Design, Roll Control Evaluation and Flight Test of Inflatable-Winged UAVs in Two Configurations

Abstract

1. Introduction

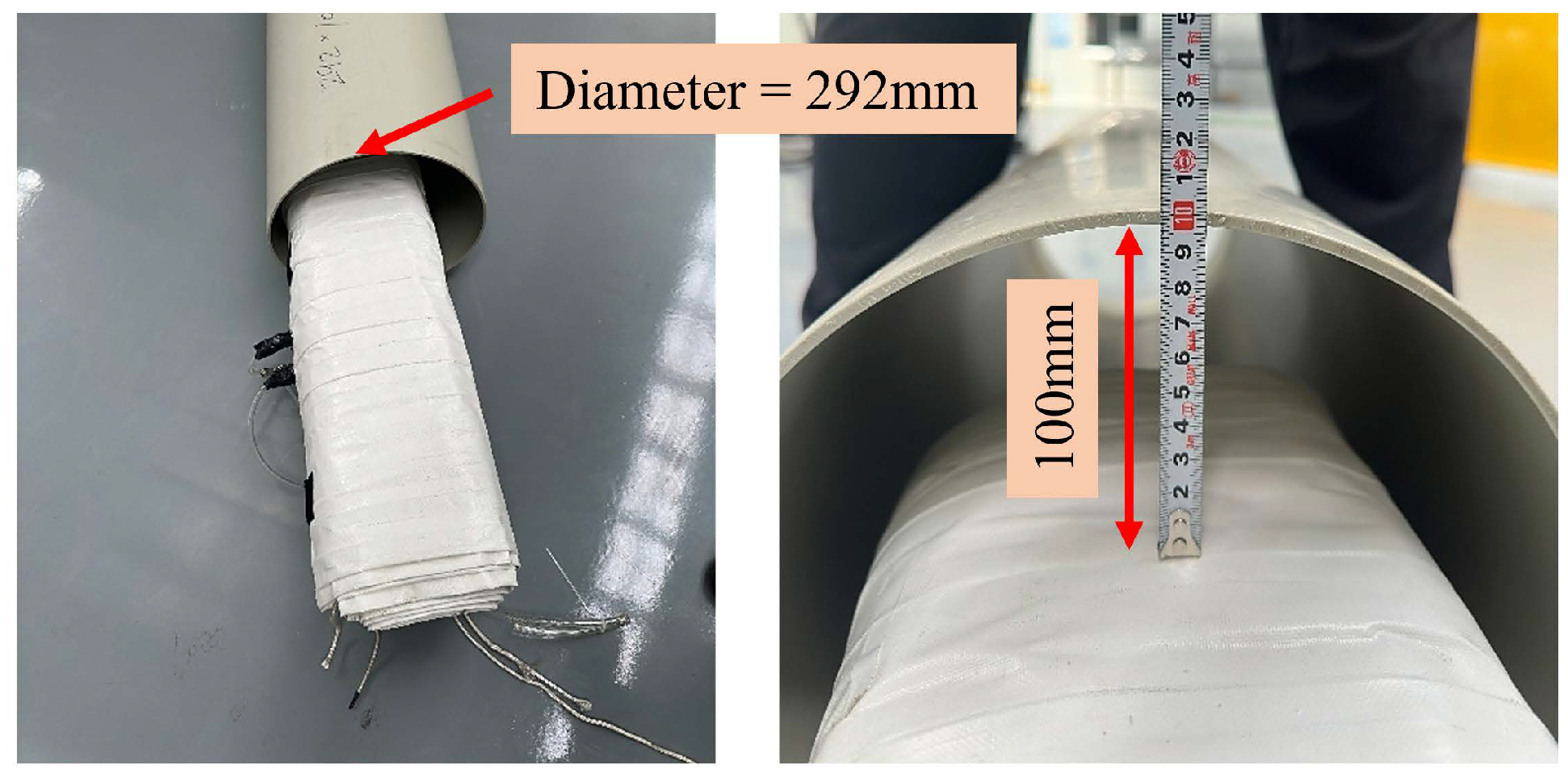

2. Design and Ground Tests of Inflatable Wing

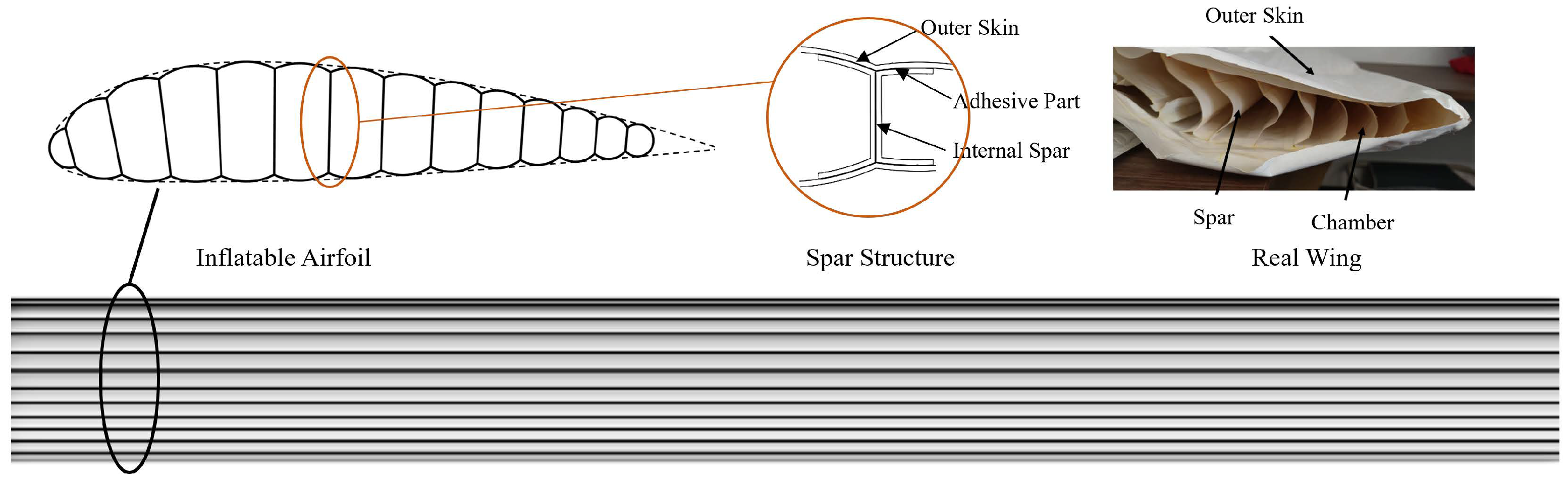

2.1. Inflatable Wing Design

2.2. Ground Tests of Inflatable Wing

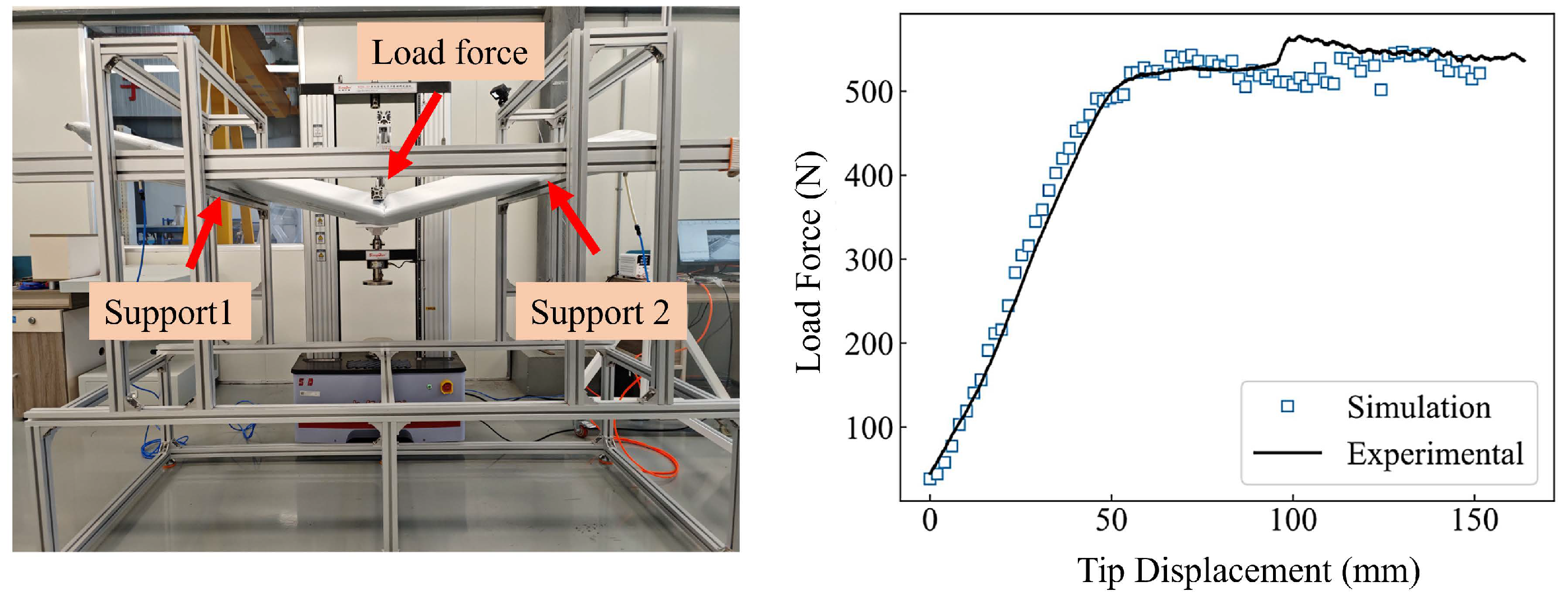

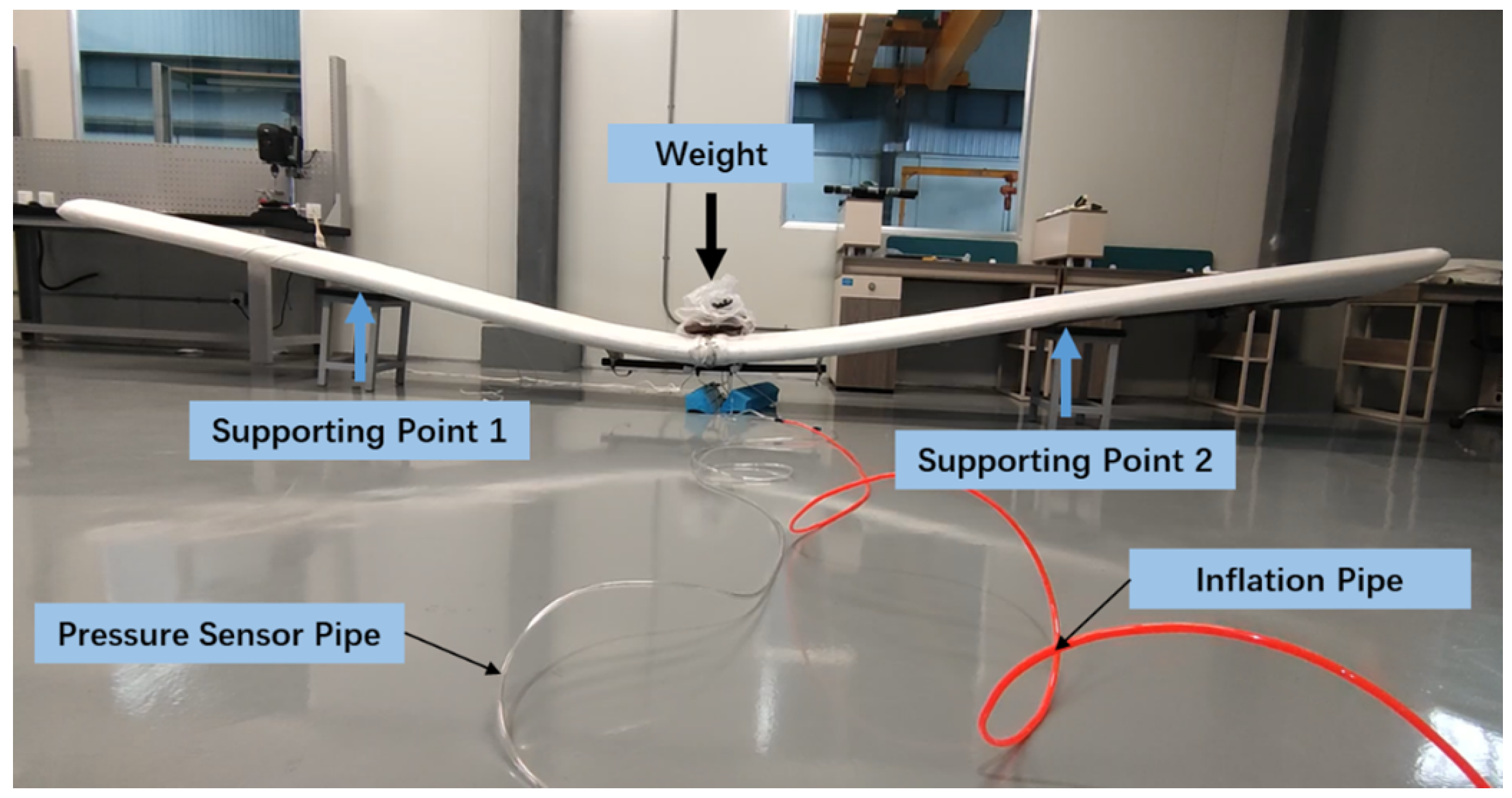

2.2.1. Load Tests

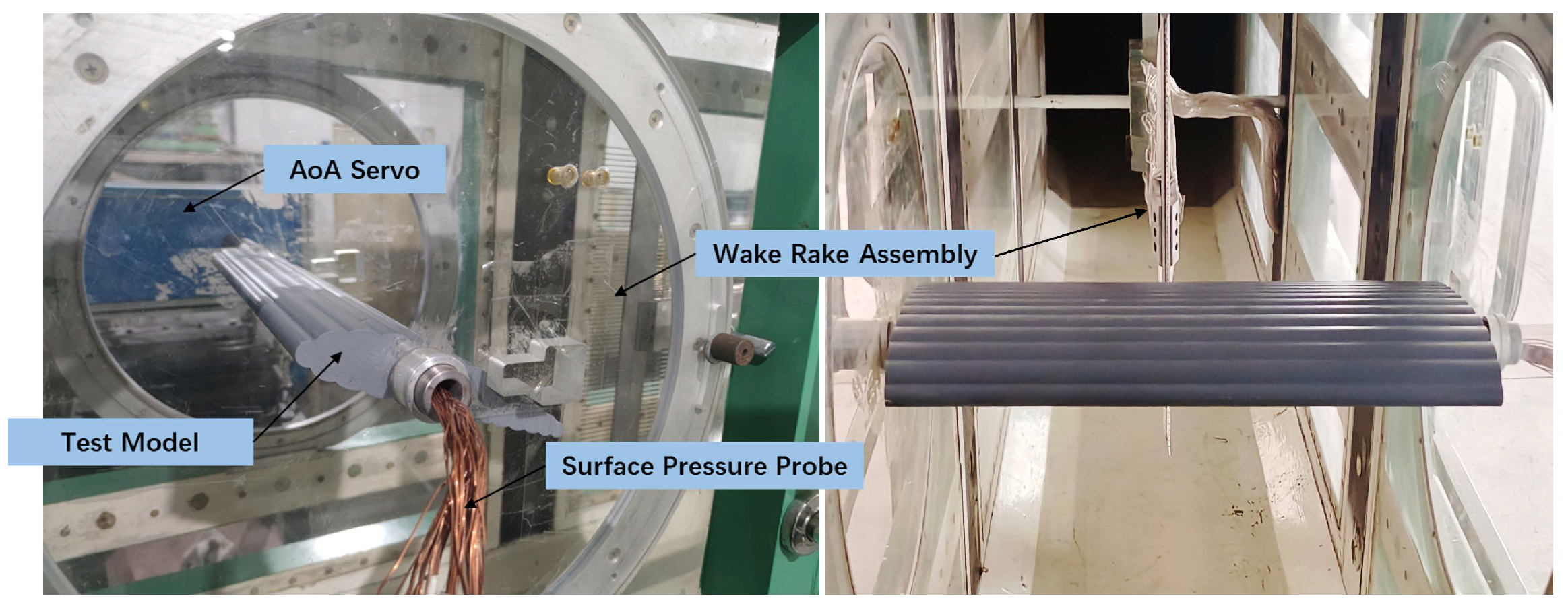

2.2.2. Wind Tunnel Tests

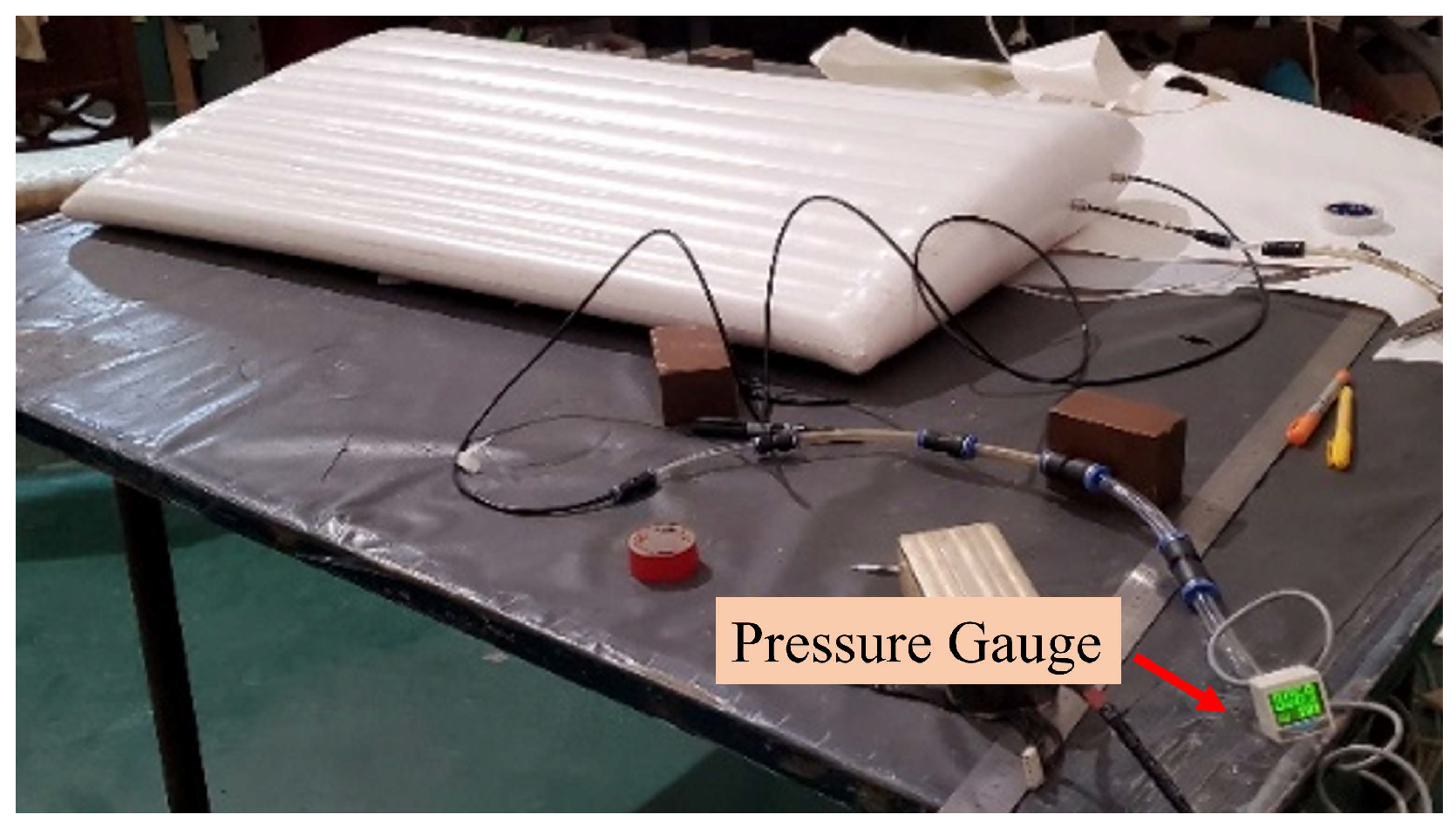

2.2.3. Pressure Retention and Resistance Tests

2.2.4. Foldability Test

3. Roll Control of Inflatable Wing

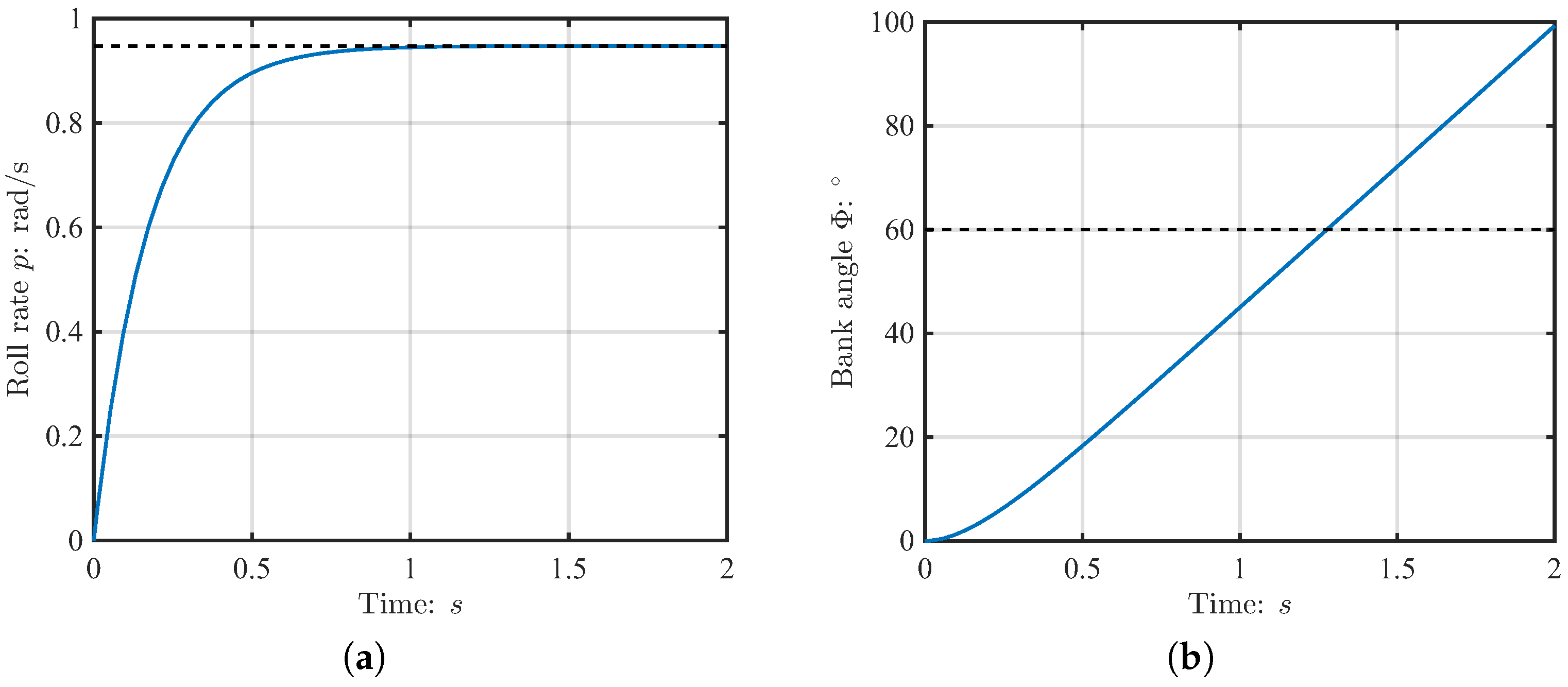

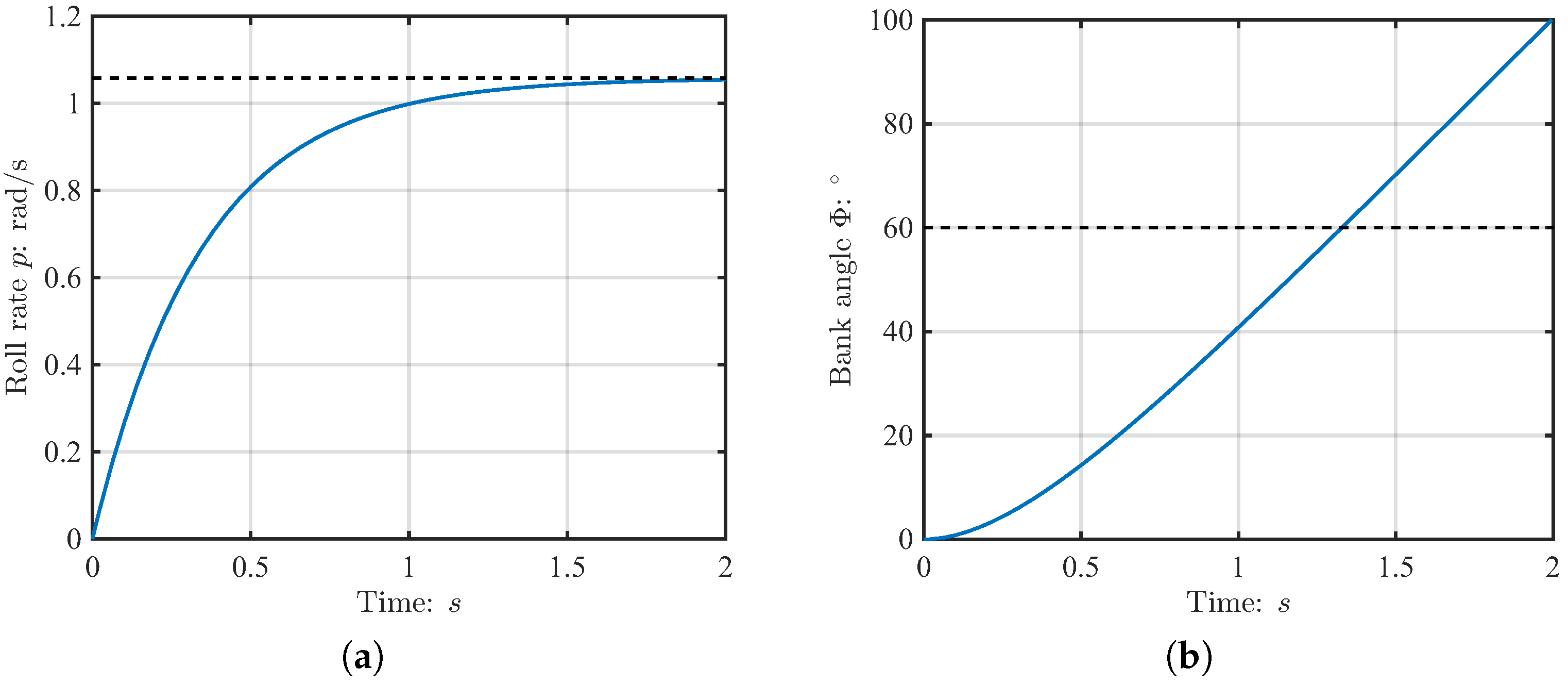

3.1. Roll-Control Requirements

- Level 1: °C in 1.7 s; flying qualities are clearly adequate to accomplish the mission’s flight phases.

- Level 2: °C in 2.5 s; flying qualities remain adequate to perform the mission’s flight phases with moderate degradation in mission effectiveness.

- Level 3: °C in 3.4 s; degraded flying qualities remain adequate to stabilize the vehicle.

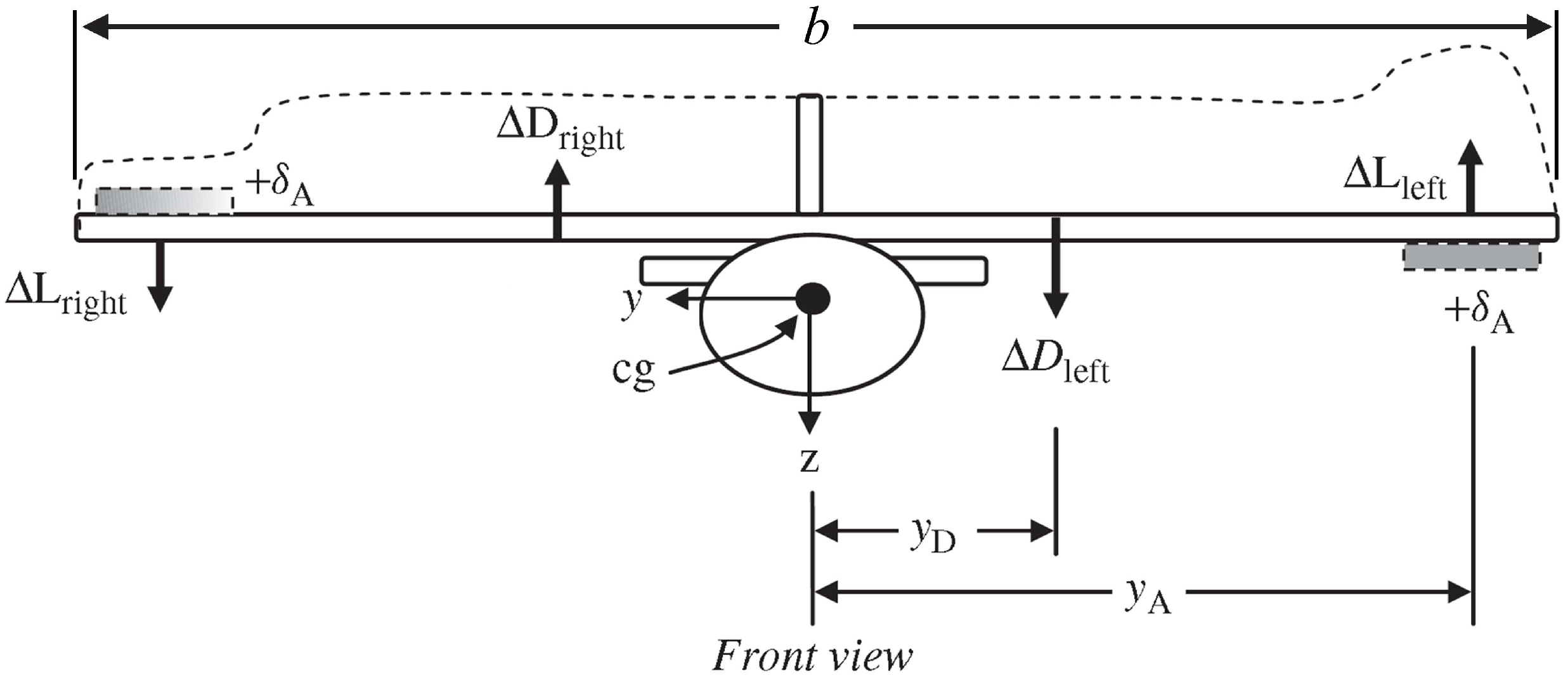

3.2. Roll-Control Principles

3.3. Manipulation of Inflatable Wing

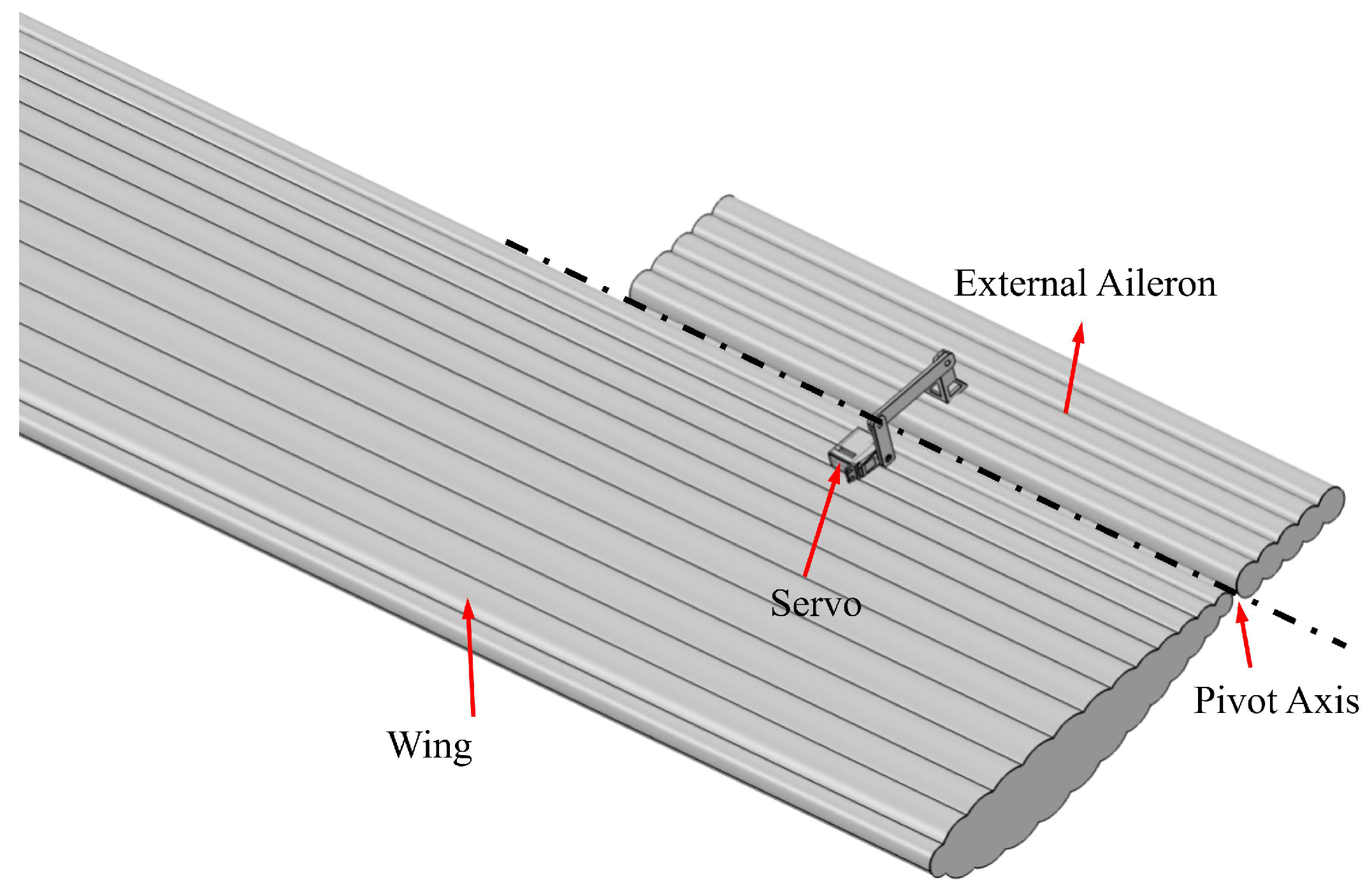

3.3.1. External Trailing-Edge Control Surfaces

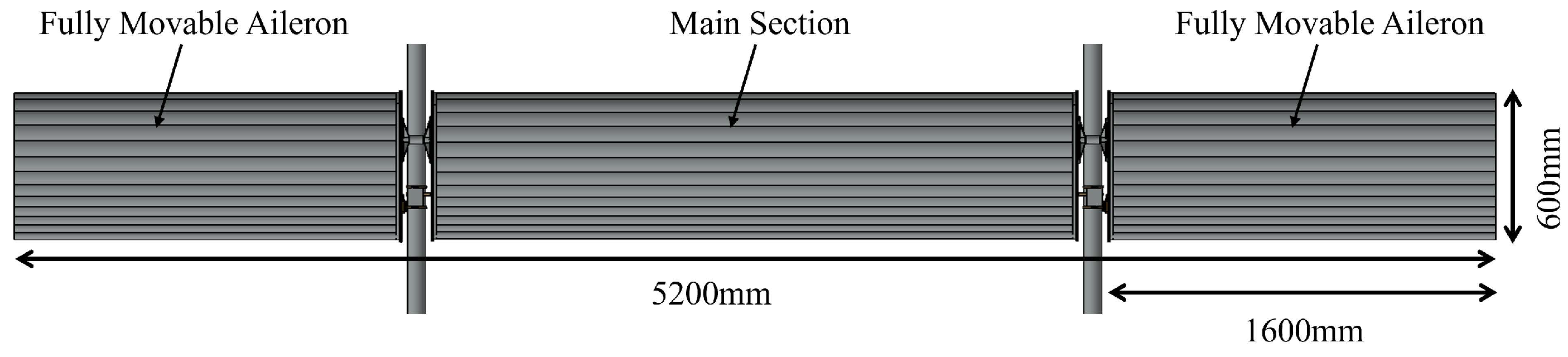

3.3.2. Fully Movable Control Surfaces

4. Prototype 1: Design and Fight Tests

4.1. Design Requirement

4.2. Vehicle Description

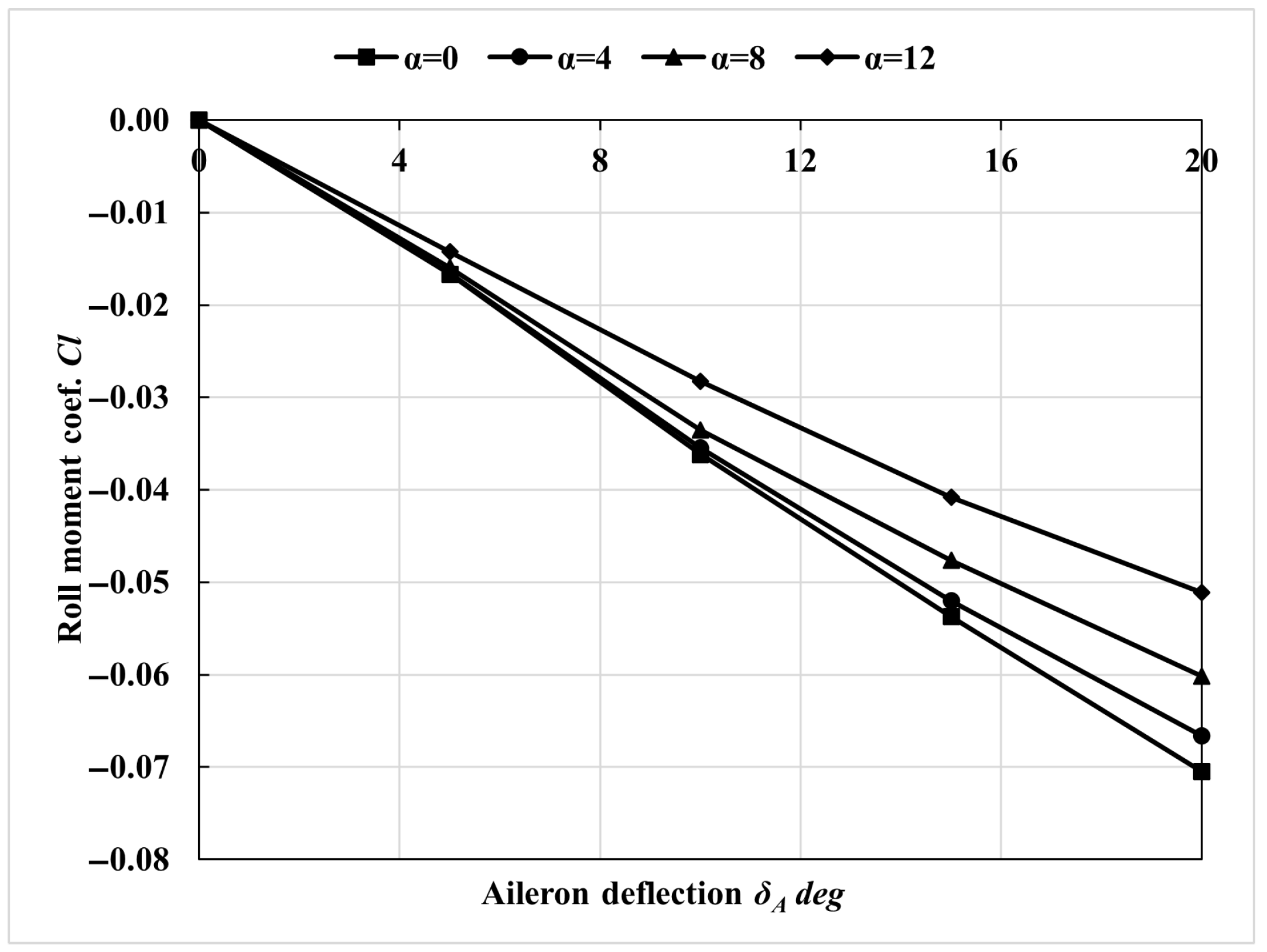

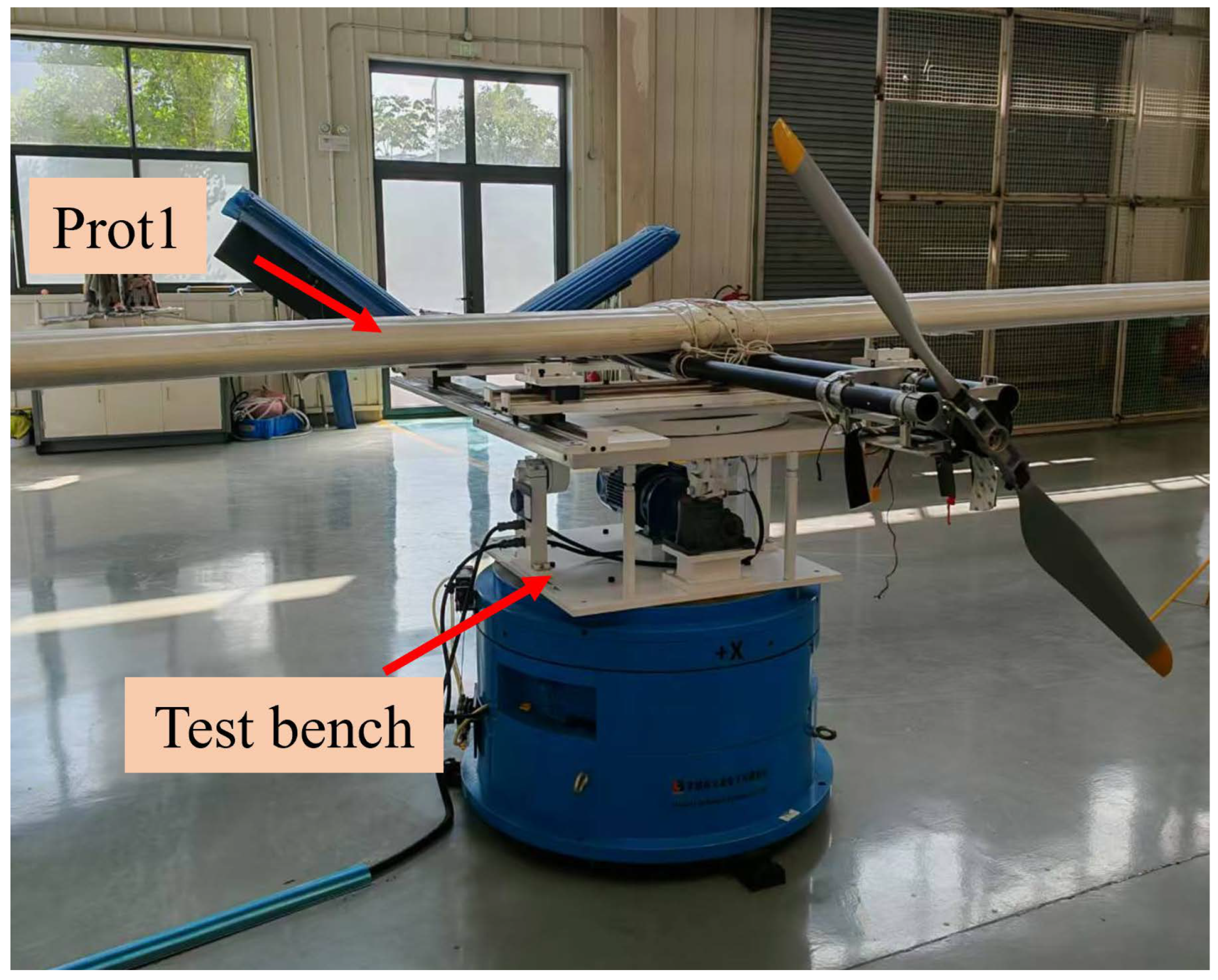

4.3. Evaluation of Roll Control Effectiveness

4.4. Flight Tests of Prot1

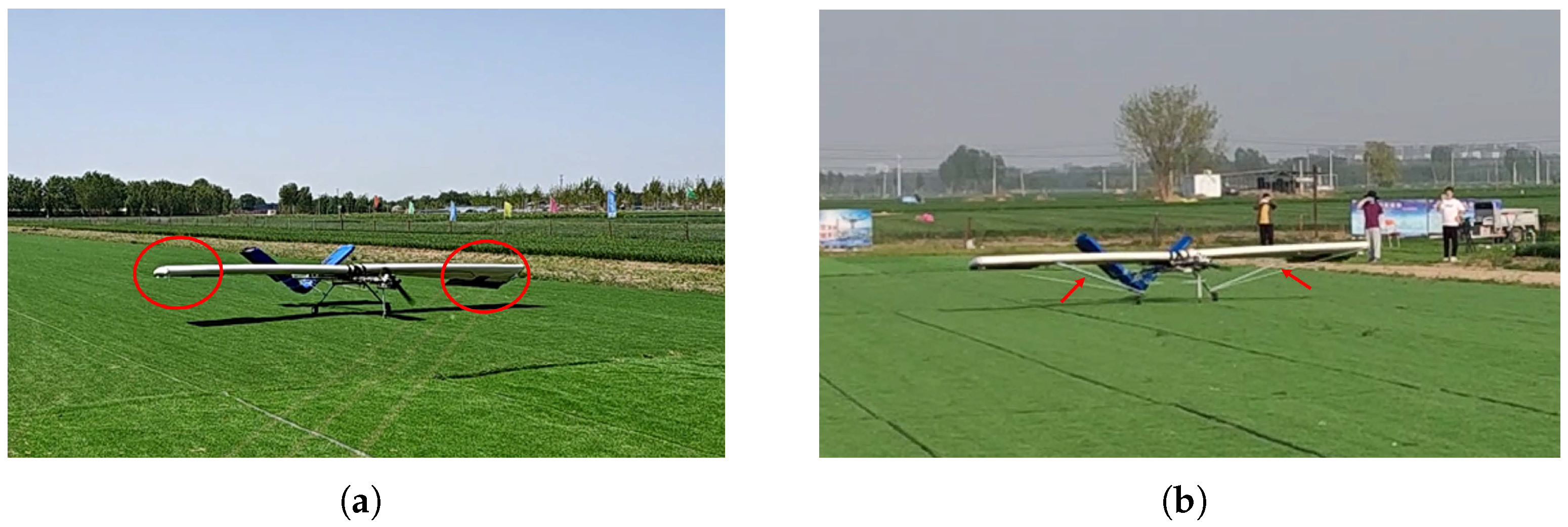

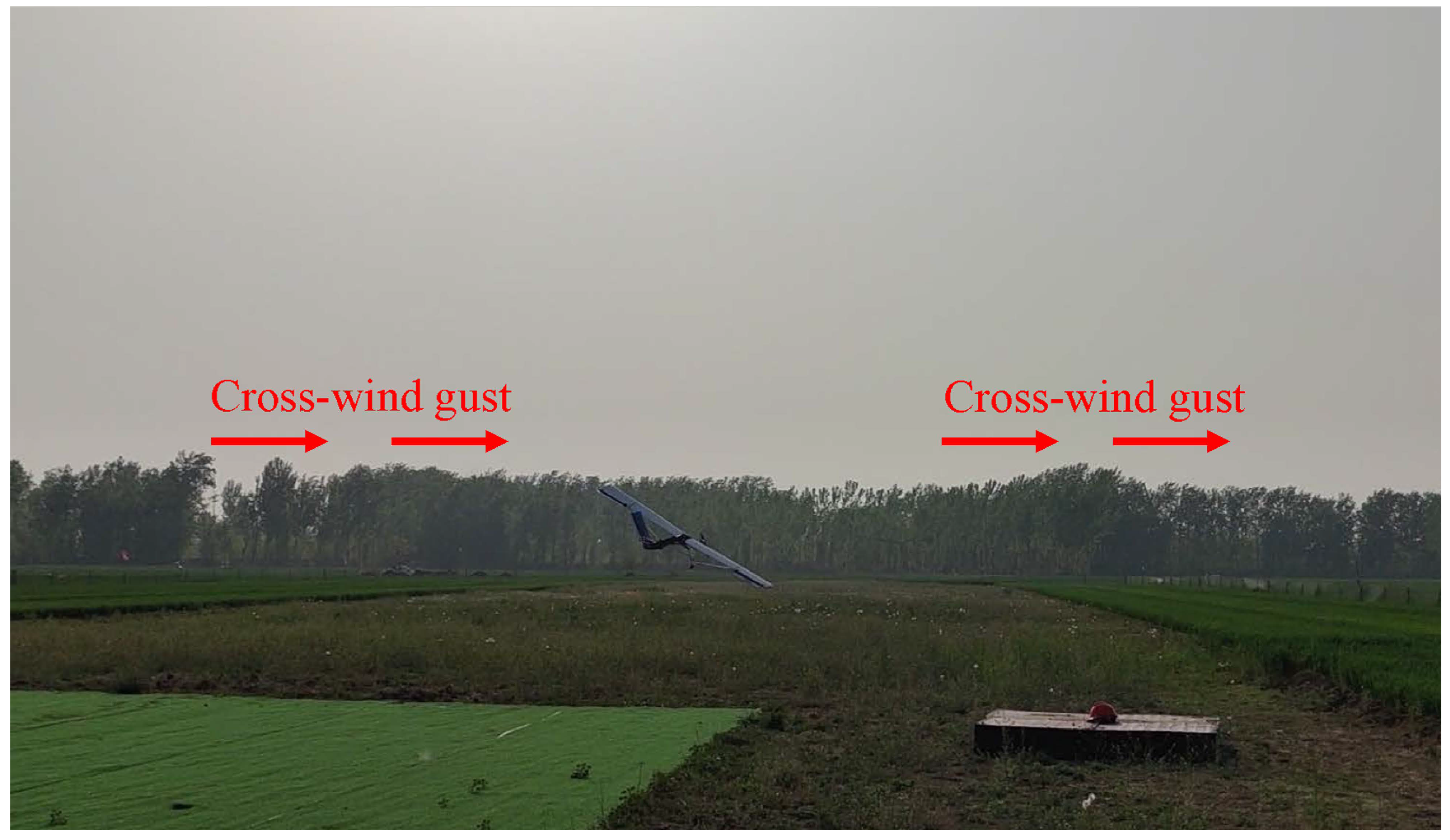

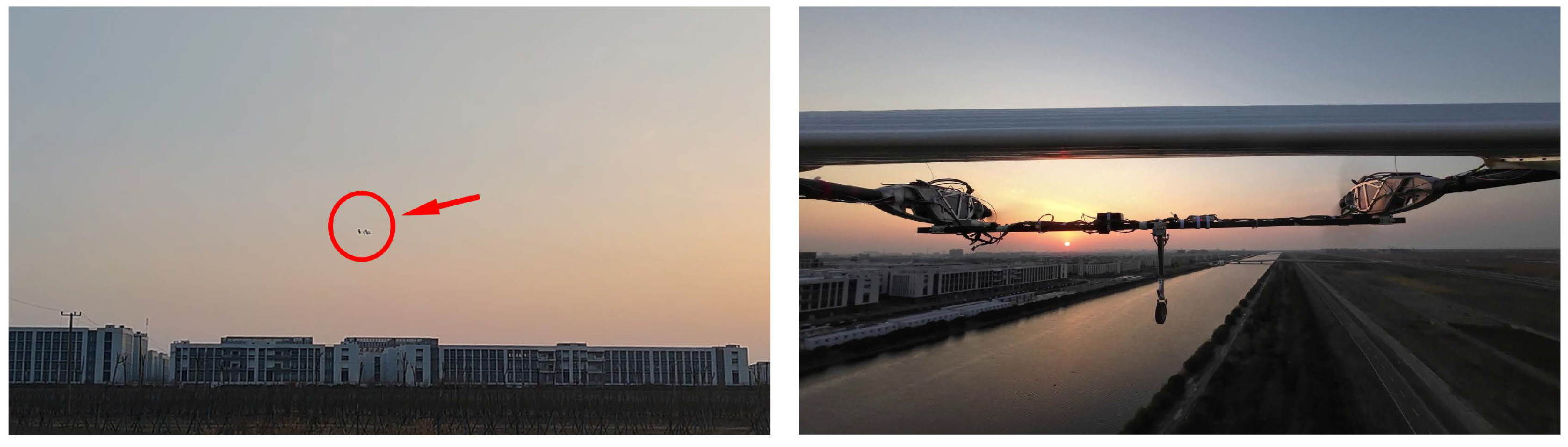

4.5. Challenges Encountered by Prot1

5. Prototype 2: Design and Fight Tests

5.1. Key Improvements

- Transition from a single-fuselage to a twin-fuselage configuration: Due to the limited load-bearing capacity of the inflatable wing, the twin-fuselage design facilitates a more uniform load distribution across the inflatable wings, thereby reducing dependency on the internal pressure for structural support.

- Redesign of inflatable wing: The initial 6-m single inflatable wing has been modified into a segmented design. This change reduces the manufacturing complexity and mitigates the torsional deformation issues observed in the first prototype.

- Redesign of control surfaces: The external trailing-edge control surfaces of the first prototype have been replaced with fully movable ailerons, along with fully movable horizontal and vertical tails. This design can compensate for the torsional issues associated with the main wing by utilizing asymmetric deflection of the fully movable ailerons.

- Upgrade of propulsion system: The single-thrust configuration has been upgraded to a twin-thrust setup. This allows for differential thrust, providing auxiliary yaw control input.

5.2. Vehicle Overview

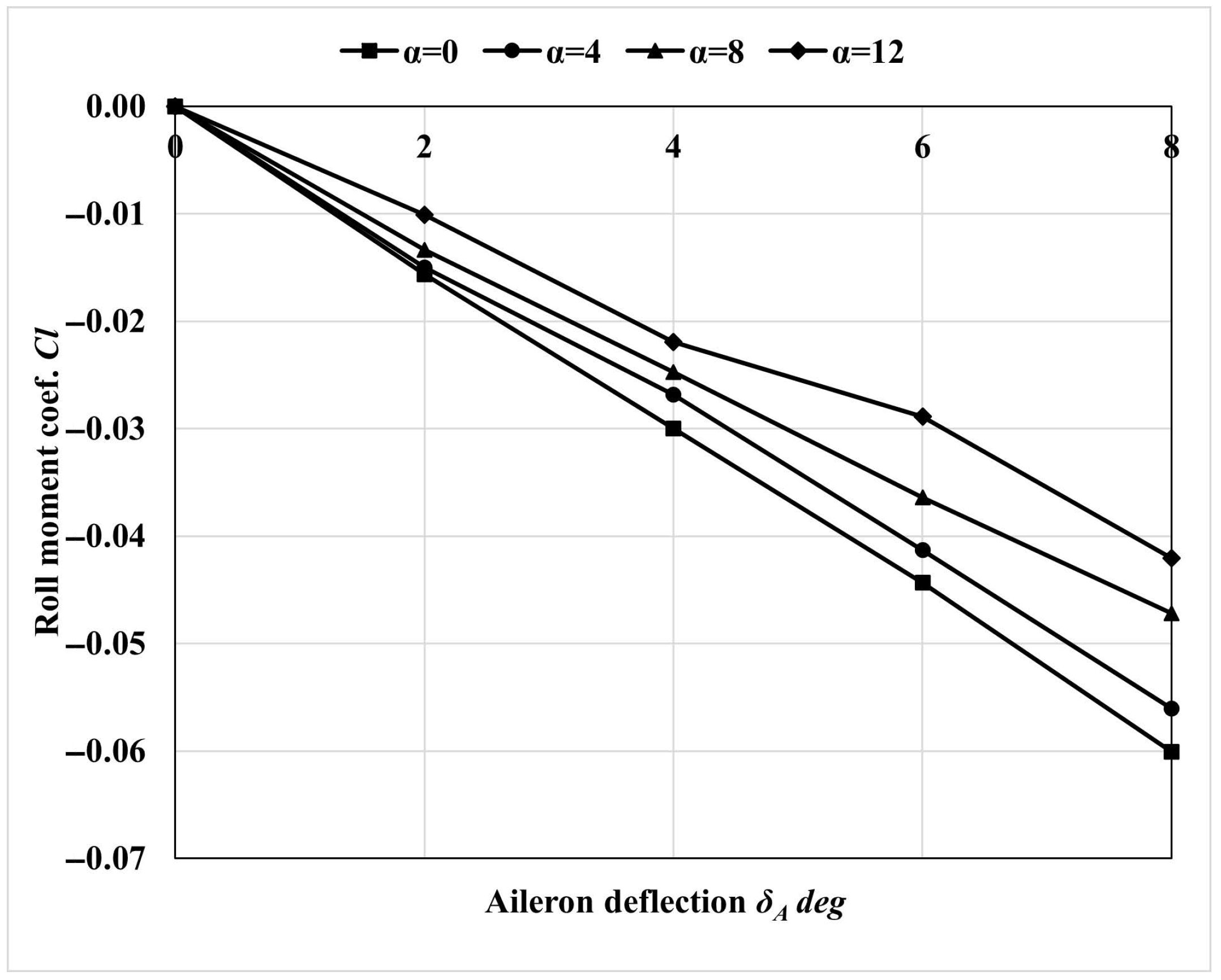

5.3. Evaluation of Control Effectiveness

5.4. Flight Tests of Prot2

5.5. Prototypes Flight Tests Summary

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stadvec, E. The Inflatoplane; Essco: Akron, OH, USA, 1980. [Google Scholar]

- Cocke, B.W. Wind-Tunnel Investigation of the Aerodynamic and Structural Deflection Characteristics of the Goodyear Inflatoplane; NACA-RM-L58E09; National Advisory Committee for Aeronautics: Washington, DC, USA, 1958. [Google Scholar]

- Jacob, J.; Smith, S.; Cadogan, D.; Scarborough, S. Expanding the Small UAV Design Space with Inflatable Wings. In Proceedings of the Aerospace Technology Conference and Exposition, Long Beach, CA, USA, 18–20 September 2007. [Google Scholar] [CrossRef]

- Cadogan, D.; Smith, T.; Lee, R.; Scarborough, S.; Graziosi, D. Inflatable and Rigidizable Wing Components for Unmanned Aerial Vehicles. In Proceedings of the 44th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Norfolk, VA, USA, 7–10 April 2003. [Google Scholar] [CrossRef]

- Murray, J.; Pahle, J.; Thornton, S.; Vogus, S.; Frackowiak, T.; Mello, J.; Norton, B. Ground and Flight Evaluation of a Small-Scale Inflatable-Winged Aircraft. In Proceedings of the 40th AIAA Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 14–17 January 2002. [Google Scholar] [CrossRef]

- Simpson, A.D.; Rawashdeh, O.; Smith, S.W.; Jacob, J.; Smith, W.T.; Lumpp, J.E. BIG BLUE: High-altitude UAV demonstrator of Mars airplane technology. In Proceedings of the 2005 IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2005. [Google Scholar] [CrossRef]

- Simpson, A.; Jacob, J.; Smith, S.; Rawashdeh, O.; Lumpp, J.; Smith, W. BIG BLUE II: Mars Aircraft Prototype with Inflatable-Rigidizable Wings. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–13 January 2005. [Google Scholar] [CrossRef]

- Wade, P.; Rachel, N. Historical Perspective on Inflatable Wing Structures. In Proceedings of the 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Palm Springs, CA, USA, 4–7 May 2009. [Google Scholar] [CrossRef]

- Lebeau, R.; Reasor, D.; Gilliam, T.; Schloemer, A.; Hauser, T.; Johansen, T. Numerical Comparison of Flow over Bumpy Inflatable Airfoils. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef]

- Ghobadi, K.; Pifer, E.; Lebeau, R.; Bramesfeld, G.; Mcquilling, M. A Computational and Experimental Investigation of Flow Over an Inflatable Wing. In Proceedings of the 30th AIAA Applied Aerodynamics Conference, New Orleans, LA, USA, 25–28 June 2012. [Google Scholar] [CrossRef]

- Beltz, J.; Lebeau, R. A Comparison of Computational and Experimental Results for Three-Dimensional Flow over a Undulating Inflatable Wing. In Proceedings of the 34th AIAA Applied Aerodynamics Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar] [CrossRef]

- Breuer, J.; Ockels, W.; Luchsinger, R. An inflatable wing using the principle of Tensairity. In Proceedings of the 48th AIAA Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2007; Volume 5. [Google Scholar] [CrossRef]

- Ma, N.; Liu, L.; Meng, F.; Meng, J. Structural design and modal behaviors analysis of a new swept baffled inflatable wing. Def. Technol. 2023, 24, 382–398. [Google Scholar] [CrossRef]

- Wei, J.; Hou, S.; Xia, Q.; Tan, H. Structural design and dynamic analysis of an inflatable delta wing. Aerosp. Sci. Technol. 2023, 139, 108371. [Google Scholar] [CrossRef]

- Rakshith, K.; Dusane, C.; Mistri, S.; Pant, R. Analytical Modelling of Baffled Inflatable Wing for Failure Prediction. In Proceedings of the AIAA Aviation 2019 Forum, Dallas, TX, USA, 17–21 June 2019. [Google Scholar] [CrossRef]

- Mao, Z.; Li, Z.; Chen, B.; Ge, H.; Xu, Y.; Wang, J.; Chen, X. Prediction method for mechanical properties of inflatable wing and its buckling failure mechanism. Aerosp. Sci. Technol. 2025, 163, 110304. [Google Scholar] [CrossRef]

- Cadogan, D.; Scarborough, S.; Gleeson, D.; Dixit, A.; Jacob, J.; Simpson, A. Recent Development and Test of Inflatable Wings. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, RI, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Butt, L.; Kurdi, M.; Kapania, R.; Asheghian, L. Aeroelastic Analysis and Optimization of a Rigid/Inflatable Wing. In Proceedings of the AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Denver, CO, USA, 4–7 April 2011. [Google Scholar] [CrossRef]

- Simpson, A.; Smith, S.; Jacob, J. Aeroelastic Behavior of Inflatable Wings: Wind Tunnel and Flight Testing. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007. [Google Scholar] [CrossRef]

- Rendall, T.; Chang, C.; Marzocca, P.; Bollt, E.; Zamankhan, P. Aeroelastic Behavior of a Non-rigidizable Inflatable UAV Wing. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, RI, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Simpson, A.; Jacob, J. Aerodynamic Control of an Inflatable Wing Using Wing Warping. In Proceedings of the 35th AIAA Fluid Dynamics Conference and Exhibit, Toronto, ON, Canada, 5–9 June 2005. [Google Scholar] [CrossRef]

- Simpson, A.; Jacob, J.; Smith, S. Flight Control of a UAV with Inflatable Wings with Wing Warping. In Proceedings of the 24th AIAA Applied Aerodynamics Conference, San Francisco, CA, USA, 5–8 June 2006. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H. Inflatable Wing Design Parameter Optimization Using Orthogonal Testing and Support Vector Machines. Chin. J. Aeronaut. 2012, 25, 887–895. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, H. Inflatable airfoil structure optimization on flying wing Buoyancy-lifting unmanned aerial vehicles. In Proceedings of the 2017 IEEE International Conference on Unmanned Systems (ICUS), Beijing, China, 27–29 October 2017; pp. 254–259. [Google Scholar] [CrossRef]

- Ma, N.; Meng, J.; Luo, J.; Liu, Q. Optimization of thermal-fluid-structure coupling for variable-span inflatable wings considering case correlation. Aerosp. Sci. Technol. 2024, 153, 109448. [Google Scholar] [CrossRef]

- Ge, H.; Xu, Y.; Sun, D.; Chen, X.; Chen, B. Design and Flight Test of a Compact and Rapidly-Deployable Air-Launched Inflatable-Winged Aircraft. In Proceedings of the AIAA SCITECH 2025 Forum, Orlando, FL, USA, 6–10 January 2025. [Google Scholar] [CrossRef]

- Moorhouse, D.J.; Woodcock, R.J. Military Specification-Flying Qualities of Piloted Airplanes; Technical Report MIL-F-8785C; Department of Defense: Dayton, OH, USA, 1980. [Google Scholar]

- Moorhouse, D.J.; Woodcock, R.J. Background Information and User Guide for MIL-F-8785C, Military Specification-Flying Qualities of Piloted Airplanes; Technical Report AFWAL-TR-81-3109; Flight Dynamics Laboratory, Air Force Wright Aeronautical Laboratories, Wright-Patterson AFB: Dayton, OH, USA, 1982. [Google Scholar]

- Prosser, C.F.; Wiler, C.D. RPV Flying Qualities Design Criteria; Technical Report AFFDL-TR-76-125; Air Force Flight Dynamics Laboratory: Dayton, OH, USA, 1976. [Google Scholar]

- Greene, K.M.; Kunz, D.L.; Cotting, M.C. Toward a Flying Qualities Standard for Unmanned Aircraft. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar] [CrossRef]

- Sadraey, M.H. Aircraft Design; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; Chapter 12; pp. 631–753. [Google Scholar] [CrossRef]

- Doepke, E.; Ashcraft, S.W.; Thamann, M.A.; Smith, S.W. Design of a Rapid Prototype Wing Warping Test Aircraft. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013. [Google Scholar] [CrossRef]

- Gudmundsson, S. General Aviation Aircraft Design-Applied Methods and Procedures; Butterworth-Heinemann: Waltham, MA, USA, 2022. [Google Scholar] [CrossRef]

| Components | Parameters | Values |

|---|---|---|

| Wing | Wingspan | 6 m |

| Mean chord length | 0.6 m | |

| Aspect ratio | 10 | |

| Airfoil | NACA4318 (Inflatable) | |

| Tail (single side) | Wingspan | 1.2 m |

| Mean chord length | 0.5 m | |

| Aspect ratio | 2.4 | |

| Airfoil | NACA0015 (Inflatable) | |

| Fuselage | Length | 3.5 m (telescopic) |

| Parameter | ||||

|---|---|---|---|---|

| Value | 60 | −0.55 | 0.28 | 20 |

| Unit | kg·m2 | – | – | degrees |

| Data source | Experiment | CFD | CFD | Design result |

| Components | Parameters | Values |

|---|---|---|

| Wing | Wingspan | 5.2 m |

| Mean chord length | 0.6 m | |

| Aspect ratio | 8.67 | |

| Airfoil | NACA4318 (Inflatable) | |

| Horizontal Tail | Wingspan | 2 m |

| Mean chord length | 0.6 m | |

| Aspect ratio | 3.33 | |

| Airfoil | NACA4318 (Inflatable) | |

| Vertical Tail (single side) | Wingspan | 0.5 m |

| Mean chord length | 0.5 m | |

| Aspect ratio | 1 | |

| Airfoil | NACA0015 (Inflatable) | |

| Fuselage | Length | 3.5 m (twin-boom) |

| Parameter | ||||

|---|---|---|---|---|

| Value | 52 | −0.48 | 0.4 | 8 |

| Unit | kg·m2 | – | – | degrees |

| Data source | Experiment | CFD | CFD | Design result |

| Items | Prot1 | Prot2 |

|---|---|---|

| Basic configuration | Single-fuselage, cantilevered main wing, single-thrust system | Twin-fuselage, segmented wing sections, twin-thrust system |

| Maximum takeoff weight | 40 kg | 45 kg |

| Manipulation method | External trailing-edge control surfaces on the main wing and tails | Fully movable ailerons and tails |

| Flights (including ground taxiing tests) | 10 times | 16 times |

| Maximum flight altitude | ≈40 m | ≈75 m |

| Maximum velocity reached | ≈20 m/s | ≈25 m/s |

| Control responses (evaluated by the drone pilot) | -Pitch: Adequate | -Pitch: Adequate |

| -Yaw: Adequate | -Yaw: Adequate | |

| -Roll: Adequate | -Roll: Adequate | |

| Anomalies before flight | Asymmetric torsion in the main wing | None |

| Corrective measures | Auxiliary supports and ropes | — |

| Anomalies during flight (evaluated by the drone pilot) | - Sustained oscillations in the roll axis (due to wing asymmetric torsion), necessitating continuous control adjustments | - Poor wind resistance, occasional instability under gusty conditions |

| - Poor wind resistance, occasional instability under gusty conditions | ||

| Wing deformation (during flight) | -Obvious upwards deformation without auxiliary supports and ropes | -Not visually noticeable |

| -Not visually noticeable with auxiliary supports and ropes | ||

| Flight crashes | Yes, caused by combined effect of wing asymmetric torsion and sudden crosswind | Yes, caused by sudden crosswind |

| Other observations | Inflatable wing remained intact after ground rollovers and crash | Inflatable wing remained intact after crash |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, H.; Sun, D.; Chen, X.; Mao, Z.; Xu, Y.; Chen, B.; Xu, Y. Design, Roll Control Evaluation and Flight Test of Inflatable-Winged UAVs in Two Configurations. Aerospace 2025, 12, 976. https://doi.org/10.3390/aerospace12110976

Ge H, Sun D, Chen X, Mao Z, Xu Y, Chen B, Xu Y. Design, Roll Control Evaluation and Flight Test of Inflatable-Winged UAVs in Two Configurations. Aerospace. 2025; 12(11):976. https://doi.org/10.3390/aerospace12110976

Chicago/Turabian StyleGe, Hang, Donglei Sun, Xinmin Chen, Zebei Mao, Yonghui Xu, Boyang Chen, and Yixiang Xu. 2025. "Design, Roll Control Evaluation and Flight Test of Inflatable-Winged UAVs in Two Configurations" Aerospace 12, no. 11: 976. https://doi.org/10.3390/aerospace12110976

APA StyleGe, H., Sun, D., Chen, X., Mao, Z., Xu, Y., Chen, B., & Xu, Y. (2025). Design, Roll Control Evaluation and Flight Test of Inflatable-Winged UAVs in Two Configurations. Aerospace, 12(11), 976. https://doi.org/10.3390/aerospace12110976