Hardware-in-the-Loop Testing of Spacecraft Relative Dynamics and Tethered Satellite System on a Tip-Tilt Flat-Table Facility

Abstract

1. Introduction

2. System Architecture

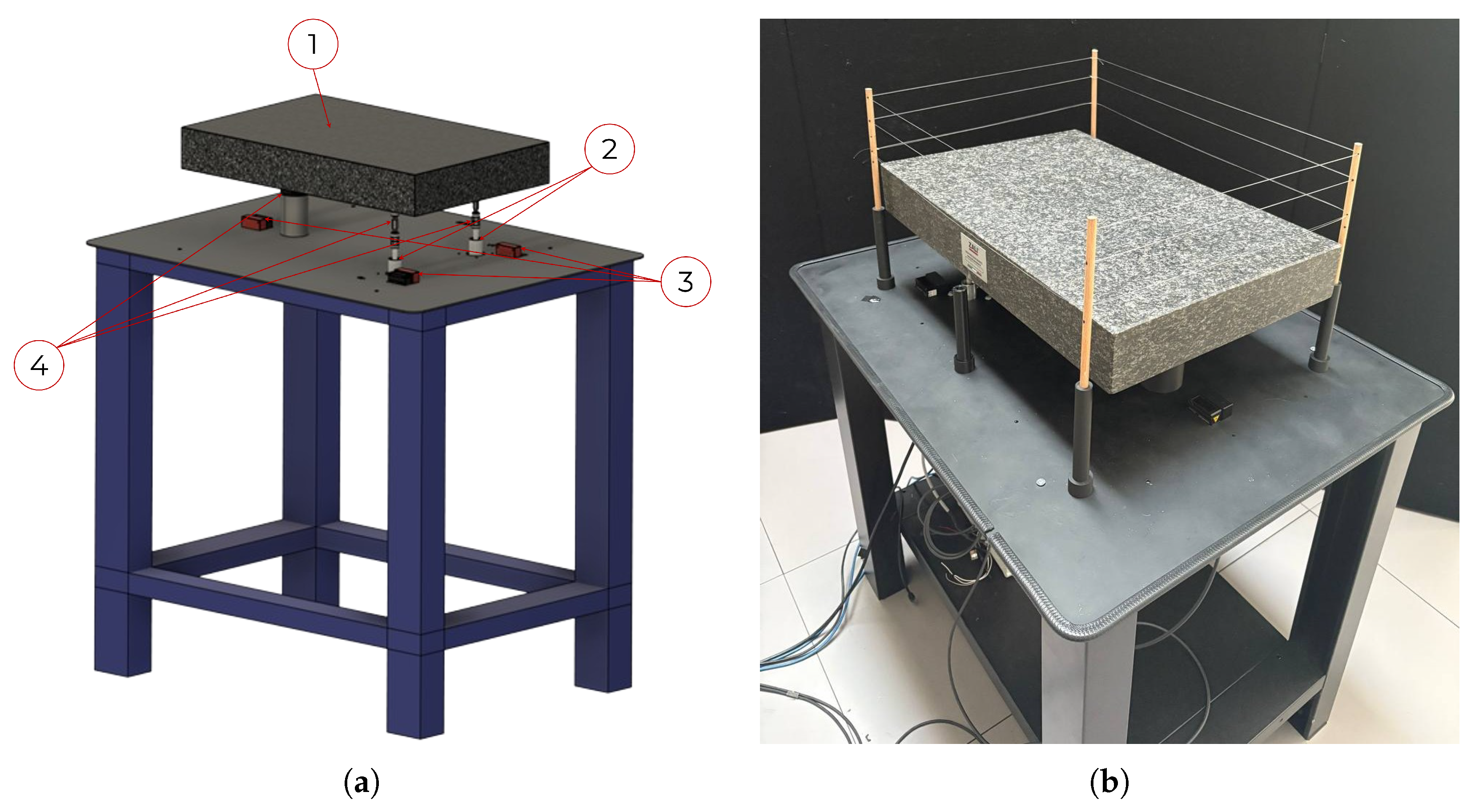

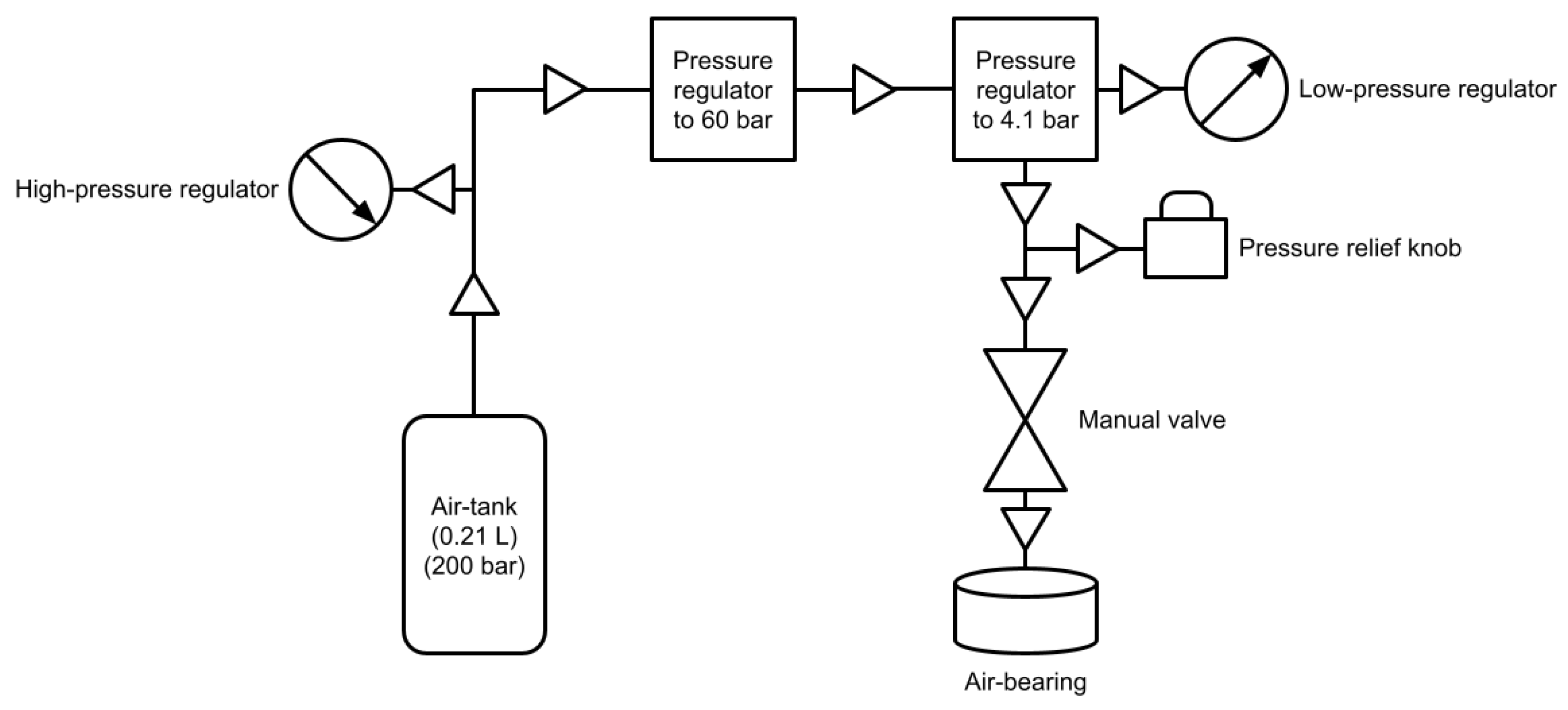

2.1. Floating Platform

2.2. Floating Spacecraft Simulator

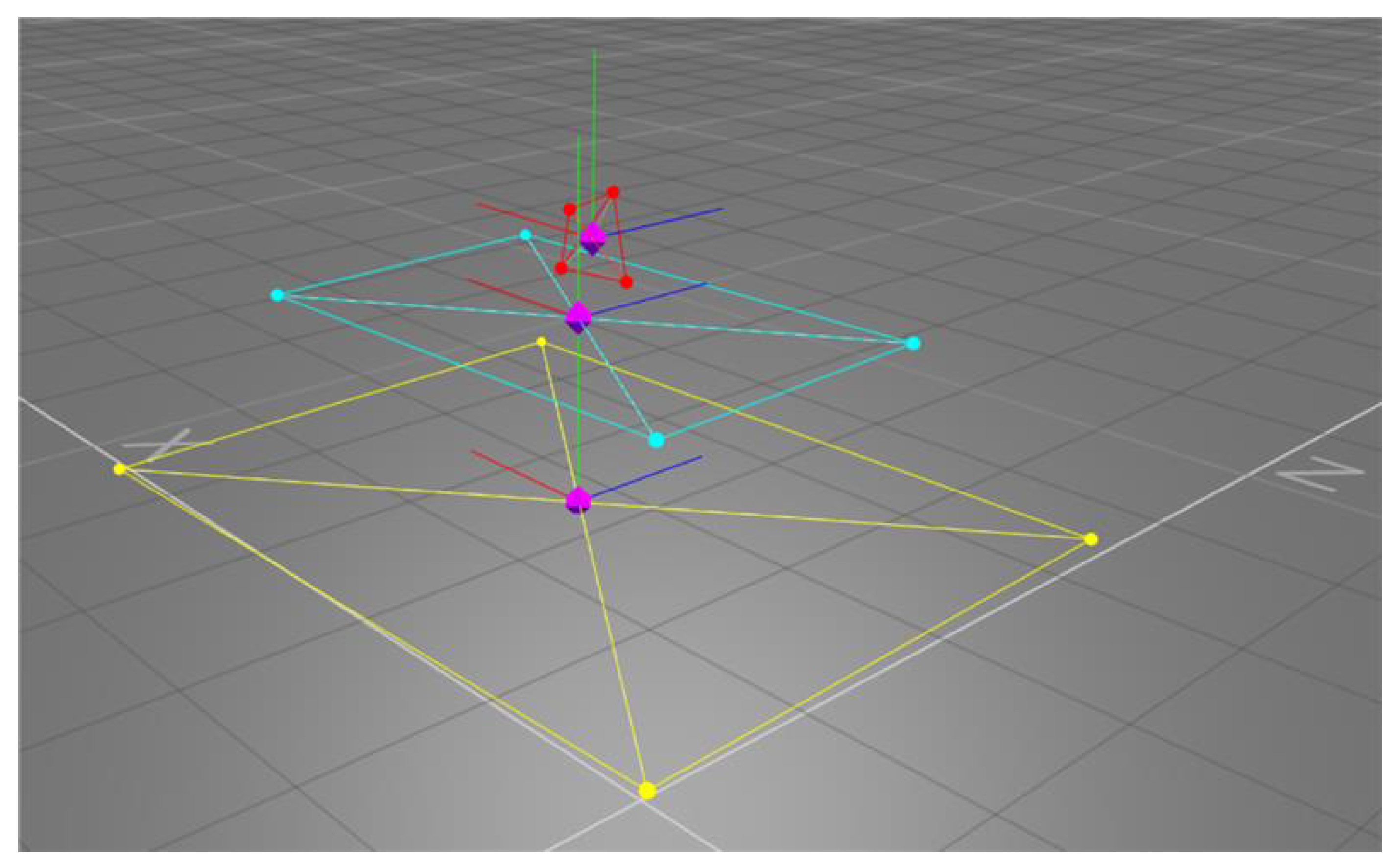

2.3. Motion Capture System

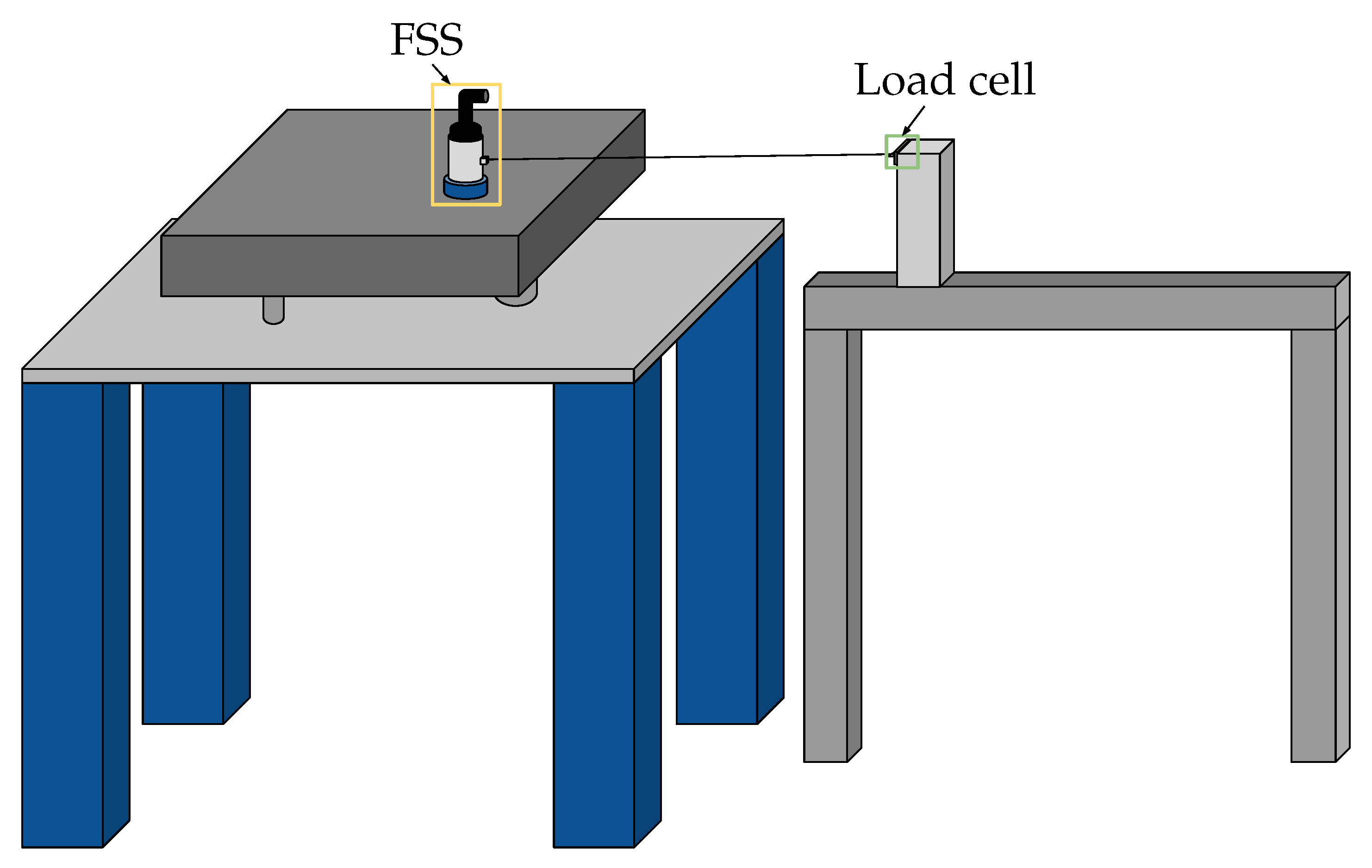

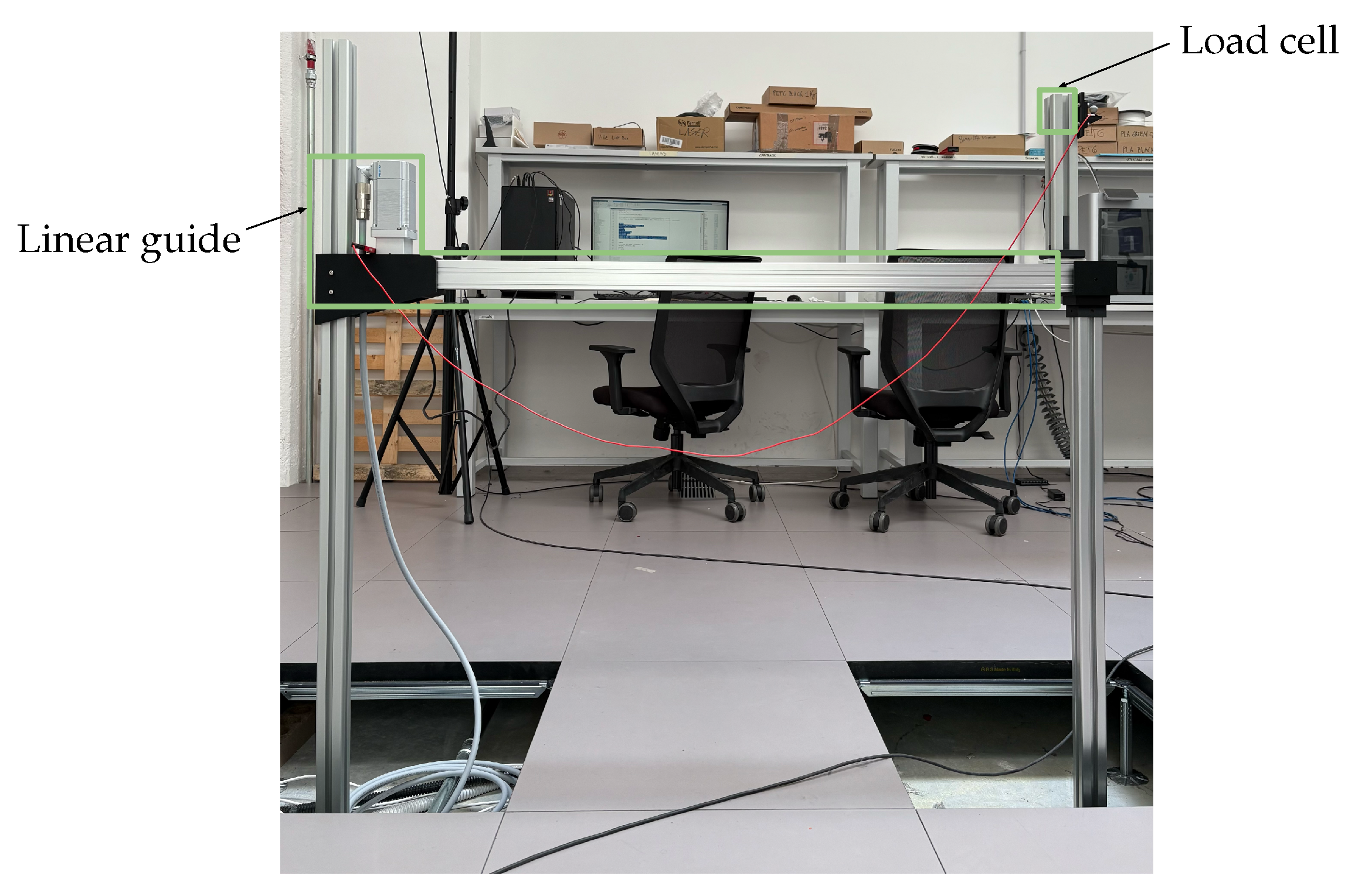

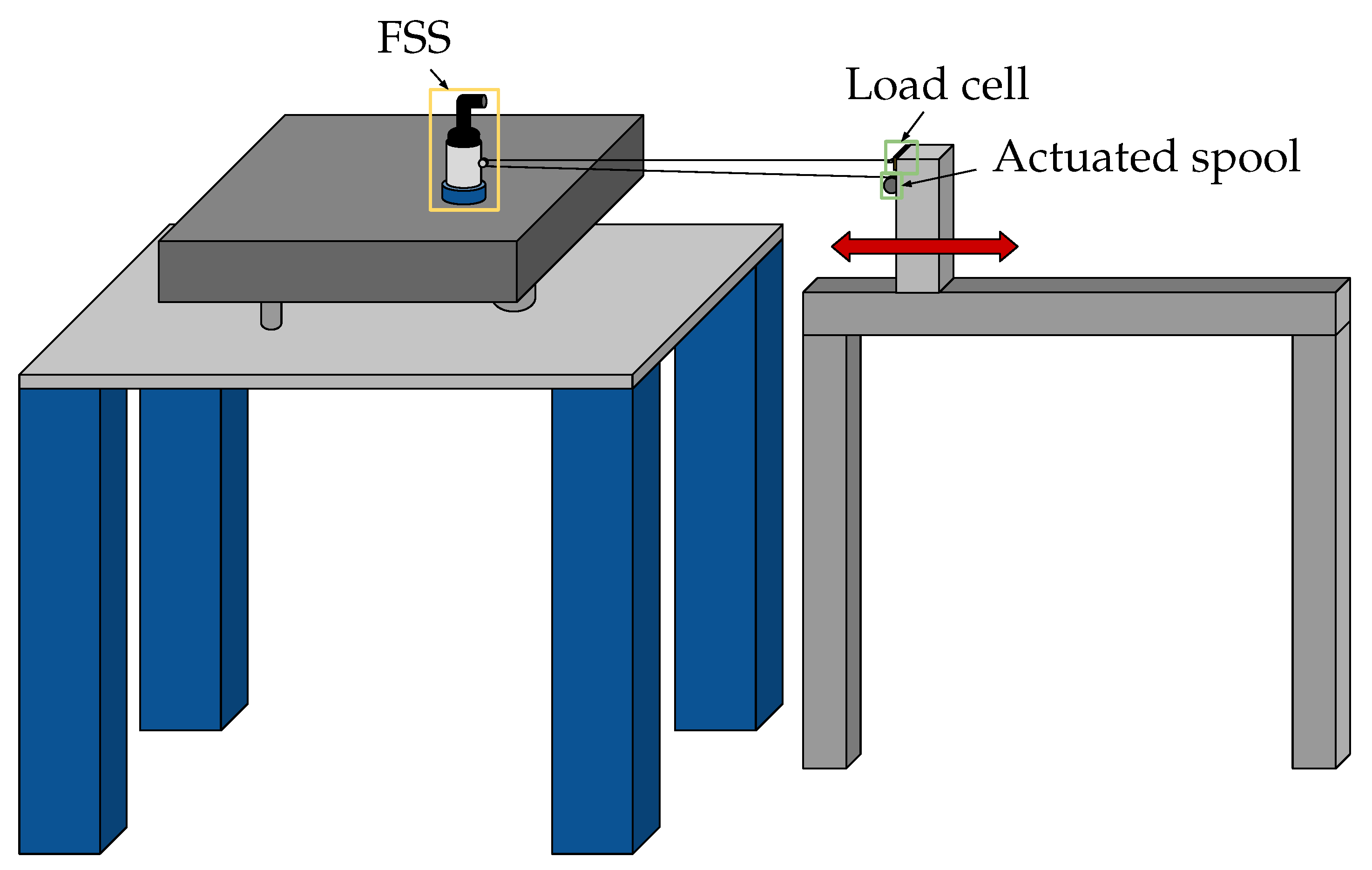

2.4. Tether Testing System

3. Mathematical Models for On-Orbit Dynamics

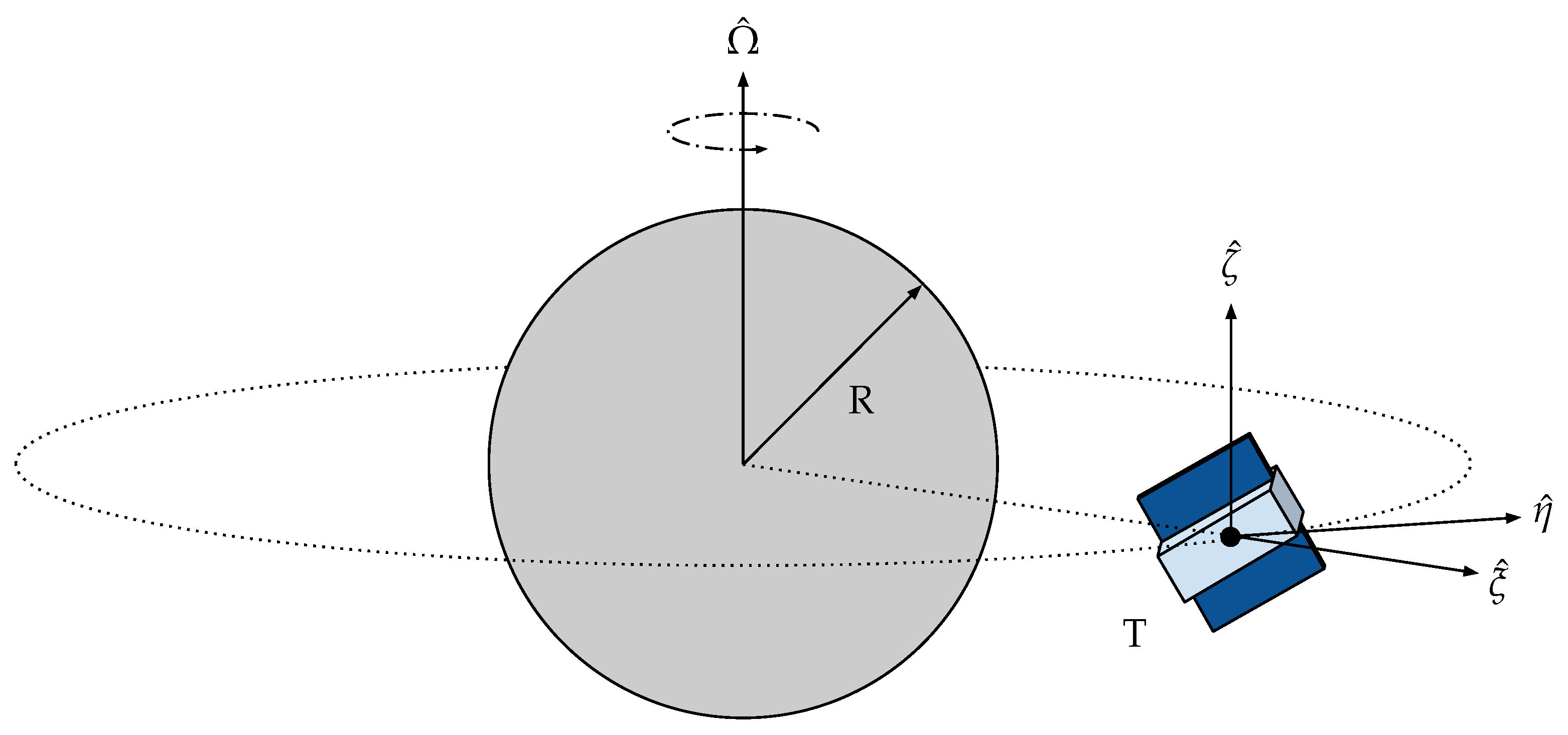

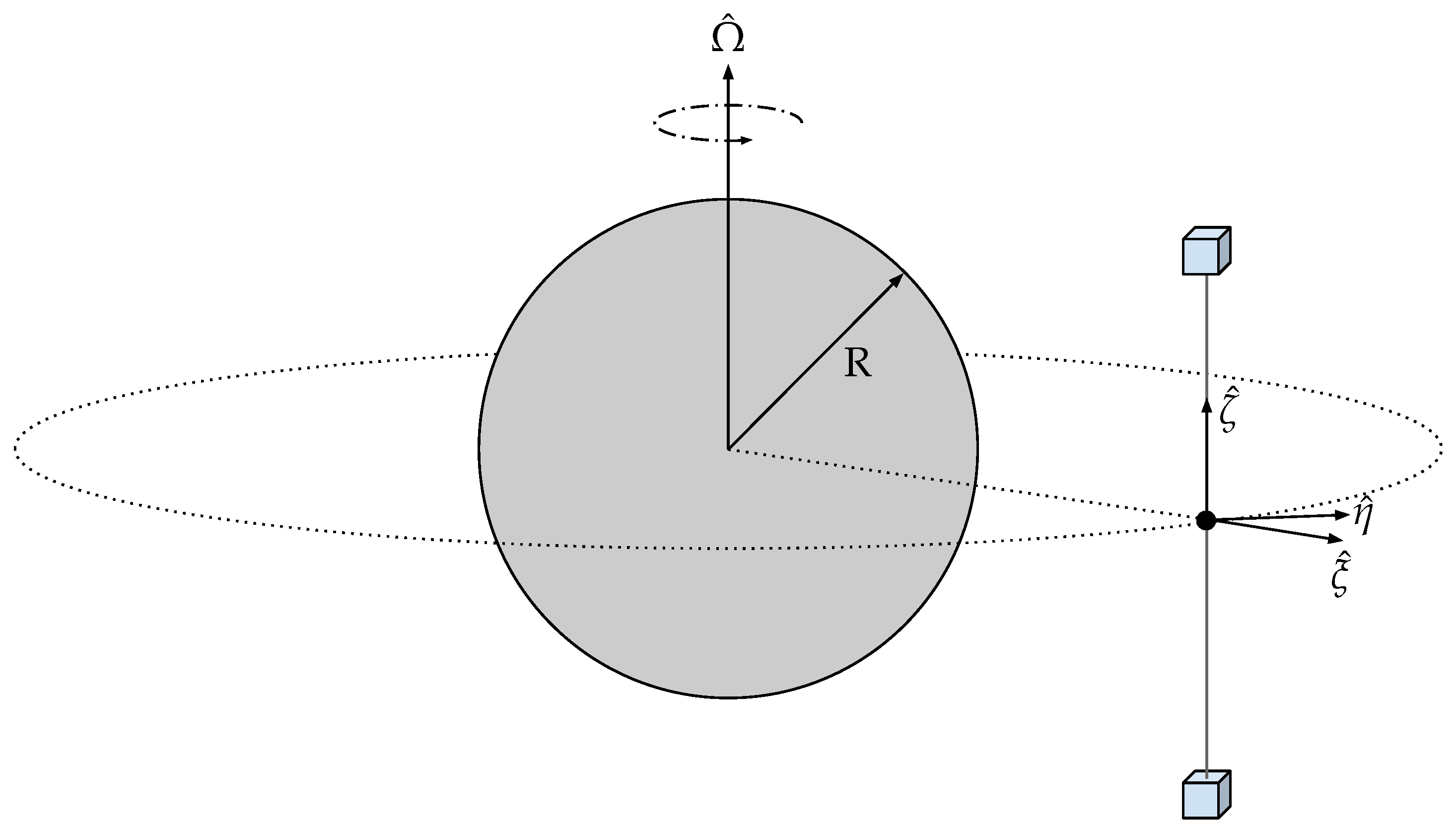

3.1. In-Orbit Dynamical Model

3.2. Buckingham Theorem and Scaled Orbital Dynamics

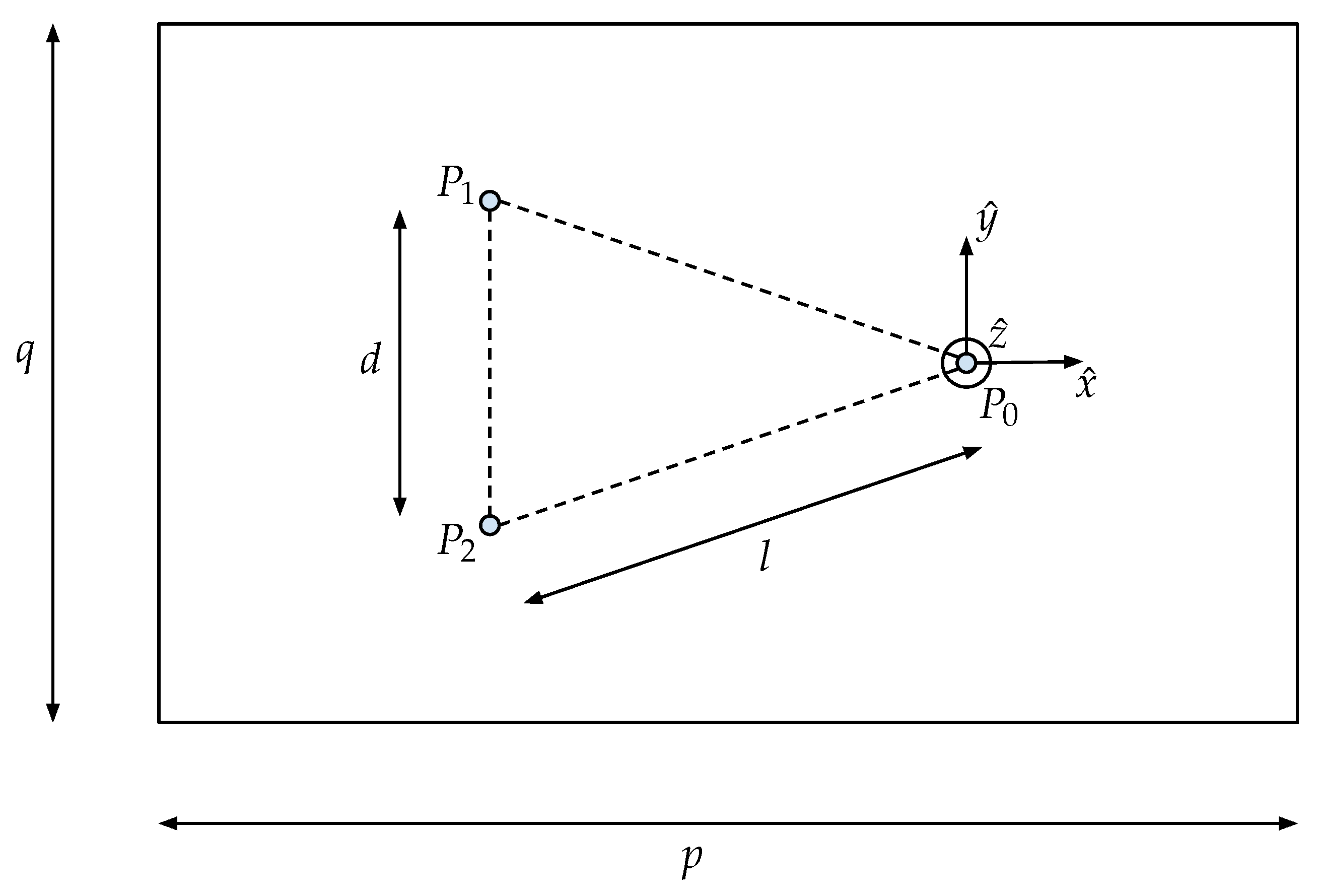

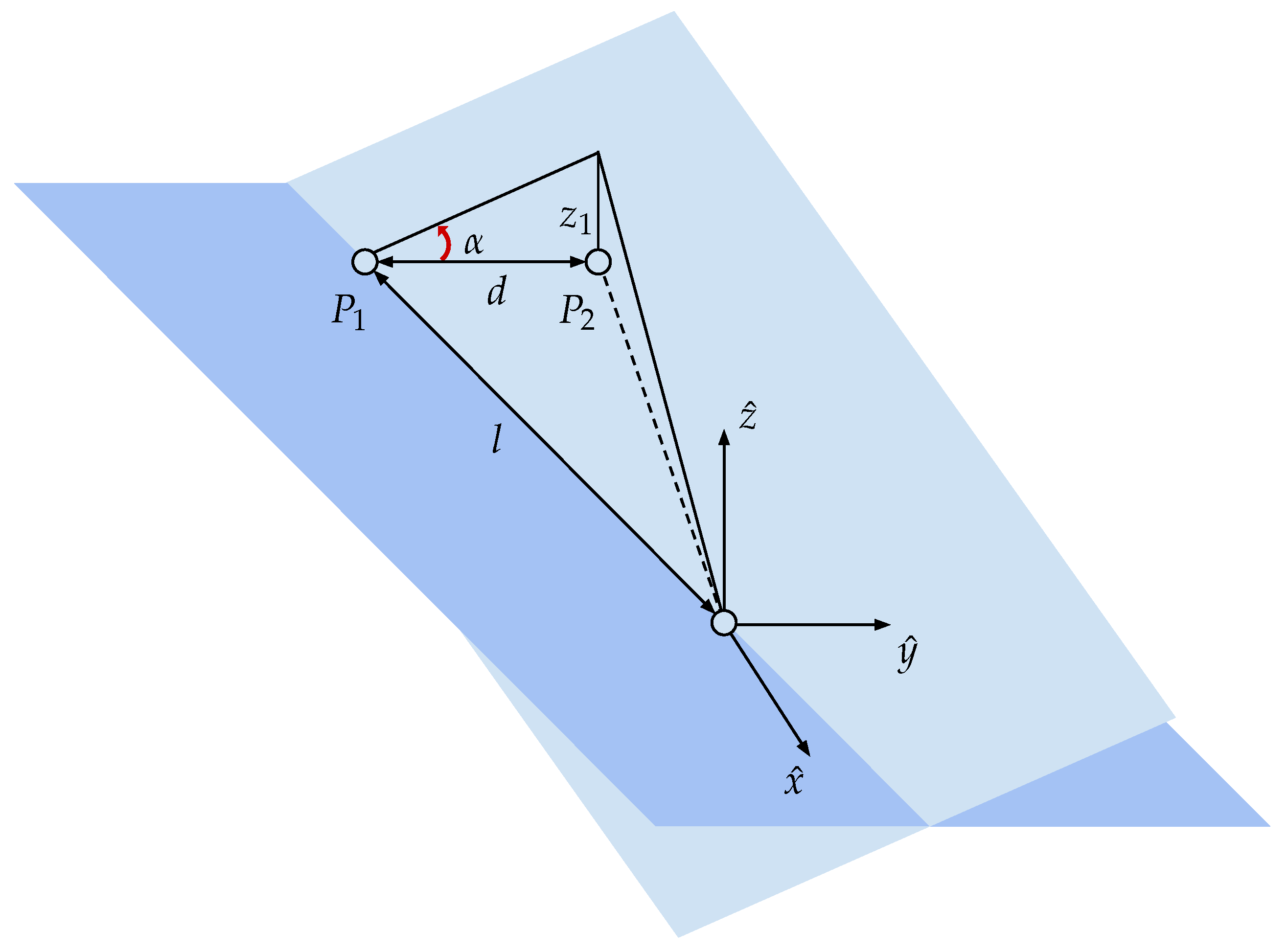

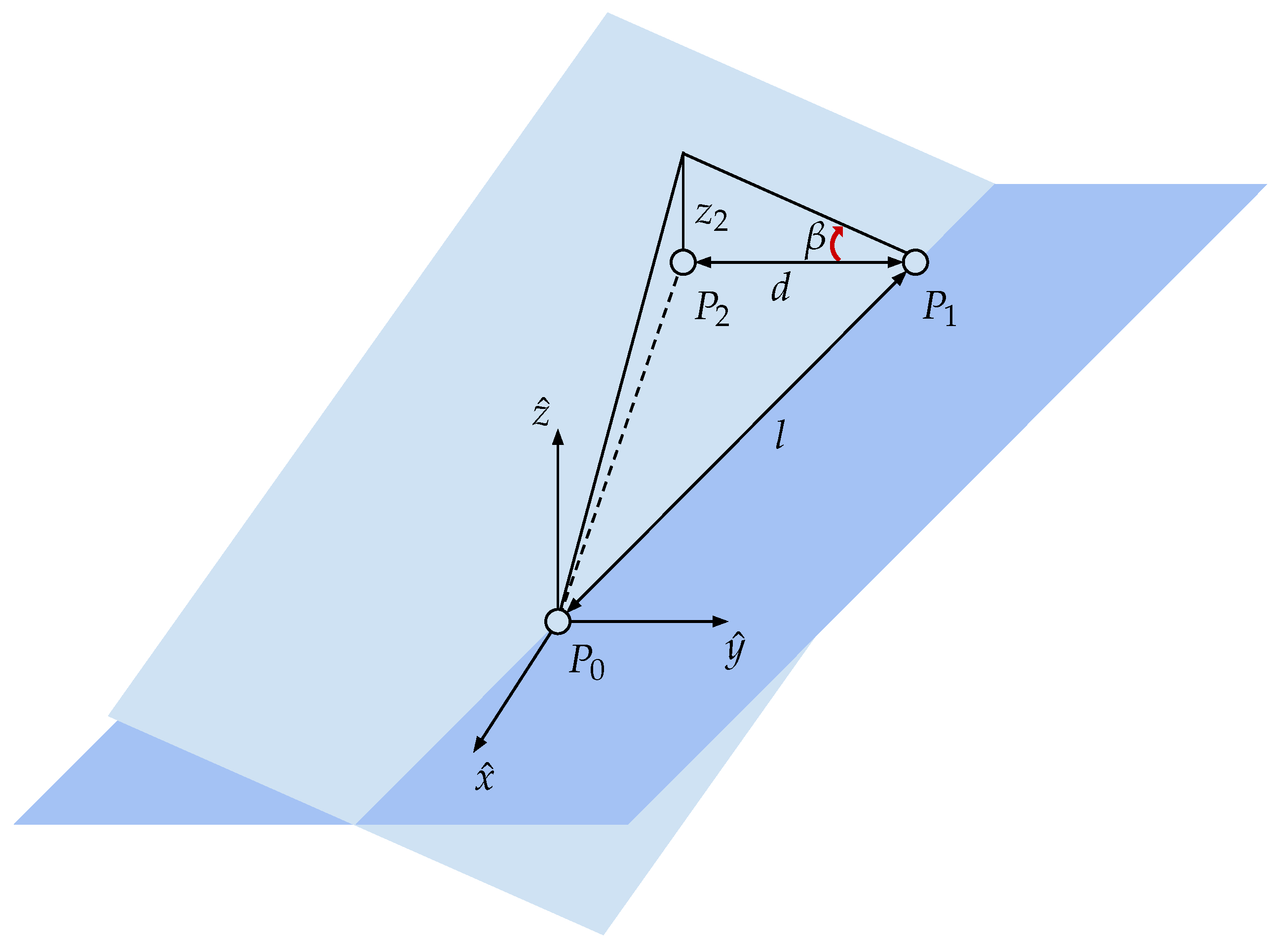

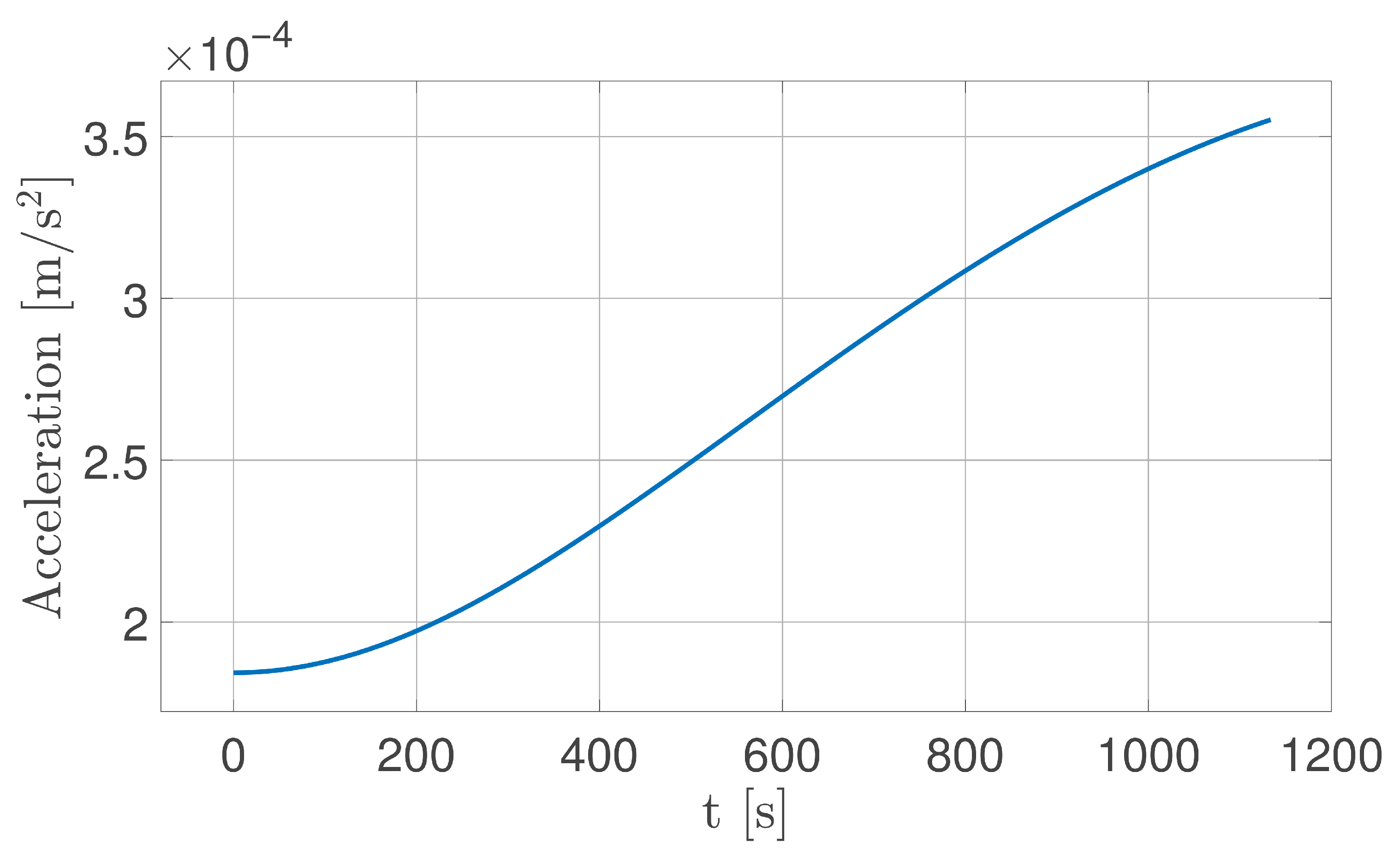

3.3. Testbed System and Models

4. Test Campaign

4.1. Closed-Loop Calibration

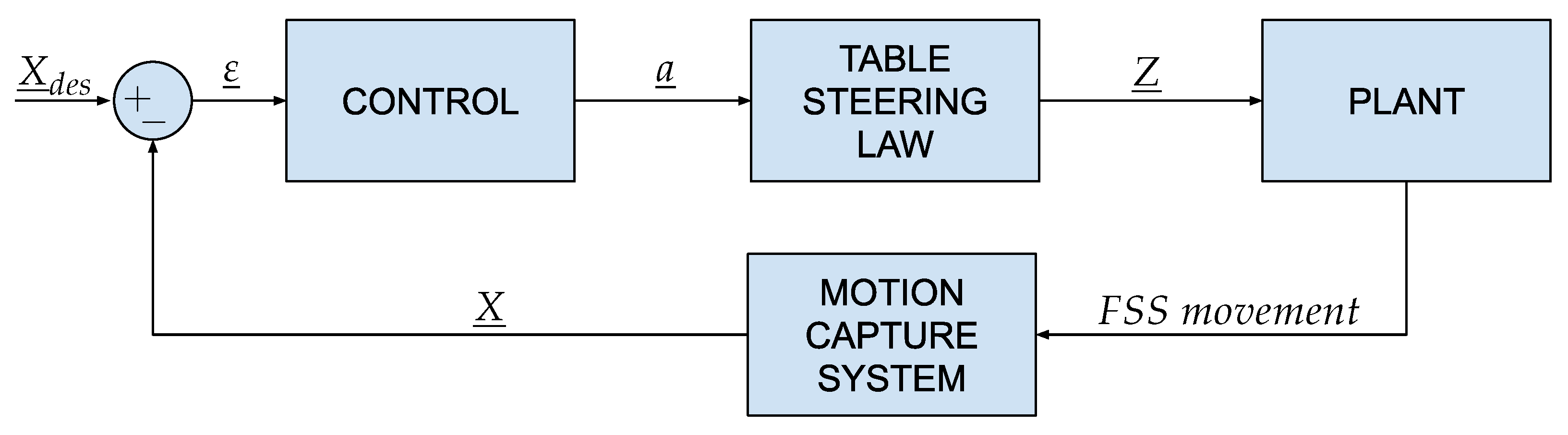

4.2. Emulation of Linearized Relative Dynamics

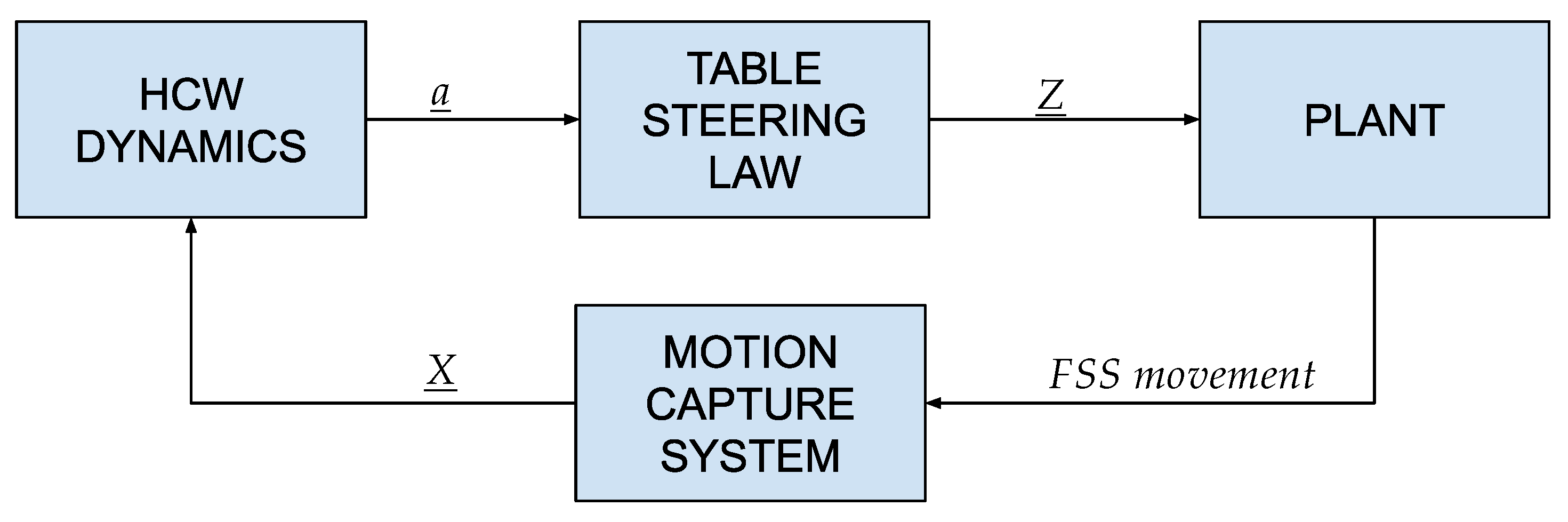

4.3. Fully Deployed Tether Dynamics

5. Numerical and Experimental Results

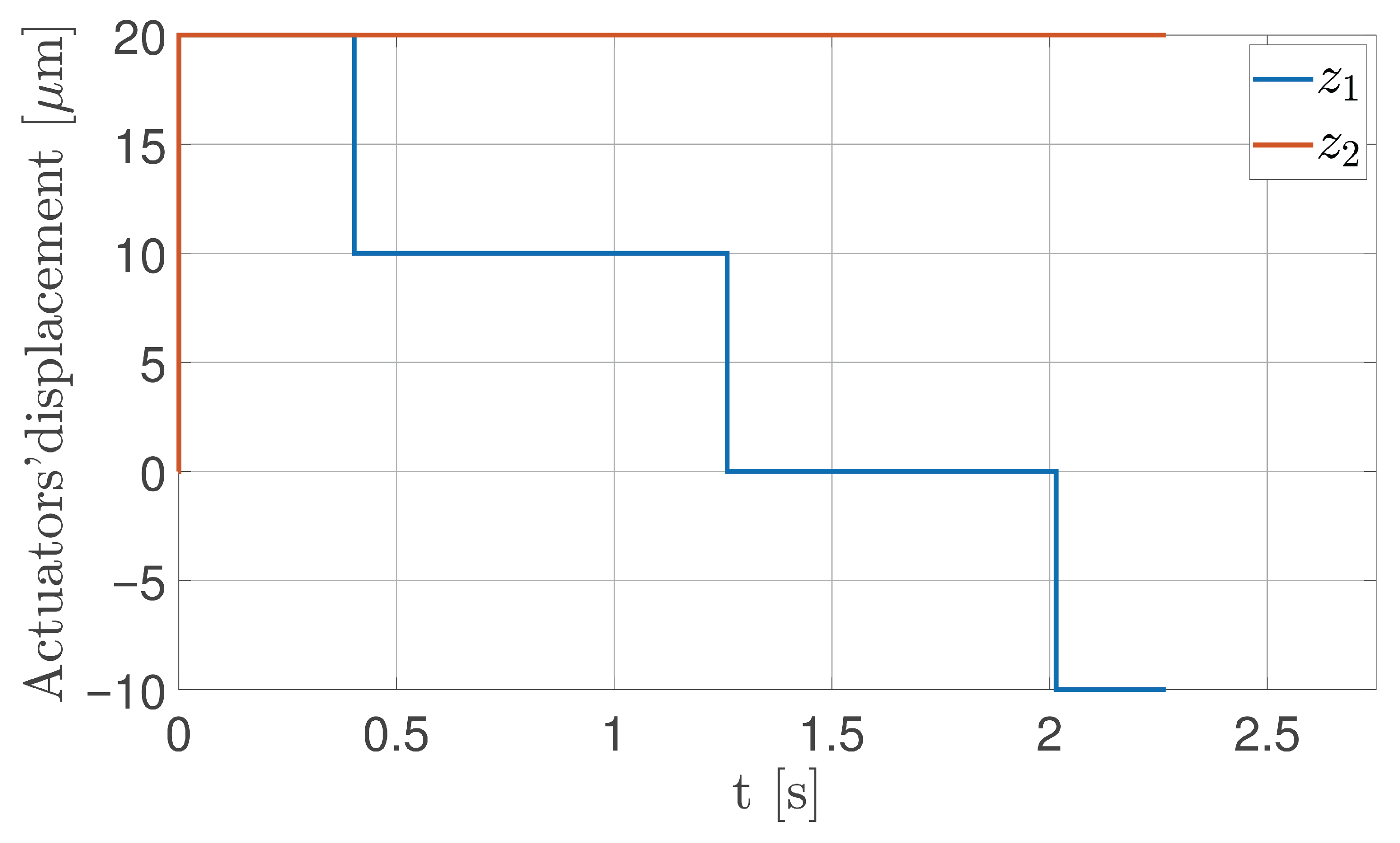

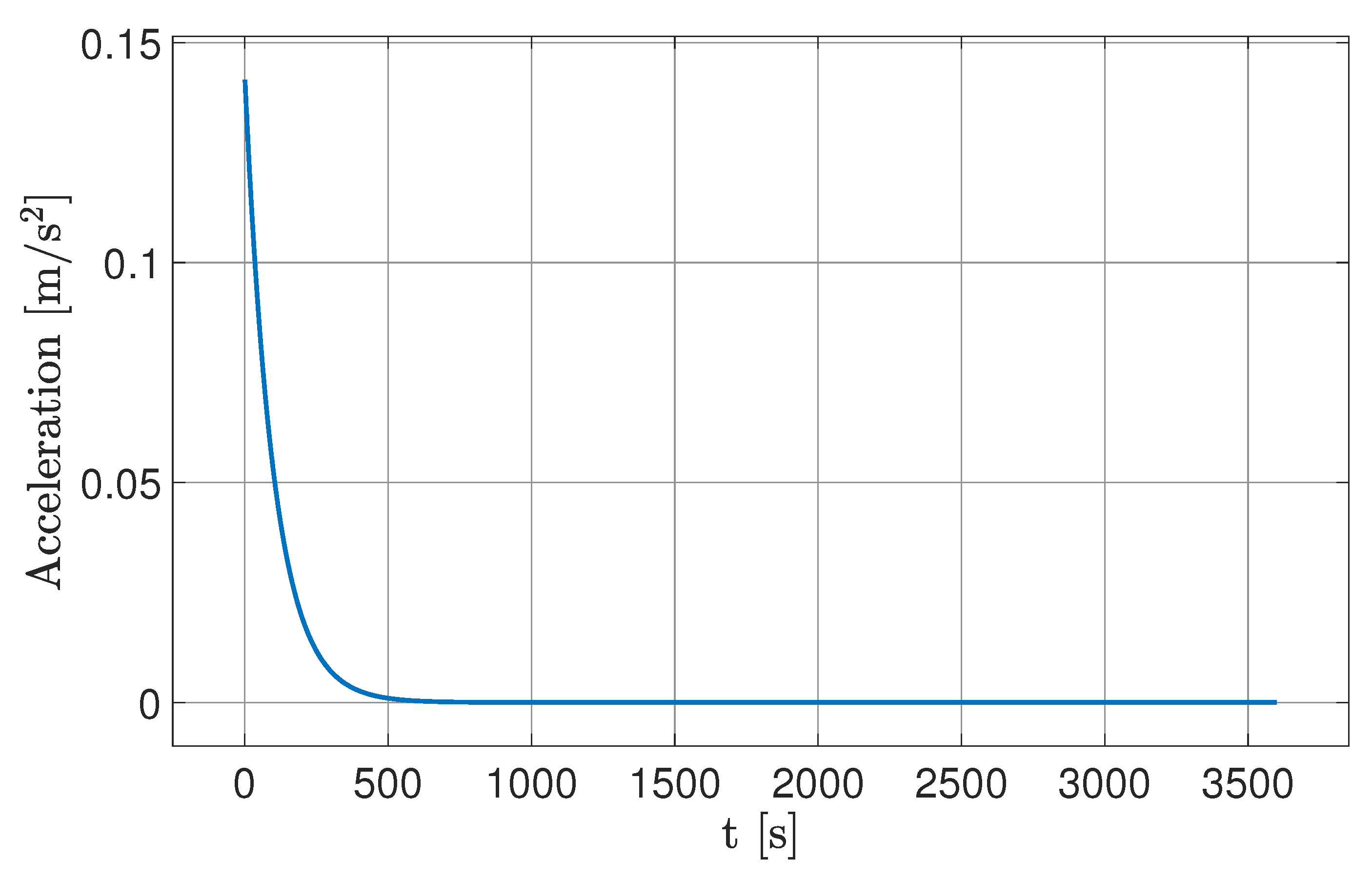

5.1. Closed-Loop Calibration

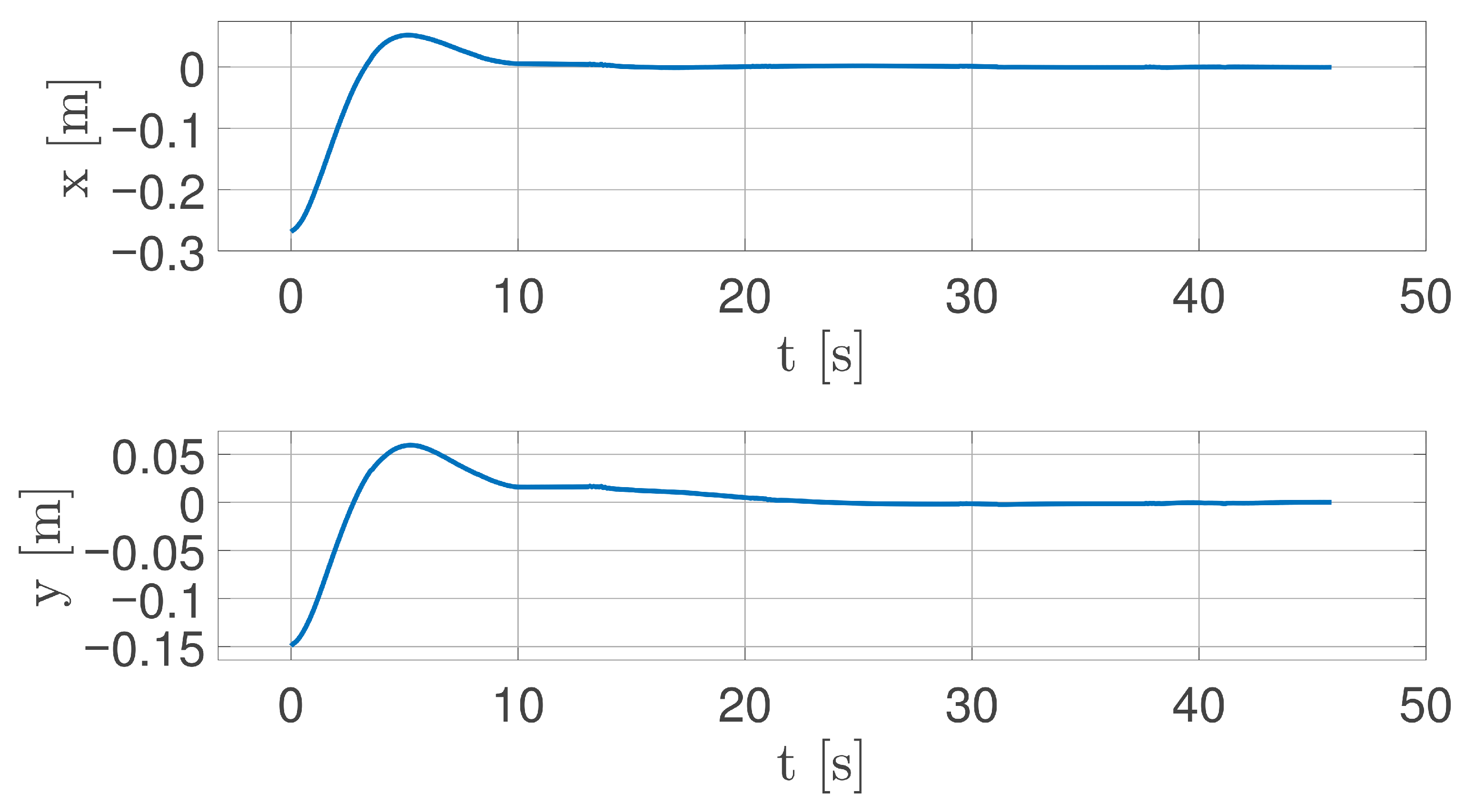

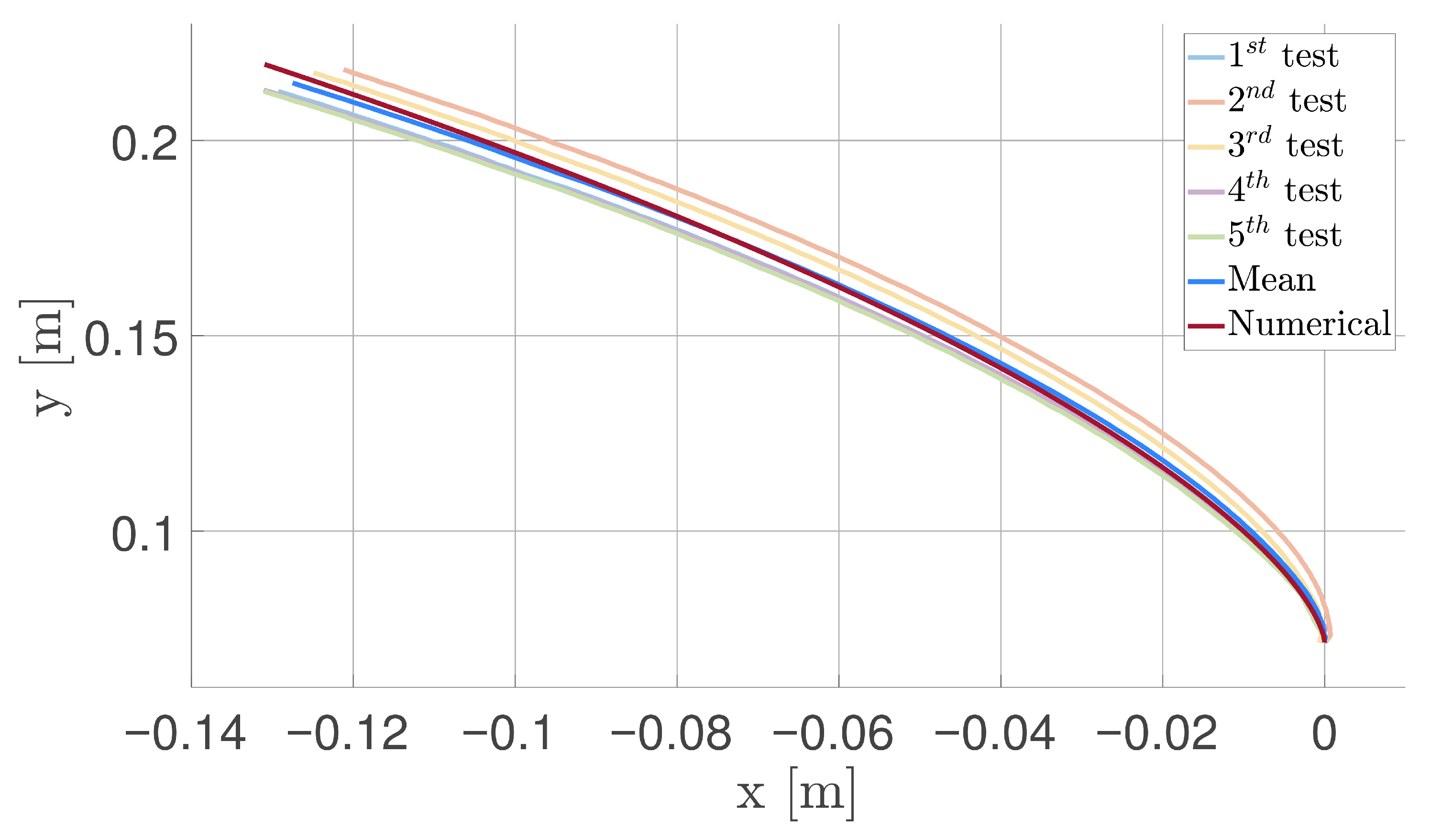

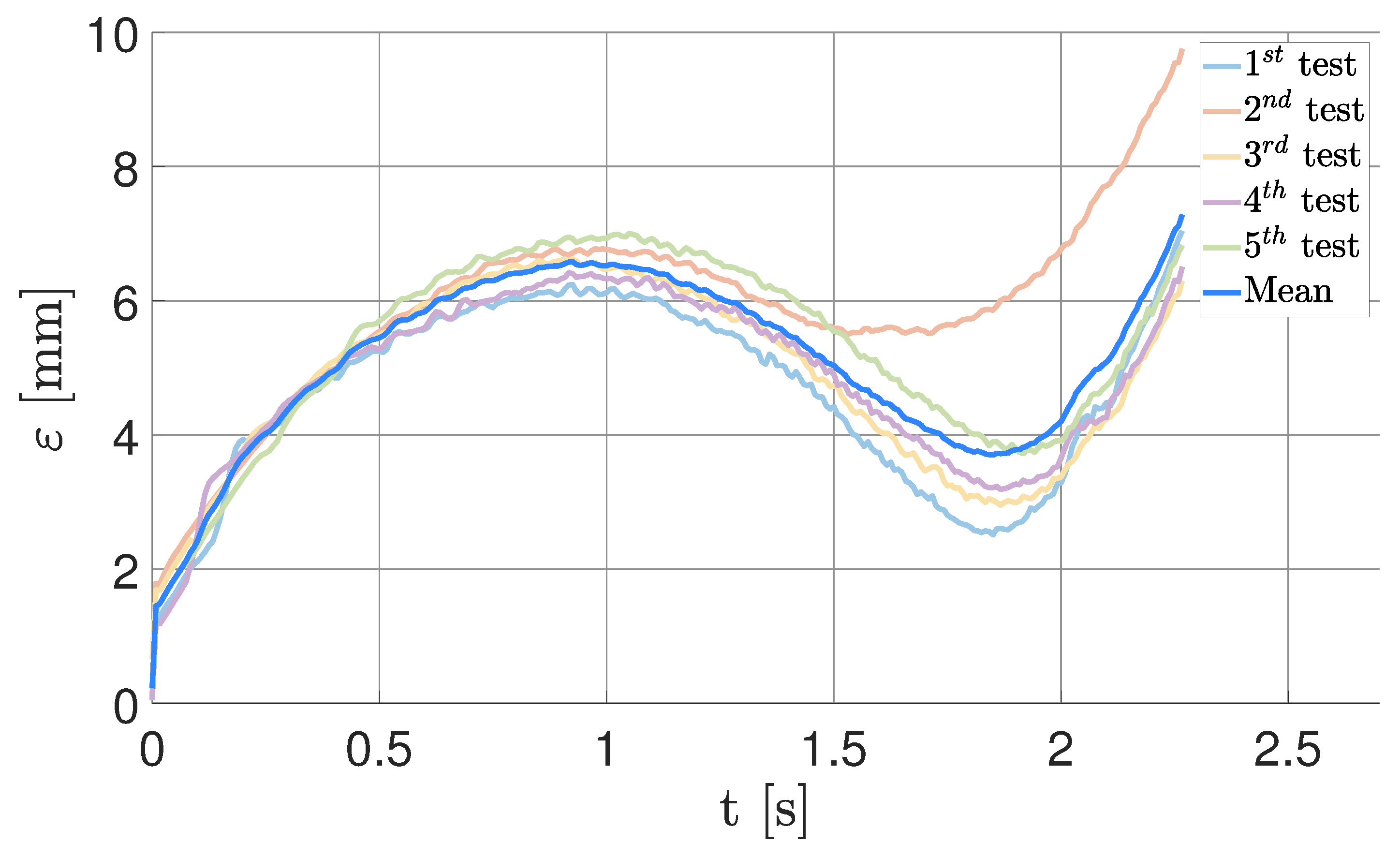

5.2. Emulation of Linearized Relative Dynamics

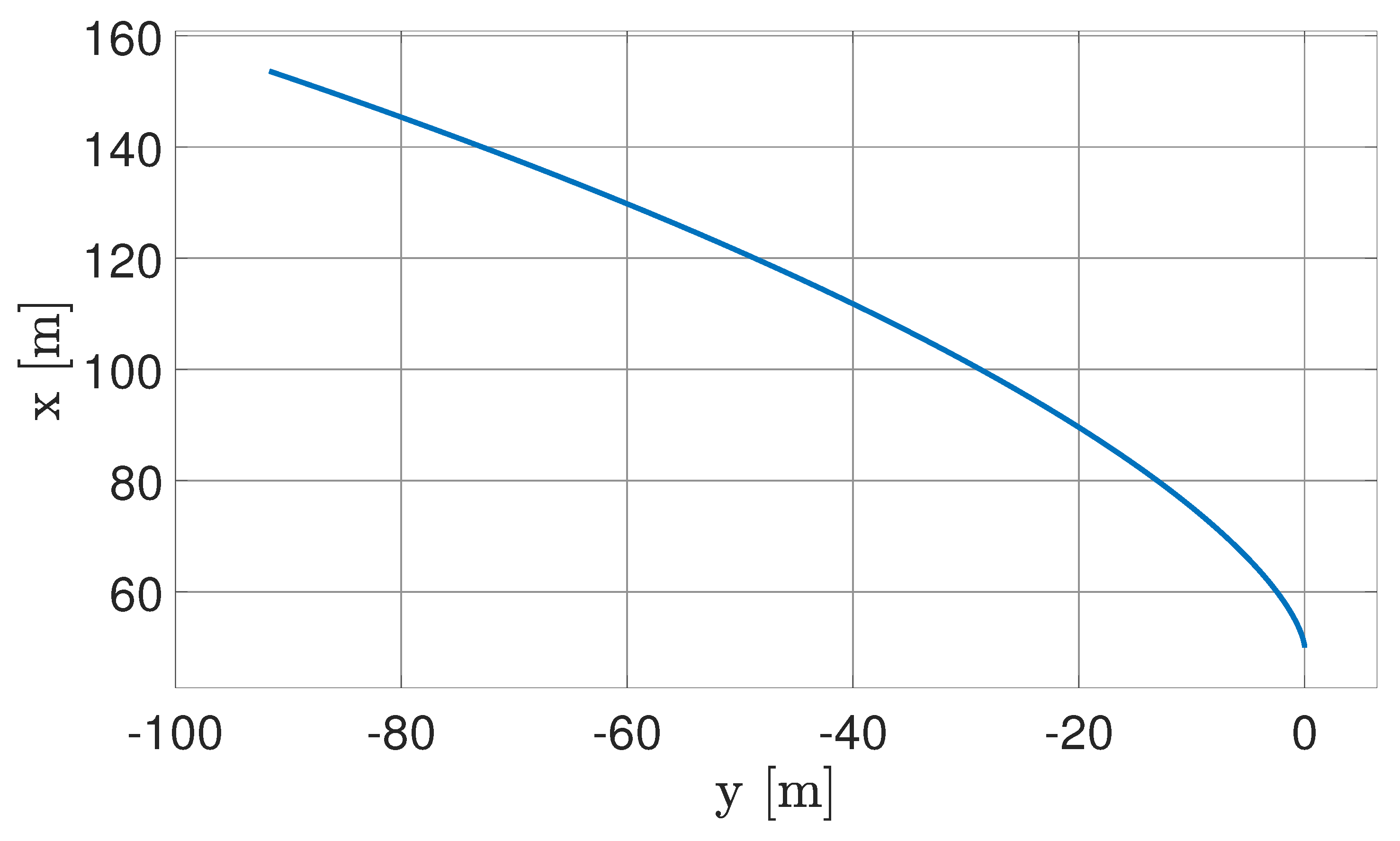

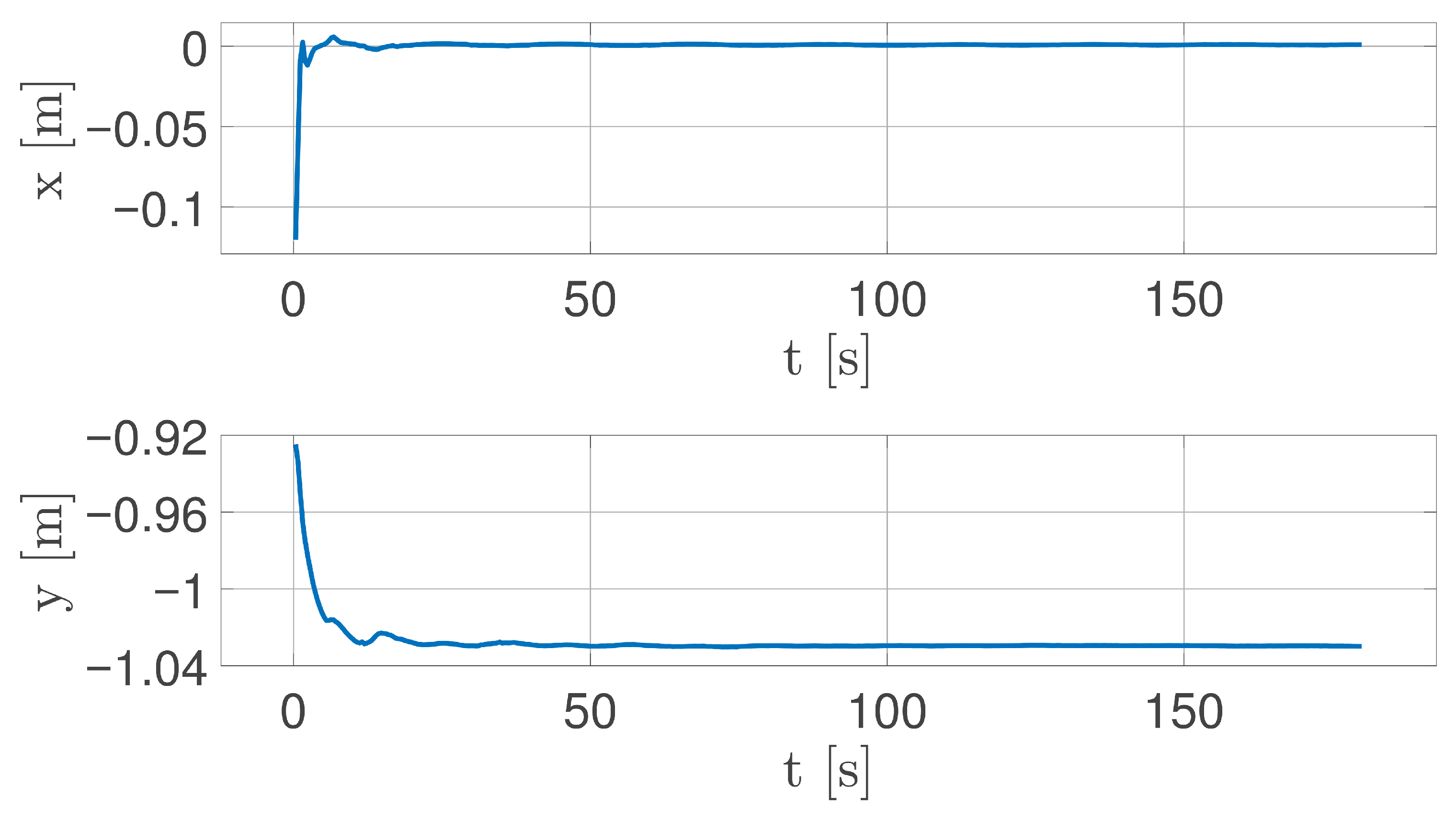

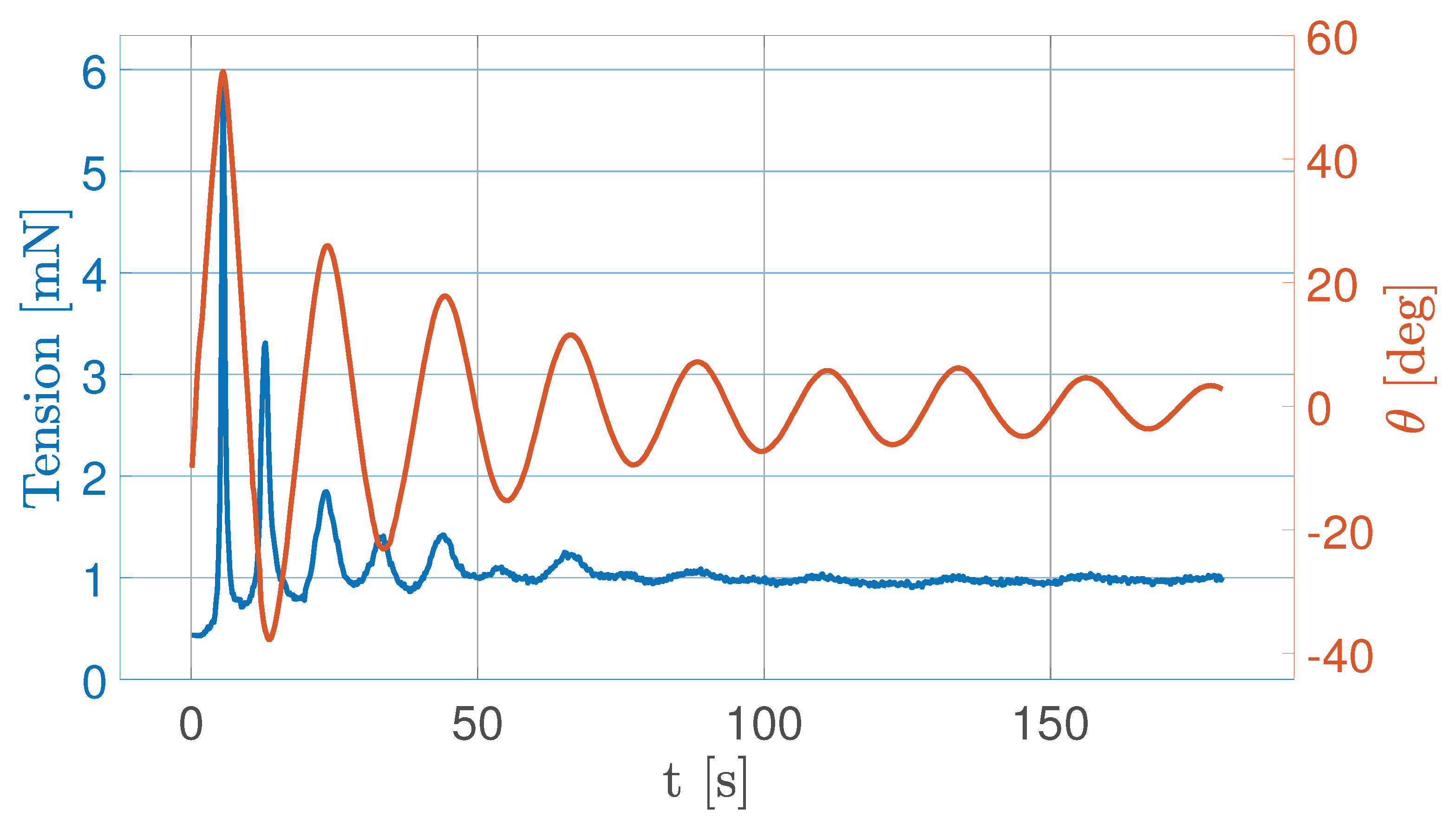

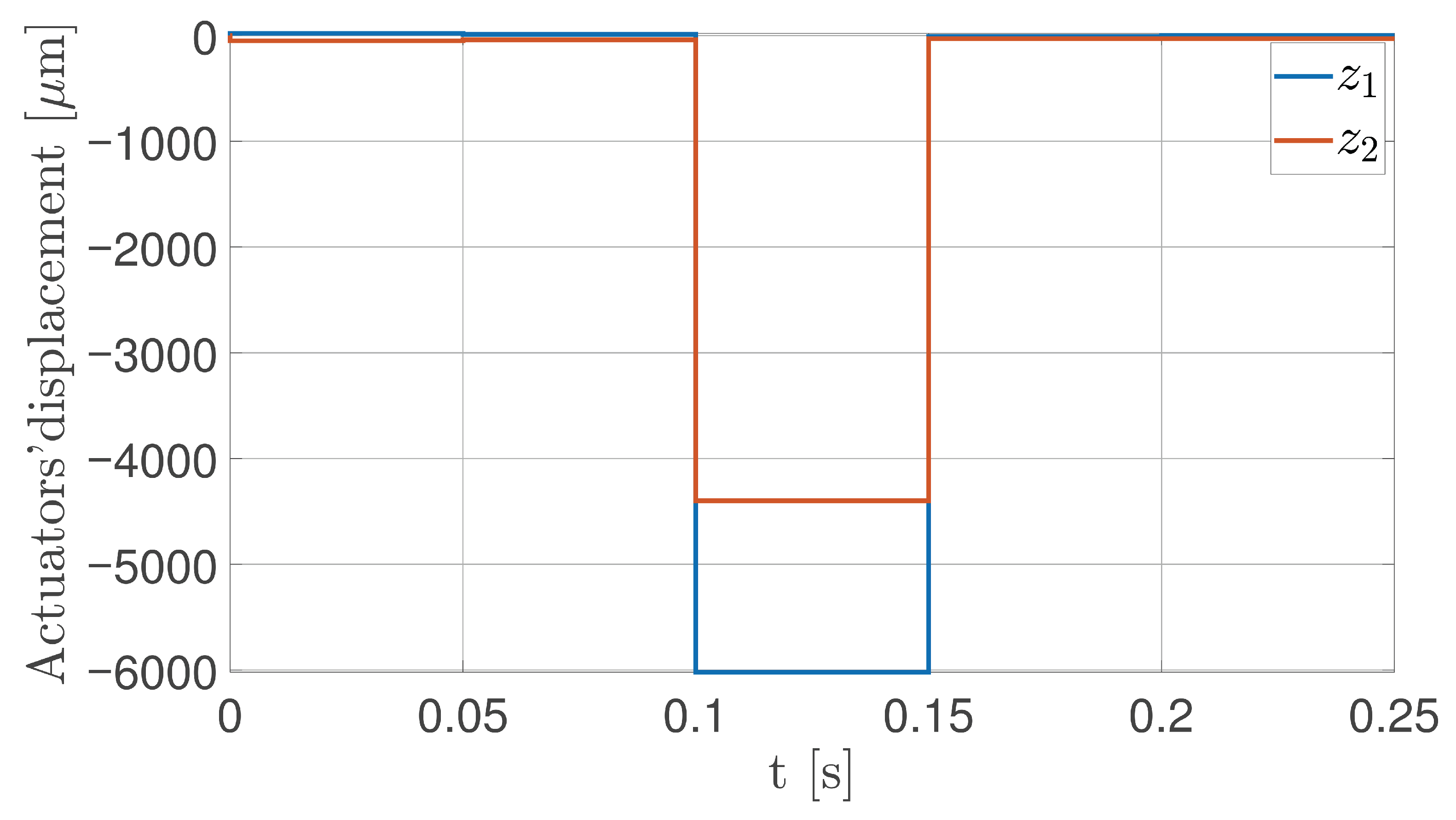

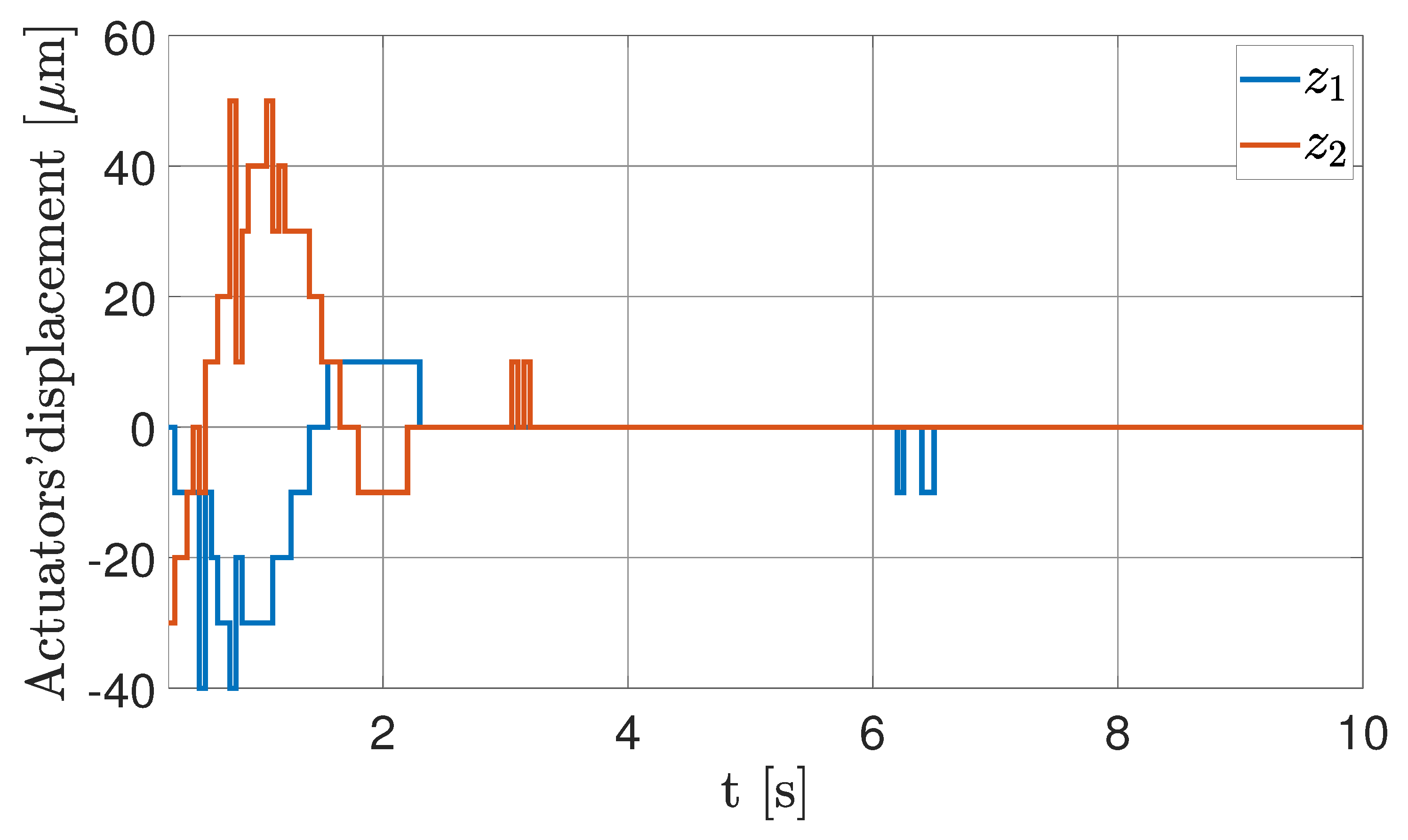

5.3. Fully Deployed Tether Dynamics

6. Conclusions

7. Patents

- (1)

- “Method and Apparatus for the Stabilization of a Satellite Formation”, [37].Description: “The invention relates to a method for stabilization of the orbital motion set-up of a group of satellites bound to a tether. To this end, the tension of the tether that connects two or more satellites is controlled in order to keep them in the desired flight formation. This effect is obtained by perturbing a satellite to generate a tension component in the tether, which results in a recoil force that brings the system back into a condition of equilibrium. According to a preferred embodiment, the tension T of the tether is obtained by adjusting the disposition of one or more aerodynamic surfaces provided on the satellites at the ends of the tether”.

- (2)

- “Dynamically tilting flat table to impart a time-varying gravity-induced acceleration on a floating spacecraft simulator”, [38].Description: “Disclosed is a planar test bed comprising a planar surface and further comprising mechanical couplings in mechanical communication with the planar table and the supporting legs. The mechanical couplings are translatable to provide three degrees of freedom for orientation of the planar surface. A processor receives position and velocity information describing an object on the planar surface, and calculates a relative acceleration typically using a function aR = f(t, xR, vR, μt). The processor communicates with the mechanical couplings to establish an orientation where a local gravity vector projects onto the planar surface and generates acceleration with magnitude and direction substantially equal to the desired acceleration aR The operations occur in cyclic fashion so the desired accelerations and planar orientations are updated as an object transits over the planar surface”.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CCS | Cartesian Coordinate System |

| DCM | Direction Cosine Matrix |

| EoM | Equation of Motion |

| FP | Floating Platform |

| FSS | Floating Spacecraft Simulator |

| GN&C | Guidance, Navigation, and Control |

| HCW | Hill–Clohessy–Wiltshire |

| HIL | Hardware-In-the-Loop |

| MC | Master Console |

| MCS | Motion Capture System |

| LQR | Linear Quadratic Regulator |

| LVLH | Local-Vertical–Local-Horizontal |

| PID | Proportional–Integrative–Derivative |

| TSS | Tethered Satellite System |

| TTS | Tether Testing System |

| VLEO | Very Low Earth Orbit |

References

- Curti, F.; Romano, M.; Bevilacqua, R. Lyapunov-Based Thrusters’ Selection for Spacecraft Control: Analysis and Experimentation. J. Guid. Control. Dyn. 2010, 33, 1143–1160. [Google Scholar] [CrossRef]

- Romano, M.; Friedman, D.A.; Shay, T.J. Laboratory Experimentation of Autonomous Spacecraft Approach and Docking to a Collaborative Target. J. Spacecr. Rocket. 2007, 44, 164–173. [Google Scholar] [CrossRef]

- Wilde, M.; Clark, C.; Romano, M. Historical survey of kinematic and dynamic spacecraft simulators for laboratory experimentation of on-orbit proximity maneuvers. Prog. Aerosp. Sci. 2019, 110, 100552. [Google Scholar] [CrossRef]

- Fernandez, B.R.; Herrera, L.; Hudson, J.; Romano, M. Development of a tip-tilt air-bearing testbed for physically emulating proximity-flight orbital mechanics. Adv. Space Res. 2023, 71, 4332–4339. [Google Scholar] [CrossRef]

- De Stefano, M.; Mishra, H.; Giordano, A.M.; Lampariello, R.; Ott, C. A Relative Dynamics Formulation for Hardware- in-the-Loop Simulation of On-Orbit Robotic Missions. IEEE Robot. Autom. Lett. 2021, 6, 3569–3576. [Google Scholar] [CrossRef]

- Shabana, A.A. Dynamics of Multibody Systems, 1st ed.; Cambridge University Press: New York, NY, USA, 2020. [Google Scholar]

- Rybus, T.; Seweryn, K. Planar air-bearing microgravity simulators: Review of applications, existing solutions and design parameters. Acta Astronaut. 2016, 120, 239–259. [Google Scholar] [CrossRef]

- Pletser, V.; Kumei, Y. Parabolic flights. In Generation and Applications of Extra-Terrestrial Environments on Earth; University Medical Center: Amsterdam, The Netherlands, 2015; pp. 61–73. [Google Scholar]

- Seibert, G.; Battrick, B.T. The History of Sounding Rockets and Their Contribution to European Space Research; ESA Publications Division Noordwijk: Noordwijk, The Netherlands, 2006. [Google Scholar]

- Lappa, M. Space research. In Fluids, Materials and Microgravity; Elsevier: Amsterdam, The Netherlands, 2004; pp. 1–37. [Google Scholar] [CrossRef]

- Zappulla, R.; Virgili-Llop, J.; Zagaris, C.; Park, H.; Romano, M. Dynamic Air-Bearing Hardware-in-the-Loop Testbed to Experimentally Evaluate Autonomous Spacecraft Proximity Maneuvers. J. Spacecr. Rocket. 2017, 54, 825–839. [Google Scholar] [CrossRef]

- Virgili-Llop, J.; Zagaris, C.; Zappulla, R.; Bradstreet, A.; Romano, M. A convex-programming-based guidance algorithm to capture a tumbling object on orbit using a spacecraft equipped with a robotic manipulator. Int. J. Robot. Res. 2019, 38, 40–72. [Google Scholar] [CrossRef]

- Virgili-Llop, J.; Zagaris, C.; Park, H.; Zappulla, R.; Romano, M. Experimental evaluation of model predictive control and inverse dynamics control for spacecraft proximity and docking maneuvers. CEAS Space J. 2018, 10, 37–49. [Google Scholar] [CrossRef]

- Virgili-Llop, J.; Romano, M. Simultaneous Capture and Detumble of a Resident Space Object by a Free-Flying Spacecraft-Manipulator System. Front. Robot. AI 2019, 6, 1–24. [Google Scholar] [CrossRef]

- Boge, T.; Wimmer, T.; Ma, O.; Zebenay, M. EPOS–A Robotics-Based Hardware-in-the-Loop Simulator for Simulating Satellite RvD Operations. In Proceedings of the 10th International Symposium on Artificial Intelligence, Robotics and Automation in Space, Sapporo, Japan, 29 August–1 September 2010. [Google Scholar]

- Eun, Y.; Park, S.Y.; Kim, G.N. Development of a hardware-in-the-loop testbed to demonstrate multiple spacecraft operations in proximity. Acta Astronaut. 2018, 147, 48–58. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, W.; Chen, T.; Wen, H.; Jin, D. Characterizing an Air-Bearing Testbed for Simulating Spacecraft Dynamics and Control. Aerospace 2022, 9, 246. [Google Scholar] [CrossRef]

- Cho, D.M.; Jung, D.; Tsiotras, P. A 5-dof experimental platform for spacecraft rendezvous and docking. In Proceedings of the AIAA Infotech@ Aerospace Conference, Seattle, WA, USA, 6–9 April 2009; p. 1869. [Google Scholar]

- Yu, B.; Geng, L.; Wen, H.; Chen, T.; Jin, D. Ground-based experiments of tether deployment subject to an analytical control law. Acta Astronaut. 2018, 151, 253–259. [Google Scholar] [CrossRef]

- Yu, B.; Huang, Z.; Geng, L.; Jin, D. Stability and ground experiments of a spinning triangular tethered satellite formation on a low earth orbit. Aerosp. Sci. Technol. 2019, 92, 595–604. [Google Scholar] [CrossRef]

- Mantellato, R.; Lorenzini, E.; Sternberg, D.; Roascio, D.; Saenz-Otero, A.; Zachrau, H. Simulation of a tethered microgravity robot pair and validation on a planar air bearing. Acta Astronaut. 2017, 138, 579–589. [Google Scholar] [CrossRef]

- Bologna, F. Design, Integration and Testing of a Small Floating Spacecraft Simulator. Master’s Thesis, Politecnico di Torino, Turin, Italy, 2023. [Google Scholar]

- Kulke, J. Conceptual Design of an Open-Source Hardware Simplified Floating Spacecraft Simulator. Master’s Thesis, Naval Postgraduate School, Monterey, CA, USA, 2022. [Google Scholar]

- OptiTrack Motion Capture System, Medium Volume Cameras Characteristics. Available online: https://optitrack.com/ (accessed on 18 July 2025).

- Ciarcià, M.; Cristi, R.; Romano, M.M. Emulating Scaled Clohessy–Wiltshire Dynamics on an Air-Bearing Spacecraft Simulation Testbed. J. Guid. Control. Dyn. 2017, 40, 2496–2510. [Google Scholar] [CrossRef]

- Ogundele, A.D.; Fernandez, B.R.; Virgili-Llop, J.; Romano, M. A tip-tilt hardware-in-the-loop air-bearing test bed with physical emulation of the relative orbital dynamics. In Proceedings of the 29th AAS/AIAA Space Flight Mechanics Meeting, Maui, HI, USA, 13–17 January 2019; Volume 168, pp. 3781–3799. [Google Scholar]

- Buckingham, E. On Physically Similar Systems; Illustrations of the Use of Dimensional Equations. Phys. Rev. 1914, 4, 345–376. [Google Scholar] [CrossRef]

- Bridgman, P.W. Dimensional Analysis; Yale University Press: New Haven, CT, USA, 1922. [Google Scholar]

- Gillies, D.C.; Lehoczky, S.L.; Szofran, F.; Watring, D.A.; Alexander, H.A.; Jerman, G.A. Effect of residual accelerations during microgravity directional solidification of mercury cadmium telluride on the USMP-2 mission. J. Cryst. Growth 1997, 174, 101–107. [Google Scholar] [CrossRef]

- Nelson, E. Predicting Residual Acceleration Effects on Space Experiments. Available online: https://gipoc.grc.nasa.gov/pims/MMAP/PIMS_ORIG/MEIT/MEIT_pdfs/meit2004/Section_7.pdf (accessed on 18 July 2025).

- Monti, R.; Paterna, D.; Savino, R. Counter-measures to mitigate residual-g effects on microgravity experiments on the space station. Acta Astronaut. 2002, 50, 209–216. [Google Scholar] [CrossRef]

- Wolf, R.; Rogers, M.; Alexander, J. A residual acceleration data analysis and management system. Adv. Space Res. 1993, 13, 261–265. [Google Scholar] [CrossRef]

- Wie, B. Space Vehicle Dynamics and Control; AIAA: Reston, VA, USA, 1998. [Google Scholar]

- Aliberti, S.; Quadrelli, M.B.; Romano, M. A distributed space radar sounder using a cross-track flying tethered satellite system. Acta Astronaut. 2024, 221, 266–282. [Google Scholar] [CrossRef]

- Bevilacqua, R.; Romano, M. Rendezvous Maneuvers of Multiple Spacecraft Using Differential Drag Under J2 Perturbation. J. Guid. Control. Dyn. 2008, 31, 1595–1607. [Google Scholar] [CrossRef]

- Aliberti, S.; Quadrelli, M.B.; Romano, M. Dynamics and Aerodynamic Control of a Cross-Track Tether Satellite System. ESA GNC-ICATT 2023. Available online: https://www.esa-gnc.eu/paper/?paper_id=23098 (accessed on 18 July 2025).

- Romano, M.; Aliberti, S.; Apa, R.; Matonti, C.L. Method and Apparatus for the Stabilisation of a Satellite Formation. WO2024252252, 12 December 2024. Available online: https://patents.google.com/patent/US5810295A/en (accessed on 18 July 2025).

- Virgili-Llop II, J.; Zappulla, R.; Romano, M. Dynamically Tilting Flat Table to Impart a Time-Varying Gravity-Induced Acceleration on a Floating Spacecraft Simulator. Available online: https://patents.google.com/patent/US10297168B1/en?oq=10297168 (accessed on 18 July 2025).

| Value | Unit of Measurement | |

|---|---|---|

| Granite slab | ||

| Manufacturer | Zali Precision | |

| Size | 630 × 400 × 80 | [mm × mm × mm] |

| Mass | 60 | [kg] |

| Planarity | 2.5 | [μm] |

| Actuator | ||

| Manufacturer | Nanotech | |

| Quantity | 2 | |

| Maximum speed | 30 | [mm/s] |

| Step resolution | 0.01 | [mm/step] |

| Motor holding torque | 1.12 | [Nm] |

| Stroke | 38.1 | [cm] |

| Step angle | 1.8 | [deg] |

| Laser Sensor | ||

| Manufacturer | Micro-Epsilon | |

| Quantity | 3 | |

| Power voltage | 24 | [V] |

| Power consumption | <2 | [W] |

| Start of Measuring Range (SMR) | 5 | [cm] |

| End of Measuring Range (EMR) | 15 | [cm] |

| Measuring range (MR) | 10 | [cm] |

| Weight | 30 | [g] |

| Wavelength | 670 | [nm] |

| MCS | Value | Unit of Measurement |

|---|---|---|

| Manufacturer | OptiTrack | |

| Number of cameras | 4 | |

| Resolution | 1.3 | [Megapixel] |

| Latency | 8.3 | [ms] |

| Position accuracy | ±0.20 | [mm] |

| Attitude accuracy | ±0.50 | [deg] |

| Frame rate | 120 | [FPS] |

| Cover area | 9 × 9 | [m × m] |

| Tripod height | 215 | [cm] |

| Load cell | Value | Unit of Measurement |

|---|---|---|

| Manufacturer | Futek | |

| Quantity | 1 | |

| Max load | 2 | [mN] |

| Natural frequency | 140 | [Hz] |

| Mass | 0.0193 | [kg] |

| Tether length | 1 | [m] |

| Value | Unit of Measurement | |

|---|---|---|

| Maximum acceleration | 1.1688 | m/s2 |

| Minimum acceleration | 0.0025 | m/s2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Governale, G.; Pastore, A.; Clavolini, M.; Li Vigni, M.; Bellinazzi, C.; Matonti, C.L.; Aliberti, S.; Apa, R.; Romano, M. Hardware-in-the-Loop Testing of Spacecraft Relative Dynamics and Tethered Satellite System on a Tip-Tilt Flat-Table Facility. Aerospace 2025, 12, 884. https://doi.org/10.3390/aerospace12100884

Governale G, Pastore A, Clavolini M, Li Vigni M, Bellinazzi C, Matonti CL, Aliberti S, Apa R, Romano M. Hardware-in-the-Loop Testing of Spacecraft Relative Dynamics and Tethered Satellite System on a Tip-Tilt Flat-Table Facility. Aerospace. 2025; 12(10):884. https://doi.org/10.3390/aerospace12100884

Chicago/Turabian StyleGovernale, Giuseppe, Armando Pastore, Matteo Clavolini, Mattia Li Vigni, Christian Bellinazzi, Catello Leonardo Matonti, Stefano Aliberti, Riccardo Apa, and Marcello Romano. 2025. "Hardware-in-the-Loop Testing of Spacecraft Relative Dynamics and Tethered Satellite System on a Tip-Tilt Flat-Table Facility" Aerospace 12, no. 10: 884. https://doi.org/10.3390/aerospace12100884

APA StyleGovernale, G., Pastore, A., Clavolini, M., Li Vigni, M., Bellinazzi, C., Matonti, C. L., Aliberti, S., Apa, R., & Romano, M. (2025). Hardware-in-the-Loop Testing of Spacecraft Relative Dynamics and Tethered Satellite System on a Tip-Tilt Flat-Table Facility. Aerospace, 12(10), 884. https://doi.org/10.3390/aerospace12100884