A Method for the Life Assessment of Aero-Engine Turbine Disks Based on a Time-Varying Load Spectrum

Abstract

1. Introduction

2. Methodology

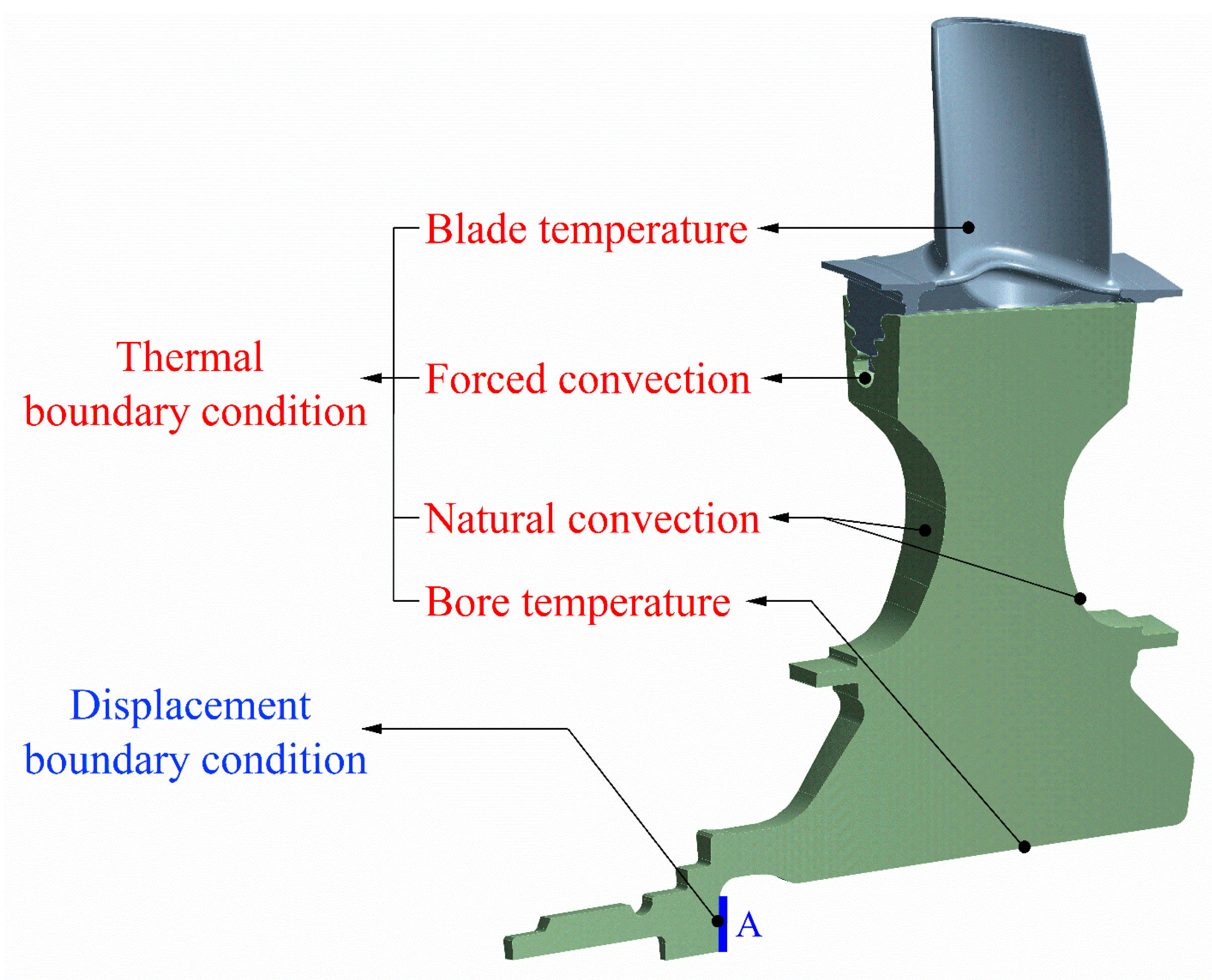

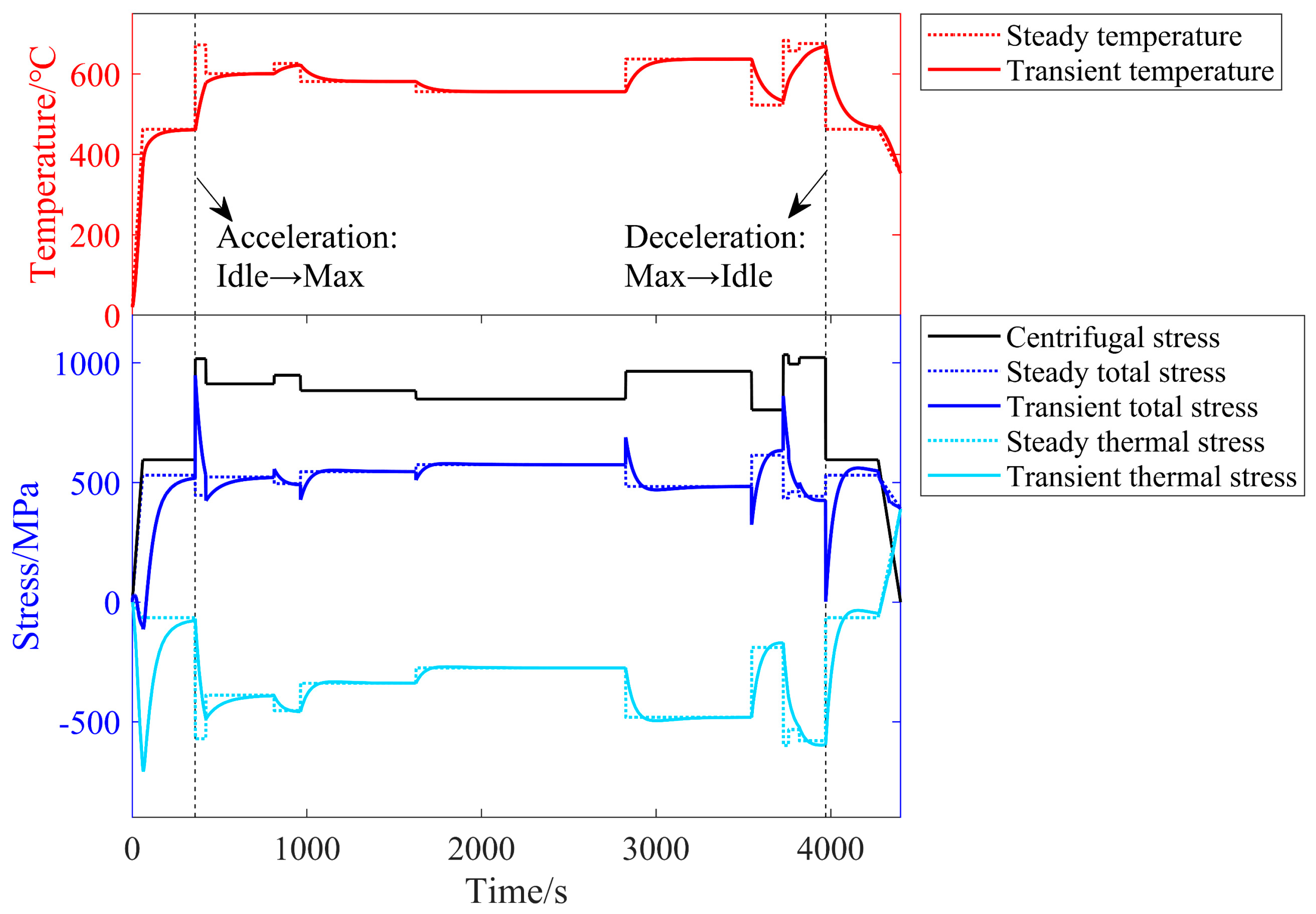

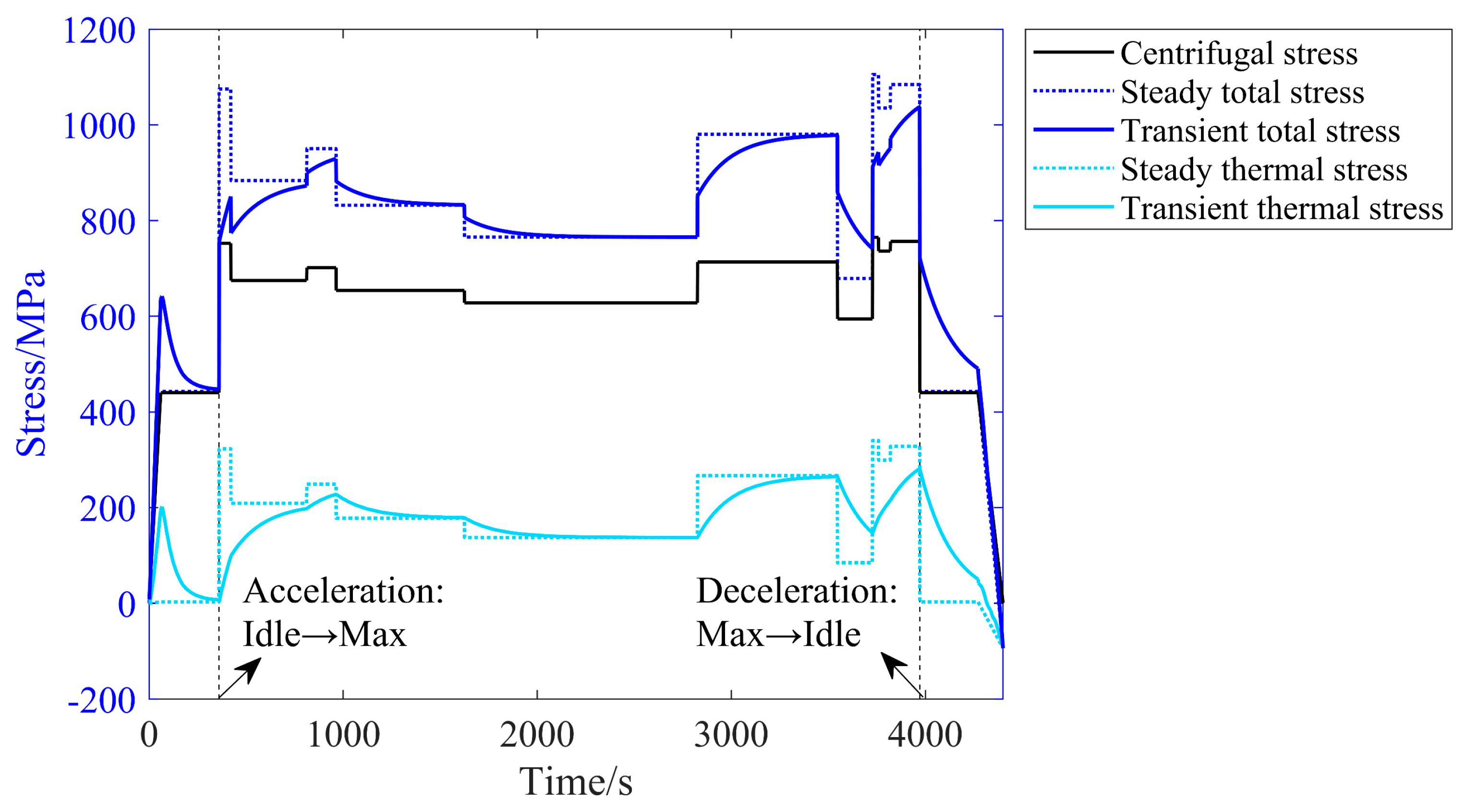

2.1. Surrogate Model for Transient Processes in Turbine Disks

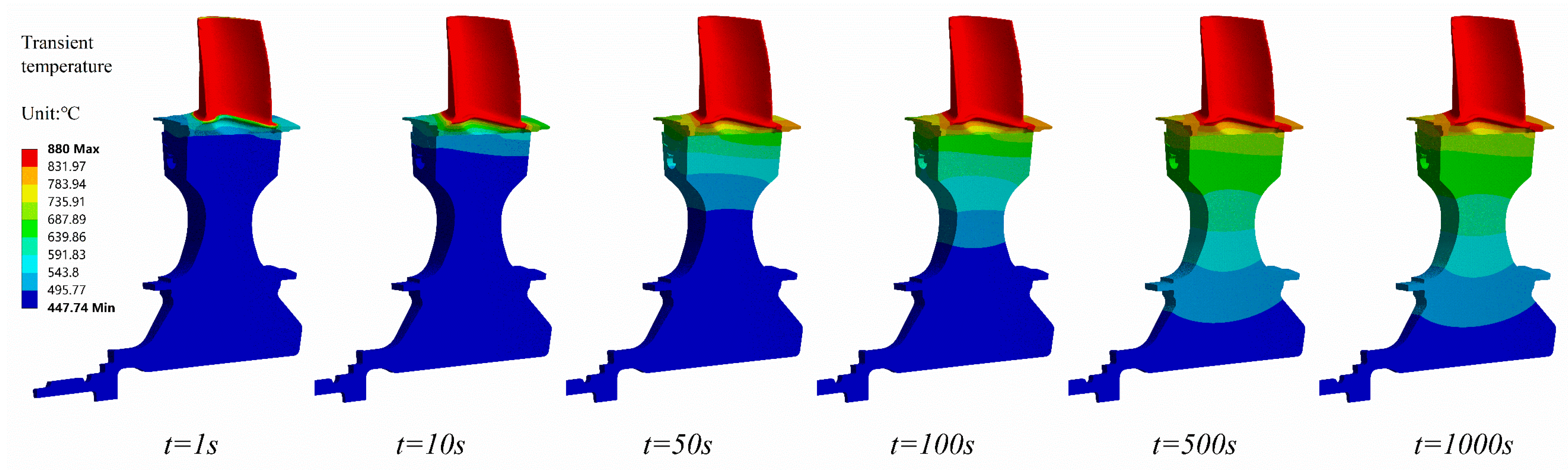

2.1.1. Transient Temperature at Critical Points

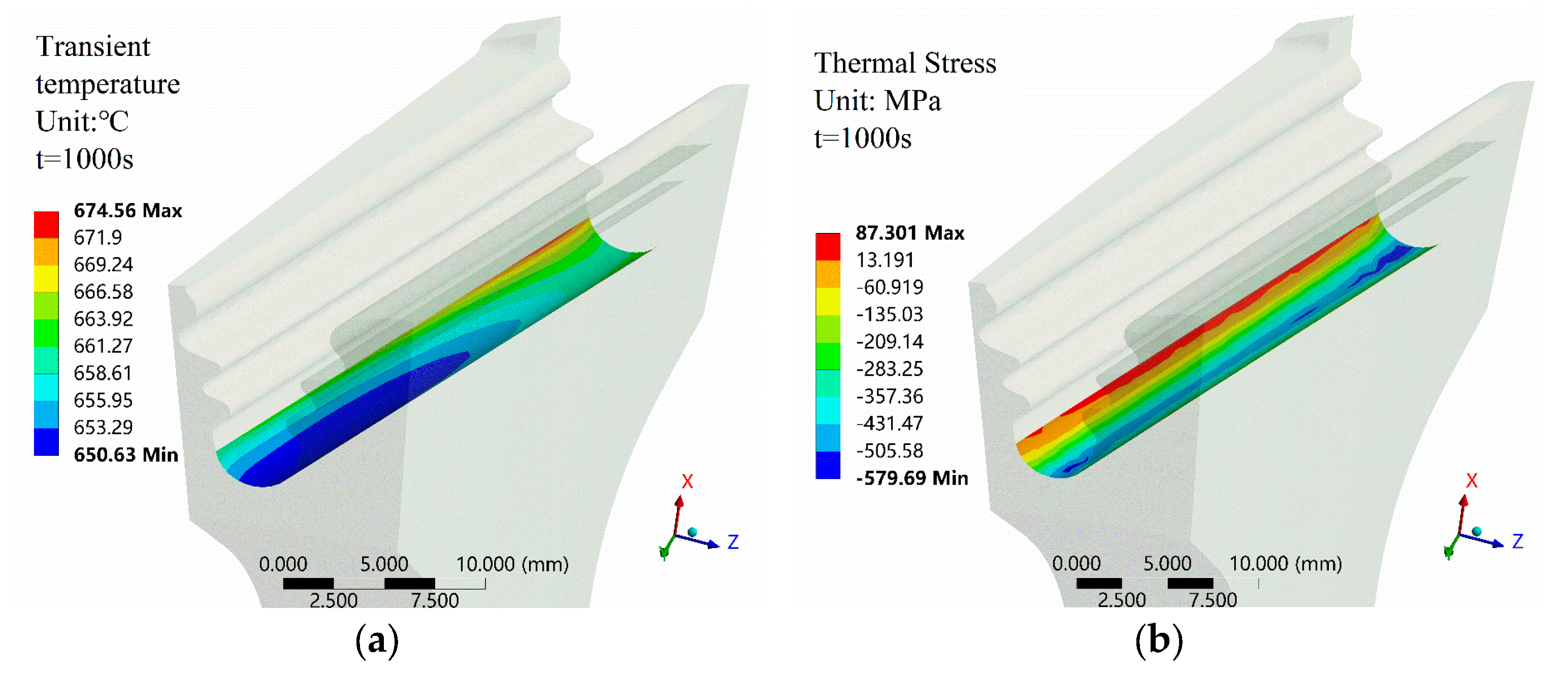

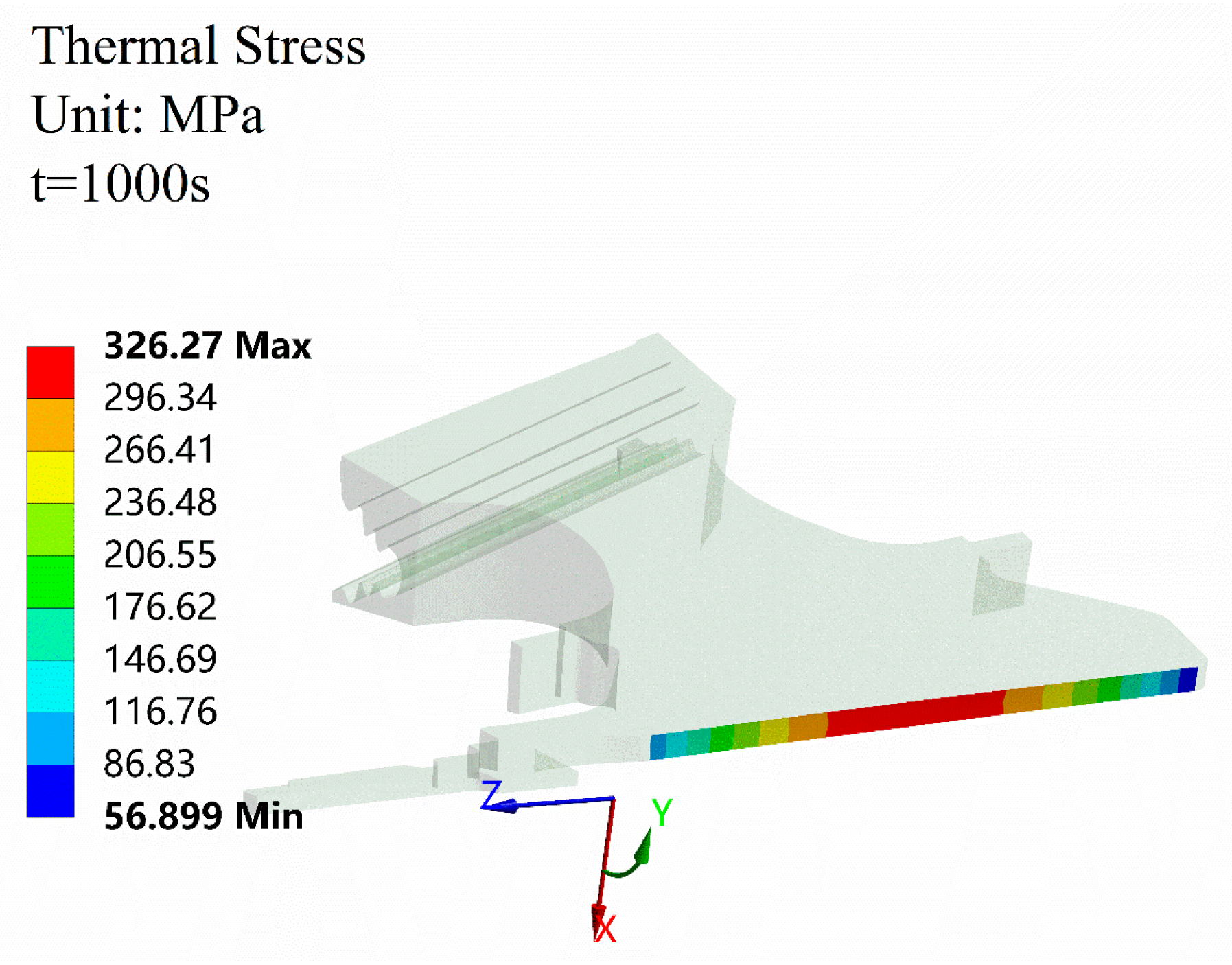

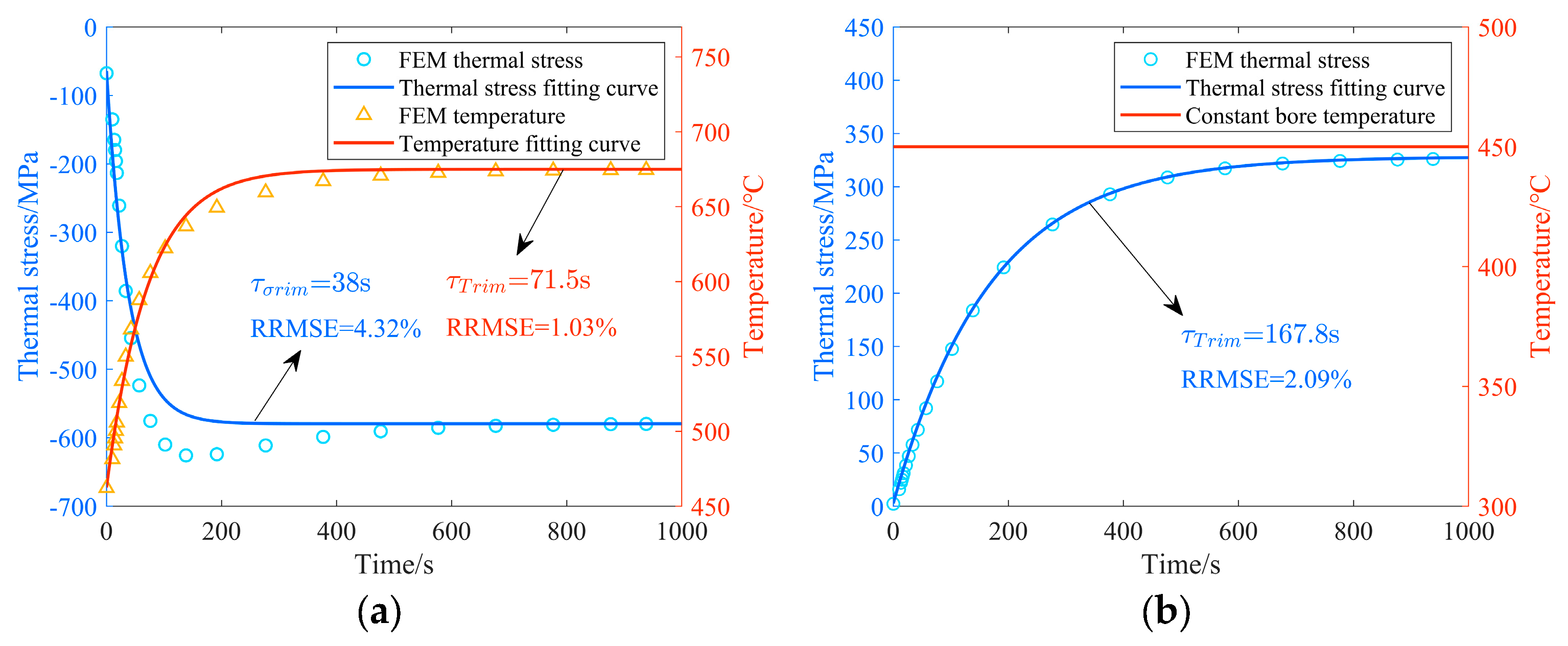

2.1.2. Transient Thermal Stress at Critical Points

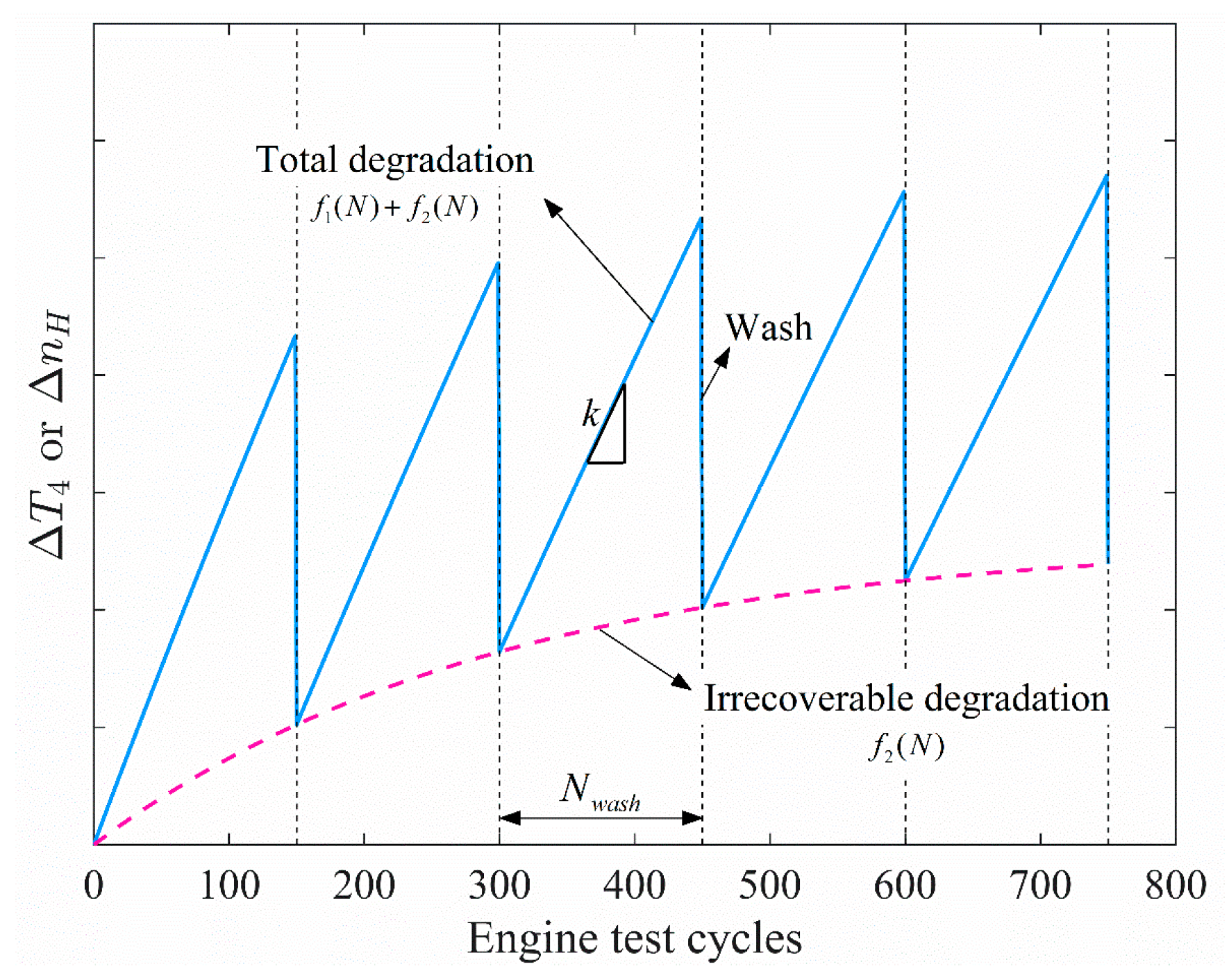

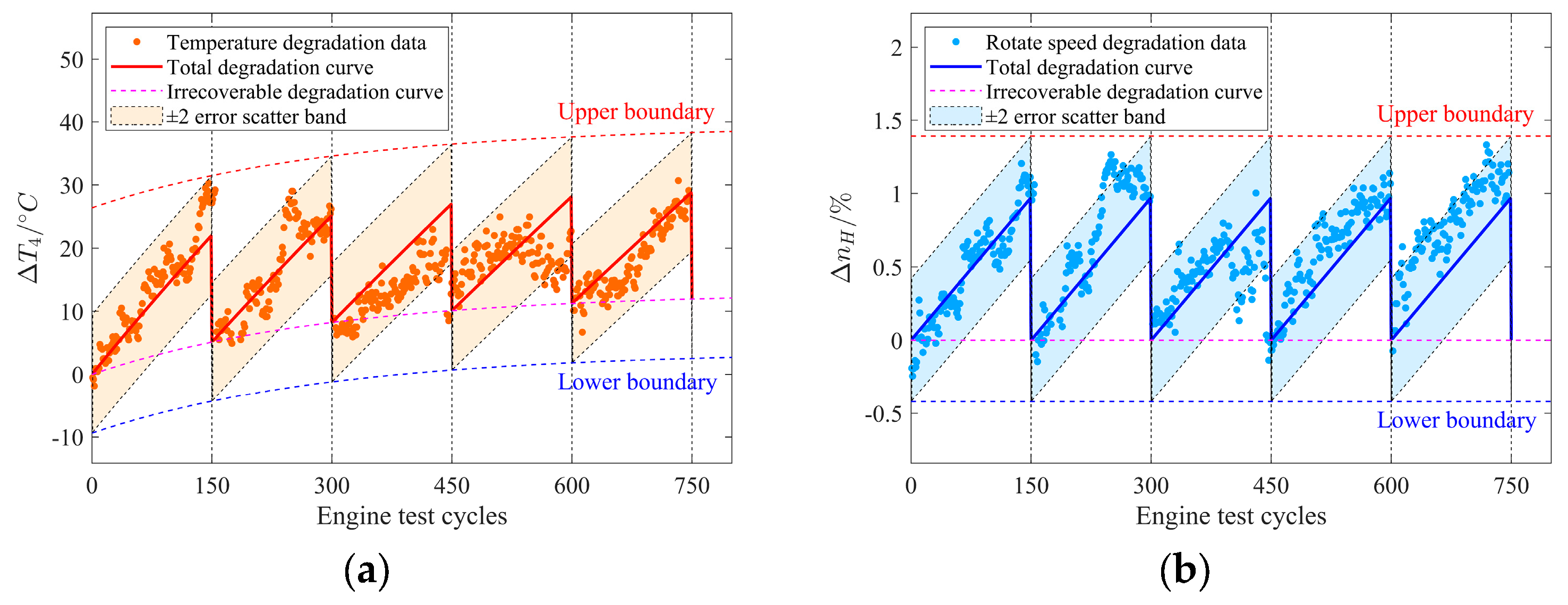

2.2. Performance Degradation Characteristic Model

2.3. Life Assessment of Turbine Disks

3. Results and Discussion

3.1. Fitting of the Surrogate Model for Transient Processes Based on the FEM Simulation Results

3.2. Fitting of the Performance Degradation Characteristic Model

3.3. Compilation of Time-Varying Load Spectrum and Life Assessment of Turbine Disks

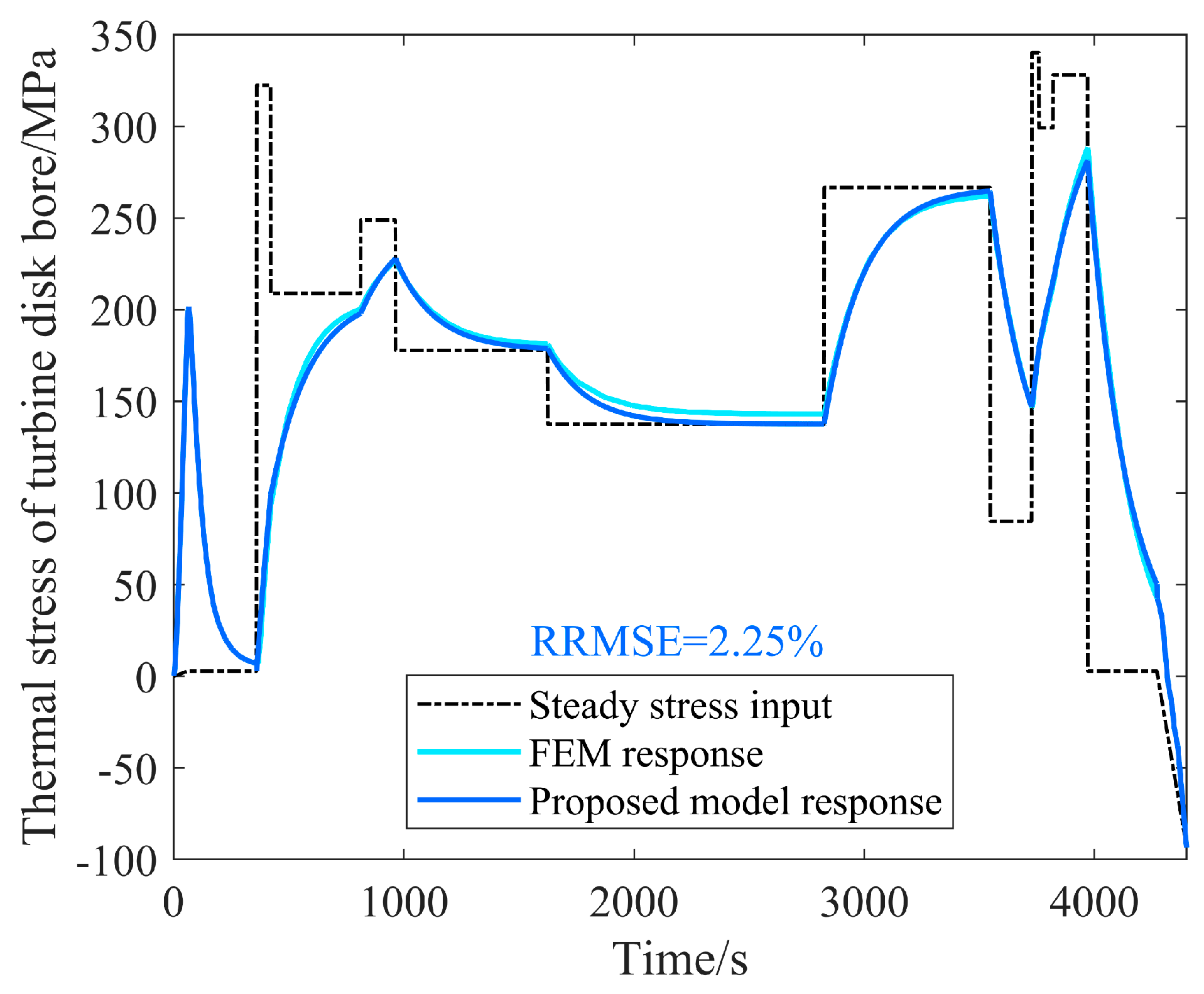

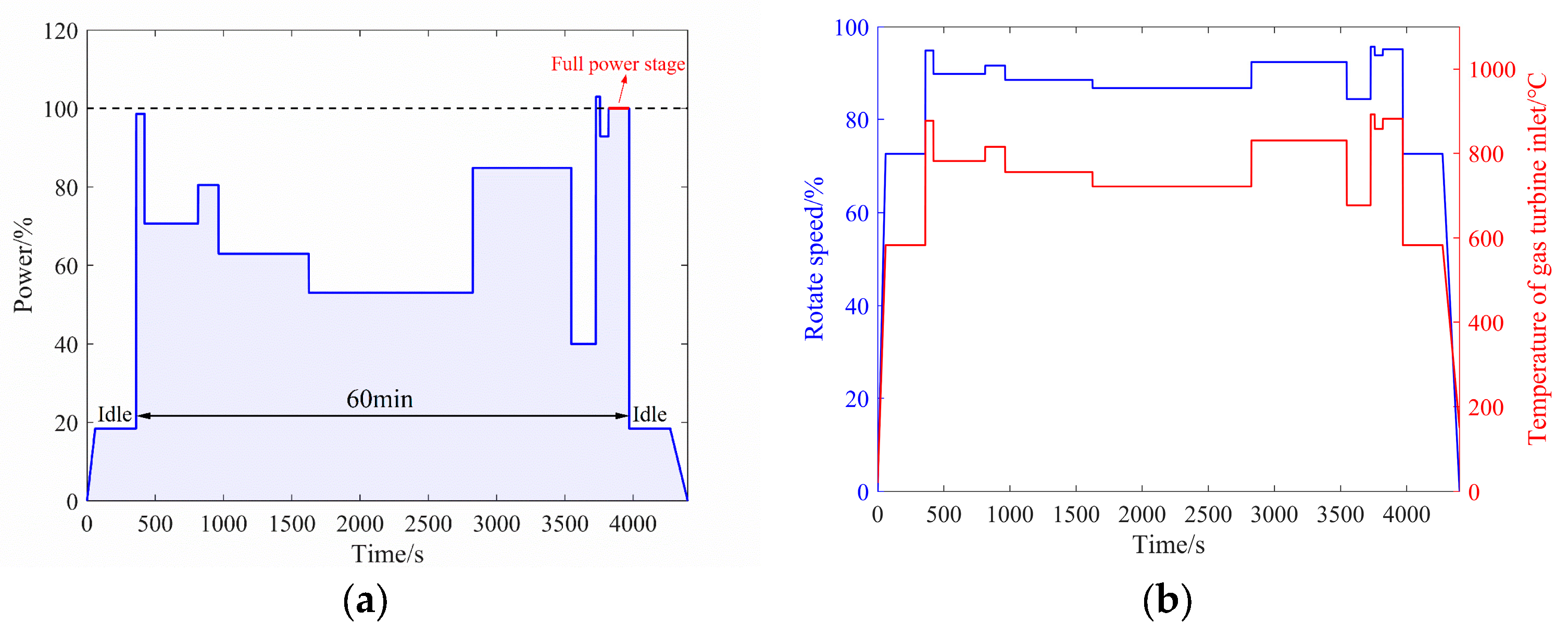

3.3.1. Short-Term Time-Varying Characteristics

3.3.2. Long-Term Time-Varying Characteristics

3.3.3. Life Assessment

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, L.; Bai, G.; Fei, C. Probabilistic LCF life assessment for turbine discs with DC strategy-based wavelet neural network regression. Int. J. Fatigue 2019, 119, 204–219. [Google Scholar] [CrossRef]

- Mu, Y.; Lu, S. Reliability prediction on creep rupture and LCF life for a turbine disk. Gas Turbine Exp. Res. 2015, 28, 13–18. [Google Scholar] [CrossRef]

- GJB241A-2010; Engine, Aircraft, Turbojet and Turbofan General Specification for. Equipment Development Department of Central Military Commission of the People’s Republic of China: Beijing, China, 2010.

- GJB/Z101-97; Engine Structural Integrity Guidance. Equipment Development Department of Central Military Commission of the People’s Republic of China: Beijing, China, 1997.

- MIL-E-5007; Engine, Aircraft, Turbojet and Turbofan General Specification for. US-NAVY, The Pentagon: Arlington County, VA, USA, 1973.

- MIL-STD-1783; Engine Structural Integrity Program (ENSIP). US-NAVY, The Pentagon: Arlington County, VA, USA, 1984.

- Niu, X.; Lu, Q.; Sun, Z.; Song, Y. A novel compilation method of comprehensive mission spectrum of aero-engine maneuvering load based on use-related mission segment. Chin. J. Aeronaut. 2023, 36, 161–170. [Google Scholar] [CrossRef]

- Jin, Y.; Sun, Z.; Song, Y.; Lin, X.; Niu, X.; Ding, J. Mission segment division of the whole aeroengine loading spectrum based on flight actions. Chin. J. Aeronaut. 2022, 35, 164–174. [Google Scholar] [CrossRef]

- Su, Q. Guidelines for Determining the Lifespan of Major Components of Aviation Turbojet and Turbofan Engines; Aviation Industrial Publishing Company: Beijing, China, 2004; pp. 24–28, 49–59. ISBN 7-80183-356-2. [Google Scholar]

- Song, Y.; Gao, D. Turbine engine composite route flight loading spectrum derivation. J. Propuls. Technol. 2000, 21, 54–56. [Google Scholar] [CrossRef]

- Song, Y.; Gao, D. Aeroengine composite maneuver loading spectrum derivation. J. Aerosp. Power 2002, 17, 212–216. [Google Scholar] [CrossRef]

- Yang, X.; Ning, X.; Shi, H. Research on turbo shaft aero engine composite flight profiles. J. Mech. Strength 2006, 28, 909–912. [Google Scholar] [CrossRef]

- Ten Have, A. A Cold Turbistan: Final Definition of a Standardized Fatigue Test Loading Sequence for Tactical Aircraft Cold Section Engine Discs; NLR-TR 87054 L; Nationaal Lucht-en Ruimtevaartlaboratorium: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Xiao, Y.; Xu, K.; Qin, H.; Jia, M. Load spectrum compiling and life prediction for turbine disc based on equivalent transformation of fatigue-creep load. J. Propuls. Technol. 2020, 41, 2316–2324. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.; Qin, H.; Xu, K.; Xiao, Y. Method for load spectrum compiling spectra under high temperature conditions based on generalized equivalent transformation theory of fatigue-creep load. J. Propuls. Technol. 2022, 43, 328–334. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Zhang, S.; Qin, T.; Yu, Z. Life consumption comparison between endurance test case and field service case for a type of aeroengine. In Proceedings of the First Symposium on Aviation Maintenance and Management-Volume I, Berlin, Germany, 25–28 November 2013; Springer: Berlin/Heidelberg, Germany, 2014; Volume 296, pp. 157–167. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Rong, Y.; Liu, C.; Dong, C.; Fu, C.; Qu, S.; Zhang, Z. Thermal mechanical fatigue cracking of a bladed disk in a turbo engine. Eng. Fail. Anal. 2024, 165, 108743. [Google Scholar] [CrossRef]

- Bruzzone, S.; Mantero, M.; Patrone, S.; Santolini, B.M.; Silingardi, A.; Traversone, L. Thermo-mechanical rotor analysis tuned by engine operational data. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; Volume 5c, ISSN 978-0-7918-5673-4. [Google Scholar]

- Ding, S.; Zhang, G.; Li, Y.; Zhou, Y. Safety analysis of transient loads on turbine disk. In Proceedings of the 2009 International Symposium on Aircraft Airworthiness, Toulouse, France, 19–21 November 2013; pp. 362–369, ISSN 978-0-982-24414-2. [Google Scholar]

- Wei, J.; Yang, H.; Zheng, P.; Wang, B.; Zheng, X. Transient tip clearance prediction model considering transient radial temperature distribution of discs in a gas turbine engine. J. Turbomach. 2024, 146, 041012. [Google Scholar] [CrossRef]

- Qian, W.; Zeng, X.; Huang, S.; Yin, X. Reliability analysis of multi-site damage with failure dependency of the turbine based on flow-thermal-solid coupling analysis and the Monte Carlo validated simulations. Eksploat. I Niezawodn.—Maint. Reliab. 2023, 25, 168771. [Google Scholar] [CrossRef]

- Fengna, Y.; Chengxiong, P.; Dongfang, Z.; Jian, T.; Jing, Y. Stress distribution and deformation analysis of gas turbine blades and disk with FEM method. In Proceedings of the ASME Power Conference Joint with ICOPE-17, Charlotte, NC, USA, 26–30 June 2017; Volume 1. [Google Scholar] [CrossRef]

- Javiya, U.; Chew, J.; Hills, N.; Scanlon, T. Coupled FE–CFD thermal analysis for a cooled turbine disk. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 3417–3432. [Google Scholar] [CrossRef]

- Li, G.; Ding, S.; Bao, M.; Sun, H. Effect of actively managed thermal-loading in optimal design of an aeroengine turbine disk. Int. Commun. Heat Mass Transf. 2017, 81, 257–268. [Google Scholar] [CrossRef]

- Ding, S.; Wang, Z.; Li, G.; Liu, C.; Yang, L. Transient stress control of aeroengine disks based on active thermal management. Appl. Therm. Eng. 2016, 103, 16–27. [Google Scholar] [CrossRef]

- Ding, S.; Li, Y. A safety design evaluation on transient thermal stress in turbine disk. Procedia Eng. 2014, 80, 609–627. [Google Scholar] [CrossRef][Green Version]

- Ding, S.; Li, Y.; Li, G. Evaluation of thermal loadings to ameliorate stress in a rotating disk. J. Thermophys. Heat Transf. 2014, 28, 667–678. [Google Scholar] [CrossRef]

- Ding, S.; Li, G.; Deng, M. Experimental study of an actively managed thermal loading method in turbine disk. J. Thermophys. Heat Transf. 2014, 28, 39–49. [Google Scholar] [CrossRef]

- Hunag, J.; Wang, Q.; Lu, F. Research status and prospect of gas path fault diagnosis for aeroengine. J. Nanjing Univ. Aeronaut. Astronaut. 2020, 52, 507–522. [Google Scholar] [CrossRef]

- NASA. Adaptive Gas Turbine Engine Control for Deterioration Compensation Due to Aging; NASA: Washington, DC, USA, 2003. [Google Scholar]

- Li, X.; Ding, Q.; Sun, J. Remaining useful life estimation in prognostics using deep convolution neural networks. Reliab. Eng. Syst. Saf. 2018, 172, 1–11. [Google Scholar] [CrossRef]

- Sun, X.; Jafari, S.; Fashandi, S.A.M.; Nikolaidis, T. Compressor degradation management strategies for gas turbine aero-engine controller design. Energies 2021, 14, 5711. [Google Scholar] [CrossRef]

- Pang, S.; Li, Q.; Feng, H. A hybrid onboard adaptive model for aero-engine parameter prediction. Aerosp. Sci. Technol. 2020, 105, 105951. [Google Scholar] [CrossRef]

- Li, Y. Gas turbine performance and health status estimation using adaptive gas path analysis. J. Eng. Gas Turbines Power 2010, 132, 041701. [Google Scholar] [CrossRef]

- Zhang, Y.; Xin, Y.; Liu, Z.-W.; Chi, M.; Ma, G. Health status assessment and remaining useful life prediction of aero-engine based on BiGRU and MMoE. Reliab. Eng. Syst. Saf. 2022, 220, 108263. [Google Scholar] [CrossRef]

- Kim, T.; Sohn, S. Multitask learning for health condition identification and remaining useful life prediction: Deep convolutional neural network approach. J. Intell. Manuf. 2021, 32, 2169–2179. [Google Scholar] [CrossRef]

- Li, Z.; Wu, J.; Yue, X. A shape-constrained neural data fusion network for health index construction and residual life prediction. IEEE Trans. Neural Netw. Learn. Syst. 2021, 32, 5022–5033. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Hu, Z.; Zhang, H. Remaining useful life prediction of aero-engine enabled by fusing knowledge and deep learning models. Reliab. Eng. Syst. Saf. 2023, 229, 108869. [Google Scholar] [CrossRef]

- Ren, L.; Qin, H.; Cai, N.; Li, B.; Xie, Z. A hybrid degradation evaluation model for aero-engines. Sustainability 2023, 15, 29. [Google Scholar] [CrossRef]

- Wei, Z.; Jafari, S.; Zhang, S.; Nikolaidis, T. Hybrid wiener model: An on-board approach using post-flight data for gas turbine aero-engines modelling. Appl. Therm. Eng. 2021, 184, 116350. [Google Scholar] [CrossRef]

- Saxena, A.; Goebel, K. Turbofan Engine Degradation Simulation Data Set. NASA Prognostics Data Repository, NASA AMES Research Center, Moffett Field, CA. 2008. Available online: https://phm-datasets.s3.amazonaws.com/NASA/6.+Turbofan+Engine+Degradation+Simulation+Data+Set.zip (accessed on 28 March 2025).

- Zhang, J.; Chang, H. Heat Transfer; Science Press: Beijing, China, 2015; pp. 26–27. ISBN 978-7-03-043342-8. [Google Scholar]

- Debnath, L. Linear Partial Differential Equations for Scientists and Engineers, 4th ed.; Birkhauser: Boston, MA, USA, 2007; ISBN 978-0-8176-4560-1. [Google Scholar]

- Hu, S. Automatic control Theory; Science Press: Beijing, China, 2013; pp. 29–30. ISBN 978-7-03-037056-3. [Google Scholar]

- Xu, B.; Liu, X. Applications Elastoplastic Mechanical; Tsinghua University Press Pub: Beijing, China, 1995; pp. 385–388. ISBN 7-302-01800-6. [Google Scholar]

- Diakunchak, I. Performance deterioration in industrial gas-turbines. J. Eng. Gas Turbines Power-Trans. ASME 1992, 114, 161–168. [Google Scholar] [CrossRef]

- Robinson, E.L. Effect of temperature variation on the long-time rupture strength of steels. Trans. Am. Soc. Mech. Eng. 1952, 74, 777–780. [Google Scholar] [CrossRef]

- Hales, R. A method of creep damage summation based on accumulated strain for the assessment of creep-fatigue endurance. Fatigue Fract. Eng. Mater. Struct. 1983, 6, 121–135. [Google Scholar] [CrossRef]

- Takahashi, Y.; Dogan, B.; Gandy, D. Systematic evaluation of creep-fatigue life prediction methods for various alloys. J. Press. Vessel Technol. 2013, 135, 061204. [Google Scholar] [CrossRef]

- Wang, R.-Z.; Zhang, X.-C.; Tu, S.-T.; Zhu, S.-P.; Zhang, C.-C. A modified strain energy density exhaustion model for creep–fatigue life prediction. Int. J. Fatigue 2016, 90, 12–22. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, X.; Song, Y.; Sun, Z. A novel damage constitutive model for creep deformation and damage evolution prediction. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 798–813. [Google Scholar] [CrossRef]

- Mu, L. Investigation on Low Cycle fatigue Life Prediction Method of Single Crystal Turbine Blades Based on Critical Plane Approach. Ph.D. Thesis, University of Chinese Academy of Sciences, Beijing, China, 2017. [Google Scholar]

| Variables | Time Constants | Transfer Functions | RRMSE (Step Input) | RRMSE (Load Spectrum Input) |

|---|---|---|---|---|

| 71.5 | 1.03% | 0.69% | ||

| 38 | 4.32% | 3.74% | ||

| 167.8 | 2.09% | 2.25% |

| Constants | (°C) | (MPa) | (%) | (GPa) | (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Values | 550 | 1546 | 41.2% | −0.07 | −0.73 | 190.8 | 1543 | 0.09 |

| 360 | 1698 | 94.9 | −0.07 | −0.84 | 209.6 | 1530 | 0.07 |

| Constants | (MPa) | (MPa) | (kJ/mol) | (J/mol·K) | ||

|---|---|---|---|---|---|---|

| Values | 593 (600 °C) 309 (650 °C) | 1440 (600 °C) 1255 (650 °C) | 17.1 | 8.314 | 1.853 | −0.4244 |

| Time-Varying Characteristics | ||

|---|---|---|

| Transient Process | Performance Degradation | |

| Spectrum A | × | × |

| Spectrum B | √ | × |

| Spectrum C | √ | √ |

| Critical Points | Spectrum Type | Total Damage | Fatigue Damage | Creep Damage | Proportion of Creep Damage | Life | Life Deviation |

|---|---|---|---|---|---|---|---|

| Fir-tree slot root | A | 0.3952 | 5.6 × 10−6 | 0.3952 | 100% | 4107 | −23.9% |

| B | 0.3952 | 0.1363 | 0.2589 | 65.5% | 7560 | 40% | |

| C | 0.3952 | 0.1251 | 0.2701 | 68.3% | 5400 | 0% | |

| Disk bore | A | 0.3952 | 0.3952 | 1.3 × 10−6 | 0% | 9010 | −38.5% |

| B | 0.3952 | 0.3952 | 1.7 × 10−6 | 0% | 22,911 | 56.3% | |

| C | 0.3952 | 0.3952 | 1.6 × 10−6 | 0% | 14,655 | 0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, S.; Niu, X.; Sun, Z.; Song, Y. A Method for the Life Assessment of Aero-Engine Turbine Disks Based on a Time-Varying Load Spectrum. Aerospace 2025, 12, 423. https://doi.org/10.3390/aerospace12050423

Yao S, Niu X, Sun Z, Song Y. A Method for the Life Assessment of Aero-Engine Turbine Disks Based on a Time-Varying Load Spectrum. Aerospace. 2025; 12(5):423. https://doi.org/10.3390/aerospace12050423

Chicago/Turabian StyleYao, Shunyu, Xuming Niu, Zhigang Sun, and Yingdong Song. 2025. "A Method for the Life Assessment of Aero-Engine Turbine Disks Based on a Time-Varying Load Spectrum" Aerospace 12, no. 5: 423. https://doi.org/10.3390/aerospace12050423

APA StyleYao, S., Niu, X., Sun, Z., & Song, Y. (2025). A Method for the Life Assessment of Aero-Engine Turbine Disks Based on a Time-Varying Load Spectrum. Aerospace, 12(5), 423. https://doi.org/10.3390/aerospace12050423