Toward Greener Propulsion: An LCA-Based Environmental Performance Classification of In-Space Propulsion Options †

Abstract

1. Introduction

1.1. Scope and Objectives

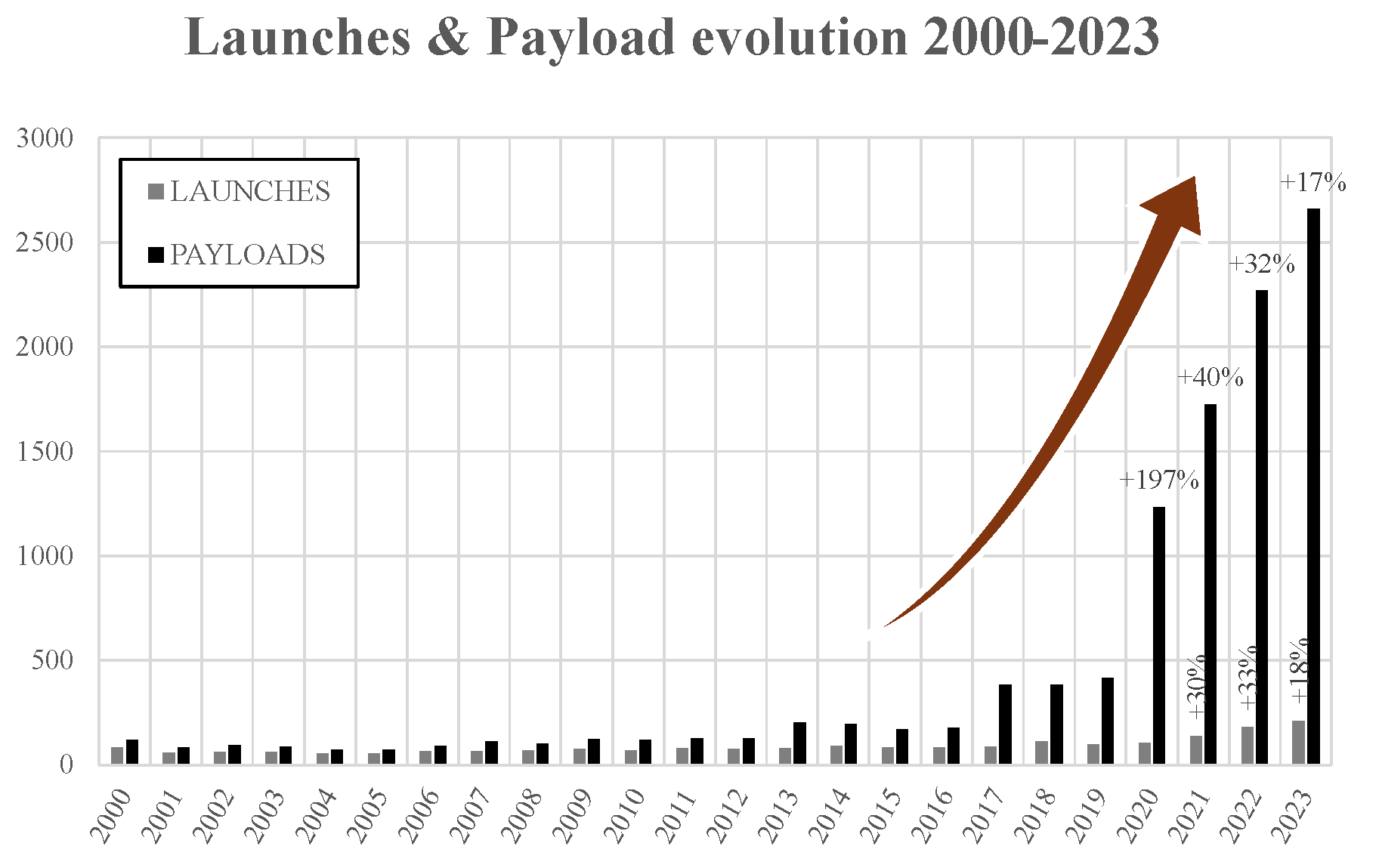

1.2. The Rapid Increase of Space Activities

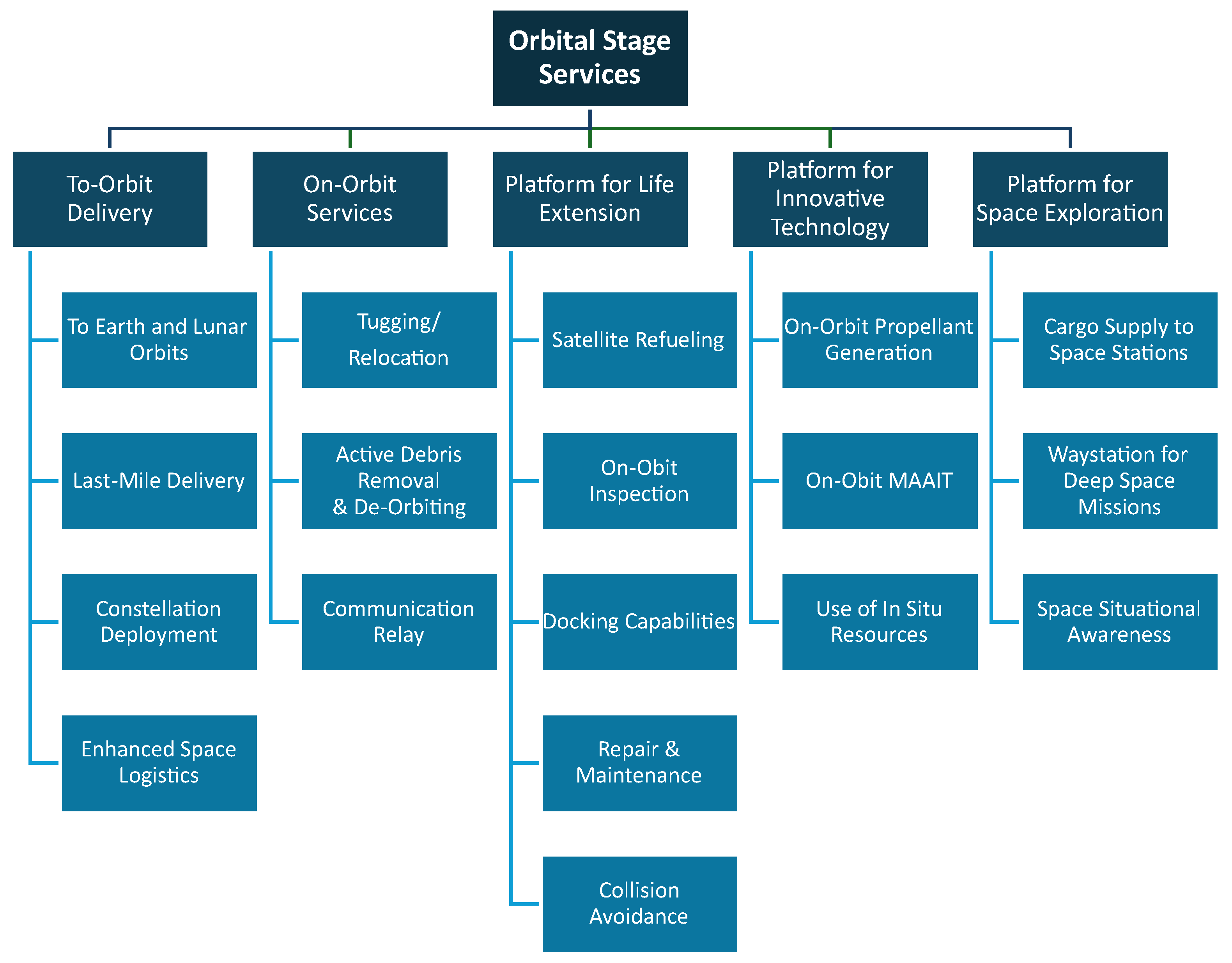

1.3. Role and Impact of Orbital Transfer Vehicles (OTVs)

1.4. The Shift Toward Greener Liquid Propulsion

1.4.1. Limitations of Traditional “Green” Claims

1.4.2. The Need for Space-Specific Environmental Assessment

2. Modeling the Environmental Performance of In-Space Propulsion Systems

2.1. Overview of In-Space Propulsive Options

- Legacy propellants: with NTO or a derivative (MON-1 or MON-3) as oxidizer, paired with hydrazine derivatives as fuel like monomethylhydrazine (MMH).

- Greener semi-hypergolic alternatives: including High-Test Peroxide (usually 98%-HTP) as oxidizer, paired with light low-vapor-pressure hydrocarbon fuels such as RP-1 or ethanol.

- Self-pressurizing systems: with nitrous oxide (N2O) as oxidizer combined with a high-vapor pressure fuel such as ethane or propylene.

2.2. Life Cycle Assessment Methodology

2.2.1. Goal and Scope

2.2.2. Functional Unit and System Boundaries

- In this study, two types of functional units are used to capture both material-level and mission-level impacts:

- -

- 1 kg of chemical or material produced.

- -

- 1 kg of propellant loaded into the spacecraft.

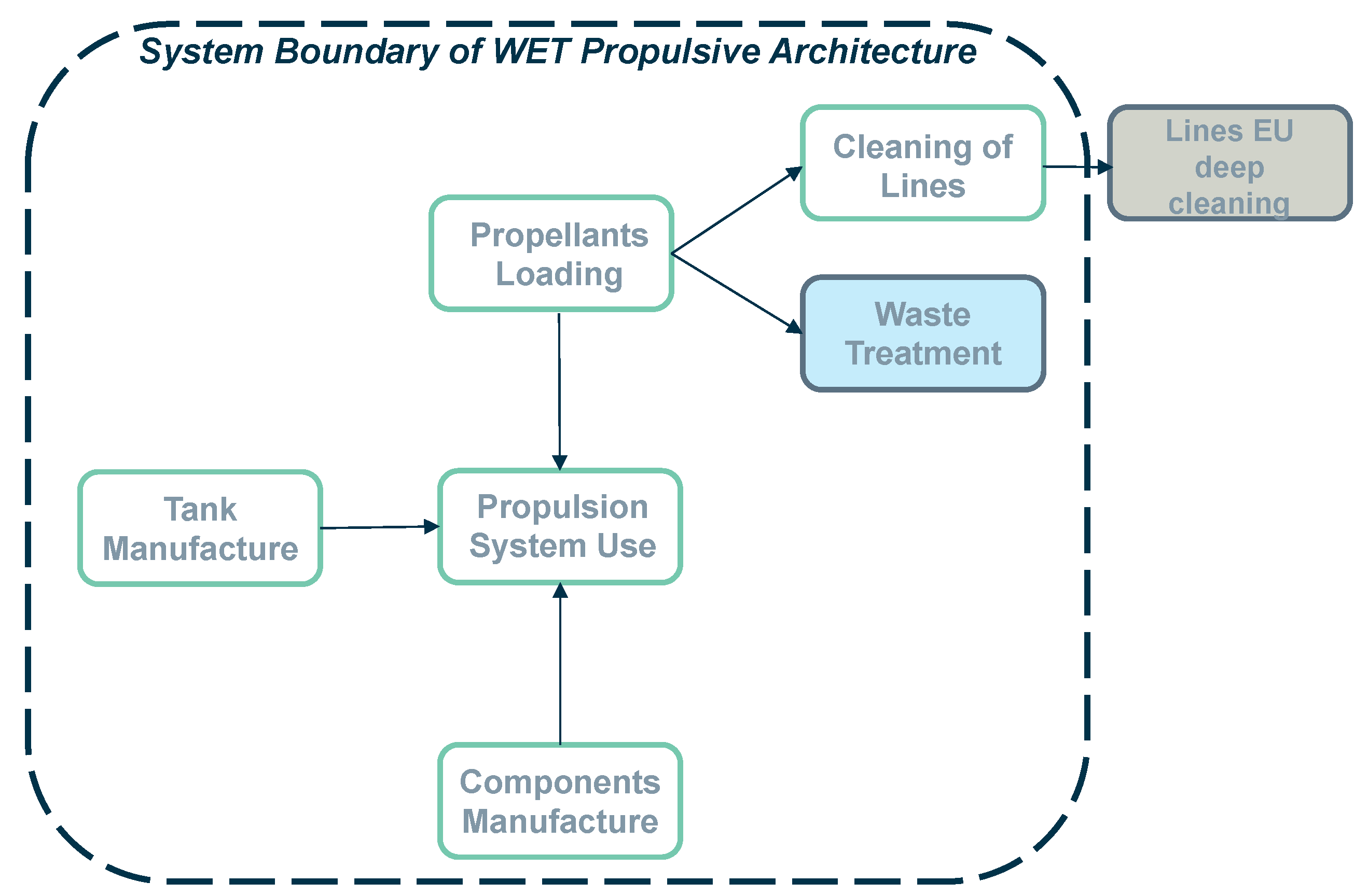

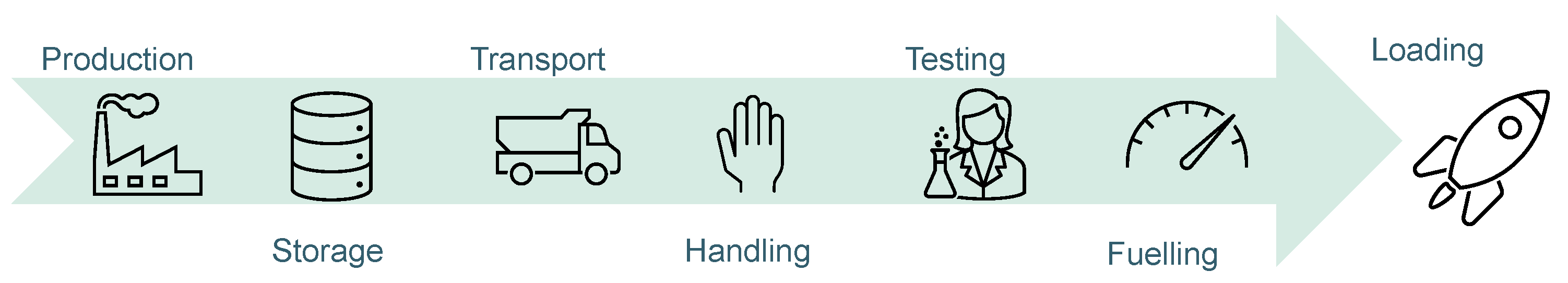

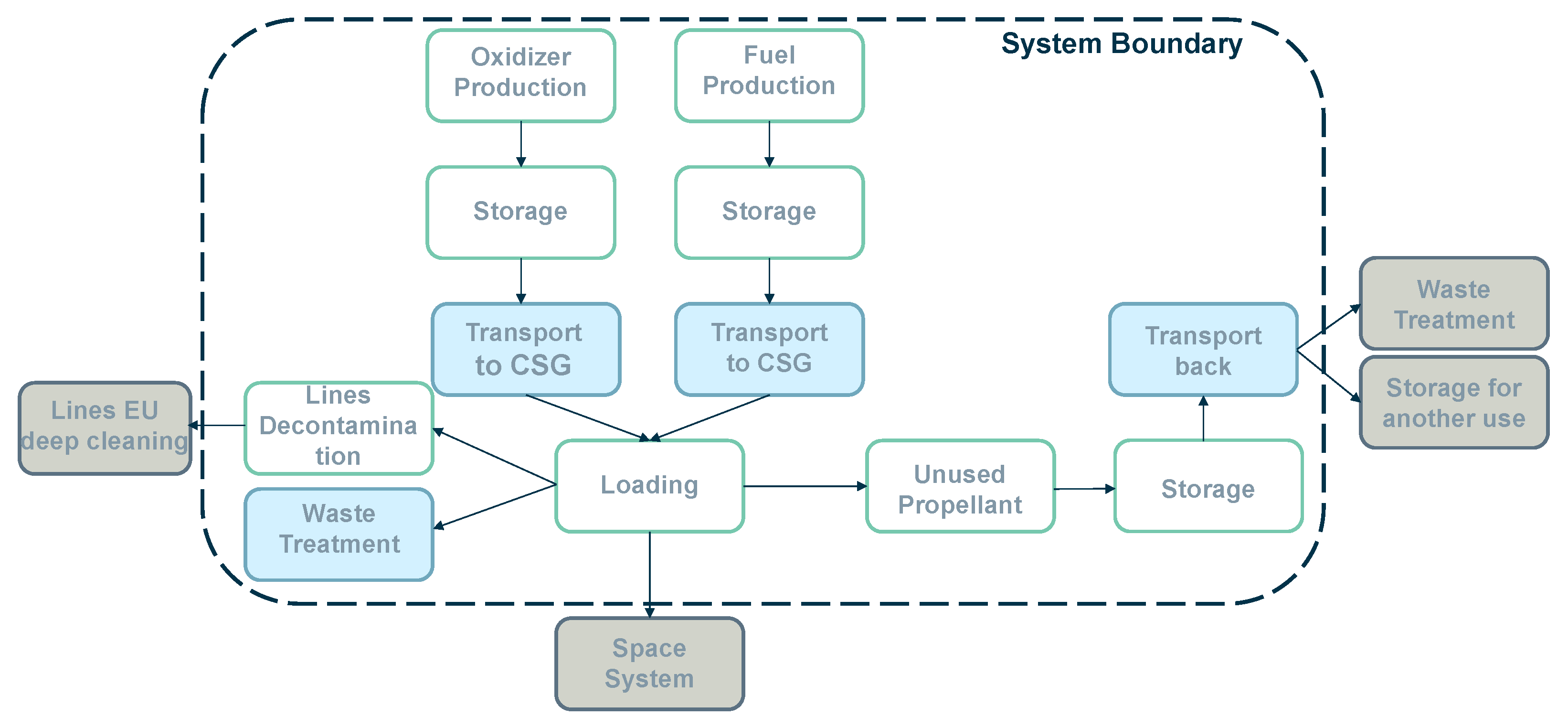

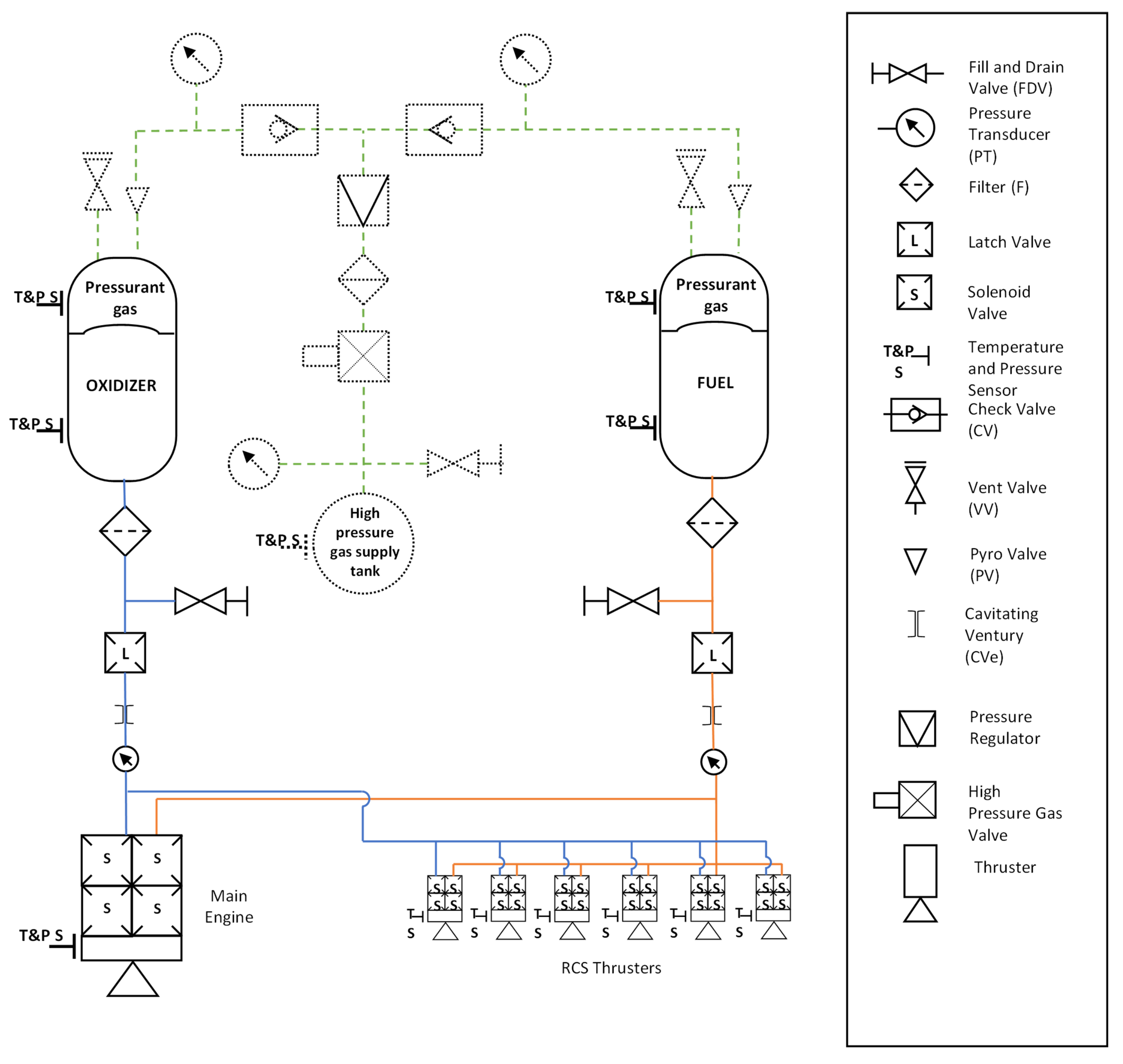

- The life cycle inventories are modeled using a cradle-to-gate approach, including the inputs of materials and processes required for the different components and chemicals that constitute the propulsion system. The defined system boundaries cover all relevant stages up to launcher integration, including production, transportation, testing, storage, handling, and fueling operations. The specific processes involved in propellant loading are illustrated in Figure 6, while Figure 9 presents the system boundary applied to the overall propulsion system modeling.

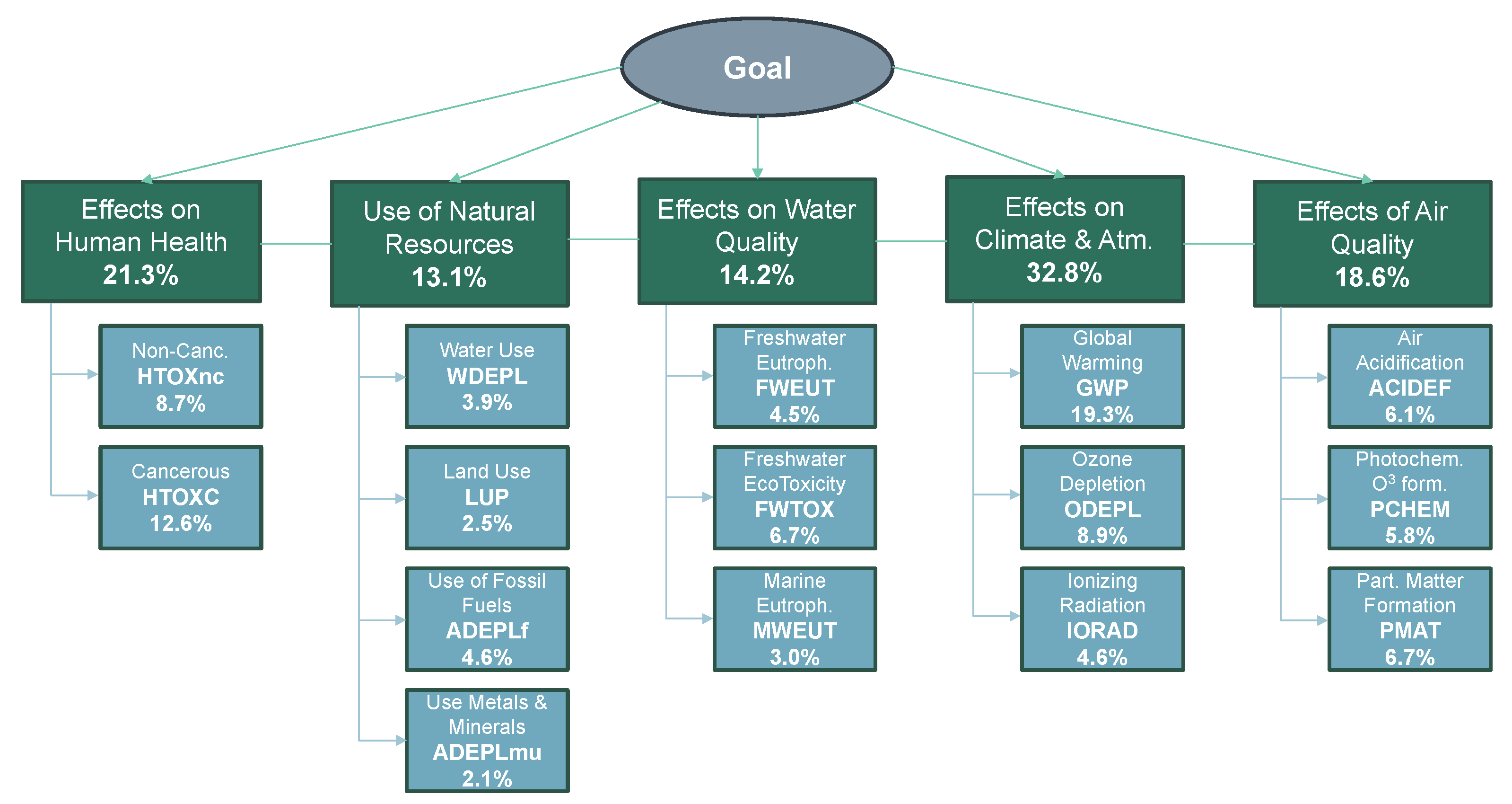

2.2.3. Environmental Impact Categories

2.3. Framework and Assumptions of the Study

- When fueling operations take place at the Guiana Space Centre (CSG), twice the amount of propellant required for the mission is transported to the site to ensure an operational backup.

- All transport operations are modeled using data from the Ecoinvent v3 database.

- A 10% production margin on the mission propellant is assumed from cradle to gate. This margin includes: (i) a 2% residual margin on the propellant mass computed from the Tsiolkovsky equation to complete the mission (ESA regulation [41]), and (ii) additional margins for ullage, line priming/purging, and transport/storage losses. The 10% margin is applied consistently to all propellant options to ensure a fair comparison. Note that this value does not represent the quantity of propellant treated during decontamination/waste treatment. Instead, decontamination is modeled separately using a fixed procedure and fixed decontaminant quantities per pipe operation, specific to each propellant combination.

- Cleanroom operations are modeled using the S5B facility at CSG for all propellant combinations although different equipment is used for each combination.

- Passivation of components and high-rigor cleaning steps specific to HTP handling are not included in the current scope.

- Any unused propellant remaining after fueling is returned to the supplier and, in theory, stored for potential reuse. However, due to the uncertainty regarding whether it is actually reused, the full production burden of this spare quantity is included within the system boundaries for each propellant combination.

- In-situ line cleaning is included in the study, but more extensive decontamination procedures, such as return transport to Europe, are excluded.

- Tank modeling considers only the flight model, excluding the qualification route development.

- To ensure consistency across the different tank types, the manufacturing processes are standardized using the titanium tank production route as the reference baseline.

2.4. Reference System and Mission Scenario

2.5. Modeling of Propulsive Architectures

2.5.1. Overview of the Reference Architecture

2.5.2. Tank Modeling and Material Selection

- is the safety factor

- L is the length of the cylindrical part and r the radius of the spherical part

- is the density of the wall material

- is the allowable stress of the wall material

- is the propellant storage pressure inside the tank

2.5.3. Definition of Dry vs. Wet Propulsive Architectures

- The dry architecture includes only the manufacturing of the components listed in Table 4, based on mass and volume estimates.

- The wet architecture expands this boundary to incorporate all mission-related operations: propellant loading, pressurizing gas, fueling losses, and line decontamination, as depicted in Figure 9.

2.5.4. Approach to Environmental Impact Comparison

3. Environmental Performance Results

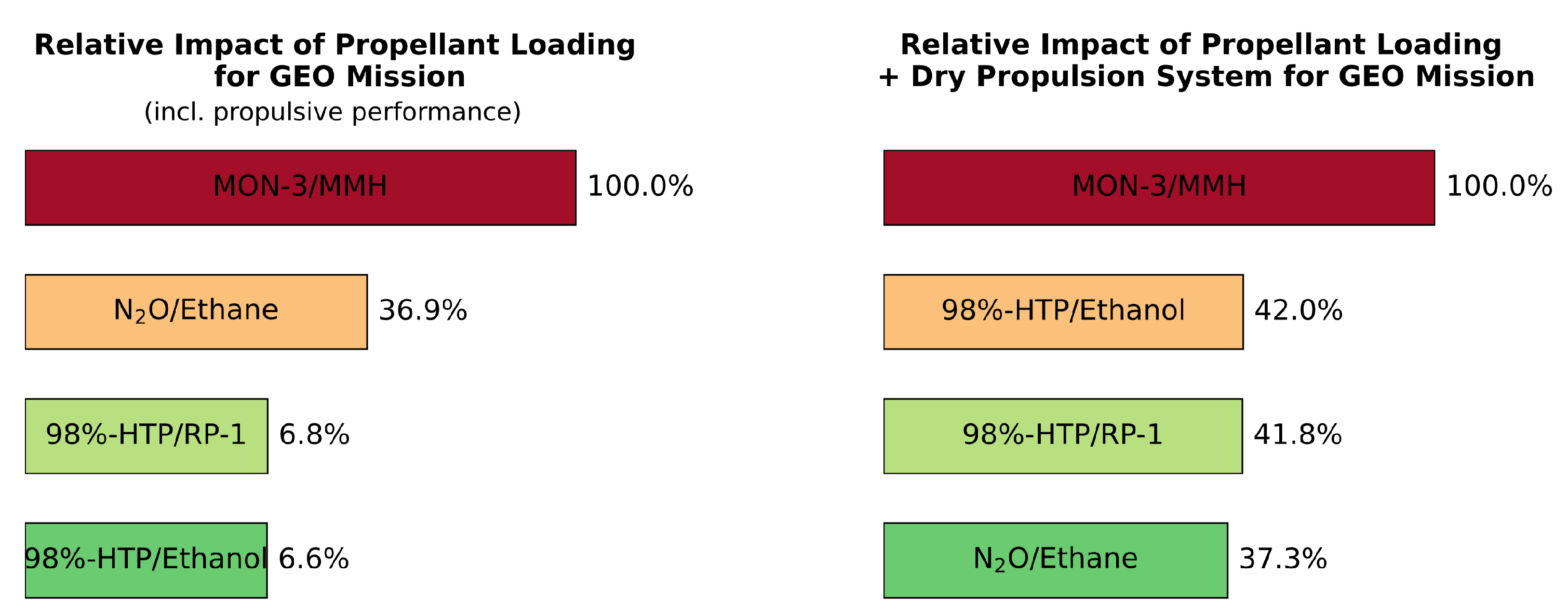

3.1. Performance-Based Comparison of Propellant Production & Loading

3.2. Phase Contributions in the Cradle-to-Gate LCA

- For MON-3 and 98%-HTP, the production phase dominates, accounting for approximately 90% of the total impact (excluding decontamination).

- In contrast, for N2O, the storage phase is the main contributor to environmental impact. This is due to nitrous oxide’s intrinsic high Global Warming Potential and the nature of its storage: although stored as a liquid under high pressure, any leakage results in the release of gaseous N2O, which is more likely to escape and directly contributes to greenhouse gas emissions. Unlike MON-3 and HTP, where potential losses are typically captured and treated through decontamination, losses of N2O during storage are released directly into the atmosphere.

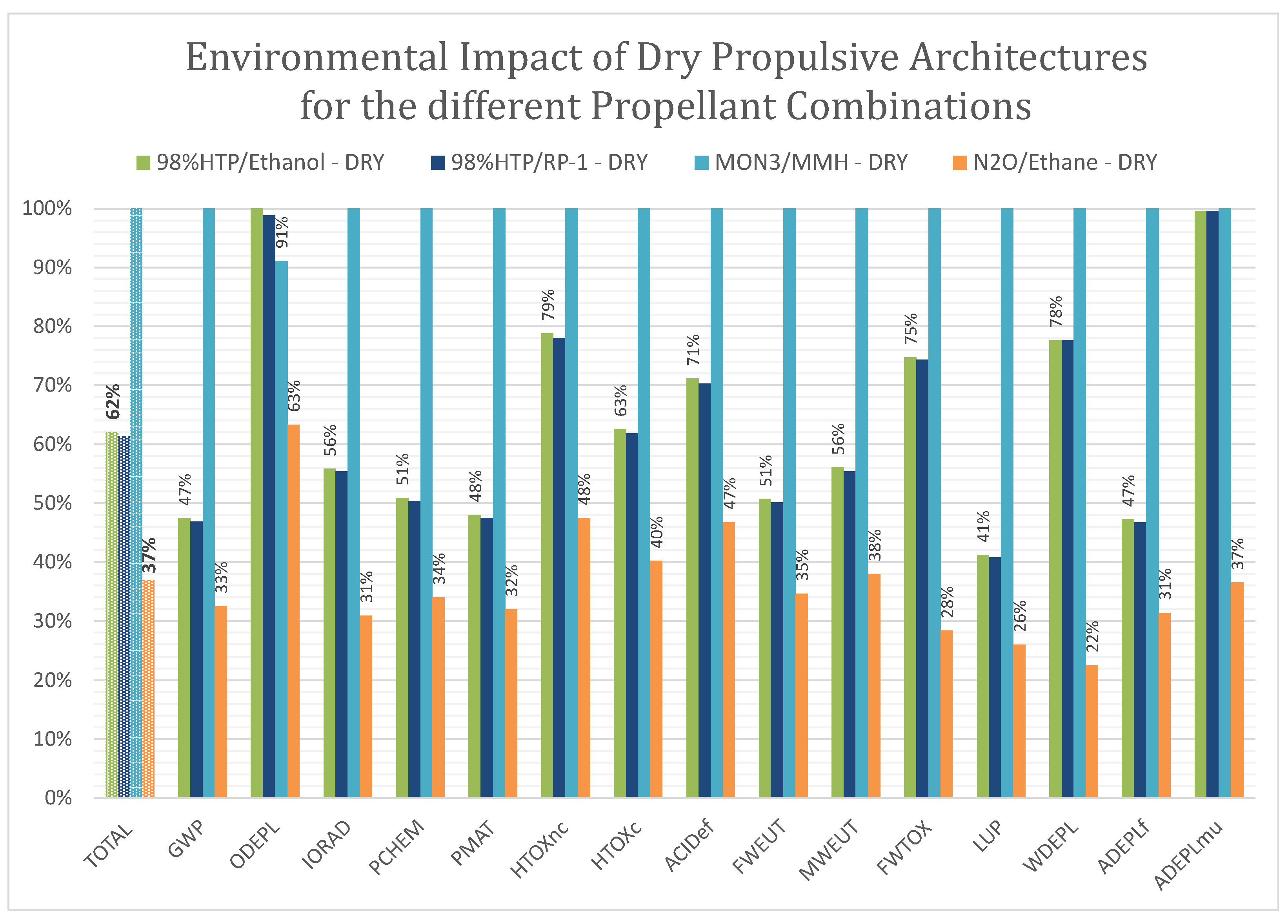

3.3. Impact of Propellant-Specific Dry Architecture

3.4. Impact of Wet Architecture Including Propellants

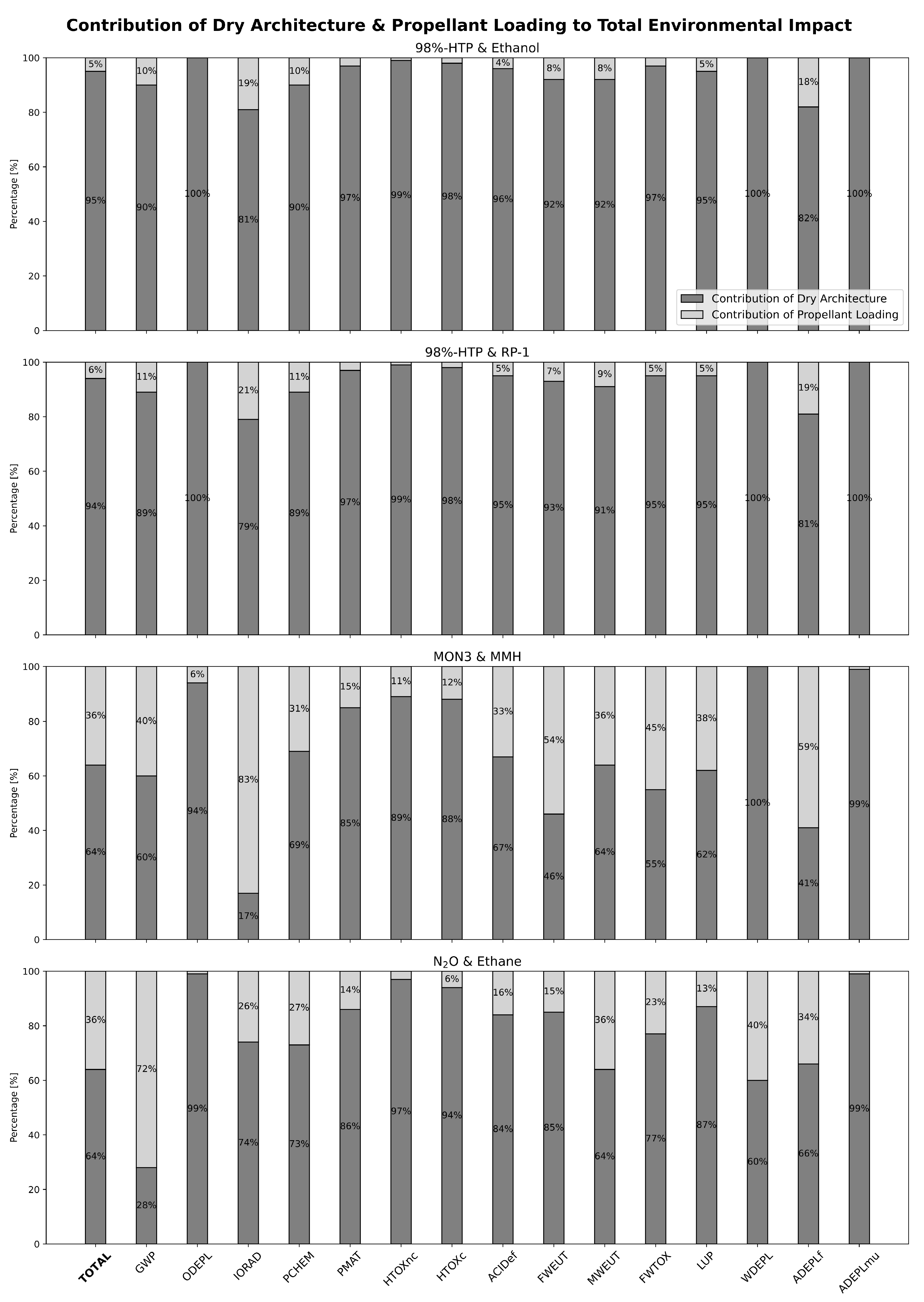

3.5. Relative Contributions: Dry Architecture vs. Propellant Loading

- For MON-3/MMH, propellant loading is the dominant contributor in several impact categories, notably Ionizing Radiation (IORAD, 83%), Fossil Resource Depletion (ADEPLF, 59%), and Freshwater Eutrophication (FWEUT, 54%).

- For HTP-based systems, propellant-related contributions remain below 21% across all categories, with the most affected being IORAD and ADEPLF.

- In the case of N2O/Ethane, Global Warming Potential (GWP) is the most impacted category, with 72% of the total attributed to propellant-loading emissions. Significant contributions are also seen in Water Depletion (WDEPL, 40%) and Marine Water Eutrophication (MWEUT, 36%).

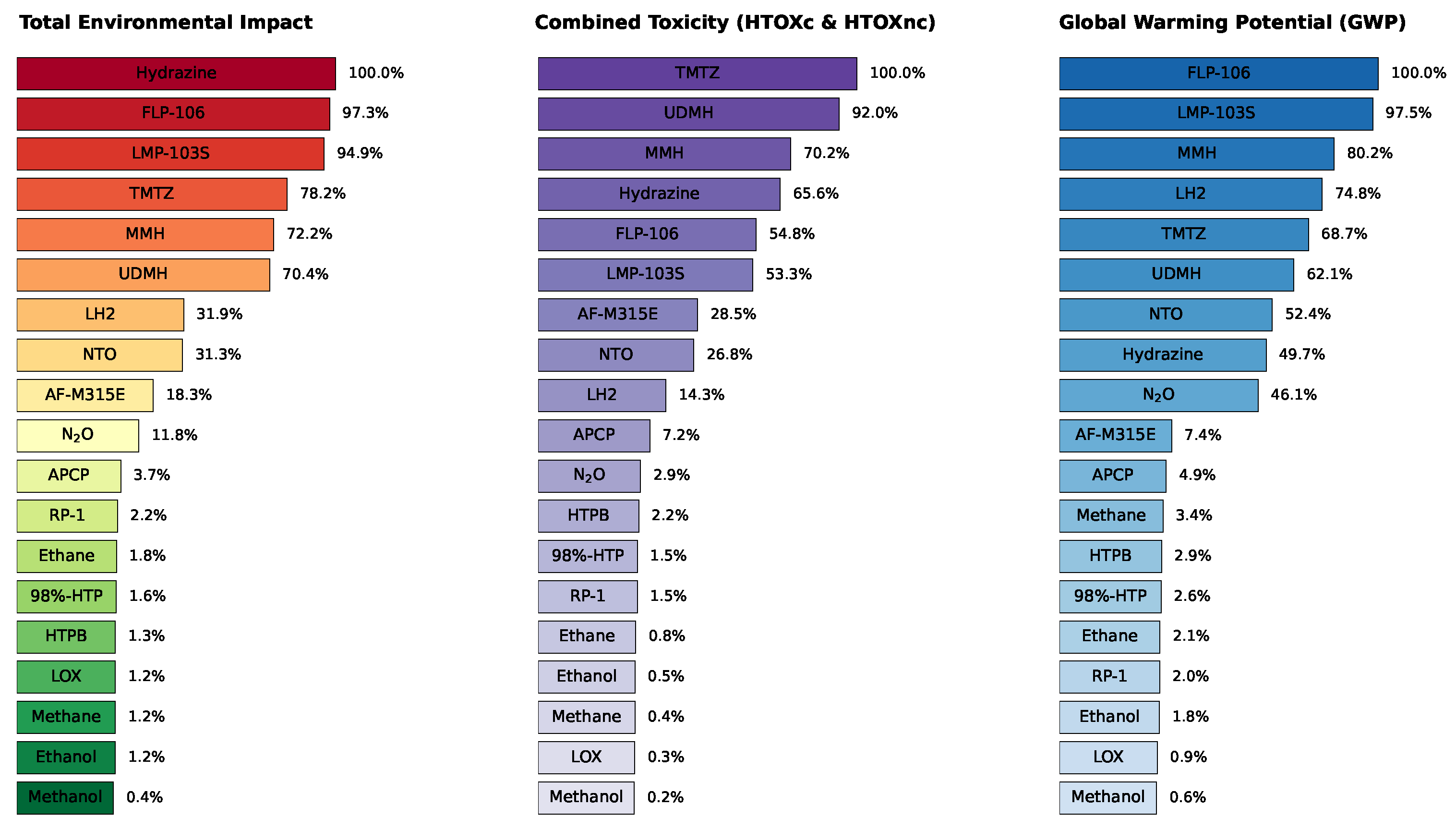

3.6. Environmental Classification of In-Space Propulsive Options

3.6.1. Classification of Propellant Loading

3.6.2. Classification of Propulsion Systems

4. Conclusions & Ways Forward

4.1. Conclusions

4.2. Next Steps

4.3. Proposed Criteria for Greener Propulsion

- Alignment: it represents a substantial, easily interpretable improvement aligned with current climate policy ambitions. For example, the EU’s “Fit for 55” aims to reduce net greenhouse gas emissions by 55% by 2030 [48] while the United States’ has pledged to cut net greenhouse gas emissions by 61-66% below 2005 levels by 2035 [49].

- Feasibility: it is already achieved by several candidate in-space propulsion systems evaluated in this study.

4.4. Recommended Metrics for Propellant Replacement

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Definition |

| ADR | Active Debris Removal |

| AHP | Analytical Hierarchy Process |

| CFRP | Carbon Fibre Reinforced Polymer |

| ECSS | European Cooperation for Space Standardization |

| ESA | European Space Agency |

| FU | Functional Unit |

| GEO | Geostationary Orbit |

| GHS | Global Harmonized System |

| GNC | Guidance, Navigation & Control |

| GWP | Global Warming Potential |

| HTOXC | Human Toxicity—Carcinogenic |

| HTOXNC | Human Toxicity—Non-Carcinogenic |

| HTP | High-Test Peroxide |

| Isp | Specific Impulse |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LEO | Low Earth Orbit |

| LRE | Liquid Rocket Engine |

| MAIT | Manufacturing, Assembly, and Integration Technology |

| MEOP | Maximum Expected Operating Pressure |

| MMH | Monomethylhydrazine |

| MON-3 | Mixed Oxides of Nitrogen |

| NTO | Nitrogen Tetroxide (N2O4) |

| N2H4 | Hydrazine |

| N2O | Nitrous Oxide |

| ODEPL | Ozone Depletion |

| OF | Oxidizer-to-Fuel Ratio |

| OTV | Orbital Transfer Vehicle |

| REACH | Registration, Evaluation, Authorization, and Restriction of Chemicals |

| RP-1 | Rocket Propellant-1 |

| SCAPE | Self-Contained Atmospheric Protective Ensemble |

| SVHC | Substance of Very High Concern |

| TRL | Technology Readiness Level |

| UDMH | Unsymmetrical Dimethylhydrazine |

References

- Dallas, J.A.; Raval, S.; Alvarez Gaitan, J.P.; Saydam, S.; Dempster, A.G. The Environmental Impact of Emissions from Space Launches: A Comprehensive Review. J. Clean. Prod. 2020, 255, 120209. [Google Scholar] [CrossRef]

- Gulczyński, M.; Vennitti, A.; Scarlatella, G.; Dominguez Calabuig, G.J.; Blondel-Canepari, L.; Weber, F.; Sarritzu, A.; Bach, C.; Deeken, J.; Schmiel, T.; et al. RLV Applications: Challenges and Benefits of Novel Technologies for Sustainable Main Stages. In Proceedings of the 72nd International Astronautical Congress, Dubai, United Arab Emirates, 25–29 October 2021. [Google Scholar]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- United States Space Command. Space-Track; United States Space Command: Colorado Springs, CO, USA, 2024. [Google Scholar]

- Blondel-Canepari, L.; Ordonez-Valles, L.; Tajmar, M.; Jasjukevics, A.; Wolf, M.; Dussy, S.; Apel, U.; Pasini, A. Roadmap Towards a Greener Kick-Stage Propulsion System. In Proceedings of the 73rd International Astronautical Congress (IAC), Paris, France, 18–22 September 2022. [Google Scholar]

- Sarritzu, A.; Blondel-Canepari, L.; Gelain, R.; Hendrick, P.; Pasini, A. Analytical Hierarchy Process-Based Trade-Off Analysis of Green and Hybrid Propulsion Technologies for Upper Stage Applications. Int. J. Energetic Mater. Chem. Propuls. 2023, 22, 1–25. [Google Scholar] [CrossRef]

- Sarritzu, A.; Pasini, A. Performance comparison of green propulsion systems for future Orbital Transfer Vehicles. Acta Astronaut. 2024, 217, 100–115. [Google Scholar] [CrossRef]

- Marshall, W.M.; Deans, M.C.; National Aeronautics and Space Administration Glenn Research Center. Recommended Figures of Merit for Green Monopropellants; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2014. [Google Scholar]

- Schmidt, E.W.; Wucherer, E.J. Hydrazine(s) vs. Nontoxic Propellants-Where Do We Stand Now? In Proceedings of the 2nd International Conference on Green Propellants for Space Propulsion (ESA SP-557), Sardinia, Italy, 7–8 June 2004. [Google Scholar]

- United Nations. Committee of Experts on the Transport of Dangerous Goods and on the Globally Harmonized System of Classification and Labelling of Chemicals—Report of the Sub-Committee of Experts on the Transport of Dangerous Goods on Its Sixty-Third Session; United Nations: New York, NY, USA, 2023. [Google Scholar]

- Becker, T.; Reiff-Musgrove, O.; Space Energetic Materials Working Group (EMWG). REACH + Regulatory and Activities Update. 2024. [Google Scholar]

- Commission to the European Parliament; European Council; European Economic and Social Committee; Committee of the Regions. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Eurocontrol. European Aviation Overview; Eurocontrol: Brussels, Belgium, 2024. [Google Scholar]

- European Commission. European Commission-Press Release Screening of Websites for “Greenwashing”: Half of Green Claims Lack Evidence; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Ragonnaud, G.; Ashton, D.; European Parliamentary Research Service. “Green Claims” Directive: Protecting Consumers from Greenwashing (PE 753.958); European Parliament: Strasbourg, France, 2024. [Google Scholar]

- Delaval, J. CleanSpace Blog. 2020. [Google Scholar]

- European Space Agency (ESA). ESA Agenda 2025—Make Space for Europe; European Space Agency: Paris, France, 2021. [Google Scholar]

- Dominguez Calabuig, G.J.; Wilson, A.; Bi, S.; Vasile, M.; Sippel, M.; Tajmar, M. Environmental life cycle assessment of reusable launch vehicle fleets: Large climate impact driven by rocket exhaust emissions. Acta Astronaut. 2024, 221, 1–11. [Google Scholar] [CrossRef]

- Pettersen, J.B.; Bergsdal, H.; Silva, E.J.; Bjørnbet, M.M.; Estrela, M.A.; Chaves, P.A.; Skaar, C. Life Cycle Assessment (LCA) of Manufacturing Process and Space Materials; ESA: Paris, France, 2016. [Google Scholar]

- European Space Agency (ESA); Pettersen, J. Life Cycle Assessment of Space Propellants; European Space Agency (ESA): Paris, France, 2016. [Google Scholar]

- European Space Agency (ESA). Space Debris User Portal; European Space Agency (ESA): Paris, France, 2023. [Google Scholar]

- European Space Agency (ESA). Space System Life Cycle Assessment (LCA) Guidelines; European Space Agency (ESA): Paris, France, 2016. [Google Scholar]

- Wilson, A.R.; Vasile, M. Life cycle engineering of space systems: Preliminary findings. Adv. Space Res. 2023, 72, 2917–2935. [Google Scholar] [CrossRef]

- Wilson, A.R.; Vasile, M. Integrating Life Cycle Assessment of Space Systems into the Concurrent Design Process. In Proceedings of the 68th International Astronautical Congress (IAC), Adelaide, Australia, 25–29 September 2017; pp. 25–29. [Google Scholar]

- Blondel Canepari, L.; Affentranger, L.; Morales Serrano, S.; Tormena, E.; Padilla Gutierrez, E.; Pasini, A.; Valencia Bel, F. Towards Greener Propulsion: Environmental Categorization of Liquid In-Space Propulsion Systems via Life Cycle Analysis. In Proceedings of the Space Propulsion 2024, Glasgow, Scotland, 20–23 May 2024. [Google Scholar]

- Schabedoth, P.E.; Pettersen, J.B. Life Cycle Assessment of Rocket Launches and the Effects of the Propellant Choice on Their Environmental Performance; NTNU: Trondheim, Norway, 2020. [Google Scholar]

- Henry, H. Life Cycle Assessment: Green Rocket Fuel; ISU: Norwood, MA, USA, 2009. [Google Scholar]

- Wilson, A.R. Advanced Methods of Life Cycle Assessment for Space Systems. Ph.D. Thesis, University of Strathclyde, Glasgow, Scotland, 2019. [Google Scholar]

- Benini, L.; Sala, S.; Manfredi, S.; Małgorzata, G.; European Commission—Joint Research Centre Institute for Environment and Sustainability. Indicators and Targets for the Reduction of the Environmental Impact of EU Consumption: Overall Environmental Impact (Resource) Indicators; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Verkammen, M. Consensus-Based Single-Score Life Cycle Assessment for Space Missions. Master’s Thesis, TU Delft, Delft, The Netherlands, 2023. [Google Scholar]

- Sala, S.; Cerutti, A.K. Development of a Weighting Approach for the Environmental Footprint; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

- Bernstein, L.; Bosch, P.; Canziani, O.; Chen, Z.; Christ, R.; Davidson, O.; Hare, W.; Huq, S.; Karoly, D.; Kattsov, V.; et al. Climate Change 2007: Synthesis Report; Canadian Electronic Library: Ottawa, ON, Canada, 2013. [Google Scholar]

- World Meteorological Organization (WMO). Scientific Assessment of Ozone Depletion; World Meteorological Organization: Geneva, Switzerland, 1998. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe 2016—A harmonized life cycle impact assessment method at midpoint and endpoint level—Report I: Characterization. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook —Recommendations for Life Cycle Impact Assessment in the European conte4xt; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.J.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC toxicity model: Recommended characterization factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13, 532–546. [Google Scholar] [CrossRef]

- Bruijn, H.; Duin, R.; Huijbregts, M.A.J.; Guinee, J.B.; Gorree, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Koning, A.; Oers, L.; et al. (Eds.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Springer: Dordrecht, The Netherlands, 2022. [Google Scholar]

- PRé Sustainability. SimaPro v9.4.0.3. [Software]. 2024. Available online: https://simapro.com/ (accessed on 20 February 2025).

- Ecoinvent Association. Ecoinvent Database v3.9.1 [Software]. 2024. Available online: https://www.ecoinvent.org (accessed on 20 February 2025).

- European Space Agency (ESA). Margin Philosophy for Science Assessment Studies; European Space Agency: Paris, France, 2012. [Google Scholar]

- Blondel-Canepari, L.; Alforja Ruiz, I.; Ayala Fernández, L.; Gelain, R.; Glaser, C.; Ordoñez Valles, L.; Sarritzu, A.; Anthoine, J.; Apel, U.; Hendrick, P.; et al. Conceptual study of technologies enabling novel green expendable upper stages with multi-payload/multi-orbit injection capability. In Proceedings of the IAC 2021, 72nd International Astronautical Congress, Dubai, United Arab Emirates, 25–29 October 2021. [Google Scholar]

- Alforja Ruiz, I.; Lavagna, M. Design of the Optimal Trajectory for Multi-Payload Multi-orbit Injection for an Upper Stage. In Proceedings of the 9th European Conference for Aeronautics and Space Sciences, Lille, France, 27 June–1 July 2022. [Google Scholar]

- d’Agostino, L. Liquid Propellant Rockets 1. 2020. [Google Scholar]

- d’Agostino, L. Liquid Propellant Rockets 2. 2020. [Google Scholar]

- Benton, J.; Ballinger, I.; Jaekle, D.; Osborn, M. Design and Manufacture of a Propellant Tank Assembly. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007; AIAA Paper 2007-5559. [Google Scholar]

- Bashmakov, I.; Nilsson, L.; Acquaye, A.; Bataille, C.; Cullen, J.; de la Rue du Can, S.; Fischedick, M.; Geng, Y.; Tanaka, K. Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar] [CrossRef]

- Erbach, G.; Jensen, L.; Chahri, S.; Claros, E. BRIEFING Towards Climate Neutrality: Fit for 55 Package; European Parliament: Strasbourg, France, 2024. [Google Scholar]

- United States of America; United Nations Framework Convention on Climate Change. The United States of America Nationally Determined Contribution: Reducing Greenhouse Gases in the United States—A 2035 Emissions Target. 2024. [Google Scholar]

| Propulsion System | PROS | CONS |

|---|---|---|

| MON-3/MMH |

High , hypergolic Well-established technology with extensive flight heritage Compatible with existing propulsion architectures and ground infrastructure | Highly toxic Complex handling & safety measures, increased operational costs Regulatory and environmental concerns may restrict future use |

| 98% HTP/Ethanol | Lower toxicity than MON-3/MMH Ethanol is renewable and widely available Good performance across a wide range of applications | Lower than MON-3/MMH Ethanol’s low energy density requires larger fuel tanks Requires an ignition strategy HTP natural decomposition demands considerations on material compatibility |

| 98% HTP/RP-1 | Higher (and broader) max than HTP/Ethanol Good storability Less toxic than hydrazine-based propellants | HTP is highly reactive and requires careful storage and handling protocols Requires an ignition system Soot formation during combustion may degrade performance and increase maintenance |

| N2O/Ethane | Low toxicity Long-term storability Easier hardware manufacturing Self-pressurizing, simplified system Inexpensive and widely available propellants | Lower vs. conventional and other greener alternatives Low propellant density demands larger tanks Requires high-pressure storage Low energy content per unit mass |

| Impact Indicator | Units | Representation | Methodology Used |

|---|---|---|---|

| Global Warming Potential (GWP) | kg CO2 eq. | Measures the potential for emissions to contribute to global climate change. | IPCC 2007(100 years) [33] |

| Ozone Depletion Potential (ODEPL) | kg CFC-11 eq. | Assesses the potential for substances to deplete the stratospheric ozone layer. | WMO 1999 ODPs [34] |

| Ionizing Radiation (IORAD) | kBq U-235 eq. | Evaluates impact from ionizing radiation, related to radioactive decay. | ReCiPe 2016 [35] |

| Photochemical Ozone Formation (PCHEM) | kg NMVOC eq. | Estimates potential for ground-level ozone (smog) formation from reactive gas emissions. | ReCiPe 2016 [35] |

| Particulate Matter Formation (PMAT) | Disease incidence | Measures health effects of fine particulate matter. | ILCD 2011 [36] |

| Human Toxicity, Non-Carcinogenic (HTOXNC) | CTUh | Assesses non-carcinogenic toxicity of chemical emissions to humans. | USEtox [37] |

| Human Toxicity, Carcinogenic (HTOXC) | CTUh | Assesses carcinogenic toxicity of chemical emissions to humans. | USEtox [37] |

| Acidification Potential (ACIDEF) | mol H+ eq. | Quantifies acidification of soil and water due to acidic emissions. | CML 2002 [38] |

| Freshwater Eutrophication (FWEUT) | kg P eq. | Measures nutrient pollution in freshwater due to phosphorus. | CML 2002 [38] |

| Marine Eutrophication (MWEUT) | kg N eq. | Assesses nitrogen enrichment in marine ecosystems. | CML 2002 [38] |

| Freshwater Ecotoxicity (FWTOX) | CTUe | Evaluates toxic effects on freshwater aquatic life. | USEtox [37] |

| Land Use Potential (LUP) | Points | Measures impact of land occupation and transformation. | ILCD 2011 [36] |

| Water Depletion (WDEPL) | m3 world eq. deprived | Quantifies freshwater use contributing to scarcity. | ILCD 2011 [36] |

| Abiotic Resource Depletion—Fossil (ADEPLF) | MJ | Assesses use of fossil energy resources. | CML 2002 [38] |

| Abiotic Resource Depletion—Minerals/Metals (ADEPLMU) | kg Sb eq. | Estimates depletion of metal and mineral resources. | ReCiPe 2016 [35] |

| Propellant Combination | Density [kg/m3] | O/F Ratio | [s] | Mass [kg] |

|---|---|---|---|---|

| MON-3/MMH | 1440/875 | 1.65 | 325 | 1024/620 |

| 98%-HTP/Ethanol | 1437/789 | 4.50 | 300 | 1420/315 |

| 98%-HTP/RP-1 | 1437/800 | 7.50 | 305 | 1514/202 |

| N2O/Ethane | 785/340 | 7.00 | 295 | 1535/219 |

| Component | MON-3 & MMH | 98% HTP & Ethanol or RP-1 | N2O & Ethane |

|---|---|---|---|

| Main Components | |||

| Oxidizer Tank | Cyl. TiAl6V4 | Cyl. AA5254 with CFRP overwrap | Cyl. C. Fiber with TiAl6V4 liner |

| Fuel Tank | Cyl. TiAl6V4 | Cyl. AA5254 with CFRP overwrap | Cyl. C. Fiber with TiAl6V4 liner |

| Pressurizing He Vessel | 2 | 2 | – |

| 3/4-inch Tubing | Titanium | Aluminum | Titanium |

| Auxiliary Components | |||

| Filters | 4 | 4 | 2 |

| Pyro Valves | 2 | 2 | – |

| Vent Valves | – | 2 | 2 |

| Fill & Drain Valves | 4 | 4 | 2 |

| Latch Valves | 2 | 2 | 2 |

| Cavitating Venturi | 2 | 2 | 2 |

| Pressure Transducers | 6 | 6 | 2 |

| Pressure Regulator | 2 | 2 | – |

| High-pressure Gas Valve | 2 | 2 | – |

| Temperature & Pressure Sensors | 6 | 6 | 4 |

| Solenoid Valves | 20 | 20 | 20 |

| Main Thrusters | 5 | 5 | 5 |

| Estimated auxiliary-component mass [kg] | 42.3 | 42.7 | 37 |

| Material | Density [kg/m3] | Ultimate Strength [MPa] | [Pa kg−1m3] |

|---|---|---|---|

| Titanium Ti6Al4V | 4420 | 950 | |

| Aluminium AA5254 | 2700 | 350 | |

| Carbon Fiber | 1900 | 2500 |

| Dry Architecture | Wet Architecture |

|---|---|

| Includes manufacturing of components | Includes all elements from the dry architecture |

| + Loading of required propellant for the mission | |

| + Decontamination of fueling lines (by propellant type) | |

| + Treatment of fueling losses | |

| + Pressurizing gas loading for mass-flow maintenance |

| Metric | Goals |

|---|---|

| Environmental Impact | Total combined environmental impact less than half the one of the legacy system; |

| Combined toxicity below 50% of the legacy system, with no carcinogenic or mutagenic risks; | |

| Global warming potential lower than the one of the legacy system. | |

| Reliability | Operational risk comparable to hydrazine-based systems; |

| Compatibility with passivation, de-orbiting strategies, and with easily demisable materials; | |

| Broad material and architectural compatibility for modularity of use. | |

| Cost | Post-qualification system expected to achieve a reduction in propulsion system cost compared with hydrazine-based systems; |

| Eliminates the need for SCAPE suits and stringent safety protocols, reducing recurring ground-operations costs relative to hydrazine baselines. | |

| Propulsive Performance | Payload capacity meeting or exceeding the one of the legacy system; |

| Operational lifespan comparable to the legacy system; | |

| No long-term performance degradation; | |

| Compatibility with the implementation of other innovative technologies. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blondel-Canepari, L.; Affentranger, L.; Morales Serrano, S.; Pasini, A. Toward Greener Propulsion: An LCA-Based Environmental Performance Classification of In-Space Propulsion Options. Aerospace 2025, 12, 1003. https://doi.org/10.3390/aerospace12111003

Blondel-Canepari L, Affentranger L, Morales Serrano S, Pasini A. Toward Greener Propulsion: An LCA-Based Environmental Performance Classification of In-Space Propulsion Options. Aerospace. 2025; 12(11):1003. https://doi.org/10.3390/aerospace12111003

Chicago/Turabian StyleBlondel-Canepari, Lily, Lorenz Affentranger, Sara Morales Serrano, and Angelo Pasini. 2025. "Toward Greener Propulsion: An LCA-Based Environmental Performance Classification of In-Space Propulsion Options" Aerospace 12, no. 11: 1003. https://doi.org/10.3390/aerospace12111003

APA StyleBlondel-Canepari, L., Affentranger, L., Morales Serrano, S., & Pasini, A. (2025). Toward Greener Propulsion: An LCA-Based Environmental Performance Classification of In-Space Propulsion Options. Aerospace, 12(11), 1003. https://doi.org/10.3390/aerospace12111003