Research on the Cooling Characteristics of the Circular Ring Structure of Aircraft Engine Endoscope Probes

Abstract

1. Introduction

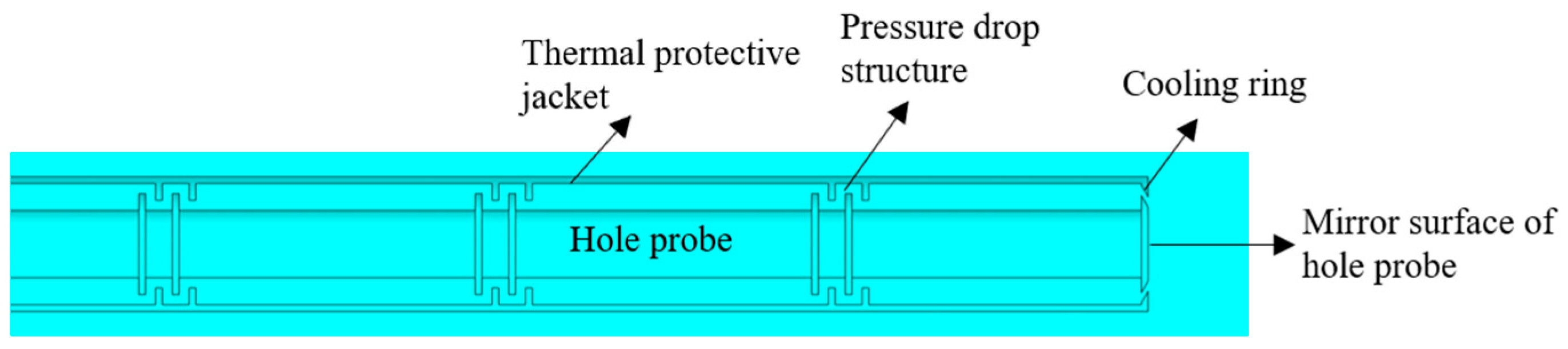

2. Physical Model

3. Numerical Computation

3.1. Computational Domain and Boundary Conditions

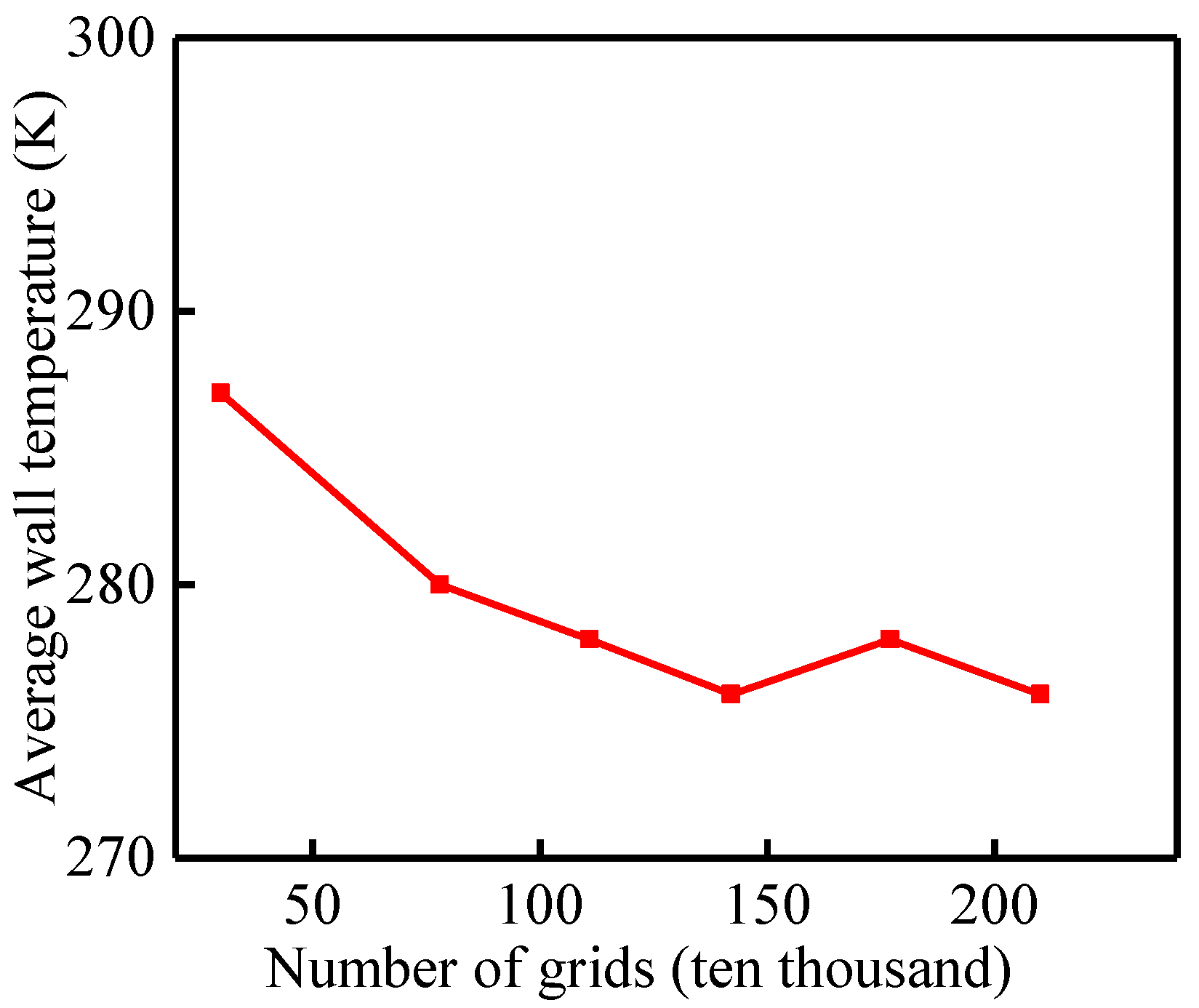

3.2. Irrelevance Verification

4. Results and Analysis

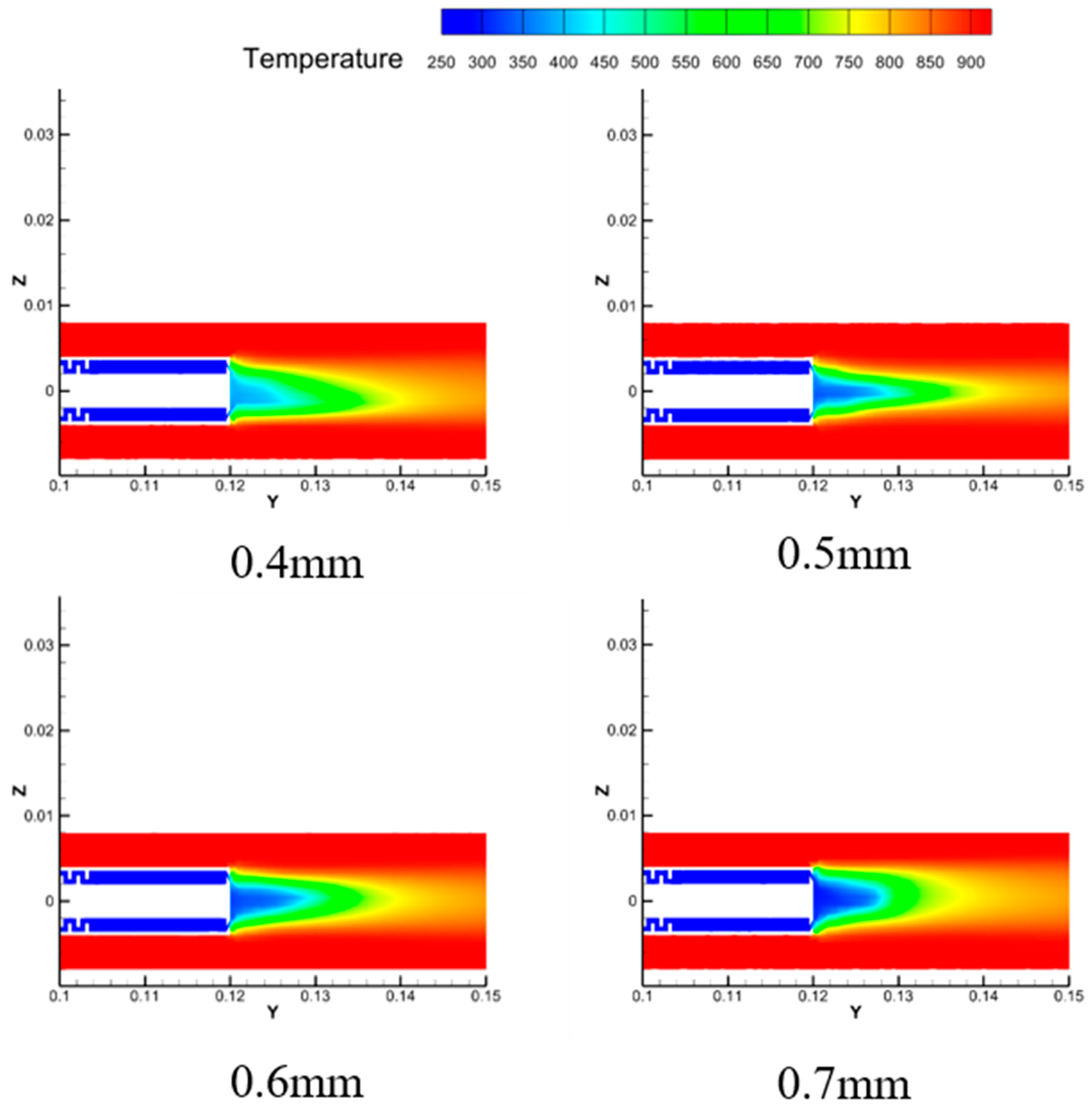

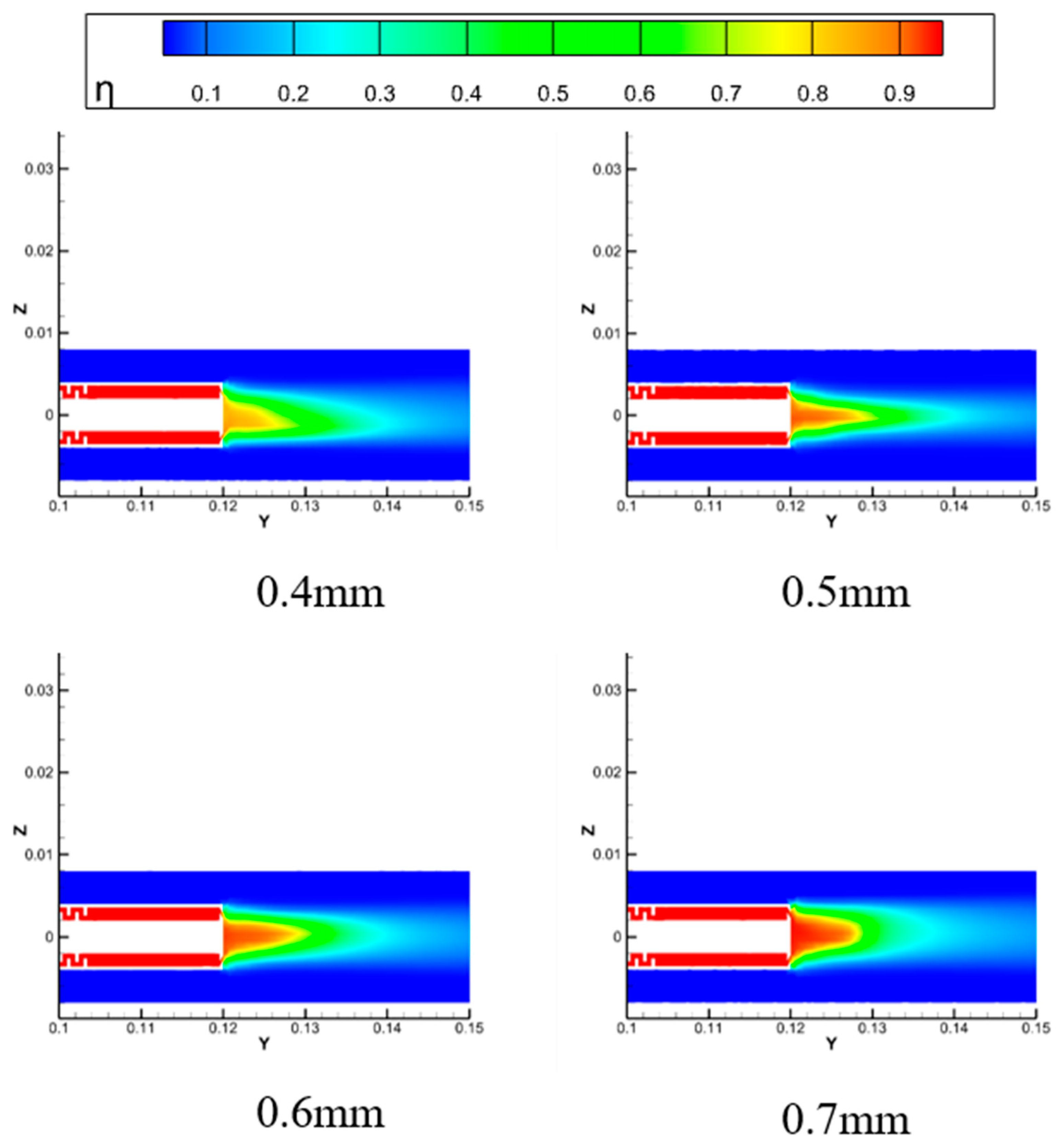

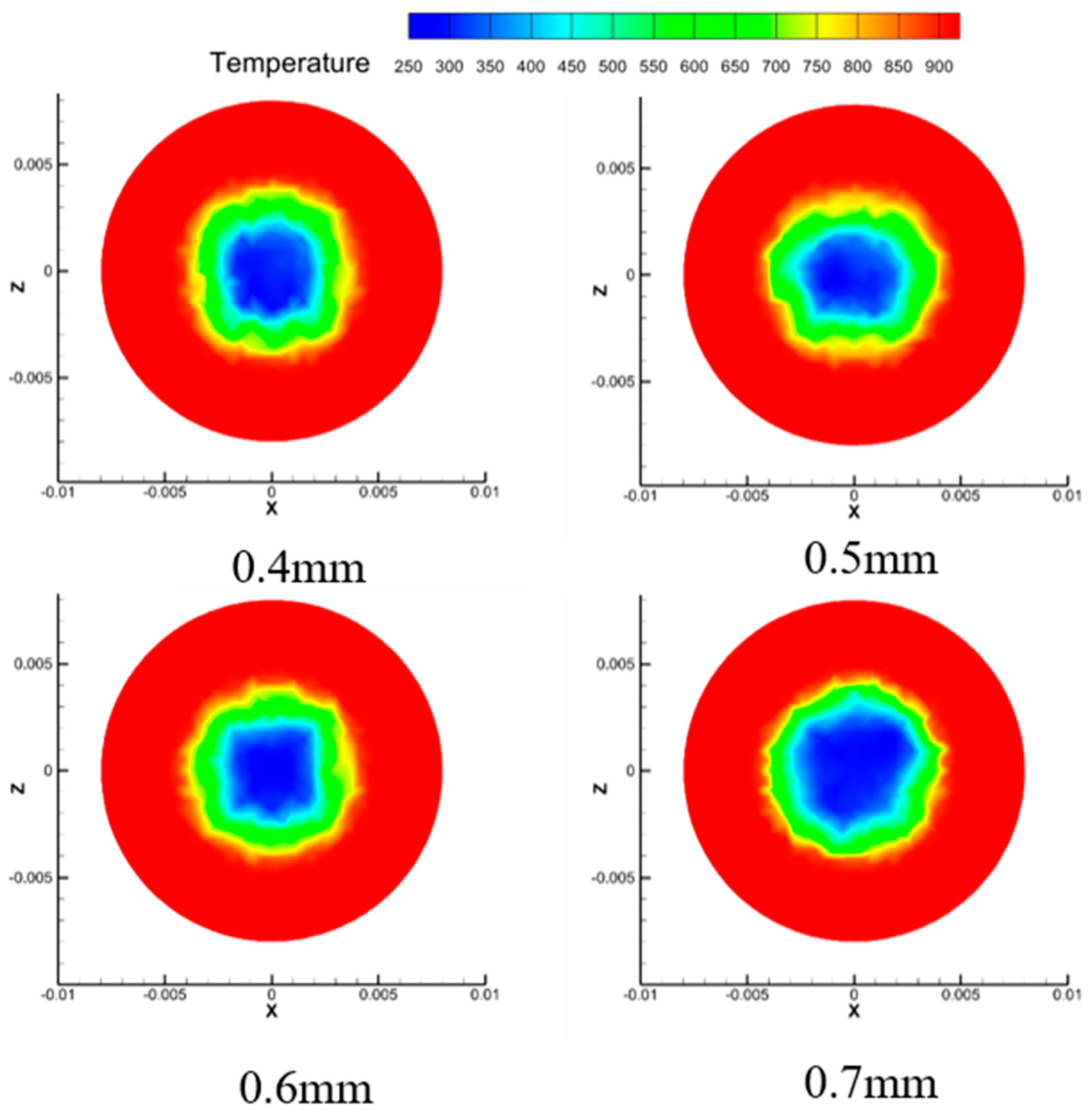

4.1. The Influence of Exit Width on the Cooling Characteristics of Hole Probe

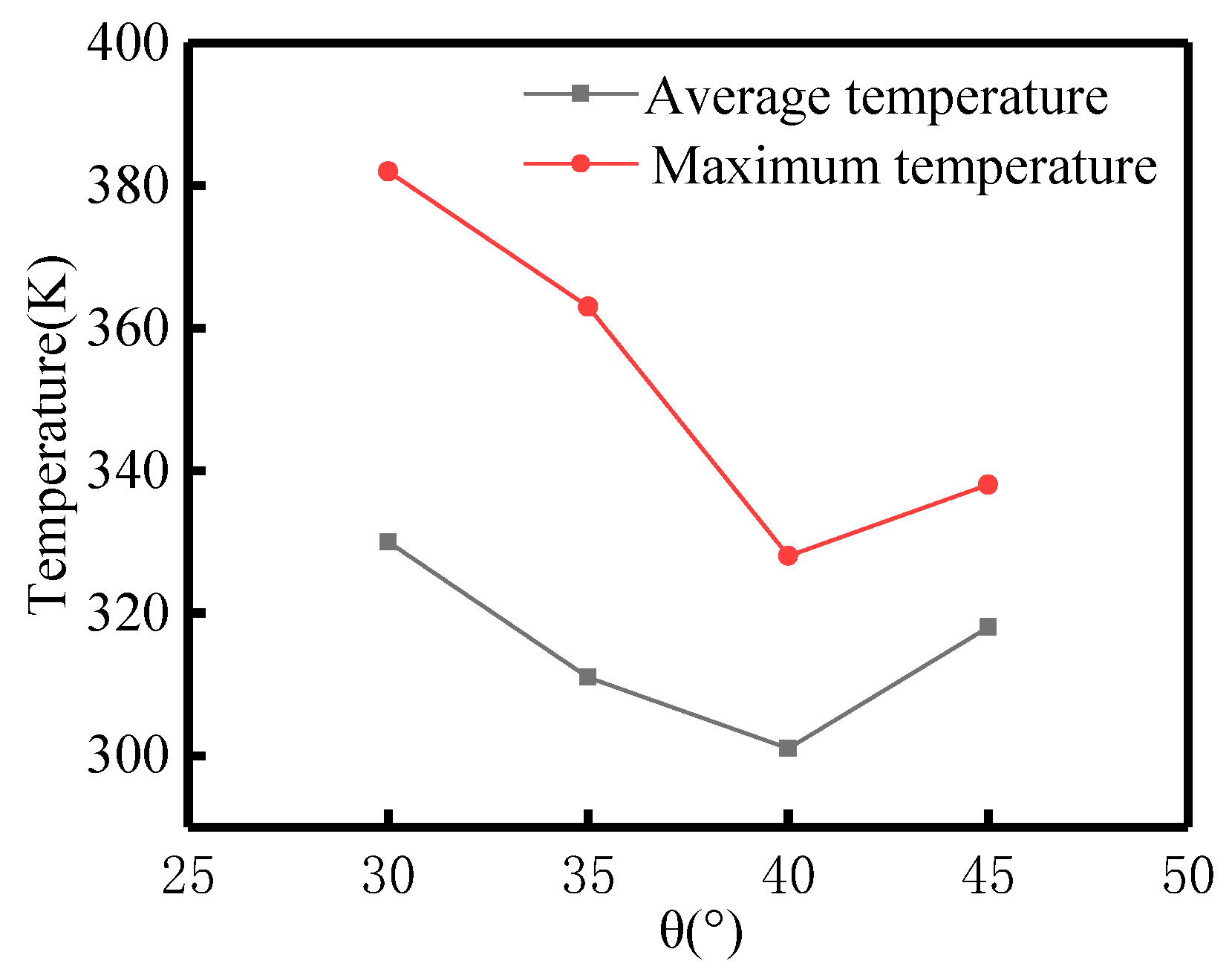

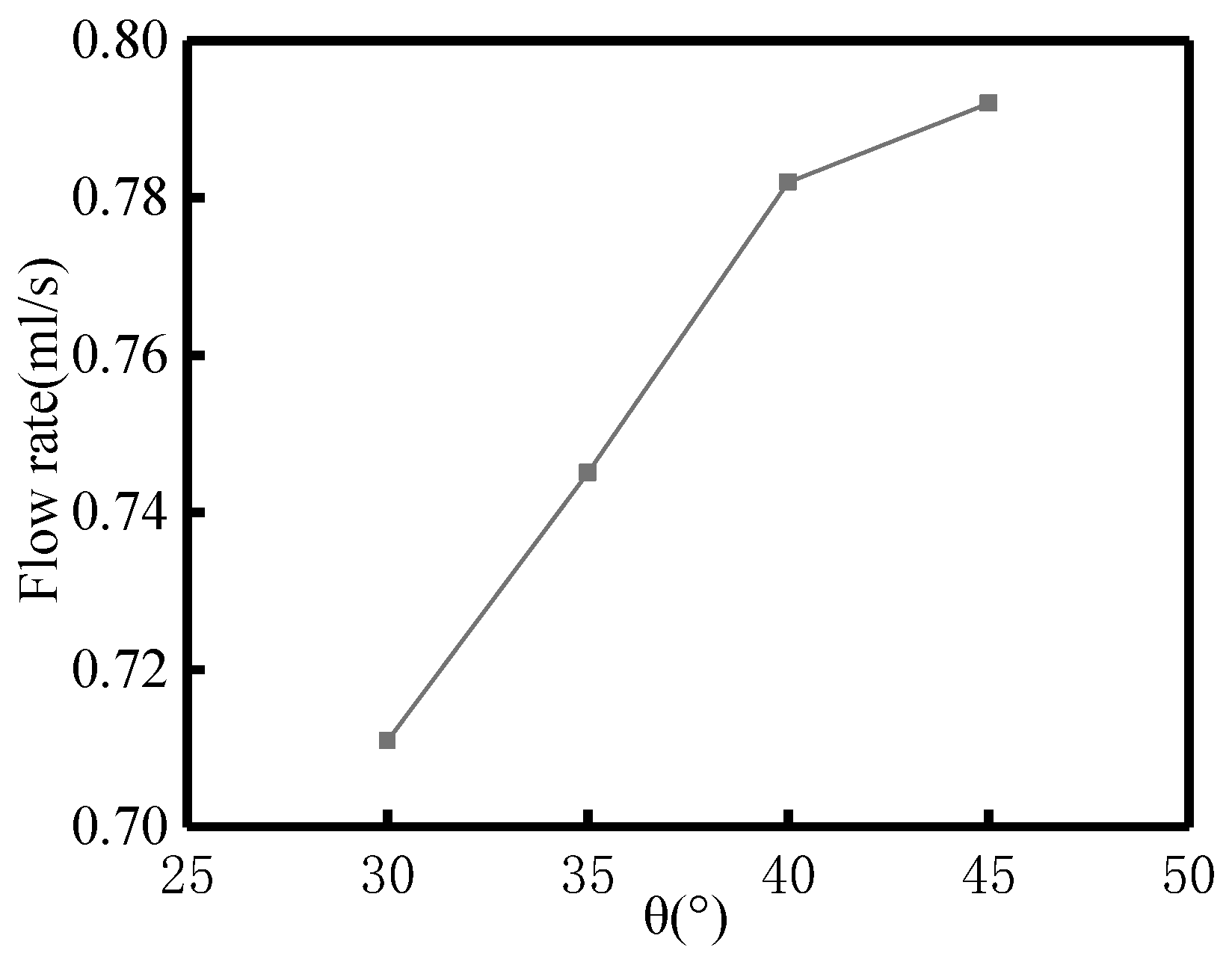

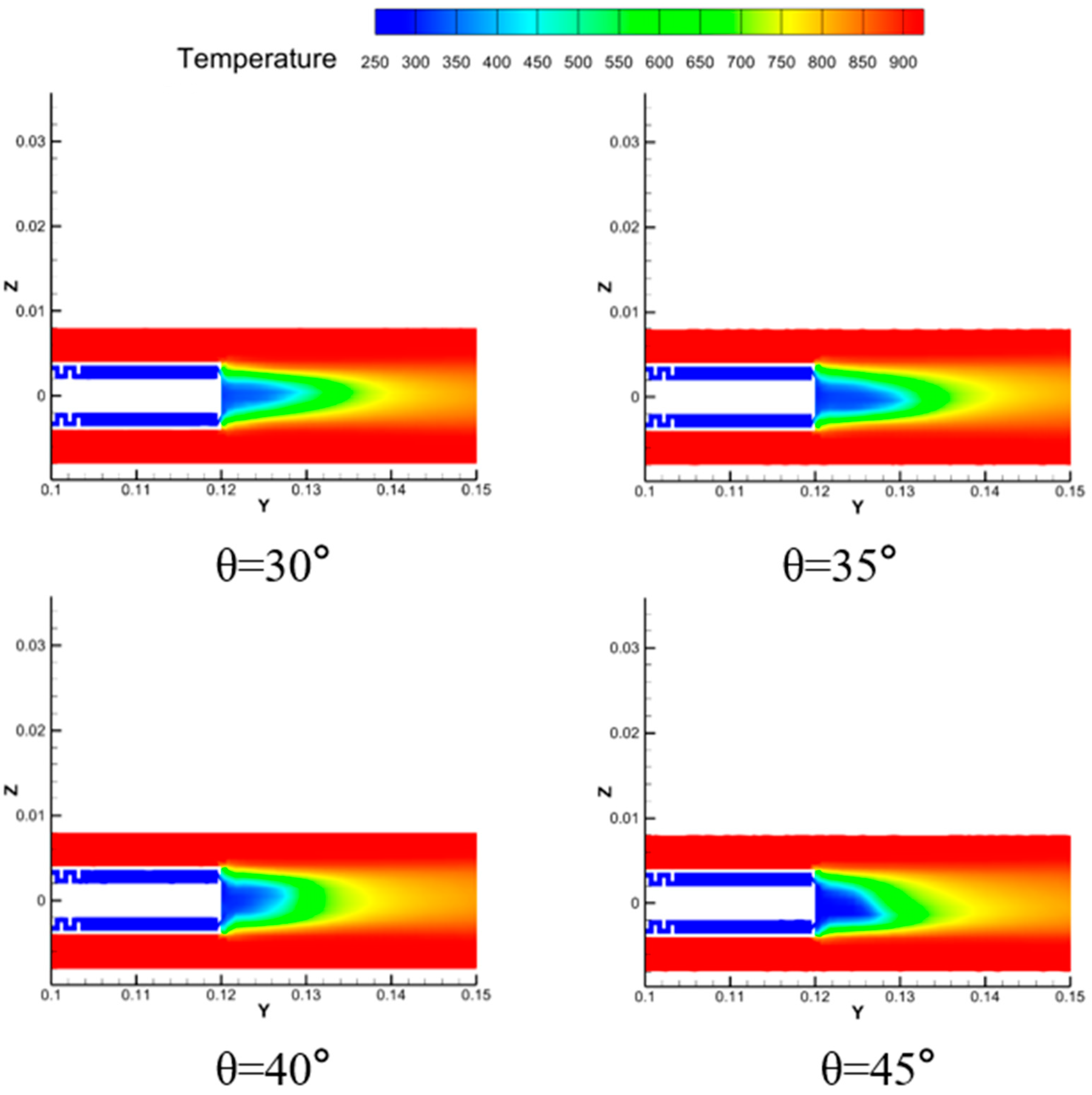

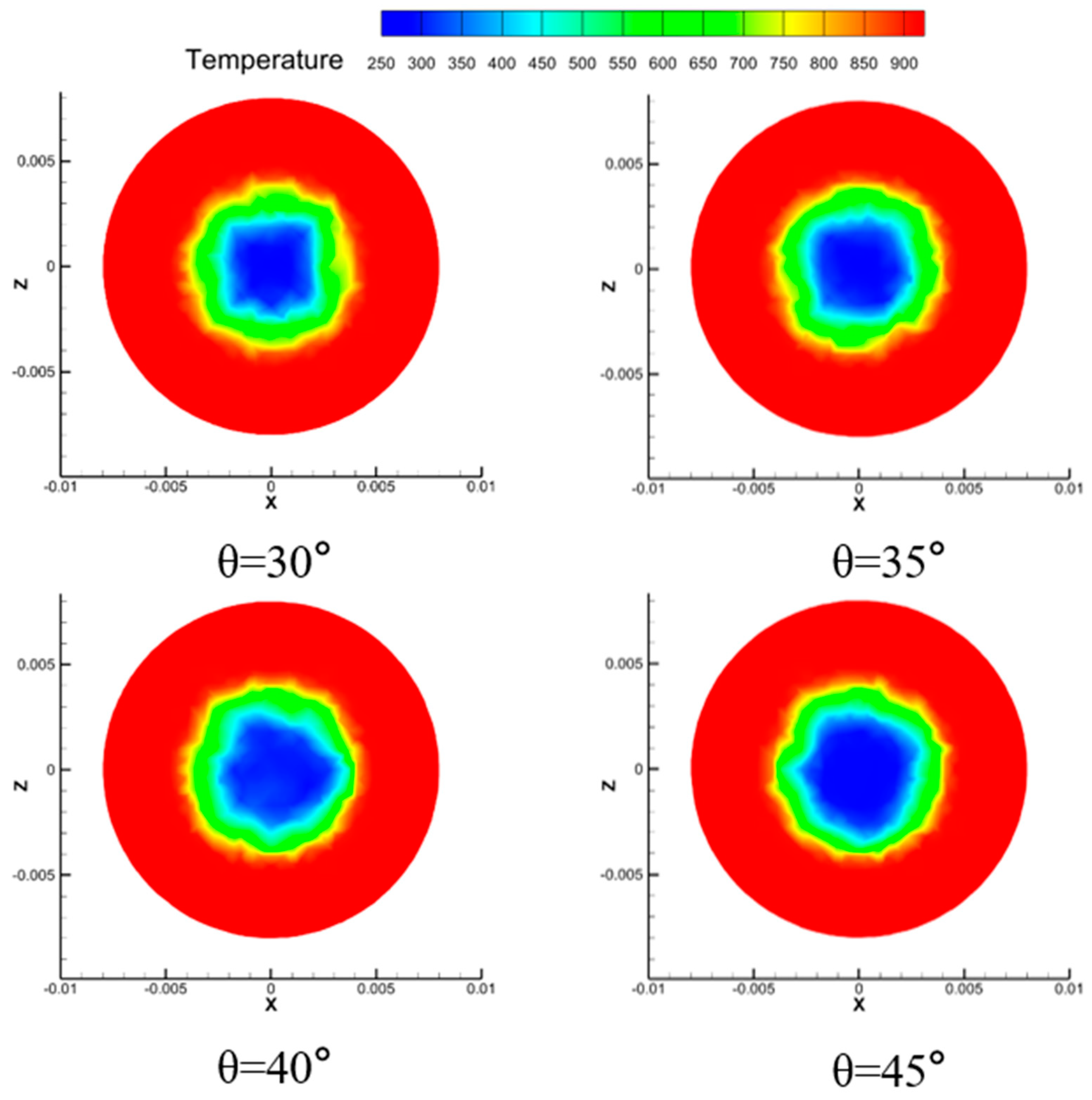

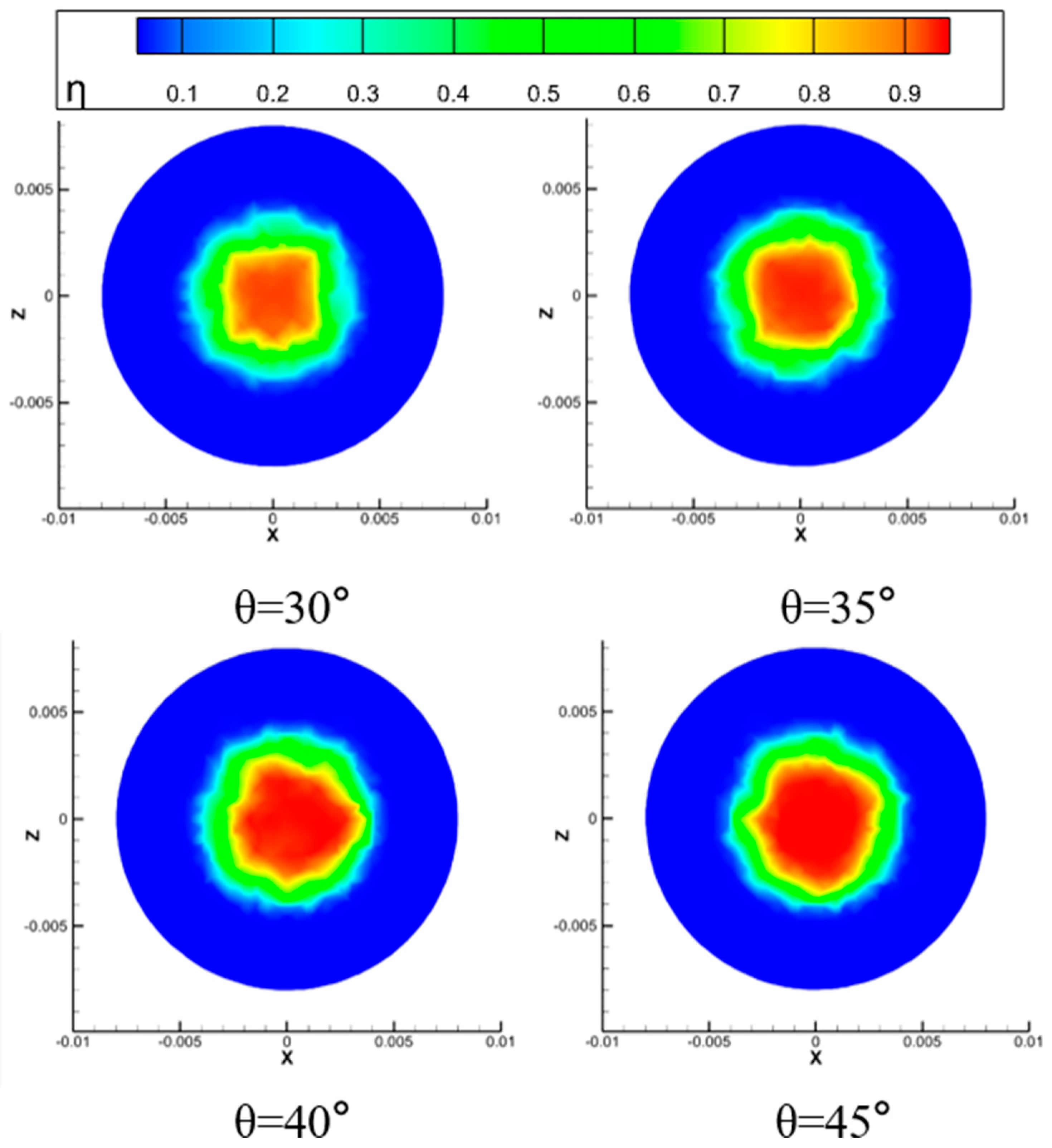

4.2. The Influence of Opening Angle on the Cooling Characteristics of Hole Probe

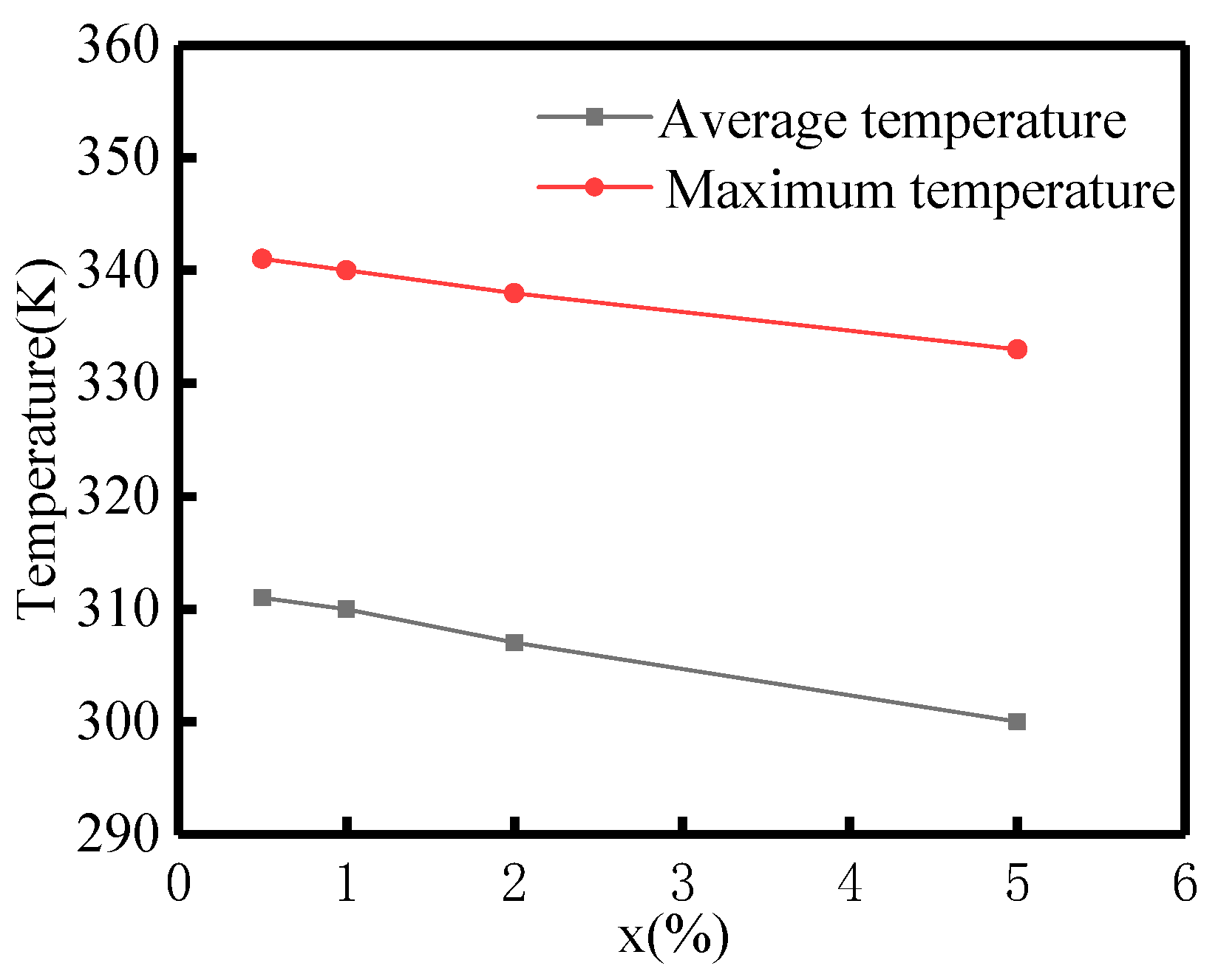

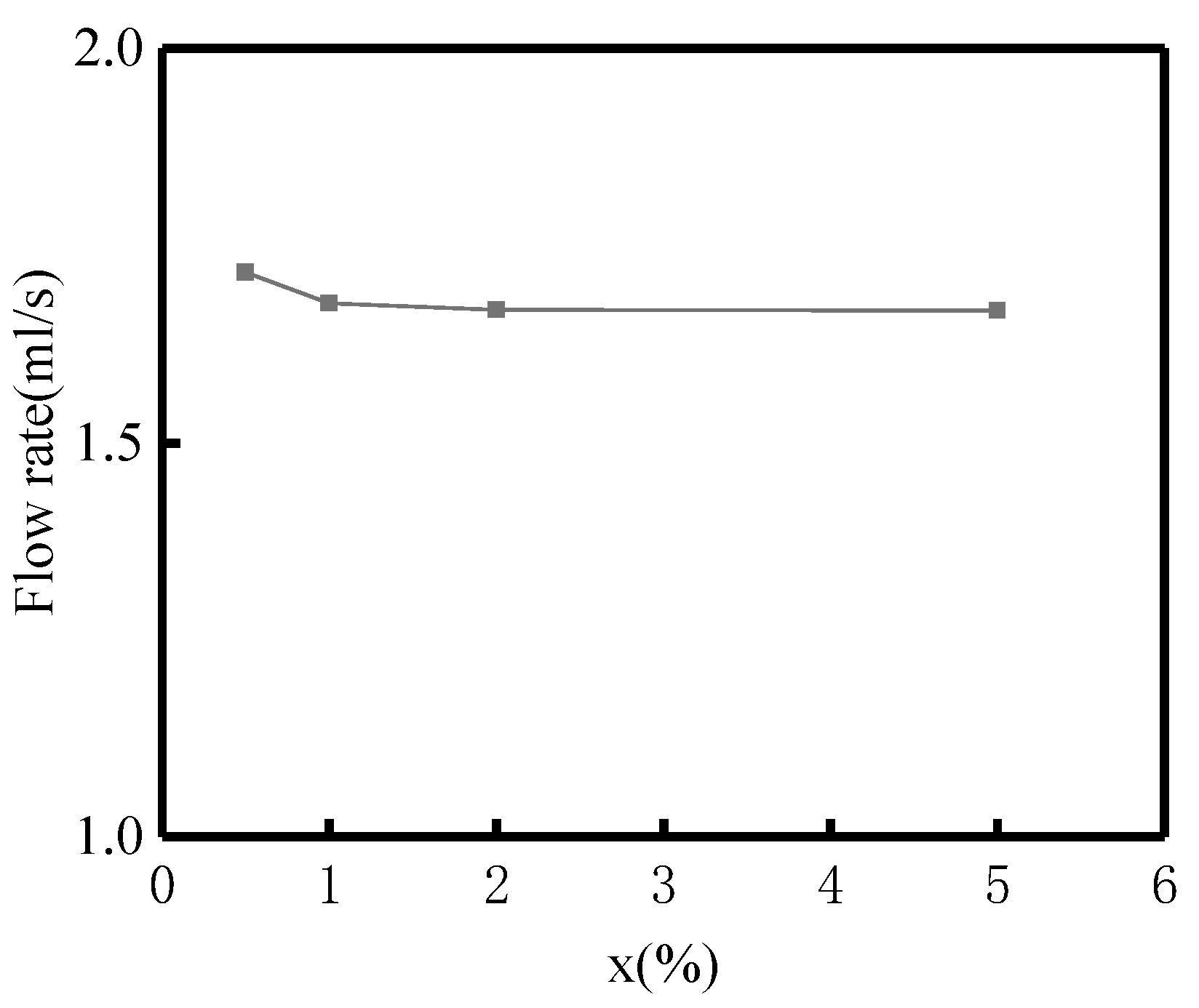

4.3. The Effect of Mixing Liquid Nitrogen on the Cooling Characteristics of Hole Probe

5. Conclusions

- (1)

- The cooling gas in the annular structure can effectively reduce the temperature of the probe mirror, and the larger the outlet width, the better the cooling effect. The best annular cooling structure studied in this article is a circular ring structure with an outlet width of 0.7 mm. At a cold flow temperature of 285 K and a pressure of 0.5 MPa, the temperature of the endoscope probe can be reduced to 300.25 K, and the cooling effect of the hole probe mirror surface is the best. At the same time, the flow rate also rapidly decreases, reaching 0.62 mL/s at an outlet width of 0.7 mm, which not only effectively cools but also saves cold air volume. As the width of the cooling ring increases, the frictional resistance at the outlet of the cold flow decreases, and the flow rate of the impact ring is reduced. Therefore, the lateral diffusion of cold air on the probe mirror surface is enhanced. The width of the cooling ring outlet is a key parameter that affects the cooling efficiency of the probe.

- (2)

- The opening angle of the hole probe has a significant impact on the cooling effect of the hole probe. The larger the opening angle, the lower and then higher the average and maximum temperatures of the endoscope probe surface. As the opening angle of the cooling ring increases to a suitable angle of 40°, the cooling airflow impacts the probe mirror in an appropriate form, forming a stable film protective layer and improving the cooling performance. There is an optimal value for the opening angle of the cooling ring.

- (3)

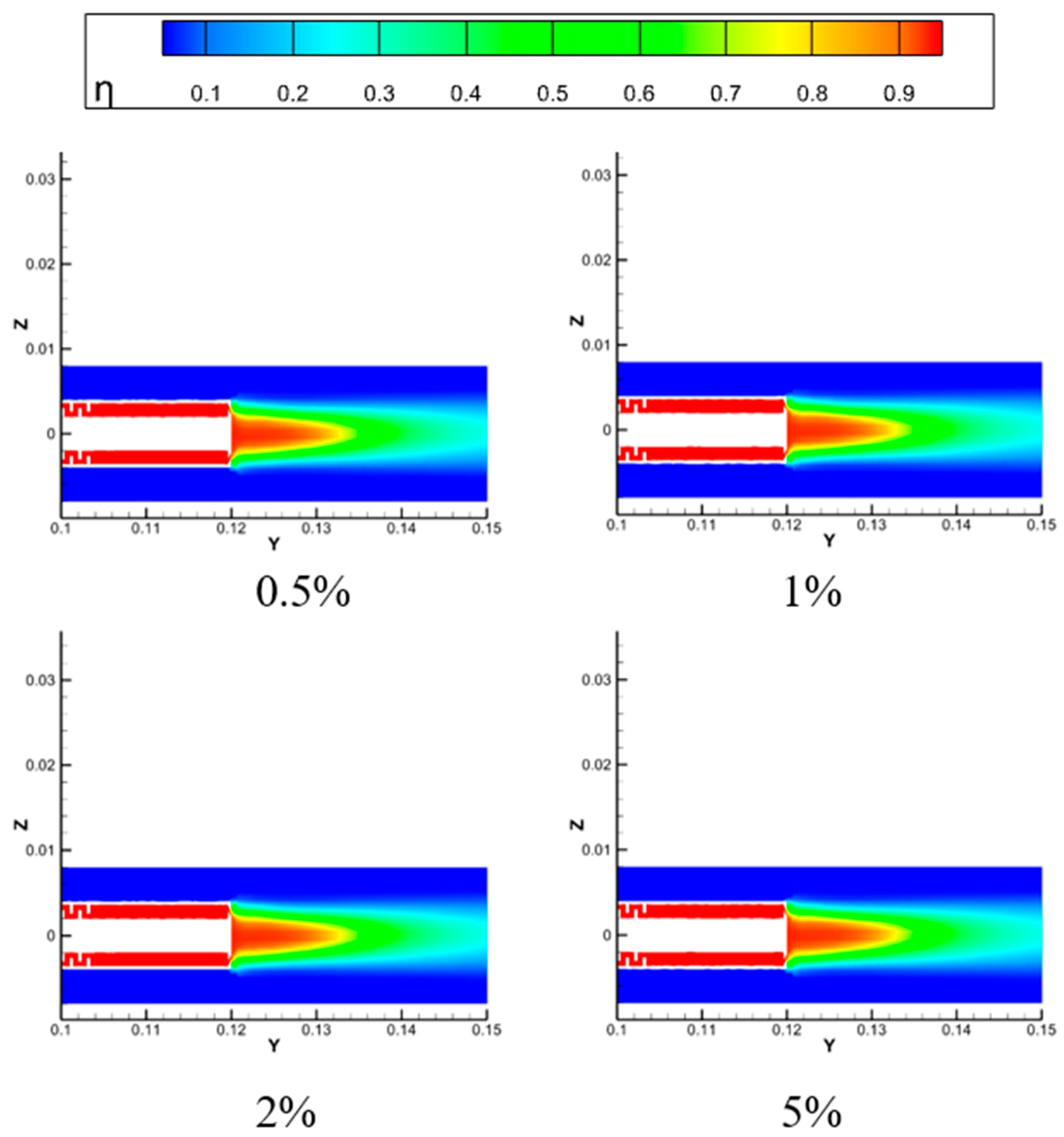

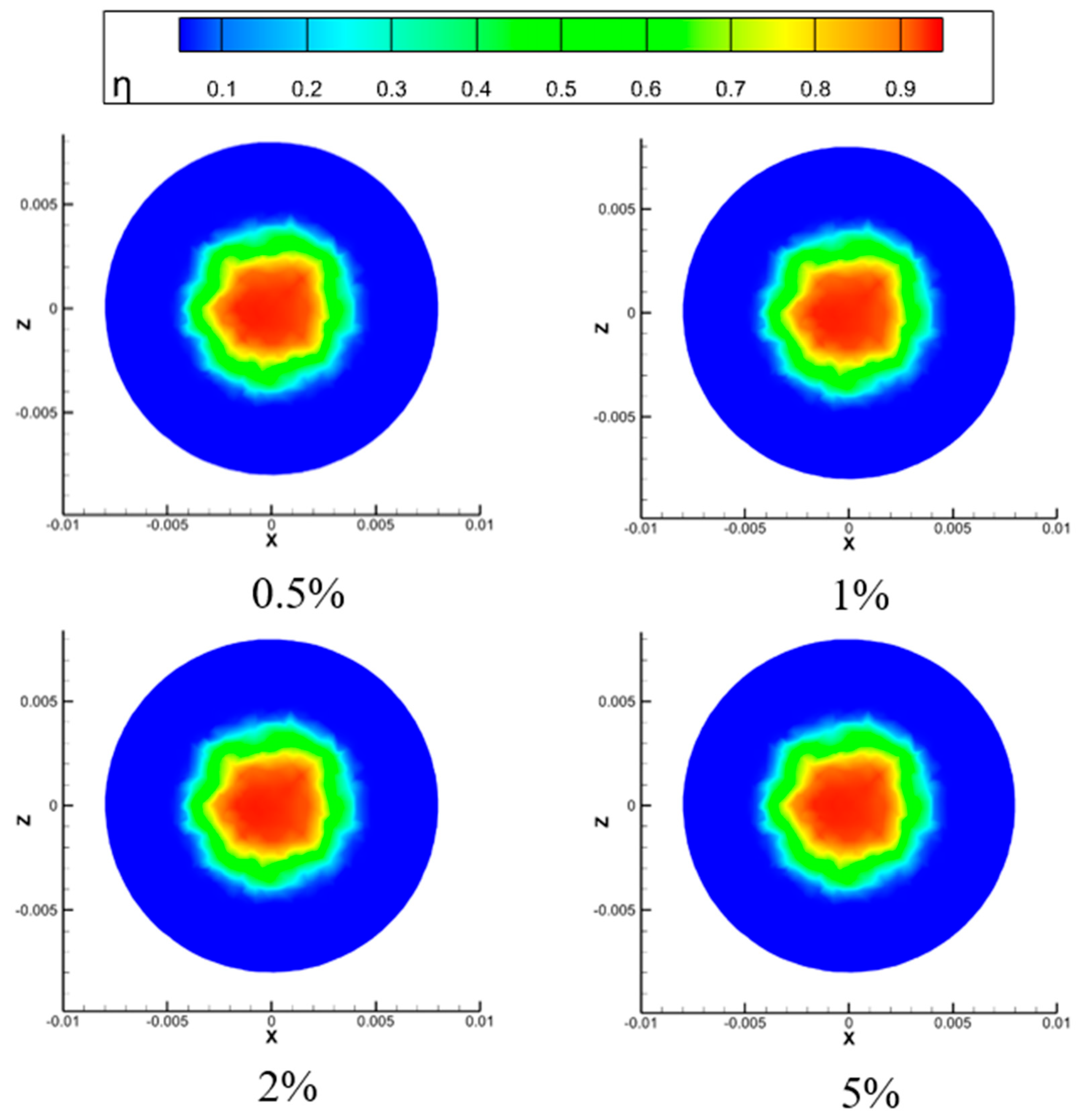

- The larger the proportion of mixed liquid nitrogen, the lower the temperature of the probe mirror. A 5% proportion of mixed liquid nitrogen can reduce the temperature of the probe mirror by about 11 K. As the proportion of mixed liquid nitrogen in the cold air increases from 0.5% to 5%, the wall temperature of the hole probe gradually decreases and reaches a minimum value of 300 K at a mixing ratio of 5%. The cold flow rate also gradually decreases, reaching 1.67 mL/s at a mixing ratio of 5%. This indicates that the use of mixed liquid nitrogen for thermal protection measures in high-temperature environments in the future has broad prospects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, J.; Xue, W.; Zhang, W.; Huang, W.; Zhang, K.; Liu, C.; Wang, Y. Analysis and Development Prediction of Technical Characteristics of Aircraft Engine Turbine Components. Gas Turbine Test. Res. 2025, 38, 20–32. [Google Scholar] [CrossRef]

- Xie, W.; Luo, J. Research progress of laser additive manufacturing technology in turbine blade materials. China Mater. Prog. 2025, 44, 750–760. [Google Scholar]

- Yan, G.; Yan, H.; Jiang, N.; Liu, Y.; Liang, Y.; Zhao, J. Experimental Study on Flow and Heat Transfer Performance of Air Coolers for New Aircraft Engines. Aircr. Engines 2023, 49, 48–53. [Google Scholar]

- Wen, Q.; Pei, X.; Tian, H.; Hou, L. Study on the Influence of Air Oil Heat Exchanger on the Overall Performance of Variable Cycle Aircraft Engine. Propuls. Technol. 2023, 44, 39–48. [Google Scholar]

- Li, Y. Analysis of Damage and Repair Technology of Aircraft Engine Blades. Intern. Combust. Engine Parts 2025, 108–110. [Google Scholar] [CrossRef]

- Lai, J. Overview of Cooling Technology for Aircraft Engine Turbine Blades. New Ind. 2021, 11, 39–40. [Google Scholar]

- Xiao, Y.; Cheng, R.; Sun, Y.; Zhou, C.; Xue, X.; Shang, S. Numerical simulation of phase change medium injection cooling for high-temperature components of aircraft engines. Aero Engine 2025, 51, 90–96. [Google Scholar]

- Fei, W.; Dan, Y.; Wang, M.; Tan, X.; Zhang, J. Numerical Study on Ultrasonic Film Cooling of Supersonic Turbine Blades. Propuls. Technol. 2016, 37, 916–921. [Google Scholar]

- Chen, S.; Dan, Y.; Zhang, J.; Tan, X.; Fei, W. Flow characteristics and film cooling properties of supersonic flow field in turbine blade cascade. J. Aeronaut. Dyn. 2013, 28, 2448–2454. [Google Scholar]

- Li, Z.; Zhang, Y.; Dong, W.; Chen, J.; Deng, B. Optimization design of efficient arrangement of gas film cooling holes on the end wall of turbine blades. J. Shanghai Jiao Tong Univ. 2025, 1–17. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Ye, Z.; Chen, J. Research on Thermal Protection Performance of Infrared Temperature Probe for Turbine Blades. Therm. Power Eng. 2024, 39, 97–105. [Google Scholar]

- Ye, Z.; Li, X.; Liu, Y.; Tan, Z.; Huai, X. Numerical simulation study on the protective performance of infrared temperature probe. J. Eng. Thermophys. 2024, 45, 205–211. [Google Scholar]

- Zhang, J.; Sun, B.; Zheng, L. Experimental study on supersonic film cooling with discrete holes in a circular straight pipe. J. Aeronaut. Dyn. 2013, 28, 813–818. [Google Scholar]

- Xue, H.; Chen, X.; Zhang, X. Research on wall temperature calculation of axisymmetric vectoring nozzle under various forms of film cooling. Adv. Aerosp. Eng. 2014, 5, 404–410. [Google Scholar]

- Zhang, X.; Wang, X. Comparative study on cooling effects of various film cooling models. J. Aeronaut. Dyn. 2002, 17, 475–479. [Google Scholar]

- Zhang, T. Research on the Design of Film Cooling Structure for Tail Nozzle. Master’s Thesis, Dalian University of Technology, Dalian, China, 2021. [Google Scholar]

- Zhai, G.; Yang, H.; Gong, W.; Wu, F.; Zeng, J.; Fu, X.; Gao, T. Numerical Analysis on Thermal and Flow Performance of Honeycomb-Structured Microchannel Cooling Plate for IGBT. Energies 2025, 18, 4455. [Google Scholar] [CrossRef]

- Vekariya, P.B.; Subbaiah, R.; Mashru, H.H. Hydraulics of microtube emitters: A dimensional analysis approach. Irrig. Sci. 2011, 29, 341–350. [Google Scholar] [CrossRef]

- Wang, H.; Xie, S.; Sai, Q.; Zhou, C.; Lin, H.; Chen, E. Experiment study on pressure drop of a multistage letdown orifice tube. Nucl. Eng. Des. 2013, 265, 633–638. [Google Scholar] [CrossRef]

- Zhang, S.; Zheng, H.; Zhang, Z.; Zhang, T.; Yang, X. Performance evaluation of film holes used for cooling the optical window of a sensor probe. Numer. Heat Transf. Part A Appl. 2025, 86, 6029–6054. [Google Scholar] [CrossRef]

- Xie, B.; Peng, F.; Lin, H.; Zhang, J.; Han, X.; Zhou, L.; Zhou, B. Research and application of a digital industrial endoscope protection fixture Chongqing Changan Automobile Co., Ltd. Jiangbei Engine Fact. 2020, 379–381. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, W. Error behavior analysis during engine hole probing. Equip. Manag. Maint. 2022, 39–40. [Google Scholar] [CrossRef]

- Wei, X. Risk Management in the Inspection Process of Aircraft Engine Holes. Aviat. Maint. Eng. 2018, 43–45. [Google Scholar] [CrossRef]

- Sun, H. Application of Industrial Endoscope in CFM56 Civil Aviation Engine Maintenance. Sci. Technol. Inf. 2019, 17, 77–78. [Google Scholar]

- Xie, G.; Liu, C.; Niu, J.; Ye, L.; Wang, R. Experimental investigation on analogy principle of conjugate heat transfer for effusion/impingement cooling. Int. J. Heat Mass Transf. 2020, 147, 118919. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 2012, 32, 1598–1605. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Mainstream inlet temperature/K | 900 |

| Mainstream inlet pressure/Pa | 101,325 |

| Mainstream export temperature/K | 900 |

| Mainstream export pressure/Pa | 101,325 |

| Cold flow temperature/K | 285 |

| Exit width/mm | 0.4, 0.5, 0.6, 0.7 |

| Opening angle/° | 30, 35, 40, 45 |

| Mixing ratio of liquid nitrogen/% | 0.5, 1, 2, 5 |

| Temperature/K | Pressure/Pa | |

|---|---|---|

| Hot flow inlet | 900 | 101,325 |

| Cold flow inlet | 250 | 500,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, H.; Xi, R.; Peng, J.; Jia, L.; Fu, C. Research on the Cooling Characteristics of the Circular Ring Structure of Aircraft Engine Endoscope Probes. Aerospace 2025, 12, 962. https://doi.org/10.3390/aerospace12110962

Zeng H, Xi R, Peng J, Jia L, Fu C. Research on the Cooling Characteristics of the Circular Ring Structure of Aircraft Engine Endoscope Probes. Aerospace. 2025; 12(11):962. https://doi.org/10.3390/aerospace12110962

Chicago/Turabian StyleZeng, Hao, Rui Xi, Jingbo Peng, Lu Jia, and Changqin Fu. 2025. "Research on the Cooling Characteristics of the Circular Ring Structure of Aircraft Engine Endoscope Probes" Aerospace 12, no. 11: 962. https://doi.org/10.3390/aerospace12110962

APA StyleZeng, H., Xi, R., Peng, J., Jia, L., & Fu, C. (2025). Research on the Cooling Characteristics of the Circular Ring Structure of Aircraft Engine Endoscope Probes. Aerospace, 12(11), 962. https://doi.org/10.3390/aerospace12110962