The Dynamic Response of Aluminum Alloy Plates Subjected to Multiple-Fragment Impacts Under Pre-Tensile Loading: A Numerical Study

Abstract

1. Introduction

2. Numerical Simulation

2.1. Numerical Simulation Setups

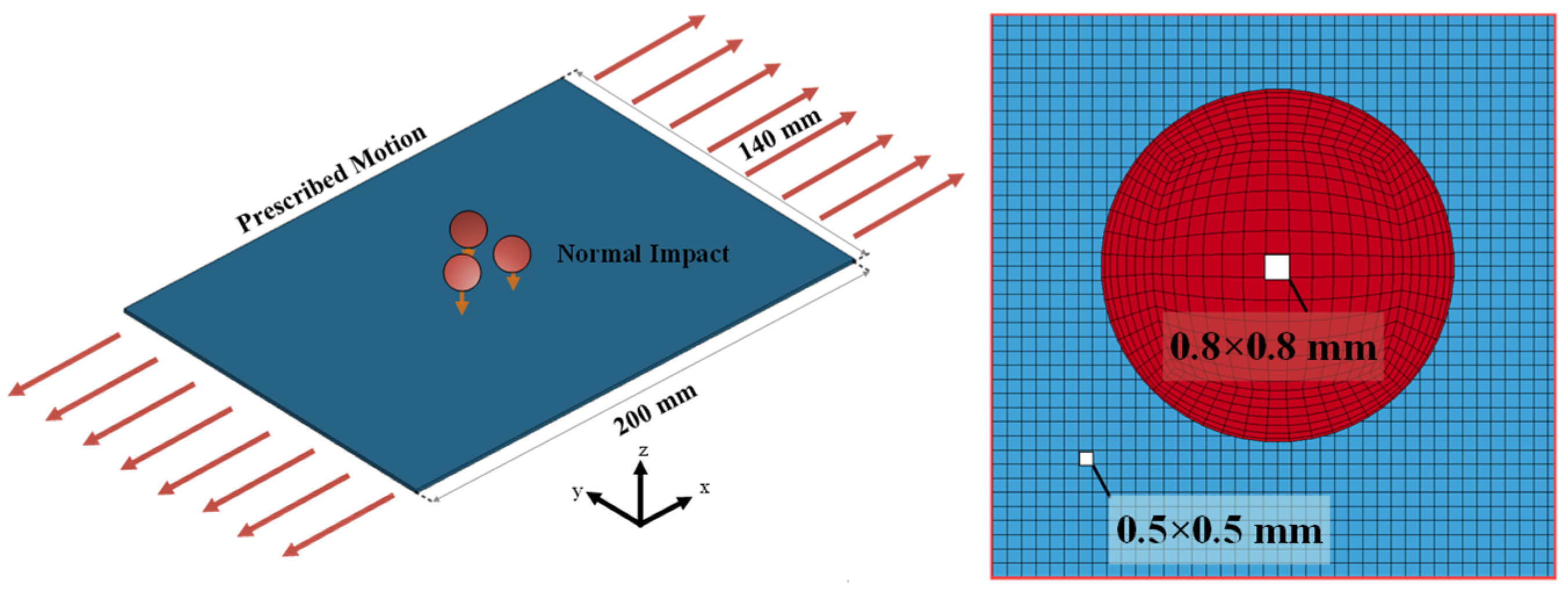

2.1.1. Model Setup

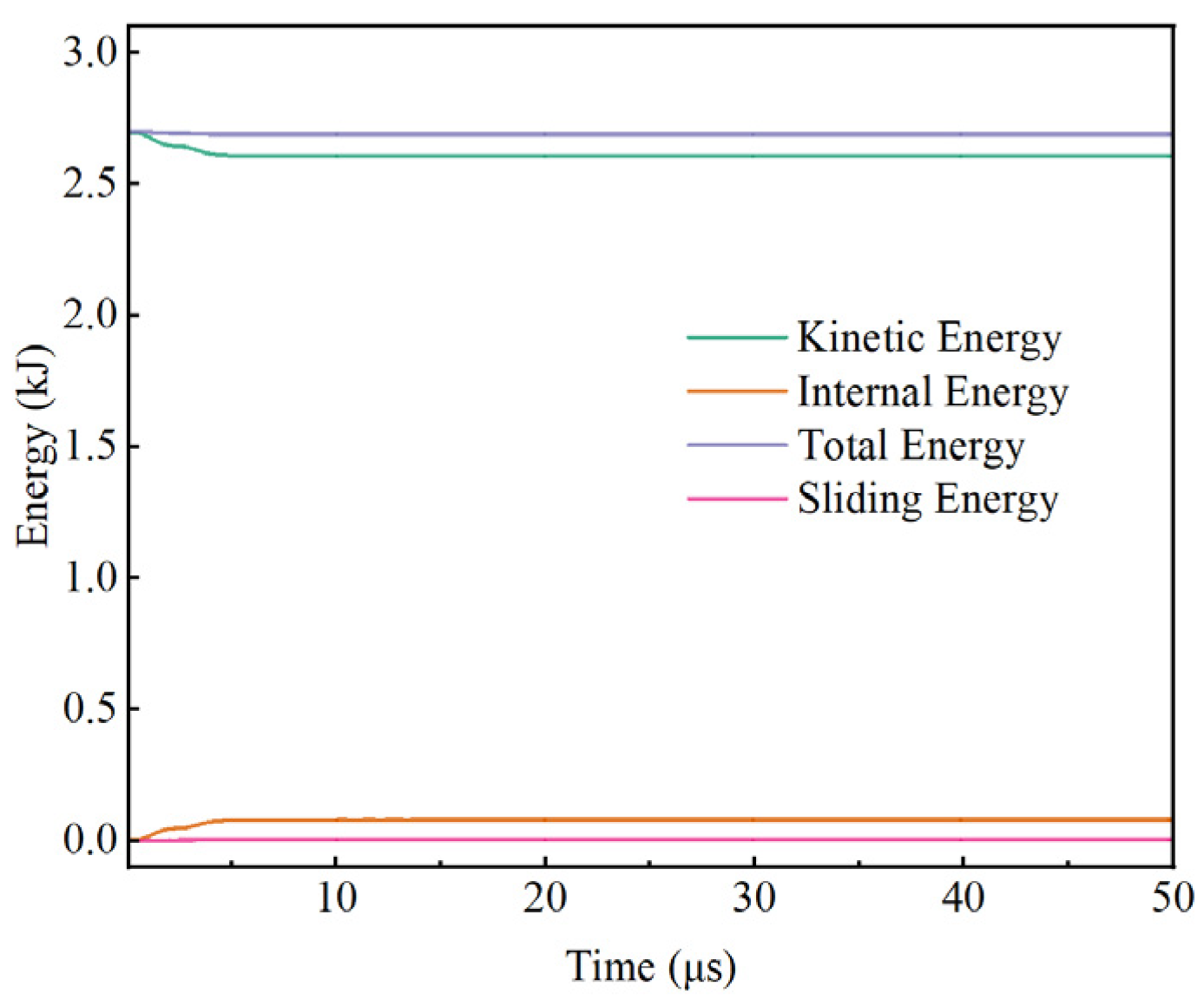

2.1.2. Mesh Converge and Energy Conservation

2.1.3. Constitutive Models

2.2. Model Validation

2.2.1. Damage Morphology Comparison

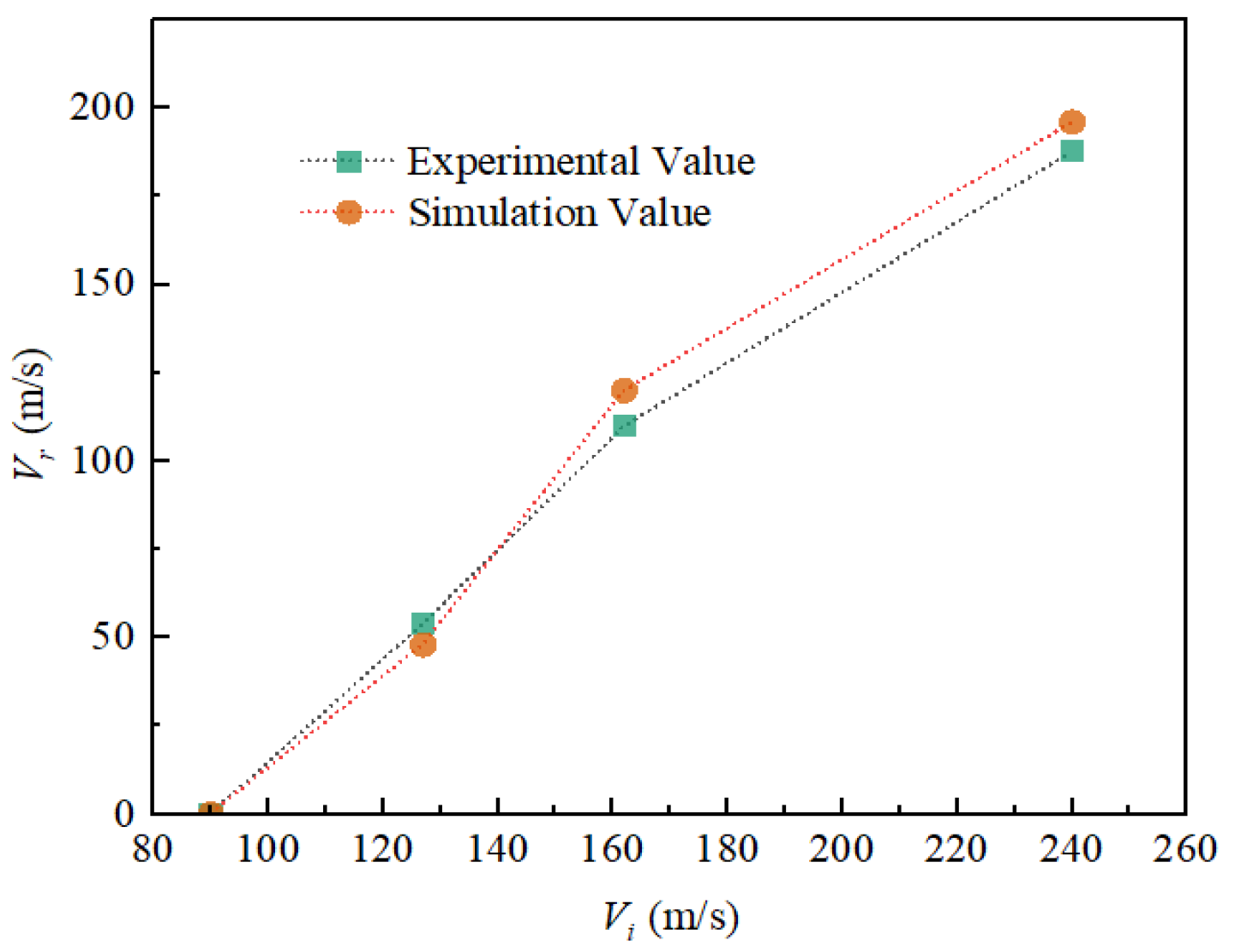

2.2.2. Residual Velocity Comparison

3. Results and Discussion

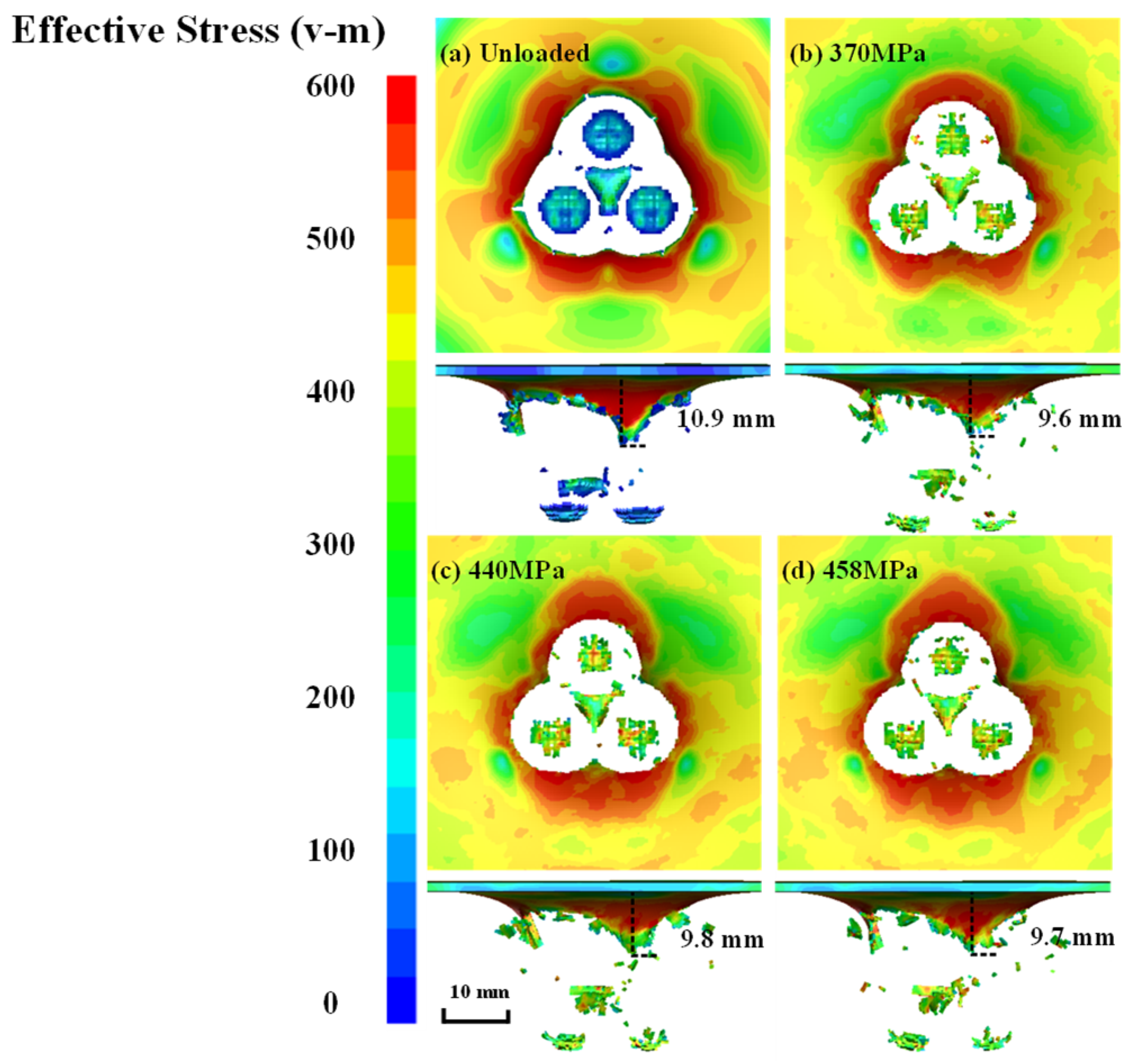

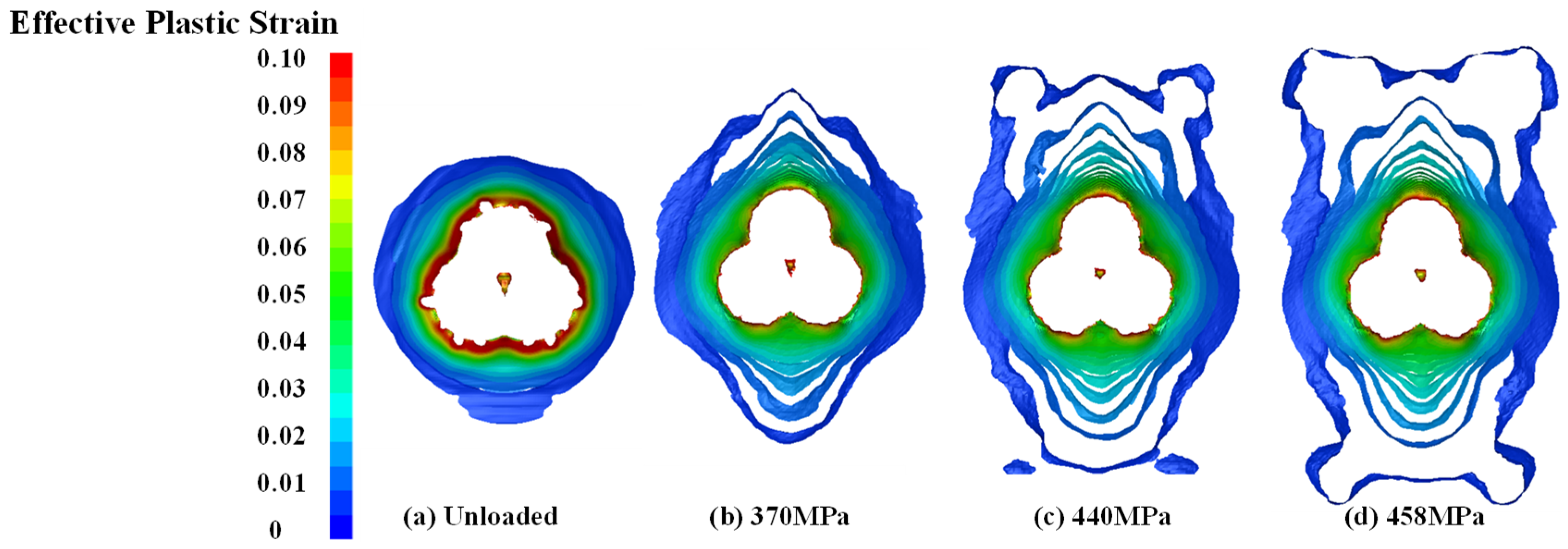

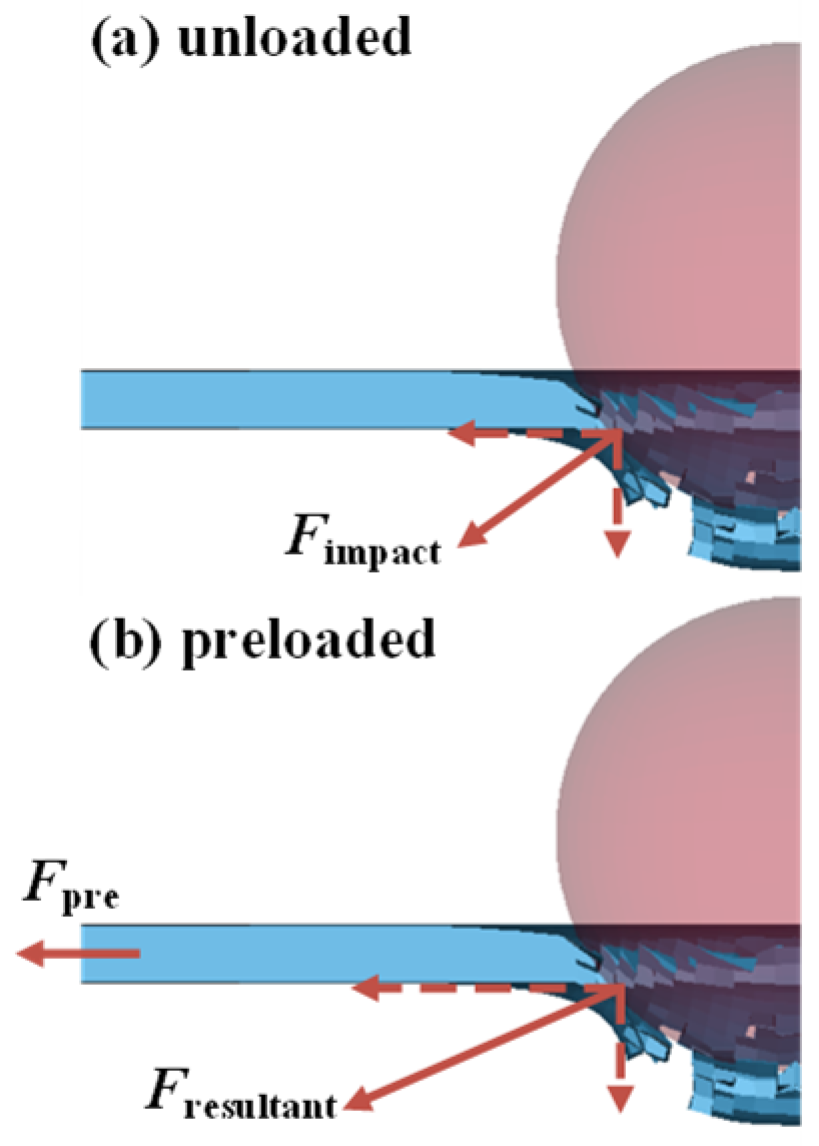

3.1. Preloaded Level

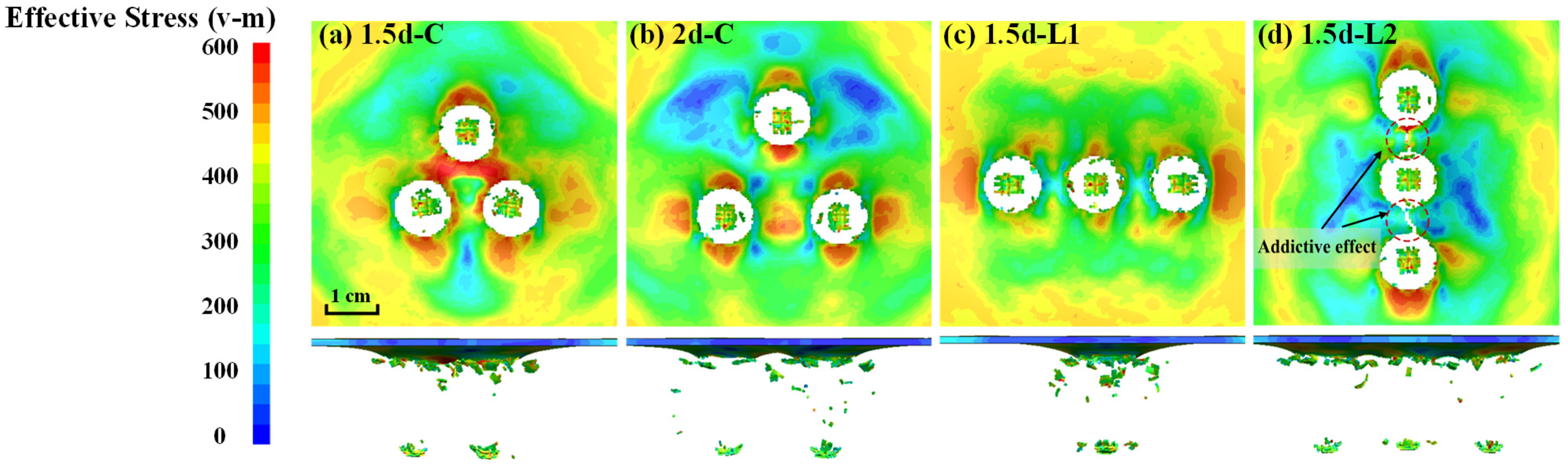

3.2. Fragment Distribution

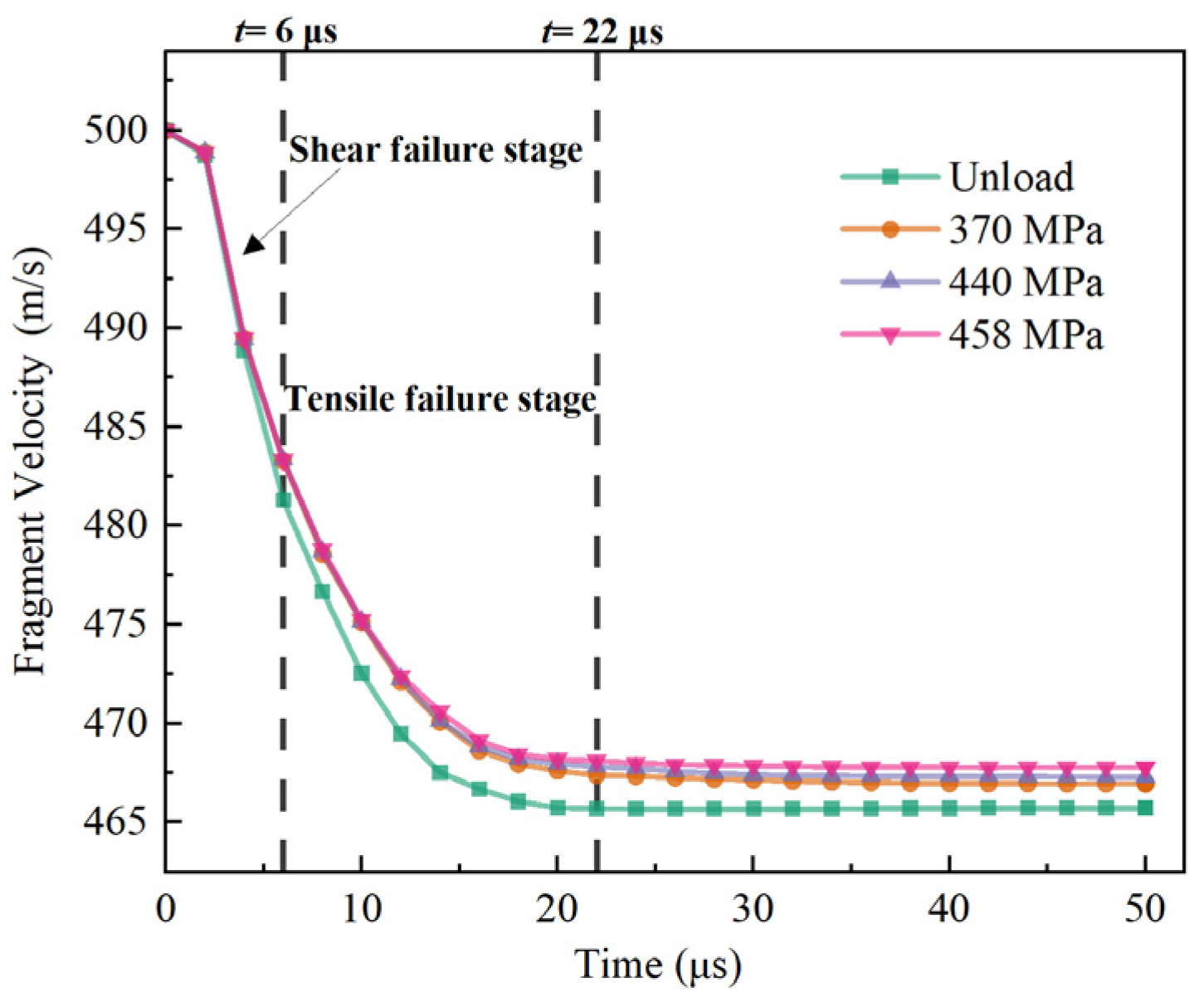

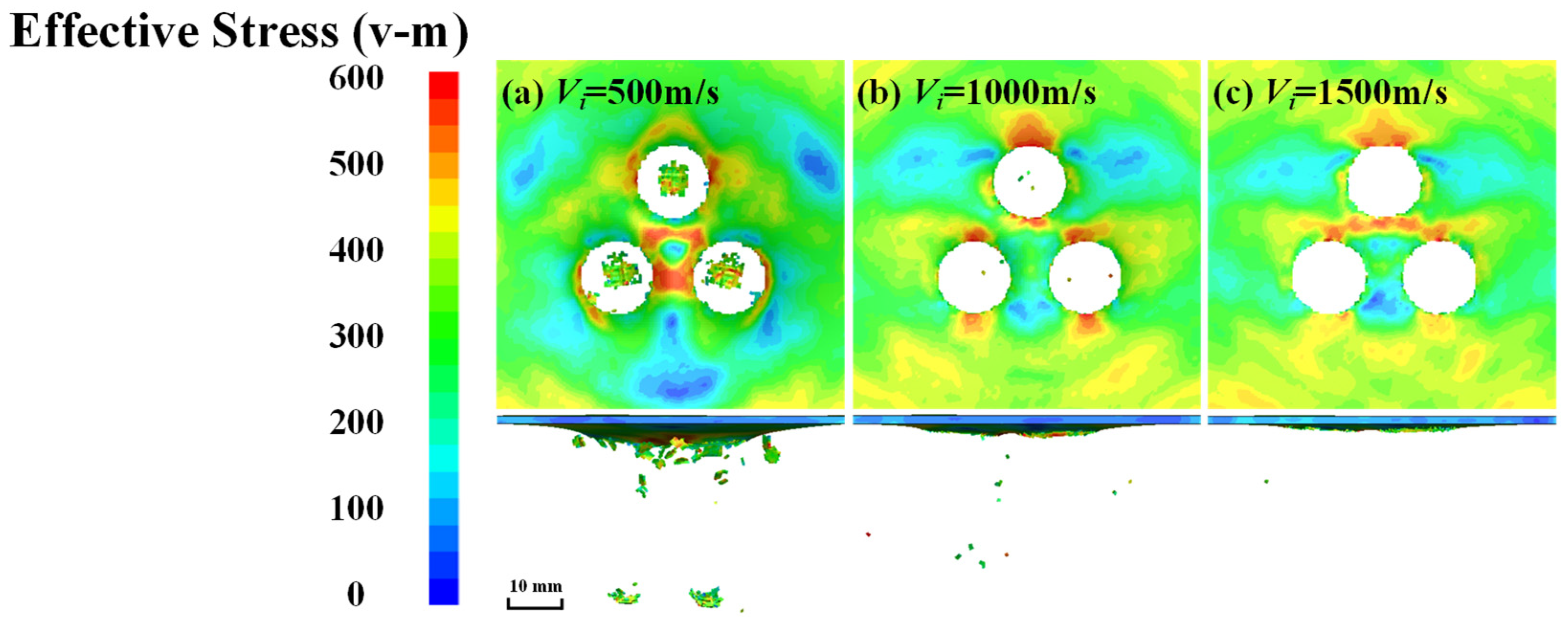

3.3. Fragment Velocity

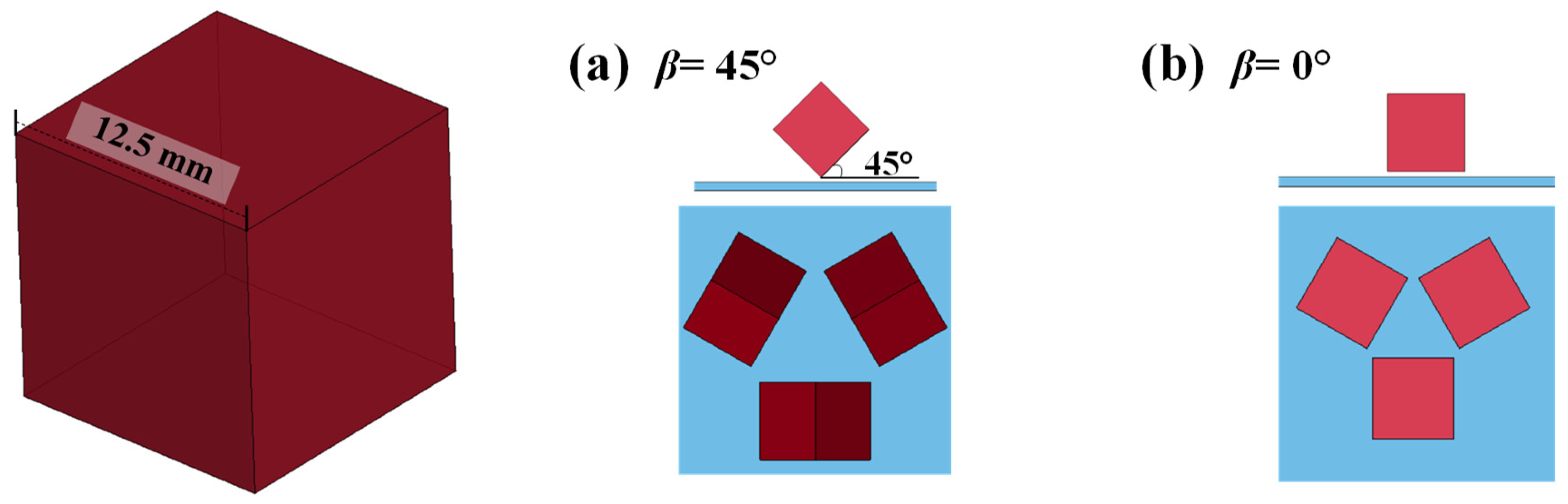

3.4. Fragment Shape and Attitude Angle

4. Conclusions

- (1)

- Tensile loading alters the propagation pattern of impact stress waves, causing them to spread in a fan shape. The region along the tensile direction experiences weaker stress, while the region perpendicular to the tensile direction experiences stronger stress.

- (2)

- Tensile loading reduces the resistance of the target plate to fragment penetration, leading to a slower rate of velocity reduction. Additionally, it decreases the interaction time between the fragment and target, resulting in higher residual velocity. However, under high-speed impact conditions, the short contact time limits the influence of the loading level on the final residual velocity.

- (3)

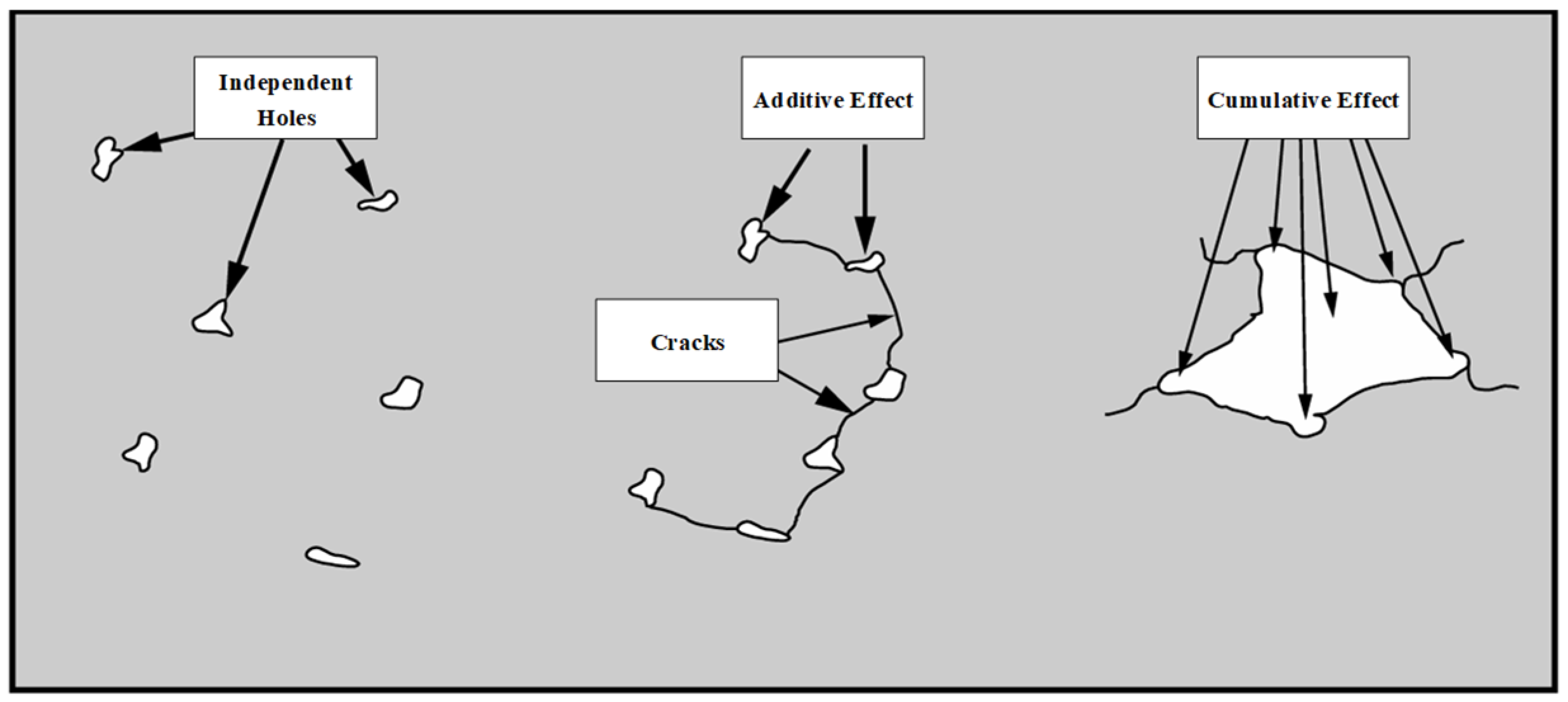

- The distribution pattern of fragments (the position of penetration holes) significantly affects the structural response under tensile conditions. Stress superposition perpendicular to the tensile direction is more likely to cause additive damage among projectiles, leading to severe net cross-sectional loss and a significant drop in load-carrying capacity, ultimately resulting in catastrophic failure.

- (4)

- Fragment velocity significantly influences damage coupling and failure mode transition under pre-tensile loading. As the fragment velocity increases, the stress coupling effect between the various penetration holes further diminishes, and the penetration behavior becomes increasingly independent.

- (5)

- Fragment geometry significantly affects target damage under pre-tensile loading. Spherical fragments cause symmetric shear plugging with uniform stress, while sharp-edged cubic fragments (e.g., β = 45°) induce localized stress concentrations, promoting crack initiation and tearing. Flat-ended cubic fragments (β = 0°) generate larger shear plugs via extensive plastic deformation. Pre-tension amplifies the following effects: sharp fragments exhibit enhanced tensile crack propagation, and flat fragments show increased perpendicular plastic deformation. Geometric variations thus modulate damage mechanisms.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pywell, M.; MacDiarmid, I. Design Aspects of Aircraft Vulnerability. In Encyclopedia of Aerospace Engineering; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Dou, M.; Fan, Z.; Li, L.; Wang, X.; Li, L. Experimental and numerical investigation on high-velocity hail impact response of TC4 titanium alloy plates. Thin-Walled Struct. 2024, 197, 111582. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, T.; He, Y.; Ye, J.; Zhang, H.; Fan, X. Analysis of Damage of Typical Composite/Metal Connecting Structure in Aircraft under the Influences of High-Velocity Fragments. Appl. Sci. 2022, 12, 9268. [Google Scholar] [CrossRef]

- Wang, Y.-T.; He, Y.-T.; Zhang, T.; Fan, X.-H.; Zhang, T.-Y. Damage analysis of typical structures of aircraft under high-velocity fragments impact. Alex. Eng. J. 2023, 62, 431–443. [Google Scholar] [CrossRef]

- Chen, T.; Chong, J.; Changxiao, Z.; Xin, W.; Yuting, W. Mechanism of polyurea in protecting liquid-filled square aluminum tube from the impact of high-velocity projectile. Thin-Walled Struct. 2023, 182, 110315. [Google Scholar]

- Qian, L.; Qu, M. Study on terminal effects of dense fragment cluster impact on armor plate. Part II: Numerical simulations. Int. J. Impact Eng. 2005, 31, 769–780. [Google Scholar] [CrossRef]

- Qian, L.; Qu, M.; Feng, G. Study on terminal effects of dense fragment cluster impact on armor plate. Part I: Analytical model. Int. J. Impact Eng. 2005, 31, 755–767. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, Y.; Du, S.; Yang, Z.; Cheng, H.; Wang, F. Effects of the adhesive layer on the multi-hit ballistic performance of ceramic/metal composite armors. J. Mater. Res. Technol. 2021, 13, 1496–1508. [Google Scholar] [CrossRef]

- Qiang, L.; Zhang, R.; Zhao, C.; Ren, J.; Ni, C.; Zhenyu, Z.; Lu, T. Multiple ballistic impacts of thin metallic plates: Numerical simulation. ARCHIVE Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 7962–7973. [Google Scholar] [CrossRef]

- Paredes-Gordillo, M.A.; Iváñez, I.; García-Castillo, S.K. Numerical study of the simultaneous multiple impact phenomenon on CFRP plates. Compos. Struct. 2023, 320, 117194. [Google Scholar] [CrossRef]

- Göde, E.; Teoman, A.; Çetin, B.; Tonbul, K.; Davut, K.; Kuşhan, M.C. An experimental study on the ballistic performance of ultra-high hardness armor steel (Armox 600T) against 7.62 mm × 51 M61 AP projectile in the multi-hit condition. Eng. Sci. Technol. Int. J. 2023, 38, 101337. [Google Scholar] [CrossRef]

- Ball, R.E. The Fundamentals of Aircraft Combat Survivability Analysis and Design; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2003. [Google Scholar]

- Rathnasabapathy, M.; Mouritz, A.P.; Orifici, A.C. Finite element modelling of the impact response of fibre metal laminates under tension preloading. Compos. Part A Appl. Sci. Manuf. 2022, 157, 106930. [Google Scholar] [CrossRef]

- Kumar, V.V.; Rajendran, S.; Balaganesan, G.; Surendran, S.; Selvan, A.; Ramakrishna, S. High velocity impact behavior of Hybrid composite under hydrostatic preload. J. Compos. Mater. 2022, 56, 3769–3779. [Google Scholar] [CrossRef]

- Xu, S.; Li, Y.; Zhou, S.; Jiang, X.; Xie, W.; Zhang, W. Ballistic performance and damage analysis of CFRP laminates under uniaxial pretension and precompression. Int. J. Impact Eng. 2023, 178, 104620. [Google Scholar] [CrossRef]

- Gürgen, S. Impact Behavior of Preloaded Aluminum Plates at Oblique Conditions. Arab. J. Sci. Eng. 2019, 44, 1649–1656. [Google Scholar] [CrossRef]

- García-Castillo, S.K.; Sánchez-Sáez, S.; Barbero, E. Behaviour of uniaxially preloaded aluminium plates subjected to high-velocity impact. Mech. Res. Commun. 2011, 38, 404–407. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, B.; Zhang, S. The Advancement of 7XXX Series Aluminum Alloys for Aircraft Structures: A Review. Metals 2021, 11, 718. [Google Scholar] [CrossRef]

- Brar, N.S.; Joshi, V.S.; Harris, B.W. Constitutive Model Constants for Al7075-T651 and Al7075-T6. AIP Conf. Proc. 2009, 1195, 945–948. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

| Johnson–Cook Model Parameters | Symbol | 7075-T6 |

|---|---|---|

| Density (kg/m3) | R0 | 2770 |

| Poisson’s ratio | PR | 0.33 |

| Young’s modulus (GPa) | E | 71.7 |

| Static yield limit (MPa) | A | 448 |

| Strain hardening modulus | B | 343 |

| Strain hardening exponent | n | 0.41 |

| Thermal softening exponent | m | 1.0 |

| Strain rate coefficient | C | 0.0015 |

| Failure parameter D1 | D1 | 0.13 |

| Failure parameter D2 | D2 | 0.13 |

| Failure parameter D3 | D3 | −1.5 |

| Failure parameter D4 | D4 | 0.011 |

| Failure parameter D5 | D5 | 1.099 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, T.; Zhang, H.; He, Y.; Ma, L.; Ren, A. The Dynamic Response of Aluminum Alloy Plates Subjected to Multiple-Fragment Impacts Under Pre-Tensile Loading: A Numerical Study. Aerospace 2025, 12, 353. https://doi.org/10.3390/aerospace12040353

Wang Y, Zhang T, Zhang H, He Y, Ma L, Ren A. The Dynamic Response of Aluminum Alloy Plates Subjected to Multiple-Fragment Impacts Under Pre-Tensile Loading: A Numerical Study. Aerospace. 2025; 12(4):353. https://doi.org/10.3390/aerospace12040353

Chicago/Turabian StyleWang, Yitao, Teng Zhang, Hanzhe Zhang, Yuting He, Liying Ma, and Antai Ren. 2025. "The Dynamic Response of Aluminum Alloy Plates Subjected to Multiple-Fragment Impacts Under Pre-Tensile Loading: A Numerical Study" Aerospace 12, no. 4: 353. https://doi.org/10.3390/aerospace12040353

APA StyleWang, Y., Zhang, T., Zhang, H., He, Y., Ma, L., & Ren, A. (2025). The Dynamic Response of Aluminum Alloy Plates Subjected to Multiple-Fragment Impacts Under Pre-Tensile Loading: A Numerical Study. Aerospace, 12(4), 353. https://doi.org/10.3390/aerospace12040353