Modeling of Non-Uniform Interference and Deformation Prediction for Riveting Assembly of Aircraft Thin-Walled Components

Abstract

1. Introduction

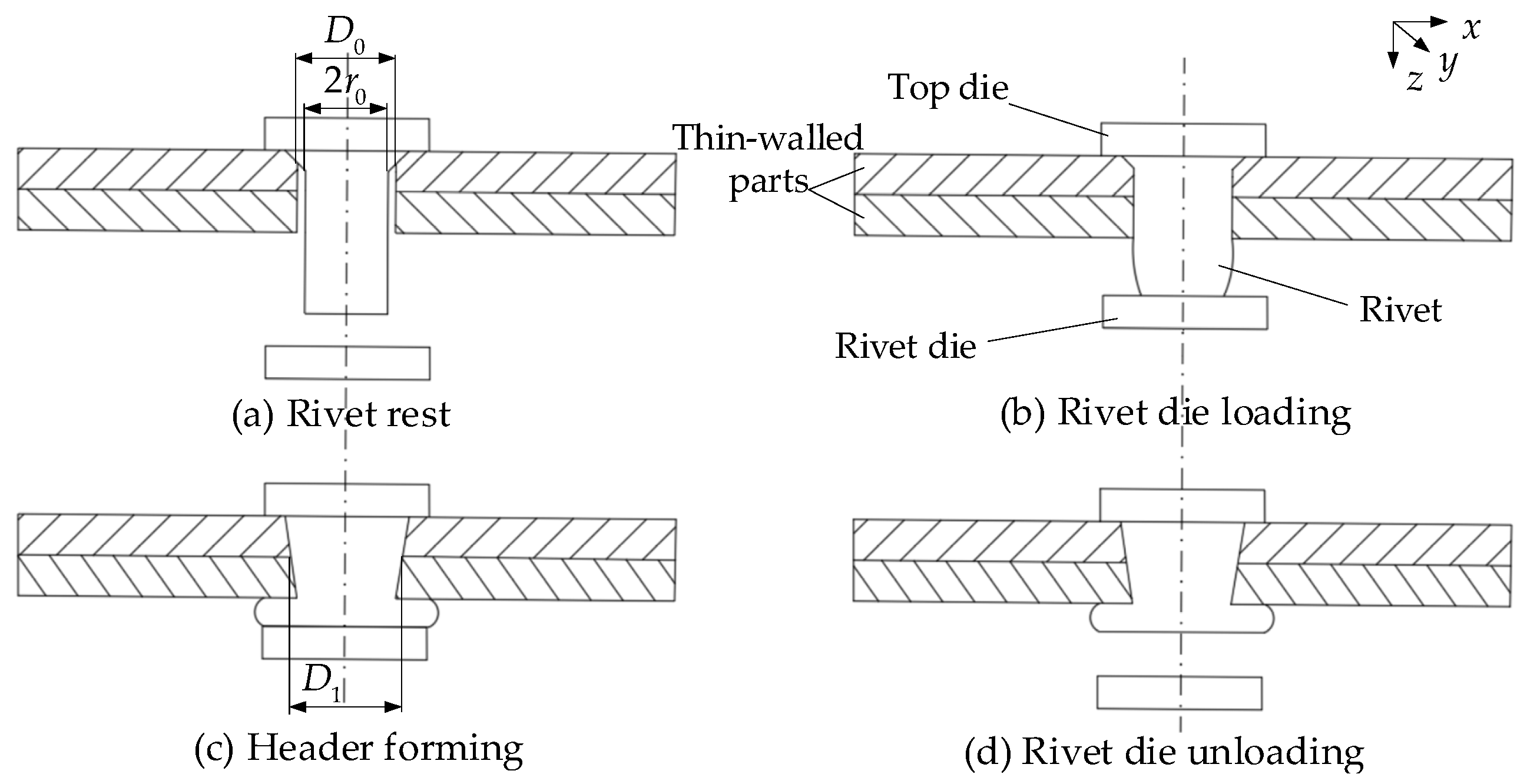

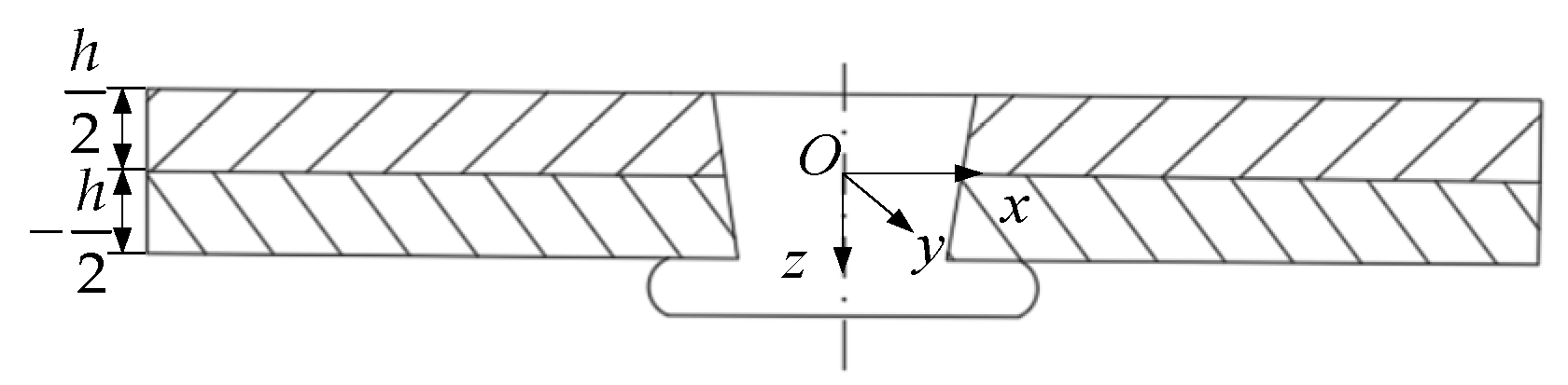

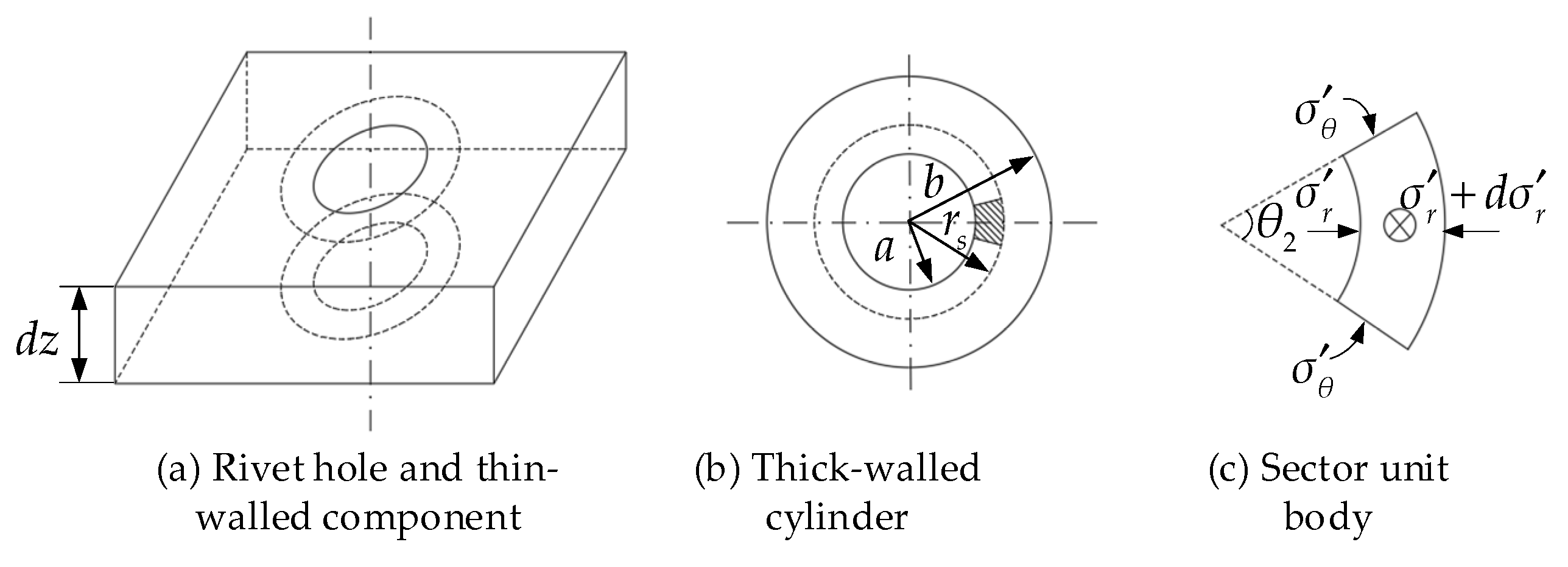

2. Non-Uniform Interference Amount in Single-Rivet Riveting

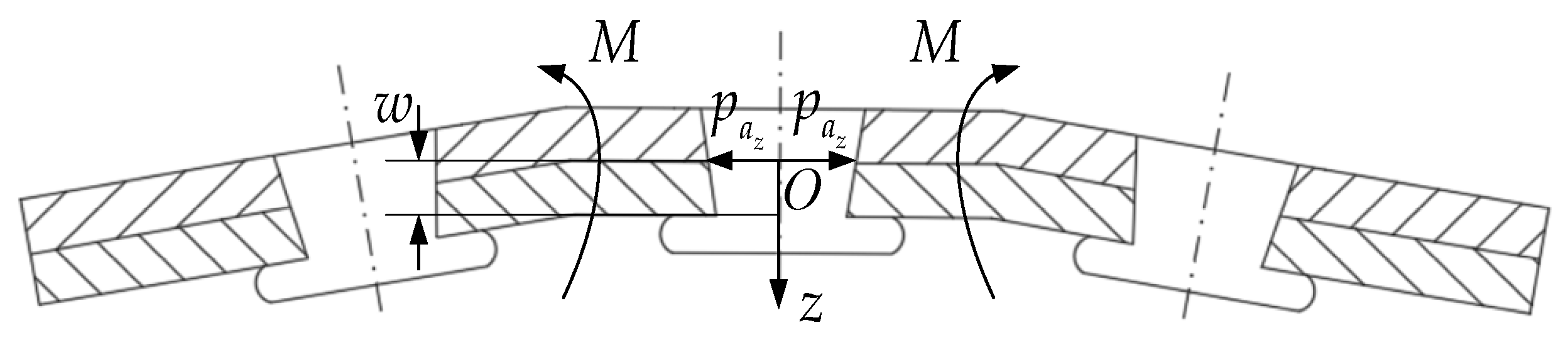

3. Non-Uniform Radial Stress in Single-Rivet Riveting

4. Riveting Deformation of Thin-Walled Components

5. Experimental Verification

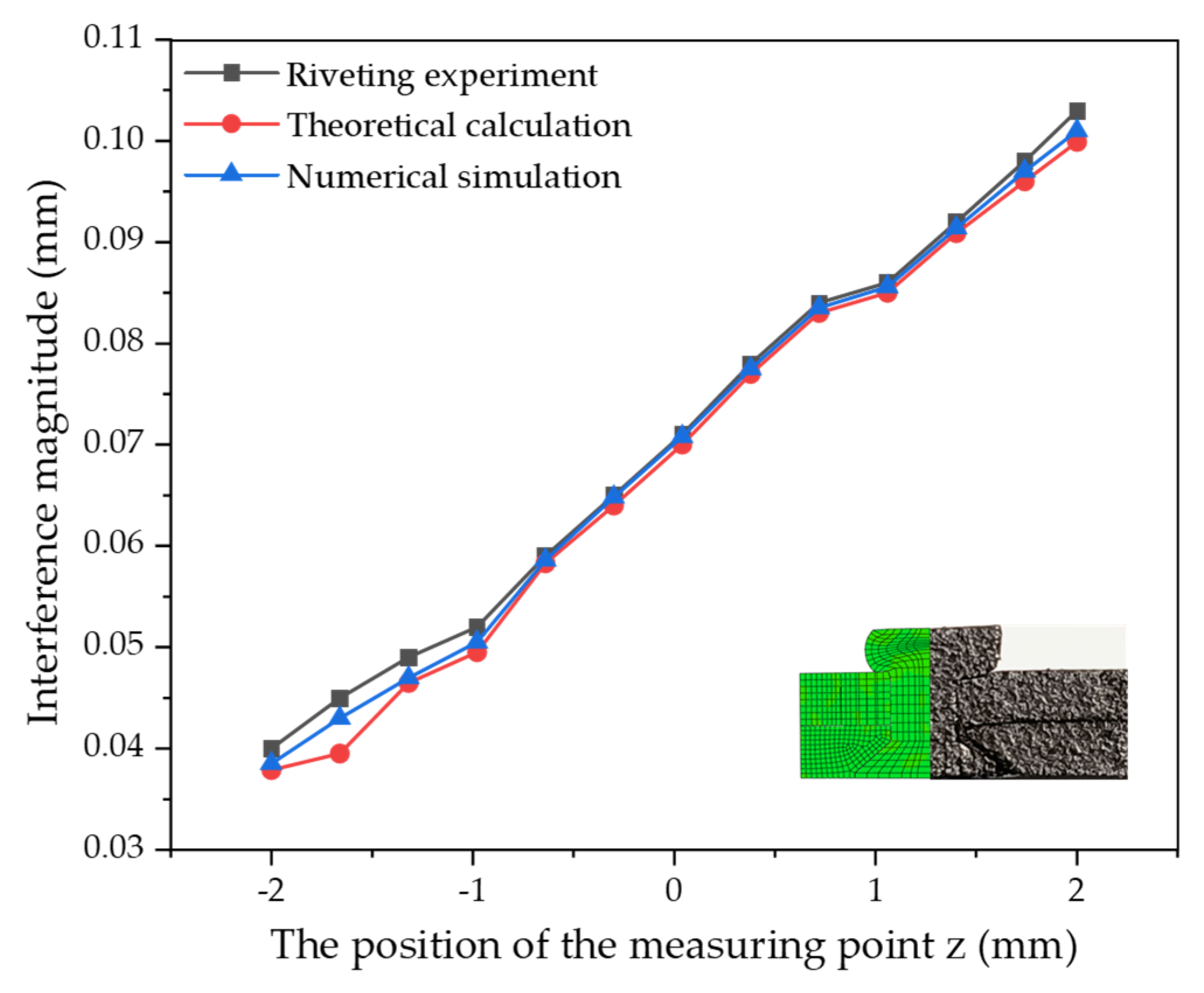

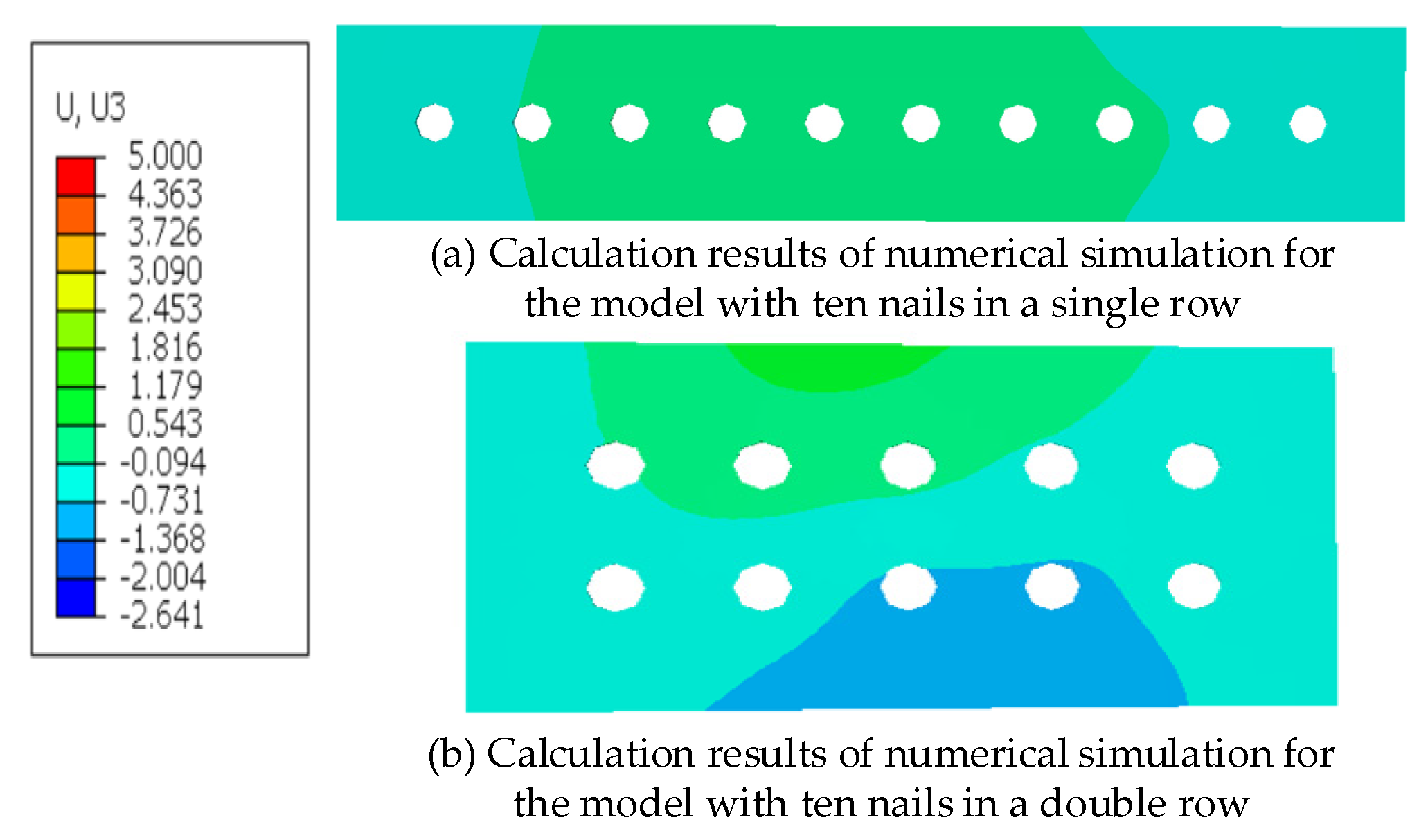

5.1. Numerical Simulation

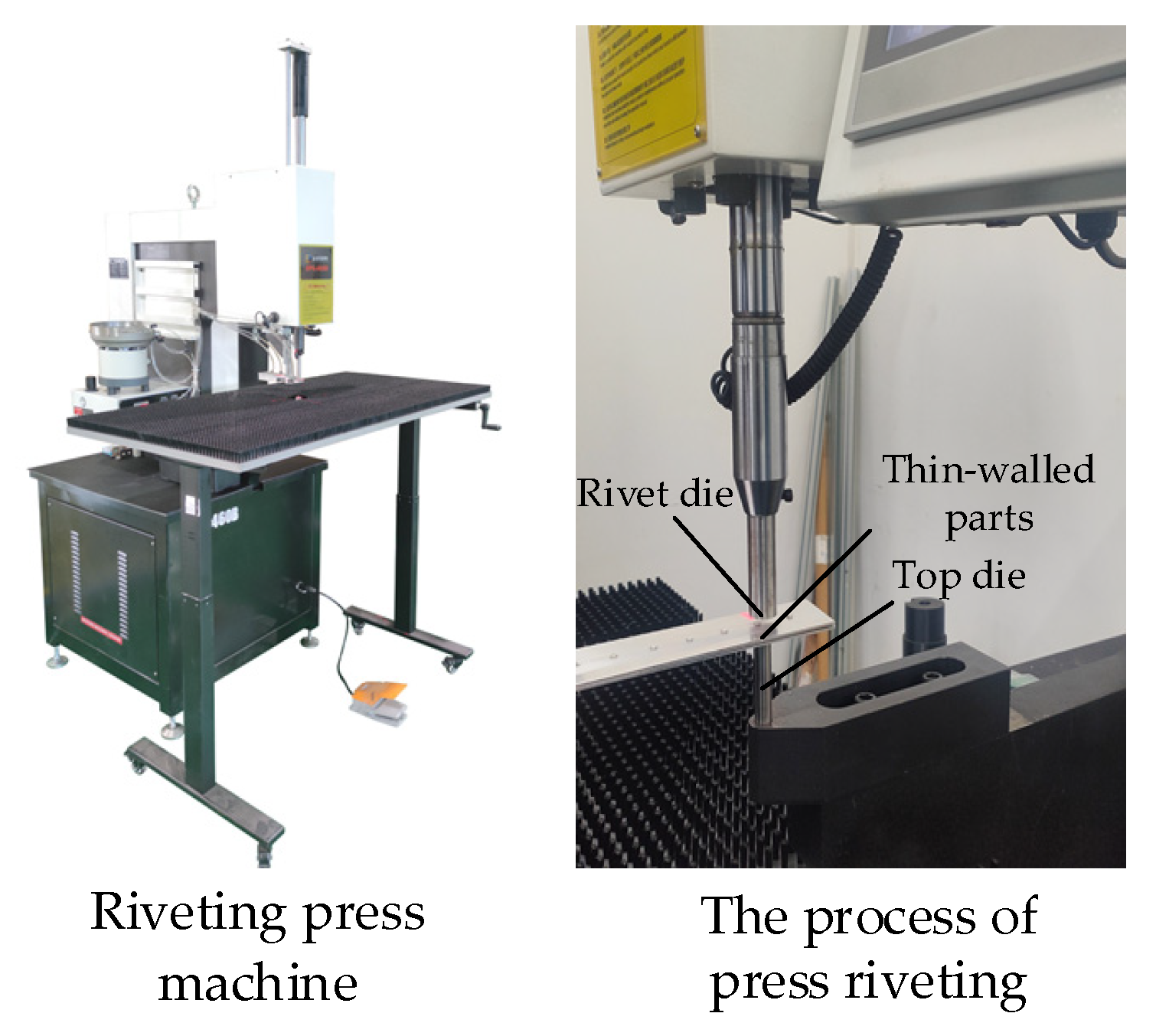

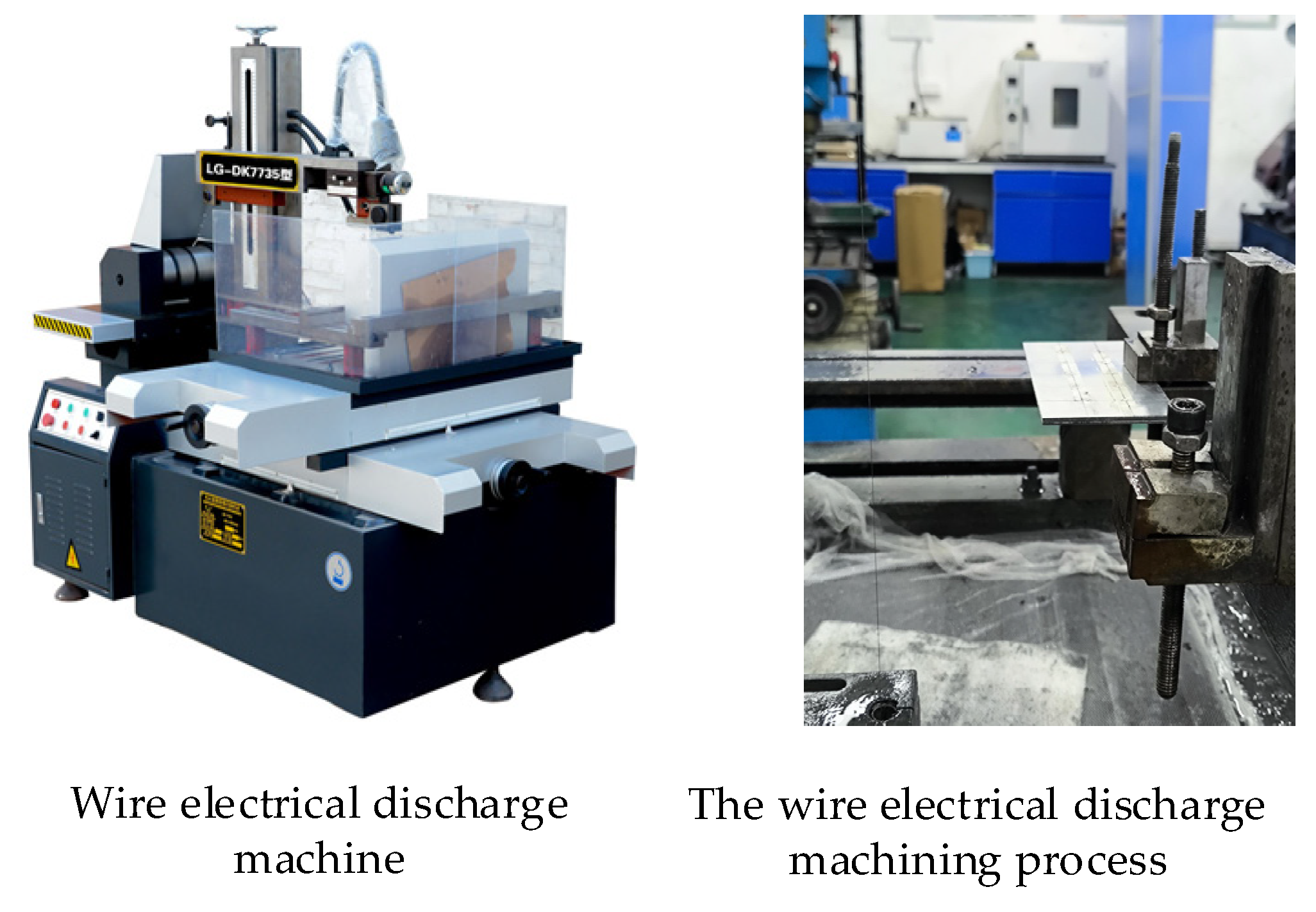

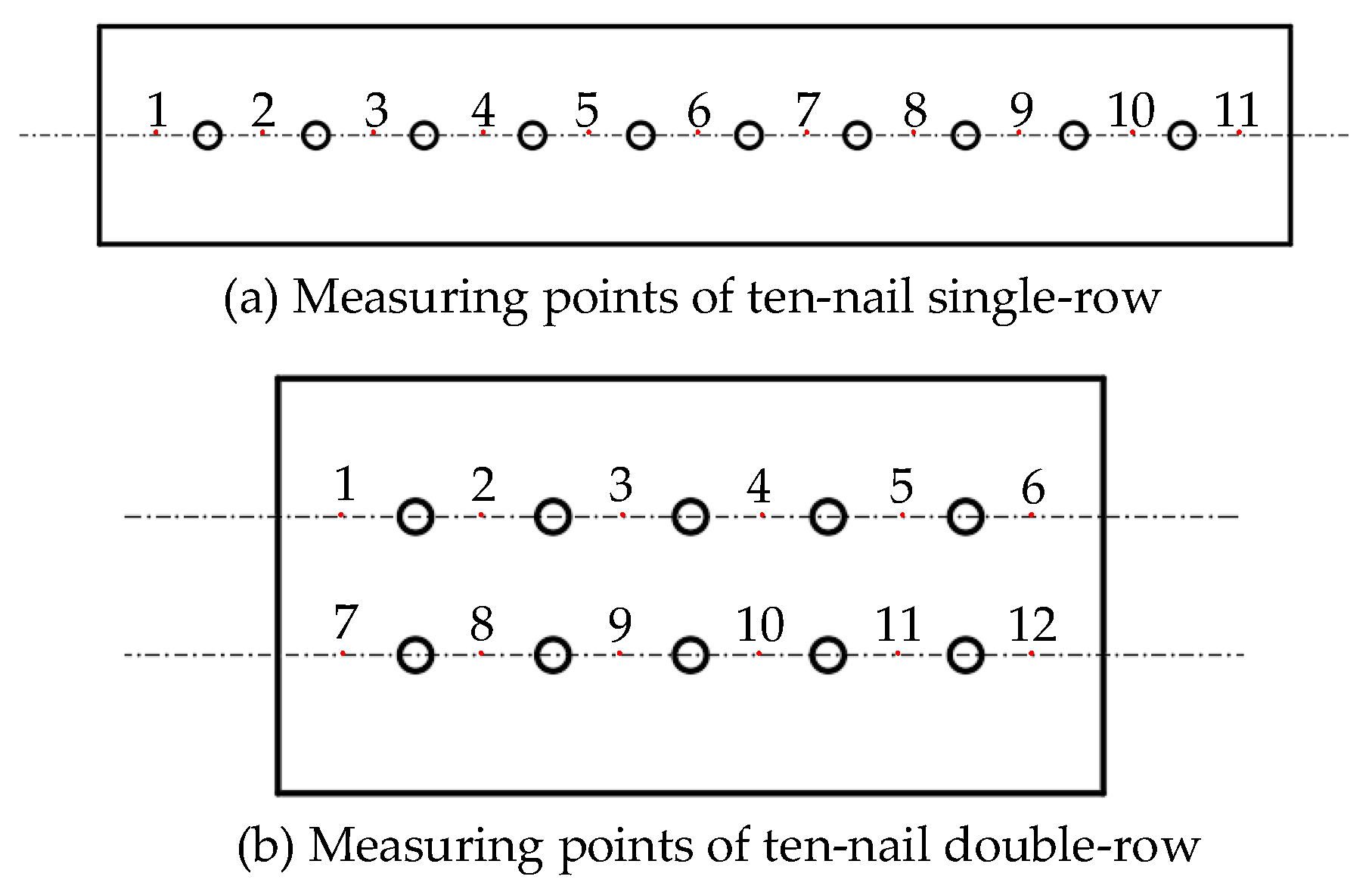

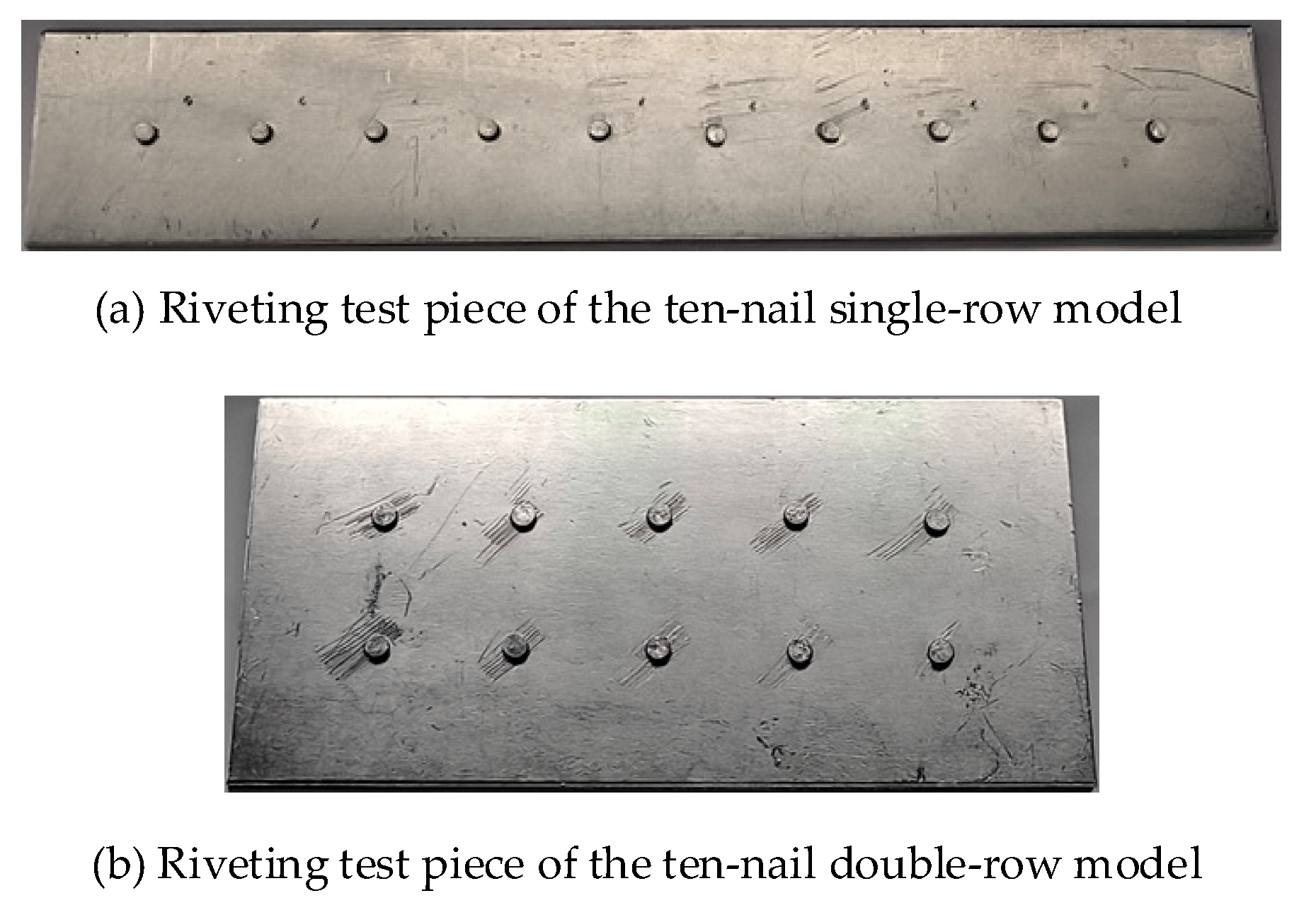

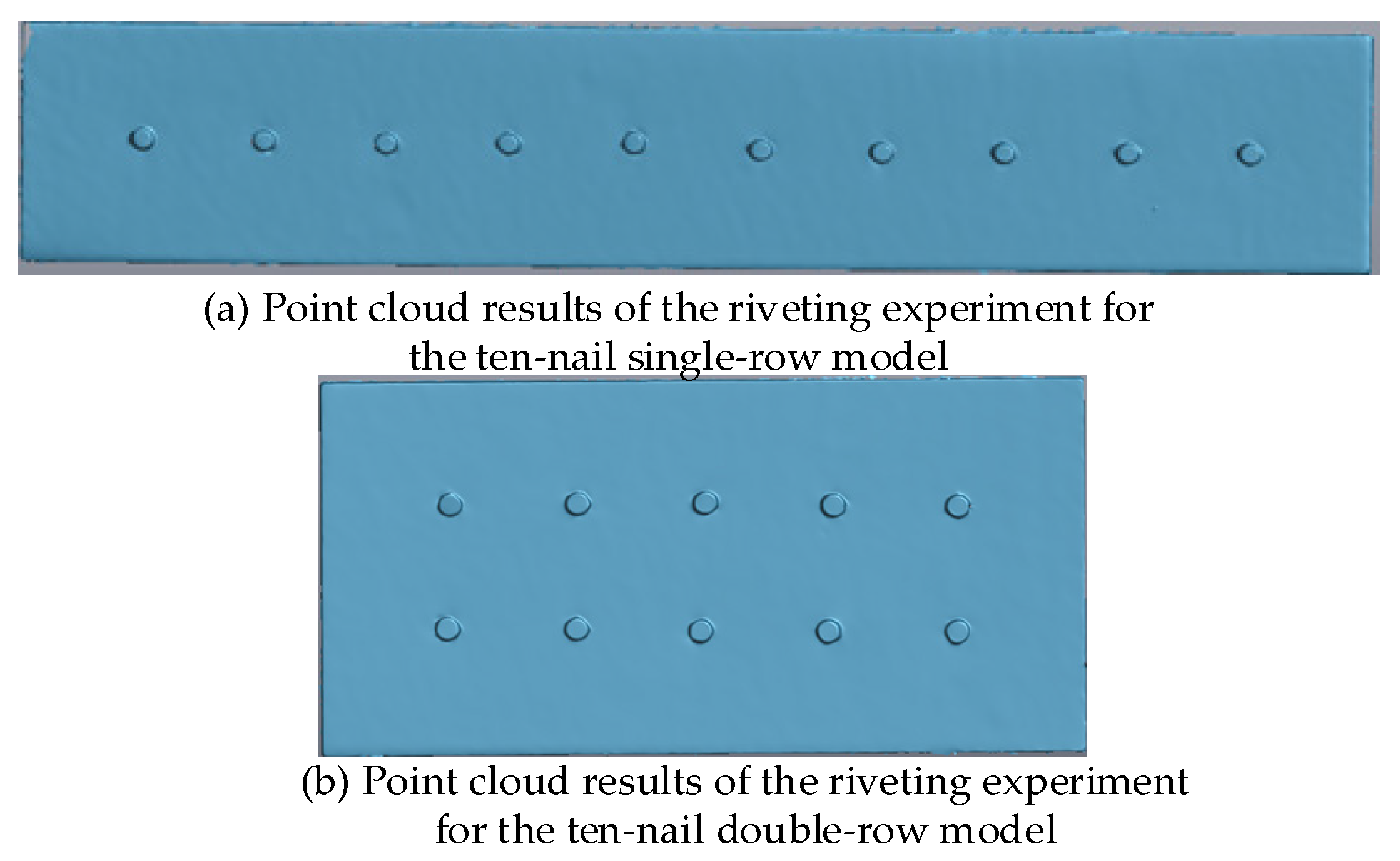

5.2. Riveting Experiment of Thin-Walled Components

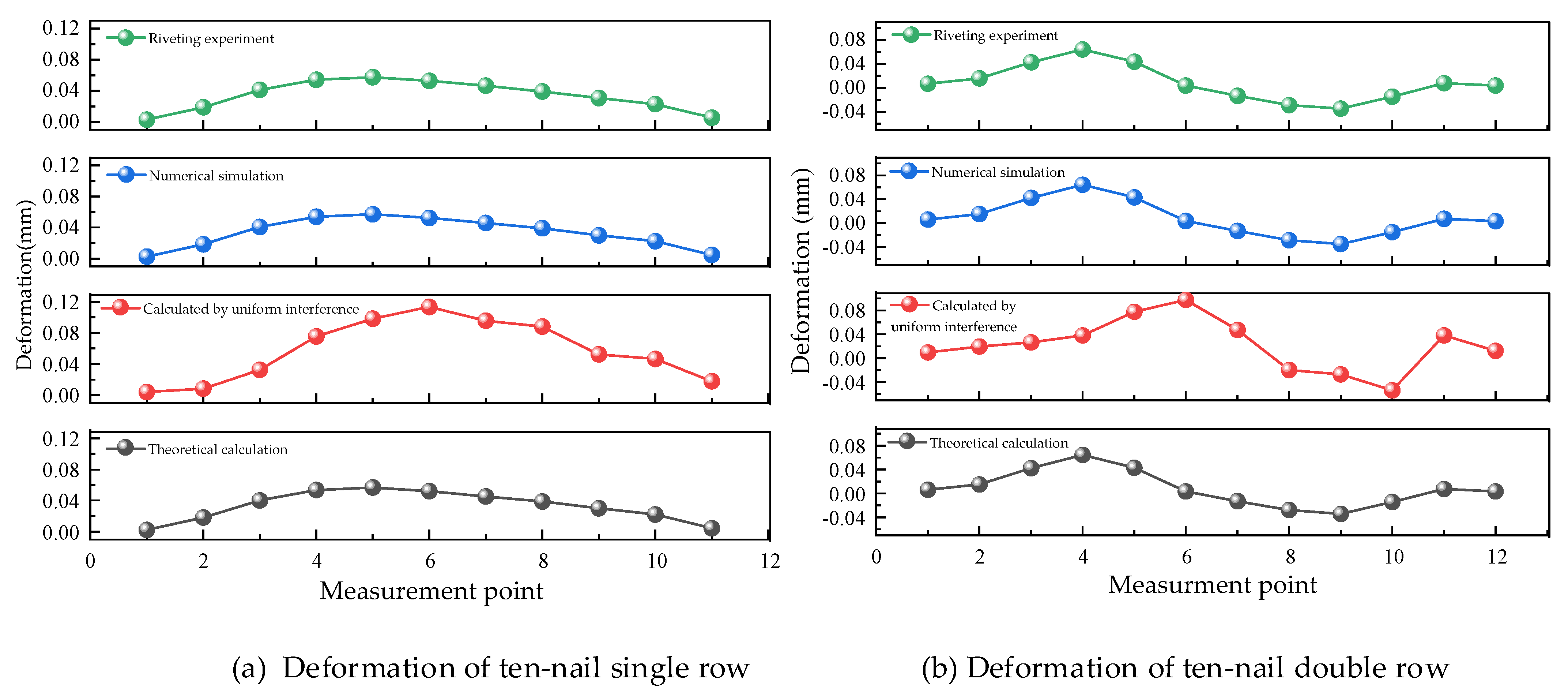

5.3. Calculation Results and Discussion

6. Conclusions

- (1)

- The non-uniform interference amount is an important factor causing the riveting deformation of thin-walled components. Through the stress analysis of the micro-element of the rivet shank, the axial distribution of the non-uniform interference amount was obtained. Based on the elastoplasticity theory, the riveting hole and the panel were simplified as a thick-walled cylinder. By combining with the axial distribution of the non-uniform interference amount, the distribution of the non-uniform radial stress was obtained. By projecting the single-rivet riveting onto the multi-rivet riveting, the total bending moment was obtained, and the deformation amount was calculated by using the thin plate theory.

- (2)

- Through numerical simulations and real experiments, it was verified that the interference amount is unevenly distributed. By comparing the interference amounts obtained from theoretical calculations, numerical simulations, and real experiments, the accuracy of the theoretical calculation of the uneven distribution of the interference amount was verified.

- (3)

- Through theoretical calculations, numerical simulations, and real experiments, it has been found that, among the measuring points of the single-row structure with ten rivets and the double-row structure with ten rivets, the deformation prediction model based on the non-uniform interference amount improves the prediction accuracy of various indicators by more than 29% compared with the calculation method of uniform interference. This further verifies the effectiveness and accuracy of the proposed prediction model. It provides a theoretical basis for the deviation transmission of aircraft digital assembly and process compensation, and enables more accurate control of aircraft assembly accuracy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, Y.; Su, M. Defect Detection Method for Aircraft Skin Riveting in Framework of YOLOv5. Mod. Aut. Technol. 2023, 7, 106–109. [Google Scholar]

- Kang, Y.; Li, G.; Song, S. Transfer and evolution of aircraft fuselage panel assembly deviation and optimization methods. Aerosp. Technol. 2024, 35, 40–51. [Google Scholar]

- Luo, Q.; Kang, Y.; Wang, T. Method of fast simulation, calculation and modeling of aircraft panel’s riveting deformation based on sub-structures. J. Mac. Des. 2024, 41, 1–8. [Google Scholar]

- Lv, G.; Li, C.; Zhao, C. Research on theoretical prediction method of rivet-forming quality considering different riveted structure parameters. Int. J. Adv. Manuf. Technol. 2024, 132, 2333–2345. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, Q.; Xiong, L. A unified evaluation method for fatigue resistance of riveted joints based on structural stress approach. Int. J. Fatigue 2022, 160, 106871. [Google Scholar] [CrossRef]

- Figueira, J.A.N.; Trabasso, L.G. Riveting-Induced Deformations on Aircraft Structures. J. Aircr. 2015, 52, 2032–2050. [Google Scholar] [CrossRef]

- Liu, G.; Huan, H.; Ke, Y. Study on analysis and prediction of riveting assembly variation of aircraft fuselage panel. Int. J. Adv. Manuf. Technol. 2014, 75, 991–1003. [Google Scholar] [CrossRef]

- Kang, Y.; Song, S.; Wang, T. Analytical Modeling of Riveting Squeezing Force Considering Non-Uniform Deformation of Rivets in Aeronautical Structures. Materials 2024, 17, 2756. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, T.; Zhu, C. Effect of riveting angle and direction on fatigue performance of riveted lap joints. Coatings 2021, 11, 236. [Google Scholar] [CrossRef]

- Nejad, R.M.; Berto, F.; Tohidi, M. Fatigue performance prediction of Al-alloy 2024 plates in riveted joint structure. Eng. Fail. Anal. 2021, 126, 105439. [Google Scholar] [CrossRef]

- Kondo, A.; Kasahara, T.; Kanda, A. A simplified finite element model of riveted joints for structural analyses with consideration of nonlinear load-transfer characteristics. Aerospace 2021, 8, 196. [Google Scholar] [CrossRef]

- Kang, Y.; Song, S.; Wang, T. Study on the Mechanism of Cumulative Deformation and Method for Suppression in Aircraft Panel Riveting. Aerospace 2024, 11, 678. [Google Scholar] [CrossRef]

- Ni, J.; Tang, W.; Xing, Y. A local-to-global dimensional error calculation framework for the riveted assembly using finite-element analysis. J. Manuf. Sci. Eng. 2016, 138, 031004. [Google Scholar] [CrossRef]

- Yang, D.; Qu, W.; Ke, Y. Local-global method to predict distortion of aircraft panel caused in automated riveting process. Assem. Autom. 2019, 39, 973–985. [Google Scholar] [CrossRef]

- Silvayeh, Z.; Brillinger, M.; Domitner, J. Deformation behavior of aluminum alloy rivets for aerospace applications. J. Mater. Res. Technol. 2024, 33, 3482–3491. [Google Scholar] [CrossRef]

- Zanatta, C.V.; Villani, E.; Mello, J.M.G. Riveting process simulation to predict induced deformations in aeronautical structures. Int. J. Adv. Manuf. Technol. 2022, 120, 7673–7687. [Google Scholar] [CrossRef]

- Li, Y. Principles of Plastic Forming of Metals; China Machine Press: Beijing, China, 2013. [Google Scholar]

- Zheng, B.; Yu, H.; Lai, X. Assembly deformation prediction of riveted panels by using equivalent mechanical model of riveting process. Int. J. Adv. Manuf. Technol. 2017, 92, 1955–1966. [Google Scholar] [CrossRef]

- Chao, Z.; Wei, T.; Xiang, Y. Experimental and numerical studies of stress/strain characteristics in riveted aircraft lap joints. J. Mech. Sci. Technol. 2019, 33, 3245–3255. [Google Scholar]

- Kang, Y.; Huan, X.; Zi, W. Three-Dimensional Characterization of Residual Stress in Aircraft Riveted Panel Structures. Aerospace 2024, 11, 552. [Google Scholar] [CrossRef]

- Li, Y. An Analysis of Riveting Process by Theoretical Nonlinear Finite Element and EXPERIMENTAL methods. Doctor Thesis, Wichita State University, Wichita, Kansas, 1998. [Google Scholar]

- Wu, S. Elastic-plastic analyses of fastener holes of interference-fit rivets and its application in fatigue life estimation. Aerosp. Technol. 1989, 12, 662–665. [Google Scholar]

- Aviation Manufacturing Engineering Handbook Editorial Board. Aviation Manufacturing Engineering Handbook (Aircraft Assembly); Aviation Industry Press: Beijing, China, 2010. [Google Scholar]

- Chang, Z.; Wang, Z.; Jiang, B. Modeling and predicting of aeronautical thin-walled sheet metal parts riveting deformation. Assem. Autom. 2016, 36, 295–307. [Google Scholar] [CrossRef]

- Chang, Z.; Wang, Z.; Xie, L. Prediction of riveting deformation for thin-walled structures using local-global finite element approach. Int. J. Adv. Manuf. Technol. 2018, 97, 2529–2544. [Google Scholar] [CrossRef]

- Xu, Z. The Theory of Elasticity (I, II); Higher Education Press: Beijing, China, 2016. [Google Scholar]

- China Aeronautical Materials Handbook Editorial Committee. China Aeronautical Materials Handbook; Standards Press of China: Beijing, China, 2001. [Google Scholar]

- Baha, S., II; Hesebeck, O. Simulation of the solid rivet installation process. SAE Int. J. Aerosp. 2010, 3, 187–197. [Google Scholar] [CrossRef]

| Material | Elastic Modulus (GPa) | Poisson’s Ratio | Yield Stress (MPa) |

|---|---|---|---|

| LY12CZ | 72.4 | 0.33 | 350 |

| LY10 | 71.0 | 0.33 | 247 |

| Method | Measurement Point | Index | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |||

| Theoretical calculation | 0.0023 | 0.0181 | 0.0402 | 0.0536 | 0.0568 | 0.0521 | 0.0453 | 0.0386 | 0.0301 | 0.0222 | 0.0045 | 0.0568 | 0.0378 |

| Calculated by uniform interference | 0.0041 | 0.0085 | 0.0324 | 0.0756 | 0.0982 | 0.1133 | 0.0957 | 0.0881 | 0.0523 | 0.0465 | 0.0179 | 0.1133 | 0.0684 |

| Numerical simulation | 0.0027 | 0.0186 | 0.0409 | 0.0539 | 0.0571 | 0.0525 | 0.0459 | 0.0389 | 0.0302 | 0.0226 | 0.0049 | 0.0571 | 0.0381 |

| Riveting experiment | 0.003 | 0.018 | 0.041 | 0.054 | 0.057 | 0.052 | 0.046 | 0.039 | 0.030 | 0.022 | 0.005 | 0.057 | 0.038 |

| Method | Measurement Point | Index | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

| Theoretical calculation | 0.0061 | 0.0151 | 0.0423 | 0.0639 | 0.0426 | 0.0034 | −0.0128 | −0.0276 | −0.0343 | −0.0142 | 0.0073 | 0.0032 | 0.0639 | 0.0378 |

| Calculated by uniform interference | 0.0096 | 0.0194 | 0.0265 | 0.0381 | 0.0775 | 0.0973 | 0.0475 | −0.0196 | −0.0268 | −0.0533 | 0.0379 | 0.0127 | 0.0973 | 0.0465 |

| Numerical simulation | 0.0063 | 0.0155 | 0.0425 | 0.0640 | 0.0431 | 0.0036 | −0.0131 | −0.0283 | −0.0346 | −0.0146 | 0.0075 | 0.0034 | 0.0640 | 0.0296 |

| Riveting experiment | 0.006 | 0.015 | 0.042 | 0.064 | 0.043 | 0.003 | −0.013 | −0.028 | −0.034 | −0.014 | 0.007 | 0.003 | 0.064 | 0.029 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Zhu, Y. Modeling of Non-Uniform Interference and Deformation Prediction for Riveting Assembly of Aircraft Thin-Walled Components. Aerospace 2025, 12, 526. https://doi.org/10.3390/aerospace12060526

Hu Y, Zhu Y. Modeling of Non-Uniform Interference and Deformation Prediction for Riveting Assembly of Aircraft Thin-Walled Components. Aerospace. 2025; 12(6):526. https://doi.org/10.3390/aerospace12060526

Chicago/Turabian StyleHu, Yuanfan, and Yongguo Zhu. 2025. "Modeling of Non-Uniform Interference and Deformation Prediction for Riveting Assembly of Aircraft Thin-Walled Components" Aerospace 12, no. 6: 526. https://doi.org/10.3390/aerospace12060526

APA StyleHu, Y., & Zhu, Y. (2025). Modeling of Non-Uniform Interference and Deformation Prediction for Riveting Assembly of Aircraft Thin-Walled Components. Aerospace, 12(6), 526. https://doi.org/10.3390/aerospace12060526