1. Introduction

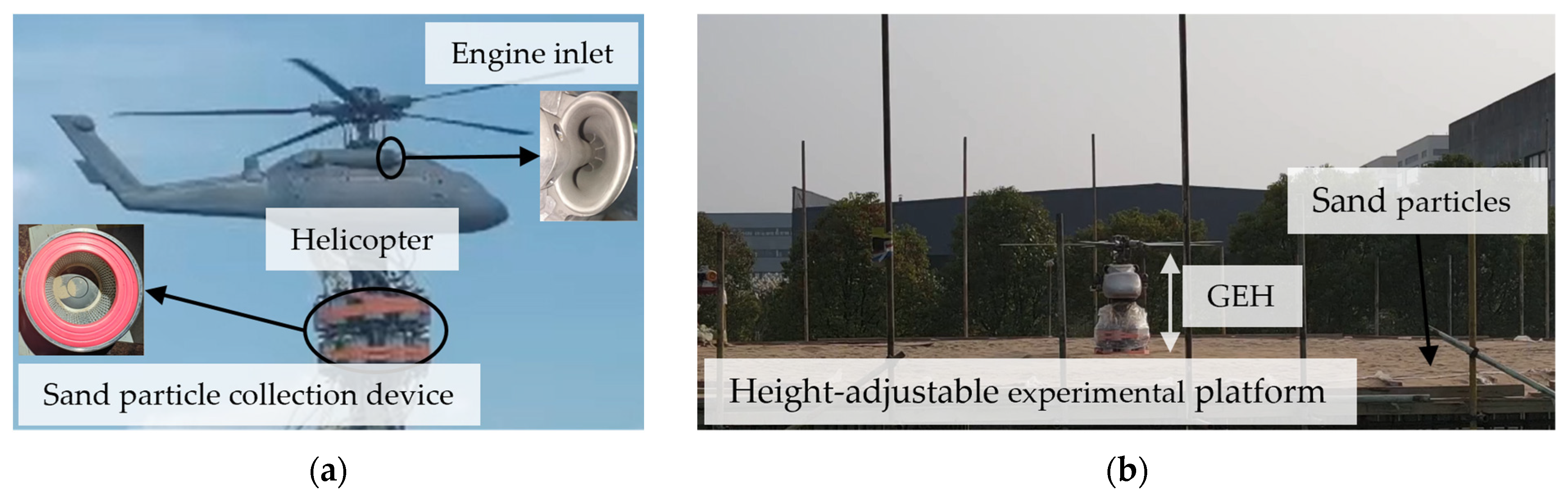

During the takeoff or landing of a helicopter in sparsely vegetated deserts, the rotor downwash entrains surface sand into a high-concentration cloud that shrouds the aircraft. Due to the engine suction, sand particles suspended near the inlet could be ingested. When operating in a Level 5 sand environment, the service life of the helicopter is reduced to one fiftieth of its design life [

1]. Through experiments, Liu et al. revealed that both engine power and fuel consumption rate degrade following a quadratic function pattern with increasing sand ingestion time [

2]. Therefore, the research on the sand ingestion behavior of helicopter engines is of great importance.

In the research on helicopter brownout, extensive research has been conducted on the formation mechanisms of sand clouds, which exhibits substantial significance for the research on sand ingestion in helicopter engines. John et al. concluded that the evolution of a ground vortex ahead of the rotor disk is seen to be a key element in the development of a sand cloud through experiments [

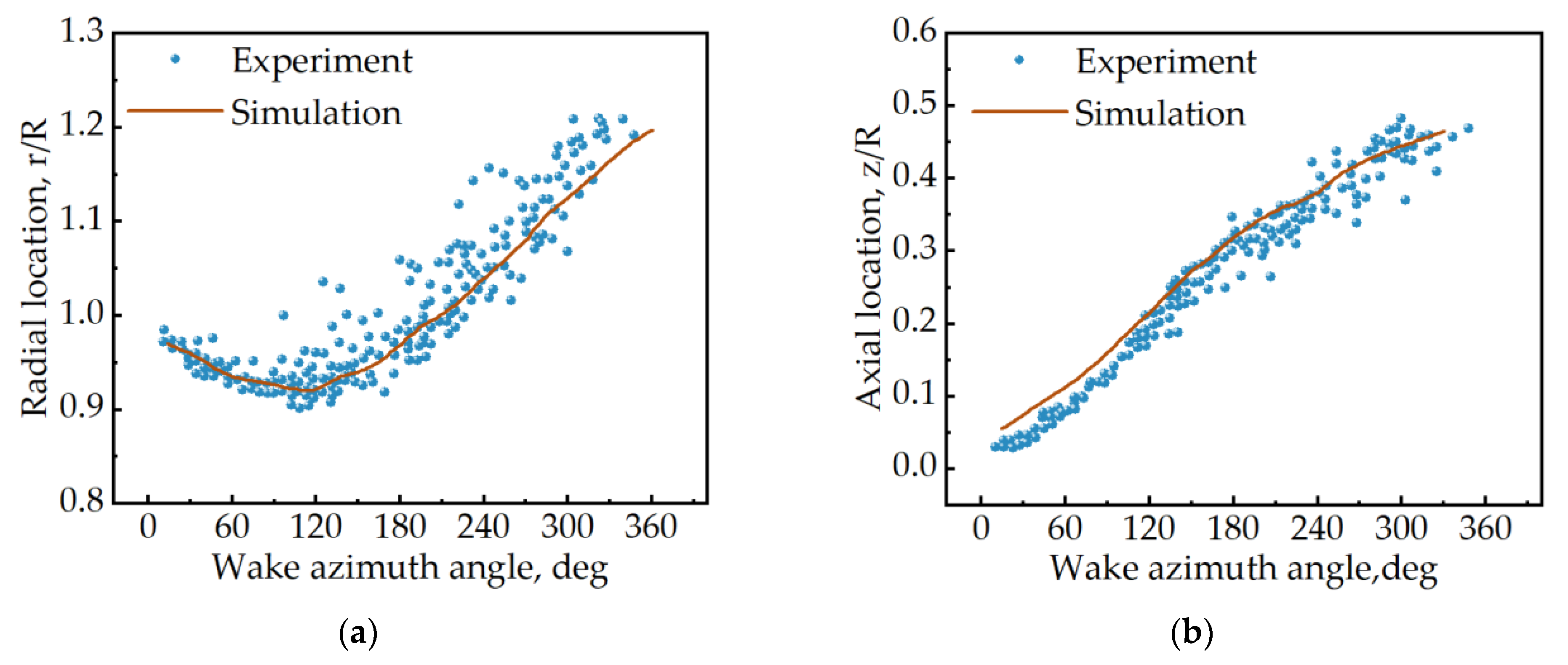

3]. Using the side-field shadowgraph method, Light et al. visualized many important phenomena. These include the variation in descent and contraction rates of the tip vortices in ground effect, and the interaction between tip vortices in the far wake [

4]. Based on the time-resolved smoke flow imaging, Curtiss observed the transient evolution of ground vortices, capturing their formation process during ground-effect hover [

5]. Furthermore, numerous scholars proposed a series of simulation methods focusing on the helicopter flow field. Hu et al. studied the rotor–fuselage–engine aerodynamic interactions utilizing CFD numerical tools. It provides simulation approaches for the study of sand ingestion in helicopter engines [

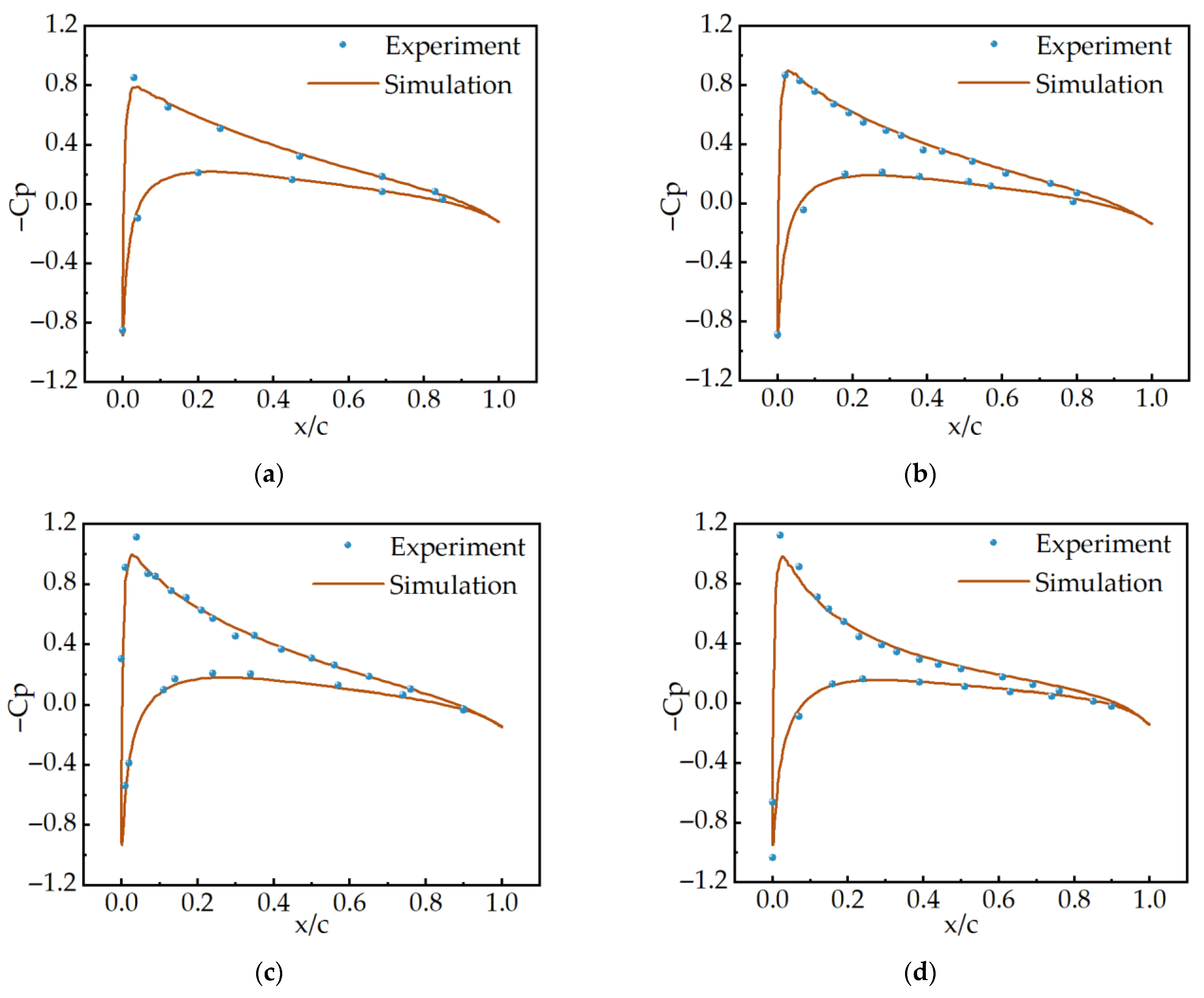

6]. Xu et al. used the multiple reference frame (MRF) method to numerically investigate the underlying mechanisms of aerodynamic interference between helicopter rotors and engine systems [

7]. Steven computed the flow field characteristics of the AH-64 helicopter considering engine suction flow on the basis of the PUMA software developed independently by the University of Pennsylvania [

8]. Although no research on sand ingestion in helicopter engines was conducted in the studies discussed above. The analysis of coupled flow fields of helicopter rotors and engines establishes a technical foundation for research on helicopter sand ingestion.

Based on the research of helicopter flow fields, considerable simulation studies were conducted on helicopter sand clouds. The evolution of a helicopter sand cloud with a crosswind was simulated using a helicopter brownout analysis method coupling a vortex-based solver with a discrete element method. The predicted sand clouds of the EH-60L agreed well with the flight-test data [

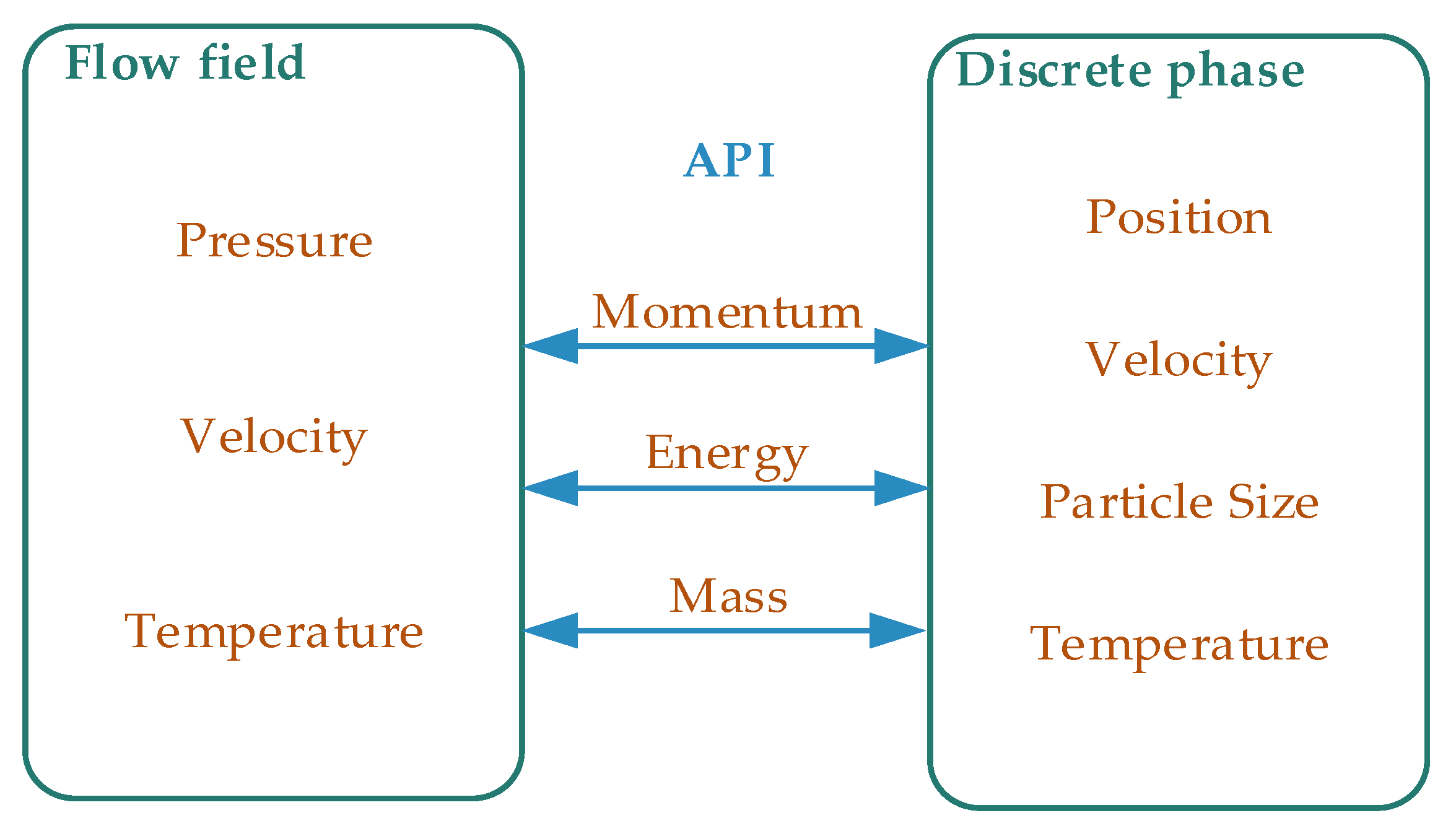

9]. The gas–solid two-phase flow model was constructed based on the Euler-Lagrangian framework. The

SST k-

ω two-equation turbulence model and the soft ball model are coupled by CFD and DEM [

10]. Bharath simulated sand clouds for rotorcraft undergoing landing. The flow field was modeled using an inviscid, incompressible, time-accurate Lagrangian free-vortex method. Particle tracking was used to model the sand cloud [

11]. Sayan et al. characterized the flow field and the SIMPLER algorithm was adopted to solve Reynolds averaged Navier–Stokes equation. The sand behavior was solved using a Eulerian-based sand transport equation [

12]. Monica demonstrated that one-way coupling of the flow and the particle motion give over an order of magnitude reduction in simulation time without any loss in accuracy [

13]. However, inter-particle collisions were not accounted for in References [

11,

12,

13]. This oversight may compromise the accuracy of the sand ingestion simulations. Further, Monica et al. proposed a Lagrangian discrete phase model (DPM), which accounts for inter-particle forces and shows close agreement with photogrammetric measurements of sand clouds [

14,

15]. Considering particle–particle collisions, Tan et al. developed a background grid mapping method to accelerate the simulation [

16]. Xu et al. used CFD-DEM coupled model to simulate sand cloud formation at GEHs and investigated how ground-effect flow fields affect sand particle states. However, the number of sand particles modeled was relatively small [

17]. These studies primarily focus on helicopter brownout, relevant simulations for sand ingestion in engines are relatively scarce. Therefore, the research direction of this paper is of great significance.

Although simulation methods have been widely used in helicopter research, the complexity of aerodynamic environments and sand particle motion cannot be fully captured by simulations. As exposed in the simulations by Phillips et al., minor changes to the setup of the simulation would potentially produce very different distribution of sand cloud [

18]. Thus, experimental research on sand ingestion by helicopter engines remains indispensable. Nicholas et al. experimentally investigated the relationship between engine sand ingestion and flight conditions [

19]. Simpson compared sand ingestion of helicopter engines under experimental and flight conditions. The results showed that morphological differences between standard test sands and natural sand particles substantially impact engine damage severity [

20]. Cowherd quantified sand densities during hover for helicopters with various configurations. The experimental data indicated a correlation with rotor disk loading [

21]. Padture found that sand particles can corrode the high-temperature ceramic coatings of engines. And methods to mitigate degradation have been proposed based on the corrosion mechanism [

22]. Although their experiments were not designed to study helicopter engine sand ingestion, they have provided experimental guidelines for the research on this phenomenon. Wang established A detailed experimental procedure for the sand ingestion of a turboshaft engine. The findings provided a scientific and rational basis and reference for the sand and dust resistance design [

23]. The experimental test showed that the airfoils collect almost 1.6% of the engine’s total mass ingested during a ground-idle operation [

24]. Przedpelski improved the engine design and enhanced the engine’s operating capability in dusty environments based on sand ingestion tests [

25]. Zhou et al. found that the simulation results of the boundary conditions of the total inlet pressure and the mass flow outlet were closer to the experimental values [

26]. It means that research on helicopter sand ingestion is a necessary prerequisite for studies on engine sand protection. Furthermore, reducing engine sand ingestion is more sensible than protecting engine blades.

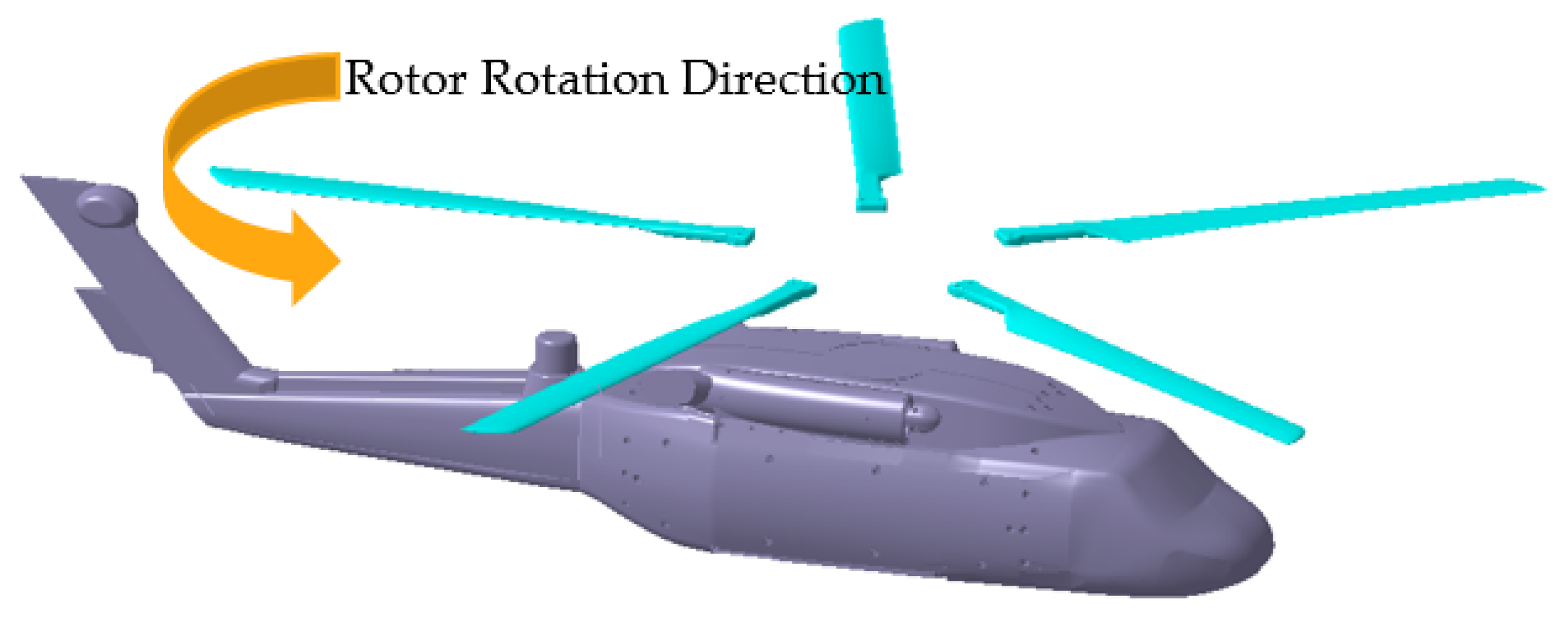

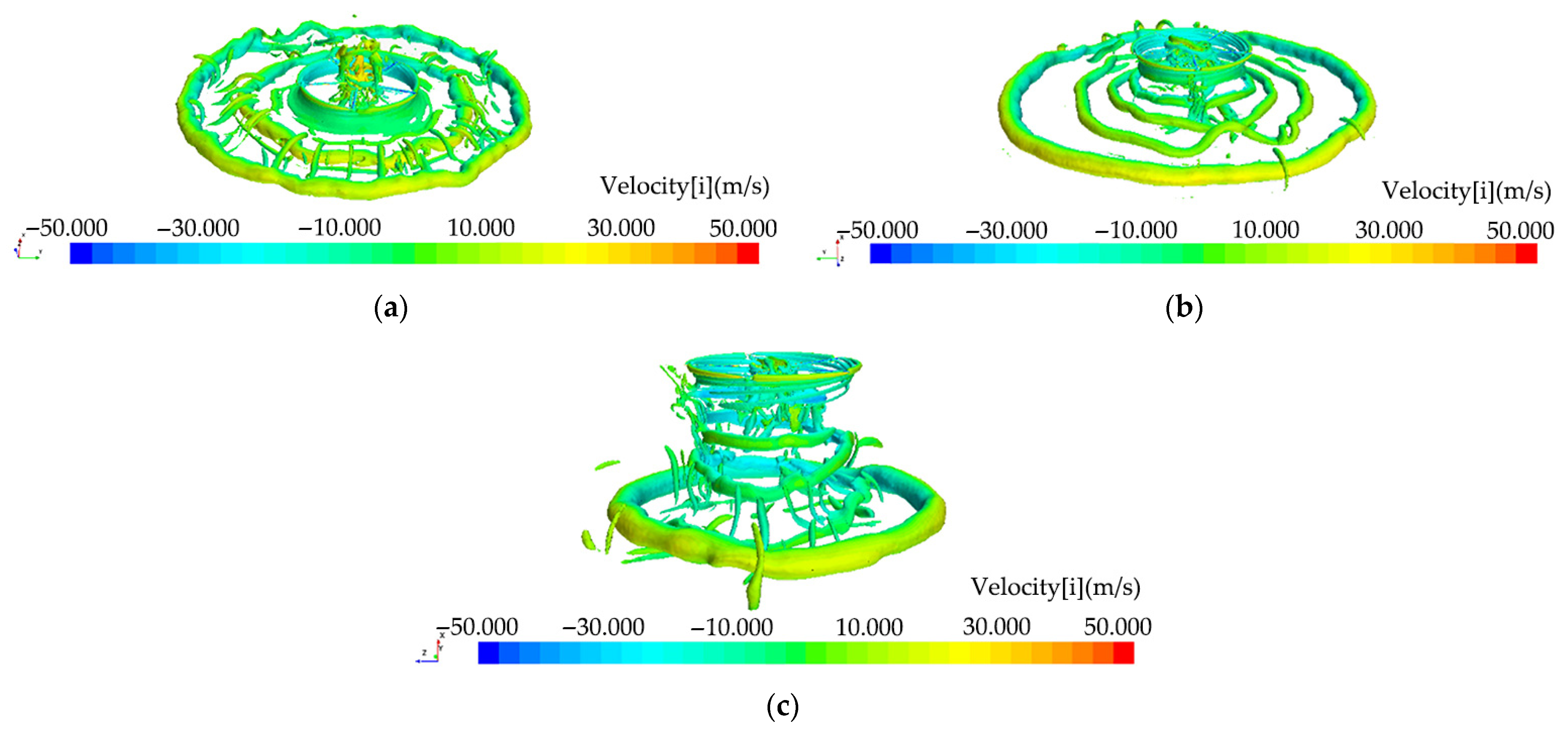

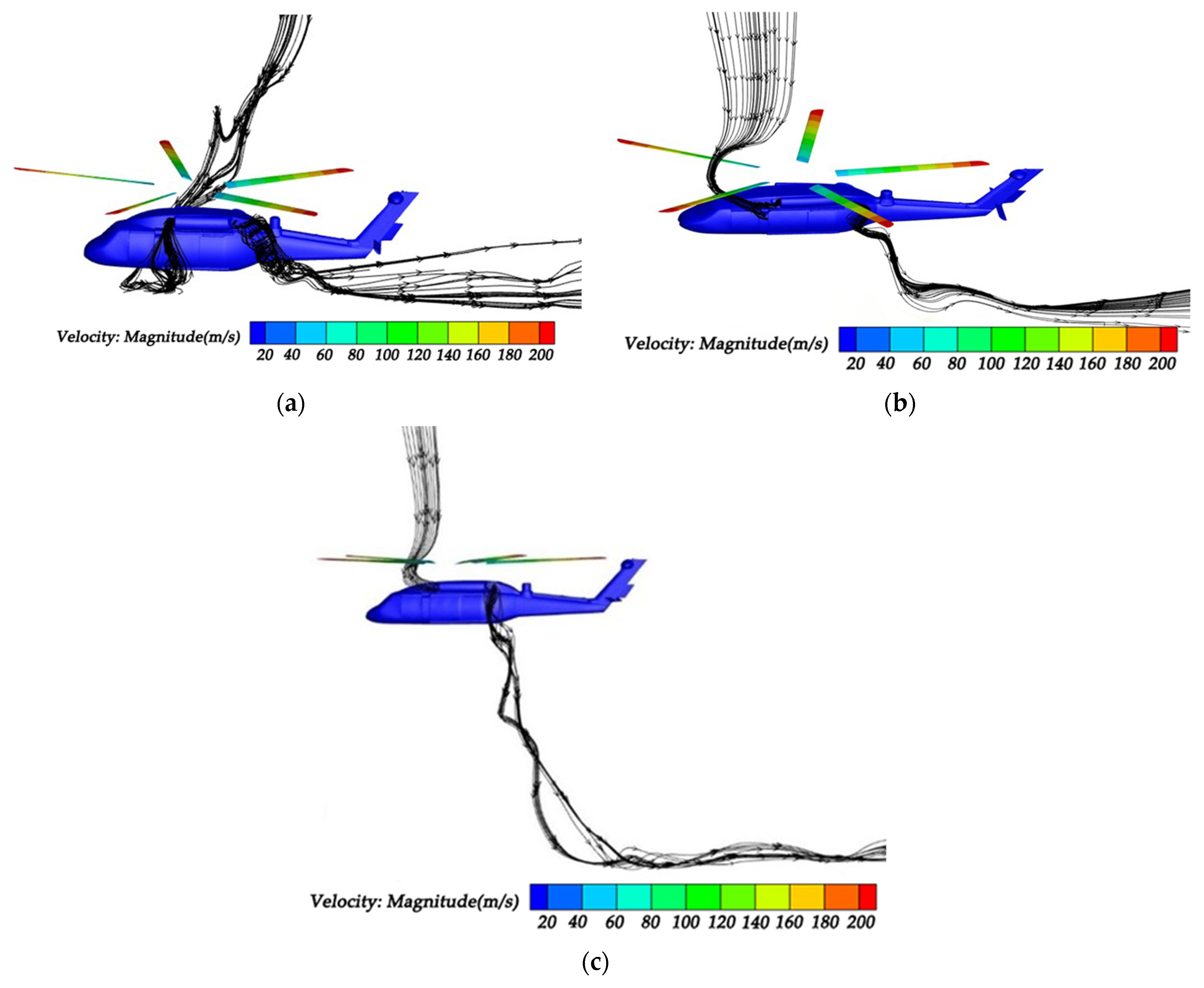

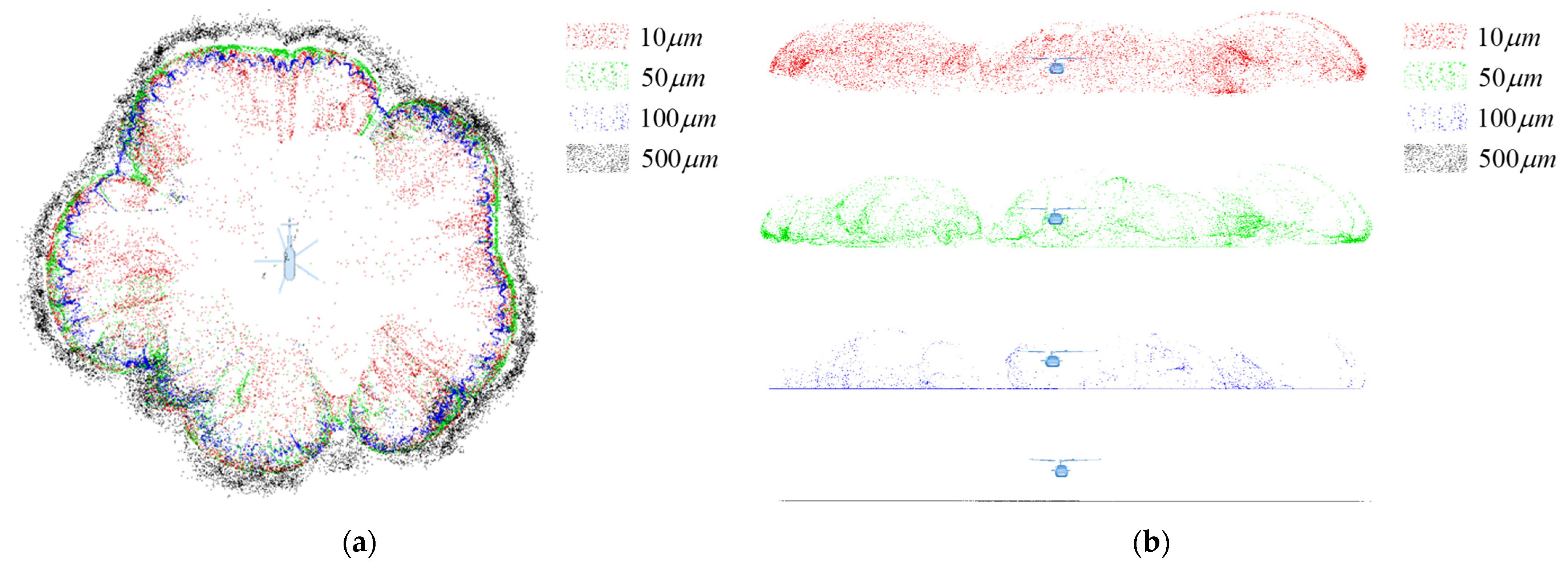

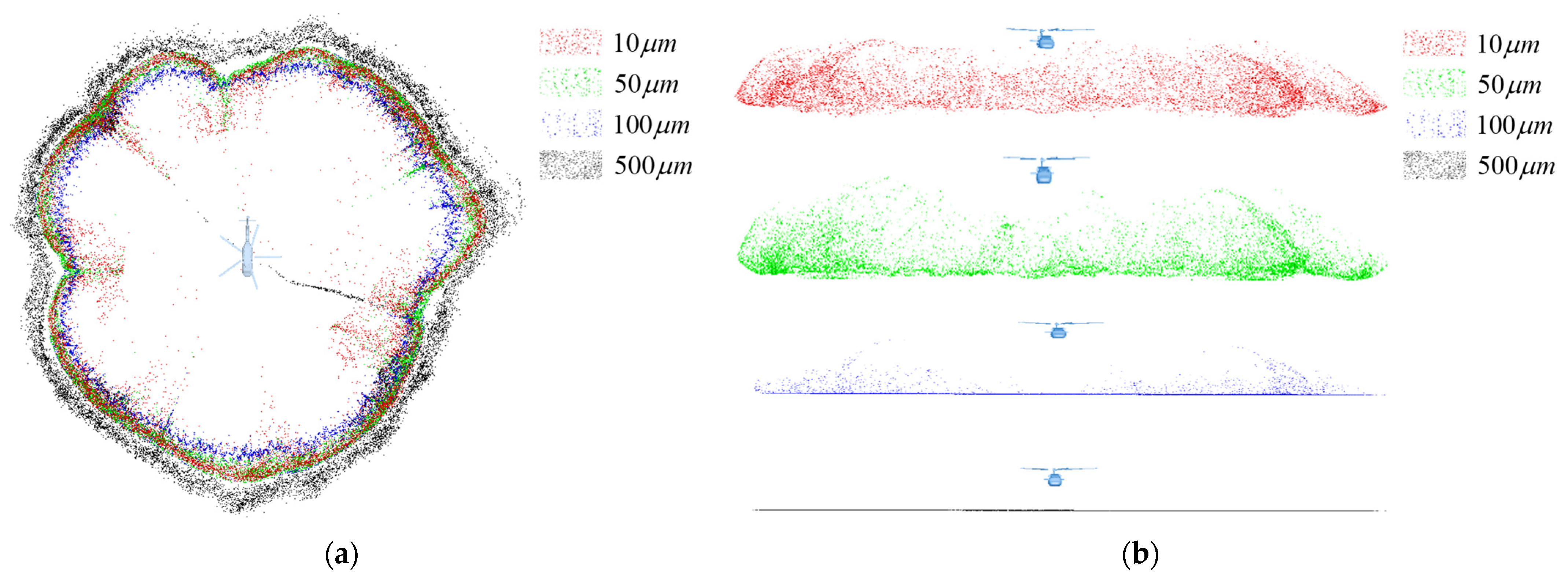

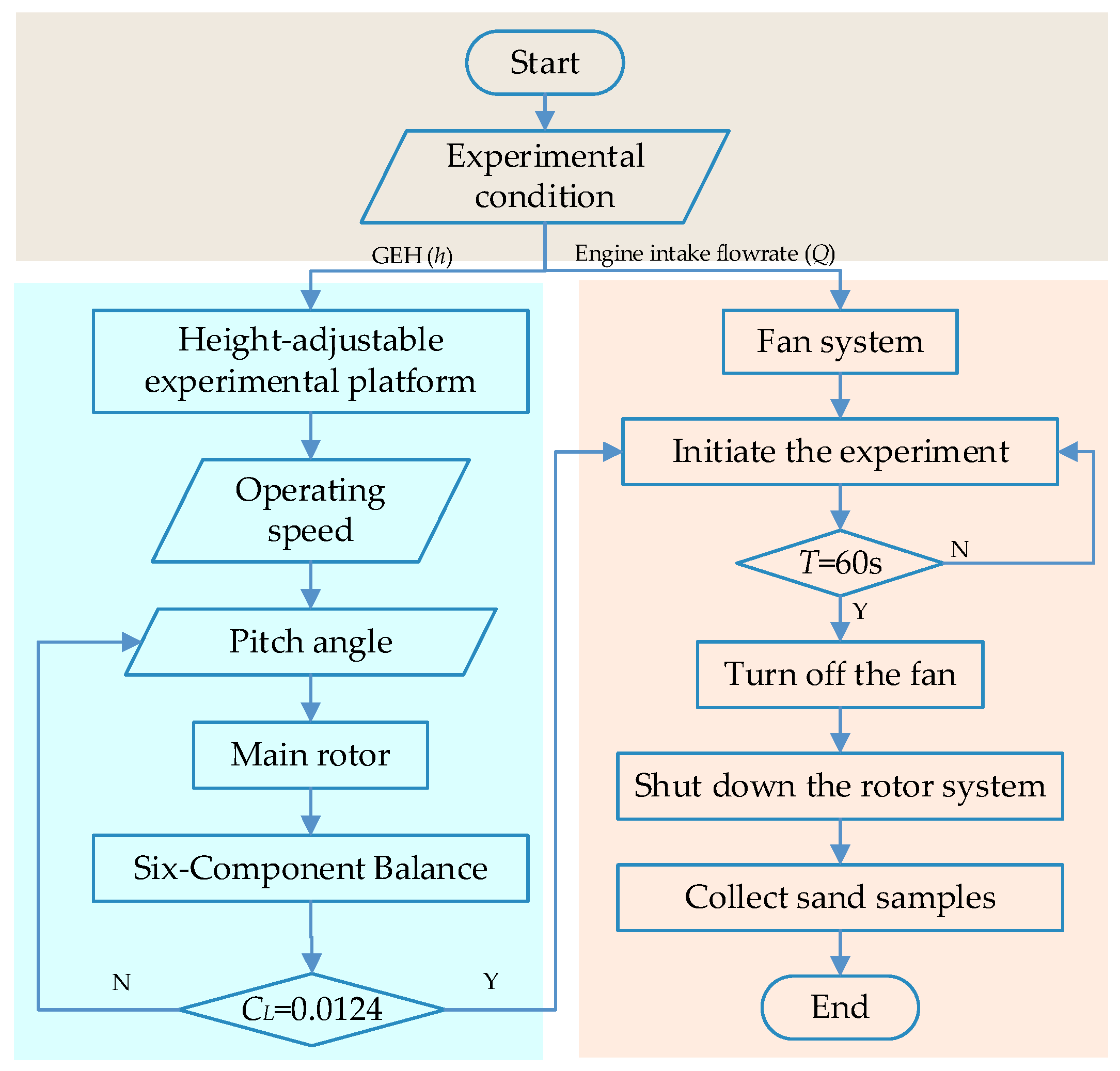

In this study, a CFD-DEM coupled simulation model was first used to analyze the coupled flow fields between the rotor and engine and the distribution of sand clouds comprising particles of varying sizes at different GEHs. Subsequently, guided by the experimental conclusions, the height of the rotor test bench was determined for conducting experimental research. These experiments elucidated the effects of engine intake flowrates on the total sand ingestion amount of the left and right inlets, as well as the concentration distribution across the inlet cross-section, at different ground-effect conditions. These findings lay a theoretical foundation for sand protection for helicopter engines, such as the design of particle separators.

5. Conclusions

Aerodynamic field analysis and sand particle motion simulations of ground-effect hovering helicopter were conducted using the CFD-DEM coupled simulation method, and helicopter engine sand ingestion experiments were carried out based on the simulation results. The following conclusions are derived:

- 1.

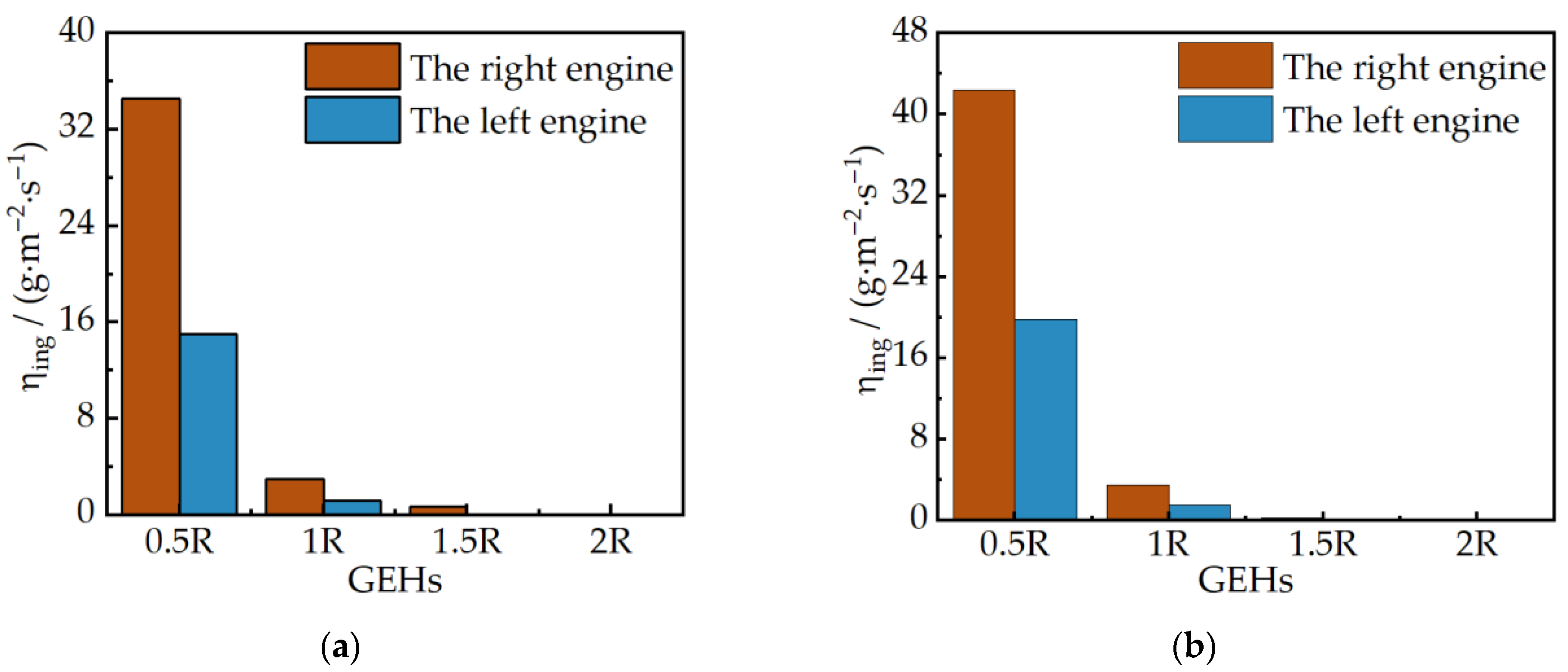

The sand ingestion amount of helicopter engines decreases nonlinearly with the increase in GEH. At lower GEHs, the direct ingestion of sand from the ground by the engine is observed, leading to a substantial increase in the sand ingestion amount.

- 2.

The rotational direction of the rotor exerts an influence on the sand ingestion of helicopter engines. For the right-handed rotating rotor of this study, the sand ingestion amount of the engine on the right side of the fuselage is greater than that of the engine on the left side.

- 3.

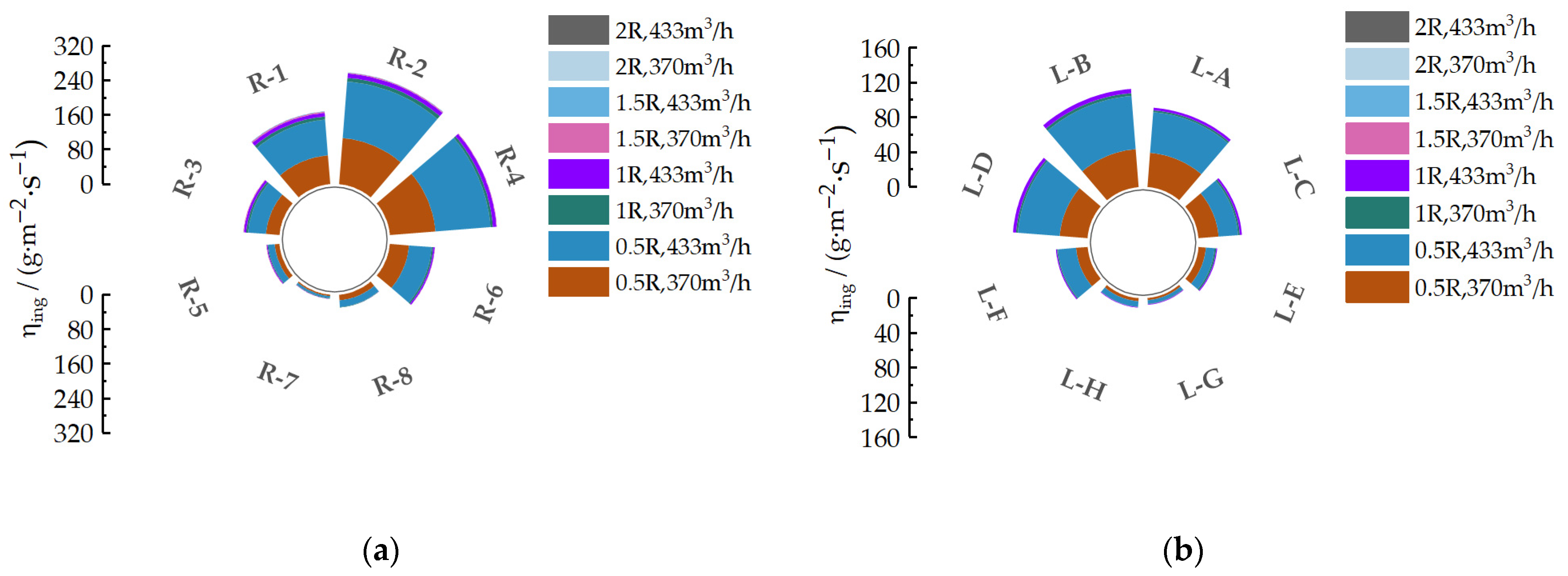

A positive correlation exists between helicopter engine sand ingestion amount and the engine intake flowrate.

- 4.

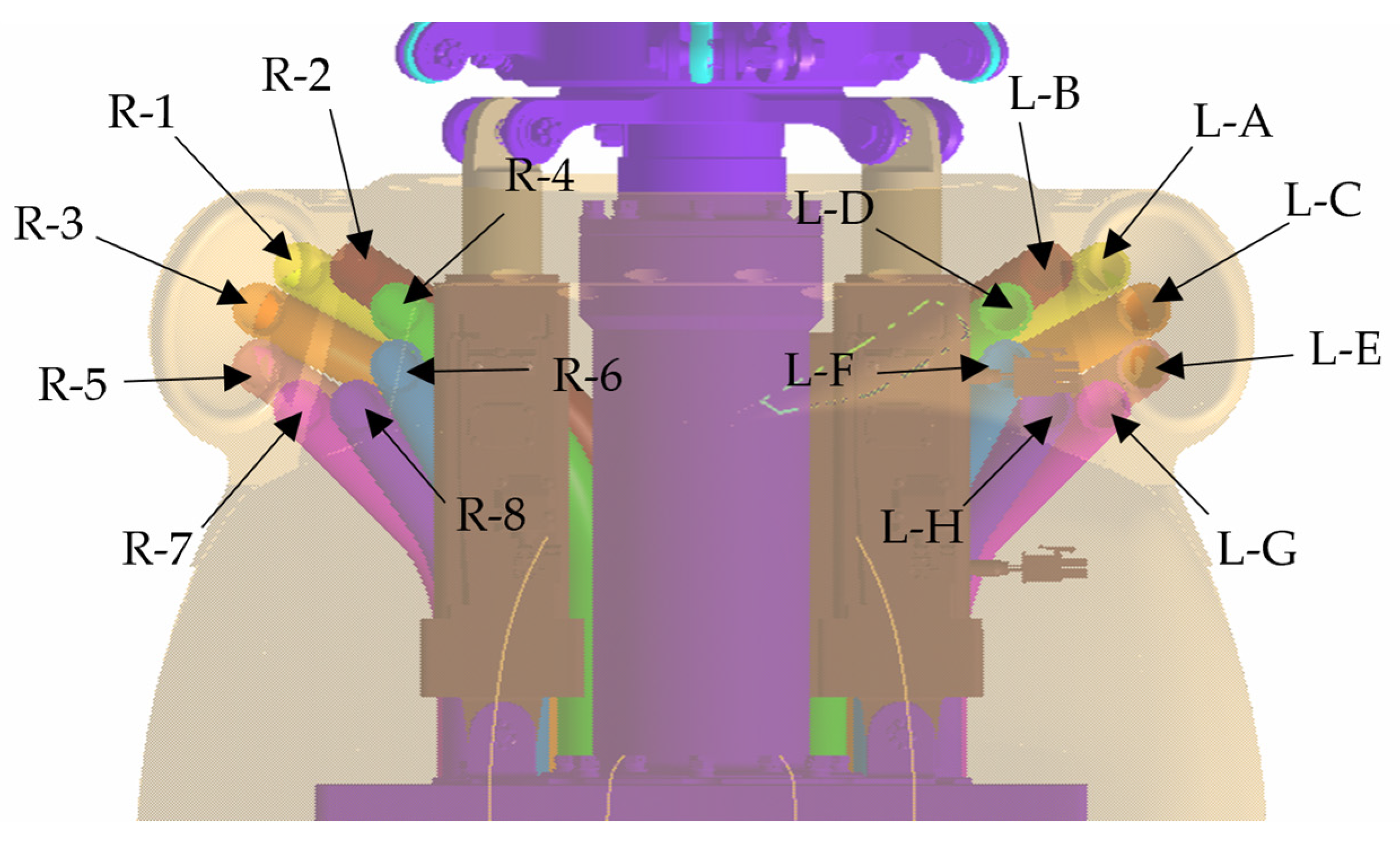

A high degree of symmetry is exhibited in the cross-sectional distribution of sand ingestion between the left and right engines. For the cross-sectional position of the engine inlet in this experiment, over 60% of the total sand ingestion is concentrated in the upper region.

Based on the research in this paper, specific guidelines are provided for helicopter engine sand prevention, which offer technical support for the design of particle separators, the preparation and distribution of standard sand for engine sand ingestion tests. Notably, the design of the air intake should possibly prevent the engine directly drawing in sand and dust particles from the ground.

Additionally, future studies can consider the dynamic similarity of dust particles and conduct further research on their particle size distribution. Regarding the asymmetrical characteristics of sand ingestion rates between the left and right air intakes, further research can be conducted on the impact of the engine air inlet direction on sand ingestion rate, so as to reduce the engine’s sand ingestion. With respect to the sand-dust concentration distribution across the air intake cross-sections, future work can focus on studying the distribution of sand-dust particles in different cross-sections of the air intake. And more scientific sand-dust particle separation can be achieved.