Impact Analysis of Temperature Effects on the Performance of the Pick-Up Ion Analyzer

Abstract

1. Introduction

2. Essential Preliminaries

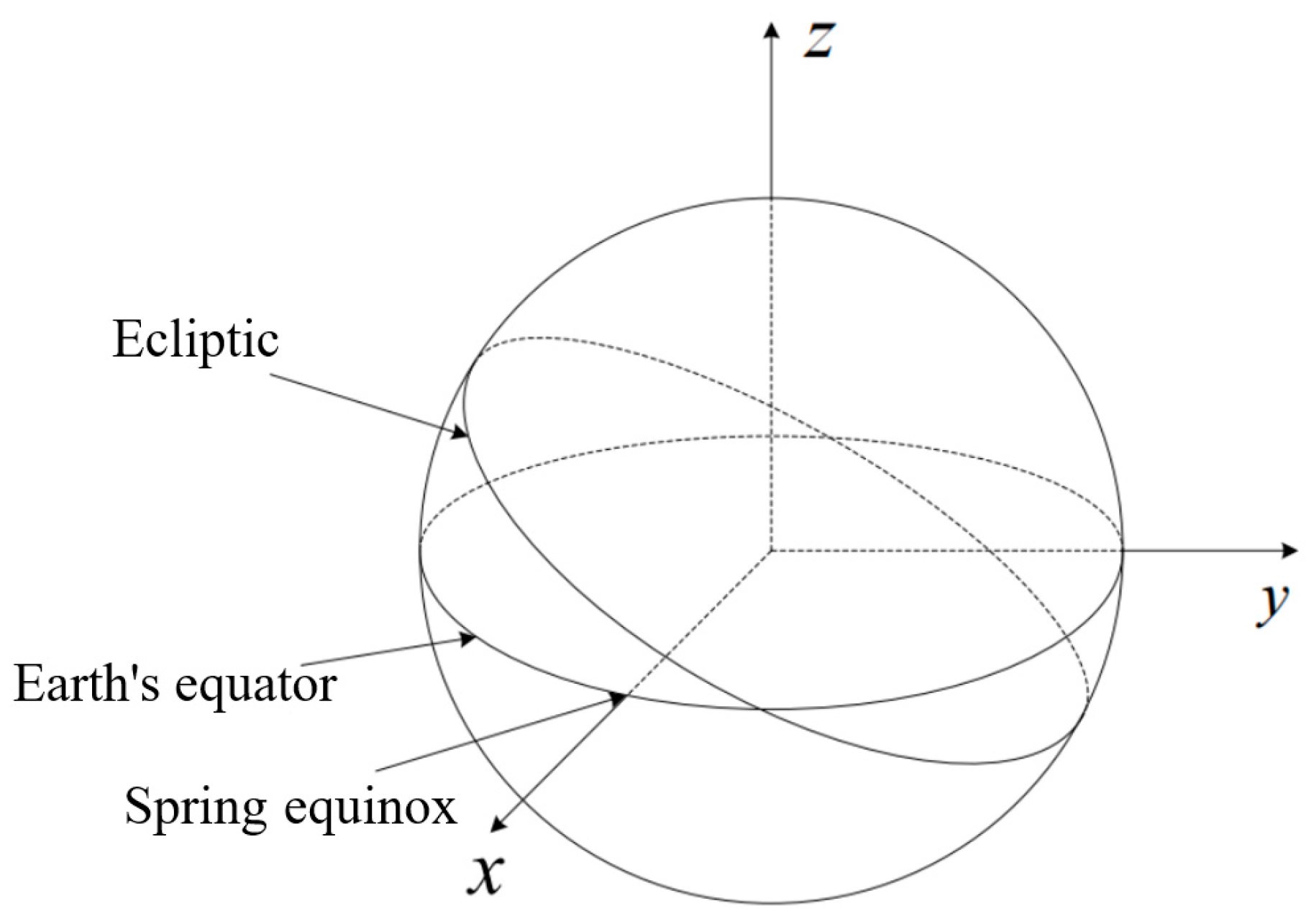

2.1. Geocentric Equatorial Inertial Coordinate System (J2000)

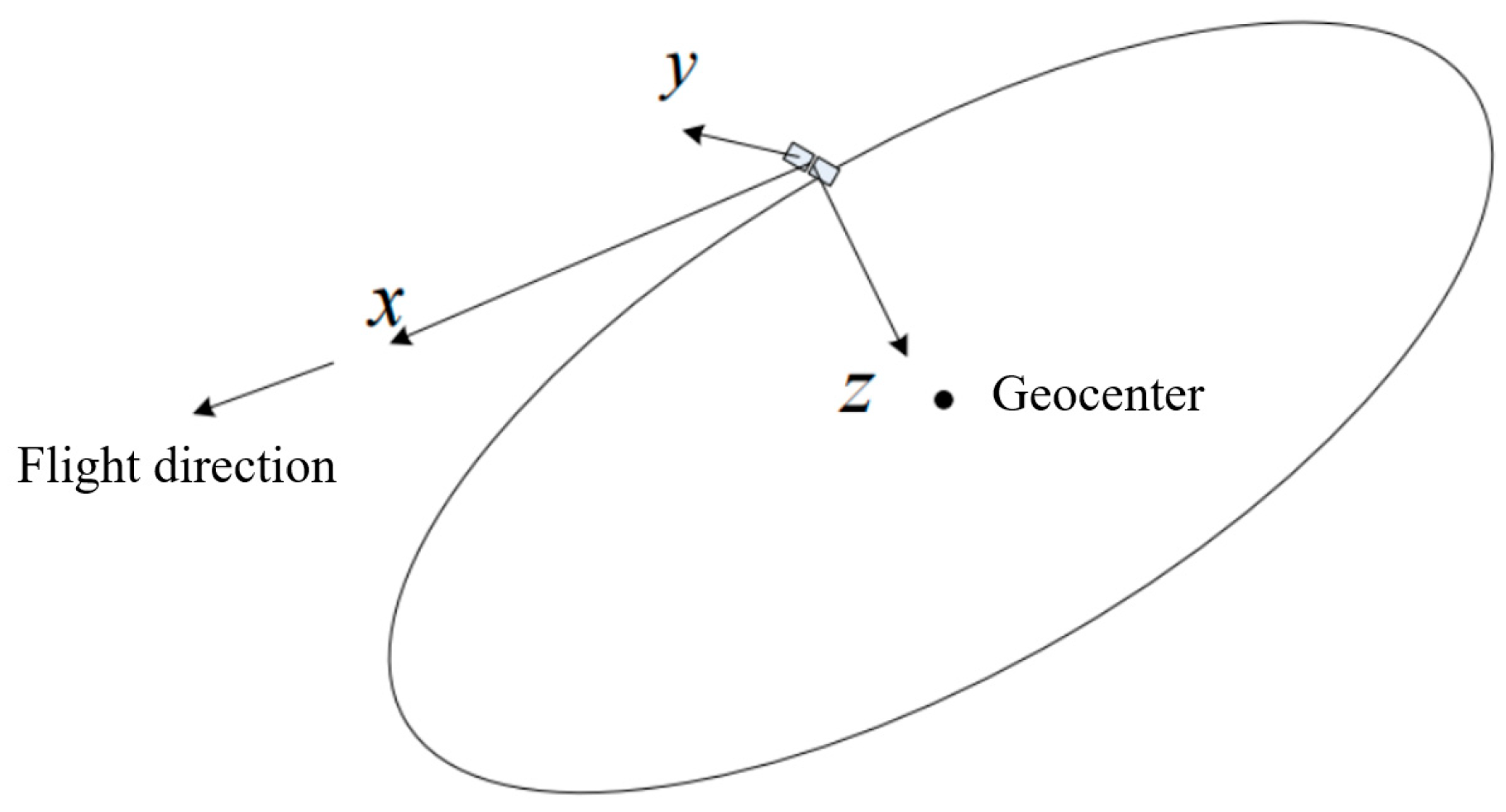

2.2. Orbital Coordinate System

- The z-axis aligns with the geocentric direction.

- The x-axis lies within the satellite orbital plane, orthogonal to the z-axis, with its positive direction coinciding with the tangential direction of the spacecraft’s velocity vector.

- The y-axis completes a right-handed orthogonal triad with the x- and z-axes.

2.3. Methodology for Constructing Coordinate Transformation Matrices

- Origin Translation: Displace the J2000 origin to the spacecraft payload’s center of mass.

- Geocentric Axis Correction: Apply geocentric fixed rotation sequences to compensate for Earth’s rotational axis deviations.

- Orbital Plane Alignment: Orient the orbital basis vectors to coincide with the J2000 frame.

- R denotes the composite rotation matrix.

- ψ, θ, and ϕ represent the orbital plane’s right ascension, inclination, and argument of latitude, respectively.

- d is the translation vector.

- tx, ty, and tz constitute the time-dependent Earth rotation parameters.

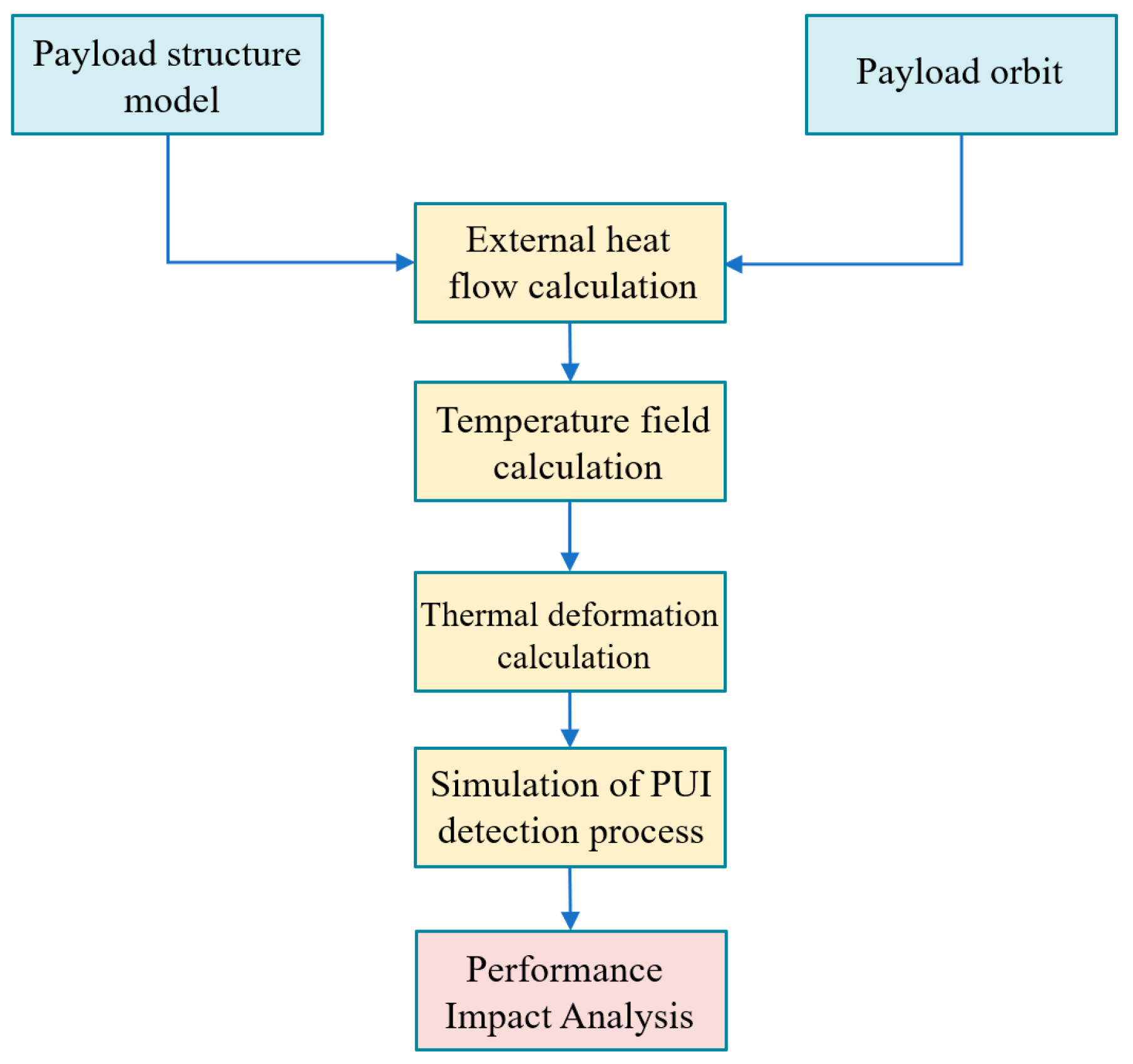

3. Proposed Method

3.1. Temperature Effect Impact Simulation Method

- External Heat Flux Calculation: Compute the external heat flux incident on the satellite surface based on its operational space environment.

- Thermal Distribution Simulation: Simulate temperature distributions and thermal deformations around the instrument using finite element methods, incorporating satellite structural and material properties.

- Performance Evaluation: Integrate deformation parameters into the PUIA detection simulation method to assess temperature-dependent influences on detection outcomes.

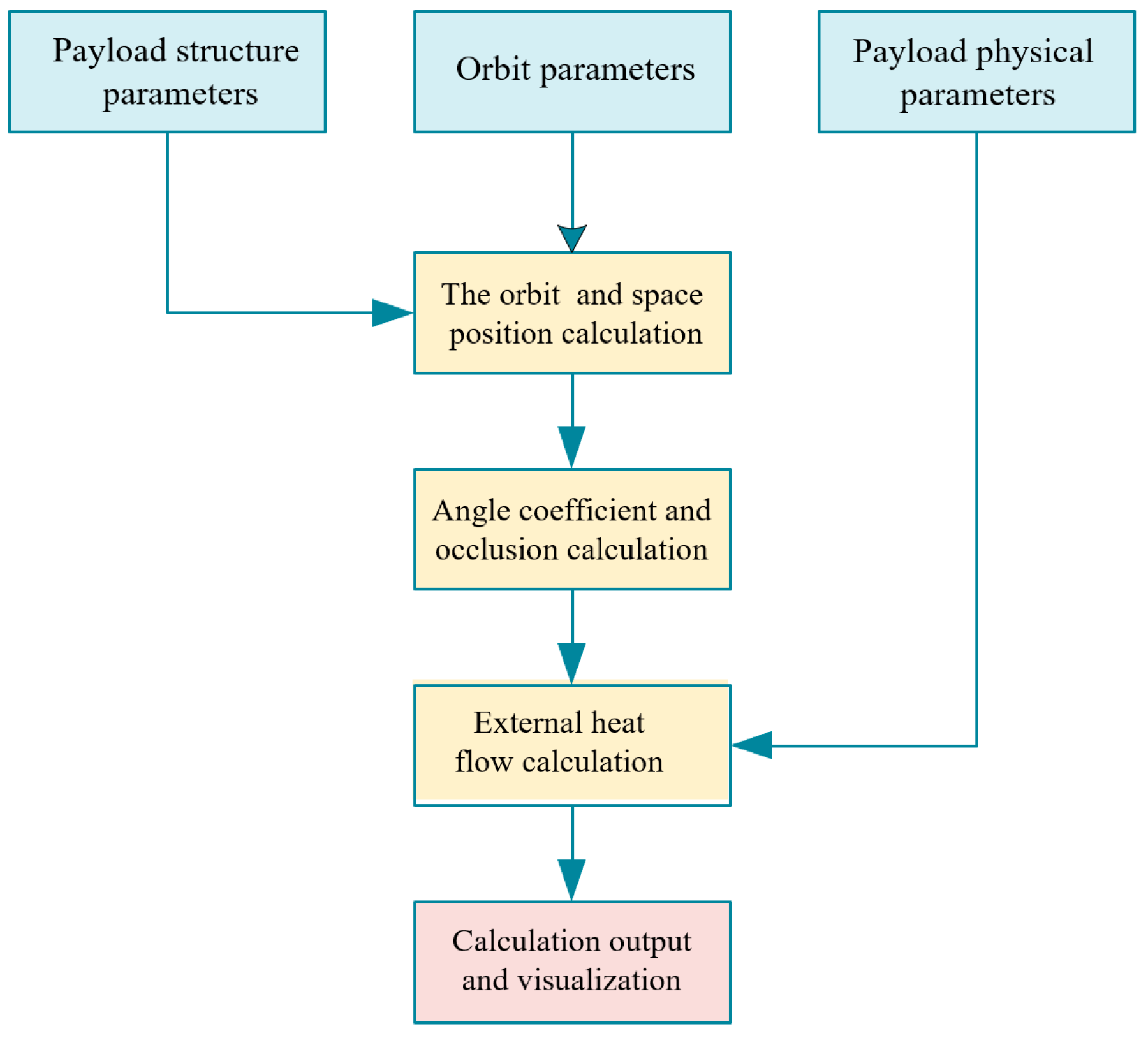

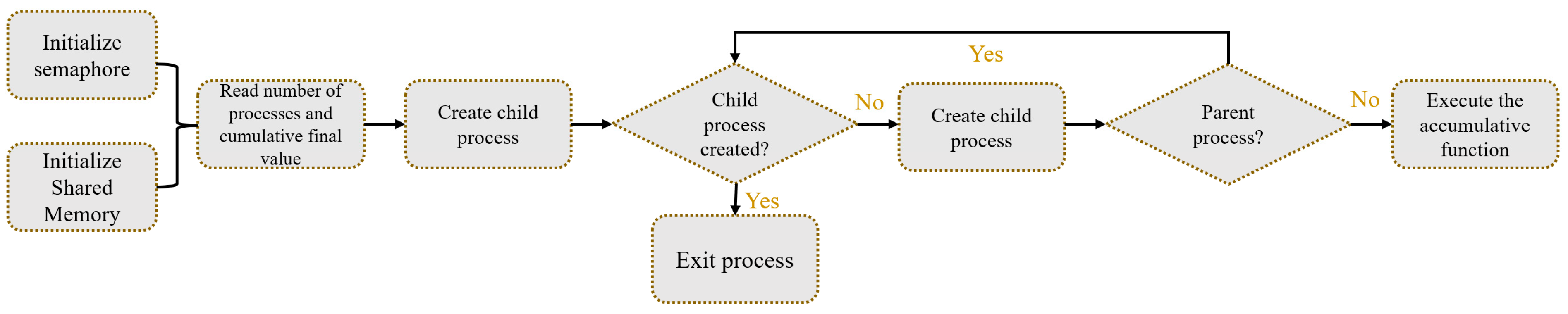

3.2. External Heat Flux Calculation Simulation Method

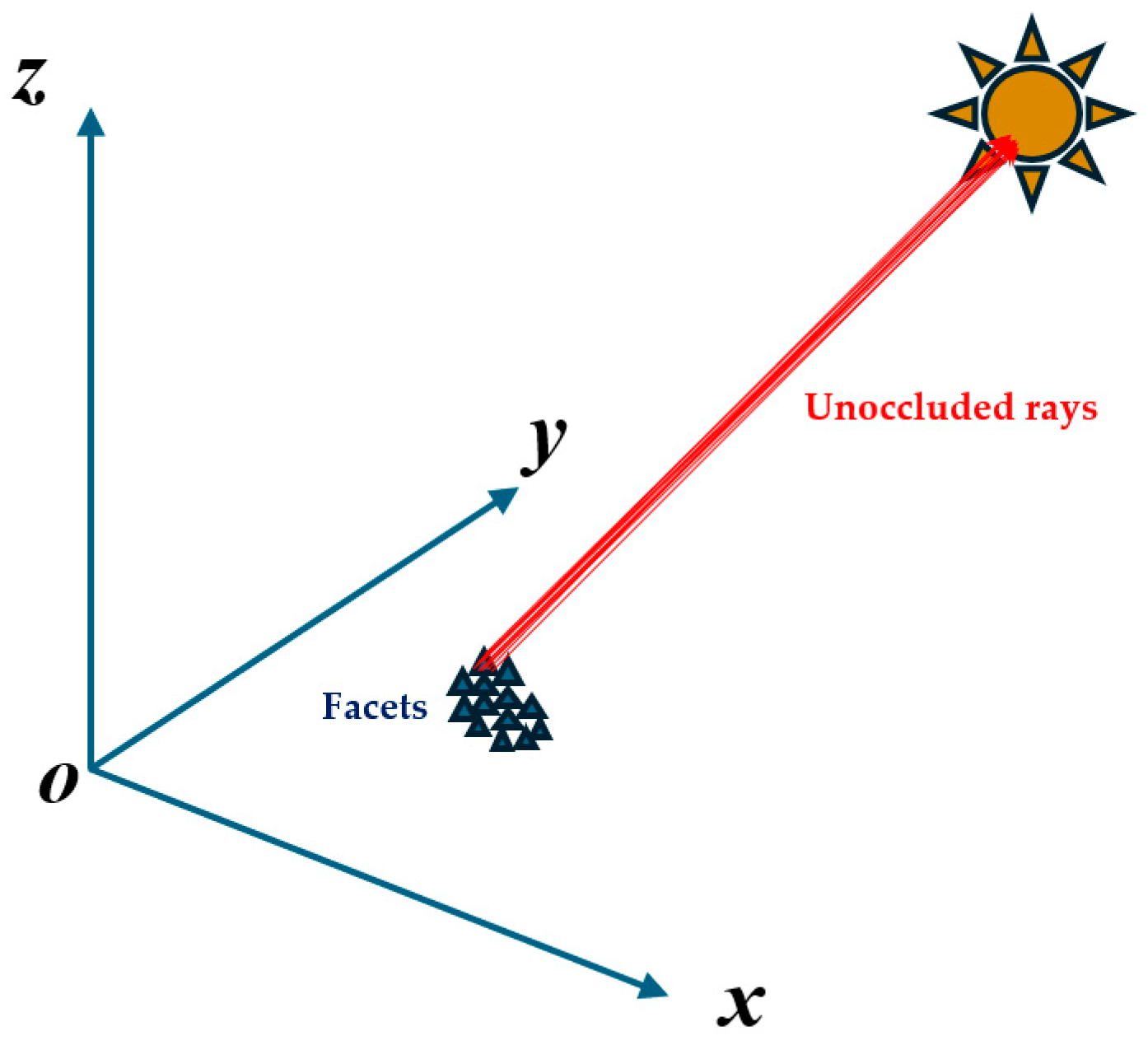

3.2.1. Occlusion Calculation

- If a ray intersects with any facet other than the target facet, it is marked as occluded.

- If a ray exclusively interacts with the target facet without structural obstruction, it is counted as valid.

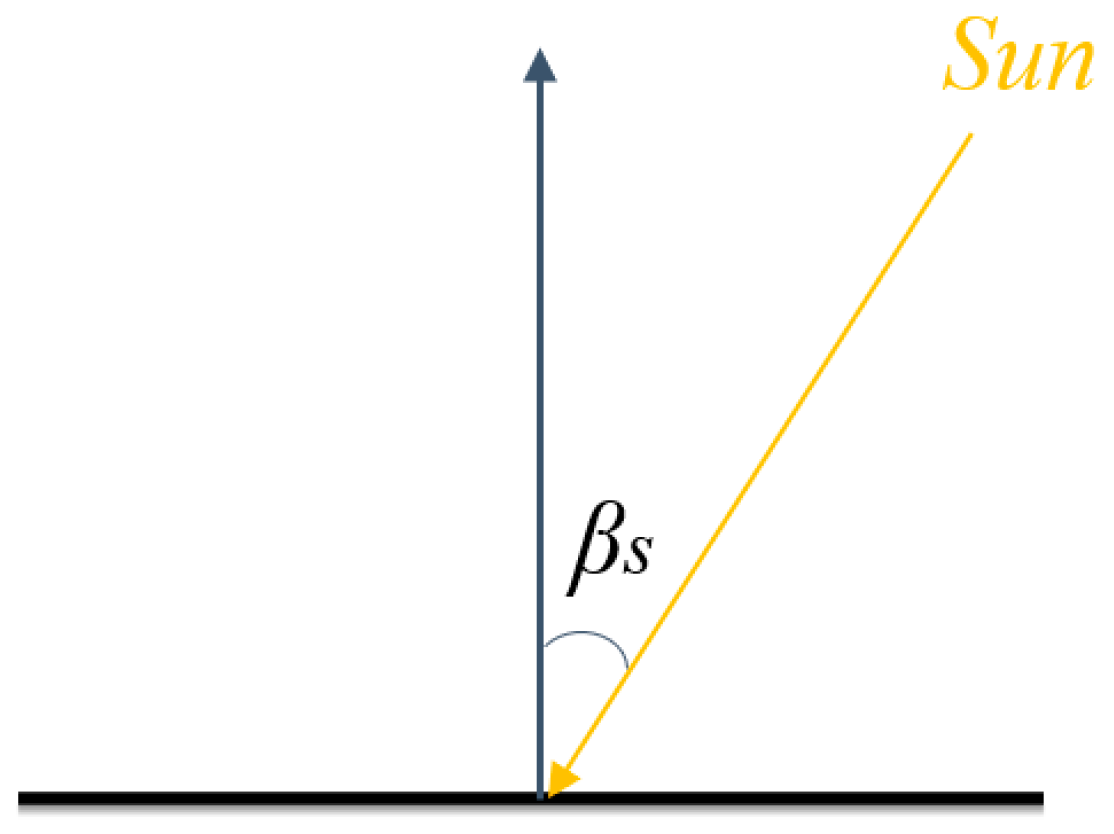

3.2.2. Methodology for External Heat Flux Calculation

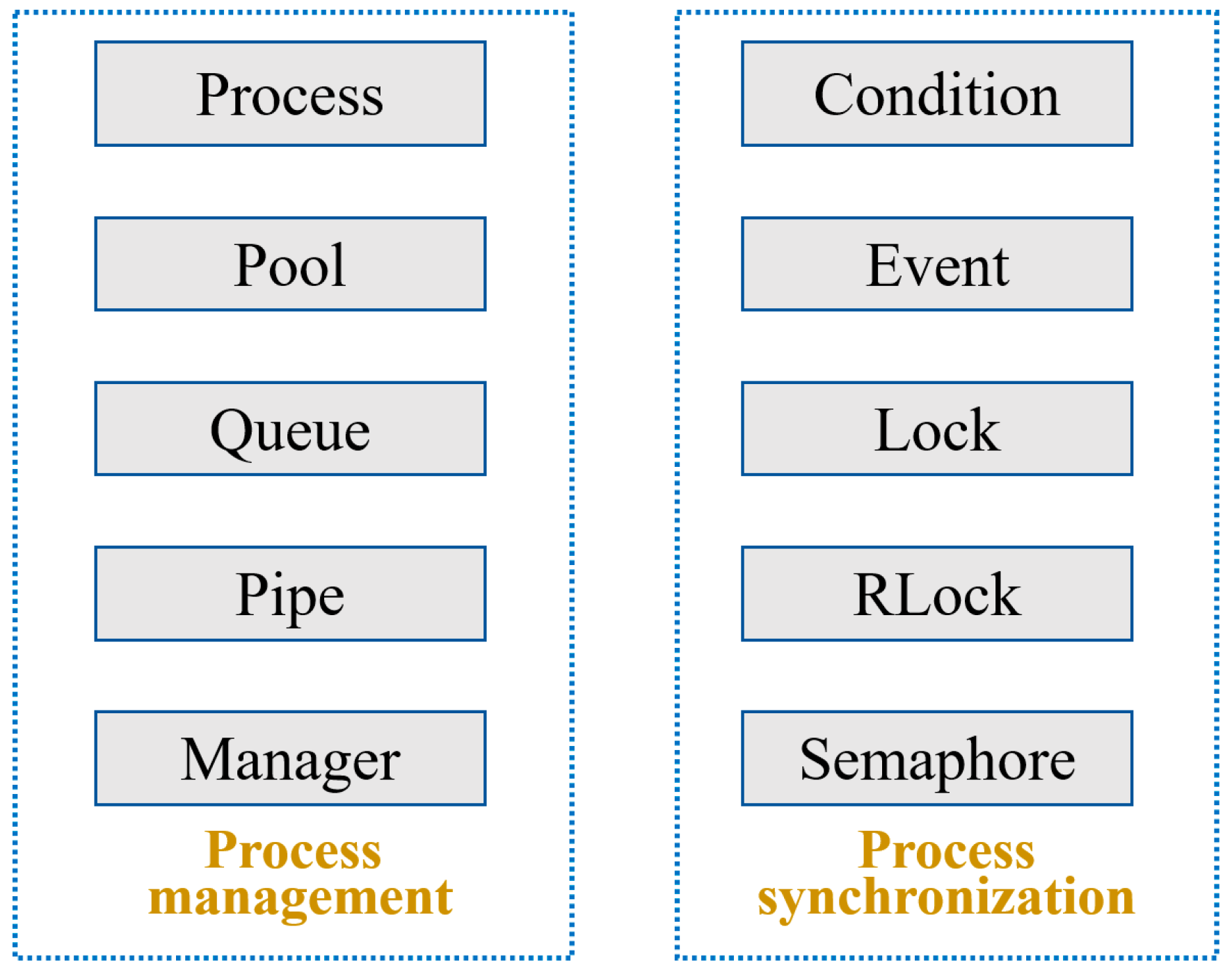

3.3. Parallel Temperature Field Computation Based on LU Decomposition

3.3.1. Target Equilibrium Equation

- (1)

- Direct Solar Radiation (Qsun) to the target unit Pi

- (2)

- The heat exchange (Qexchange) between the target unit Pi and the adjacent unit Pj

- (3)

- The heat radiated outward (Qself) from the target unit Pi

- (4)

- Changes in the internal energy (Qtempr) from the target unit Pi

3.3.2. Solution of the Target Equilibrium Equation

- Factorization Phase: Parallelization of independent row/column operations.

- Triangular System Solving: Concurrent execution of forward and backward substitution tasks across multicore architectures.

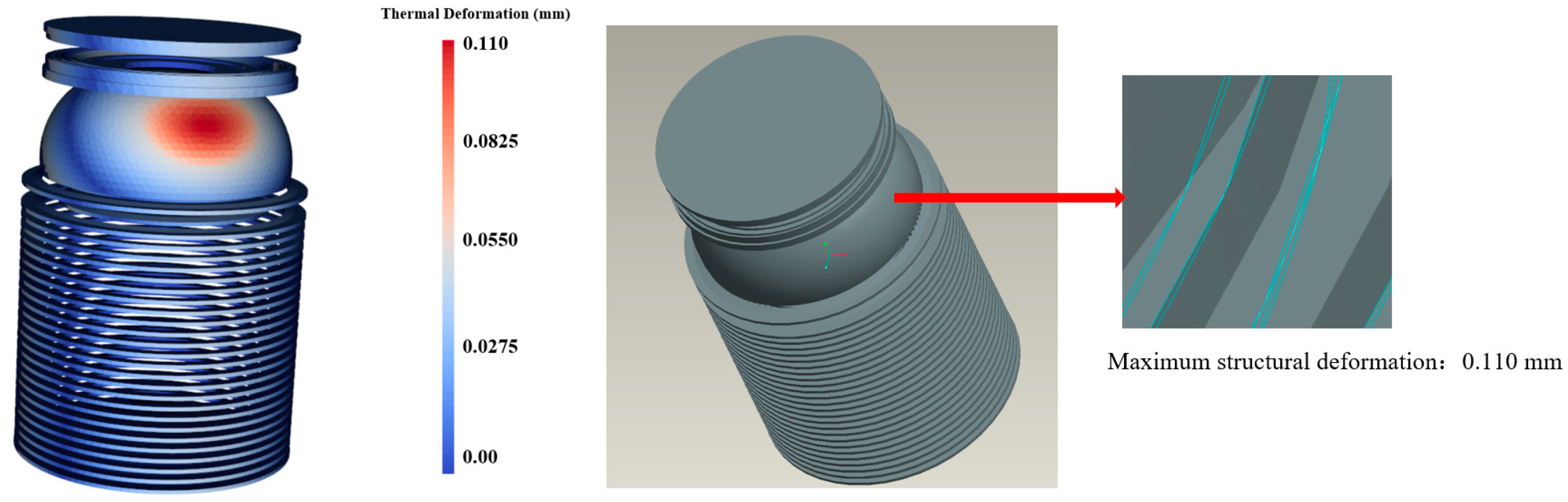

3.4. Calculation of Thermoelastic Deformation

4. Experiment and Results

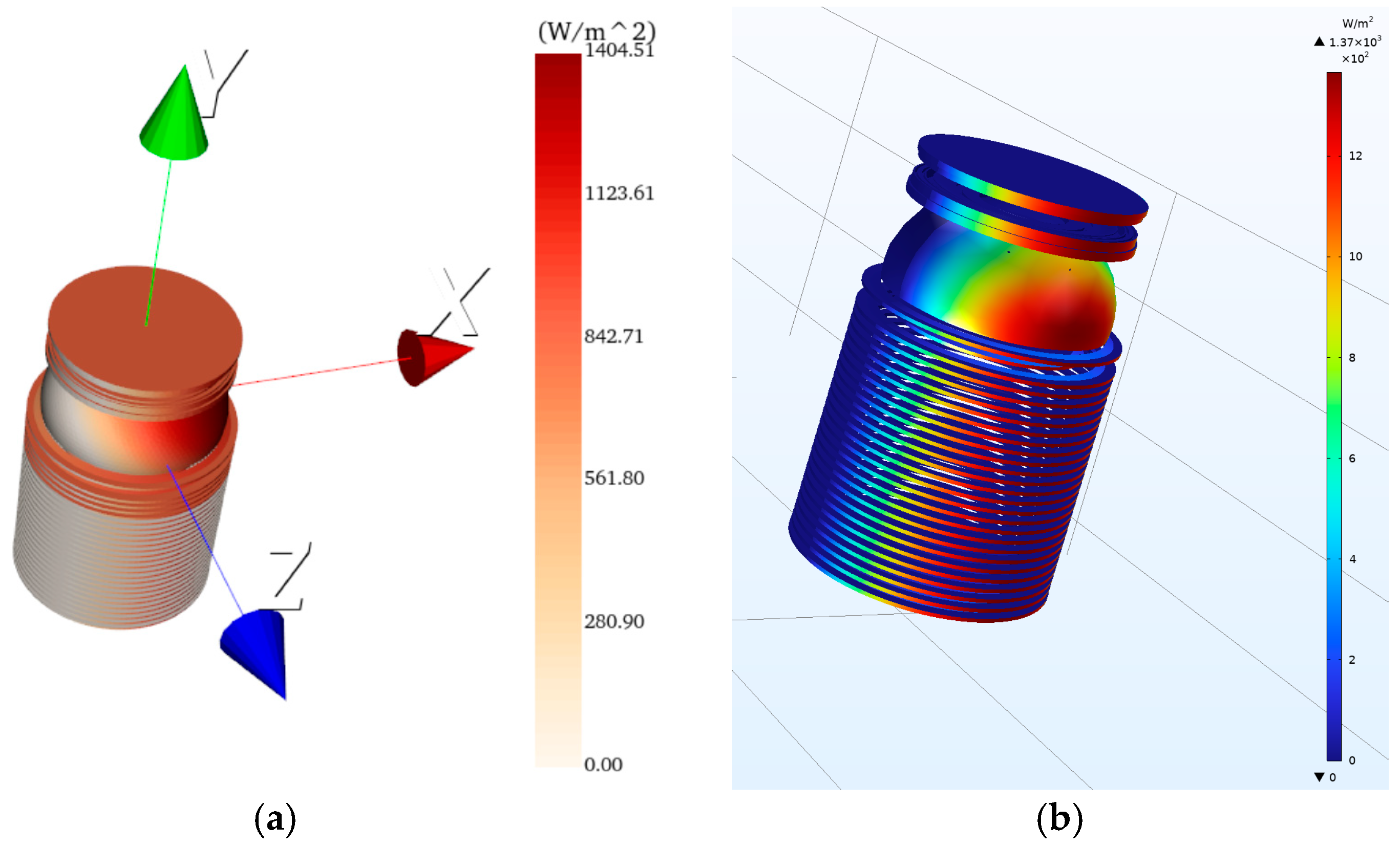

4.1. External Heat Flux Calculation Results

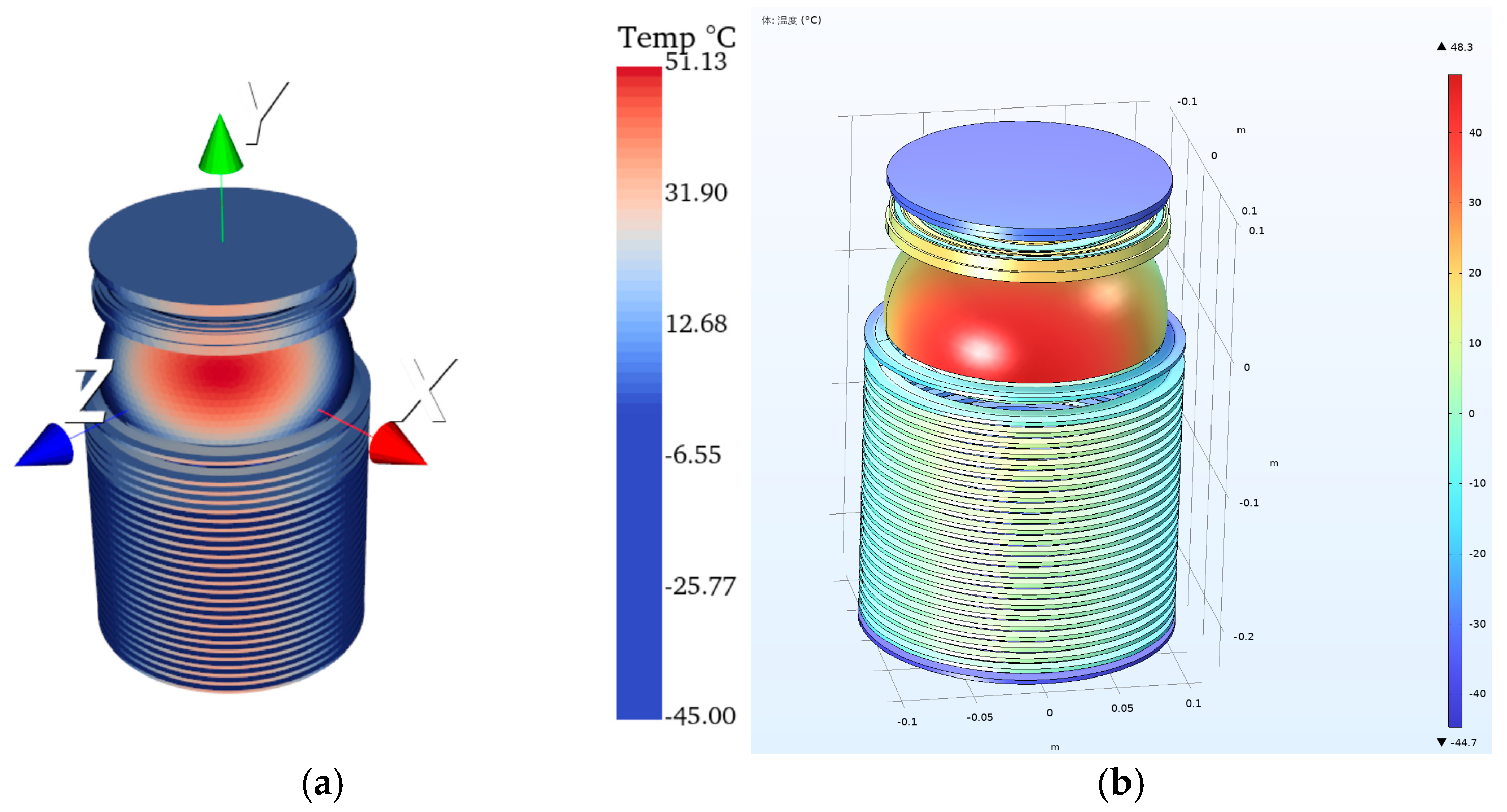

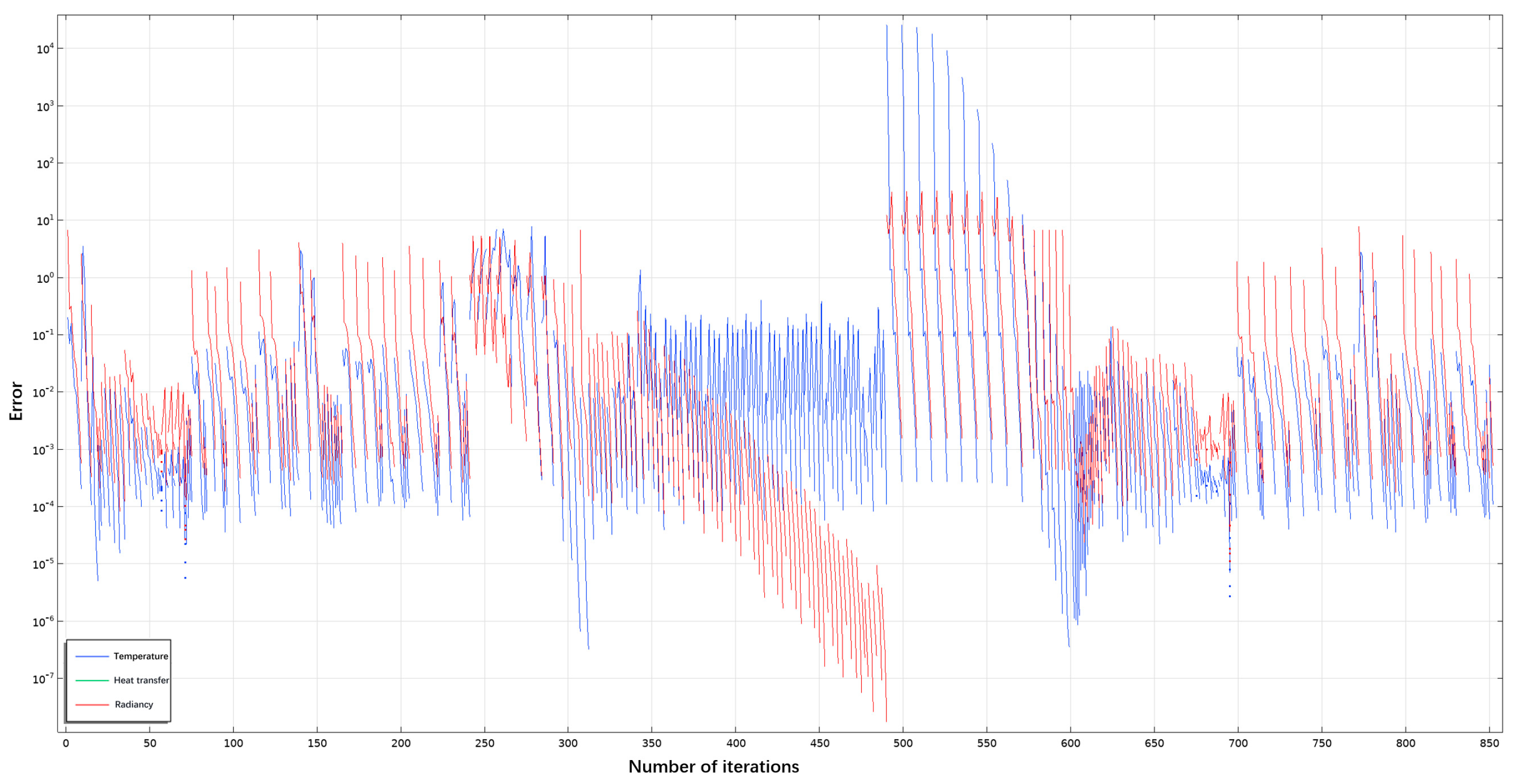

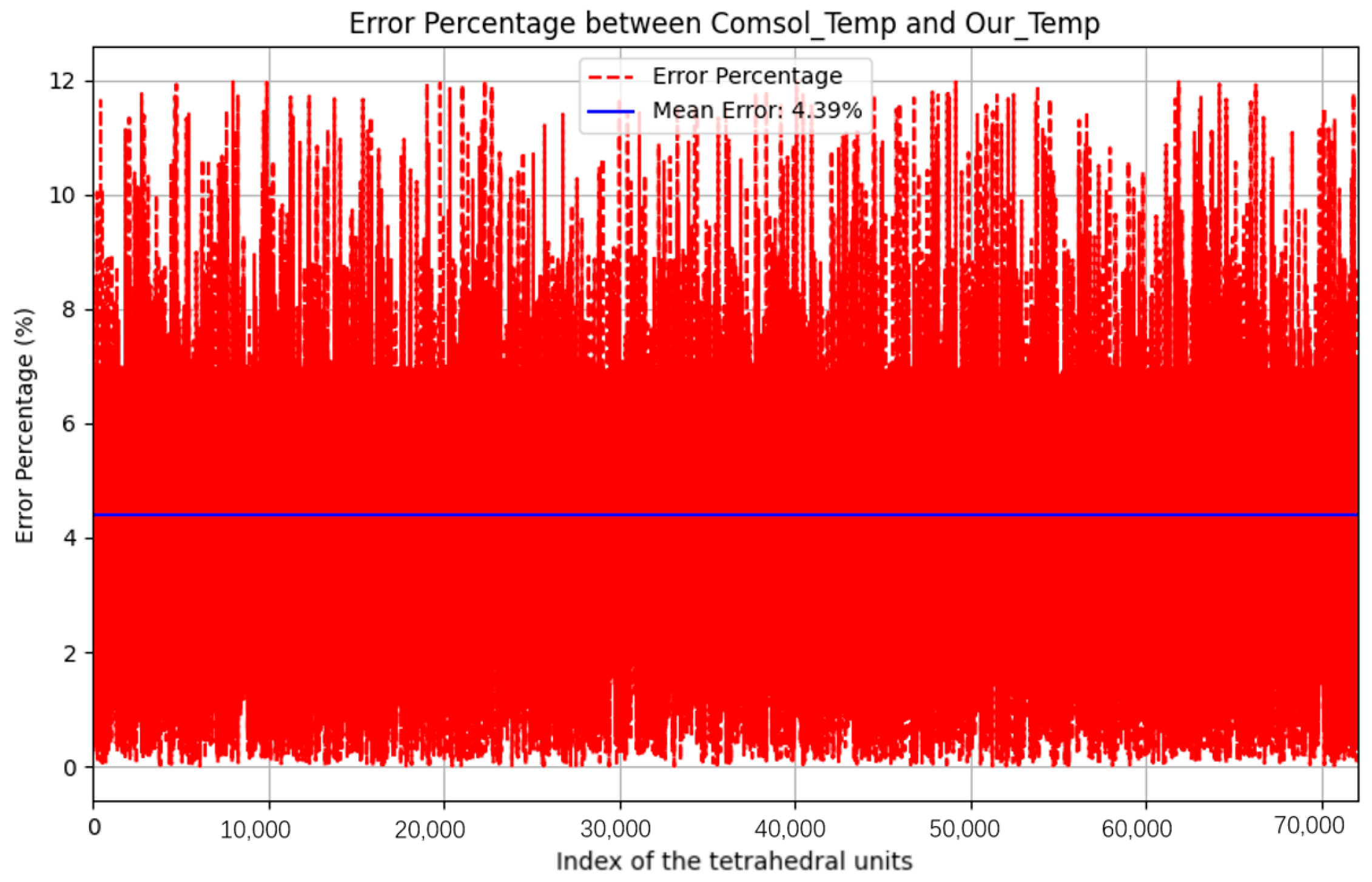

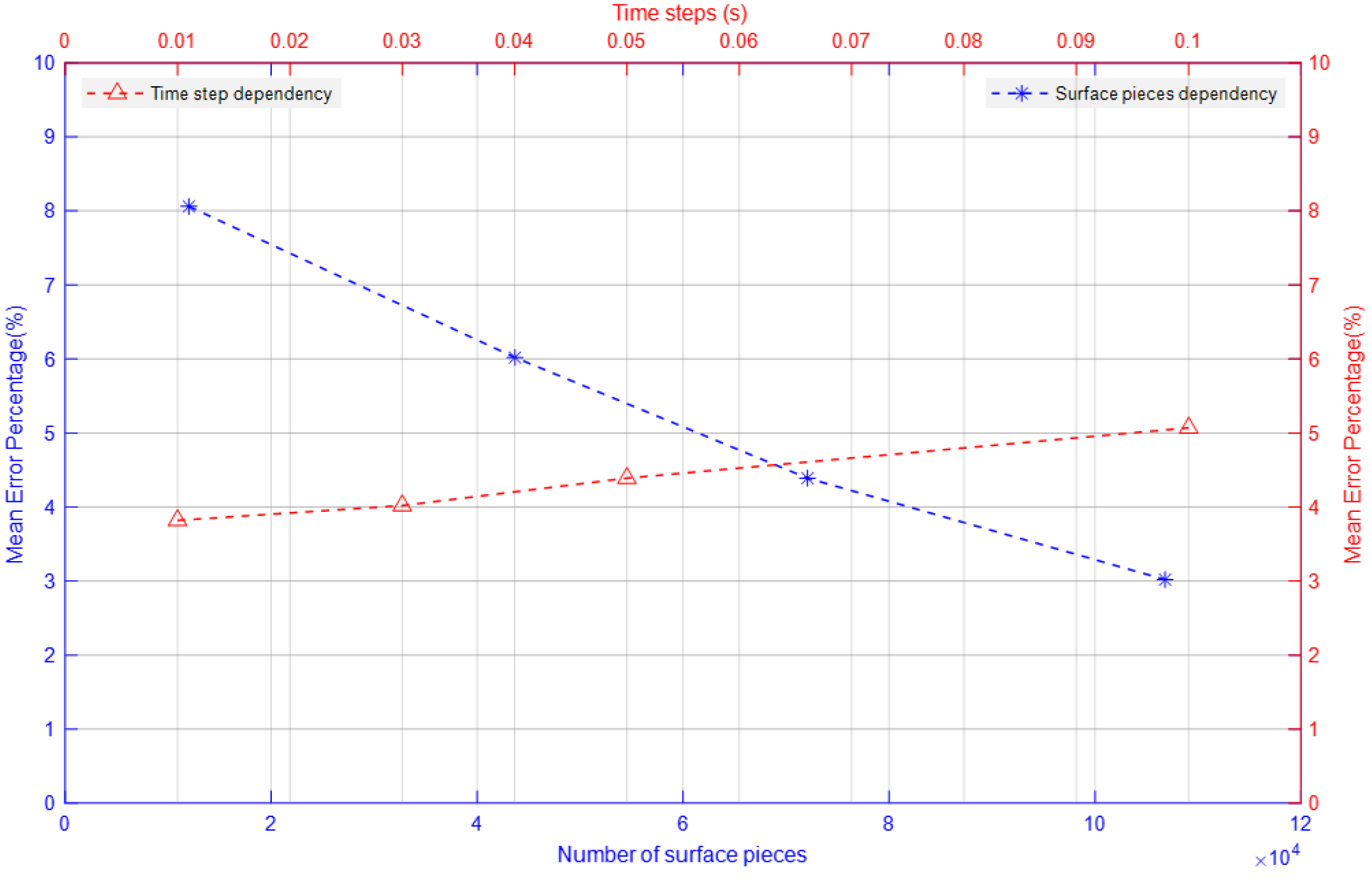

4.2. Temperature Field Calculation Results

- Sunlit surfaces exhibit thermal energy accumulation due to high absorptivity and low emissivity, resulting in localized temperatures 96.13 °C higher than shadowed surfaces.

- Shadowed surfaces approach the space environment baseline temperature under deep-space background radiation.

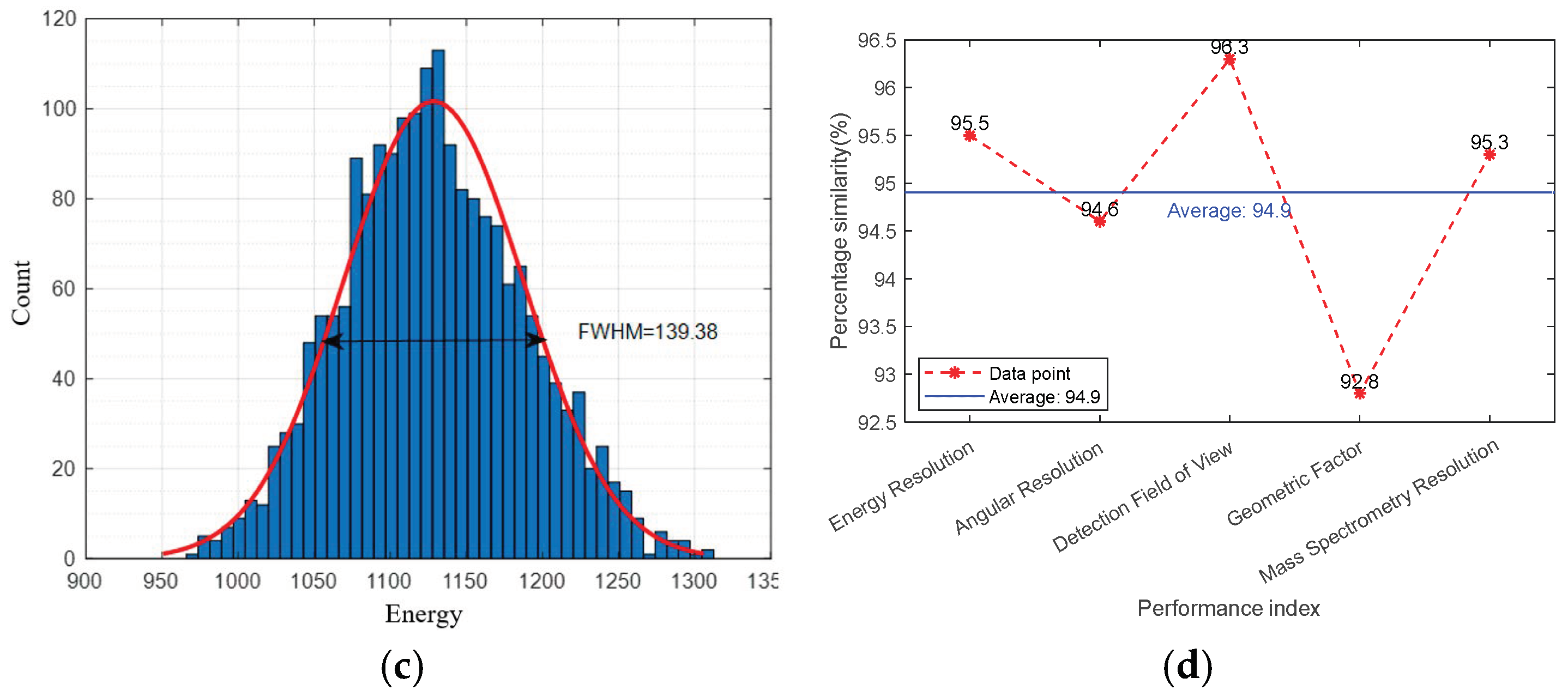

4.3. Impact of Thermoelastic Deformation on the PUIA’s Performance

5. Conclusions

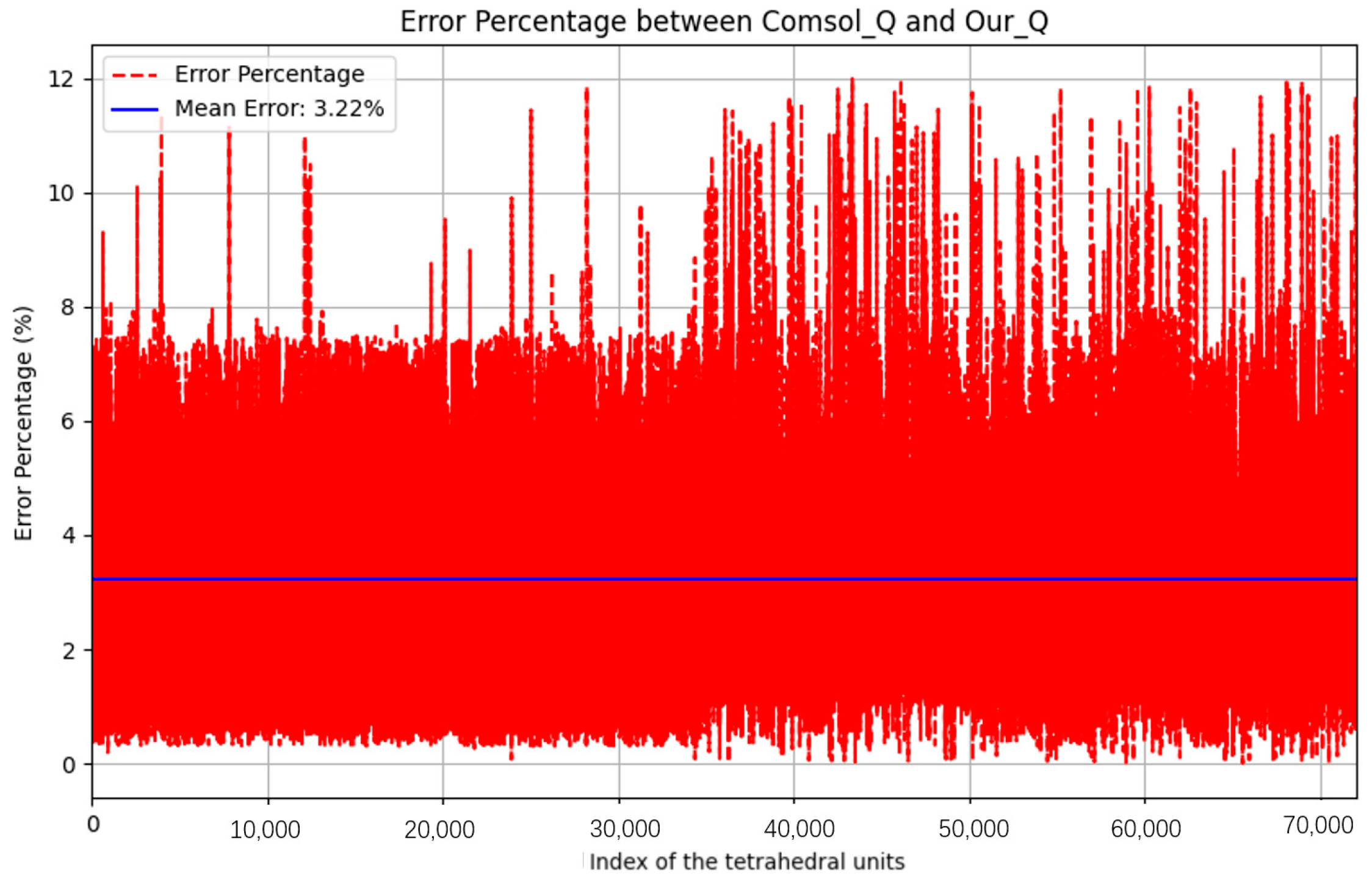

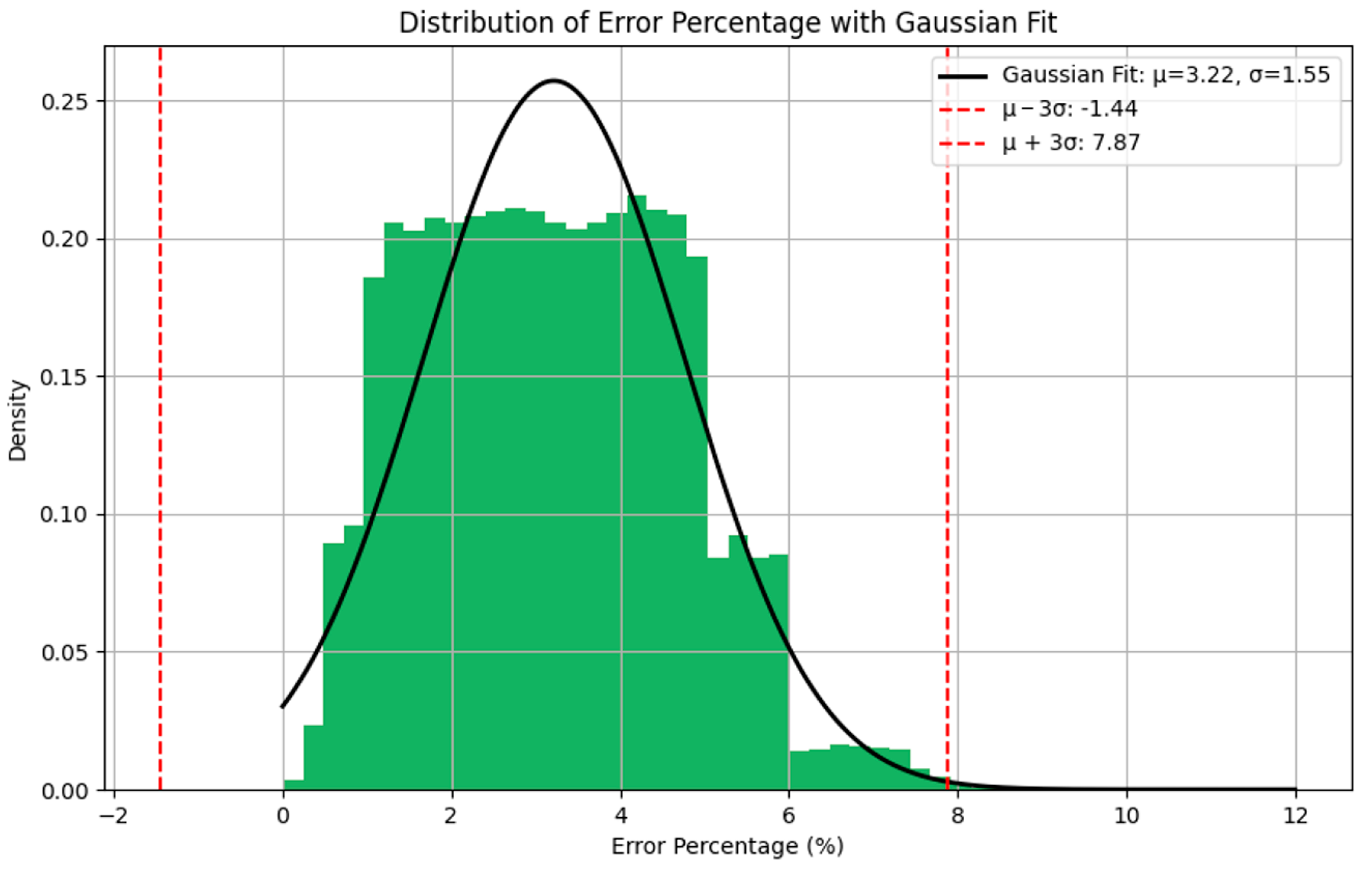

- External heat flux calculations reveal significant disparities in thermal flux density between sunlit and shadowed instrument surfaces, with a mean error of 3.22% compared to COMSOL Multiphysics 6.2® simulations. This can be used as a key input for subsequent temperature field calculations.

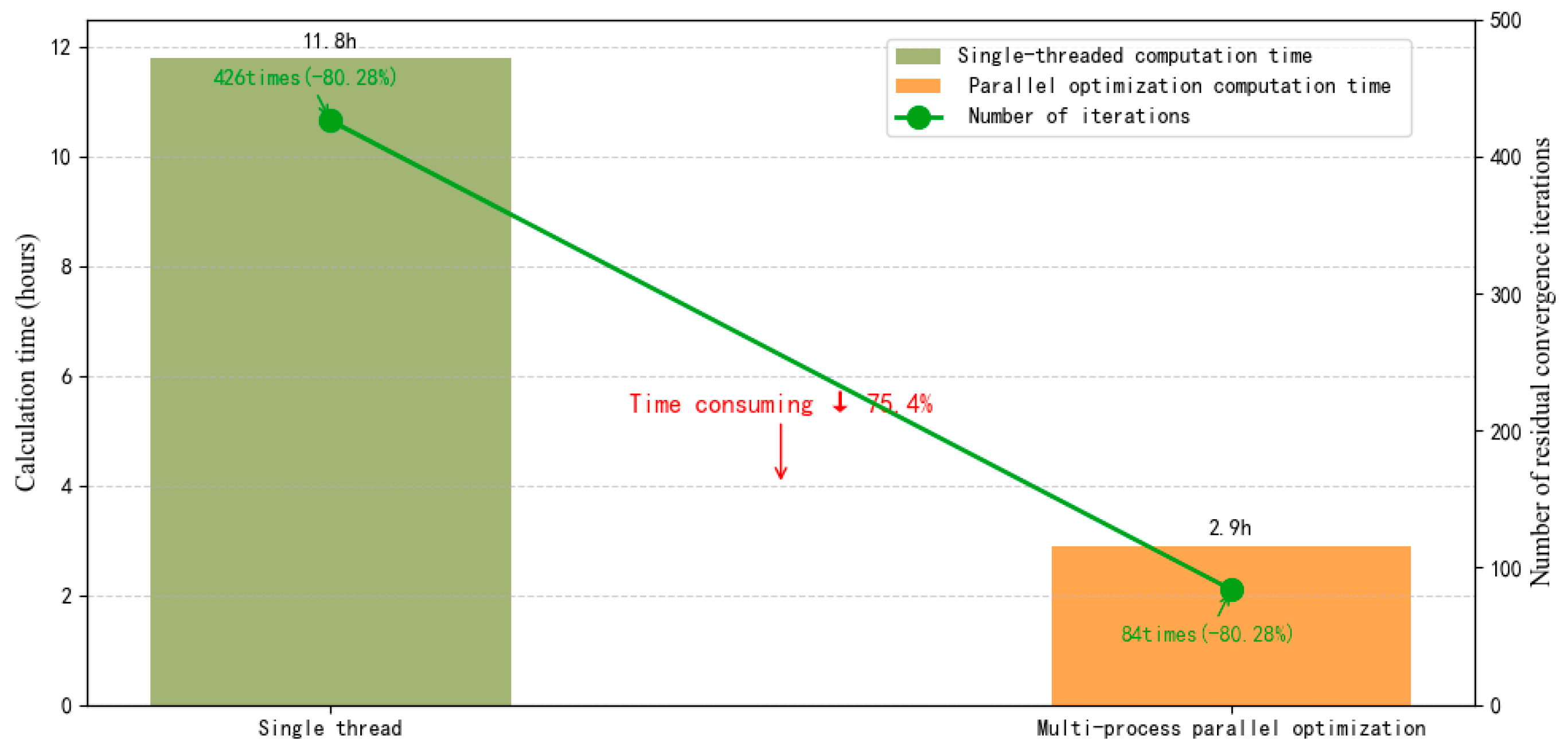

- For temperature field solutions, LU decomposition-based parallel optimization reduces computational time from 11.8 h to 2.9 h, yielding steady-state temperature distributions ranging from −45 °C to 51.13 °C. Computational errors relative to COMSOL simulations follow a Gaussian distribution (μ = 4.39%, σ = 1.66%), satisfying engineering accuracy requirements.

- Under the influence of temperature effects, the performance of the PUIA after thermal deformation is analyzed in this paper. Compared with the simulation results before thermal deformation, the ion energy resolution, angular resolution, detection field of view, geometric factor, and mass spectrometry resolution of the PUIA after thermal deformation are not more than 7.2%.

- This research reveals the thermo-mechanical coupling effect of the PUIA in the deep-space thermal environment. Through the high-precision external heat flow method and the parallel algorithm based on LU decomposition, the calculation efficiency of the temperature field was increased by 75%, and the calculation of the thermal deformation caused by the temperature layer was completed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Lei, N.; Li, S.; Zhang, J. Infrared radiation properties of a satellite on the basis of 3D reconstruction. Appl. Opt. 2024, 63, 721–729. [Google Scholar] [CrossRef] [PubMed]

- Semena, N.P. The Importance of Thermal Modes of Astrophysical Instruments in Solving Problems of Extra-Atmospheric Astronomy. Cosm. Res. 2018, 56, 293–305. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Wang, H.Y.; Zhang, C.M.; Yang, J.; Liang, X.; Gao, M.; Wang, J.; Cui, X.; Peng, W. Thermal Control Design and Simulation Calculation of the Alpha Particle X-ray Spectrometer. Chin. J. Space Sci. 2013, 33, 672–677. [Google Scholar] [CrossRef]

- Seo, H.S.; Rhee, J.; Han, E.S.; Kim, I.-S. Thermal failure of the LM117 regulator under harsh space thermal environments. Aerosp. Sci. Technol. 2013, 27, 49–56. [Google Scholar] [CrossRef]

- Gao, T.F.; Kong, L.G.; Su, B.; Zhang, A. Design and simulation of the detector for outer heliosphere pickup ions. J. Beijing Univ. Aeronaut. Astronaut. 2021, 49, 367–377. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Y.Z.; Peng, X.D.; Xue, C.B.; Su, B. A Comparative Analysis of Performance Simulation for PUI Detectors Based on Traditional Probability Model and the Vasyliunas and Siscoe Model. Sensors 2024, 24, 6233. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.H.; Chen, L.H.; Li, H.; Li, S.J.; Yang, Y.T. Computation of external heat fluxes on space camera with attitude change in geostationary orbit. Infrared Laser Eng. 2019, 48, 284–292. [Google Scholar] [CrossRef]

- Freire, P.C.; Kramer, M.; Lyne, A.G. Determination of the orbital parameters of binary pulsars. Mon. Not. R. Astron. Soc. 2001, 322, 885–890. [Google Scholar] [CrossRef]

- Lee, S.H.; Eman, K.F.; Wu, S.M. Trajectory control in the world coordinate system by an adaptive forecasting algorithm. Int. J. Prod. Res. 1989, 27, 451–461. [Google Scholar] [CrossRef]

- Geng, Y. The Design and Implementation of External Heat Flux Calculation Software Based on the 3D Structure of the Satellite. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2012. [Google Scholar]

- Li, Y.Z.; Ning, X.W.; Wang, X.M.; Shi, X.B.; Zhuang, D.M.; Wang, J. Simulating Analysis of Nano-satellite’s Orbital Thermal Environment. J. Syst. Simul. 2007, 19, 4. [Google Scholar] [CrossRef]

- Zheng, Y.H.; Ganushkina, N.Y.; Jiggens, P.; Jun, I.; Meier, M.; Minow, J.I.; O’Brien, T.P.; Pitchford, D.; Shprits, Y.; Tobiska, W.K.; et al. Space radiation and plasma effects on satellites and aviation: Quantities and metrics for tracking performance of space weather environment models. Space Weather 2019, 17, 1384–1403. [Google Scholar] [CrossRef] [PubMed]

- Anh, N.D.; Hieu, N.N.; Chung, P.N.; Anh, N.T. Thermal radiation analysis for small satellites with single-node model using techniques of equivalent linearization. Appl. Therm. Eng. 2016, 94, 607–614. [Google Scholar] [CrossRef]

- Li, P.; Cheng, H.E.; Qin, W.B. Numerical simulation of temperature field in solar arrays of spacecraft in low earth orbit. Numer. Heat Transf. Part A Appl. 2006, 49, 803–820. [Google Scholar] [CrossRef]

- Wang, L. Research on Thermal-Structural Analysis of in-Orbit Parabolidal Satellite Antenna. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2011. [Google Scholar]

- Shen, W.T.; Zhu, D.Q.; Cai, G.B. Calculation of Temperature Field and Infrared Radiation Characteristics of Midcourse Ballistic Target. J. Astronaut. 2010, 31, 2210–2217. [Google Scholar] [CrossRef]

- Perret, W.; Schwenk, C.; Rethmeier, M. Comparison of analytical and numerical welding temperature field calculation. Comput. Mater. Sci. 2010, 47, 1005–1015. [Google Scholar] [CrossRef]

- Chen, X.D.; Yang, J.; Zhao, X.D.; Fang, X.Q. The Status and Development of Finite Element Method. Manuf. Inf. Eng. China 2010, 39, 6–8. Available online: https://qikan.cqvip.com/Qikan/Article/Detail?id=34126107 (accessed on 2 April 2025).

- Zhang, J.Q.; Yu, B.; Song, C.M. The latest progress in research on the scaled boundary finite element method. Chin. J. Appl. Mech. 2022, 39, 1038–1054. Available online: https://www.researchgate.net/publication/366739588_bilibianjieyouxianyuanfadezuixinyanjiujinzhan_The_latest_progress_in_research_on_the_scaled_boundary_finite_element_method (accessed on 2 April 2025).

- Du, T.S.; Tan, T.G. Numerical Analysis and Experiments, 2nd ed.; Science Press: Beijing, China, 2012; ISBN 9787030356345. [Google Scholar]

- Ding, L.J.; Cheng, Q.Y. Numerical Calculation Methods, 2nd ed.; Beijing Institute of Technology Press: Beijing, China, 2005; ISBN 9787810453172. [Google Scholar]

- COMSOL. Newly released COMSOL Multiphysics~6.2 version. Electr. Age 2023, 18–19. Available online: https://d.wanfangdata.com.cn/periodical/dqsd202312005 (accessed on 2 April 2025).

- Zhang, D.M. Research on Temperature Characteristics of Optical Antenna for Satellite Optical Communication Terminal. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2011. [Google Scholar]

- Zienkiewicz, O.C.; Taylor, R.L.; Zhu, J.Z. The Finite Element Method: Its Basis and Fundamentals, 7th ed.; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar] [CrossRef]

- Han, J.; Dai, Q.; Zhao, Y.L.; Li, G.M. Study on Fatigue Performance of 7075-T651 Alum inum Alloys. J. Aeronaut. Mater. 2010, 30, 92–96. Available online: https://kns.cnki.net/kcms2/article/abstract?v=EKYfHJ8l29hQrTZKDauIiJmRJxe6s0xrJpceD-VgmT6-5hj4NedKtEpL__5knwWRmA70yBz6Sp6eTF8gKse7-t9it4KeZO4K7t94-uvD5Nr-0etxBtIj75dL4eNamC2--9UYHnogY2Wde3QN-zLaQqrXS84Bo5hLej7MUpq-NJuQ5GpHoqfprA==&uniplatform=NZKPT&language=CHS (accessed on 2 April 2025).

- Mínguez, J.M.; Vogwell, J. Fatigue life of an aerospace aluminum alloy subjected to cold expansion and a cyclic temperature regime. Eng. Fail. Anal. 2006, 13, 997–1004. [Google Scholar] [CrossRef]

| Parameter Name | Symbol | Value | Unit/Note |

|---|---|---|---|

| Solar constant * | 1353 | W/m2 | |

| Solar radiation absorption rate * | 0.7 | Dimensionless | |

| Number of grid cells | 90,150 | Tetrahedral Unit | |

| Number of surface pieces | 72,082 | Triangle Dlice | |

| Track radius | R | 38 | AU |

| Parameter Name | Symbol | Value | Unit/Note |

|---|---|---|---|

| Constant pressure heat capacity * | 900 | J/(kg·K) | |

| Density | 3900 | kg/m3 | |

| Thermal conductivity * | 27 | W/(m·K) | |

| Coefficient of thermal expansion | 8 × 10−6 | 1/K | |

| Young’s modulus | E | 300 | GPa |

| Boltzmann constant * | 5.67 × 10−8 | W/(m2·K2) | |

| Poisson’s ratio | 0.222 | Dimensionless |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Zhang, Y.; Peng, X.; Xue, C.; Su, B.; Zhu, Y. Impact Analysis of Temperature Effects on the Performance of the Pick-Up Ion Analyzer. Aerospace 2025, 12, 388. https://doi.org/10.3390/aerospace12050388

Cao Y, Zhang Y, Peng X, Xue C, Su B, Zhu Y. Impact Analysis of Temperature Effects on the Performance of the Pick-Up Ion Analyzer. Aerospace. 2025; 12(5):388. https://doi.org/10.3390/aerospace12050388

Chicago/Turabian StyleCao, Yu, Yuzhu Zhang, Xiaodong Peng, Changbin Xue, Bin Su, and Yiming Zhu. 2025. "Impact Analysis of Temperature Effects on the Performance of the Pick-Up Ion Analyzer" Aerospace 12, no. 5: 388. https://doi.org/10.3390/aerospace12050388

APA StyleCao, Y., Zhang, Y., Peng, X., Xue, C., Su, B., & Zhu, Y. (2025). Impact Analysis of Temperature Effects on the Performance of the Pick-Up Ion Analyzer. Aerospace, 12(5), 388. https://doi.org/10.3390/aerospace12050388