1. Introduction

Wide-speed-range hypersonic flight represents a pivotal advancement direction for next-generation aerospace vehicles. To realize large-altitude-speed-domain operations spanning subsonic/transonic/supersonic regimes, aircraft propulsion systems are evolving toward an integrated hybrid propulsion architecture. Among these, high-Mach-number hybrid propulsion systems [

1] incorporating variable-cycle turbine-based engines [

2] demonstrate exceptional technical potential for overcoming velocity–thermal coupling challenges across divergent flight conditions.

The variable cycle engine (VCE) fundamentally differs from conventional jets in the utilization of variable geometry mechanisms to adjust overall cycle work points dynamically, enabling adaptation to diverse operational conditions while simultaneously accommodating both turbojet and turbofan cycle characteristics. As a representative adjustable geometric component in VCE, the ejector nozzle [

3] significantly enhances wide-speed-range aerodynamic capability, with design variations critically influencing the overall operational efficiency of the engine.

Ejector nozzle refers to a component attached externally to the main nozzle of a jet engine, utilizing the ejector effect of the primary flow to induce bypass flow through an auxiliary annular sleeve of bleed openings. The operational principle of the ejector nozzle relies on the primary flow’s ejector capability during its ejection from the exit of the main nozzle, thereby driving the bypass secondary flow. At the throat section and divergent section, the secondary flow converges with the primary flow and then jointly expands downstream.

The ejector nozzle plays an important role in a jet engine. By regulating bypass flow parameters, the ejector nozzle can control the expansion of primary and secondary flows dynamically in the divergent section, ensuring near-complete expansion to enhance thrust while improving the propulsion system and matching performance across wide speed ranges. The exhaust flow temperature can be decreased through thermal dilution by the mixture of the primary flow and the flow induced by the ejector nozzle, which can enhance infrared stealth capability.

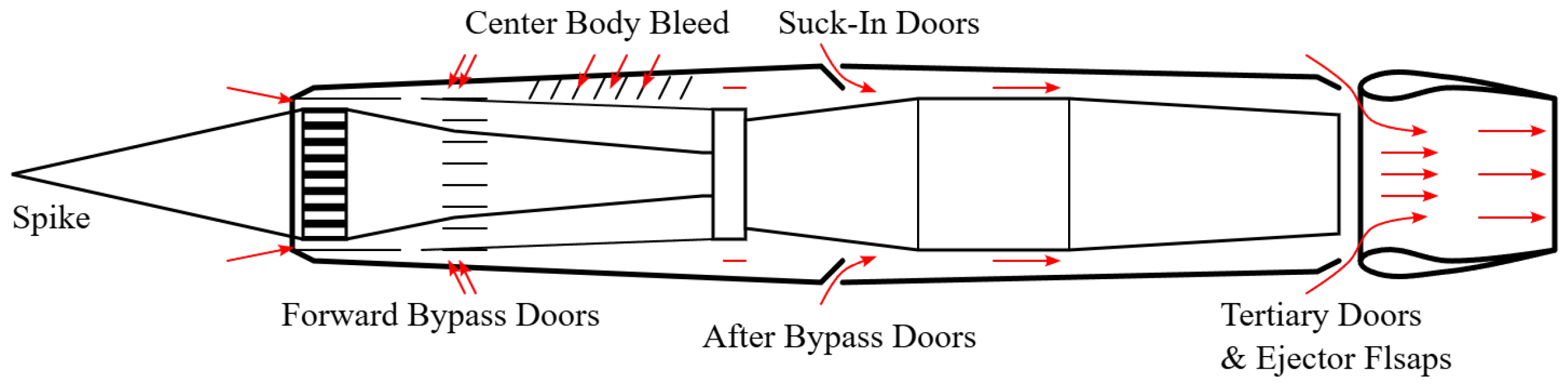

As early as the 1960s, the J-58 engine (Pratt & Whitney Group, Hartford, IN, USA) (

Figure 1) loaded on the Lockheed SR-71 Blackbird aircraft (Lockheed Corporation, Bethesda, MD, USA) represented an early successful exploration of the VCE. Its terminal third valve was integrated with the exhaust nozzle to form an ejector system, enabling flow augmentation for exhaust matching during low-speed operation [

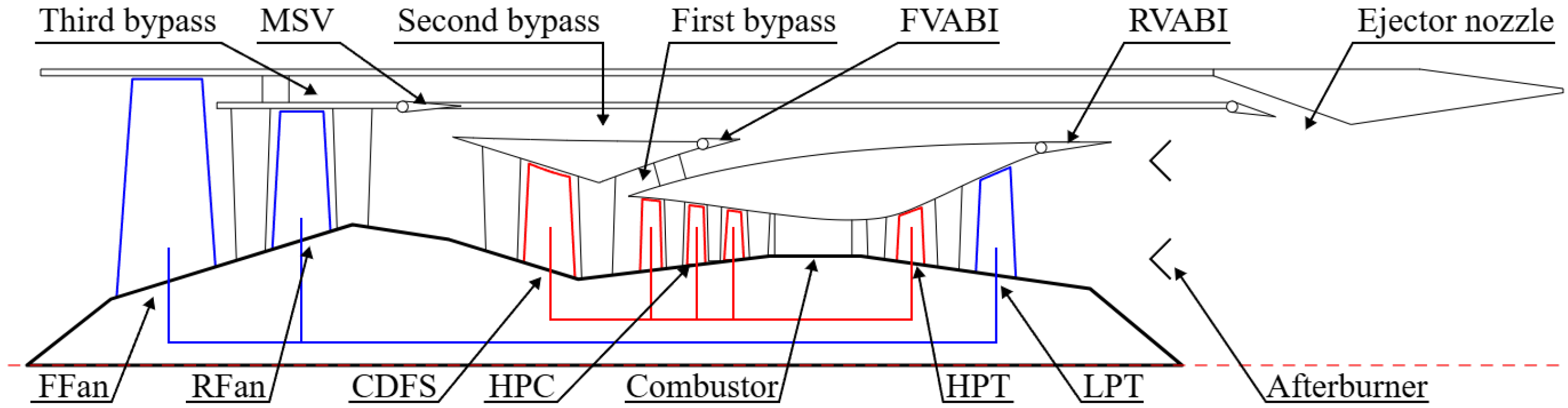

4]. In the contemporary adaptive cycle engine (ACE) (

Figure 2), the ejector nozzle utilizes a third bypass flow merged with a primary flow, effectively reducing exhaust noise and suppressing infrared signatures [

5,

6]. For the VCE, the terminal ejector nozzles employ cooler bypass flow to reduce the primary flow temperature, mitigating thermal loading on turbine blades and the afterburner while diminishing infrared radiation from engine nacelles and enhancing aircraft stealth capability.

The research on the ejector nozzle mainly focuses on three methodological domains: theoretical analysis based on a one-dimensional model [

9,

10,

11,

12,

13,

14,

15], multi-dimensional coupled simulations [

8,

13], and numerical simulation and experimental validation [

16,

17,

18,

19,

20,

21,

22,

23]. Each of these approaches is specifically developed to address different hierarchical requirements within the design process. As a critical component for inlet–exhaust flow matching, the ejector nozzle’s performance directly impacts the accuracy of iterative design evaluations during the design phase of engine development. Ejector nozzle models are predominantly established based on inviscid isentropic flow assumptions, with tailored adjustments made to accommodate specific research objectives. The Lewis Research Center [

24] developed a two-dimensional model combining method of characteristics with mixing region effects to quantify performance degradation caused by improper mixing region development. Francois Toulmay [

9] compared three analytical methods, including a global one-dimensional method, a momentum integral method, and a two-dimensional finite difference scheme, for low-speed incompressible flow conditions. B. J. Huang [

10] put forward a one-dimensional model based on the assumption of constant-pressure mixing in the constant-area section for predicting the performance of the ejector nozzle. He also claimed that with empirical coefficients, this one-dimensional model can predict performance reliably. S. K. Chou [

11] developed a one-dimensional choked boundary analysis method for ejector nozzles with the constant-pressure mixing assumption above. Shan [

12] established a semi-empirical one-dimensional incompressible ejector model, validating its reliability in predicting lobed forced mixer performance. Chen [

13] proposed a one-dimensional method based on the assumption of sonic secondary flow at the nozzle exit, incorporating it into overall engine performance analysis methodologies. Luo [

15] provided a one-dimensional ejector method for the performance perdition of a rocket-based combined cycle (RBCC) engine.

The aforementioned one-dimensional ejector nozzle model shares a common feature in treating the nozzle inner wall as adiabatic and frictionless walls, where friction losses and mixing losses in the real world are accounted for through correction coefficients. Nevertheless, their methods of modeling the mixing process between the main flow and the secondary flow vary. Constrained by computational limitations, these models primarily rely on mass, momentum, and energy conservation principles, which struggle to accurately describe the complex mixing-expansion process. There are two methods being adopted: The first method presumes that the primary and secondary flows completely mix at a constant-pressure process in a constant-area section prior to entering the divergent section. In the constant-area section, the equation for momentum conservation is set up, which divides the flow into the mixing stage, followed by the expansion stage. The second method ignores the dynamics of the mixing region, presuming that the shear layer thickness between the primary and secondary flow is zero. In this case, the mixing is modeled as the transfer of momentum and energy from the primary to the secondary flow, along with the mass being drawn from the secondary to the primary flow. The nozzle control volume’s coupled conservation equations (including mass, momentum, and energy) are solved numerically. Both methodologies exhibit inherent limitations. The first method mandates complete expansion prior to the divergent section. While this simplifies computational implementation, it requires either sufficient nozzle length to achieve uniform mixing or the incorporation of additional devices such as a lobe for forced mixing, both of which result in increasing structural weight requirements for engine integration. The second method oversimplifies mixing physics by ignoring shear layer dynamics, failing to capture the essential coupling between mixing and the expansion process.

To simultaneously account for the mixing and expansion process within the one-dimensional ejector nozzle model, additional parameters must be incorporated to characterize flow-field dynamics within the mixing region. The momentum integral method [

9] provides a viable approach by integrating flow parameters across the mixing region, enabling two-dimensional flow representation without increasing model dimensionality. The mixing layer [

25] formed between the primary and secondary flow constitutes a compressible shear flow (

Figure 3), exhibiting both complex spatiotemporal evolution and inherent self-similarity. This self-similarity manifests as tangential parameter distributions at different development stages of the shear layer, providing a foundation for integral modeling. The thickness of the mixing region is determined by both the nozzle profile and the mixing layer growth rate, which is further influenced by the velocity contrast [

25,

26] and density ratio [

27,

28] across the mixing region, while also being affected by asymmetric entrainment effects [

29] and compressibility-driven flow phenomena [

30]. By incorporating these mixing layer characteristics into the three nozzle control volume conservation equations, one-dimensional models can effectively integrate the mixing and expansion process.

Building upon the aforementioned methodologies, this paper proposed an analytical framework integrating mixing and expansion processes to re-characterize the flow-field structure within ejector nozzles. Employing numerical simulation techniques, the investigation focuses on elucidating the flow mechanisms under off-design conditions. By incorporating mixing layer development theory, a novel quasi-one-dimensional ejector nozzle model is developed to enable rapid performance evaluation. Comparative analysis with numerical simulation results validates the model’s computational efficacy and reliability.

Section 2 presents a comparison between the numerical calculation methods and experimental results;

Section 3 introduces the thermodynamic calculation methods of the quasi-one-dimensional model and analyzes the flow-field mechanisms under off-design operating conditions;

Section 4 validates the effectiveness and accuracy of the model using new ejector nozzle simulation results; and

Section 5 concludes the study.

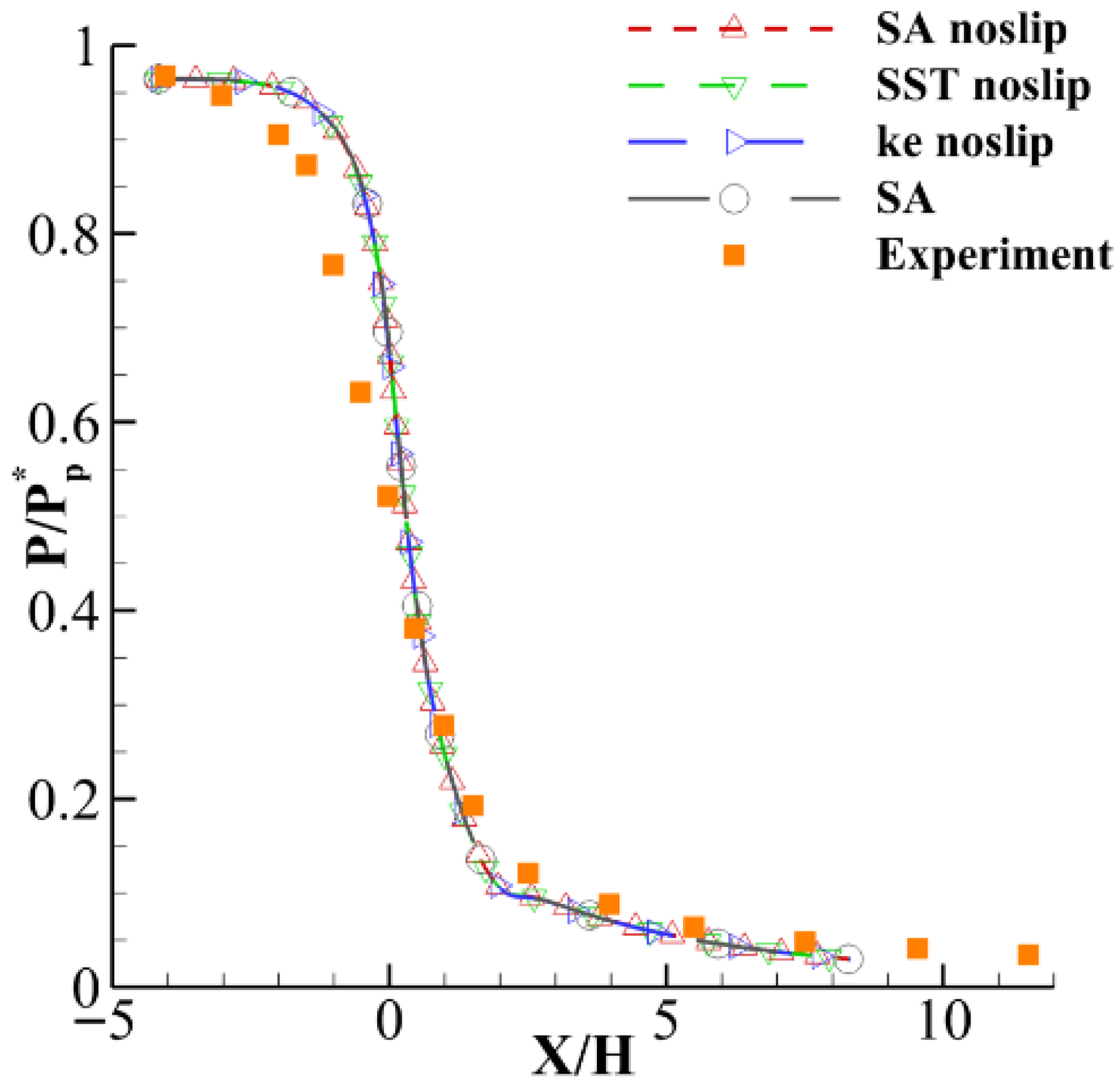

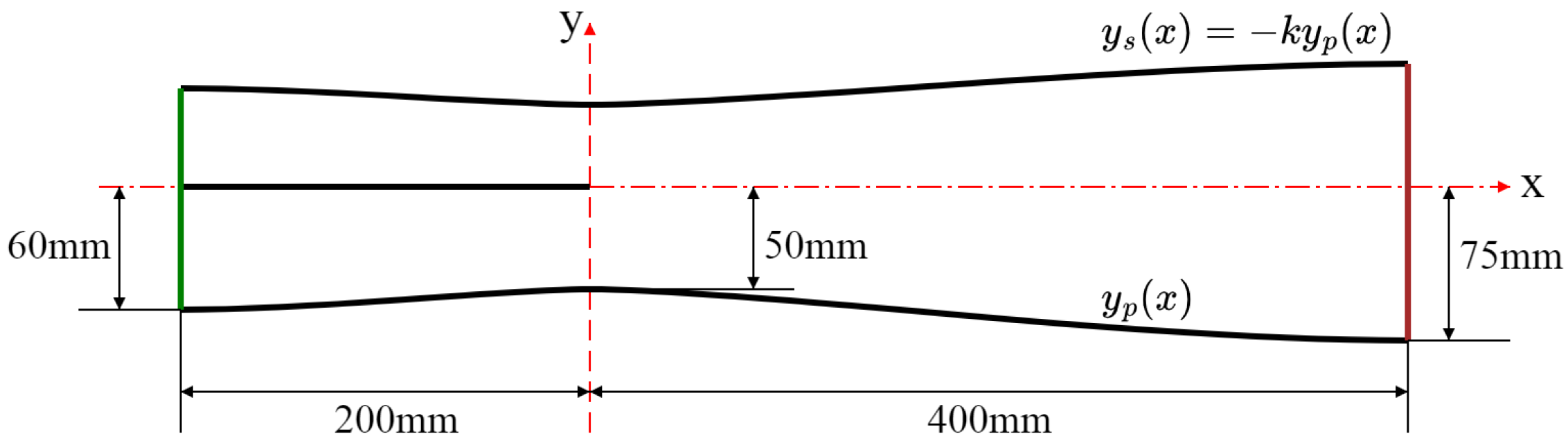

3. Ejector Model

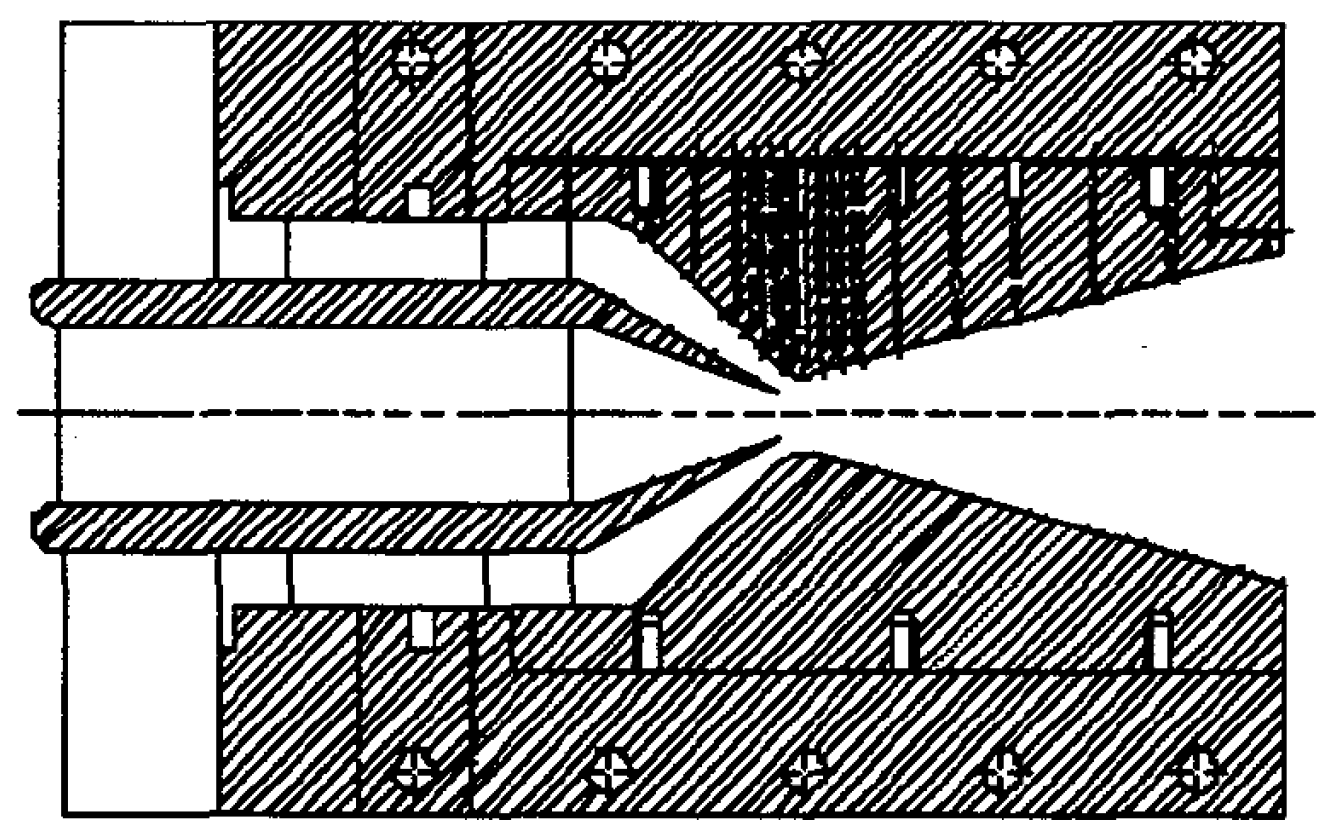

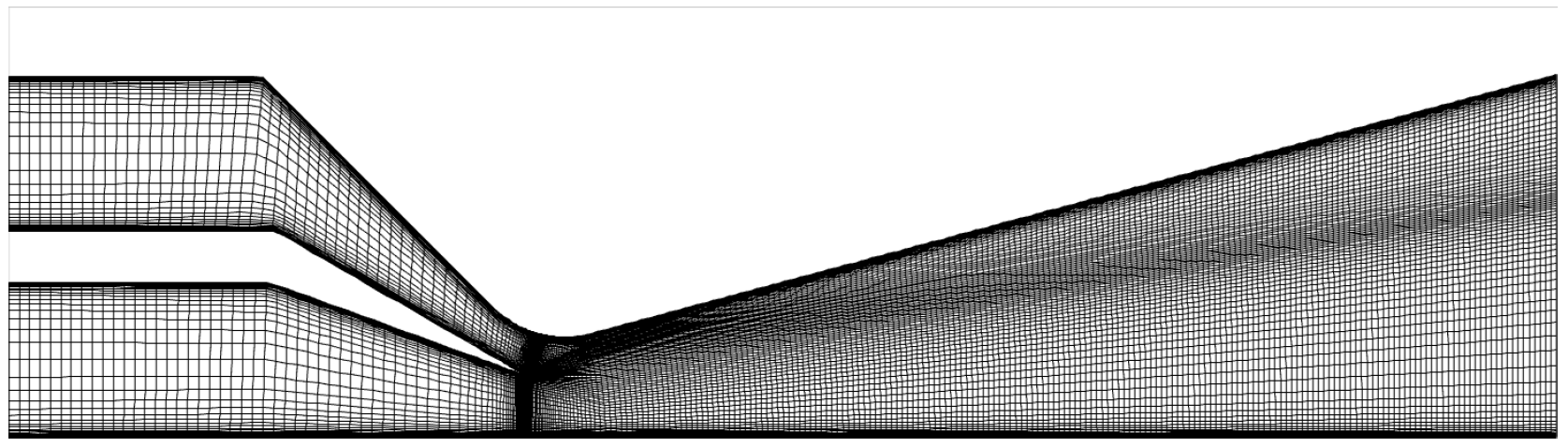

The one-dimensional ejector nozzle model usually employs an adiabatic and frictionless wall assumption. When applied, these models correct computational results to account for boundary layer losses and other effects. Numerical simulations under no-slip wall boundary conditions (

Figure 16) demonstrate that the flow-field structures (primary/secondary flow interactions and mixing region development) remain fundamentally consistent with results from no-slip boundary simulations (

Figure 9). Consequently, the introduction of this assumption has a negligible impact on the model’s validity.

3.1. Design Condition

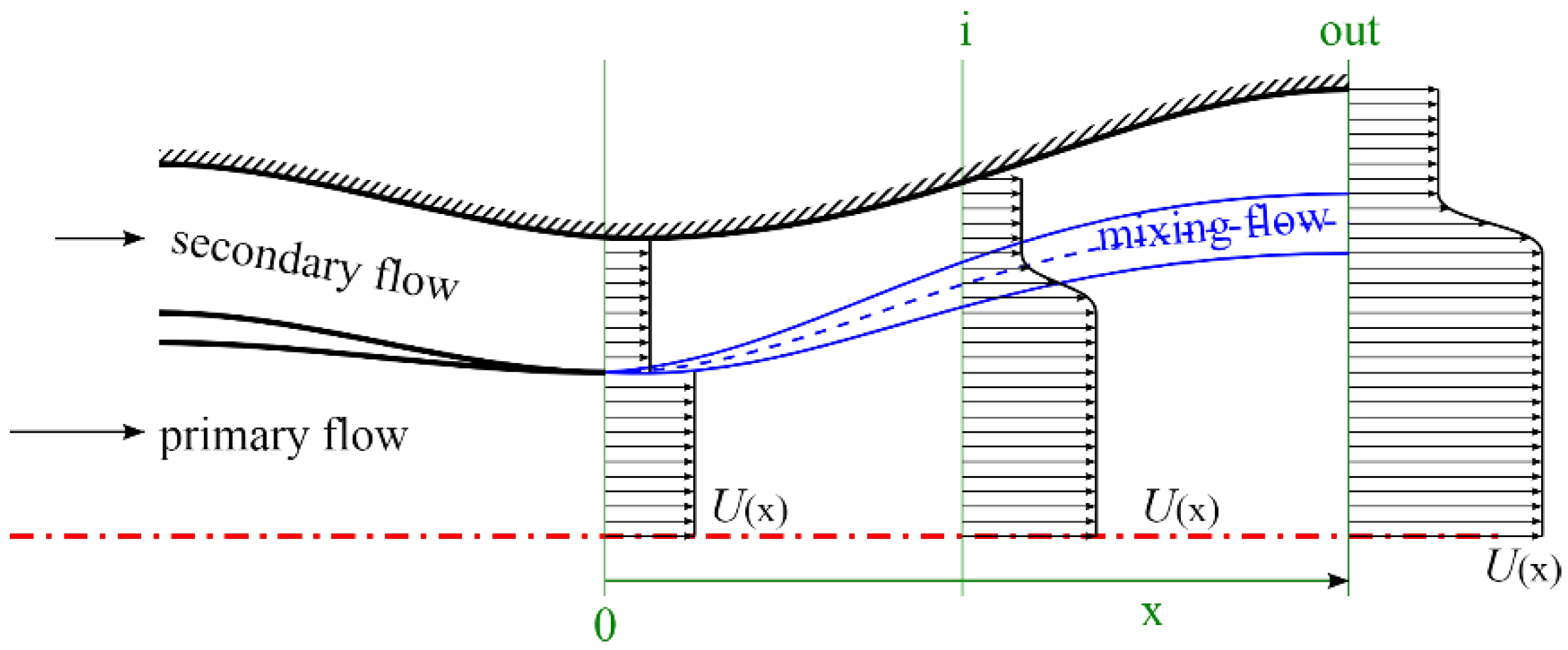

The one-dimensional theoretical analysis diagram of the ejector nozzle is simplified in

Figure 17. To simplify the flow-field structure in the divergent section, the secondary flow is injected at the cross-section of the primary nozzle throat. The primary and secondary flows enter from upstream and begin converging near the nozzle throat. With the flow direction defined as x, the intersection point of the two streams is designed as section

. From section 0 onward, the primary and secondary flow mix at their contact point, forming a mixing region (depicted by blue lines in the figure). The solid blue lines show the boundary, and the dashed blue line shows the midline. Under low backpressure conditions downstream, the flow achieves full expansion within the divergent section. The primary flow will accelerate to supersonic speed at the outlet, as well as the secondary flow, if the divergent section length allows. The primary and secondary flow aerodynamic throat positions are defined as

and

, with

and

.

The primary flow originates from turbine exhaust or afterburner outlets, possessing higher total pressure and total temperature. The secondary flow generally derives from bypass or other locations and is characterized by lower total pressure and total temperature. The secondary flow is primarily driven by static pressure differentials and ejector action, ensuring that its static pressure at section remains equal to or higher than the primary flow static pressure. However, as the secondary flow total pressure is lower than the primary flow, its Mach number at section satisfies . During concurrent mixing and expansion, the static pressure of both streams rapidly equilibrates and progressively decreases, while their Mach numbers gradually increase.

According to reference [

13], when the secondary flow expands to sonic conditions, static pressure equilibrium between the primary and secondary streams is achieved, yielding a model-predicted mass flow ratio that is in strong agreement with the experimental data. Consequently, static pressure equilibrium is assumed valid at section

, with

. As the flow continues mixing and expanding through the divergent section, the mixing region expands until both streams attain supersonic speeds at the outlet.

Figure 17 illustrates the velocity profiles at different

x sections. This fully expanded flow regime in the divergent section is conventionally adopted as the design-point condition.

The following assumptions were made in order to analyze and model the aerodynamic performance of the ejector nozzle at the design point:

Wall friction and gravity’s effects on the fluid are ignored.

The primary flow total pressure is higher than that of the secondary flow.

In the ejector, the primary and secondary flows are ideal-gas steady adiabatic flows, without considering the transition, separation, vortex, and other flow-field structures.

The flow between different sections of primary and secondary flow is isentropic.

The flow parameters in the primary and secondary flows regions are uniform at the same section.

The static pressure in the mixing region is uniform at the same section, whereas other parameters are transitional.

The primary flow is critical at section 0, and the secondary flow is critical at section i, which means , and .

According to the above assumption, the ejector nozzle model can be set up in line with the mass and energy conservation laws. Because the profile of the nozzle is unknown, the conservation law of momentum cannot be used. The equations are shown as follows:

where

x = 0, out, which represents the section

i and outlet.

The assumption provides the Mach number and static pressure equation as follows:

The calculations of the primary and secondary flow are shown as follows:

While the velocity profile in the mixing region is unknown, calculating the parameters of the mixing region is a formidable task in the most general three-dimensional case. The calculation of the mixing flow can be formulated as follows:

In the momentum integral method [

9], the velocity profile was assumed as a cubic polynomial curve for integral solutions. In one-dimensional method calculations addressing more general scenarios, it is logical to directly assume the interpolation of primary and secondary flow parameters, as presented in the following formula:

where

and

are constant on different sections of the same flow field, which are related to the ejector nozzle shape and flow state. According to the interpolation method, the integration in Equations (

8) and (

9) can be reduced as follows:

where

and

can be calculated by the ideal gas equation of state and isentropic relations from

,

, and backpressure

.

Additionally, to achieve closure of the equations, the following relationships must be incorporated: (a) nozzle geometric relations and (b) mixing layer thickness relations.

The nozzle geometric relations include the section

i and outlet as follows:

The area means the area of section i and can be given with an estimate value from the nozzle geometry and flow state.

The mixing layer thickness can be estimated using the local coordinate

x (representing the length to the start of mixing) and the mixing layer growth rate

. For two-dimensional flow, the area of the mixing region simplifies to

. For axisymmetric flow, it is defined as

, where

b means the half thickness of the layer.

can be calculated by geometry Equations (

13) and (

14) with

b.

The mixing layer growth rate

can be estimated by [

29,

30]

where

is a non-dimensional constant,

r and

s are the velocity ratio and the density ratio on both sides of the mixed layer, and

is the convective Mach number defined as follows:

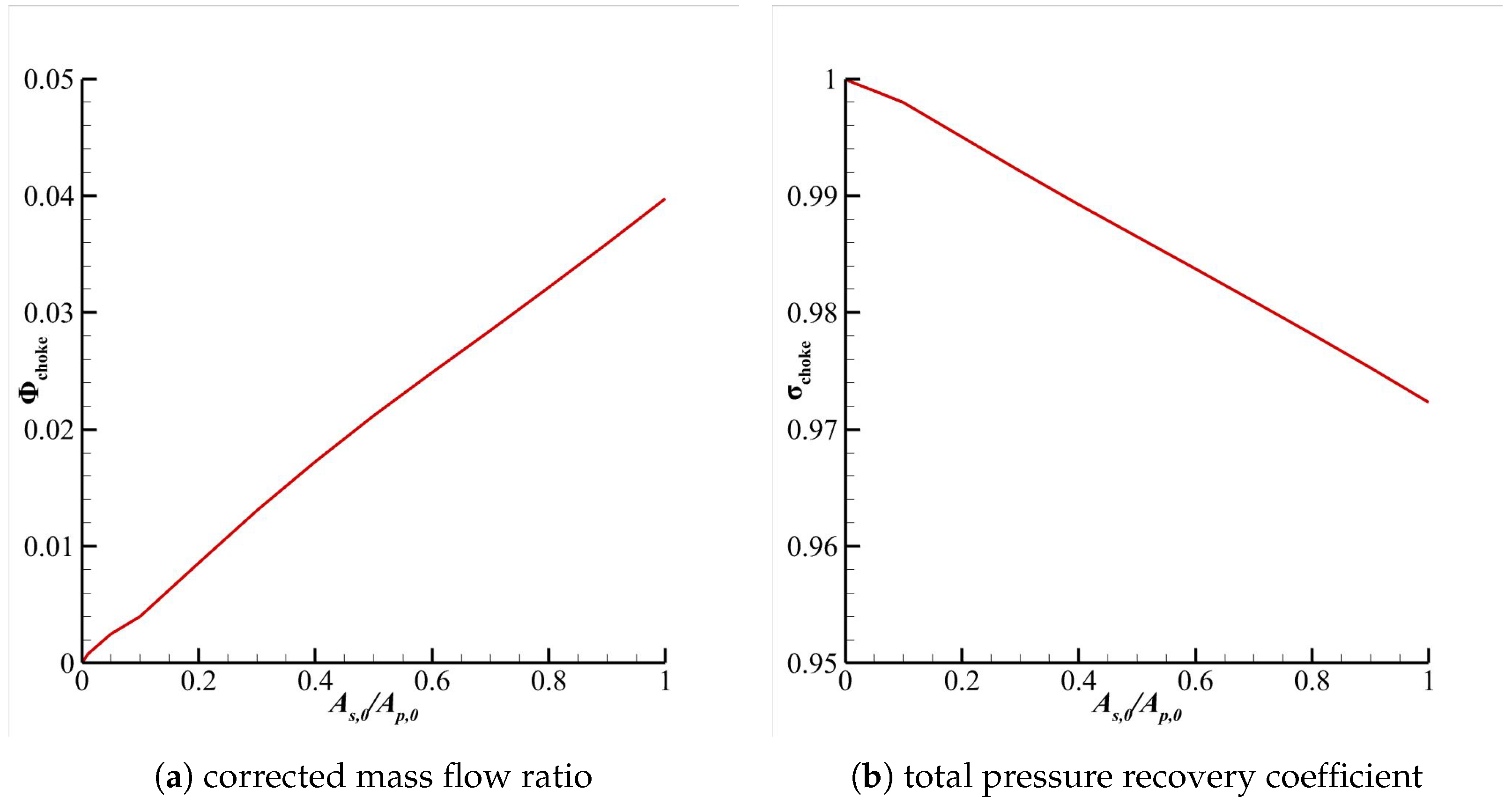

Based on the above equations and assumptions, the relevant parameters of the ejector nozzle could be calculated if the shape of the ejector nozzle is considered, with , , and .

As a one-dimensional model for ejector nozzle calculations, total pressure ratio and flow parameters are required as inputs for engine calculations. Due to the impact of the total temperature on the mass flow, the performance parameters are used to correct the mass flow ratio

and total pressure recovery coefficient

as follows:

It is important to mention that the primary and secondary streams in calculations are influenced by the total temperature and gas composition, leading to potential variations in the thermodynamic properties. Variable specific heat calculations should be performed, incorporating gas composition effects. The specific heat capacity calculation formula [

31] is given by

where the coefficients

are determined through the weighted average of measured values for each gas component, as present in

Table 1, under a composition that contains 78.084% of nitrogen, 20.9476% of oxygen, 0.9365% of argon, and 0.0319% of carbon dioxide.

For the gas in the mixing region, the gas components are determined through the weighted average of the primary and secondary flow components based on the mass flow rate of the primary and secondary flows entering the mixing region.

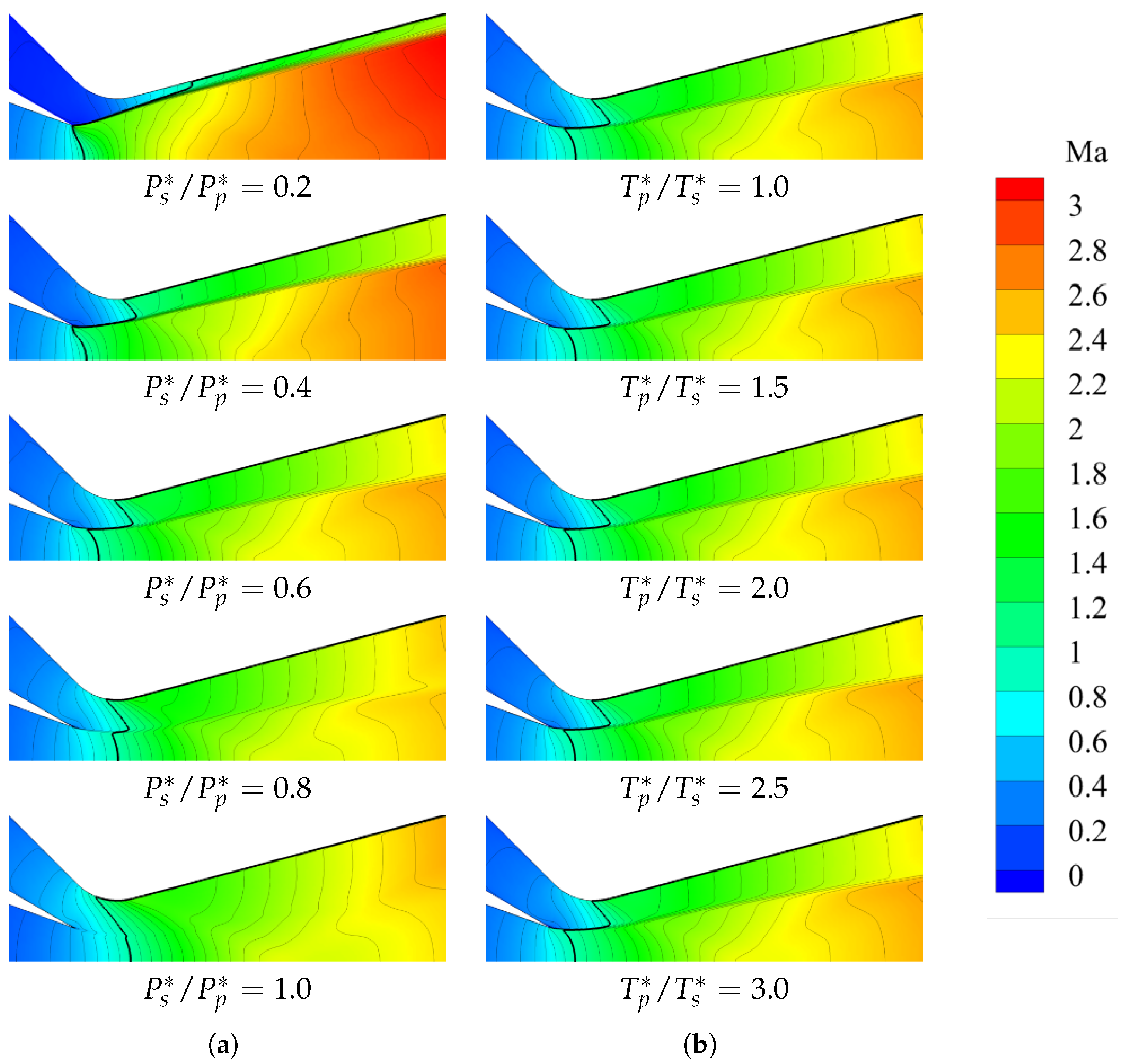

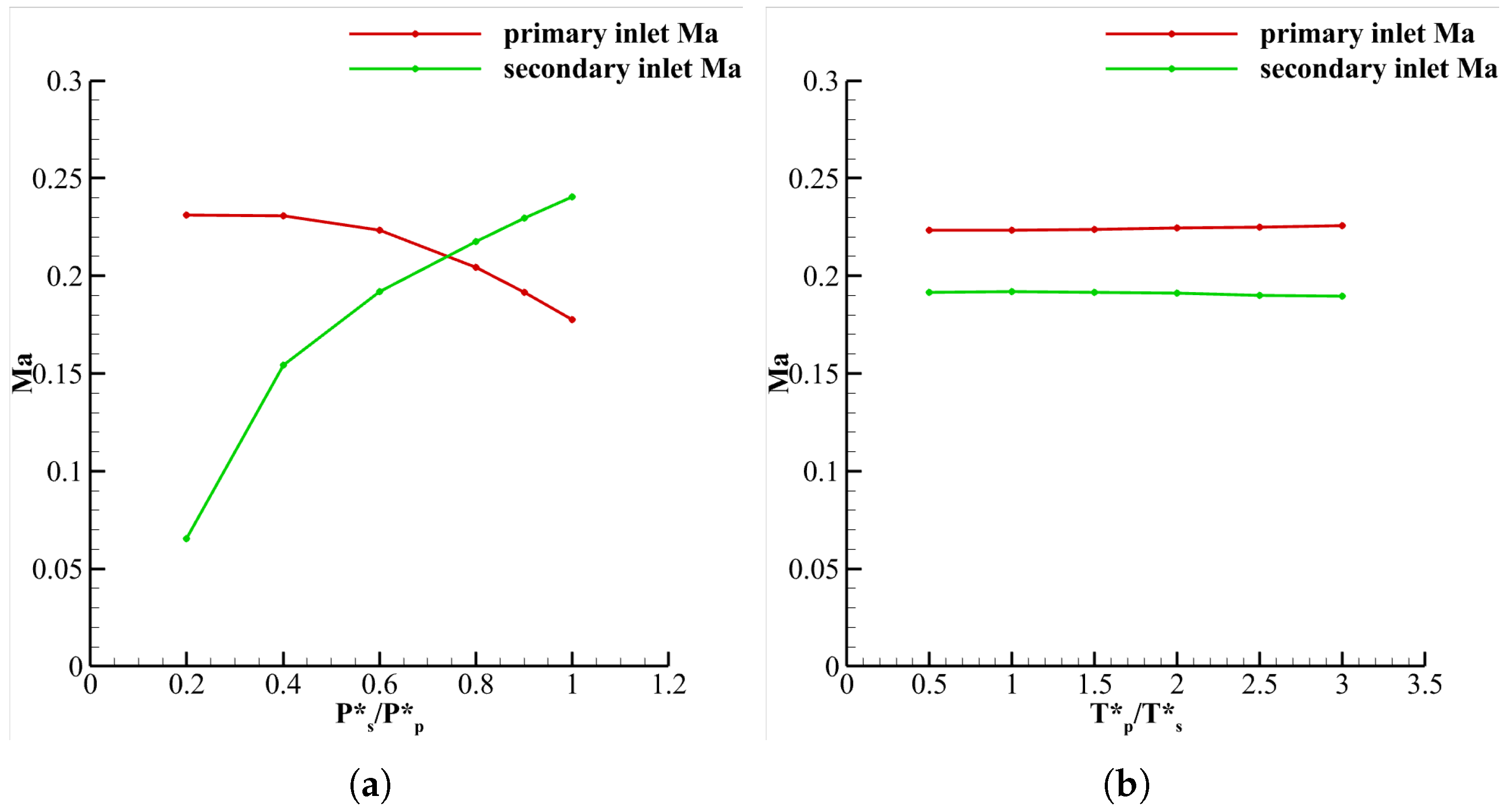

3.2. Choke State

Even under fully expanded flow regimes with extremely low backpressure, the ejector nozzle max exhibits failure to entrain the secondary flow, resulting in bypass duct blockage, where the state is called “choke state” in this paper. This phenomenon does not stem from excessive backpressure, but rather results from insufficient total pressure within the secondary flow.

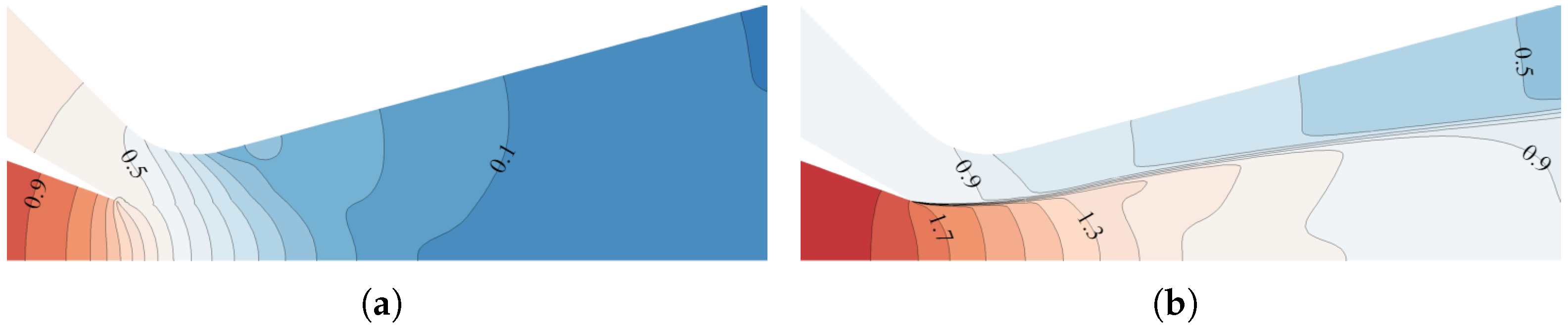

By reducing the secondary flow total pressure while adjusting the backpressure to maintain fully expanded flow conditions within the ejector nozzle, the secondary flow region proportion in the divergent section continuously diminishes. Consequently, the aerodynamic throat area of the secondary flow gradually narrows, and its throat position shifts downstream, as illustrated in

Figure 10a. When the secondary flow total pressure decreases to the critical value

, the aerodynamic throat area of the secondary flow shrinks to zero, and the secondary mass flow approaches negligible values (only minimal entrained flow penetrates into the mixing region), as shown in

Figure 18. The flow regime induces distinct structural evolution in the flow field: At section

i, the cross-section exclusively comprises the primary and mixing flow region, with complete absence of the secondary flow region; upstream of section

i, the secondary flow region persists, dominated by recirculatory vortices generated by the primary flow entrainment, whereas downstream of section

i, the primary flow becomes preponderant, and the mixing region diminishes through progressive turbulent diffusion until its complete dissipation.

In

Figure 18, when the ejector nozzle’s divergent section length is sufficiently long, the free expansion surface of the primary flow intersects the divergent section wall at section

i. If the divergent section length is insufficient, the free expansion surface fails to intersect the wall, indicating that the system has not reached the choking condition. By further reducing the secondary flow total pressure, the intersection point shifts to the nozzle outlet, establishing a new choking condition where the outlet becomes the critical section

i. This demonstrates that the choking state is intrinsically linked to the divergent section geometry. During design optimization, modifying the divergent section contour can expand the stable operational range of the ejector nozzle. Under choking conditions, the shape of the primary flow’s free expansion surface is governed by the flow parameters of both the primary and secondary flows. In two-dimensional flow fields, this surface’s geometry and position can be calculated by the method of characteristics. For one-dimensional models, the section

i position must either be specified as a geometry parameter or defined through empirical relationships.

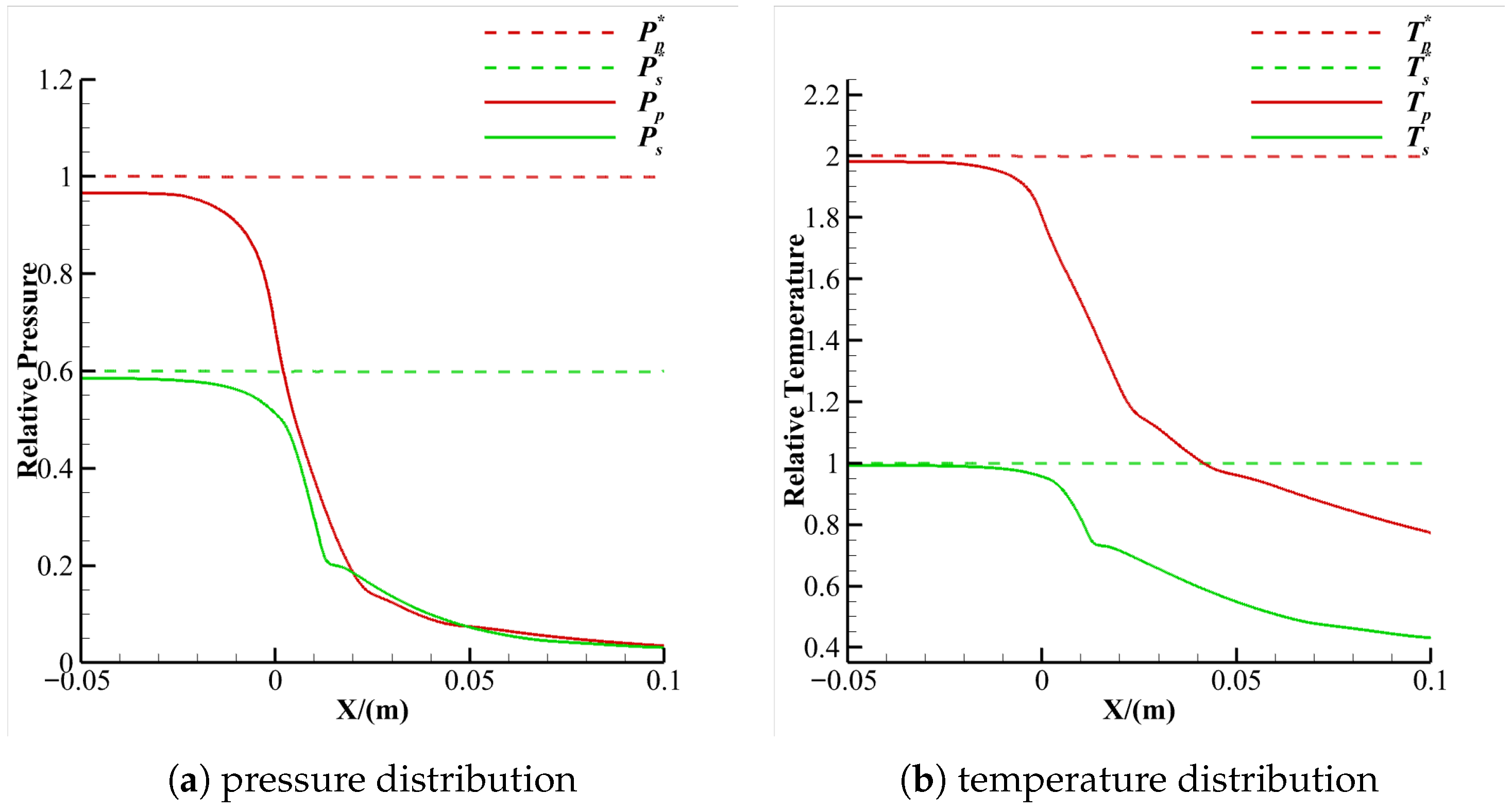

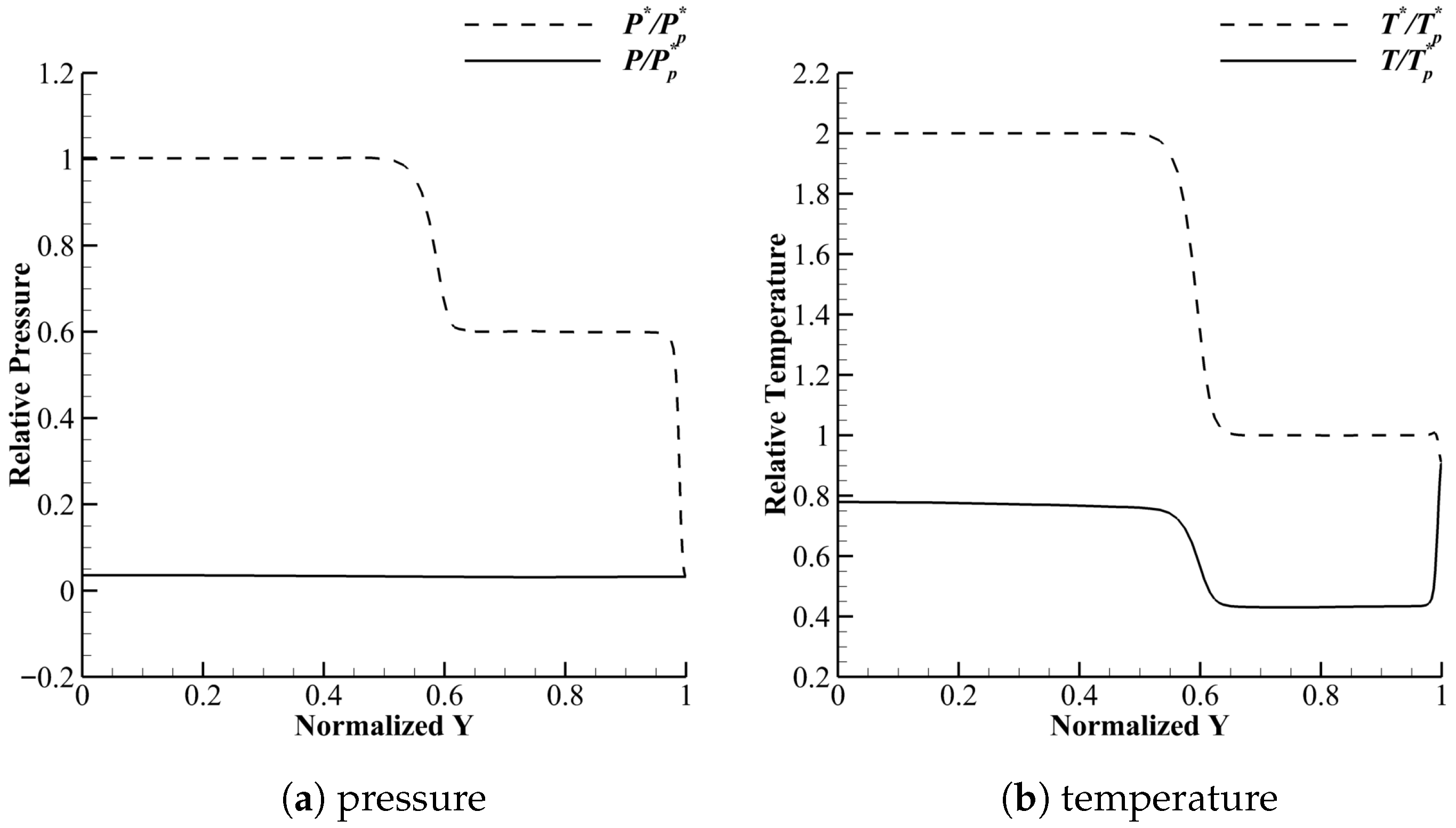

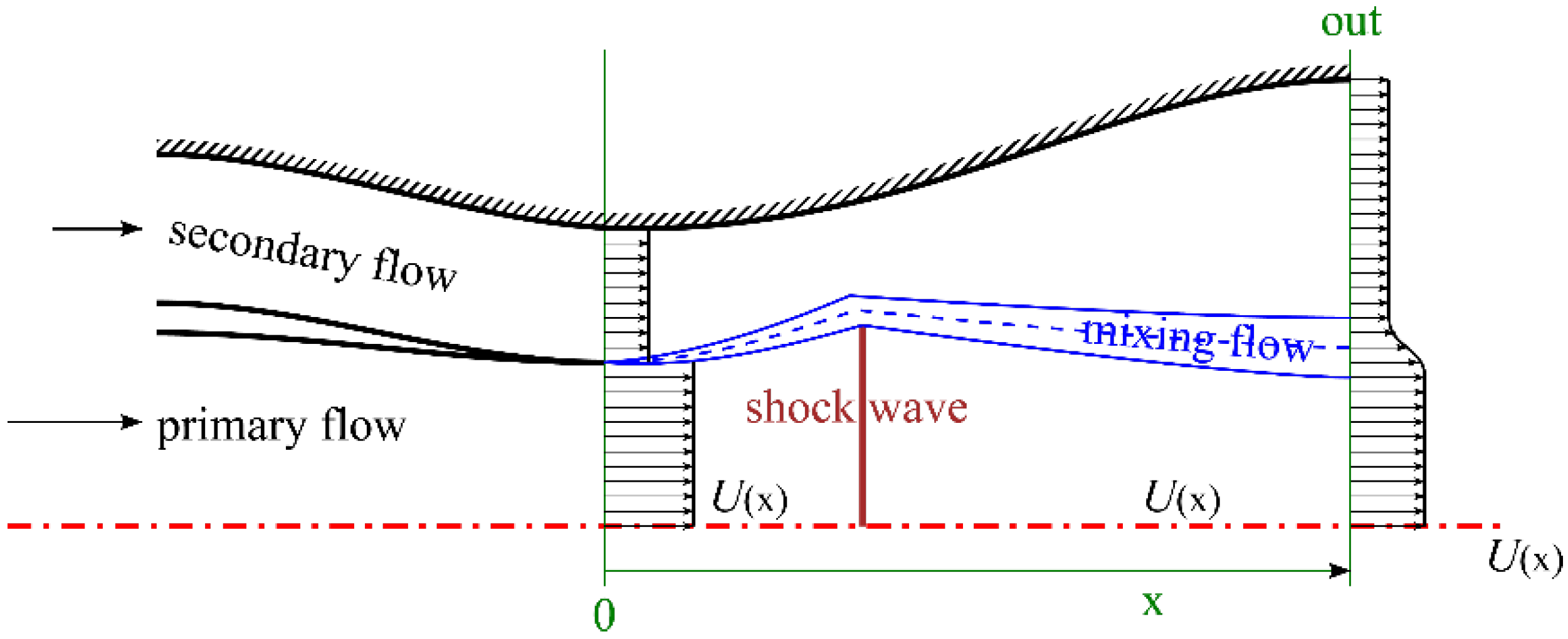

3.3. Subcritical Flow

Under high downstream backpressure conditions, the flow within the ejector nozzle remains subcritical (

Figure 19), which is similar to the operation of a conventional Laval nozzle. The nozzle is dominated by a complete subsonic flow. The maximum Mach number occurs at the primary flow location

, where

. In this regime,

. The y-direction pressure balance assumption remains valid, extending to the primary–secondary flow interface at

.

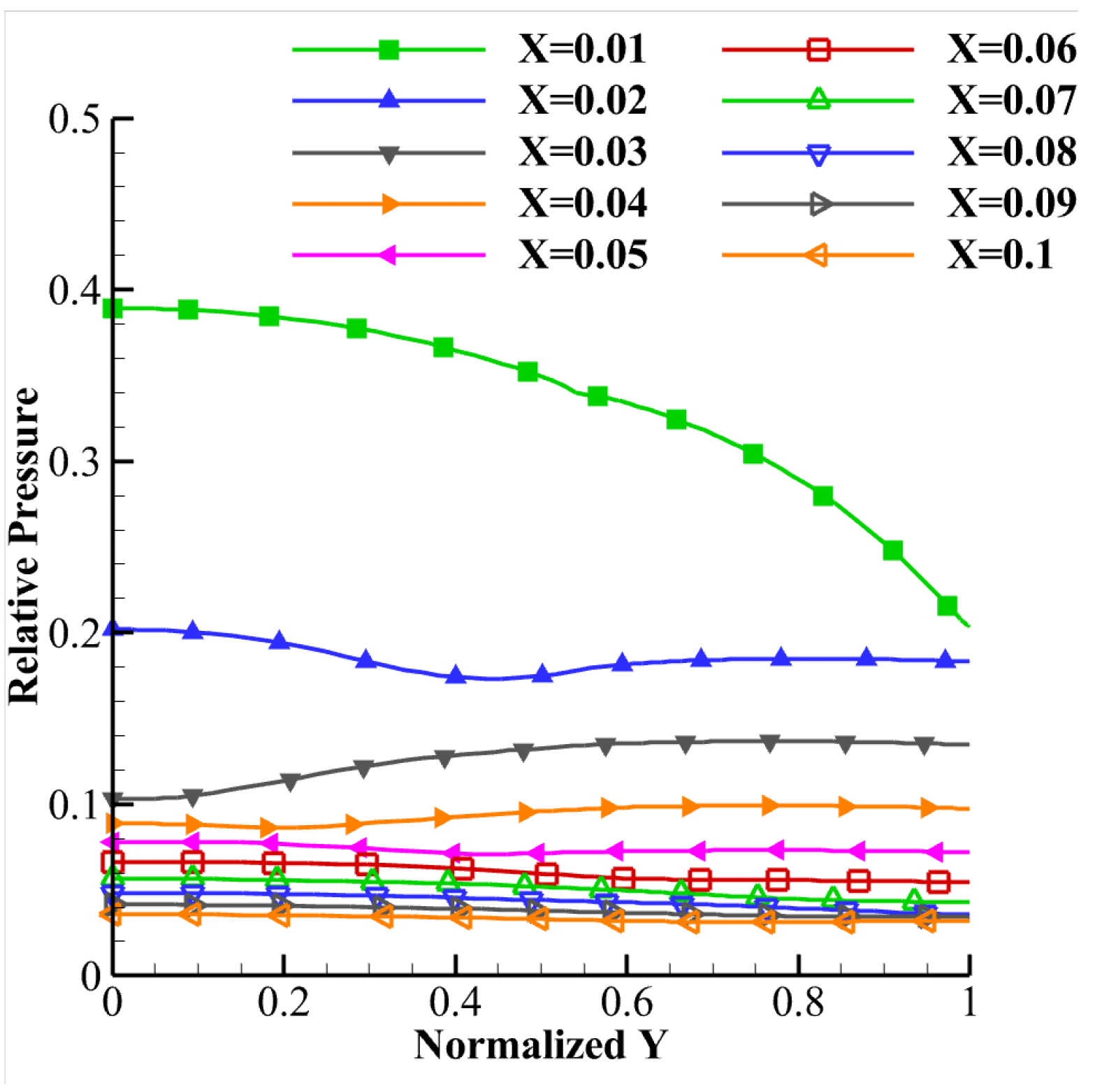

3.4. Over-Expanded Flow

When the outlet back pressure lies between the subcritical condition and the design condition outlet pressure, the flow within the ejector nozzle exhibits over-expanded characteristics. However, unlike the over-expanded flow in Laval nozzle, the dual-flow configuration (primary and secondary flows) in the ejector generates one or two normal shockwaves within the nozzle due to pressure mismatch. In a low backpressure regime, discrete normal shockwaves form independently in the primary and secondary flow regions, connected via the mixing layer transition region, as illustrated in

Figure 20 with the red solid line. In a moderate backpressure regime, the secondary flow region remains entirely subsonic, with only a weak normal shockwave developing in the primary flow region, as shown in

Figure 21.

The flow-field parameters exhibit heightened complexity due to shock-induced distortion when shockwaves develop within the divergent section. The assumption of pressure balance along the y direction becomes invalid under sun conditions, making parametric calculations across the primary, secondary, and mixing flow regions at the outlet particularly challenging. Consequently, characteristics in this regime are typically approximated through interpolation between subcritical and design condition data. Advanced computational methodologies for precise prediction in such scenarios remain an active area of research.

5. Consultation

This study systematically investigated the flow field structure within ejector nozzles, yielding the following key conclusions through integrated analytical and numerical analyses:

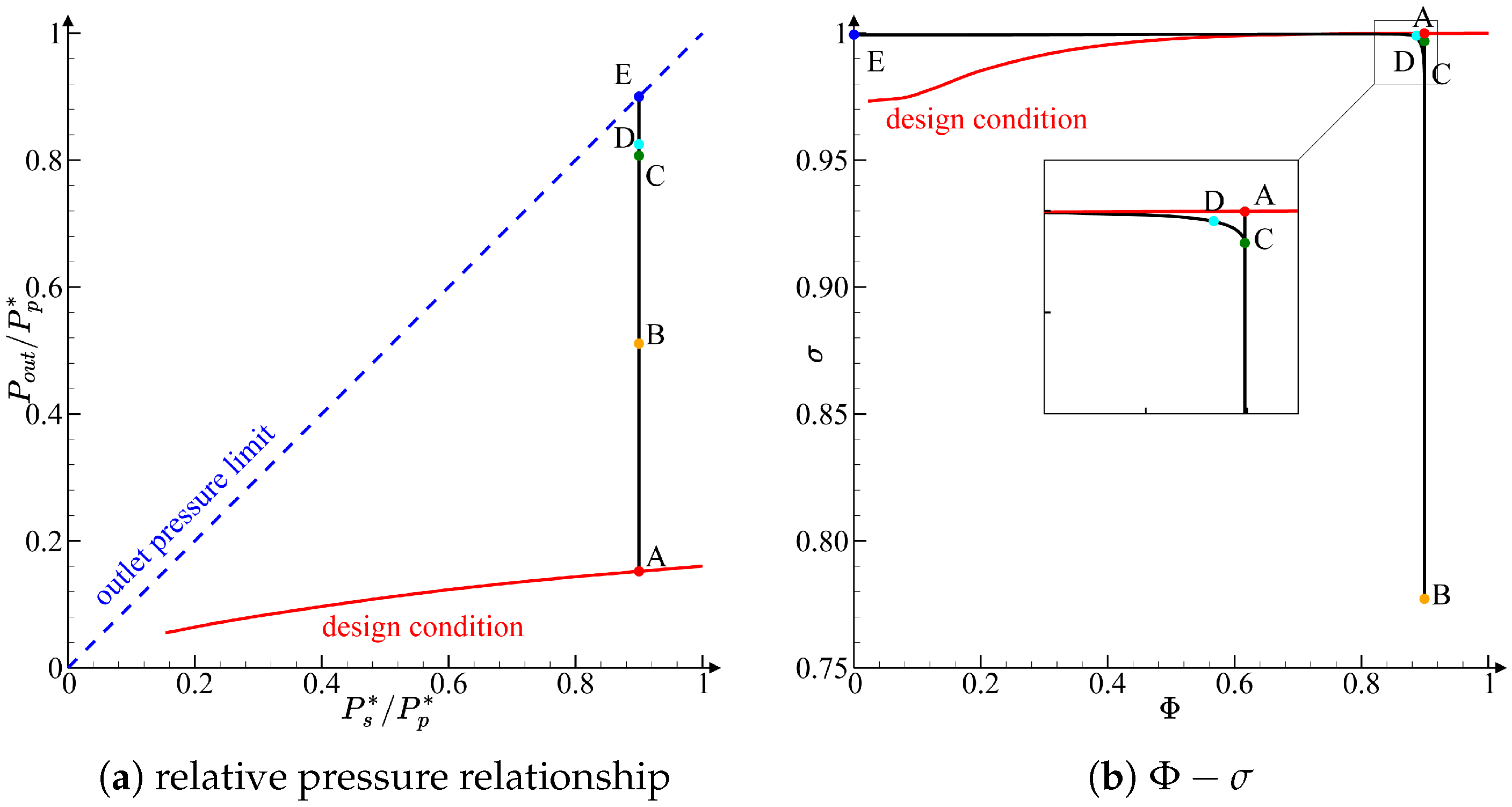

The flow field in the divergent section of the ejector nozzle has been categorized into three distinct regions: the primary flow region, the secondary flow region, and the mixing region. A quasi-one-dimensional ejector nozzle model was developed based on this zonal framework, incorporating computational algorithms for parametric analysis. Comparative validation with CFD simulations demonstrates the model’s robustness, achieving relative errors below 3% in predicting pressure recovery and mass flow characteristics. This agreement corroborates the model’s reliability for engineering applications.

Four distinct flow regimes have been identified: under-expanded, fully expanded, over-expanded (characterized by single or dual normal shockwaves), and subcritical state. Notably, the over-expanded regime in ejector nozzles exhibits unique shockwave interactions, specifically configurations with one or two normal shockwaves, which amplify total pressure losses compared to conventional convergent–divergent nozzles. These findings establish a refined classification scheme for ejector nozzle flow dynamics.

Based on the quasi-one-dimensional model, the flow and loss characteristics of the ejector nozzle under design conditions have been analyzed. Decreasing the total pressure of secondary flow will increase the mixing loss, and the total pressure recovery coefficient may decrease to 97.1% when . Additionally, the relationship between the merging plane area ratio and corrected mass flow ratio was examined. Increasing the secondary flow area at the merging plane reduces mixing losses.

In the quasi-one-dimensional ejector nozzle model, the utilization of the mixing layer growth rate for calculating the mixing region thickness demonstrates validity, primarily for axisymmetric or two-dimensional flow channels. However, this approach may exhibit limitations when applied to forced mixing mechanisms such as lobed mixer-induced flow regimes. To address this, future research could incorporate geometric modifiers like shape factors to enhance predictive accuracy.

To further verify the validity of the quasi-one-dimensional ejector model, two-dimensional ejector nozzle and axisymmetric ejector nozzle experiments will be conducted in the follow-up study. The velocity and pressure distributions at the ejector nozzle exit will be measured, and the areas of the main flow region, secondary flow region, and mixing layer region on the exit surface will be identified under different conditions. The total pressure recovery coefficient and the corrected mass flow ratio will be calculated using pressure and temperature probes placed at the inlet and outlet of the test section. Additionally, the deviation between the theoretical and actual values can be analyzed to improve the model.