1. Introduction

The total drag of a large aircraft is primarily composed of skin friction drag, induced drag, pressure drag, and interference drag. Among these, skin friction drag accounts for more than 50% of the total drag [

1], representing the most significant potential for drag reduction. As a passive turbulence reduction method, the riblet surface requires no additional control devices, offers relatively straightforward implementation, and demonstrates significant drag reduction effects, thus holding greater application potential. Since the initial exploration of drag reduction effects of riblets by Walsh et al. [

2,

3,

4,

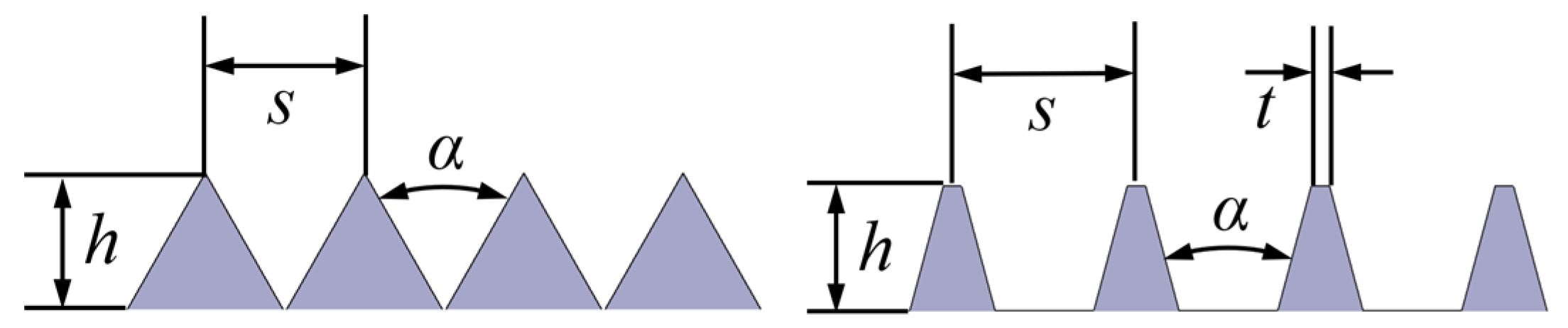

5] from NASA Langley Research Center in the 1980s, researchers have conducted extensive experimental and numerical simulation studies on this subject. Results demonstrate that triangular riblets with equal dimensionless height and width exhibit optimal drag reduction performance among various riblet configurations [

5]. Chan explored the influence of the riblet height-to-spacing ratio and found that the trend of the “k”-type behavior is associated with the destruction of near-wall cycle structures, which is indicated by the shortening of Reynolds stress structures [

6]. Regarding the drag reduction mechanism of riblets, multiple interpretations have been proposed in the literature [

7,

8,

9,

10,

11], yet a comprehensive theoretical framework has not been established to date.

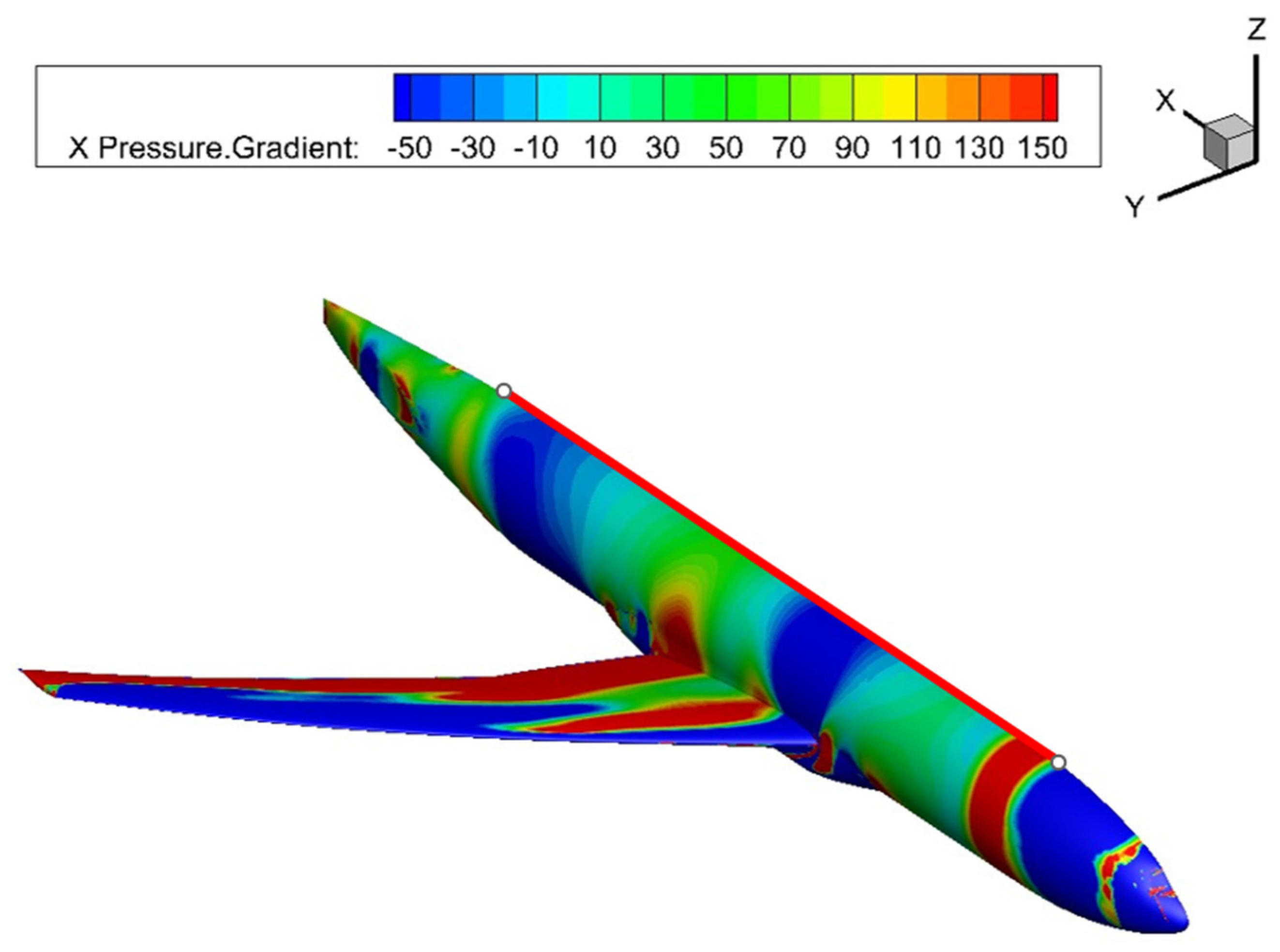

Aircraft surfaces represent a potential application scenario for riblets, which present three distinctive flow characteristics: firstly, the aircraft surface is subjected to high Reynolds number conditions; secondly, extensive adverse pressure gradient regions exist on the fuselage; finally, complex flow conditions around engine nacelles, wing-body junctions, and landing gear bays result in local flow directions that are not parallel to the fuselage centerline and dynamically adjust with changing flight attitudes, generating local crossflows. The model proposed by Wang can accurately predict the drag reduction effects of various riblet shapes (such as blade-shaped, trapezoidal, triangular, etc.) under optimal dimensions, and solves the problem that traditional models overestimate drag reduction at the optimal dimensions [

12]. However, existing research predominantly focuses on streamwise-aligned riblets under zero-pressure-gradient conditions, and due to experimental limitations, studies on riblets at high Reynolds numbers remain scarce.

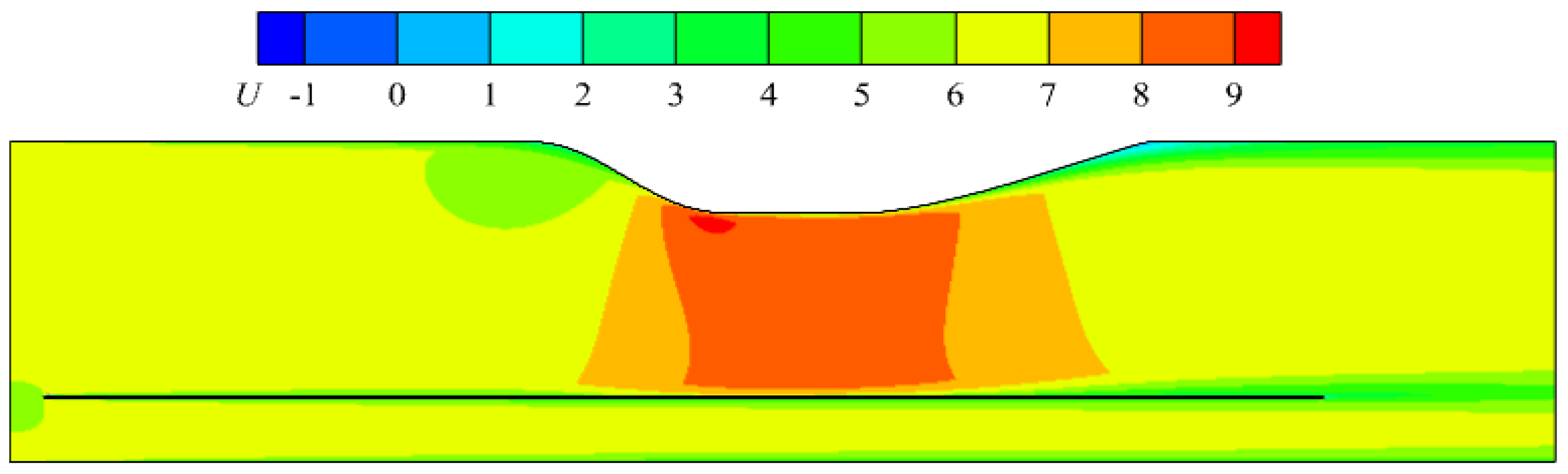

Numerous studies have investigated the effects of adverse pressure gradients on smooth flat-plate boundary layers. The presence of an adverse pressure gradient introduces certain modifications to boundary layer characteristics [

13]. High-resolution large eddy simulation was employed to comparatively analyze the drag reduction performance of riblets under zero pressure gradient and mild adverse pressure gradient conditions, which found that the drag reduction effect of riblets was only slightly improved under the mild adverse pressure gradient condition [

14]. In terms of the velocity profile, a strong adverse pressure gradient results in a slight downward shift in the log-law region in the mean velocity profile, indicating a thinning of the viscous sublayer [

15]. The Reynolds shear stress increases significantly with the intensity of the adverse pressure gradient, indicating a fundamental shift in the primary locations and mechanisms of turbulence production. The contributions and spatial distributions of the terms in the turbulent kinetic energy transport equation undergo profound modifications under such conditions [

14]. Hence, the potential influence of adverse pressure gradients on the drag reduction performance of riblets cannot be overlooked. Historically, research conclusions regarding this effect have exhibited significant contradictions: some studies suggest that adverse pressure gradients enhance the drag reduction rate of riblets [

16], while others report the opposite trend [

17,

18]. Consequently, conducting precise experimental measurements is essential to accurately characterize the drag reduction properties of riblets under realistic operating conditions.

Furthermore, the influence of local crossflow effects warrants in-depth investigation. The prevailing explanation for the drag reduction mechanism of riblets posits that their streamwise-periodic geometry suppresses the spanwise fluctuations of near-wall streamwise vortices, which are recognized as the primary instigators of turbulent bursting events and consequent wall friction generation. Park investigates the effect of yaw angle on the drag reduction performance of riblets in turbulent channel flow through direct numerical simulations. When the yaw angle α < 12°, riblets can still achieve drag reduction; however, their drag-reduction performance deteriorates as the yaw angle increases [

19]. Li also found that the riblet drag reduction rate decreases with the increase in the yaw angle, and its critical yaw angle decreases as the immersion height increases [

20]. Consequently, further experimental assessment of crossflow effects under varying Reynolds numbers and adverse pressure gradient conditions is necessary.

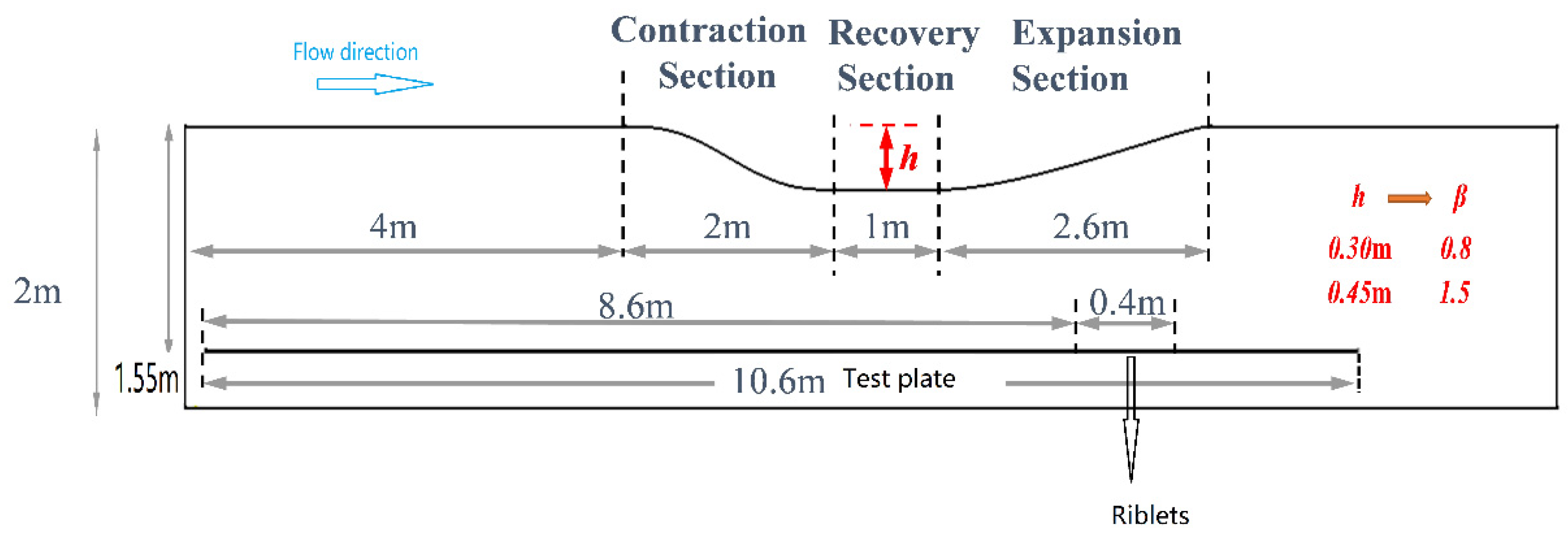

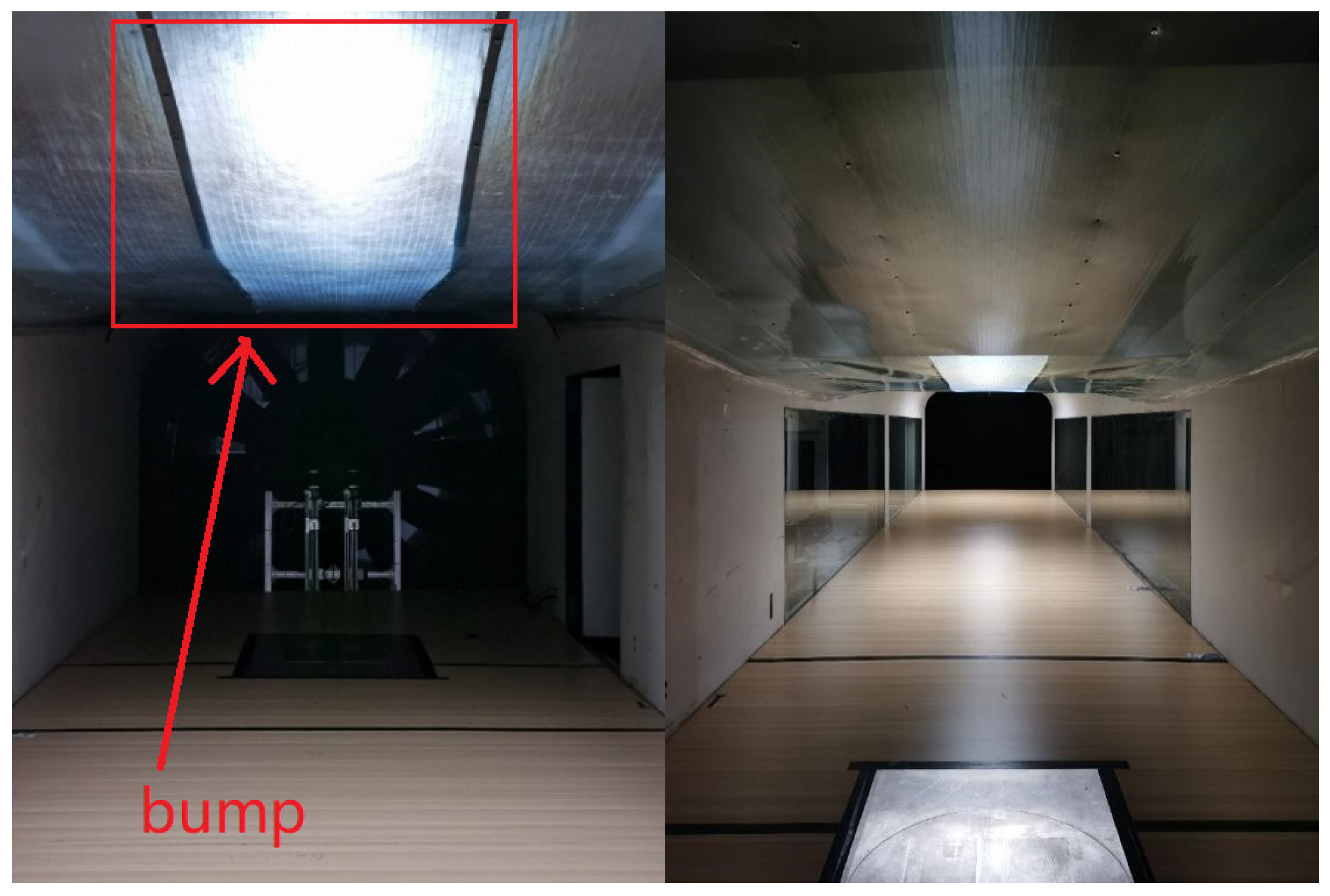

In summary, within the historical context of optimizing aerodynamic drag for large aircraft, obtaining experimental data that closely aligns with actual operating conditions is paramount for the modeling of riblets on such aircraft. This paper investigates the effects and underlying mechanisms of adverse pressure gradients and crossflow on the drag reduction rate of riblets under moderate-to-high Reynolds number conditions. The paper is structured as follows. Experimental setup describes the experimental methodology, including Experimental facilities, geometry of Riblets and design of TBL. The next two sections present drag reduction rate and turbulent statistics of riblets, respectively. The final section summarizes the conclusions.

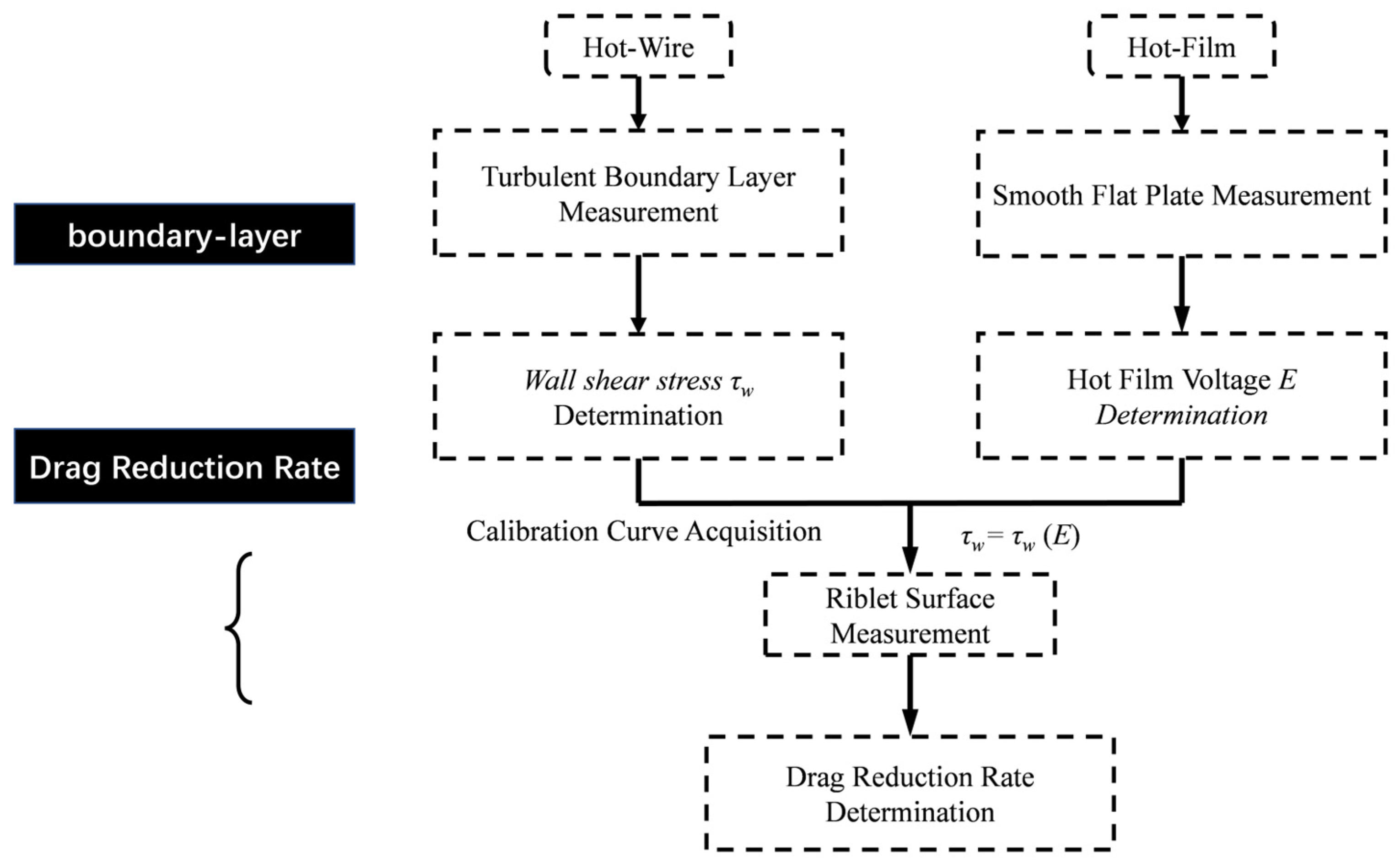

3. Drag Reduction Rate of Riblets

Under both zero pressure gradient and the aforementioned adverse pressure gradient conditions, drag reduction rates of riblet surfaces relative to smooth walls were measured using hot-film probes (also referred to as wall shear stress sensors). Conventional practice employs in situ calibration for this type of wall shear stress probe. Therefore, under smooth-wall conditions, the local wall shear stress

was first measured using hot-wire anemometry at various freestream velocities, while simultaneously recording the hot-film voltage

. This procedure established the calibration curve

for the hot-film probe. Subsequently, the smooth wall was replaced with a riblet surface to measure the drag reduction rate under varying freestream velocities (thus varying dimensionless riblet spacing

), yaw angles, and pressure gradient conditions. The measurement procedure is illustrated in

Figure 9:

The drag reduction rate is defined by Equation (1), where

represents the wall shear stress of the smooth surface and

represents the wall shear stress of the riblet surface. As described in

Figure 1, two measurement positions were designed in this experiment, enabling the following measurement protocol: during preliminary measurements, both positions are equipped with smooth flat plates. Subsequently, the smooth plate at Position 1 is replaced with a riblet-mounted plate, while Position 2 remains equipped with the smooth plate. This configuration offers the advantage of monitoring temporal variations in wall shear stress through repetitive measurements at Position 2. Given that the drag reduction rate of riblet surfaces typically ranges from 5% to 10%, this arrangement effectively eliminates the influence of freestream velocity fluctuations in the wind tunnel, thereby enhancing both the accuracy and efficiency of drag reduction rate measurements.

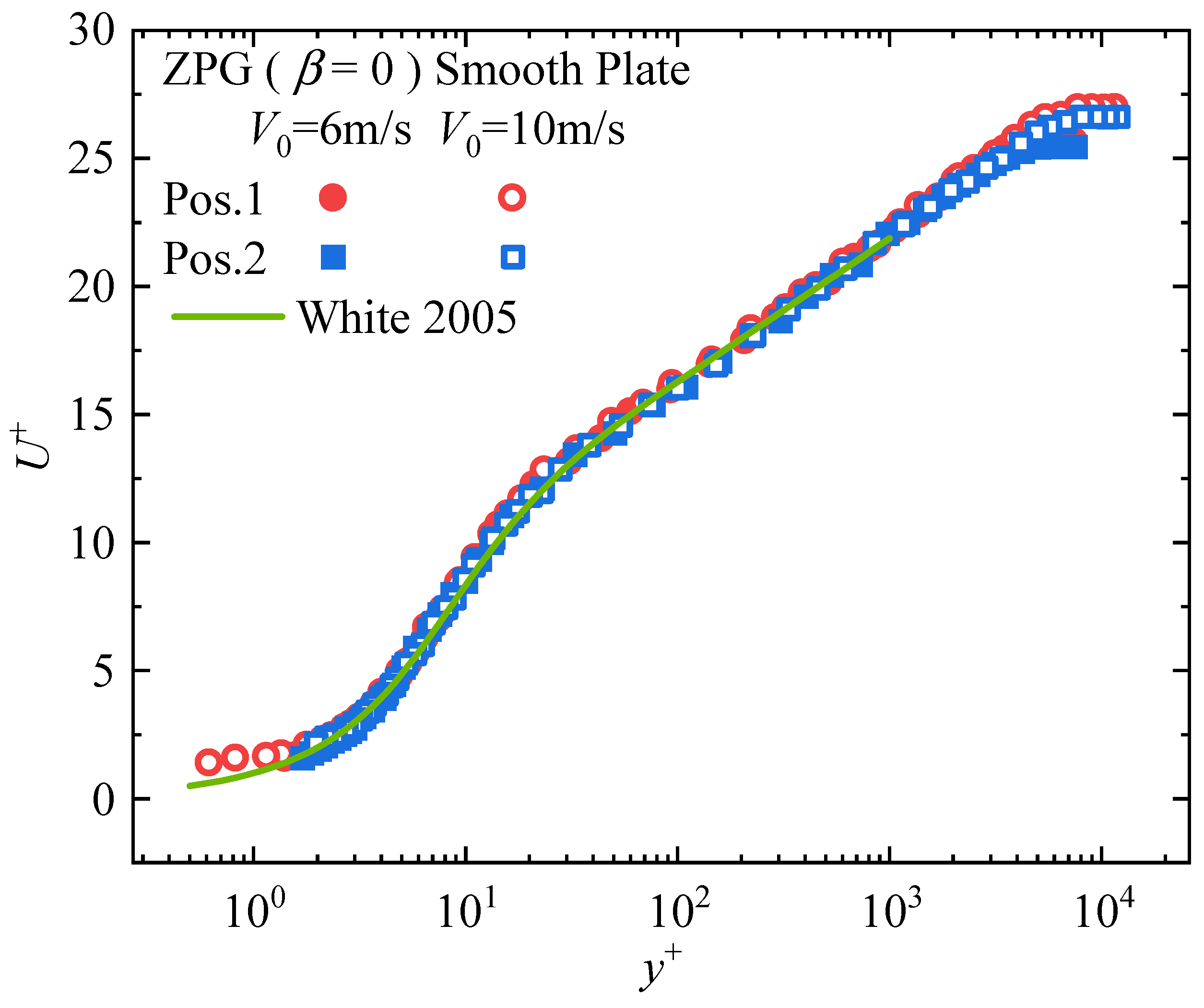

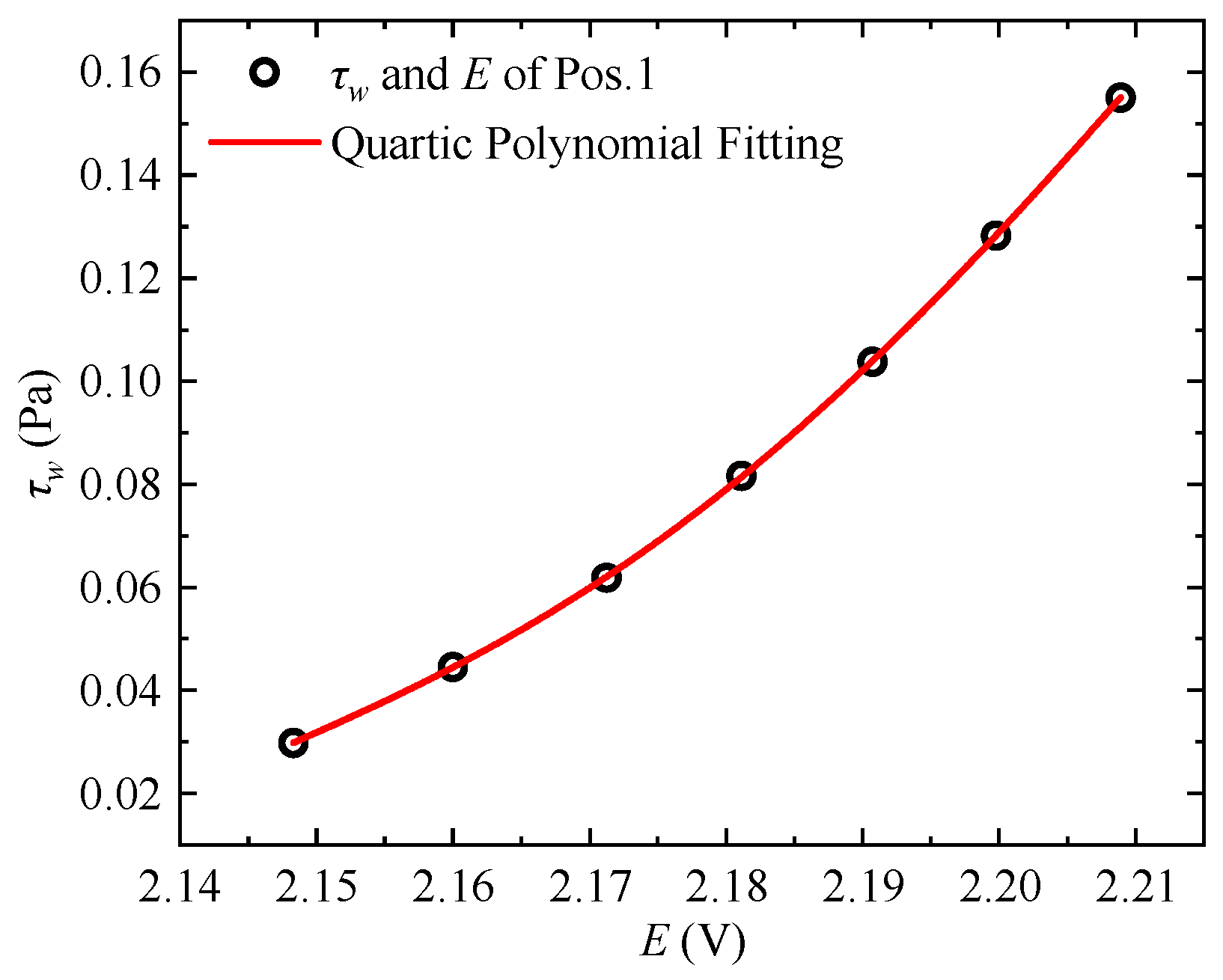

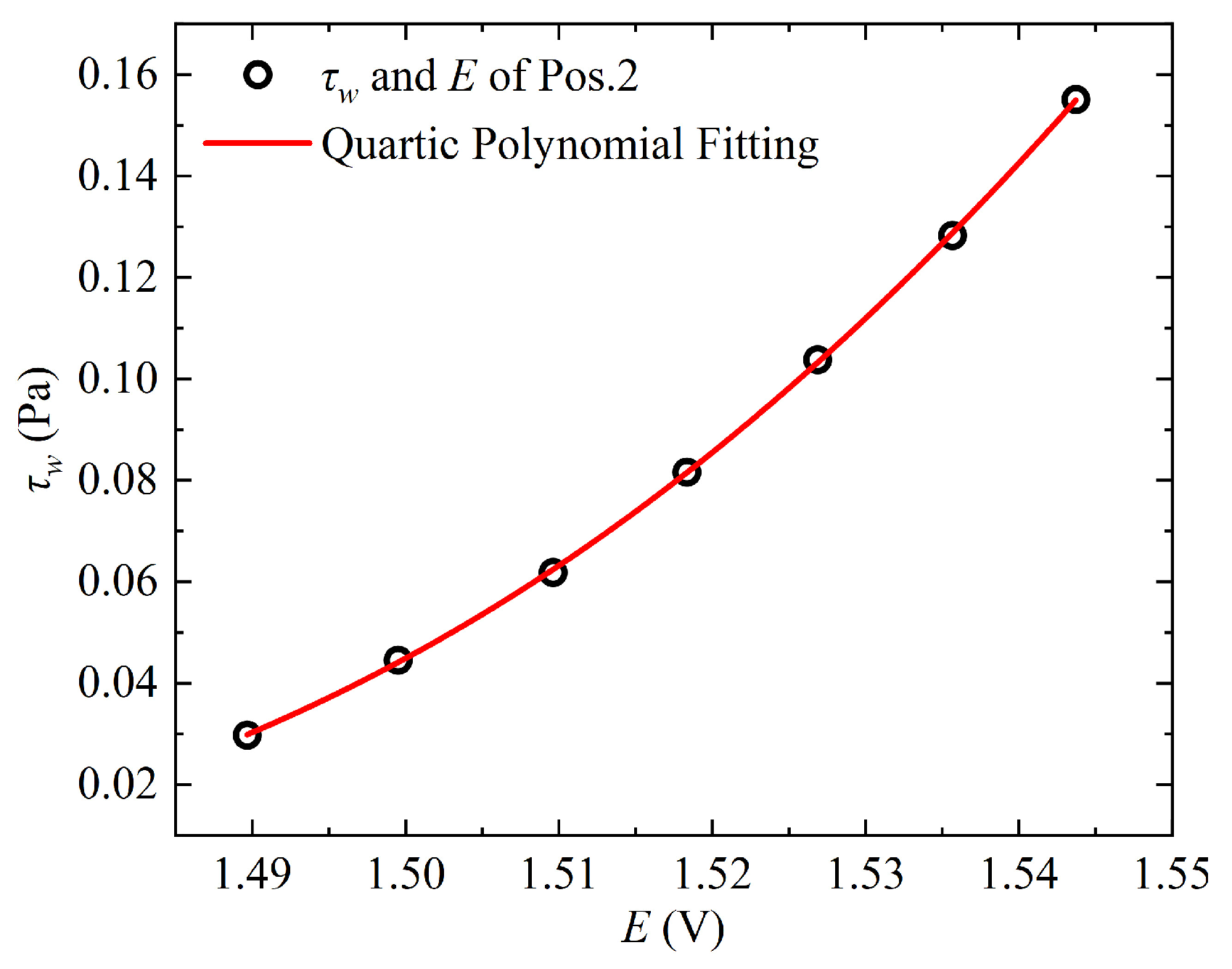

Simultaneous measurements of the viscous sublayer velocity profiles at Measurement Position 1 (Pos. 1) and Position 2 (Pos. 2) were conducted using hot-wire probes under various freestream velocities. The wall shear stress was determined through linear fitting of the velocity gradient in the viscous sublayer. Concurrently, the voltage outputs from the hot-film probes at both positions were recorded, and fourth-order polynomial fitting was applied to establish the calibration curves, as shown in

Figure 10 and

Figure 11. The corresponding fitting functions are given by Equation (2) and Equation (3), respectively. It should be noted that prior to each measurement of the drag reduction rate on the riblet surface, in situ calibration of the hot-film probes must be performed under smooth-wall conditions to obtain updated calibration curves.

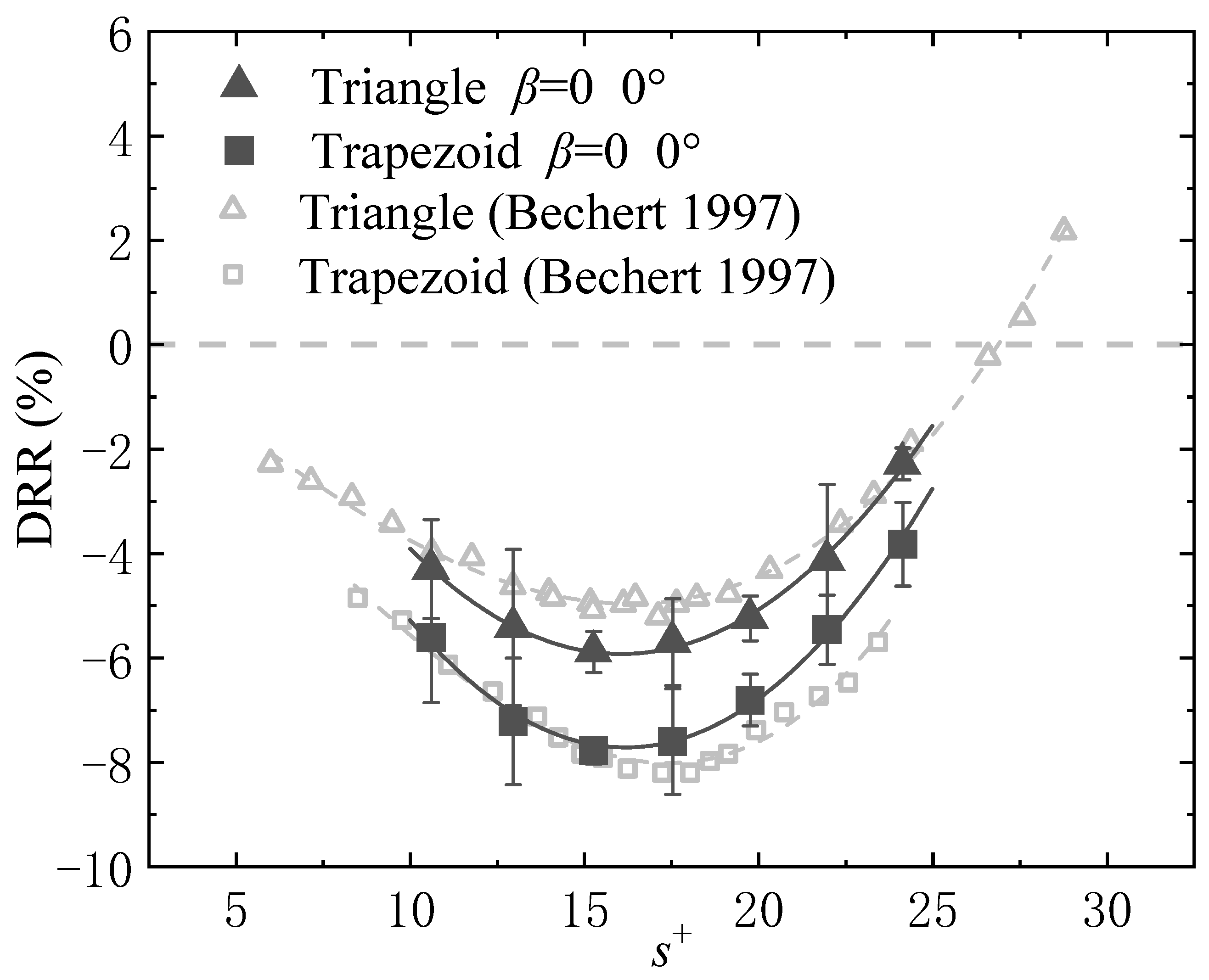

Following in situ calibration of the hot-film probes, the smooth surface was replaced with a riblet surface to determine the drag reduction rate. For each measurement point, the procedure was repeated three times to eliminate random errors, thereby establishing the corresponding error bands. Under zero pressure gradient conditions, the present experimental data were compared with measurements by Bechert et al. [

27], whose study achieved a maximum friction Reynolds number of

. The results are presented in

Figure 12. It can be observed that under zero pressure gradient conditions and without yaw angle (i.e., absence of crossflow effects), the experimental results from this study show close agreement with those reported by Bechert et al. [

27] for both triangular and trapezoidal riblets. Furthermore, the trapezoidal riblets exhibit a higher drag reduction rate compared to the triangular riblets. As discussed by Bechert et al., trapezoidal riblets are more suitable for application on aircraft surfaces. The triangular riblets in this study exhibit a higher drag reduction rate than those reported in Ref. [

27], while the trapezoidal riblets show a comparatively lower drag reduction efficiency. Moreover, the peak drag reduction for trapezoidal riblets occurs at a lower dimensionless spacing

compared to the reference study. Furthermore, although the maximum friction Reynolds number

in this study reaches 6000—an order of magnitude higher than that in the experiments by Bechert et al. [

27]—the drag reduction rate remains largely unchanged. This leads to the following conclusion: Within the range of Reynolds numbers investigated in this study (

), the increase in Reynolds number does not qualitatively alter the drag reduction performance of the riblets.

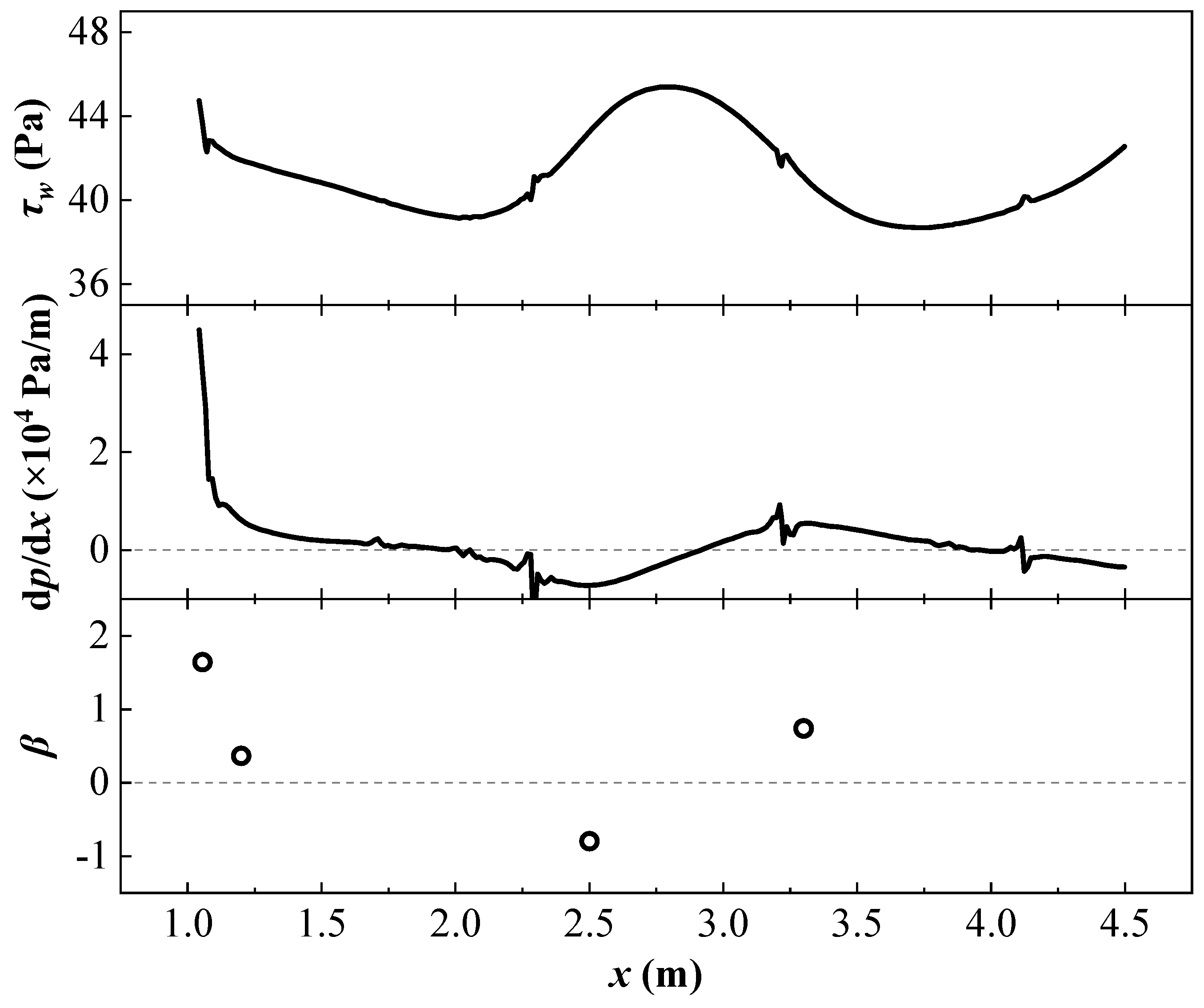

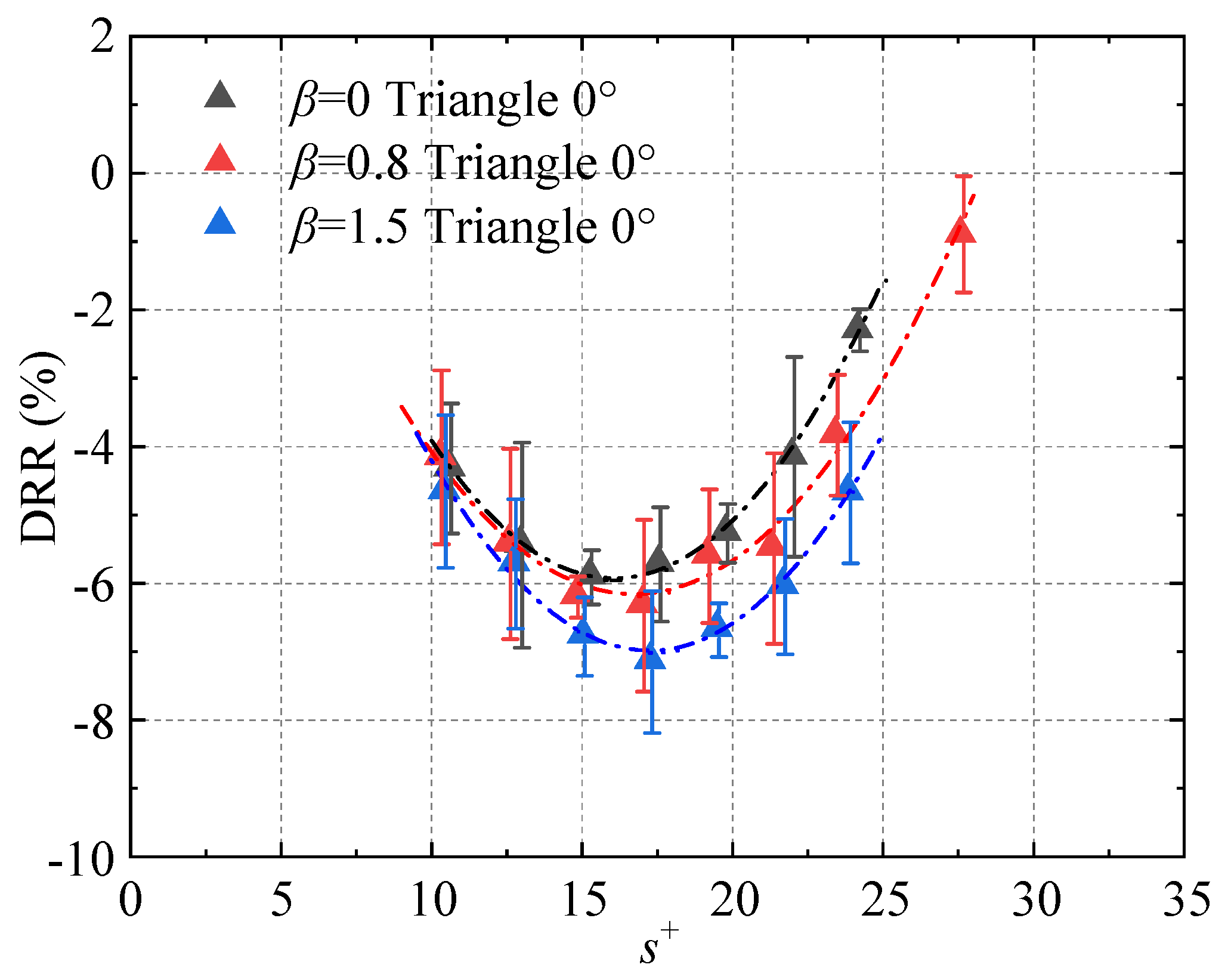

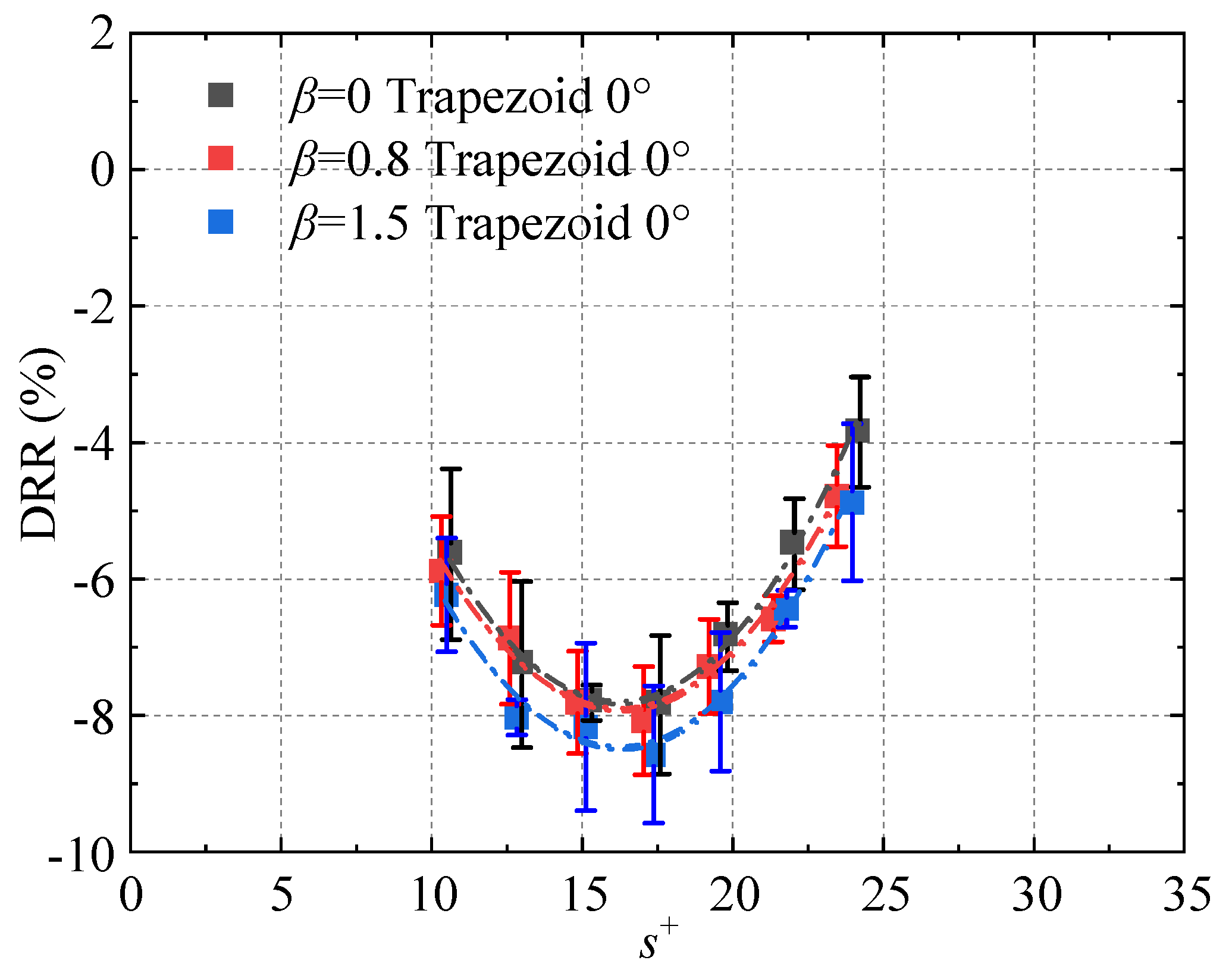

The following section examines the effects of adverse pressure gradients on the drag reduction performance of riblets. The drag reduction rates for both triangular and trapezoidal riblets under

β = 0, 0.8, and 1.5 conditions are presented in

Figure 13 and

Figure 14, respectively. It is evident that the adverse pressure gradient exerts a positive effect on the drag reduction performance of riblets. The drag reduction rate increases with the intensity of the adverse pressure gradient, which is consistent with the findings reported by Debisschop and Nieuwstadt [

13]. Accordingly, the drag reduction rates obtained in this study are compared with the results from the aforementioned literature, as shown in

Figure 15. Debisschop and Nieuwstadt similarly constructed an adverse pressure gradient environment using a contraction–expansion section configuration. They employed an oil-floating force balance to measure the overall wall shear stress of a flat plate equipped with triangular riblets and subsequently determined the drag reduction rate by comparing these results with measurements obtained from a smooth flat plate under identical conditions. The experimental results from this study exhibit remarkable agreement with those reported by Debisschop and Nieuwstadt, providing strong mutual validation. This consistency reinforces the conclusion that a moderate adverse pressure gradient can enhance the drag reduction performance of riblets, provided it does not induce flow separation.

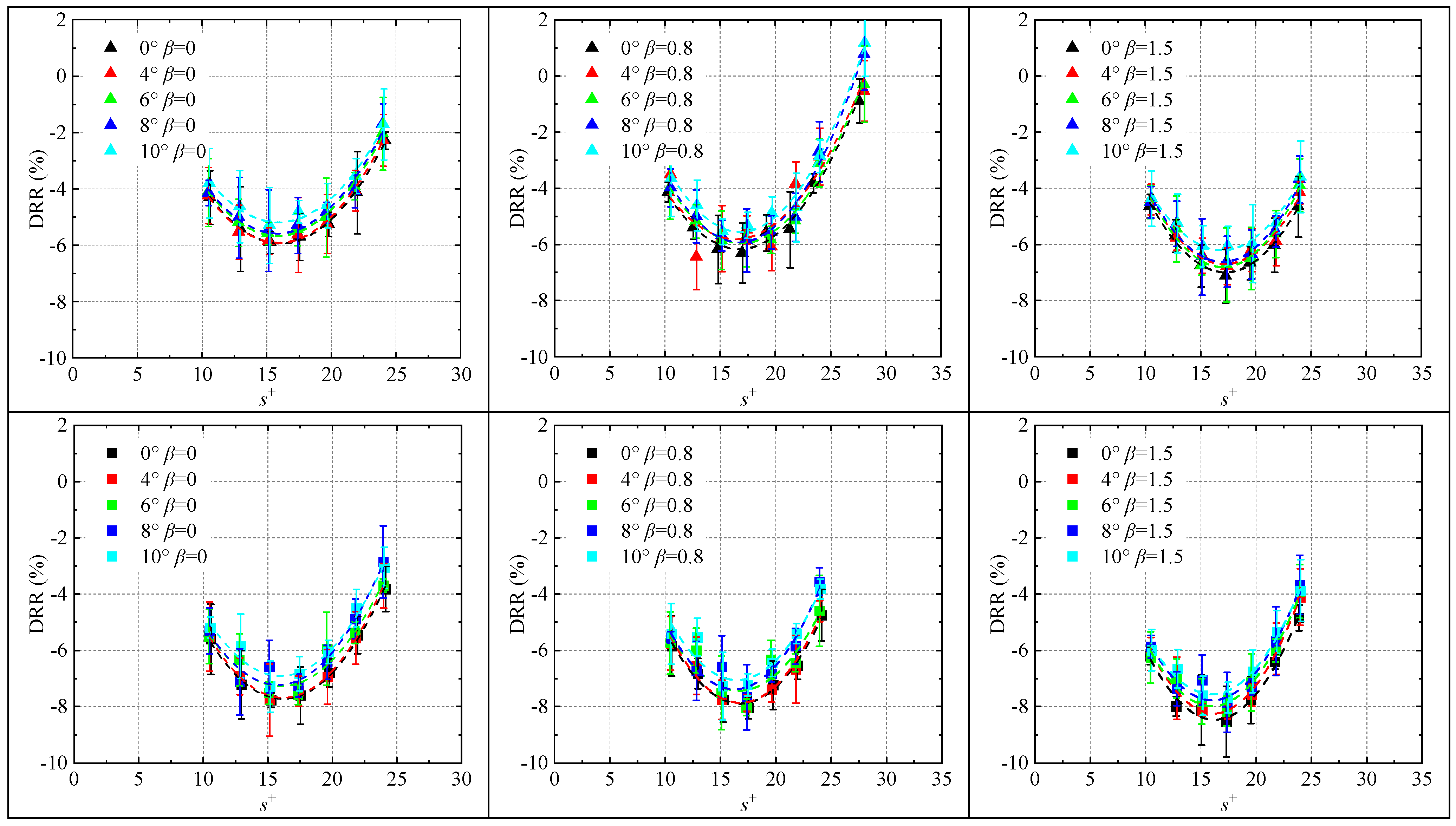

Further investigation was conducted on the effect of yaw angle (crossflow effects) on the drag reduction rate of riblets. In this experiment, crossflow conditions were generated by rotating the riblet surfaces to specific yaw angles, i.e.,

. The measured drag reduction rates are presented in

Figure 16. It is evident that under all adverse pressure gradient conditions, the drag reduction rate progressively decreases with increasing yaw angle (crossflow effects), indicating that crossflow suppresses the drag-reducing effectiveness of riblets. This finding necessitates that the design of riblet surfaces on aircraft must account for the local flow direction of the surrounding flow field. Riblets should be aligned with the actual local streamlines to optimize drag reduction performance.

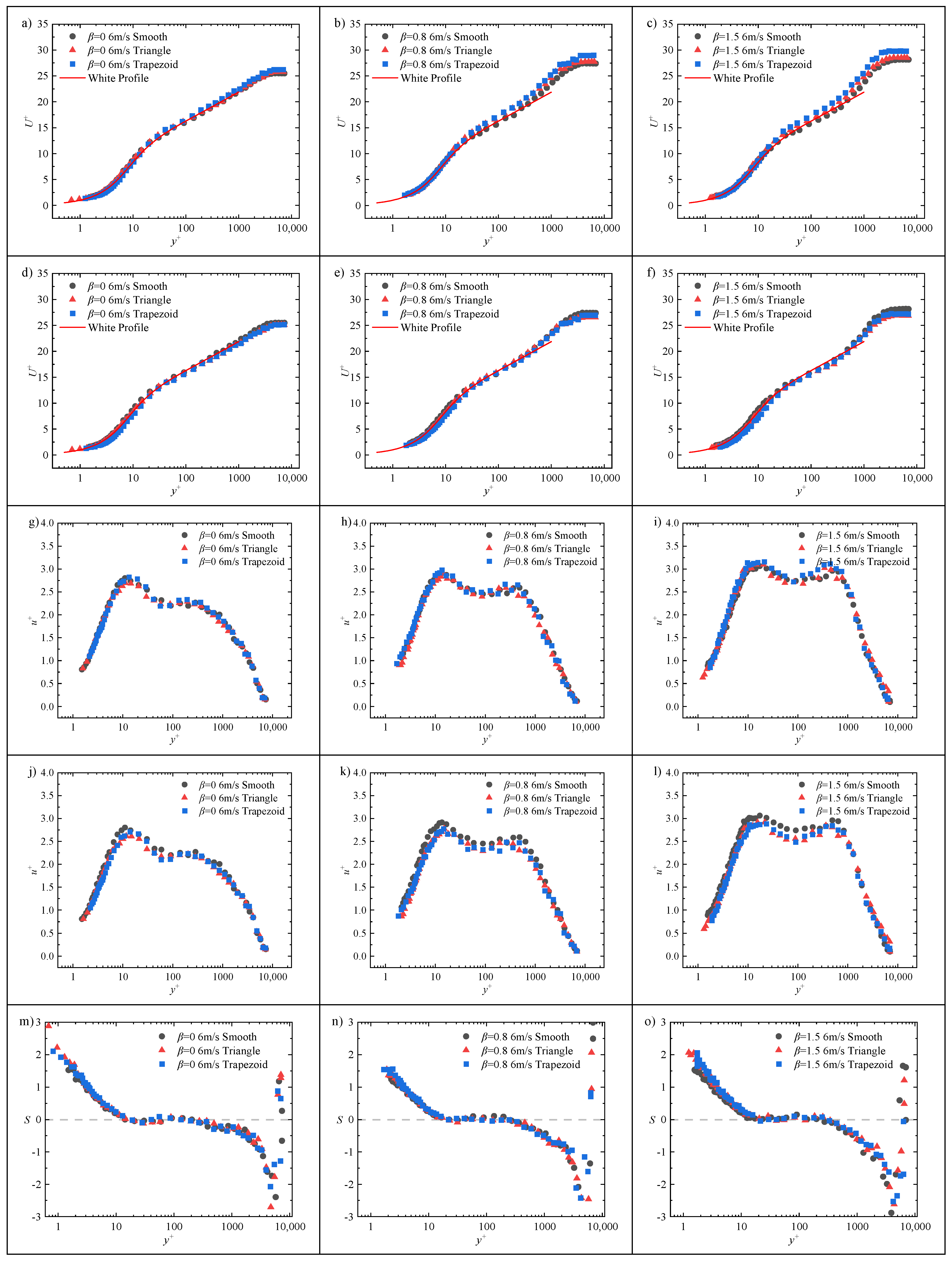

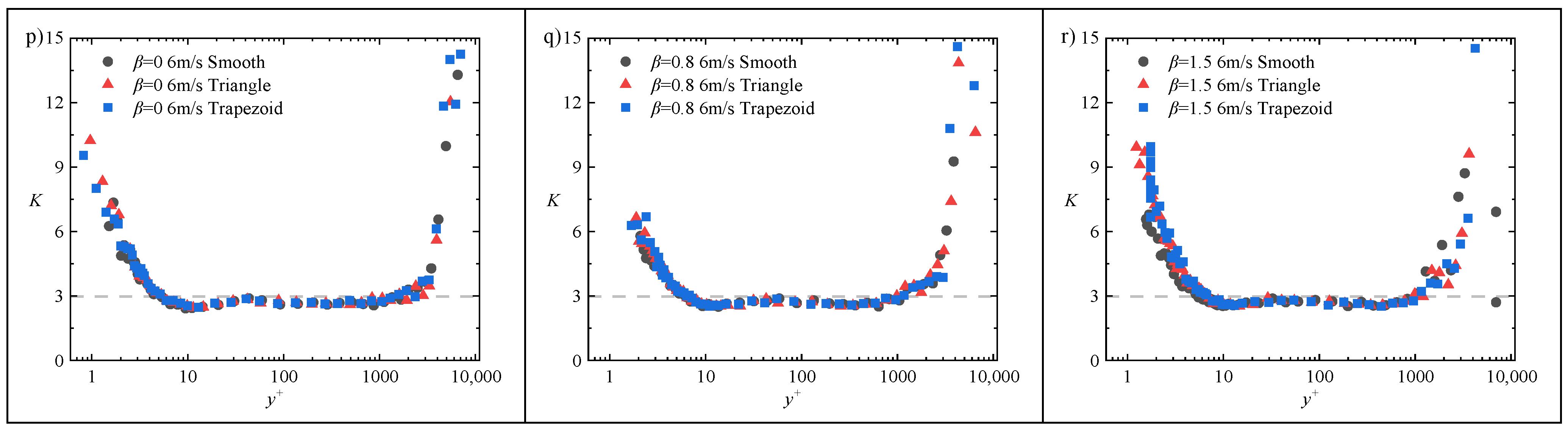

4. Basic Statistics of TBL

To investigate the mechanisms of drag reduction by riblets and the influence of adverse pressure gradients on their performance, this study employed hot-film probes for drag reduction measurements. Additionally, hot-wire anemometry was utilized to measure the turbulent boundary layers over both smooth and riblet surfaces at a freestream velocity of 6 m/s (corresponding to the optimal drag reduction regime of the non-dimensional riblet spacing

) under various adverse pressure gradient conditions. The changes in fundamental statistical quantities before and after riblet implementation were obtained, as shown in

Figure 17. As shown in

Figure 16, the drag reduction rate is no more than 8%, which means that the changes in the statistics of near-wall turbulence are not as significant as expected. This results in little variation in the velocity statistics of all orders for riblets under different environments in

Figure 17. However, the variation trend of the curve can still reflect the changes in drag reduction magnitude.

Figure 17a–c show the mean velocity profiles, non-dimensionalized using the local friction velocity

. The results demonstrate that the logarithmic region of the velocity profile over the riblet surface exhibits a consistent upward shift relative to the smooth wall. This shift, quantified as

, serves as an indicator of the drag reduction performance. Notably, the velocity profile shift

is larger for trapezoidal riblets than for triangular riblets.

Moreover, as the adverse pressure gradient intensifies, both types of riblets maintain consistent trends in the velocity profile shift . At β = 1.5, this shift effect becomes particularly pronounced. When normalized using the smooth-wall friction velocity , the logarithmic regions of the velocity profiles regain coincidence. However, a velocity deficit emerges within the range of , and the magnitude of this deficit is positively correlated with the drag reduction rate. Since the same is used for non-dimensionalization, the non-dimensional mean velocity profile effectively reflects the characteristics of the original dimensional velocity profile. Thus, at the same freestream velocity and identical wall-normal height, the local mean velocity in the viscous sublayer and buffer region of the turbulent boundary layer over the riblet surface is reduced compared to that over the smooth wall. This reduction results in a decreased slope of the linear region of the velocity profile, consequently leading to a reduction in wall shear stress. In the logarithmic region, the velocity profiles of different surface configurations resume overlapping, indicating that the local mean velocity in this region remains unaffected by the riblets. In summary, the influence of riblets on the mean velocity profile is confined to the viscous sublayer and buffer region. Therefore, the upward shift in the logarithmic region velocity profile observed when normalized using the local friction velocity is attributed to the reduction in caused by the riblets. Consequently, can serve as a quantitative measure of the change in wall shear stress.

Constrained by the limitations of the hot-wire measurement, the Reynolds stress distribution of turbulent fluctuations within the boundary layer cannot be obtained. However, the fluctuations in the velocity field can indirectly reflect the interaction mechanism between near-wall turbulent structures and the wall surface.

Figure 17d–f presents the fluctuating velocity profiles, similarly non-dimensionalized using the local

. The conclusions drawn are fundamentally consistent with those of the mean velocity profiles. The fluctuating velocity profiles over the riblet surface exhibit a slight increase in the plateau near the logarithmic and wake regions, as well as in the potential flow region, compared to the smooth wall. This is again attributed to the reduction in the local

. When non-dimensionalized using the smooth-wall friction velocity

, the fluctuating velocity profiles reflect the inherent characteristics of the pre-non-dimensionalization data. Within the region

y+ < 100, the fluctuating velocities exhibit a discernible reduction, a trend that becomes more pronounced under adverse pressure gradient conditions. The decrease in velocity fluctuations indicates a reduction in the energy of the flow structures within this region. This demonstrates that riblets effectively attenuate smaller-scale energy-containing structures above the wall, thereby diminishing their capacity to induce wall-normal momentum mixing. Consequently, the associated wall shear stress is reduced, leading to drag reduction.

For all flow conditions, the skewness and flatness factors deviate from their standard values and show an increase within the region

< 15. When the skewness factor exceeds zero, it indicates an increased distribution of the probability density function of the local velocity fluctuations on the positive semi-axis. This condition corresponds to “sweep events” (Q2 events) in the turbulent boundary layer, where high-speed fluid from above suddenly intrudes downward into the low-speed fluid near the wall due to disturbances, resulting in strong impact and sweeping effects on the low-speed fluid in the near-wall region, causing the mixing of streamwise momentum in the wall-normal direction. The fluctuating velocity characteristics manifest as

,

, indicating an increase in positive streamwise velocity fluctuations. This leads to a right-skewed probability density function and a positive value of the skewness factor. Further comparison between the riblet surface and the smooth wall clearly reveals that the skewness factor values are higher over the riblet surface. At first glance, this phenomenon might suggest an increased frequency of sweep events. However, the underlying reason is that the riblets attenuate the strength of the near-wall streamwise vortices. Since streamwise vortices normally possess the significant ability to accumulate low-speed fluid, the introduction of riblets suppresses this capability, leading to a substantial reduction in the frequency of ejection events. In fact, while the probability of sweep events also decreases, the suppression of ejection events is more pronounced, resulting in an overall increase in the skewness factor. Regarding the flatness factor, a value greater than 3 indicates a more concentrated distribution of the probability density function for local velocity fluctuations, characterized by a higher peak. Riblets also cause the flatness factor to increase within the region

< 15 compared to the smooth wall. Together, these observations indicate that within

< 15, the presence of the wall leads to a deviation of the probability distribution of fluctuating velocities in the near-wall flow field from the Gaussian distribution characteristic of isotropic turbulence, resulting in anisotropy. Compared to the smooth wall, the influence of riblets on both higher-order statistical quantities is confined to the region

< 15. After riblet implementation, both the skewness and flatness factors exceed those of the smooth wall, a phenomenon consistent with the findings of Choi et al. [

6]. It is noteworthy that under riblet-induced modifications, the magnitude of increase in both skewness and flatness factors grows with the intensity of the adverse pressure gradient.