Simulation Analysis and Experimental Verification of the Transport Characteristics of a High-Volume CubeSat Storage Device

Abstract

1. Introduction

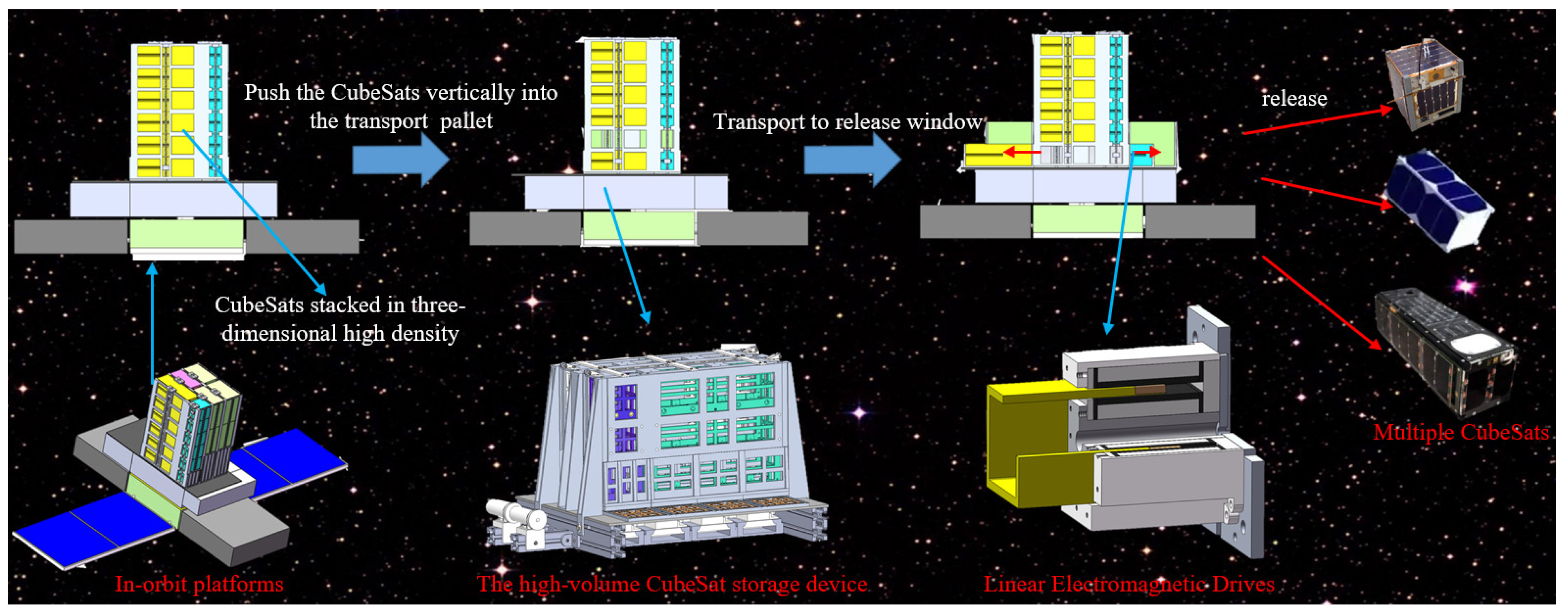

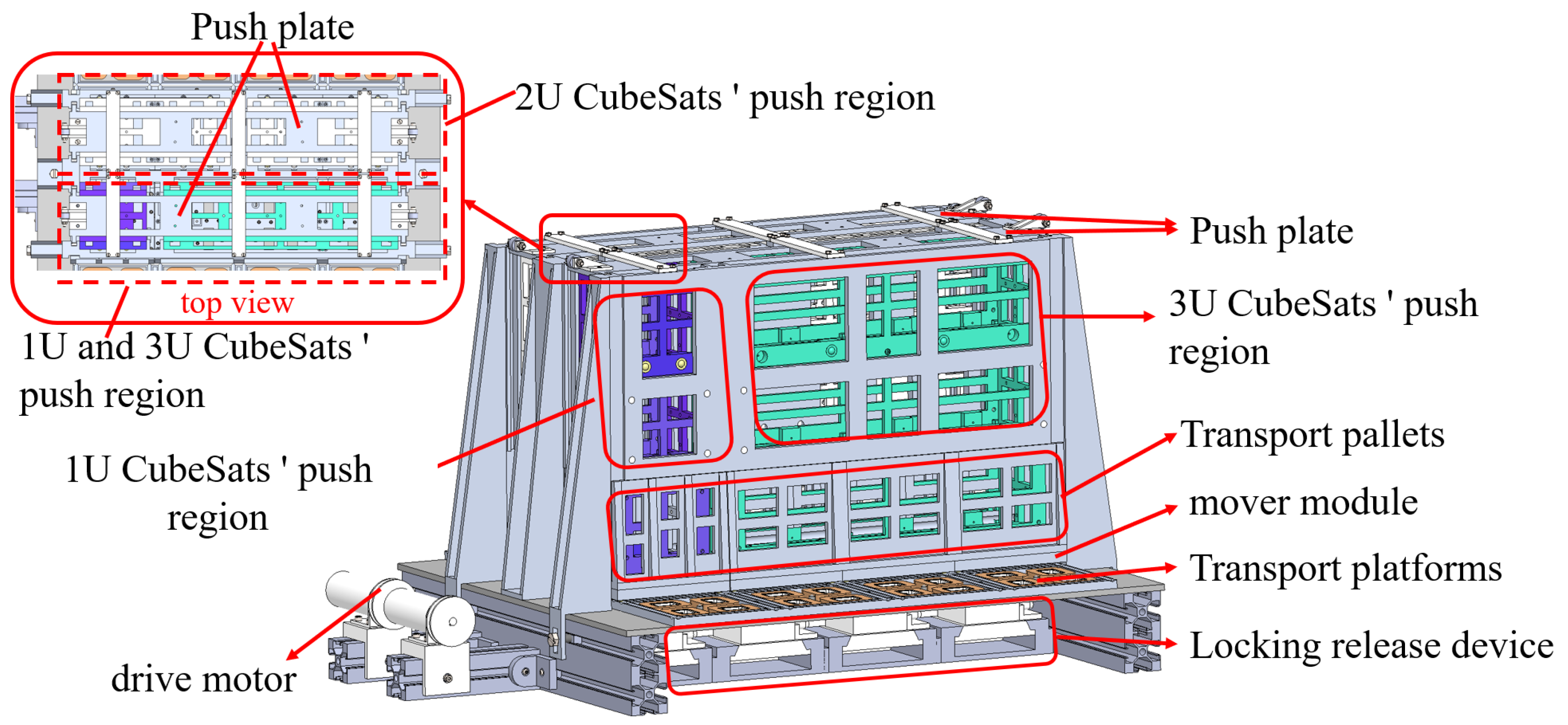

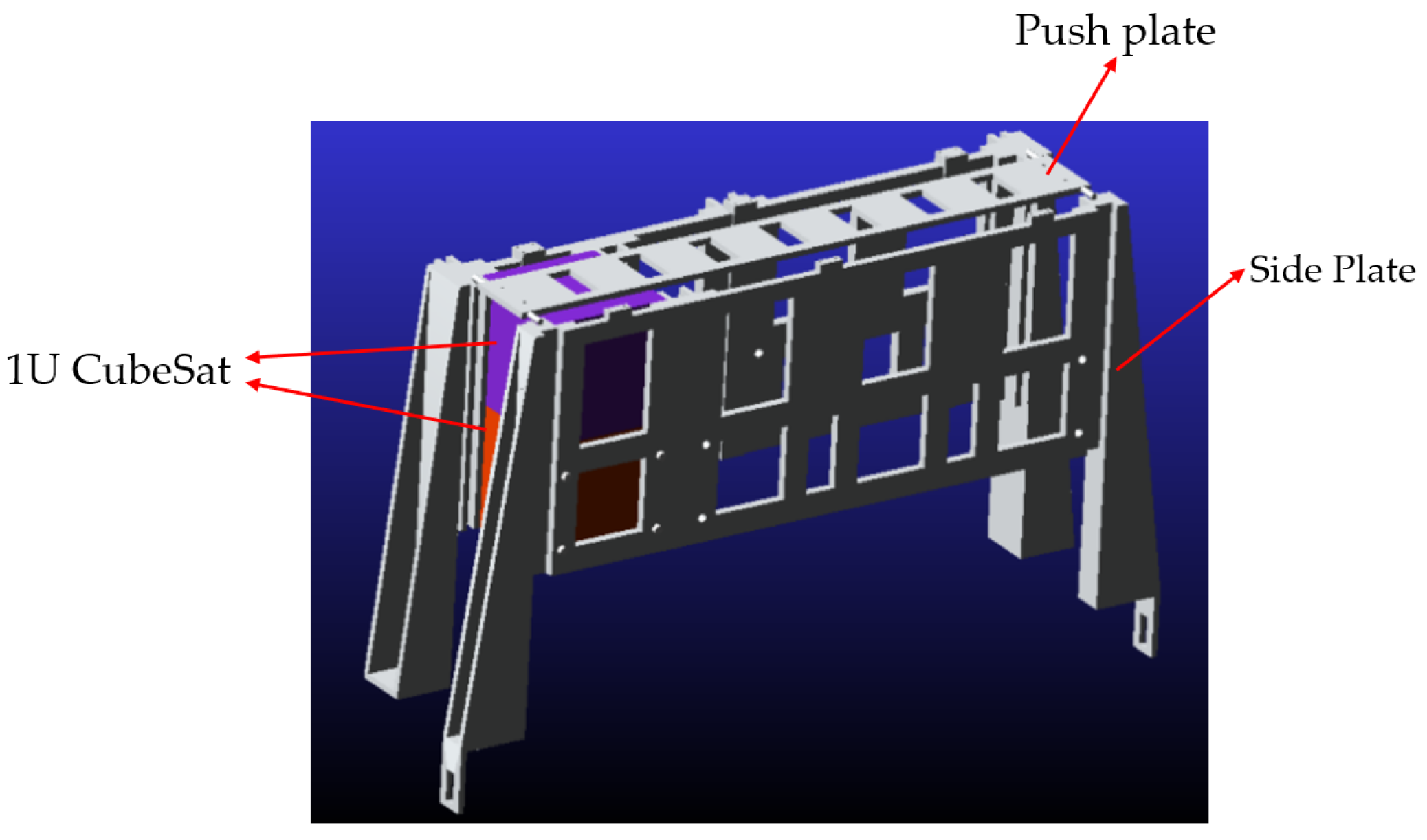

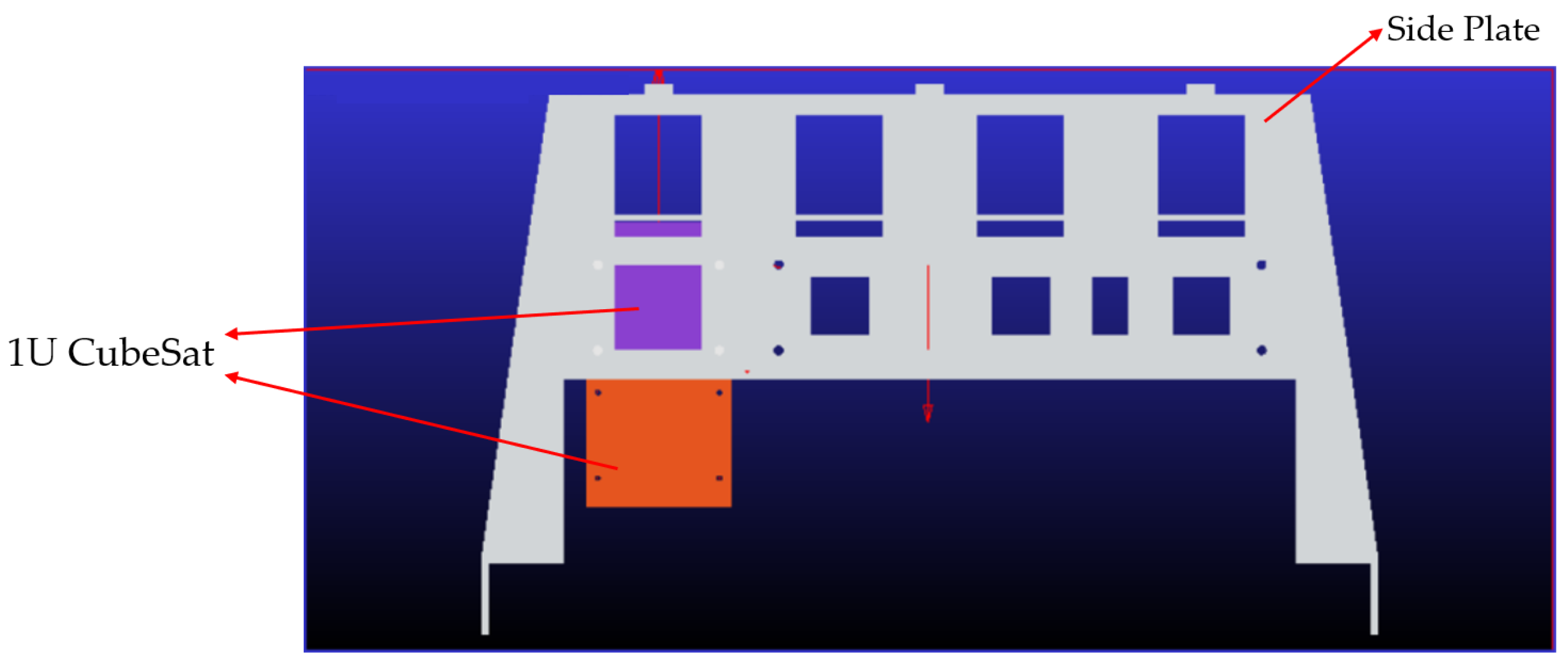

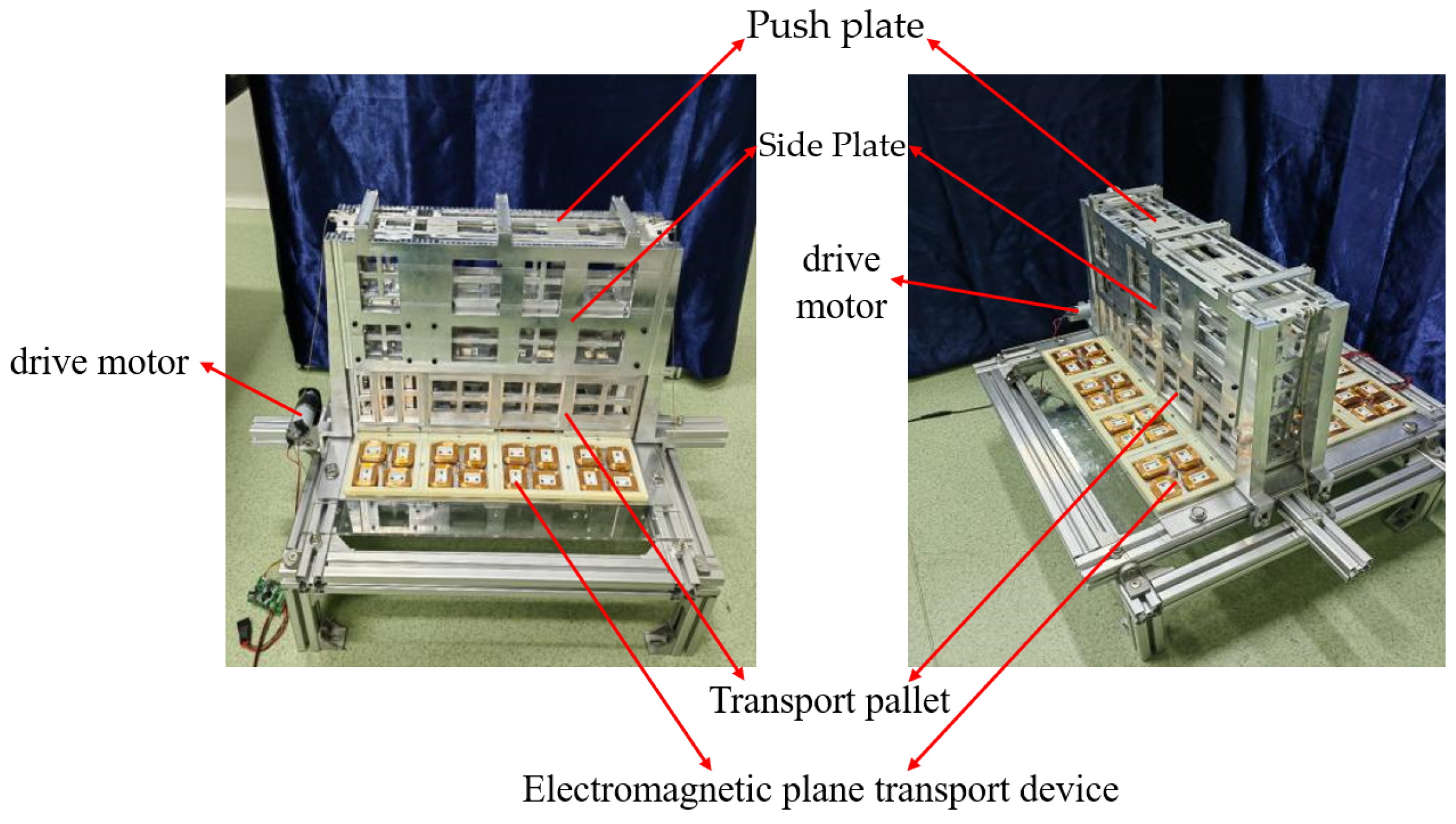

2. Structure and Working Principle

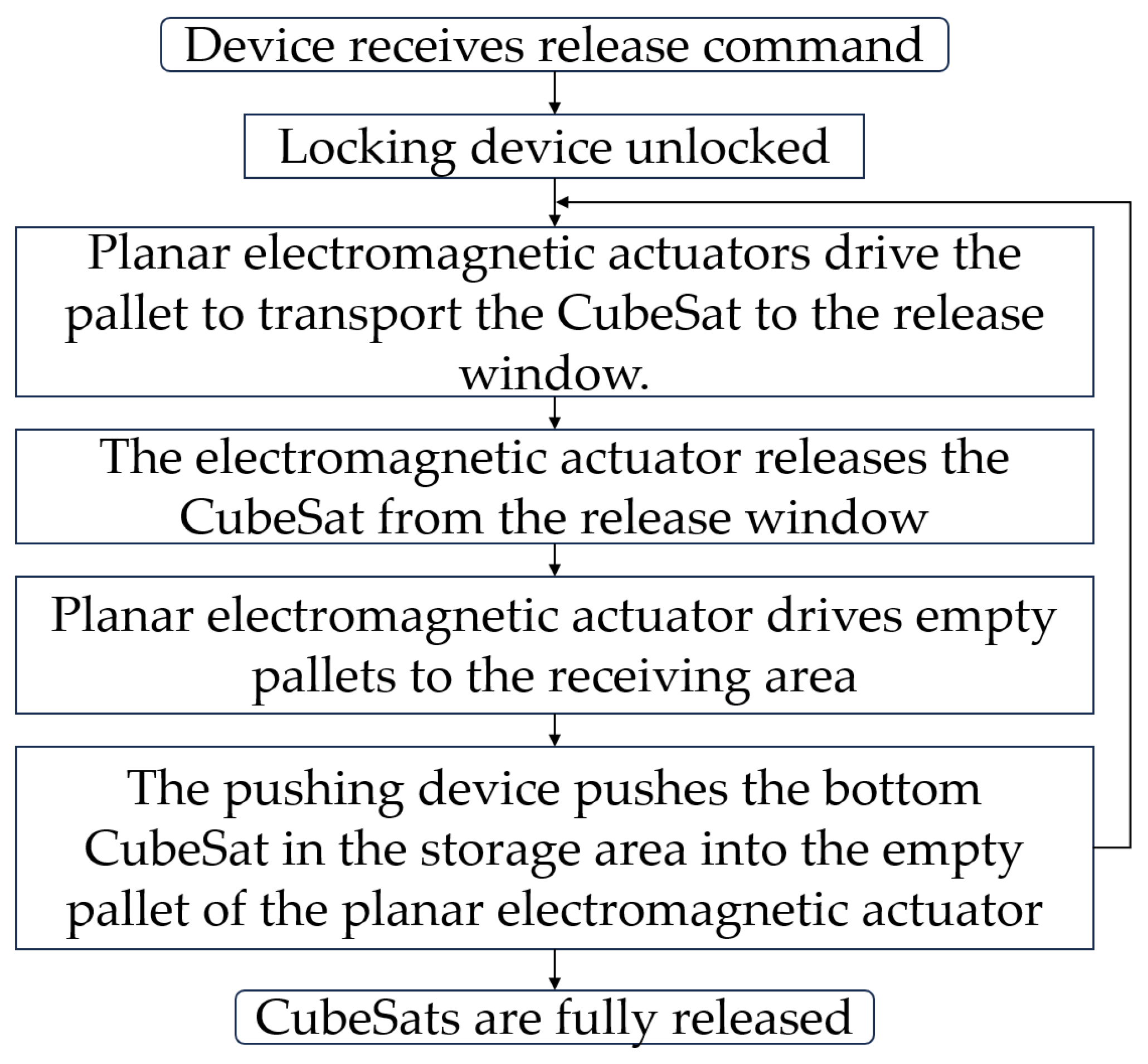

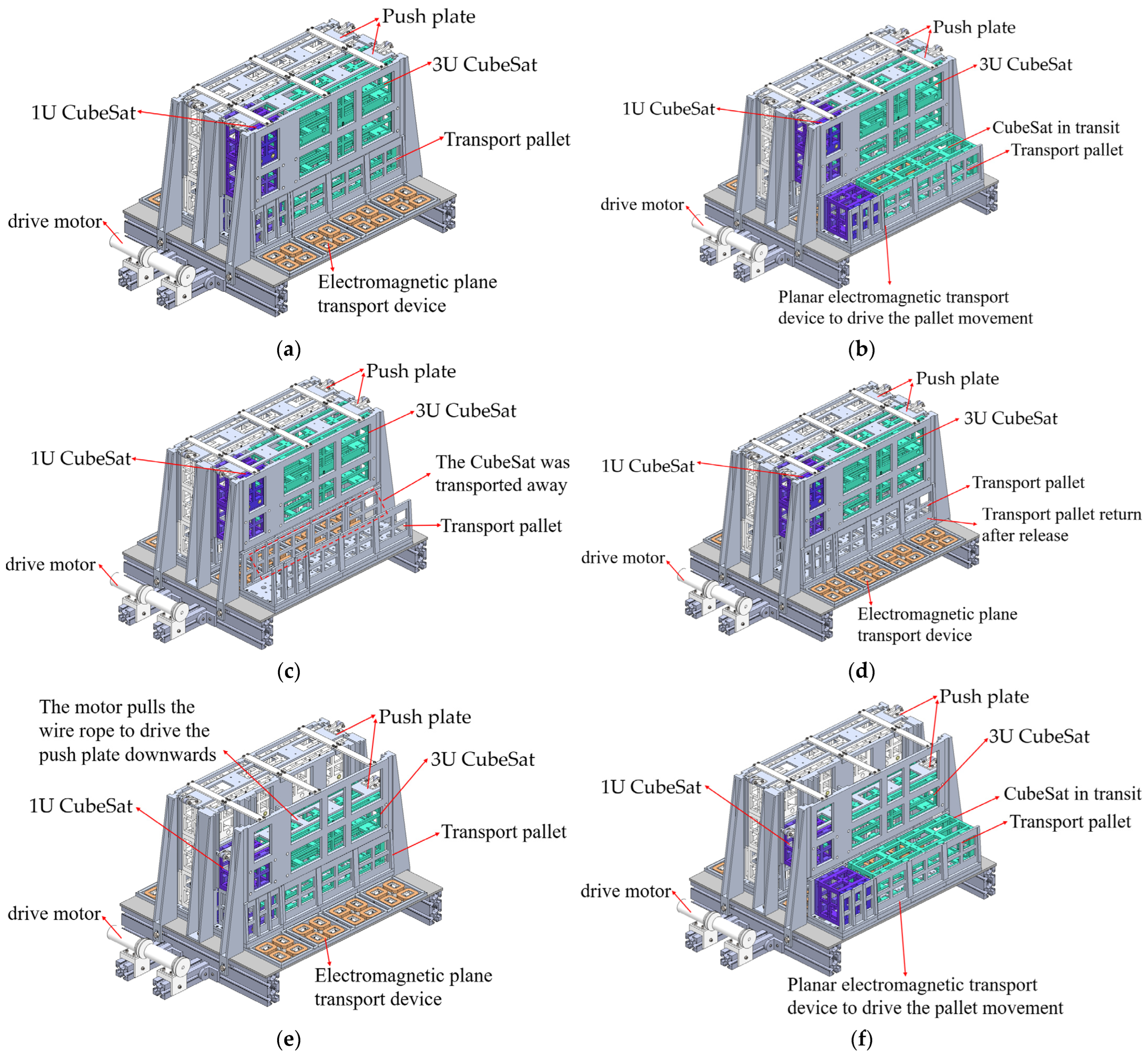

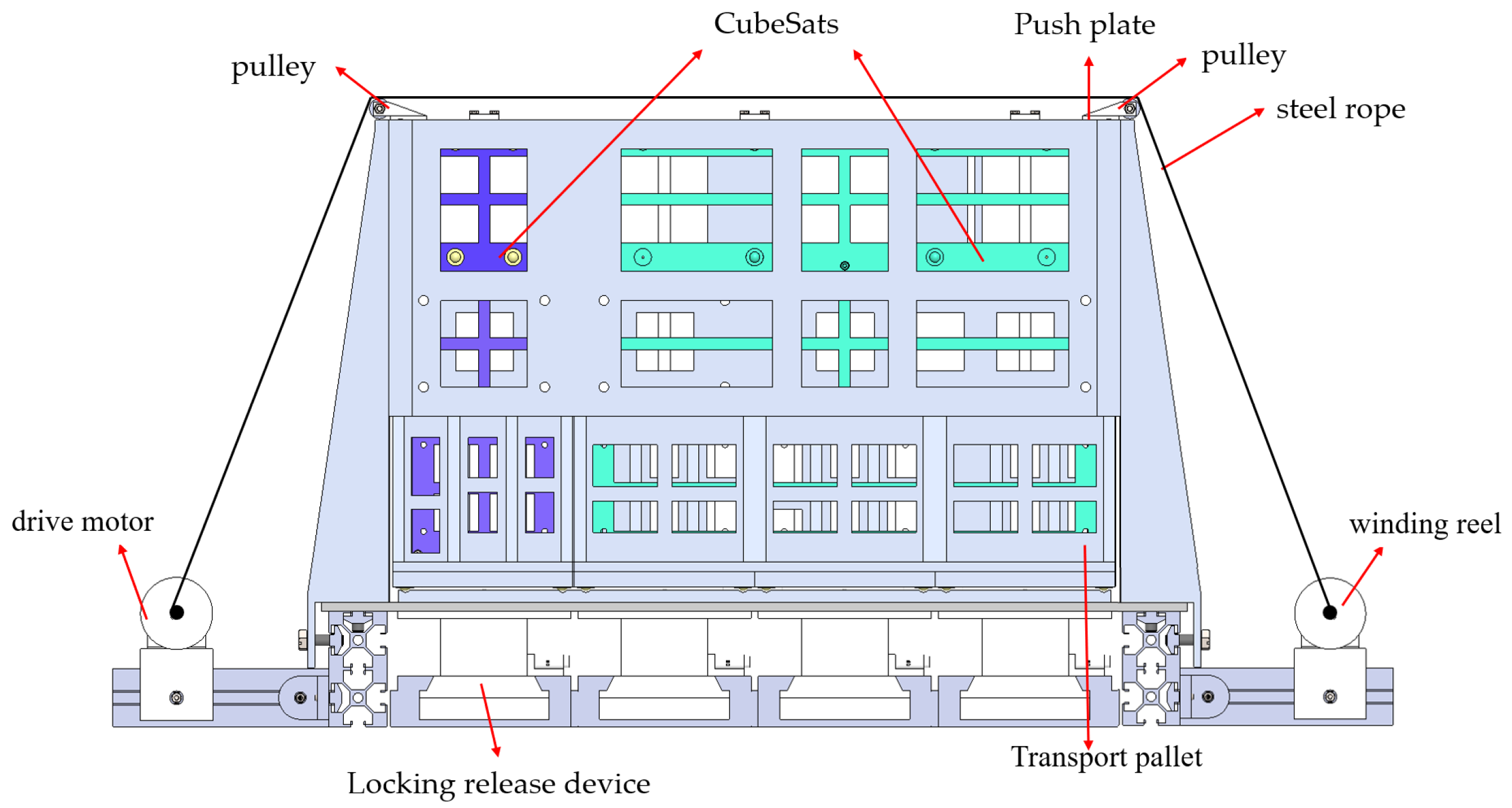

2.1. Macro Workflow

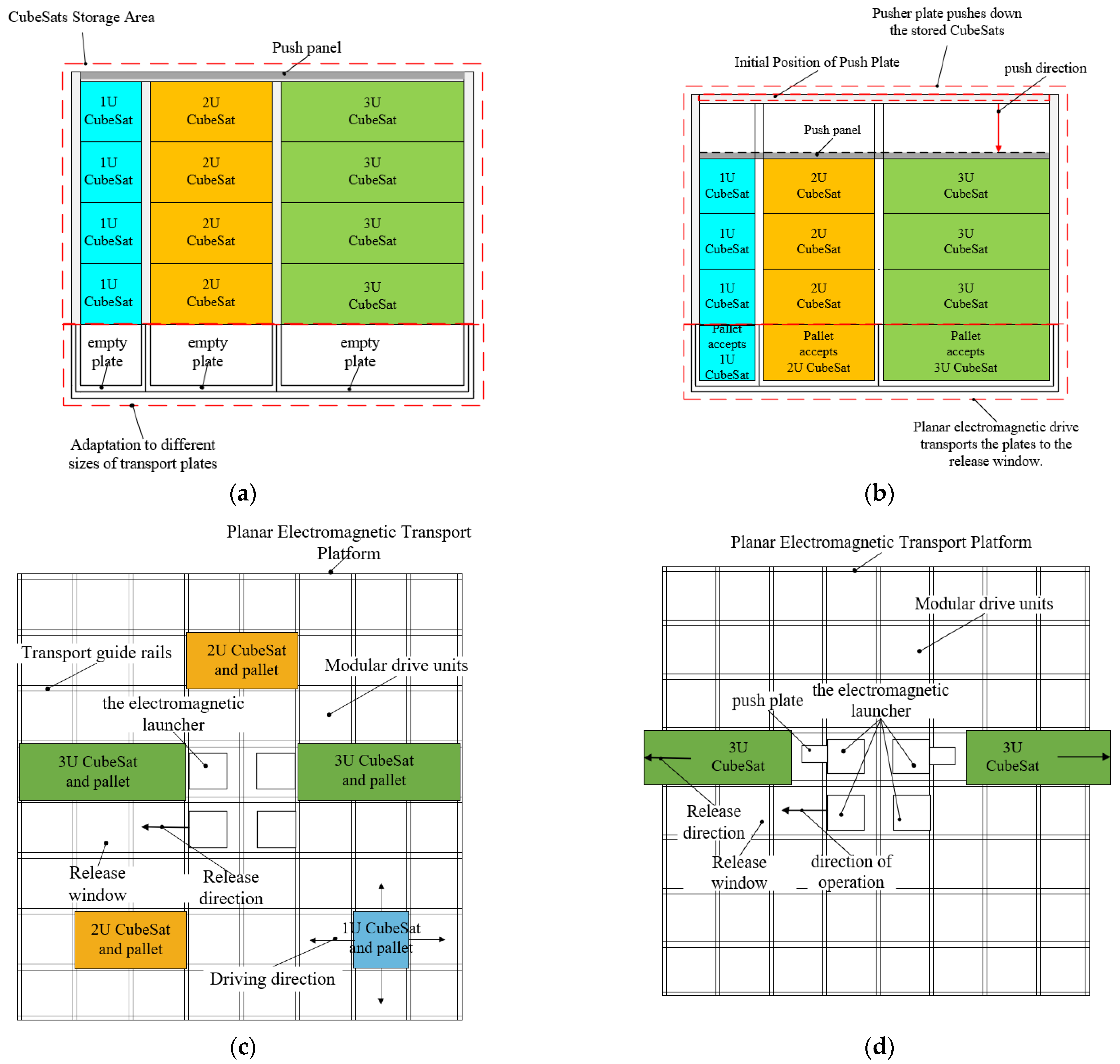

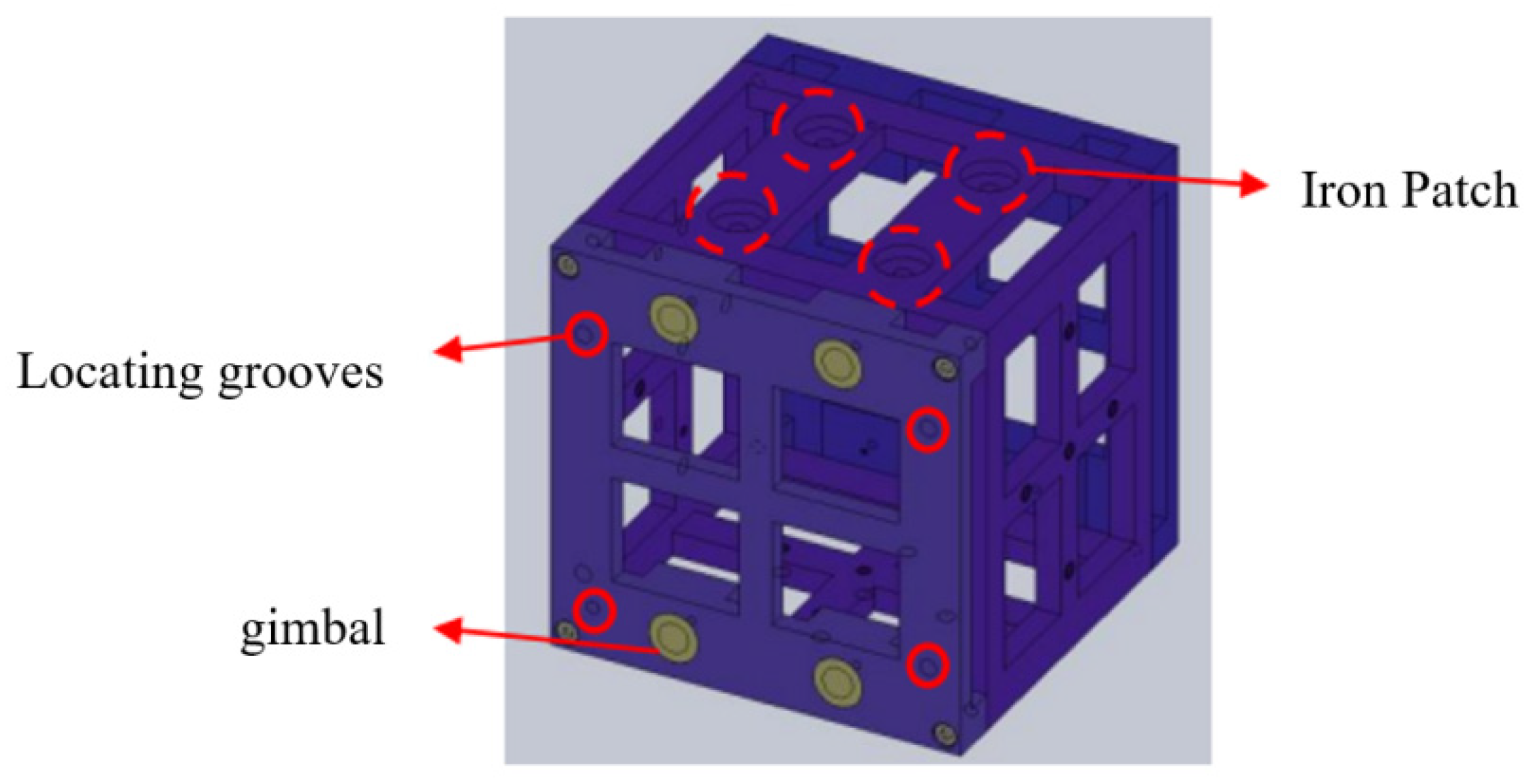

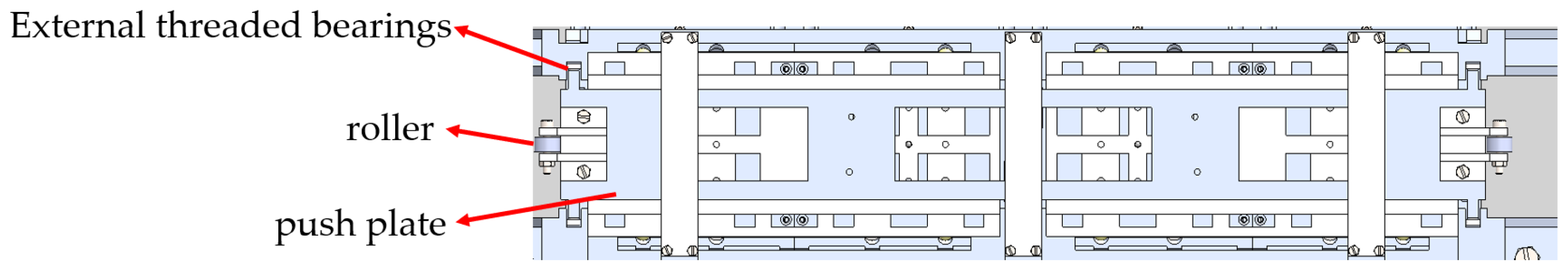

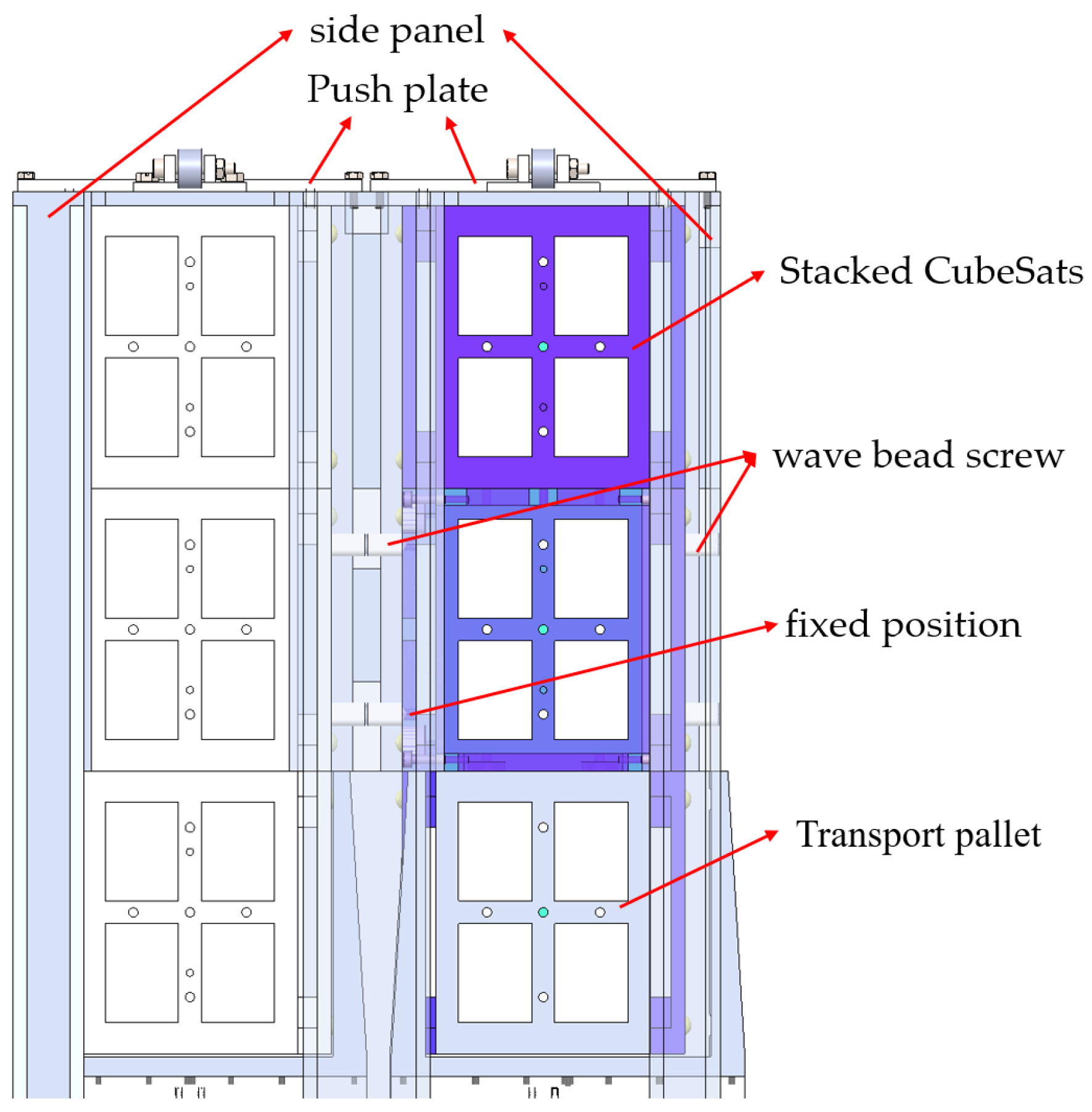

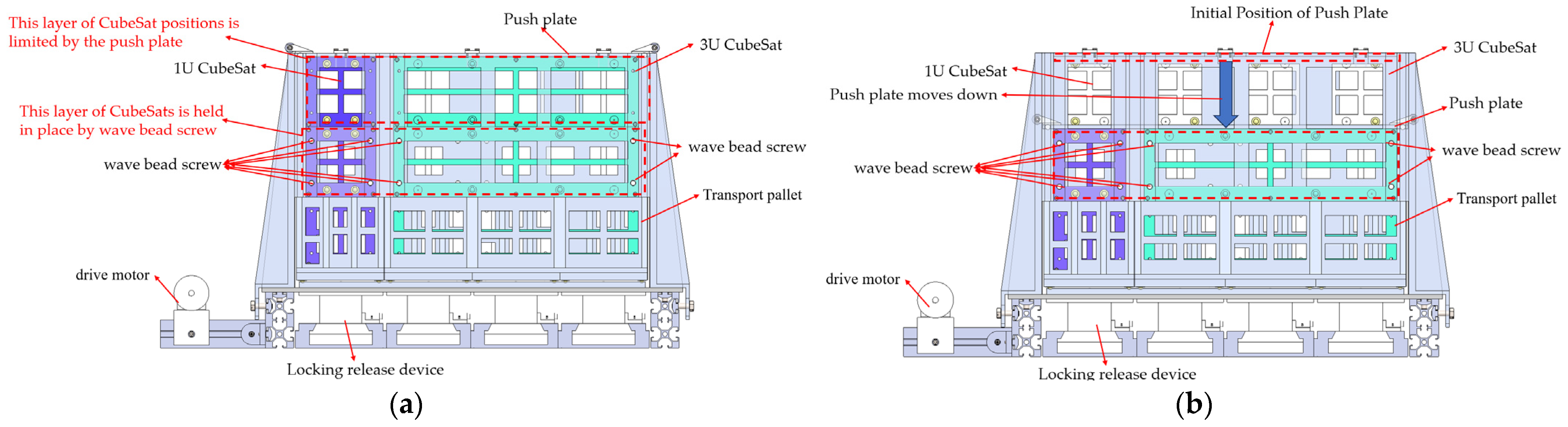

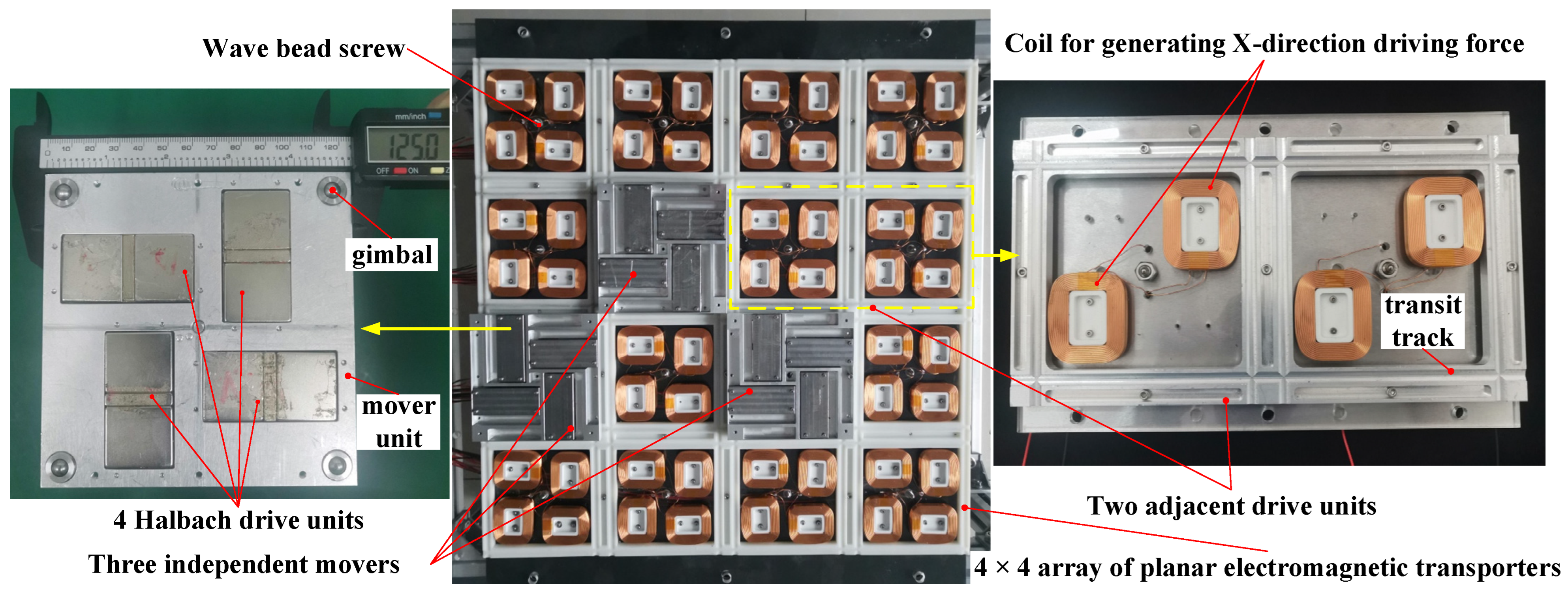

2.2. Transit Release Working Principle

- (1)

- In this paper, the volume of the 1U CubeSat is assumed to be 100 × 100 × 100 mm3, the volume of the 2U CubeSat is 200 × 100 × 100 mm3, and the volume of the 3U CubeSat is 300 × 100 × 100 mm3.

- (2)

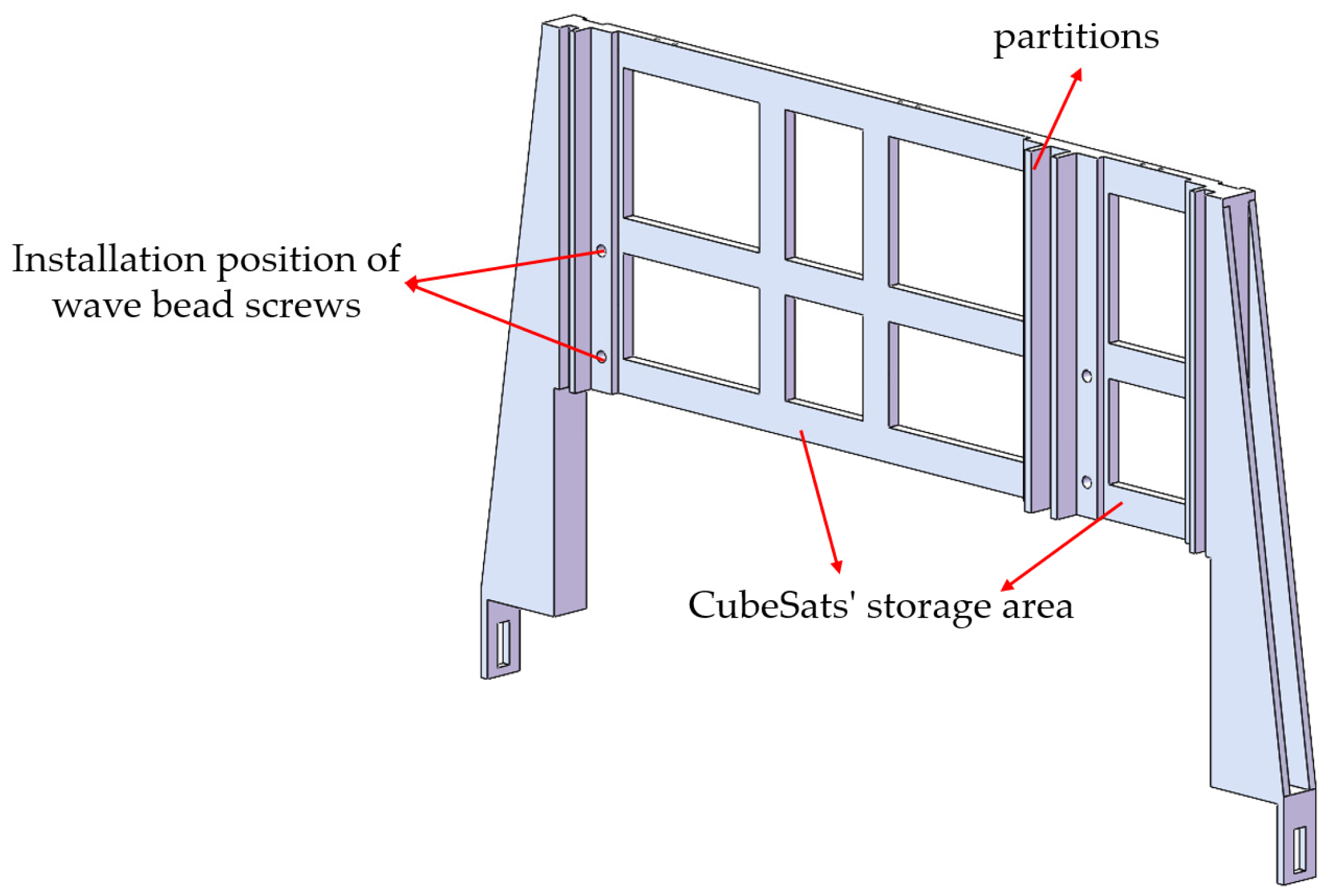

- The outer part of the wave bead screw features threads that connect to the storage device. Inside, there is a spring that interacts with the end of a steel ball, serving to position and lock it in place. This structure is illustrated in Figure 2.

- (3)

- The ideal state corresponds to the CubeSat’s storage and post-ejection condition under uniform force distribution, collision-free ejection processes, and smooth downward motion of the motor-driven pusher plate.

2.3. Principle of Storage Device

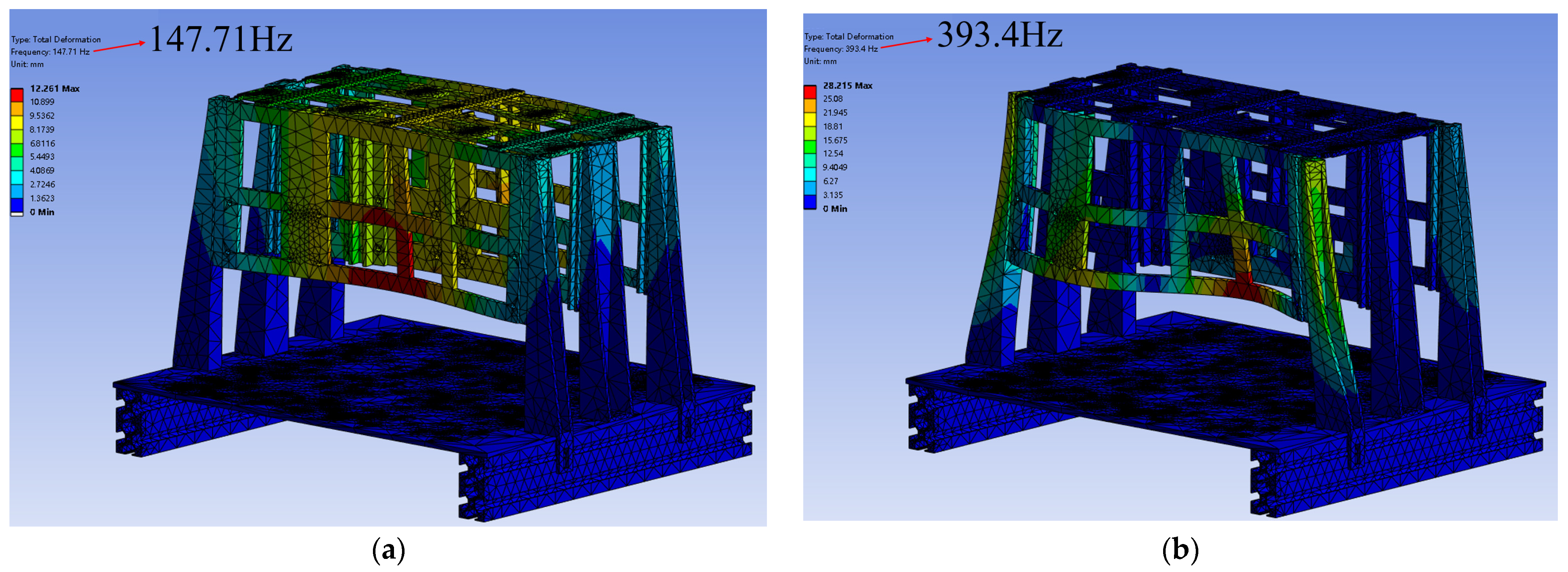

3. Modal Simulation of Devices and Thermal Simulation of Space Environment

3.1. Modal Simulation of Devices

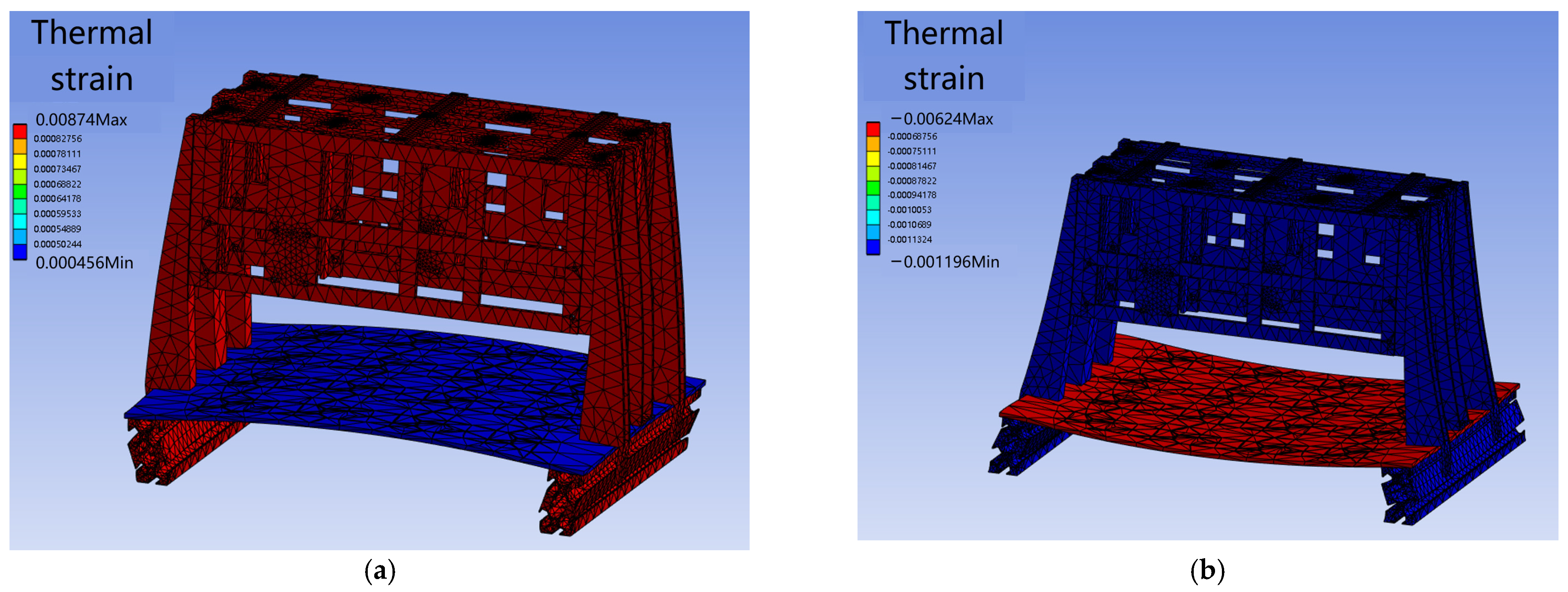

3.2. Thermal Simulation of Space Environment

4. Characteristics Analysis

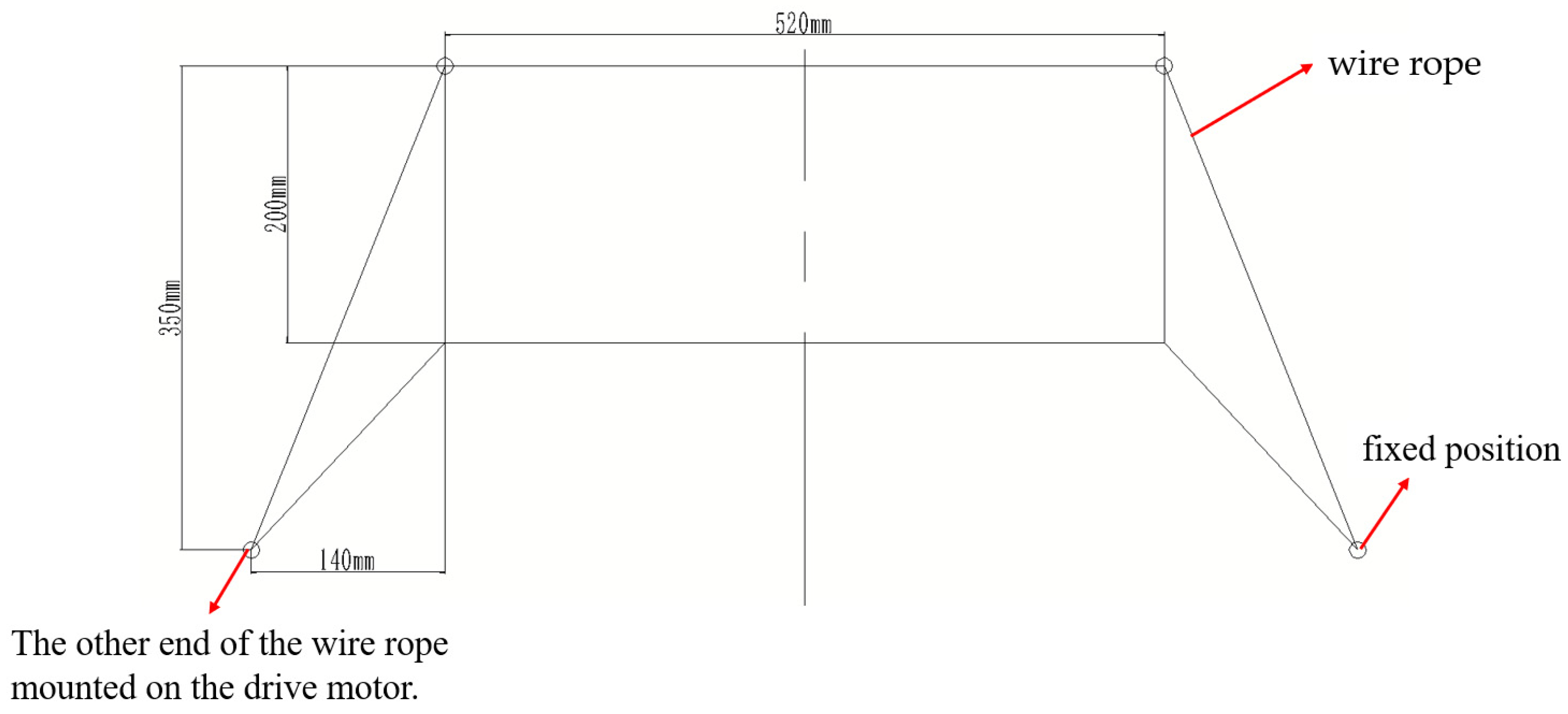

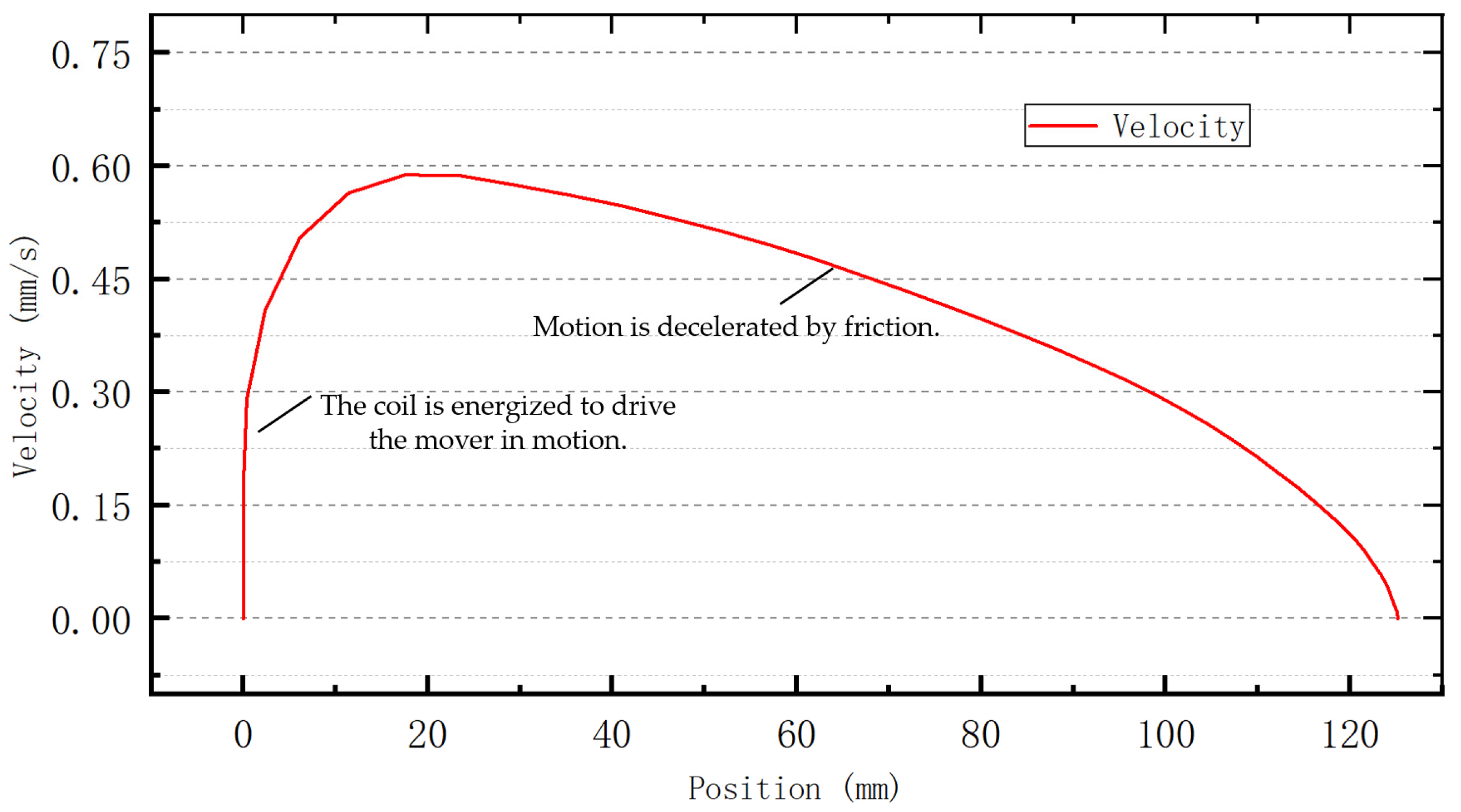

4.1. Push Motor Selection

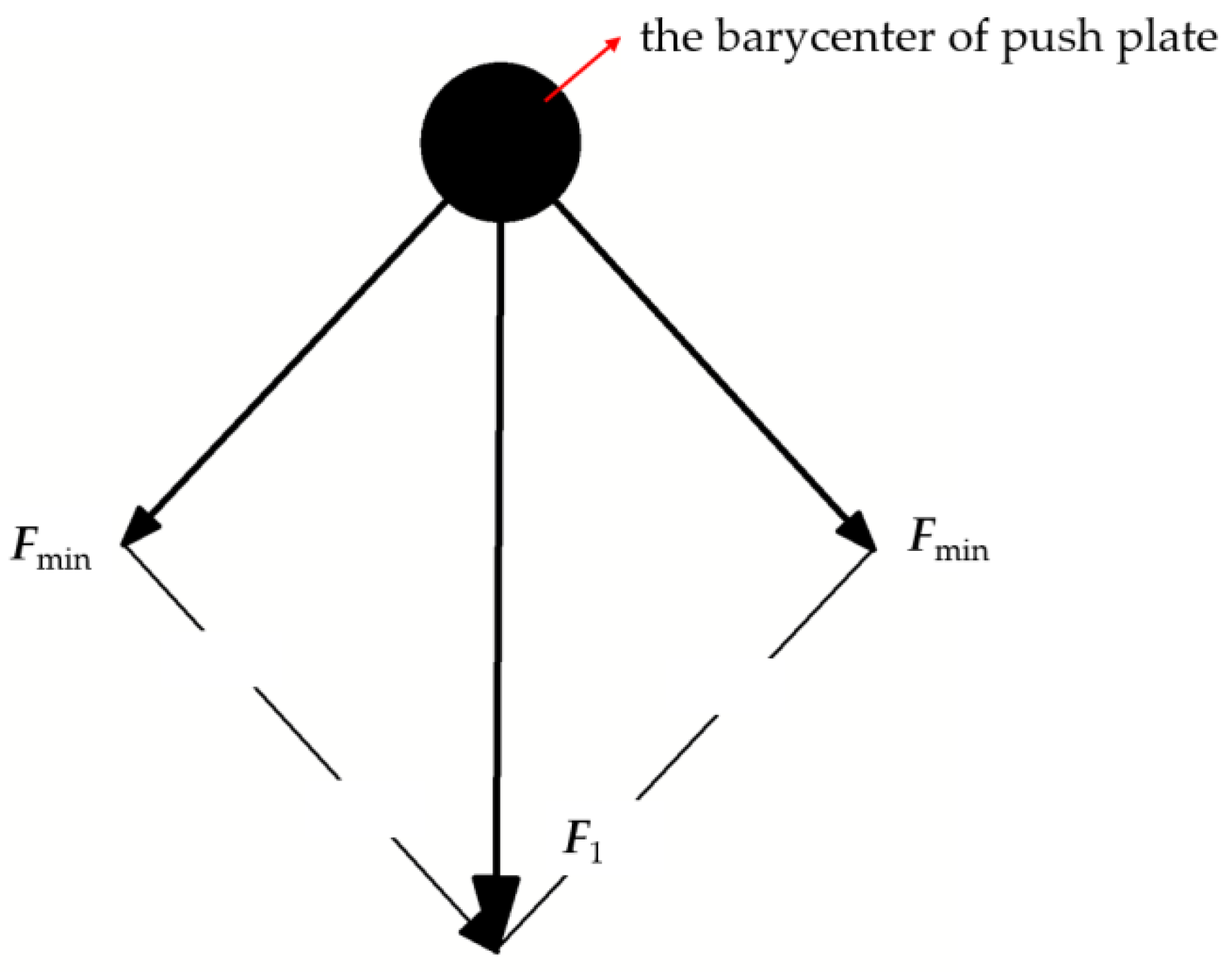

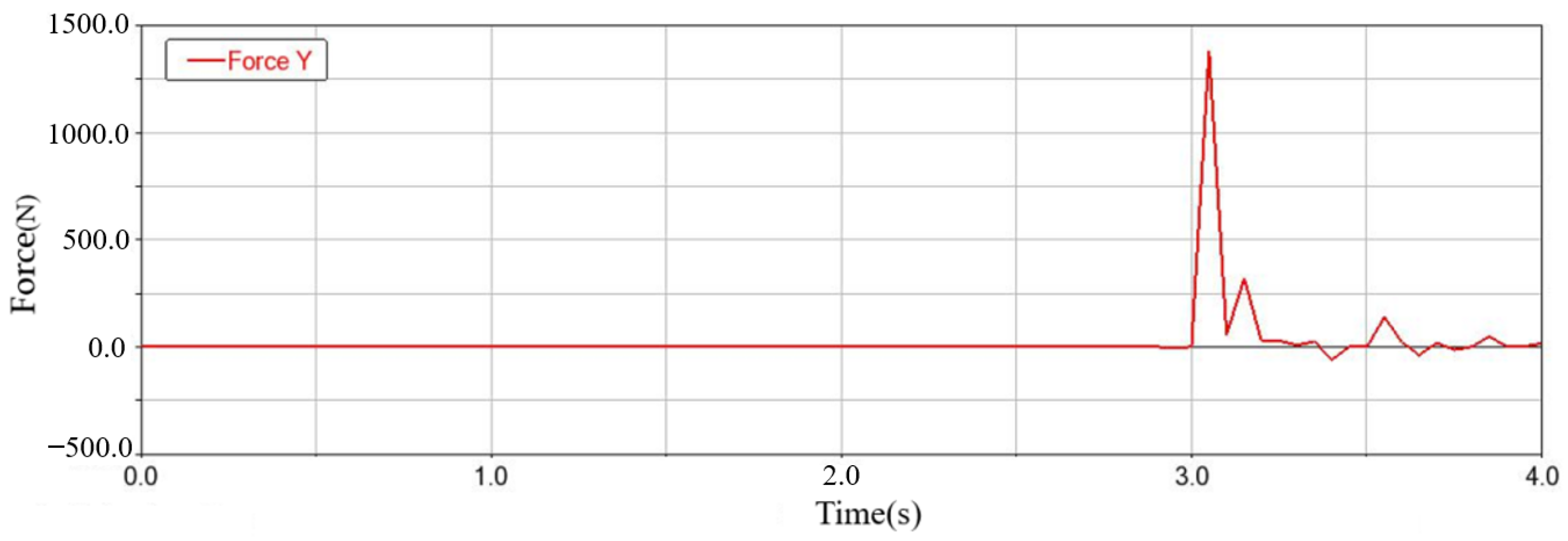

4.2. Analysis of Push Process Dynamics

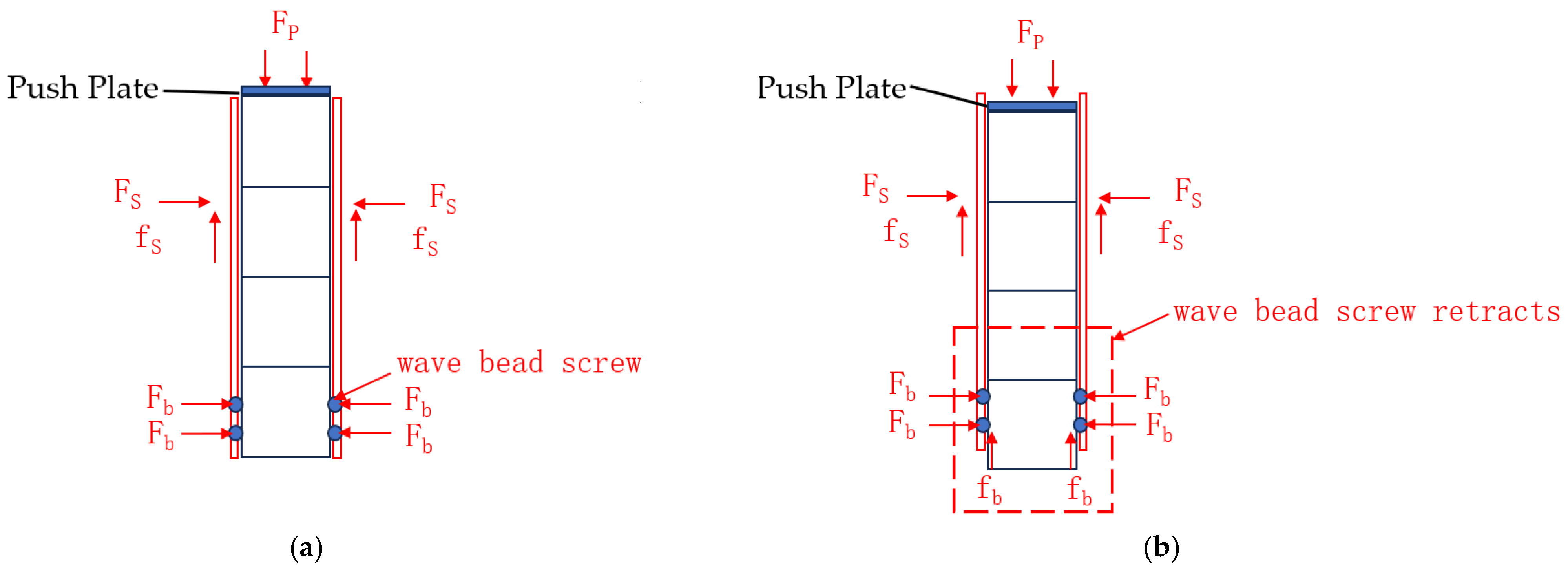

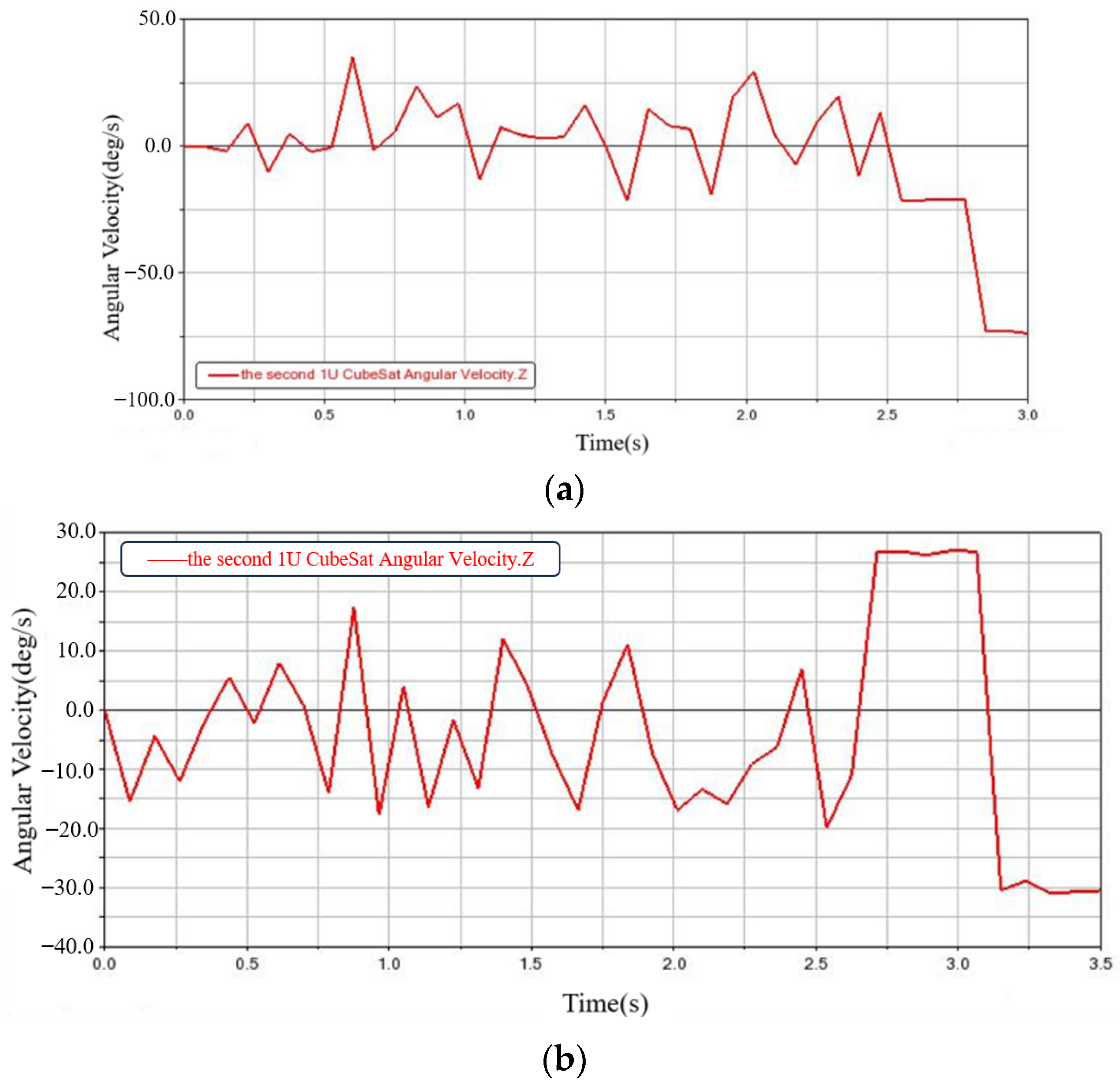

4.3. Influence of the Wave Bead Screw on the Push Attitude of a CubeSat

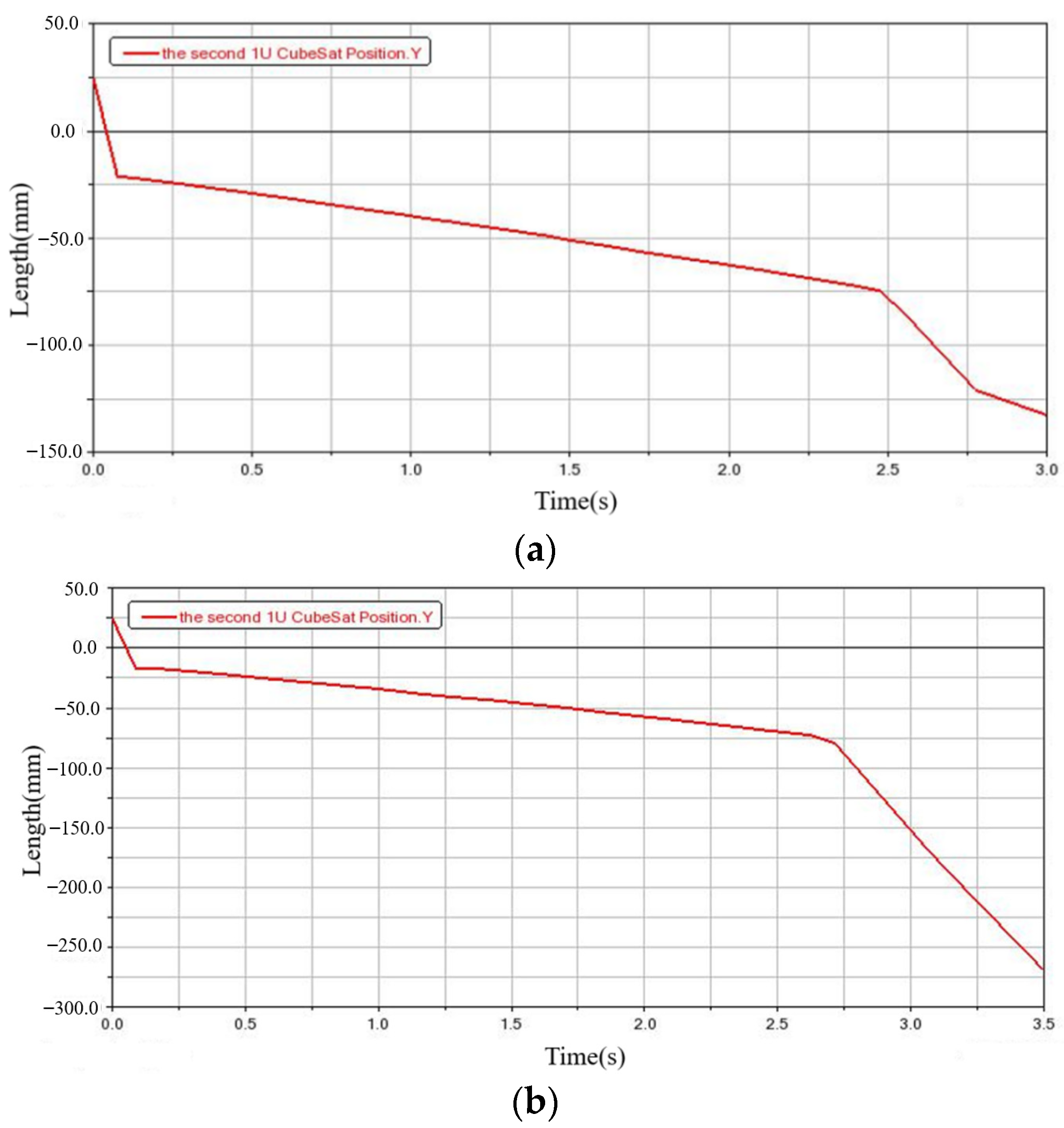

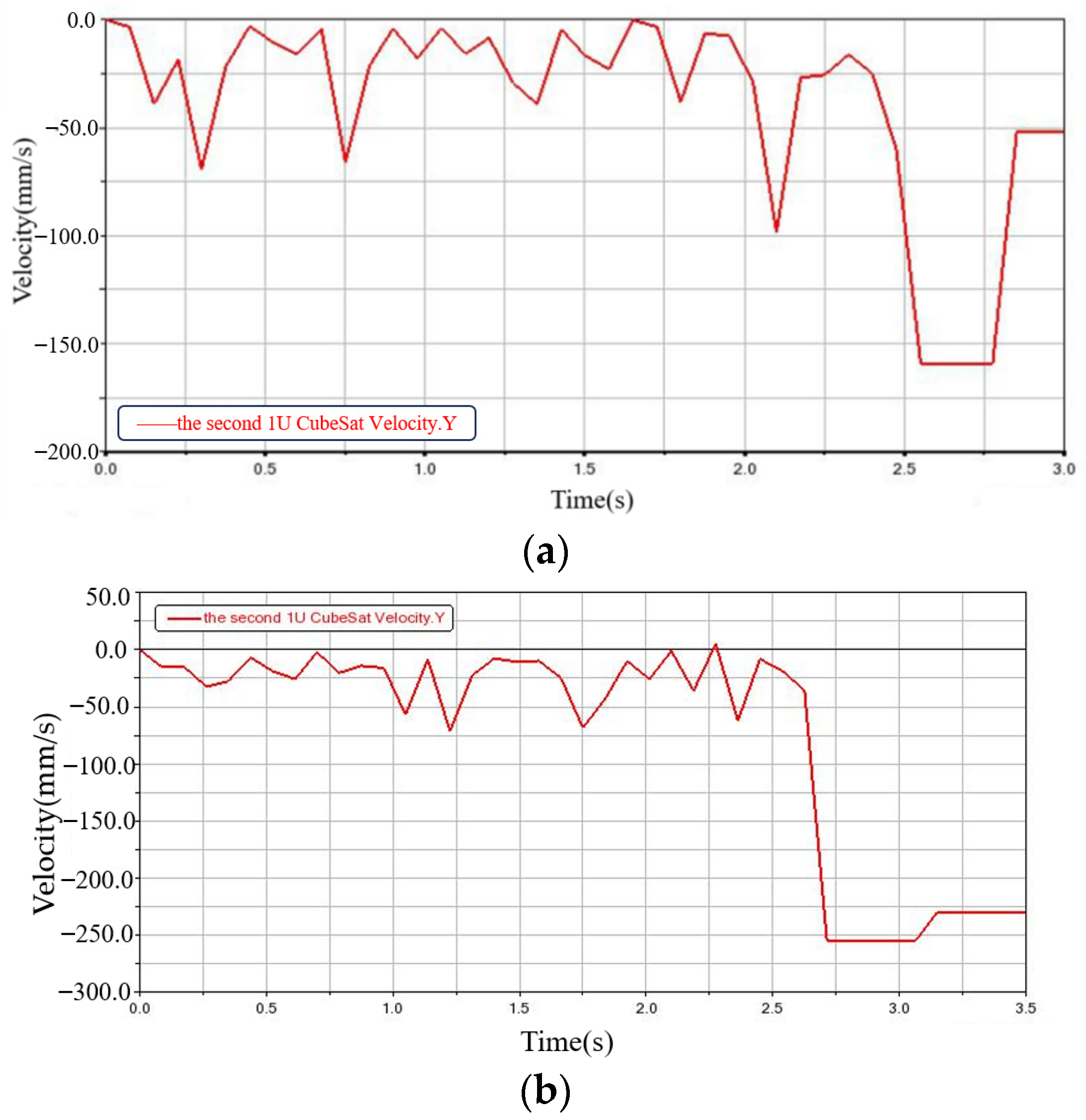

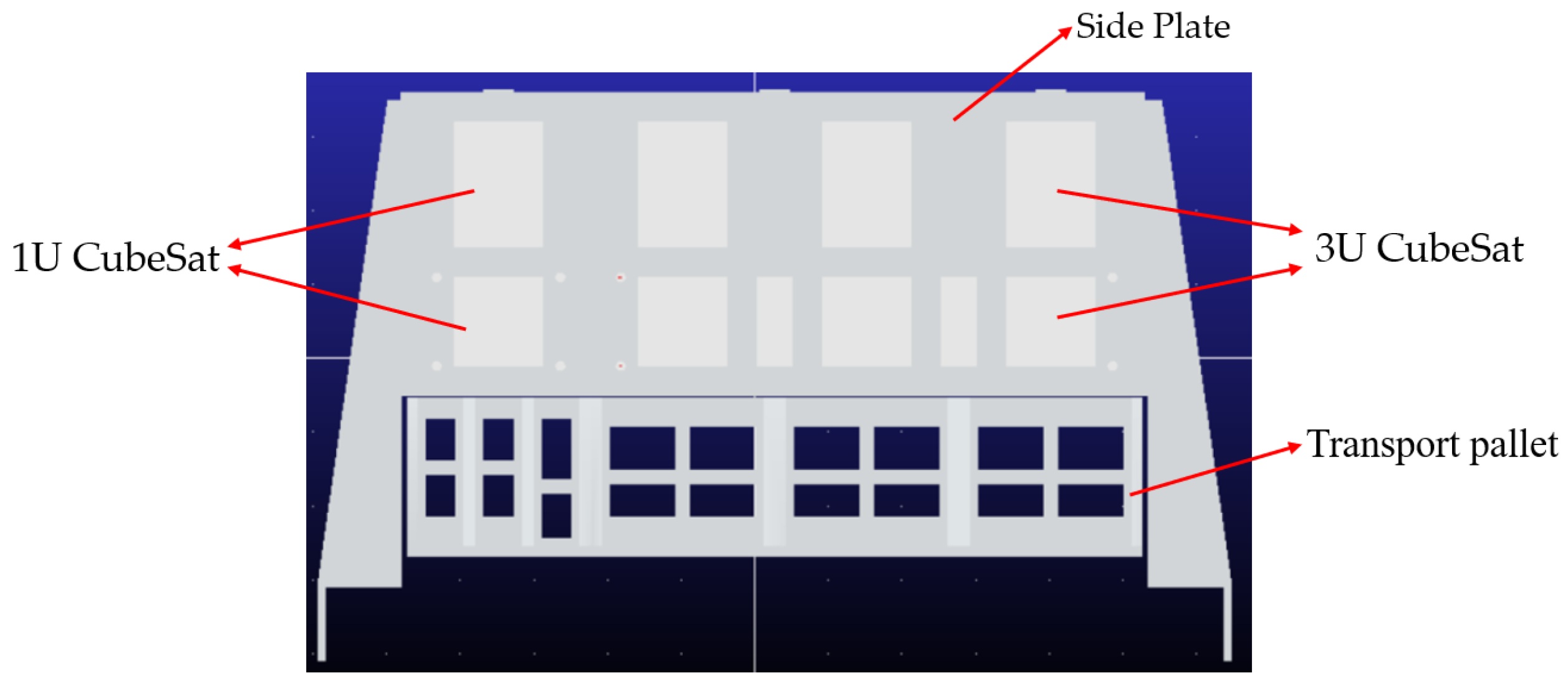

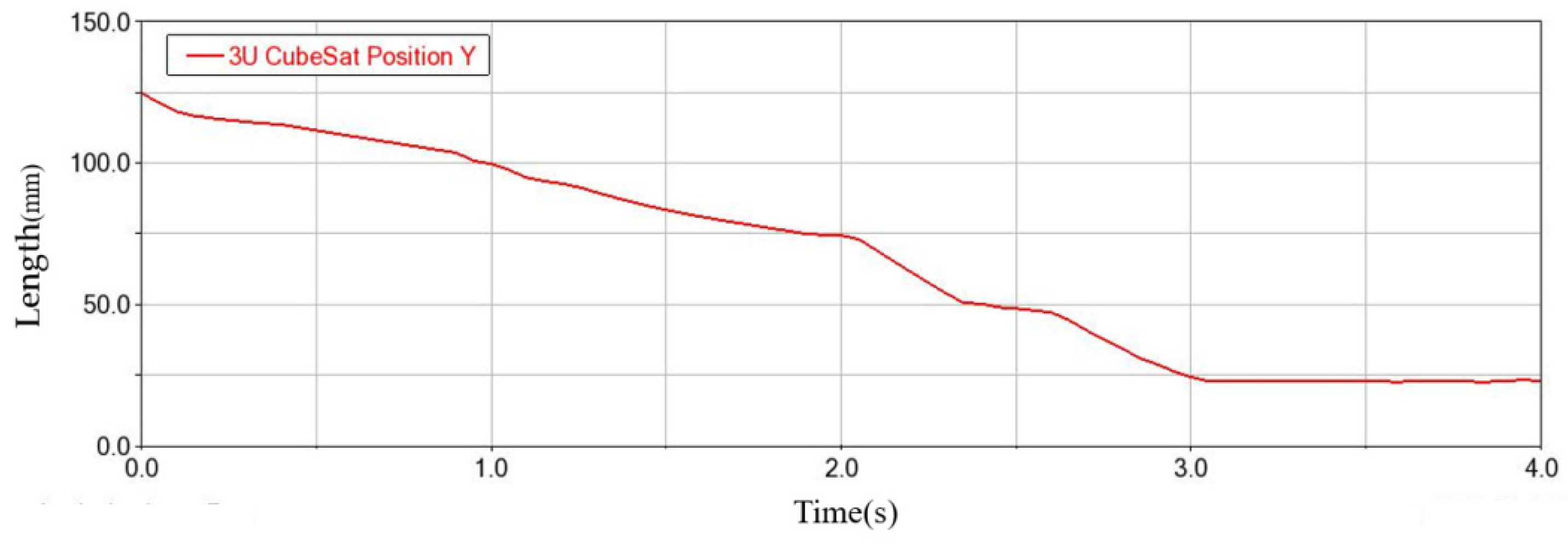

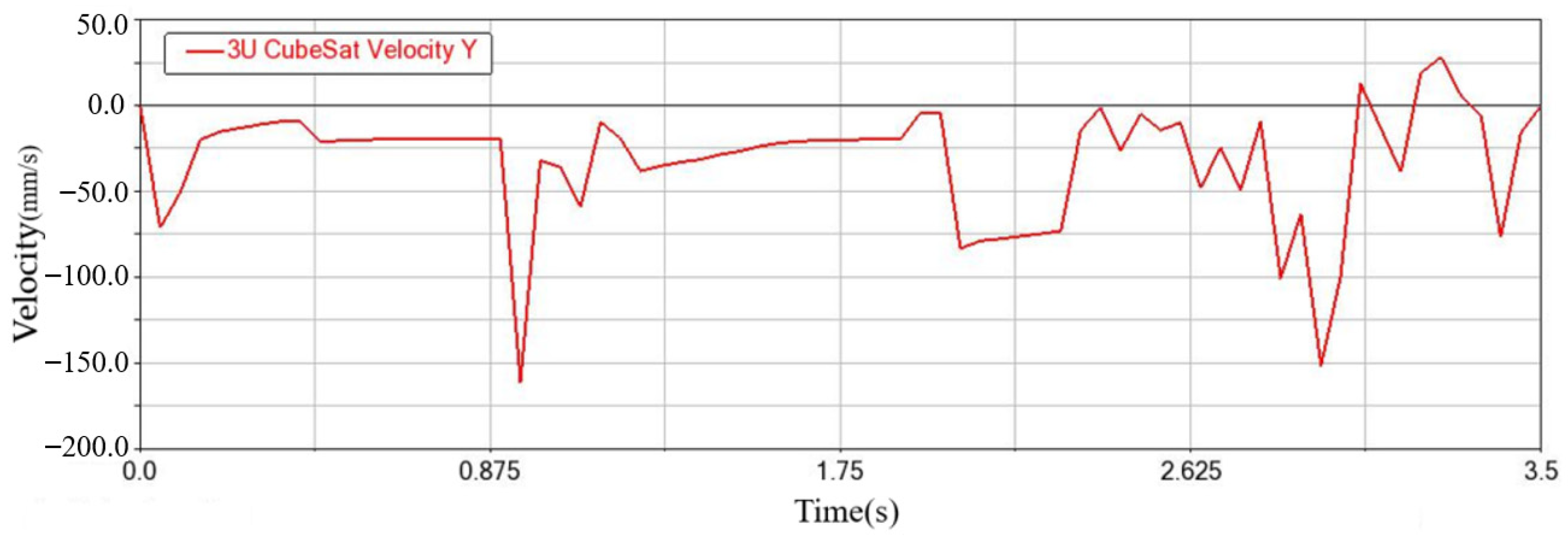

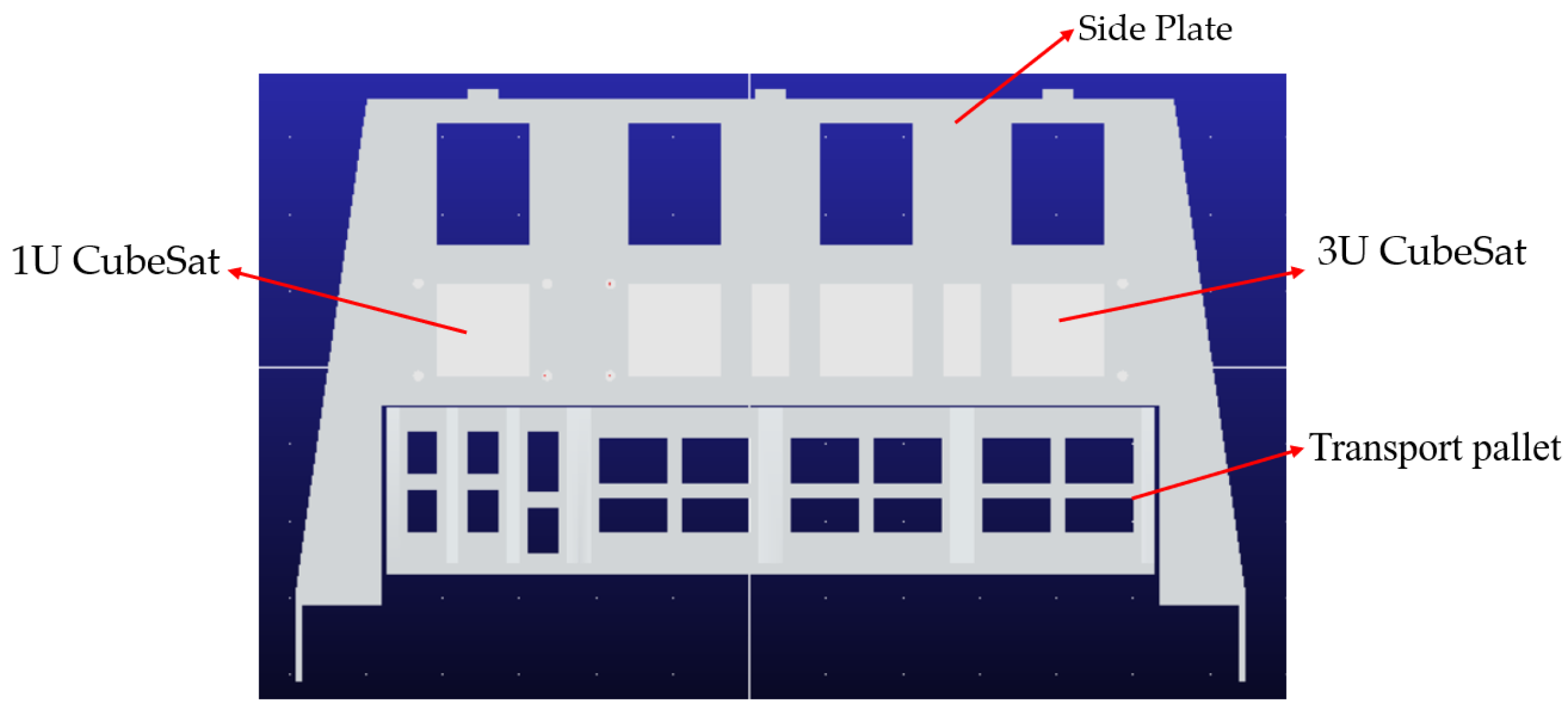

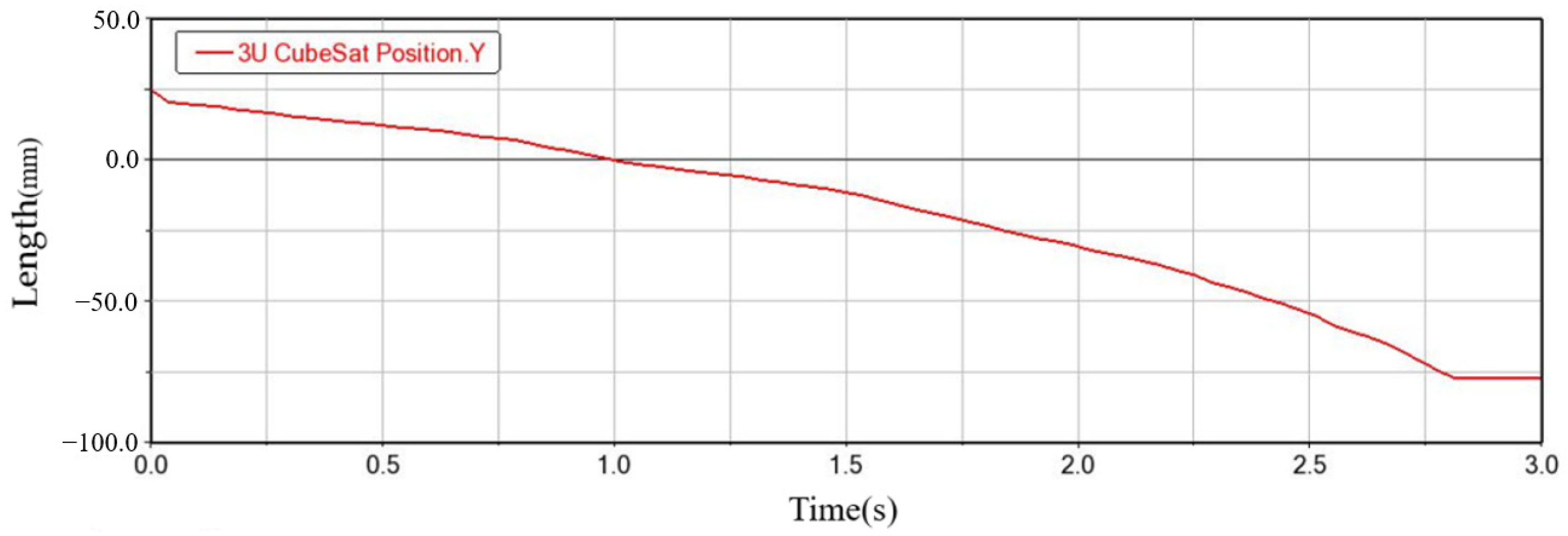

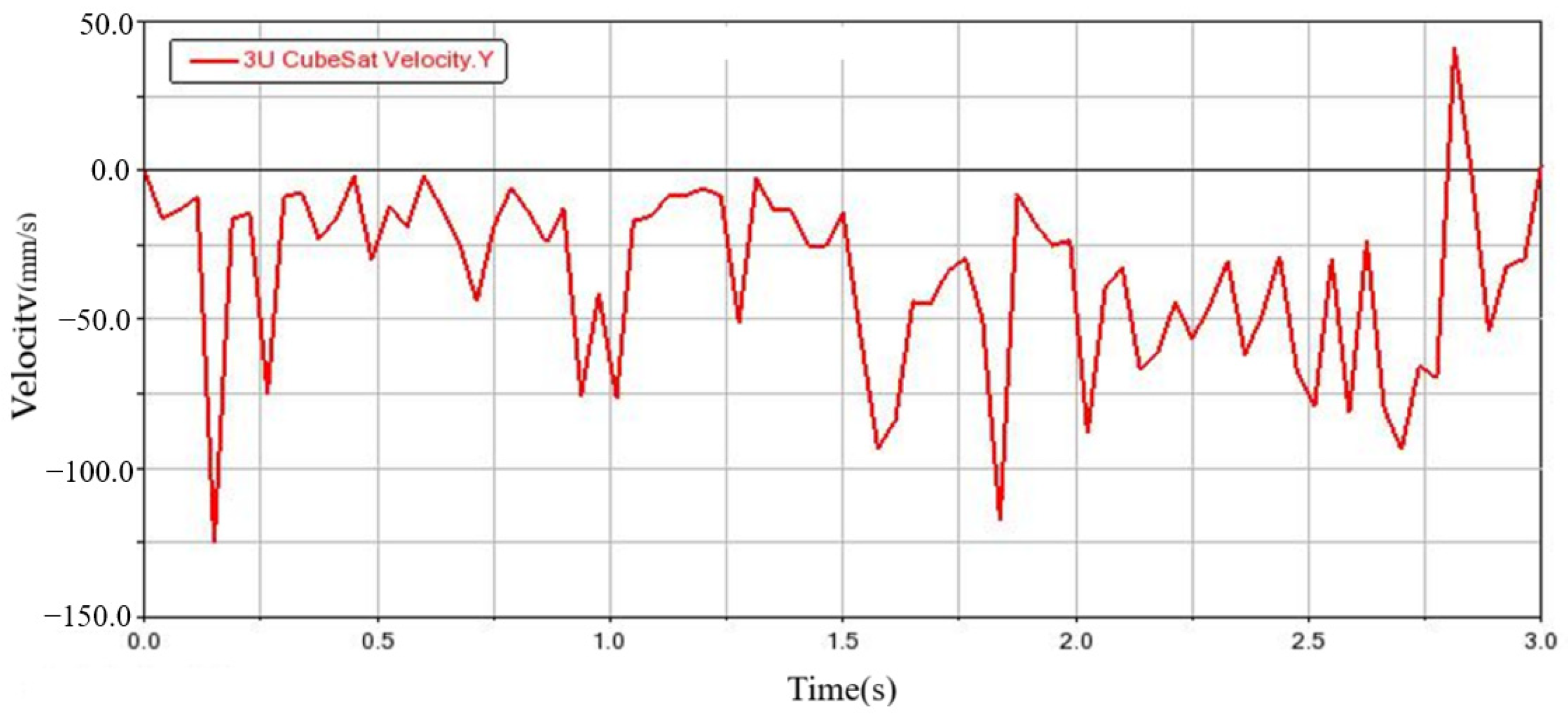

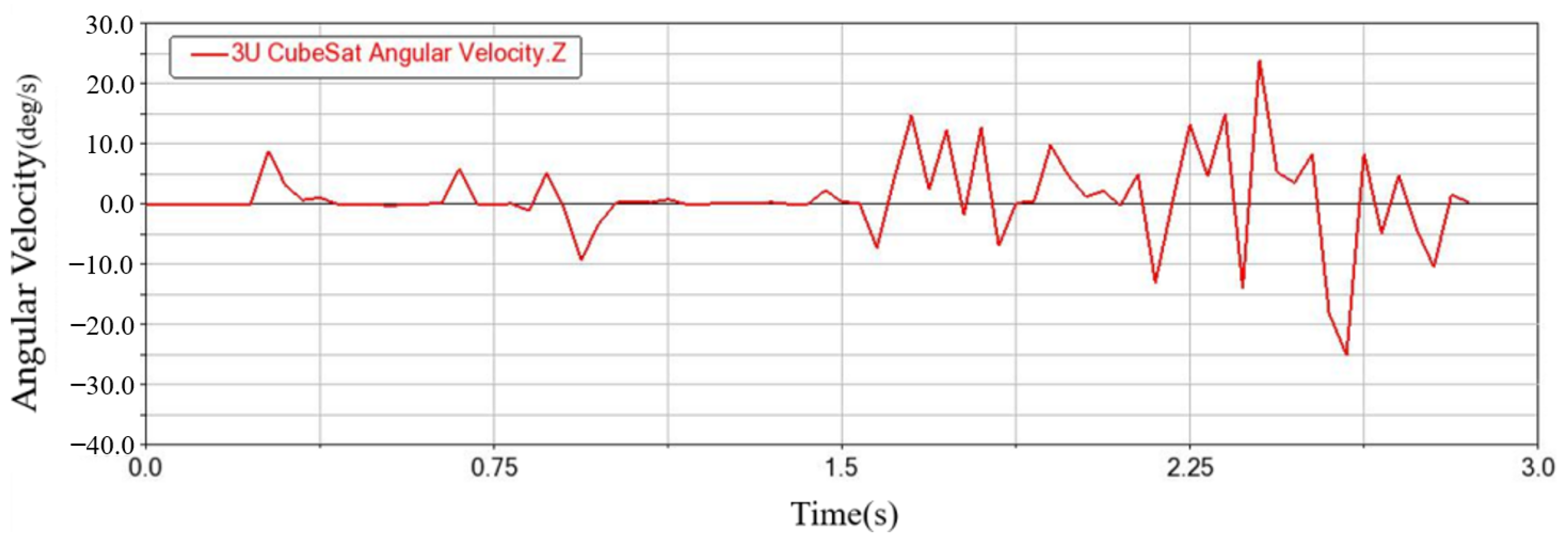

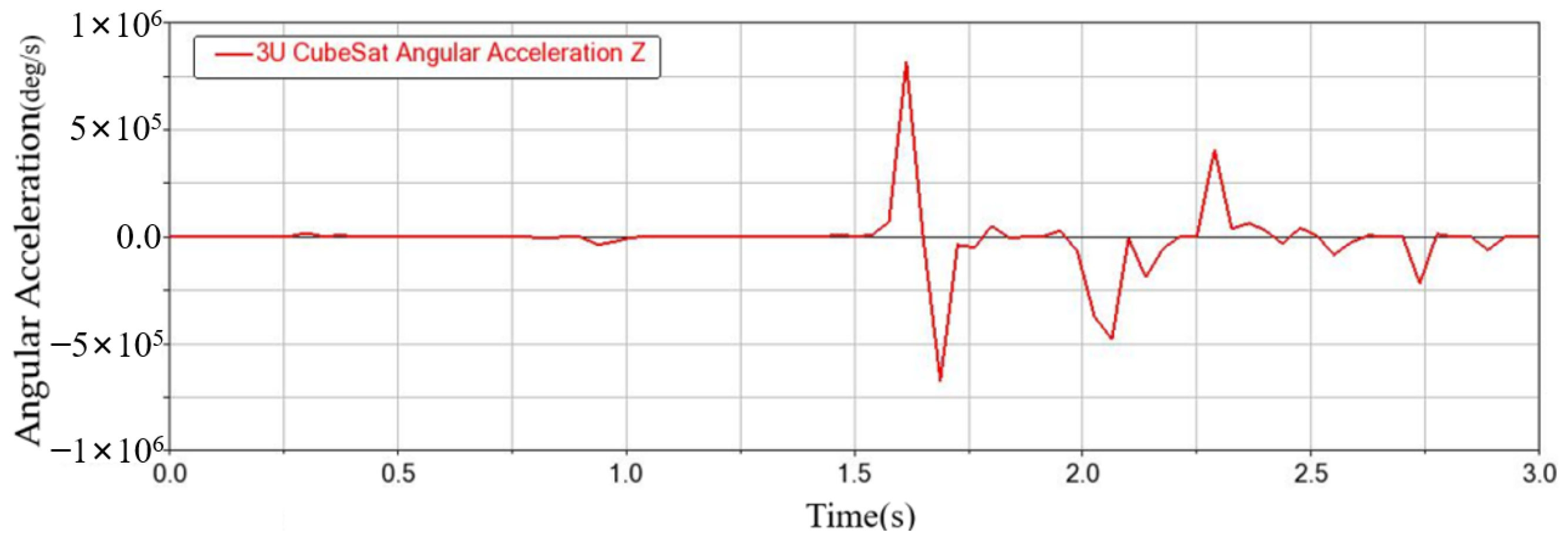

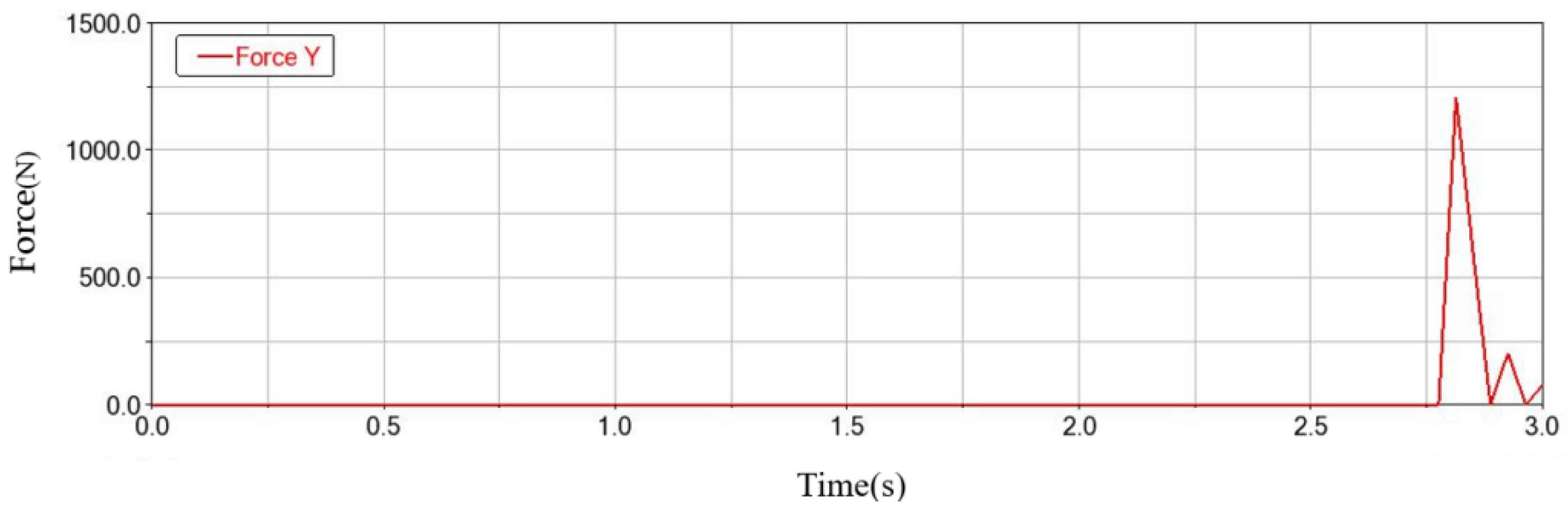

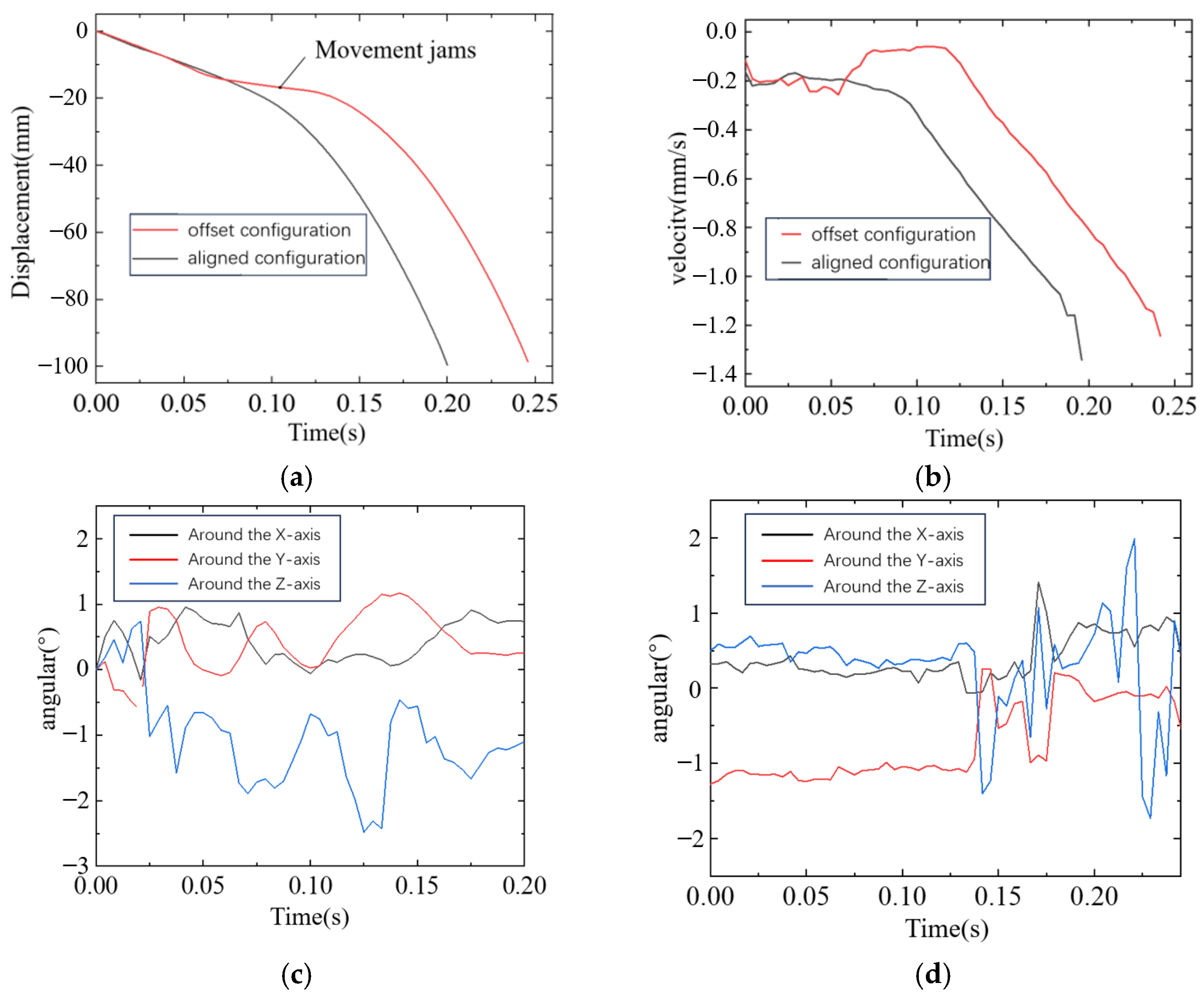

4.4. CubeSat Entry Transport Pallet Attitude Analysis

- A 1U configuration CubeSat is assumed to have a mass of 1.3 kg.

- A 2U configuration CubeSat is assumed to have a mass of 2.6 kg.

- A 3U configuration CubeSat has a mass of 4 kg.

- The static friction coefficient between the CubeSat and the transport pallet is set to 0.36.

- The dynamic friction coefficient is 0.3.

- All other parameters align with those specified in Table 2.

- The push force remains directed along the negative y-axis.

5. Experiment Investigation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bao, W.M.; Wang, X.W. Develop high reliable and low-cost technology of access to space, embrace new space economy era. China Aerosp. 2019, 20, 23–30. [Google Scholar]

- Kutter, B.F.; Sowers, G.F.; Cislunar, F. Transportation supporting a self-sustaining space economy. In Proceedings of the AIAA SPACE 2016, Long Beach, CA, USA, 13–16 September 2016. [Google Scholar]

- Lombardo, M.; Zannoni, M.; Gai, I.; Casajus, L.G.; Gramigna, E.; Manghi, R.L.; Tortora, P.; Di Tana, V.; Cotugno, B.; Simonetti, S.; et al. Design and analysis of the cis-lunar navigation for the Argo moon CubeSat mission. Aerospace 2022, 9, 659. [Google Scholar] [CrossRef]

- Bouwmeester, J.; Guo, J. Survey of worldwide pico- and nanosatellite missions, distributions and subsystem technology. Acta Astronaut 2010, 67, 854–862. [Google Scholar] [CrossRef]

- Poghosyan, A.; Golkar, A. CubeSat evolution: Analyzing CubeSat capabilities for conducting science missions. Prog. Aerosp. Sci. 2017, 1, 59–83. [Google Scholar] [CrossRef]

- Saeed, N.; Elzanaty, A.; Almorad, H.; Dahrouj, H.; Al-Naffouri, T.Y.; Alouini, M.-S. CubeSat communications: Recent advances and future challenges. IEEE Commun. Surv. Tutor. 2020, 22, 1839–1862. [Google Scholar] [CrossRef]

- Toorian, A.; Diaz, K.; Lee, S. The CubeSat approach to space access. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2008; Volume 5, pp. 1–14. [Google Scholar]

- Nason, I.; Puig-Suari, J.; Twiggs, R. Development of a family of picosatellite deployers based on the CubeSat standard. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 9–16 March 2002; p. 1. [Google Scholar]

- Dobrowolski, M.; Grygorczuk, J.; Kedziora, B.; Tokarz, M.; Borys, M. Dragon—8u nanosatellite orbital deployer. In Proceedings of the 42nd Aerospace Mechanisms Symposium, Baltimore, MD, USA, 14–16 May 2014; pp. 1–10. [Google Scholar]

- Johnson, M.D. Satellite Deployer System i.e., CubeSat Deployer for Use in the Field of Space Transportation, Has Ejector Mechanism That Pushes or Pulls Satellite Out of Receptacle, Where Satellite Is Deployed from Launch Vehicle by Ejector Mechanism After Releasable Mechanism Is Released. US2023348116-A1, 2 November 2023. [Google Scholar]

- Mohamed, R. Design and Implementation of Ground Support Equipment for Characterizing Performance of XPOD and CNAPS & Thermal Analysis of CNAPS Pressure Regulator Valve. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2009. [Google Scholar]

- Pranajaya, F.M.; Zee, R.E. The generic nanosatellite bus: From space astronomy to formation flying demo to responsive space. In Proceedings of the International Conference on Advances in Satellite and Space Communications, Siena-Tuscany, Italy, 10–11 September 2009; pp. 134–140. [Google Scholar]

- Wu, H.; Wang, D.; Zhang, X.; Zhao, C.; Wang, D. Development and inspiration of the Dutch space innovation solutions company. Space Ind. Manag. 2018, 408, 52–56. (In Chinese) [Google Scholar]

- Xie, C. Research on Design Analysis Method and Key Technology of Star-Arrow Separation Mechanism of Picosatellite. Doctoral Dissertation, Zhejiang University, Hangzhou, China, 2014. (In Chinese). [Google Scholar]

- Launch Services for Small Satellites and CubeSats. Available online: https://www.exolaunch.com/ (accessed on 5 May 2025).

- Zhao, Y.; Yue, H.; Yang, F.; Zhu, J. A High Thrust Density Voice Coil Actuator With a New Structure of Double Magnetic Circuits for CubeSat Deployers. IEEE Trans. Ind. Electron 2022, 69, 13305–13315. [Google Scholar] [CrossRef]

- Zhao, Y.; Yue, H.; Zhu, J.G.; Yang, F. Armature Reaction Analysis and Suppression of Voice Coil Actuator Based on an Improved Magnetic Equivalent Circuit Model. IEEE Trans. Ind. Electron. 2024, 71, 7599–7609. [Google Scholar] [CrossRef]

- Gue, K.R. Very high density storage systems. IIE Trans. 2006, 38, 79–90. [Google Scholar] [CrossRef]

- SpaceX. Starlink Multi-Satellite Separation System. Available online: https://www.starlink.com/ (accessed on 20 January 2025).

- Zhao, Y.; Yue, H.; Zhu, J.G.; Yang, X.Z. A Planar Electromagnetic Actuator With Passive Adsorption for CubeSats Transport in a Weightless Environment. IEEE Trans. Ind. Electron. 2023, 70, 10396–10407. [Google Scholar] [CrossRef]

- Li, F.; Niu, D.; Li, T.; Xue, Y.; Huang, X. Research and design of cloud monitoring and management system for intelligent stereo garage. J. Eng. 2019, 22, 8335–8338. [Google Scholar] [CrossRef]

- Brezovnik, S.; Gotlih, J.; Balič, J.; Gotlih, K.; Brezočnik, M. Optimization of an automated storage and retrieval systems by swarm intelligence. Procedia Eng. 2015, 100, 1309–1318. [Google Scholar] [CrossRef]

- Nils, B.; Konrad, S. A survey on single crane scheduling in automated storage/retrieval systems. Eur. J. Oper. Res. 2016, 254, 691–704. [Google Scholar]

- Carlo, H.J.; Iris, F.A.; Vis, B. Sequencing dynamic storage systems with multiple lifts and shuttles. Int. J. Prod. Econ. 2012, 140, 844–853. [Google Scholar] [CrossRef]

- Ekren, B.Y.; Heragu, S.S. Simulation based performance analysis of an autonomous vehicle storage and retrieval system. Simul. Model. Pract. Theory 2011, 19, 1640–1650. [Google Scholar] [CrossRef]

- Kallo, N.; Koltai, T. Increasing customer satisfaction in queuing systems with rapid modelling. In Rapid Modelling and Quick Response; Springer Nature: London, UK, 2010; pp. 119–130. [Google Scholar]

- Zielinski, A.E.; Delguercio, M.A. Analytical study of the injection of a moving projetile into a railgun. IEEE Trans. Plasma Sci. 2011, 39, 235–240. [Google Scholar] [CrossRef]

- Bai, T.; Kong, L.; Huang, J.; Jiang, F.; Zhang, L. Thermal design and verification of micro remote-sensing satellite in low inclination orbit. Opt. Precis. Eng. 2020, 28, 2497–2506. (In Chinese) [Google Scholar] [CrossRef]

| Performance | Deployment Speed | Satellite Capacity | Modularity | Autonomy | Volume Efficiency | |

|---|---|---|---|---|---|---|

| Name | ||||||

| P-POD | The third generation P-POD has a hatch unlock time of 45 ms Very quickly | 3U | Low level of modularity and poor expandability | Auto-releasable, higher | Single capsule to hold a single CubeSat, less volumetrically efficient | |

| Dragon | CubeSat separation speed is about 1.5 m/s. Very quickly | 200 mm × 200 mm × 200 mm | Low level of modularity and poor expandability | Auto-releasable, higher | Single capsule to hold a single CubeSat, less volumetrically efficient | |

| XPOD | Very quickly | 100 mm × 100 mm × 100 mm 100 mm × 100 mm × 300 mm 200 mm × 200 mm × 200 mm 200 mm × 200 mm × 400 mm | Low level of modularity and poor expandability | Auto-releasable, higher | Single capsule to hold a single CubeSat, less volumetrically efficient | |

| SPL | CubeSat separation speed is about 1.4 m/s. Very quickly | 1U, 2U, 3U, and 12U | Low level of modularity and poor expandability | Auto-releasable, higher | Single capsule to hold a single CubeSat, less volumetrically efficient | |

| RAFT | Separation speeds of 2.6 m/s and 1.2 m/s, respectively. Very quickly | Two 1U CubeSats | Low level of modularity and poor expandability | Auto-releasable, higher | Single capsule to hold a single CubeSat, less volumetrically efficient | |

| Exopod | Deployment velocities are calculated based on the physical properties of the mechanical springs. 1U CubeSats can be released at speeds of up to 2 m/s Very quickly | Maximum capacity 16U | Low level of modularity and poor expandability | Auto-releasable, higher | Single capsule to hold a single CubeSat, less volumetrically efficient | |

| Starlink | Slowly | Suitable for customized satellites | Rockets on board, satellites folded and stacked | Auto-releasable, higher | High storage volume efficiency | |

| The Mengtian Experiment Module | Release speed not less than 1 m/s | Micro-nano-satellites with dimensions less than 1000 mm × 500 mm × 700 mm and a mass of 10 kg–200 kg. | Low level of modularity and poor expandability | Requires astronaut collaboration, lower | Separate storage in a warehouse, requiring larger storage space | |

| Our device | Quickly | 1U–3U, maximum capacity 24U | CubeSat zoned stacked storage with high expandability | Auto-releasable, higher | High storage volume efficiency | |

| First-Order Formation | Second-Order Formation | Third-Order Formation | Fourth-Order Formation | Five-Step Formation | Sixth-Order Formation | |

|---|---|---|---|---|---|---|

| Frequency (Hz) | 147.71 | 168.32 | 269.17 | 305.45 | 353.4 | 393.4 |

| Parameter Name | Parameter Value |

|---|---|

| Input voltage | 24 V |

| Rated speed | 80 rpm |

| Maximum no-load speed | 98 rpm |

| No-load current | 0.26 A |

| Rated torque | 14 kgf⋅cm |

| Extreme load torque | 50 kgf⋅cm |

| Parameter Name | Set Point |

|---|---|

| Contact force index, n | 1.4 |

| Normal embedding depth, δ | 0.1 mm |

| Bead screw spring stiffness factor, K | 6.25 N/mm |

| Coefficient of static friction between CubeSat and pusher plate and frame | 0.36 |

| Coefficient of dynamic friction between CubeSat and push plate and frame | 0.3 |

| Coefficient of static friction between two CubeSats | 1.4 |

| Coefficient of dynamic friction between two CubeSats | 1.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhang, Y.; Zhao, Z.; Li, C.; Zhang, L.; Yang, X.; Yue, H.; He, C.; Zhu, J.; Halishi, Y.e.; et al. Simulation Analysis and Experimental Verification of the Transport Characteristics of a High-Volume CubeSat Storage Device. Aerospace 2025, 12, 466. https://doi.org/10.3390/aerospace12060466

Zhao Y, Zhang Y, Zhao Z, Li C, Zhang L, Yang X, Yue H, He C, Zhu J, Halishi Ye, et al. Simulation Analysis and Experimental Verification of the Transport Characteristics of a High-Volume CubeSat Storage Device. Aerospace. 2025; 12(6):466. https://doi.org/10.3390/aerospace12060466

Chicago/Turabian StyleZhao, Yong, Yuhao Zhang, Zeming Zhao, Chenyuan Li, Lili Zhang, Xiaoze Yang, Honghao Yue, Caiting He, Jianlei Zhu, Ye erken Halishi, and et al. 2025. "Simulation Analysis and Experimental Verification of the Transport Characteristics of a High-Volume CubeSat Storage Device" Aerospace 12, no. 6: 466. https://doi.org/10.3390/aerospace12060466

APA StyleZhao, Y., Zhang, Y., Zhao, Z., Li, C., Zhang, L., Yang, X., Yue, H., He, C., Zhu, J., Halishi, Y. e., Wu, Y., Xing, G., & Kezierbieke, M. (2025). Simulation Analysis and Experimental Verification of the Transport Characteristics of a High-Volume CubeSat Storage Device. Aerospace, 12(6), 466. https://doi.org/10.3390/aerospace12060466