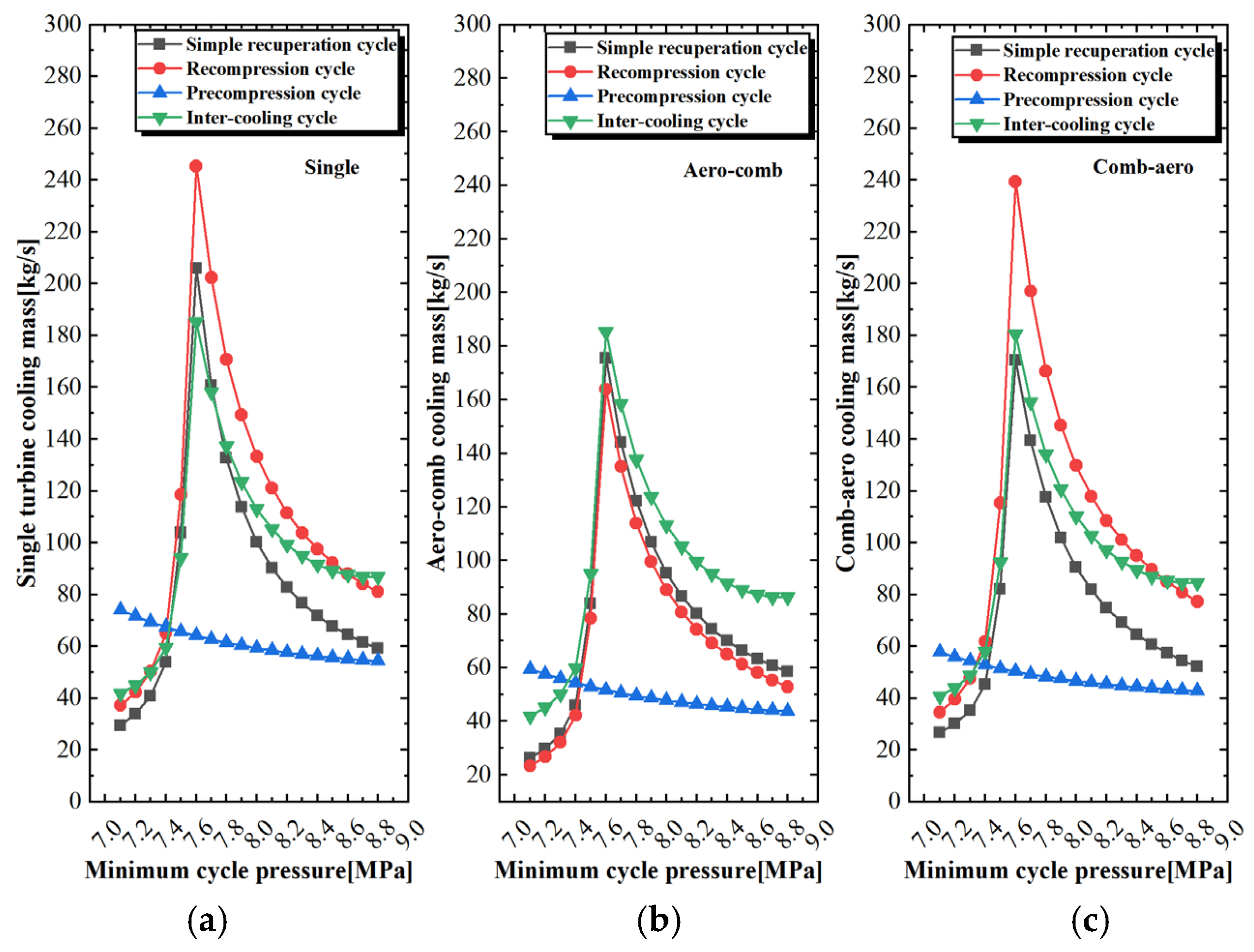

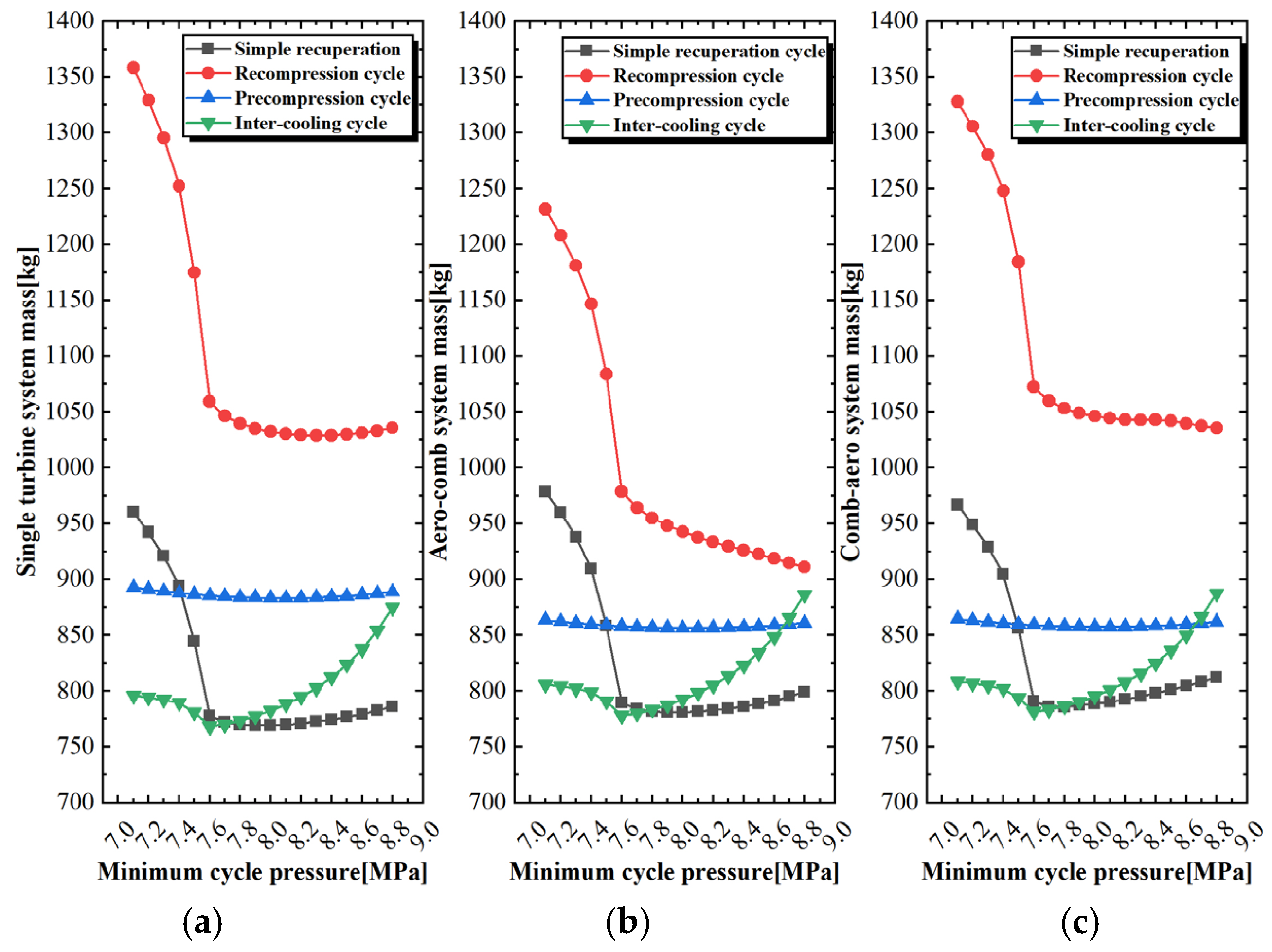

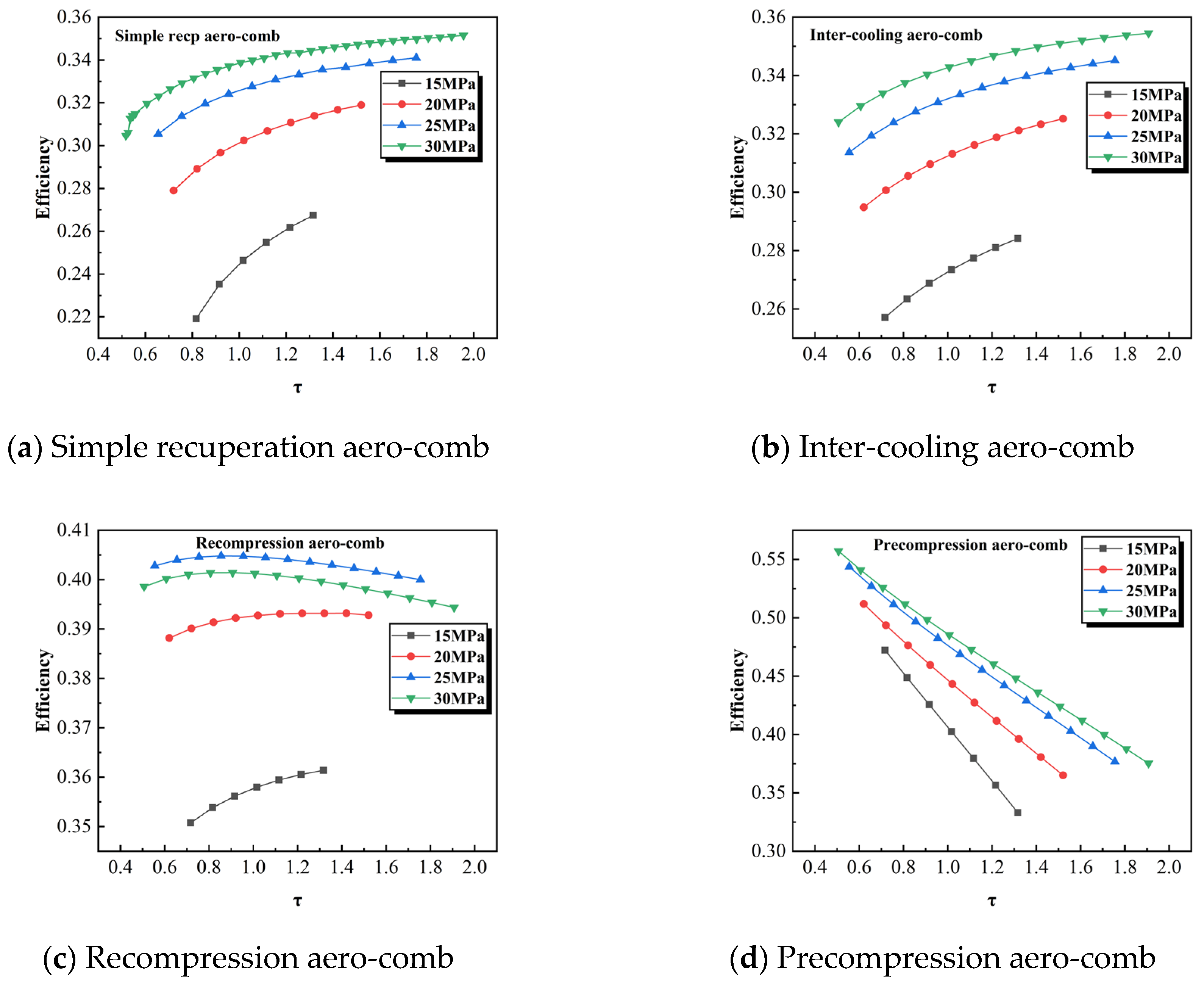

In response to the two primary heat sources of hypersonic vehicles, this study designs 4 groups comprising 12 dual-heat-source sCO2 closed Brayton cycle configurations based on four traditional cycle architectures: simple recuperative cycle, recompression cycle, precompression cycle, and intercooling cycle.

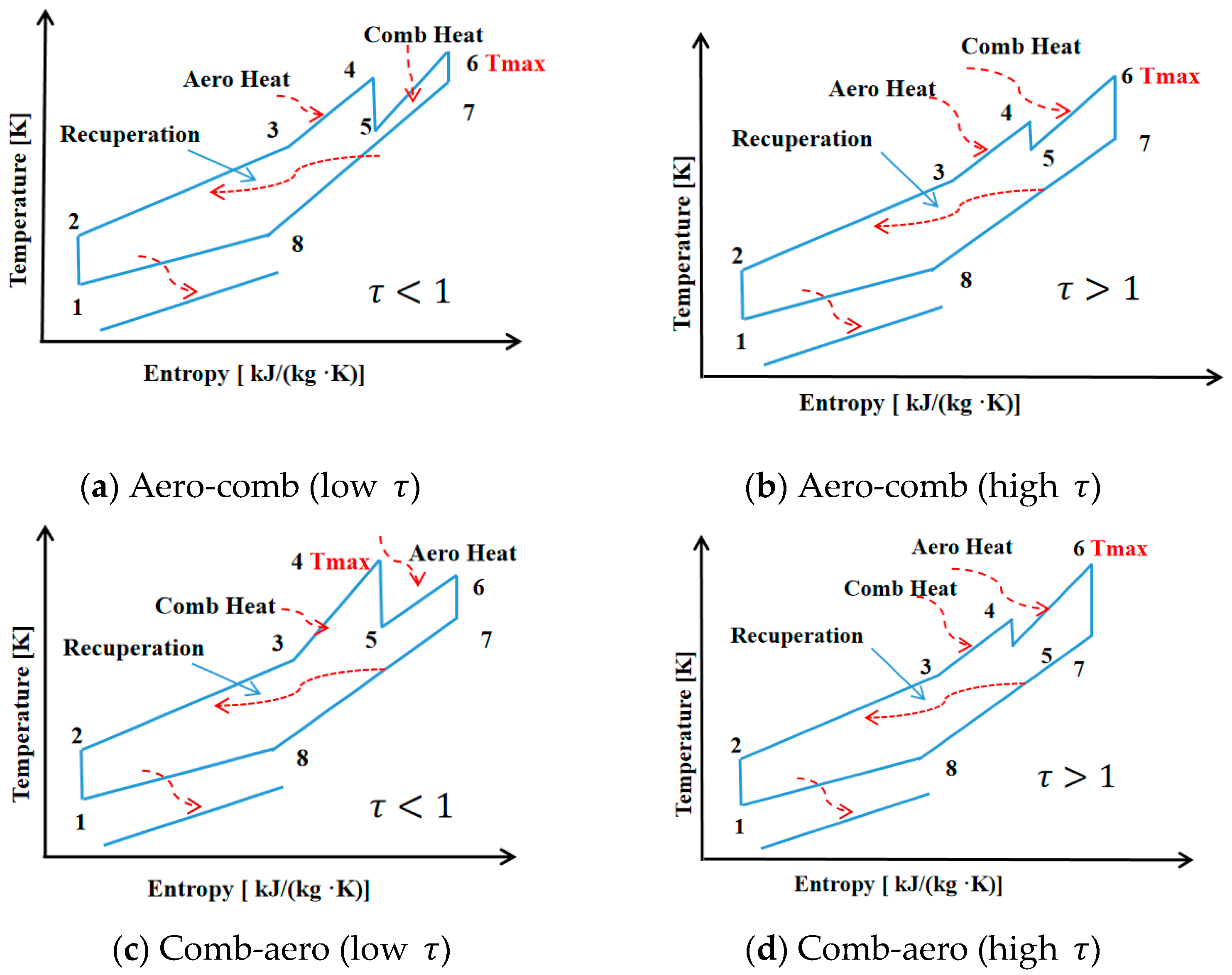

The main thermal characteristic difference between aero heat and comb heat lies in their different heat loads, which in turn lead to differences in cycle performance. The specific reason is as follows: in the calculation of a dual-turbine reheat cycle, it is necessary to ensure that the maximum temperature does not exceed the preset temperature. However, due to the difference in power between the two heat sources, the location of the maximum temperature is uncertain, which in turn affects the area enclosed by the temperature-entropy (T-S) diagram, i.e., the cycle performance. When Aero heat comes first and comb heat comes after, if it is assumed that the maximum temperature appears after the aero heat source (before the first turbine), calculations under any turbine expansion ratio distribution coefficient show that the fluid temperature after passing through the comb heat source always exceeds the preset, so the assumption is incorrect. If it is assumed that the maximum temperature appears after the comb heat source (before the second turbine), the calculation converges and the assumption is correct. When comb heat comes first and aero heat comes after, the comb heat has a larger heat load. Under a lower turbine expansion ratio distribution coefficient (i.e., a larger expansion ratio for the first turbine), the maximum temperature appears after the comb heat source (before the first turbine). Under a higher turbine expansion ratio distribution coefficient (i.e., a larger expansion ratio for the second turbine), although the fluid temperature increases after passing through the comb heat source, the temperature and pressure after work done by the first turbine remain relatively high. After being further heated by the aero heat source, a higher temperature is achieved, so the maximum temperature appears after the aero heat source (before the second turbine). This is illustrated using four T-S diagrams:

Figure 1a shows the T-S diagram of the aero-comb configuration under a high turbine expansion ratio coefficient;

Figure 1b shows the T-S diagram of the aero-comb configuration under a low turbine expansion ratio coefficient. It can be seen that in both cases, the maximum temperature appears before the second turbine.

Figure 1c shows the T-S diagram of the comb-aero configuration under a low turbine expansion ratio coefficient, where the maximum temperature appears before the first turbine.

Figure 1d shows the T-S diagram of the comb-aero configuration under a high turbine expansion ratio distribution coefficient, where the maximum temperature appears before the second turbine. In the calculations, the location of the maximum temperature needs to be assumed and confirmed. Therefore, in the configuration of dual-turbine reheat, the comb-aero and aero-comb sequences affect the cycle performance and thus should be considered as two separate configurations.

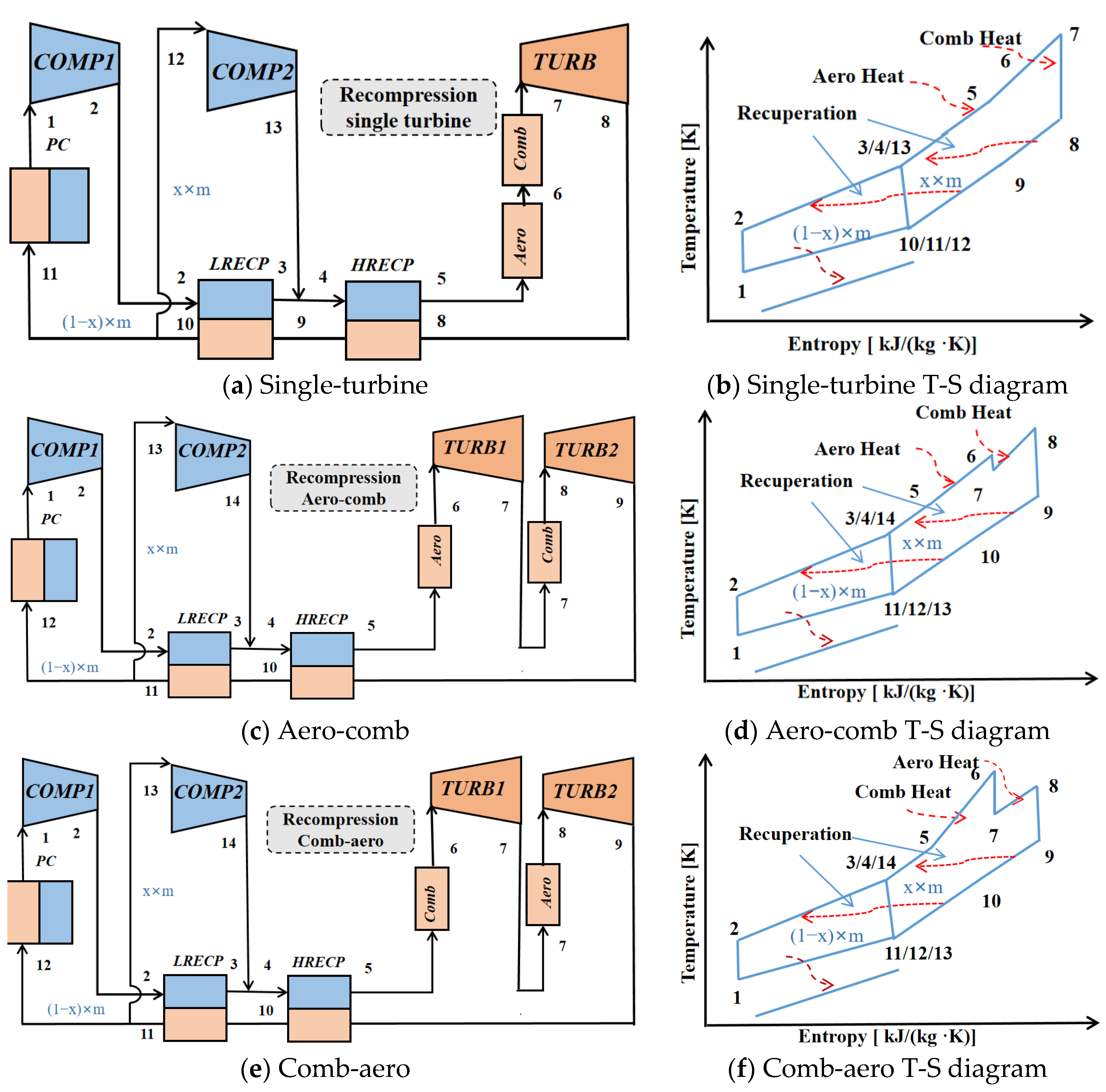

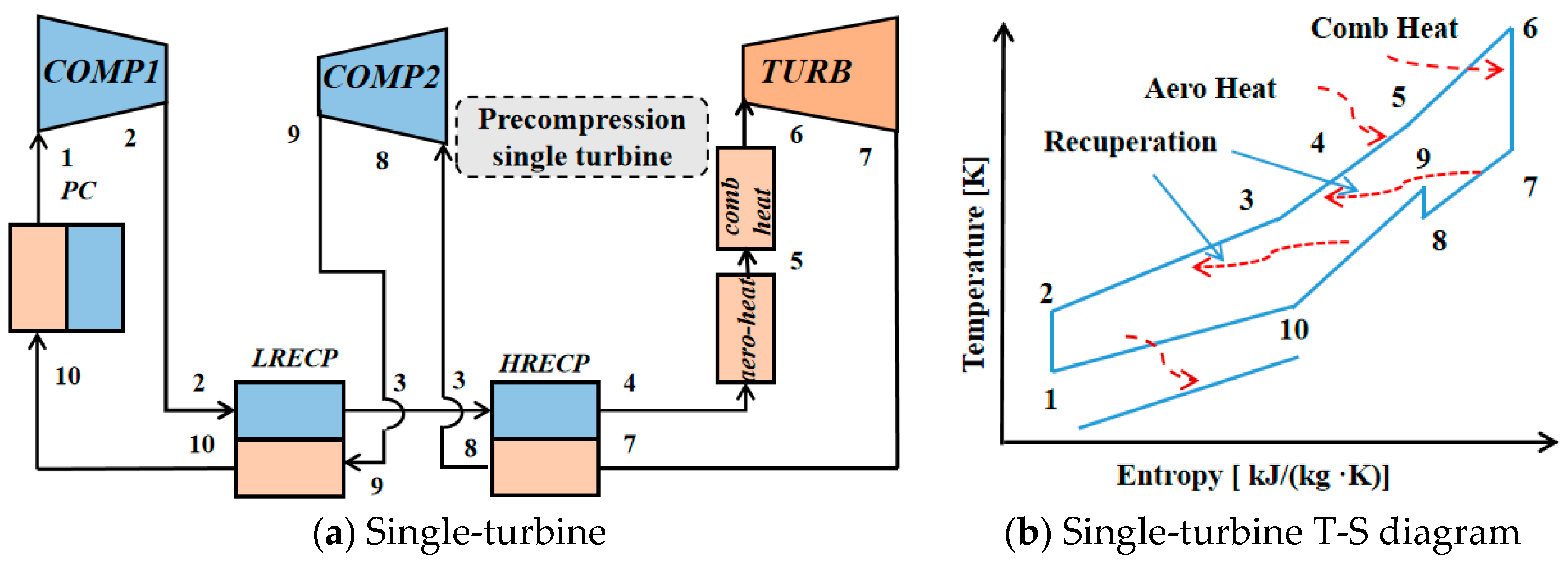

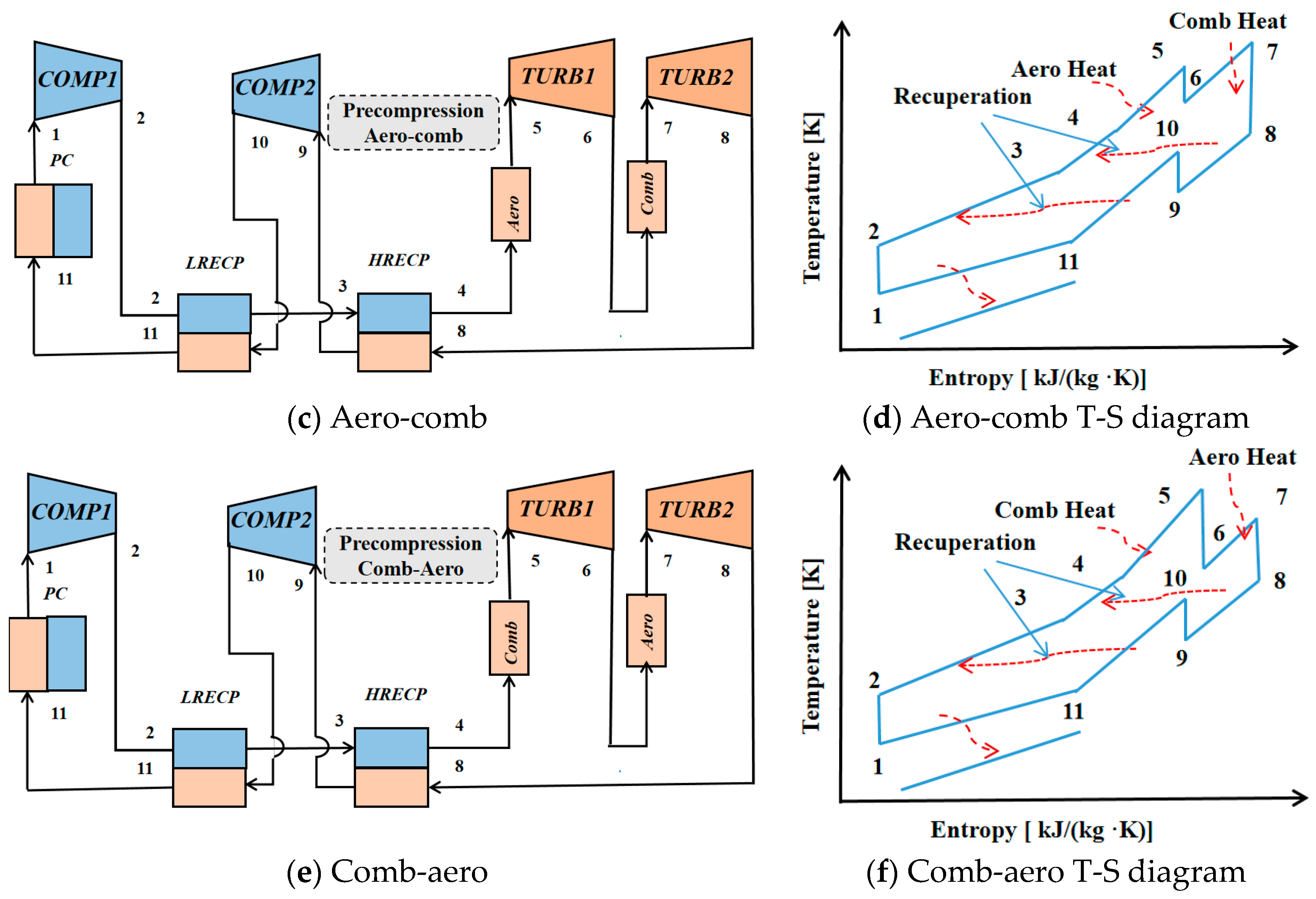

Figure 2,

Figure 3,

Figure 4 and

Figure 5 illustrate the layouts and T-S diagrams of these cycles. The characteristic of aero-comb is that the CO

2 first absorbs heat in the aerodynamic heat source, then expands and works in the first turbine, and then absorbs heat in the combustion chamber heat source and works in the second turbine; comb-aero is the opposite, the medium passes through the combustion chamber heat source, the first turbine, the aerodynamic heat source and the second turbine in sequence. These 12 cycles are as follows: simple recuperation single-turbine cycle, simple recuperation “aero-comb”, simple recuperation “comb-aero”, recompression single-turbine layout, recompression “aero-comb”, recompression “comb-aero”, precompression single-turbine cycle, precompression “aero-comb”, precompression “comb-aero”, intercooling single-turbine, intercooling “aero-comb”, and intercooling “comb-aero”. The red dotted lines in the figures represent the heat transfer directions.