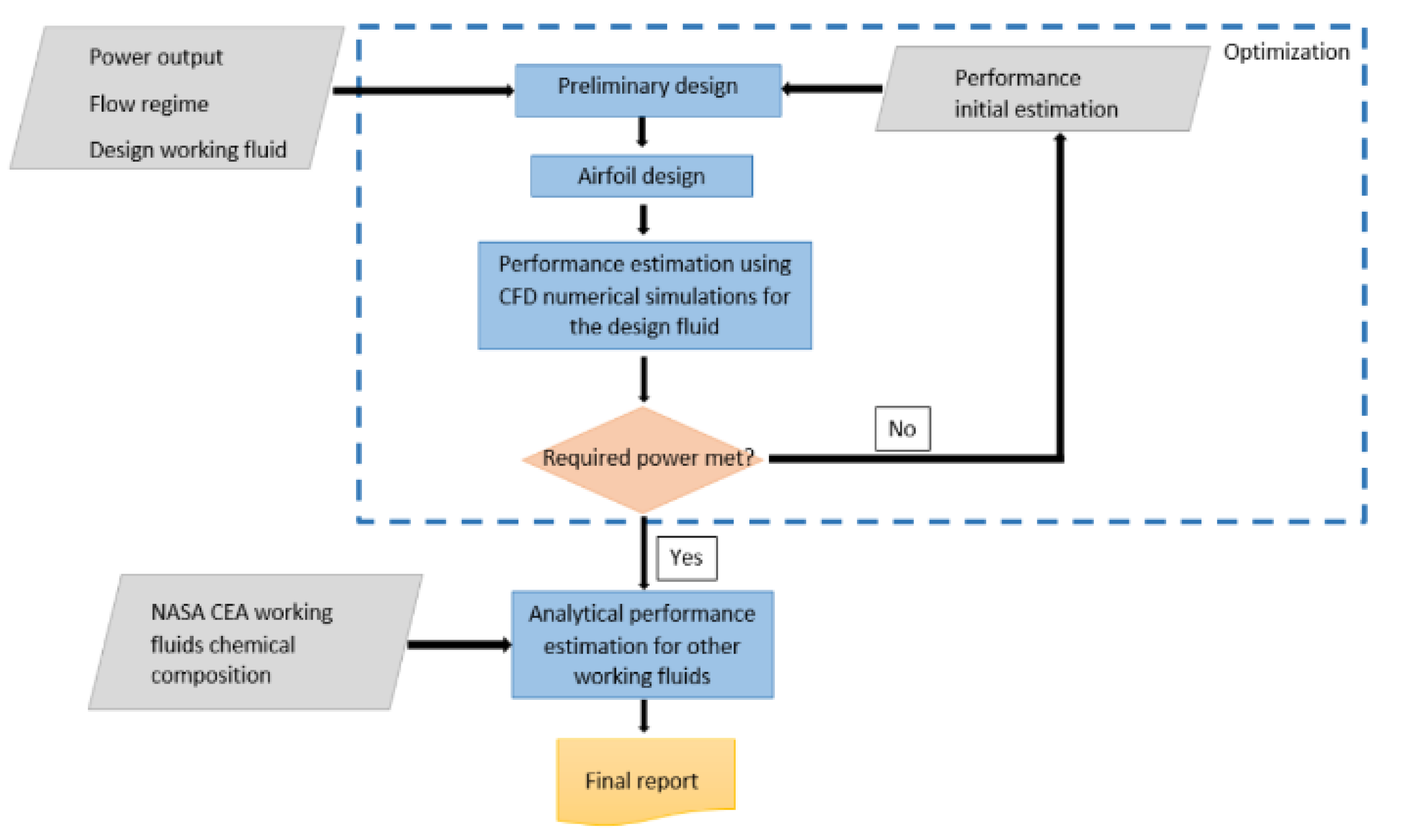

1. Introduction

Space propulsion strategies are currently undergoing a significant transformation. Unlike in the past, where overcoming technical challenges was the primary objective, today’s focus increasingly incorporates societal and economic pressures driving the shift toward more sustainable solutions. Reusable launchers, once a distant ambition, have now garnered serious interest from both governmental programs and private enterprises. Another key direction in space programs is the pursuit of alternative propellants, those that are more environmentally friendly, cost-effective, and widely accessible. The overarching goal is to develop more reliable and versatile launchers, capable of multiple uses and adaptable to various working fluids. These aims are clearly outlined in the European Space Agency’s Future Launchers Preparatory Programme (FLPP) [

1]. Nevertheless, launchers are highly complex systems, with decades of development needed to reach flight-ready technology readiness levels. Thus, transitioning to greener propellants ideally requires minimal system redesign. Simultaneously, technological advancements in electronics have driven demand for micro launchers, capable of delivering 1–100 kg payloads into Low Earth Orbit (LEO). Over 2500 nano- and microsatellites were projected for launch between 2018 and 2023 [

2]. That same year, two 13.5 kg Mars Cube One satellites completed a Mars flyby, marking the first use of CubeSats in interplanetary space [

3]. In response, several micro launchers are already operational, with many more in development. Notably, JAXA’s SS-520 launched a 4 kg payload to LEO, making it one of the smallest launchers to achieve orbital success [

4]. A detailed inventory of small launch vehicles, both existing and emerging, is provided in [

5] and updated in [

6]. Despite the global pandemic, this sector continued to evolve, with numerous propulsion systems progressing in maturity. A comparative assessment of small launcher developments between 2018 and 2020 is presented in [

7]. Analyzing launcher concepts under 100 kg payload capacity reveals diverse design approaches, including variations in propellant types (liquid, solid, hybrid), launch platforms (ground-based, air-launched), and propulsion mechanisms (traditional turbopumps, electric pumps).

Selecting a rocket propulsion system for a high-cost, multi-year program requires substantial effort in performance evaluation and the development of rational, quantitative comparison methods. Multiple analyses are conducted to assess critical criteria aligned with mission requirements, which directly inform propulsion system specifications.

For instance, solid propellants are typically chosen for tactical and ballistic missiles due to their readiness, compactness, and minimal handling risks. In contrast, liquid propellants dominate space applications, main propulsion stages, upper stages, and attitude control systems, thanks to their higher specific impulse, cleaner exhaust, compatibility with green fuels like hydrogen or methane, and precise thrust control through multiple pulses [

8].

A key subsystem in liquid propulsion is the turbopump, responsible for delivering propellants to the combustion chamber under high pressure. While electric pumps are emerging, traditional turbopumps remain the standard. These systems, though sharing features with gas turbine machinery, must be lighter and achieve higher specific work. Consequently, rocket turbopumps often incorporate supersonic turbines, which, despite their high specific load, suffer from efficiency losses due to shockwave-induced flow disturbances at the stator exit [

9].

Supersonic turbine interest has re-emerged with novel launcher architectures and innovative gas turbine cycles, such as detonation-based systems [

10]. Historically explored for high-pressure steam applications, their potential in rocket propulsion became evident decades ago [

11], though public access data later became limited. More recent research focuses on shape optimization [

12], partial admission [

13], and adjoint-based methods for improving stator vane performance under off-design conditions [

14].

Despite this, advancements remain scarce, particularly for micro-scale applications. Compact supersonic turbines remain challenging for their design, manufacturing, and instrumentation. The studies showed that the main disadvantages of supersonic turbines are the high losses associated with supersonic flow and caused by the shock wave phenomenon. These losses are significant in value and can reach up to 30% when a normal shock wave exists [

15].

As micro-launcher development progresses, requirements for reliability and adaptability also extend to turbine components. A critical step toward increased adaptability is the ability to change working fluids, reflecting fuel changes, without redesigning the entire system. This necessitates methods that can rapidly and accurately predict turbine performance for alternative fluids based on nominal operating data.

Recent research has increasingly focused on the aerodynamic and thermodynamic challenges of supersonic turbines operating with unconventional working fluids, particularly in Organic Rankine Cycle (ORC) and supercritical CO2 systems.

Mach similarity (sometimes called Mach number similarity or Mach scaling) is a scaling principle used in turbomachinery and fluid dynamics. The idea is that if two geometrically similar machines (e.g., turbines, compressors, pumps, fans) operate at the same Mach number distribution (local velocity/speed of sound ratio) and Reynolds number is sufficiently high, their aerodynamic performance will be similar, even if the working fluids or sizes differ. This principle is widely applied in design, testing, and scaling of turbomachinery, especially when direct experimentation with the real machine or fluid is impractical.

Mach similarity is most actively applied in ORC turbines and sCO2 turbines, but also widely used in aerospace, cryogenic pumps, refrigeration compressors, and scaled aerodynamic testing. Its main advantage is enabling the use of air test rigs to replicate the aerodynamics of machines designed for exotic, hazardous, or expensive fluids. However, it has important limitations, mainly due to Reynolds number mismatch and non-ideal gas effects. Engineers typically combine it with empirical corrections and CFD to ensure reliable performance predictions.

Traditional similarity laws have been shown to lose predictive accuracy when gas properties such as specific heat ratio deviate significantly. Guardone and colleagues have emphasized the role of non-ideal compressible fluid dynamics in turbomachinery [

16]. Conti et al. [

17] proposed similarity parameters for non-ideal one-dimensional isentropic expansions and showed how the critical pressure ratio in sonic conditions strongly depends on the thermodynamic nonideality of the fluid. Experimental work in linear cascades has provided rare but valuable benchmarks: Conti et al. [

18] quantified shock-related losses in organic vapors, and Tosto et al. [

19] showed that thermodynamic nonideality of the fluid can affect machine operability, namely critical choking can occur in turbines. Complementing these efforts, high-fidelity simulations (LES and DDES) have examined shock–boundary layer interactions and trailing-edge losses in supersonic blades [

20] while data-driven surrogates have begun to accelerate multi-row cascade performance predictions [

21]. Despite this progress, most available methods remain tuned to specific fluids or geometries, and open cross-fluid datasets are scarce. Consequently, there remains a research gap in developing rapid, property-aware predictive frameworks capable of transforming existing turbine performance maps when the working fluid is changed, without resorting to full computational or experimental campaigns.

Moreover, Mach similarity assumes that matching Mach numbers is sufficient to achieve aerodynamic similarity. However, the Reynolds number (Re) also governs boundary layer behavior, including transition, separation, and losses. This issue is particularly significant for miniature turbines, where viscous losses dominate. When the turbomachine is very small, surface-to-volume effects such as tip clearances, leakage, and friction become dominant. Small-scale machines are also more sensitive to surface roughness, since boundary layers are thin at high Re but considerably thicker at low Re with other fluids. Consequently, scaling from air tests means that losses, stall margins, and efficiency do not scale perfectly. For these reasons, true full similarity (Re + Mach + geometry) is rarely achievable outside carefully chosen scales, and the extent to which Mach similarity can be achieved at very small scales remains an open question.

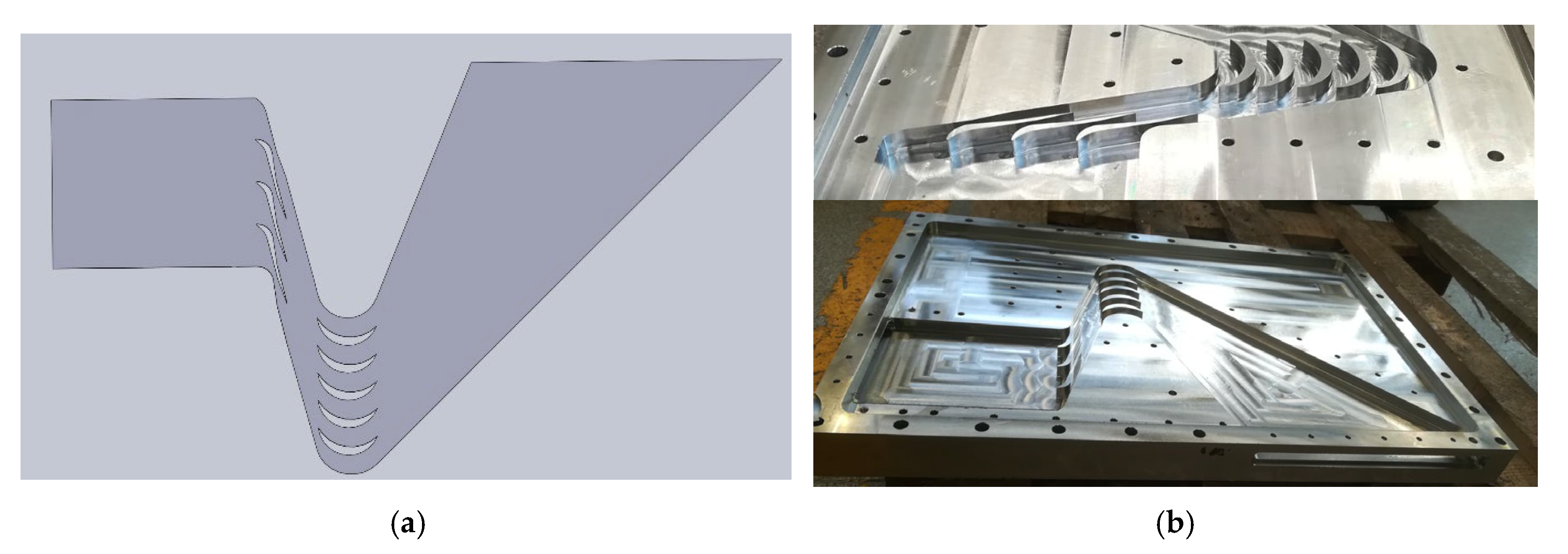

The primary objective of this study is the development and experimental validation of a methodology for the rapid prediction of supersonic micro turbine performance under varying working fluid. This paper presents the initial stage of validation: the experimental assessment of a Mach-similarity-based approach for predicting turbine performance across different working fluids, using stator-only experiments.

The case study concerns a supersonic turbine intended for a micro-launcher with a 100 kg payload capacity. Tests were carried out with two working fluids, air and methane, to evaluate the accuracy of the proposed method in estimating performance across fluids at a very small scale. Unlike existing applications of Mach similarity (e.g., in ORC and CO2 turbines), this study focuses on comparing flow similarity within a supersonic turbine vane using air and methane, rather than air and a traditional ORC organic fluid. While an organic fluid, methane’s performance is often contrasted with other hydrocarbons like n-hexane, n-pentane, and cyclopentane, which are frequently chosen based on their thermal stability and performance characteristics for specific ORC applications.

The unique contribution of this work lies in the experimental validation of Mach similarity for the stator of a very small turbine—where full similarity is rarely achievable—using methane as the working fluid. Methane is particularly relevant for green micro-launchers and, in this context, provides the additional benefit of operating at higher Reynolds numbers compared to air.

Beyond validation, the approach shows promise for evaluating new turbine designs under varying working conditions or for enabling multi-fluid optimization without high computational costs.

4. Results

4.1. Test Matrix

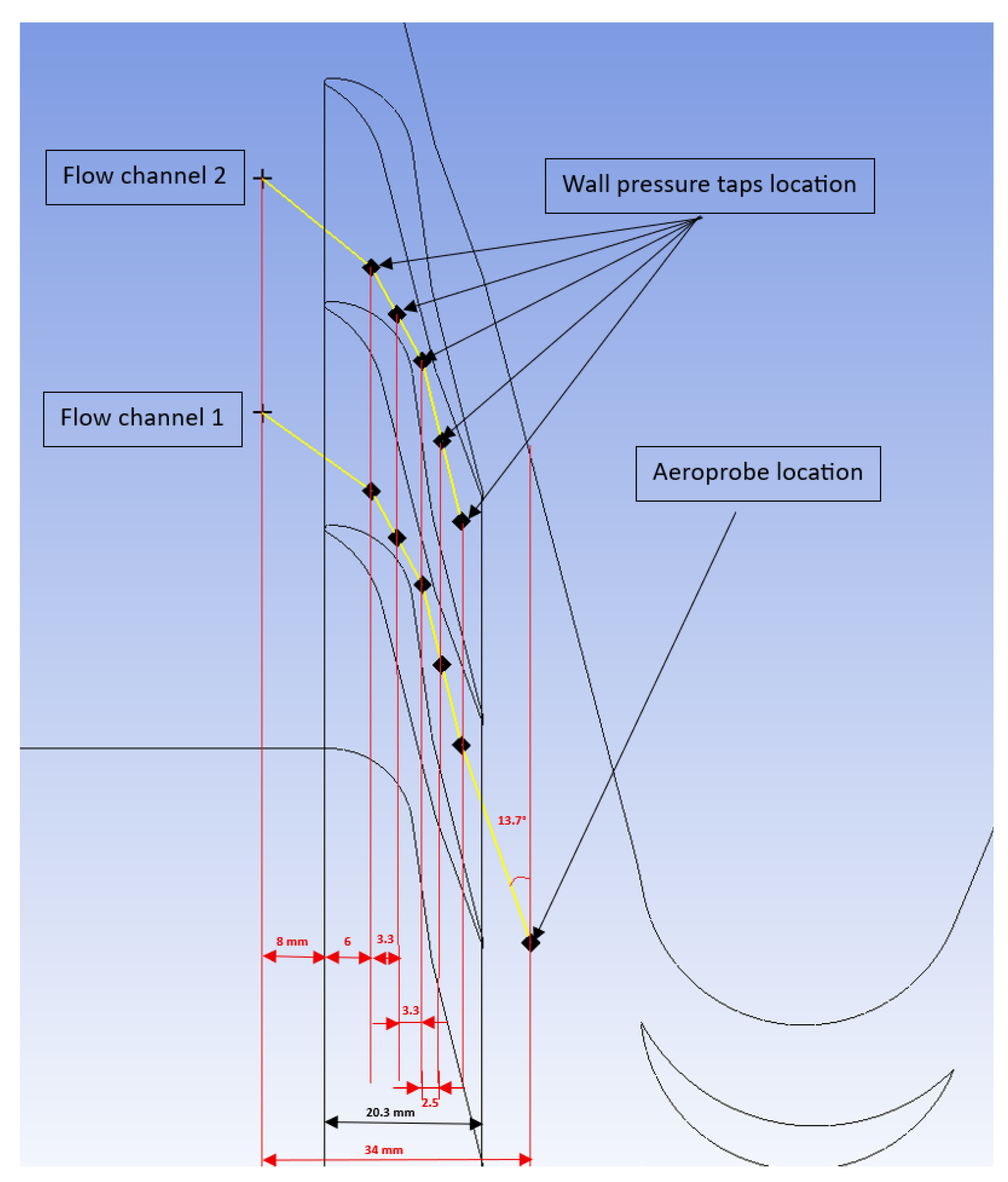

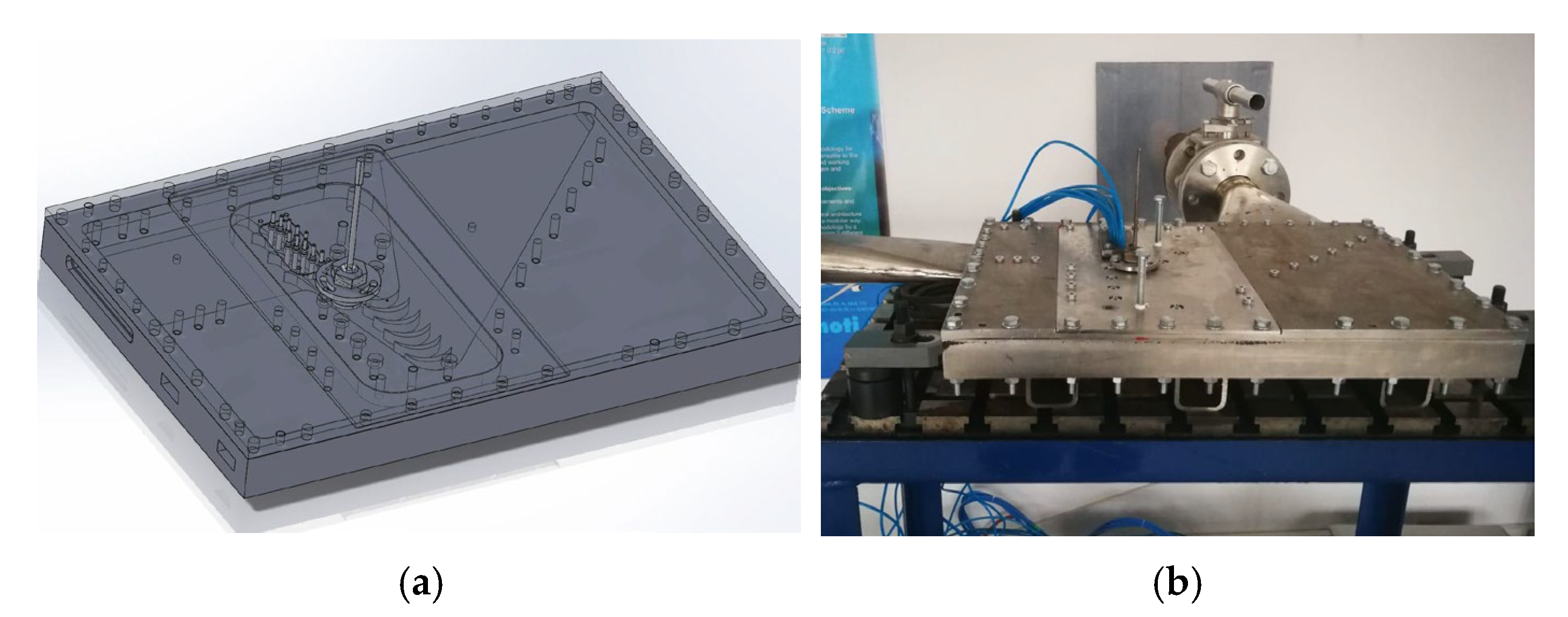

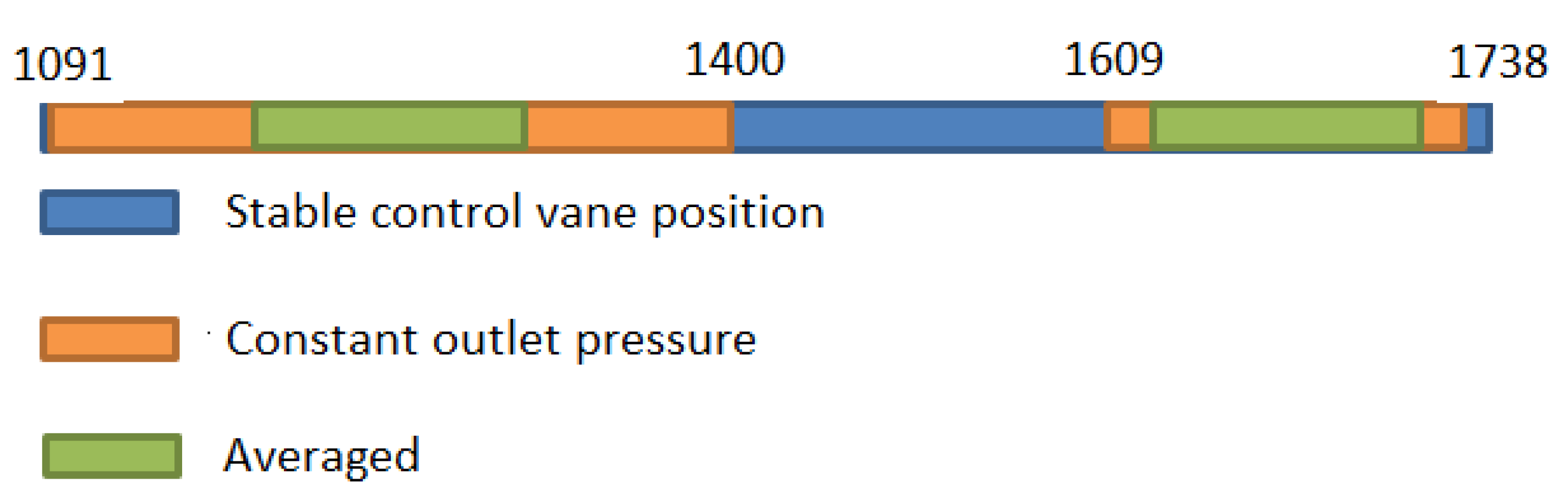

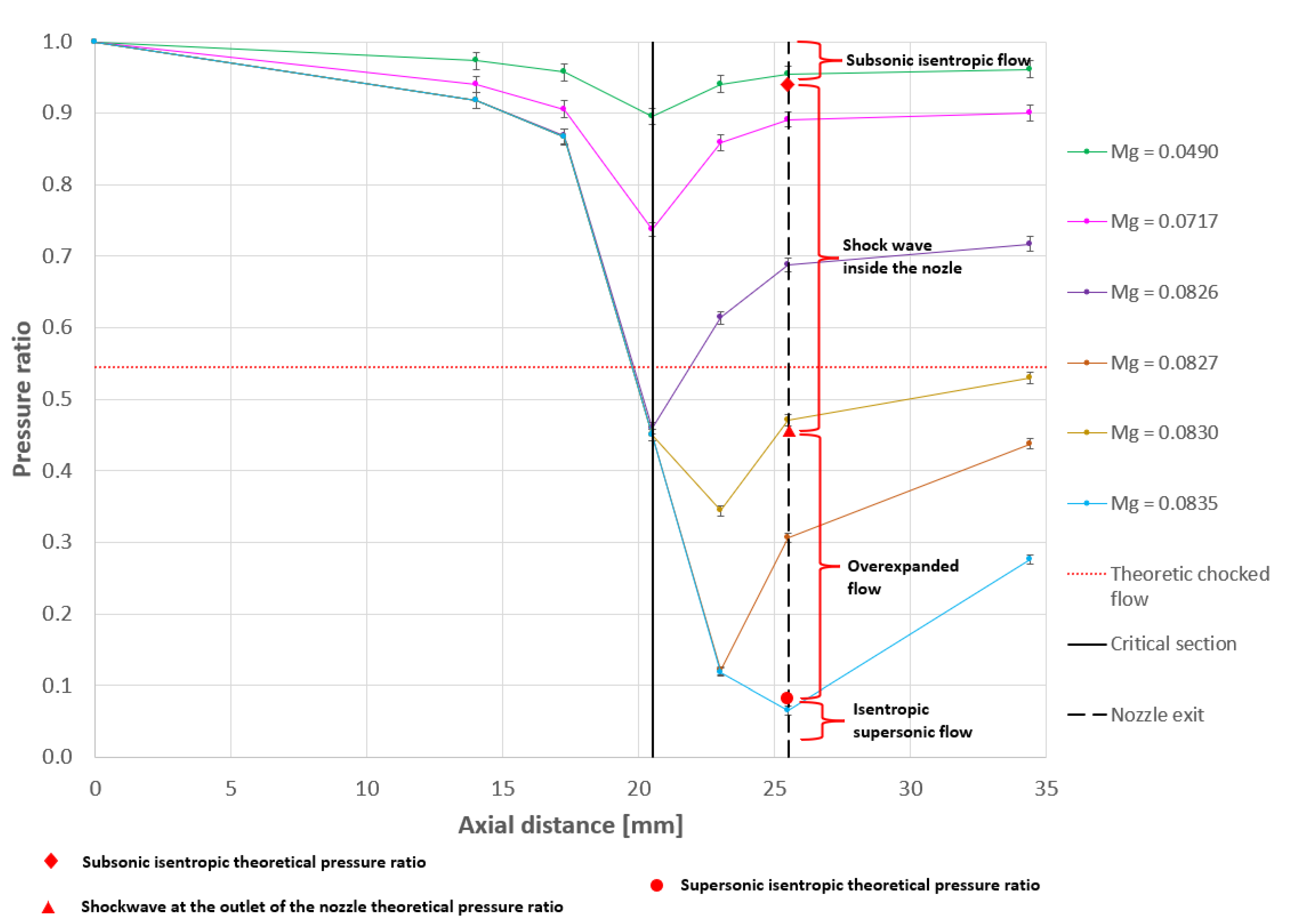

By varying the pressure ratio between the nozzle inlet and the back pressure at the outlet, a full spectrum of flow regimes was experimentally captured for both air and methane. These regimes include subsonic isentropic flow, flow with an internal shock wave within the nozzle, flow with a shock wave located outside the nozzle, and fully isentropic supersonic flow.

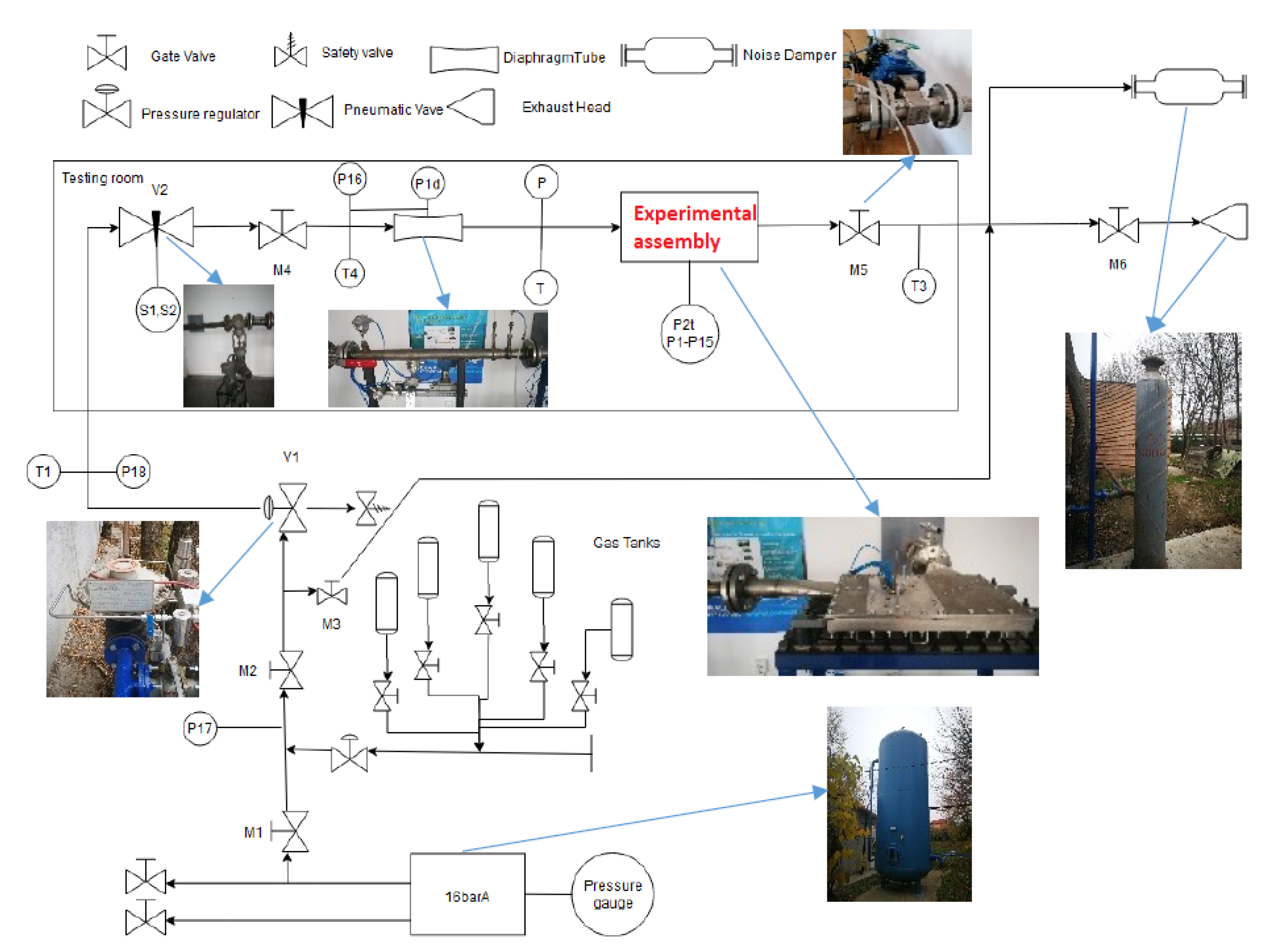

Figure 10 illustrates this range for tests conducted with methane at a constant inlet pressure of 4.5 bar and varying back pressure at the outlet of the experimental model. This was achieved by using the pressure regulator and the control valves shown in

Figure 6. The back pressure was not measured, as it was not a parameter of interest, but rather it was used for controlling the mass flow rate. This is a test rig solution for allowing experiments to take place in a wide range of regimes. In practice, this is useful to determine the turbine stator behavior and understand where the turbine has the best performances and less losses.

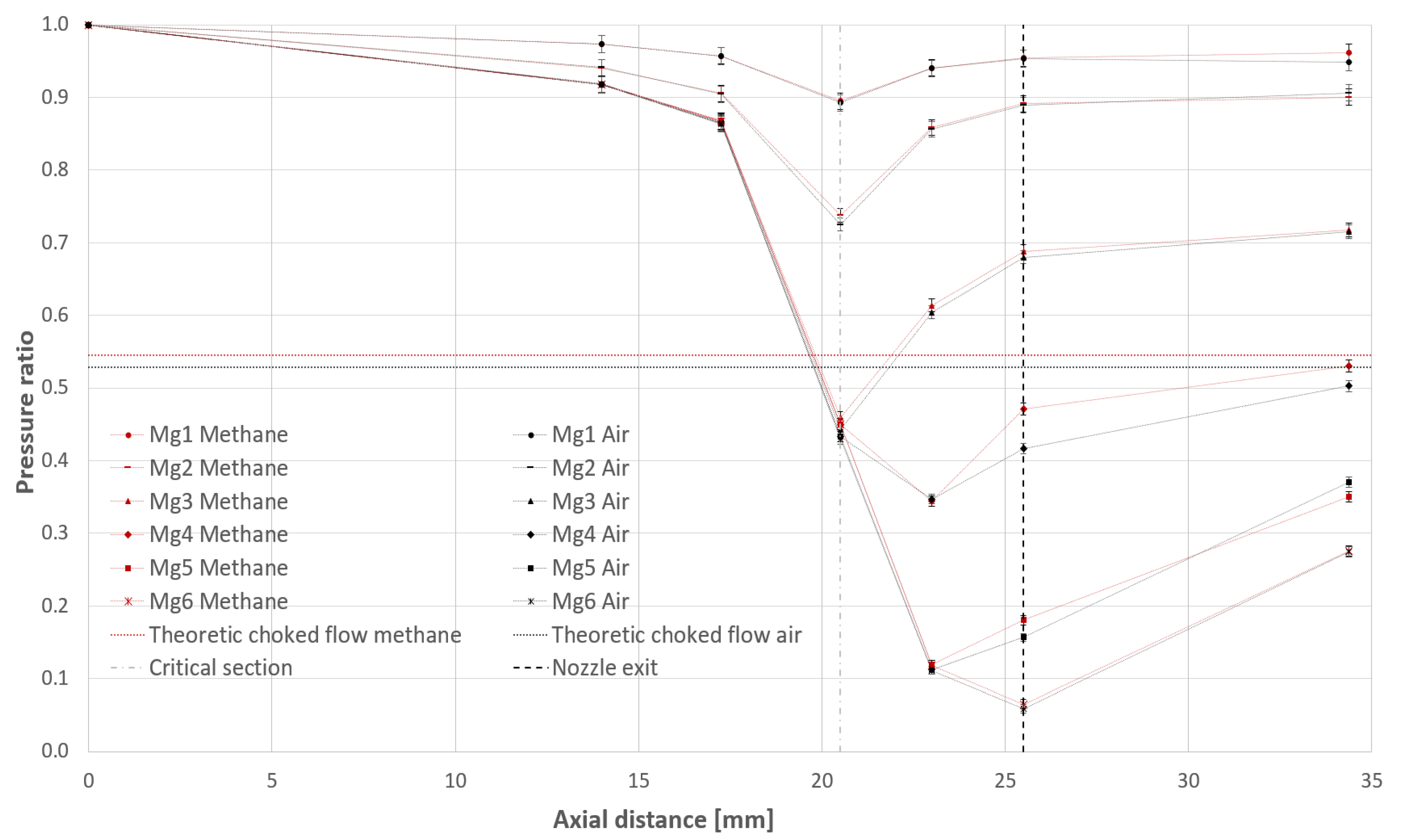

The legend in

Figure 10 indicates the corresponding mass flow rates measured for each case, in kg/s. Theoretical pressure ratio thresholds, defining the transition between subsonic isentropic flow, a normal shock located at the nozzle exit, and fully isentropic supersonic flow were calculated for both working fluids. These values are presented in

Table 4, along with the theoretical critical pressure ratio below which the flow becomes choked at the nozzle throat.

Figure 10 also includes two vertical lines and a horizontal one. The first vertical line is the location of the critical section, corresponding to the minimum area of the nozzle and axial location 20.6 in

Figure 4. The second vertical line is the nozzle exit, corresponding to the mean point on the line uniting the trailing edge of a vane with the suction side of the adjacent vane and normal to the flow inside the flow channel, or axial location 25.5, on current

Figure 4. The horizontal line corresponds to the theoretical value for the pressure ratio for chocked flow for the existing nozzle.

According to the data presented in

Figure 10, along with the nominal regime, a full range of regimes were obtained experimentally, including:

- -

Subsonic isentropic flow, for which the theoretical pressure ratio between the back flow at the exit of the nozzle and the inlet pressure in this case needs to be above 0.959

- -

Shockwave inside the nozzle, for which the pressure ratio needs to be above the computed theoretic value for shockwave at the outlet of the nozzle, namely 0.463

- -

Shockwave outside of the nozzle, for which the pressure ratio needs to be below 0.463

- -

Designed isentropic supersonic flow, for which the theoretic pressure ratio needs to be around 0.078, which is the nominal regime intended for this turbine to work at.

A comparative view of the flow regimes tested on methane and air, both in terms of absolute flow parameters as well as reduced mass flow rate, computed according to Equation (10) is given in

Table 5. The bolded values are representative of the nominal flow regime.

The measured pressure ratios corresponding to the regimes synthesized in

Table 5 are represented graphically in

Figure 11.

Figure 11 gives in red the pressure ratio variation along the flow channel for 6 regimes tested on methane, corresponding to regimes 1 to 6 in

Table 5, meaning Mg1 Methane has a mass flow rate of 0.049 kg/s of methane. Similarly, in black, are the pressure ratio variations for the 6 regimes tested on air, for which the flow details are also given in

Table 5. Thus, flow regime 6 from

Table 5 corresponding to a mass flow rate of 0.1301 kg/s of air, is Mg6 Air in the legend of

Figure 11.

The thin dotted line linking the measured values are only for helping with following the corresponding values from a regime and are not representative of true variation between measuring points. For example, for the nominal regime (regime 6), it is expected that the static pressure will remain relatively constant downstream of the nozzle exit and to increase abruptly after the shock wave, right before the last measurement point [

24].

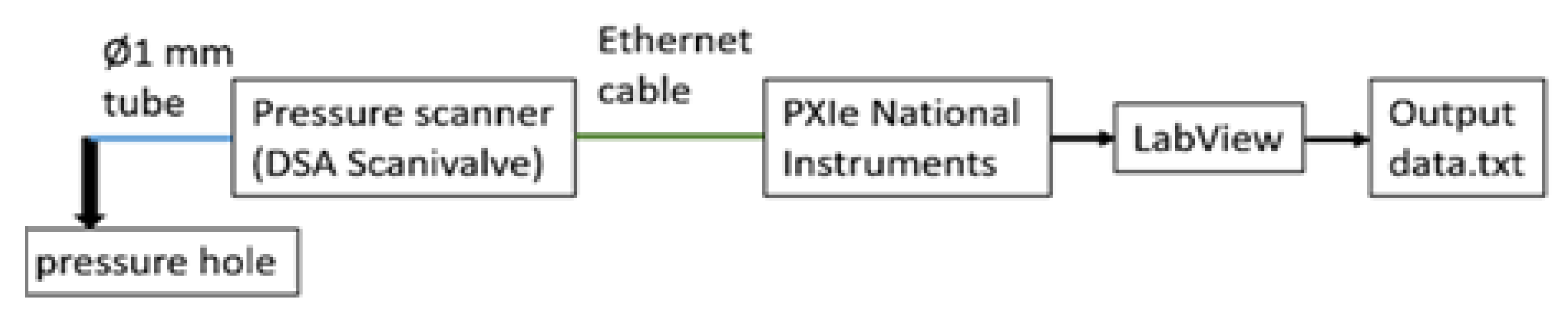

The measurement uncertainty for the pressure ratio computed with the method described in

Section 3.4 is also reported in

Figure 10 and

Figure 11. The values are visibly small, with maxim values of +/−0.0135 bar for both air and methane for the pressure ratio corresponding to the location of the 5-hole probe, downstream of the nozzle exit and the shockwave in flow regime 5. The maximum pressure ratio error as percentage of the pressure ratio is registered for the regimes with supersonic flow, in the divergent area of the nozzle, where the absolute pressure ratios are minimum, between the critical section and the nozzle exit.

A first observation is that the experiments on the two fluids cover similar flow regimes, most of them with 7% of each other in terms of reduced mass flow rate.

Another important observation is that the measured critical pressure ratio is smaller than the theoretical values for both fluids, with about 17%.

The difference between the theoretical values and the measured values can be caused by manufacturing variations. For a turbine of this scale, where the blade height is 10 mm, the minimum distance between two consecutive blades is 3 mm and the pressure hole dimeter is only 0.3 mm, even a tight manufacturing tolerance of 0.03 mm represents 1% of the minimum distance and 10% of the hole dimeter, which can affect the distribution of the flow.

Along with the positioning of the probes and manufacturing tolerances, another explanation for the measured critical pressure ratio values being lower than the theoretical values is the fact that the theoretical value does not account for the thickness of the boundary layer. It was proven in the literature that the values of the choking pressure ratio are lower than those of the inviscid theory and monotonically decrease with an increase in the wall boundary layer thickness. The relative difference between the two values for the two fluids remains similar however, with the methane measured pressure ratio being 3.95% higher than the air value, as compared to a theoretical difference of 3.12%. The value considered here for the measured critical pressure ratio is the average of the critical pressure ratio measured for the last four measured regimes in which the critical pressure ratio is reached. All measured critical pressure ratio values are within 2% of the average, for both air and methane. All this data is synthesized in

Table 6.

4.2. Nominal Regime Comparisson

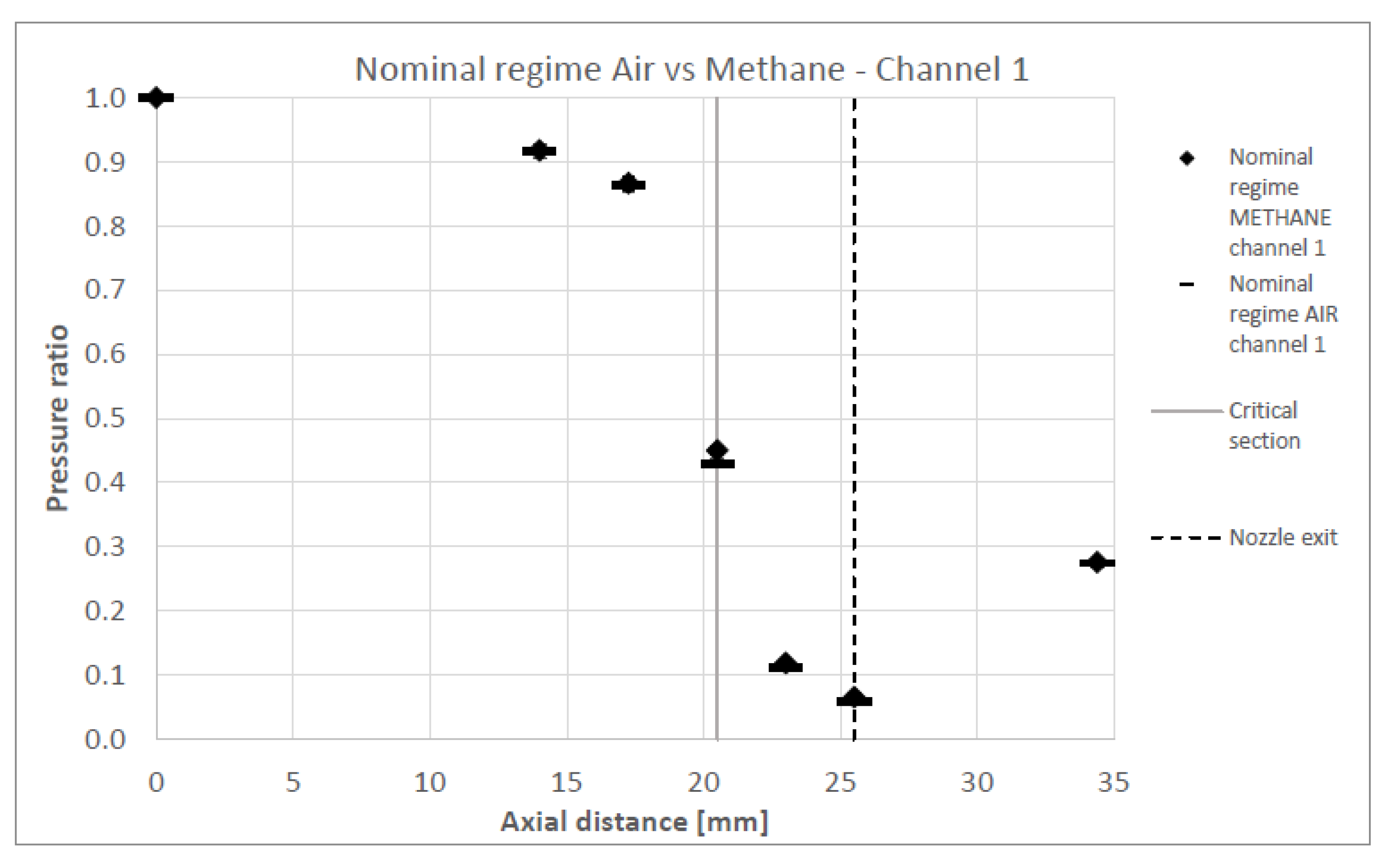

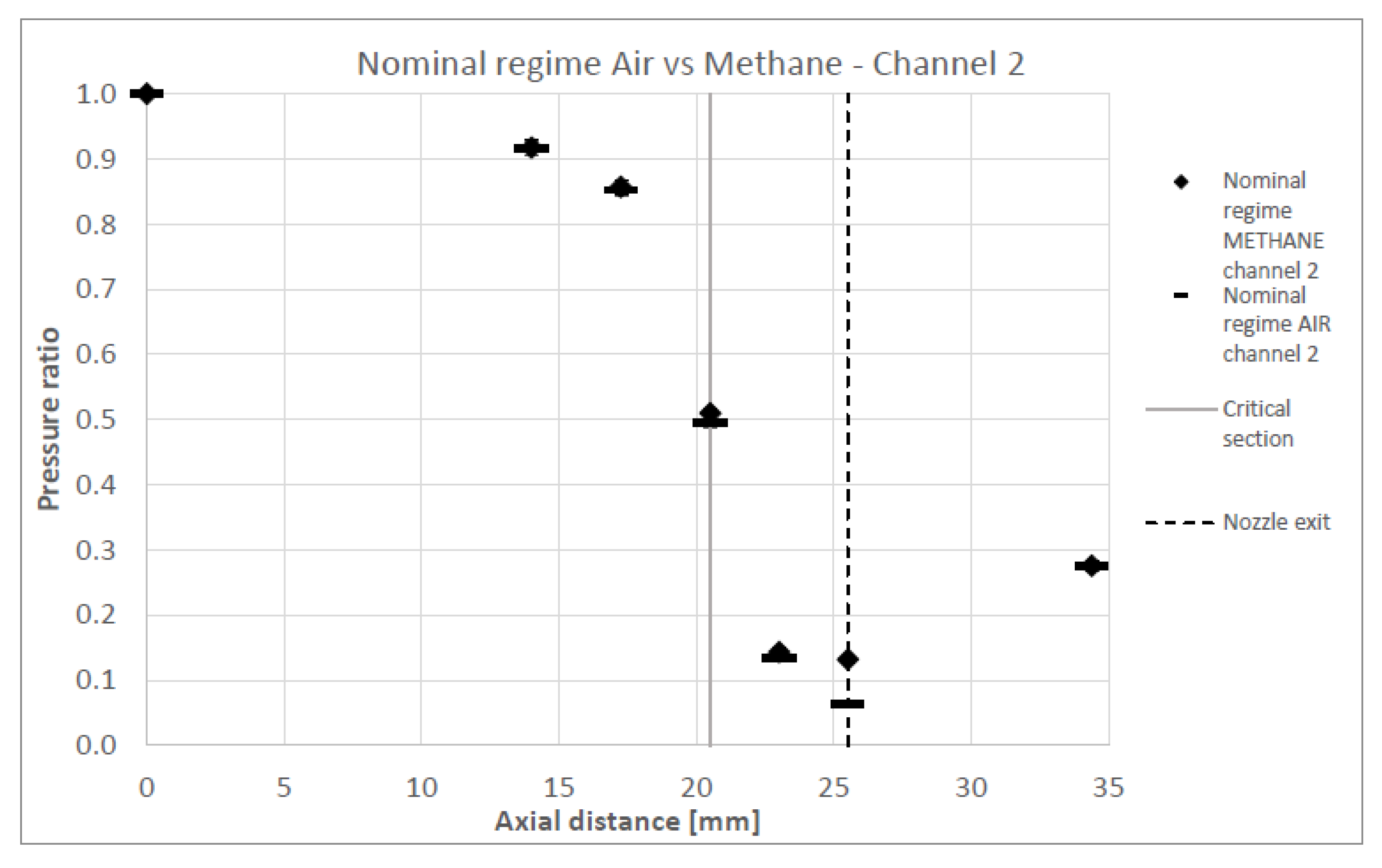

The primary objective is to compare the experimental data obtained at the nominal operating regime using methane with that obtained using air, for both flow channels, in order to validate the turbine performance estimation method and its predicted performance values. This comparison is illustrated in

Figure 12 for flow channel 1 and in

Figure 13 for flow channel 2.

The results indicate that, for both fluids, the flow accelerates through the convergent section of the stator, reaching sonic conditions at the throat. It then continues to accelerate through the divergent section, extending to the nozzle exit. Downstream of the nozzle, a significant rise in static pressure is observed, indicating the presence of a shock wave beyond the nozzle exit. The experimental data for methane and air show very close agreement, with differences falling within the measurement uncertainty for most data points in both channels, except at the nozzle exit of channel 2.

Discrepancies between the two channels may be attributed to manufacturing tolerances or to variations induced by the influence of adjacent walls, which are not perfectly periodic and could affect local flow conditions.

The experimental results represented in

Figure 12 and

Figure 13 confirm that the methodology used for preserving the flow characteristics when the working fluid changes gives good results for the assessed inlet parameters.

Comparing the nominal regime flow parameters, the differences between the measured values and the theoretic values for air are negligible (as seen in

Table 7).

There is a slight difference in mass flow rate between the theoretic mass flow rate for air and the mass flow rate obtained during the tests, but is under 0.5%. Similarly, there is a difference between the mass flow rate computed using the Mach similarity criterion for methane and the mass flow rate obtained on the test rig. As expected, the error is a bit higher for methane, where the Mach similarity criterion applied for changing the working fluid induces additional approximations. However, this error is below 10%. This difference is seen in the reduced mass flow rate values as well.

By applying the formula demonstrated in

Section 2.3, in Equation (11) it is possible to analytically compute the corresponding mass flow rate on methane (fluid b in the formula) based on the air (fluid a in the formula) flow parameters. For the similarity parameter to be invariant, as defined by Equation (11), using the total pressure and temperature at the turbine inlet measured values for methane and air for each of the 6 equivalent tested regimes, the methane mass flow rate can be analytically computed. The turbine inlet Mach number of the absolute velocity is estimated to a value of 0.3. This leads to

Considering the air properties, R

sp,a = 287 J/kg·K and k

a = 1.4 and methane, R

sp,b = 518 J/kg·K and k

b = 1.32, this leads to an equivalent mass flow rate for methane based on the air values.

Table 8 compares the experimental values of the methane mass flow rate to the values computed based on the method described in

Section 2.3 starting from air flow parameters. Here, for validation purposes, and comparing the measured values of the mass flow rate with the analytically computed ones, the measured values for the pressure on methane are used. When using the method in practice, without experimental data, the pressure and temperature values can be chosen and the rotational speed and mass flow rate computed or the other way around.

The results show that the developed analytical equations can quickly estimate the mass flow rate of a known turbine when using a new fluid (methane), with completely different properties, such as gas constant, based on the known values for a base fluid (air). For all measured regimes, the values are below 7%.

4.3. Total Pressure Losses

Good agreement between experimental results and numerical results for air at a subsonic and at nominal regime has been shown in [

24]. CFD data was obtained using Ansys CFX for the nominal regime for air ideal gas. The k-ε turbulence model was used and the total pressure and total temperature at the inlet and the mass flow rate at the outlet were used as boundary conditions. The computations were conducted on a 2D theoretic model and, therefore, it does not account for manufacturing tolerances and endwall losses. The mesh has approximately 250,000 elements, including a boundary layer around the blade’s walls through inflation settings.

It was also shown there that the total pressure probe at the outlet of the stator was positioned immediately downstream of the shock wave. This shows that the total pressure measurement at that location includes the shock wave losses. This is visible in

Figure 14, where the Mach number distribution from the numerical results for the nominal regime on air is given. The measurement points equivalent to the one represented in

Figure 4 are represented by black dots in

Figure 14.

To estimate the performances of the vane row, a comparison of the measured pressure losses is given in

Table 9. The initial estimation of the losses was used in the preliminary design of the nozzle and was based on literature data and experience. The pressure losses measured for air are larger with 2.9% and for methane are with 8.9% lower than the initial estimation. The difference between the measured pressure losses between the methane and air test cases is 6%.

Although these results show a good initial estimation and a difference below 10% for the expected value of the pressure losses when changing the working fluid, some observations must be made. Firstly, these values cannot be used as a comparison metric on their own because the nominal regime was measured for slightly different inlet pressures for methane as compared to air. Secondly, the total pressure at the outlet of the nozzle is measured in a single point, immediately downstream of the shockwave, in a region where there are considerable variations in the flow parameters for very small distances. For a better estimation of the losses, rather than a punctual measurement, more measurement points should be included in the experimental setup in future work. At the same time, increasing the data acquisition frequency for the total pressure measurement is required to capture the shock wave fluctuations.

Since the method heavily relies on ideal gas assumptions, real gas effects are neglected and the regime needs to be assessed accordingly. Furthermore the impact of the higher temperature and potentially the impact of combustion is neglected here as well.

5. Conclusions

This study presents the experimental validation of an analytical methodology for estimating supersonic turbine performance under variations in working fluid. A Mach-similarity-based approach was successfully applied to a stationary two-dimensional stator rig, demonstrating the feasibility of predicting turbine performance across fluids. The test campaign, conducted with both air and methane, covered the nominal operating regime of a 100 kg payload micro-launcher turbopump as well as a broad range of flow conditions, from subsonic to fully supersonic.

The results confirm that measured total pressure losses for air and methane align well with preliminary design estimates, differing by less than 10%. Pressure distributions along the nozzle also showed excellent agreement, within measurement uncertainty, thereby validating the Mach similarity criterion for fluids with comparable thermodynamic properties. Furthermore, the analytical equations developed in this work provide rapid estimates of mass flow rate: methane values could be predicted from air data within 7% of experimental results across all tested regimes.

These findings establish a practical tool for rapidly predicting turbine performance under fluid substitution. Unlike most prior studies, which have relied primarily on numerical data or limited turbine data at larger scales, this work provides experimental evidence at the micro-launcher turbopump scale on air and methane, thereby establishing a novel and application-oriented validation of Mach-similarity principles.

Such a method is particularly relevant in the transition toward environmentally sustainable propulsion systems, offering applications in hardware repurposing, digital twin development, and mission flexibility. By enabling fast screening of alternative working fluids without hardware redesign, the methodology reduces costs, accelerates development, and supports safe and efficient operation of future green launchers. A concrete example of potential applications is the need to transition to reusable, green launchers, for which a predictive model can quickly assess turbine feasibility with different propellants or fuel-rich mixtures. It is also important in mission flexibility, where fuel composition or mixture ratio may vary.

6. Limitations and Future Work

The present study was limited to stator-only experiments, without a rotor stage or direct power measurements. While this configuration enabled controlled validation of Mach similarity in the nozzle flow, it cannot capture full turbine performance under rotating conditions.

Tests were also performed at ambient temperature, which does not replicate the thermal environment of actual turbopump operation. In addition, methane tests were conducted at slightly reduced inlet pressure, which complicates direct comparison with air. The total pressure losses analysis relied on a single-point pressure measurement downstream of the shockwave, restricting spatial resolution.

Beyond the validation results, the novelty of this work lies in providing the first experimental evidence of Mach-similarity applicability for supersonic turbine stators at the micro-launcher scale. Unlike most prior studies, which are limited either to numerical assessments or to larger-scale turbomachinery, this study demonstrates experimentally that accurate performance predictions can be achieved when switching between fluids as different as air and methane. The choice of methane is particularly significant in the context of emerging green micro-launchers, where propellant flexibility and environmental considerations are becoming central to launcher design.

A second novel contribution is the demonstration that Mach-similarity principles remain valid even at very small scales, where manufacturing tolerances, viscous effects, and boundary layer thickness typically challenge similarity assumptions. By combining detailed stator measurements with a fast analytical framework, the study shows that multi-fluid adaptability can be assessed without the need for extensive CFD or repeated experimental campaigns. This creates a practical pathway for future turbopump development, enabling rapid evaluation of alternative working fluids and increasing the sustainability and flexibility of next-generation launch systems.

Future research should extend this validation to full rotating turbines under representative operating conditions to confirm overall efficiency and power predictions. Semi-empirical models could be developed using the current experimental data to further refine the analytical framework. Moreover, applying the methodology to additional fluids and to other internal flow components would broaden its utility, particularly in contexts where Mach similarity and fluid substitution can deliver both performance and sustainability benefits.