Numerical Analyses of Surge Process in a Small-Scale Turbojet Engine by Three-Dimensional Full-Engine Simulation

Abstract

1. Introduction

2. Numerical and Experimental Methods

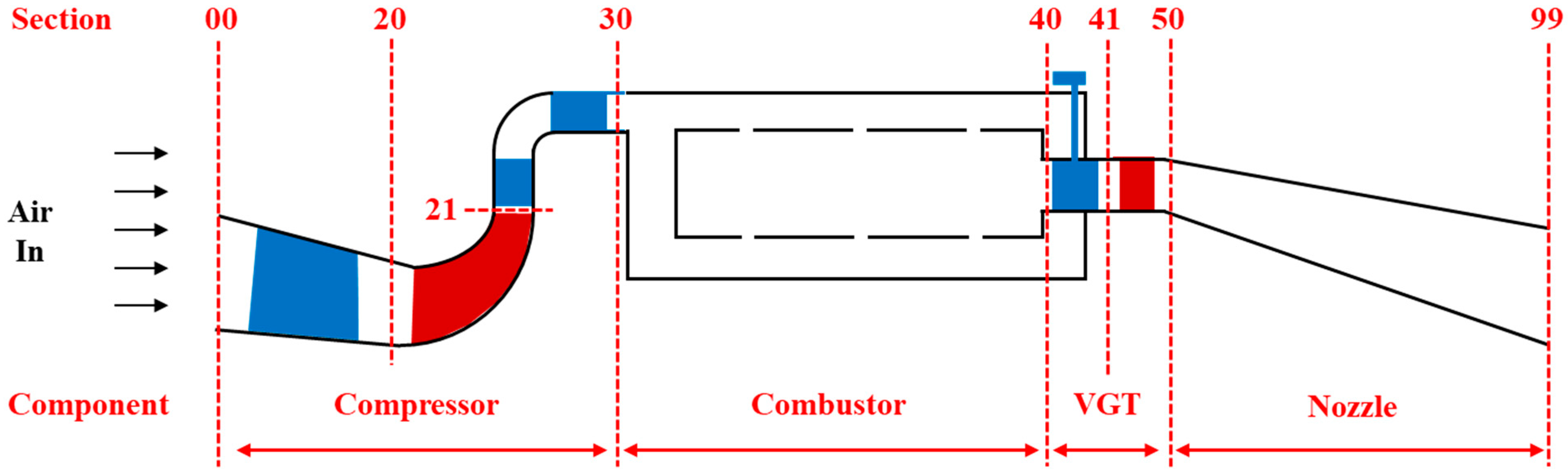

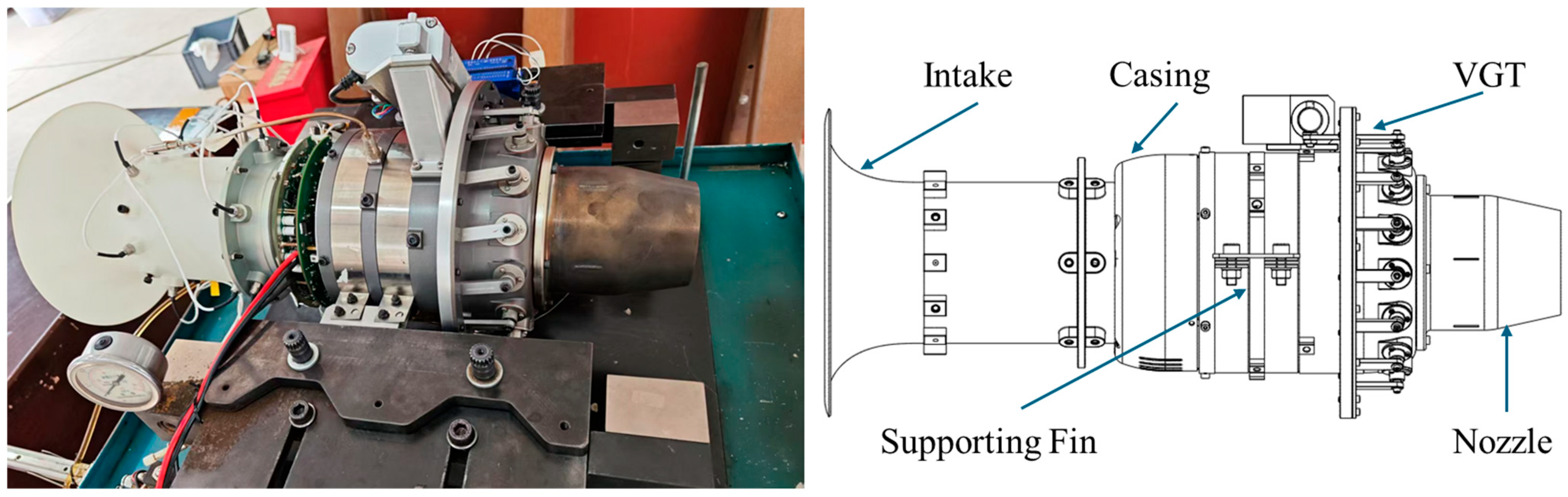

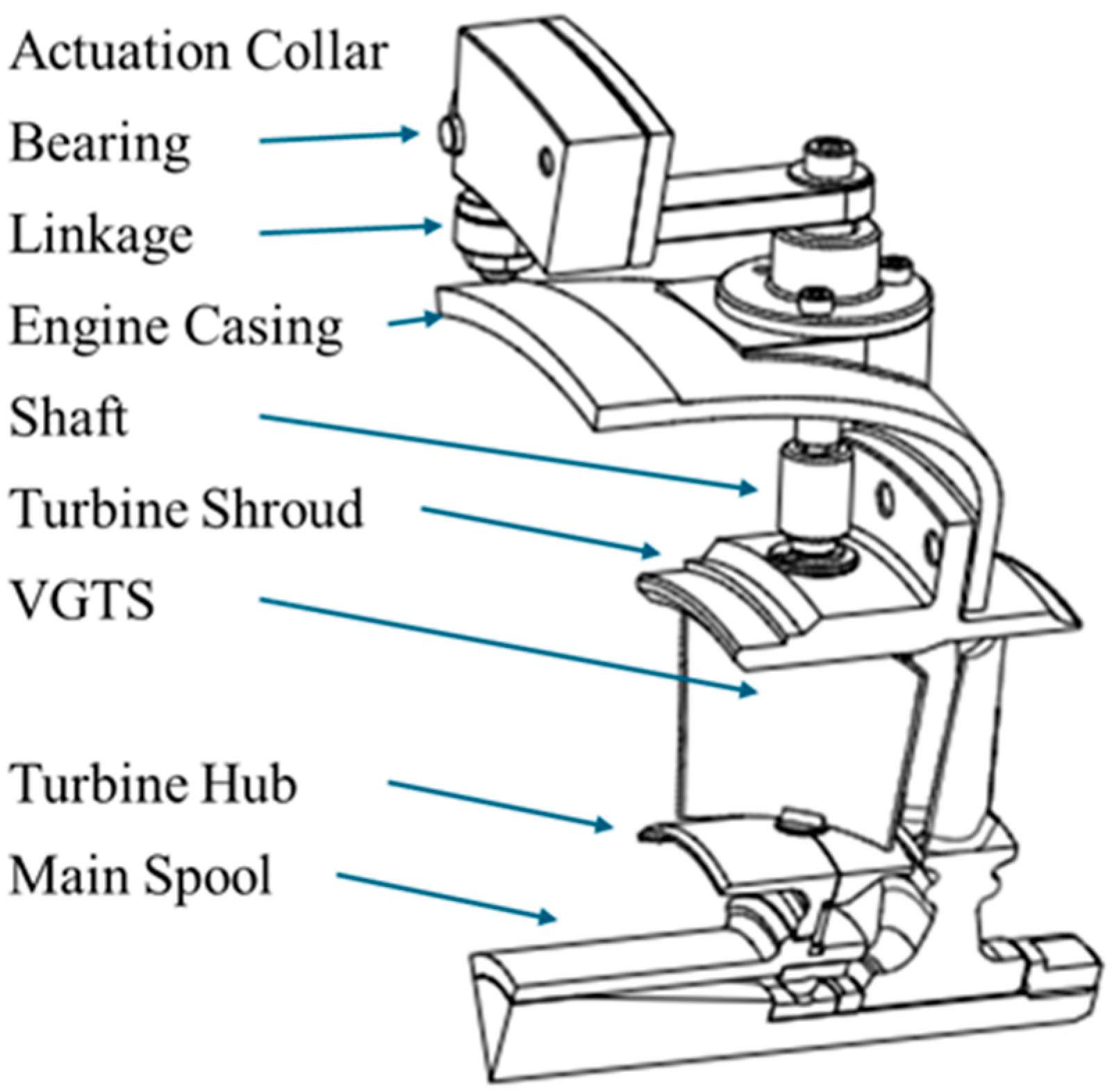

2.1. Case Description

2.2. Experimental Methods

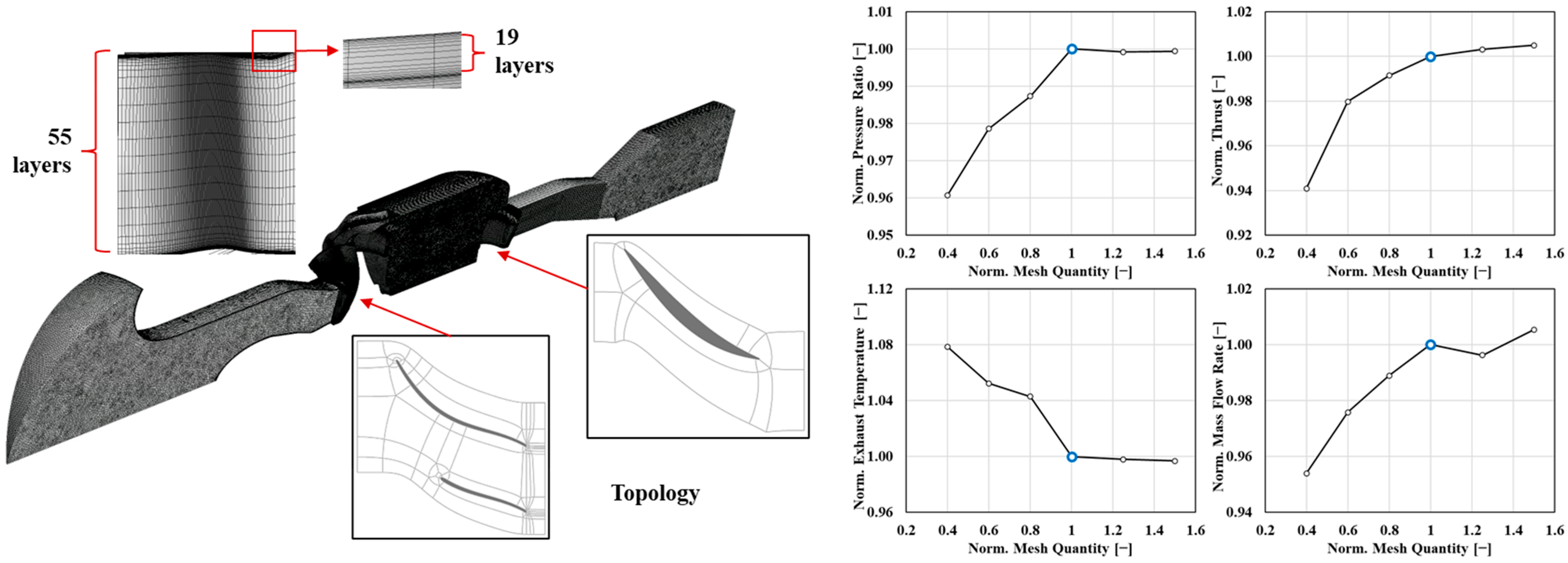

2.3. Numerical Methods

3. Results

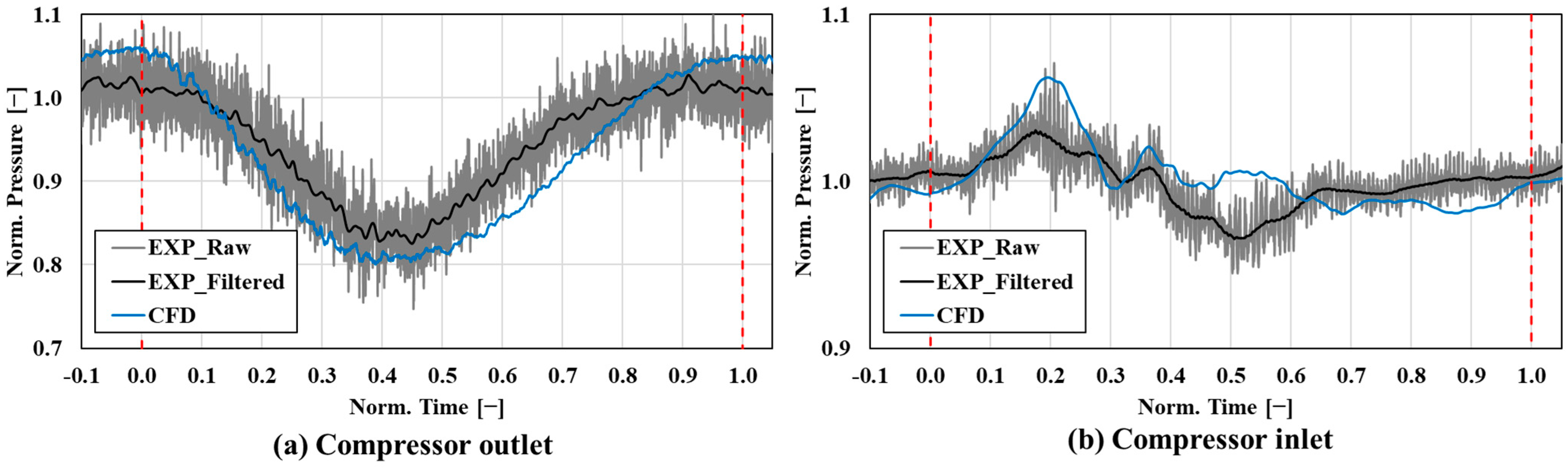

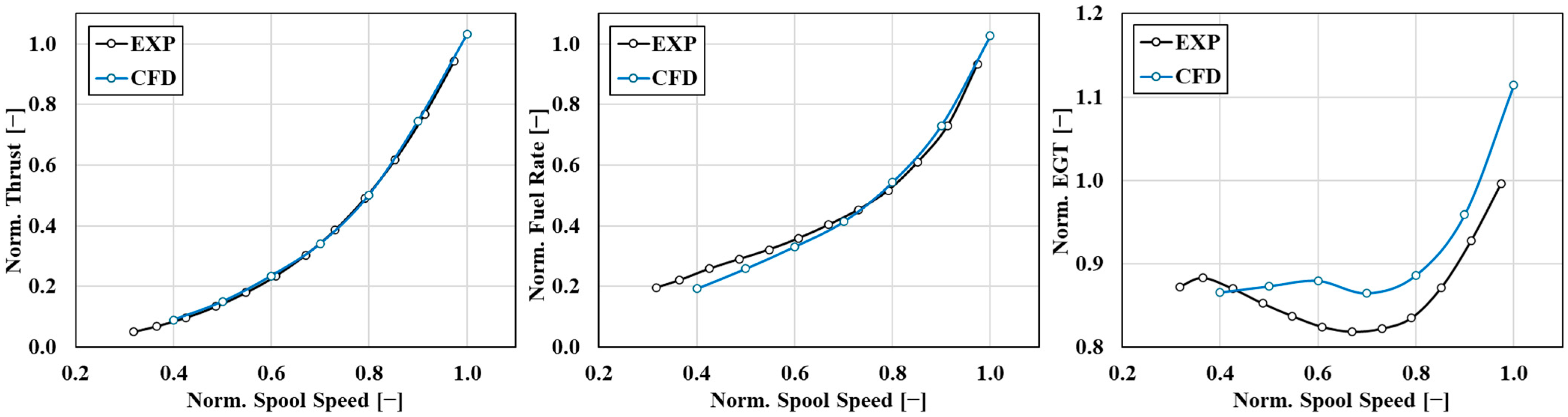

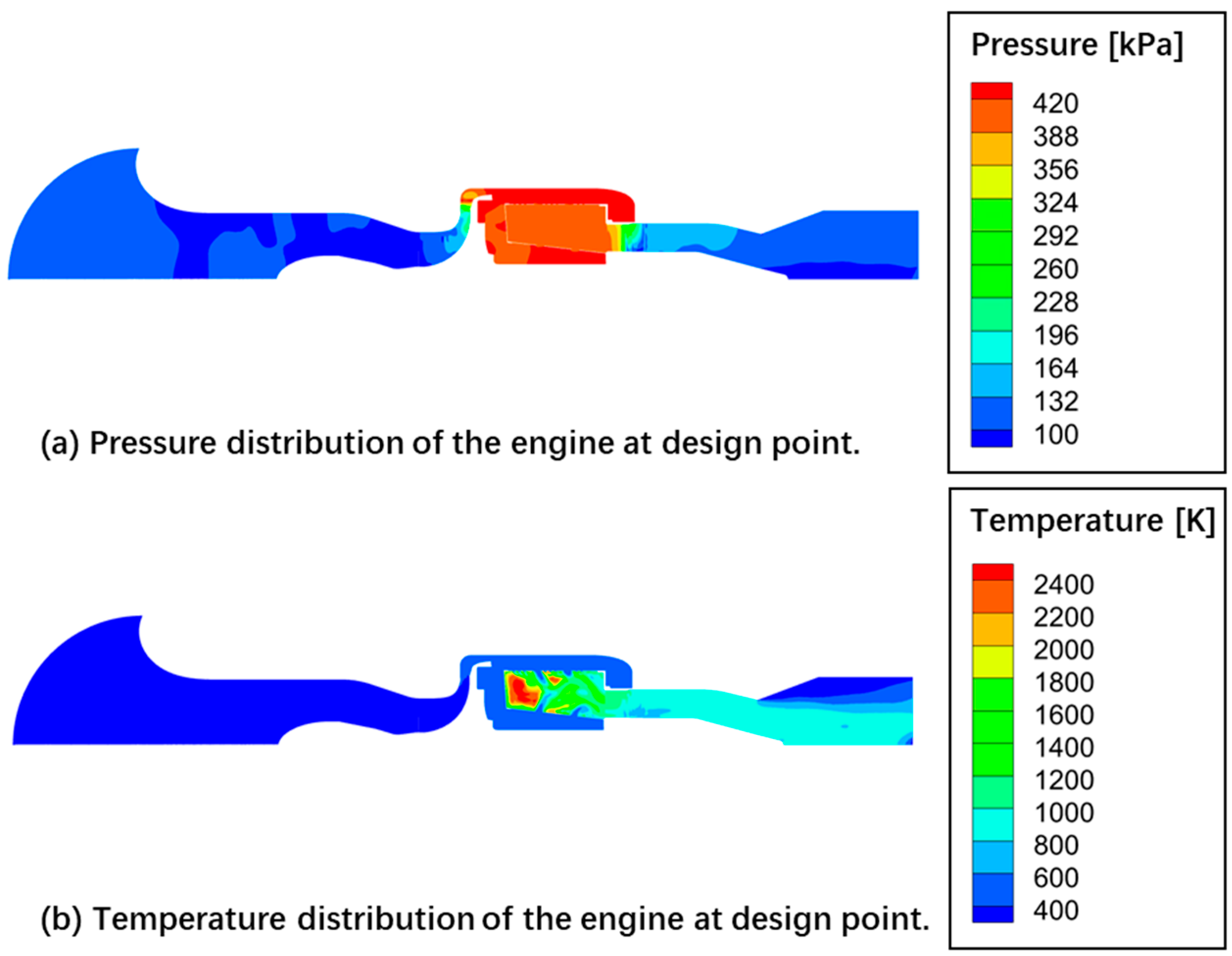

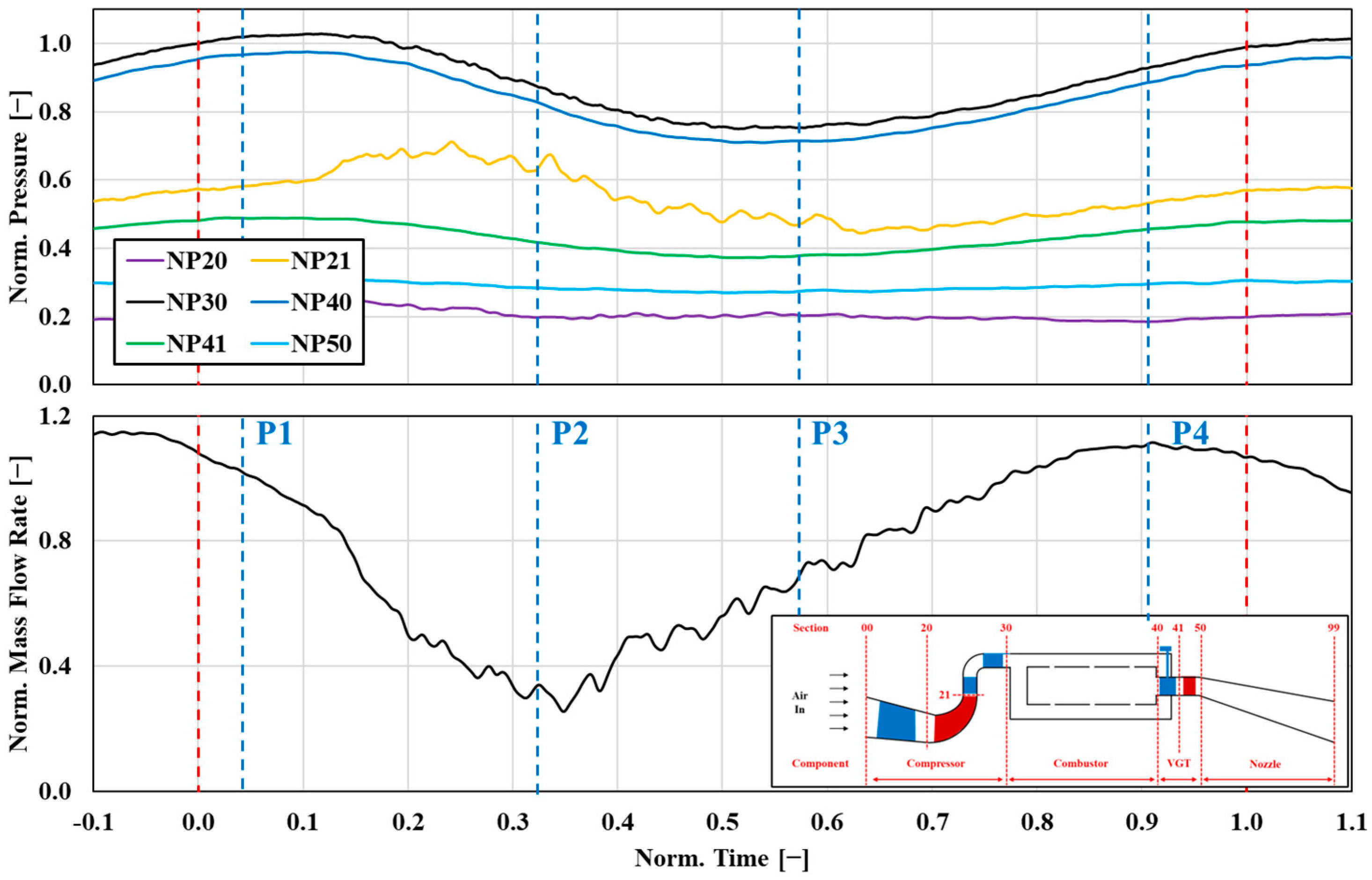

3.1. Engine Performance

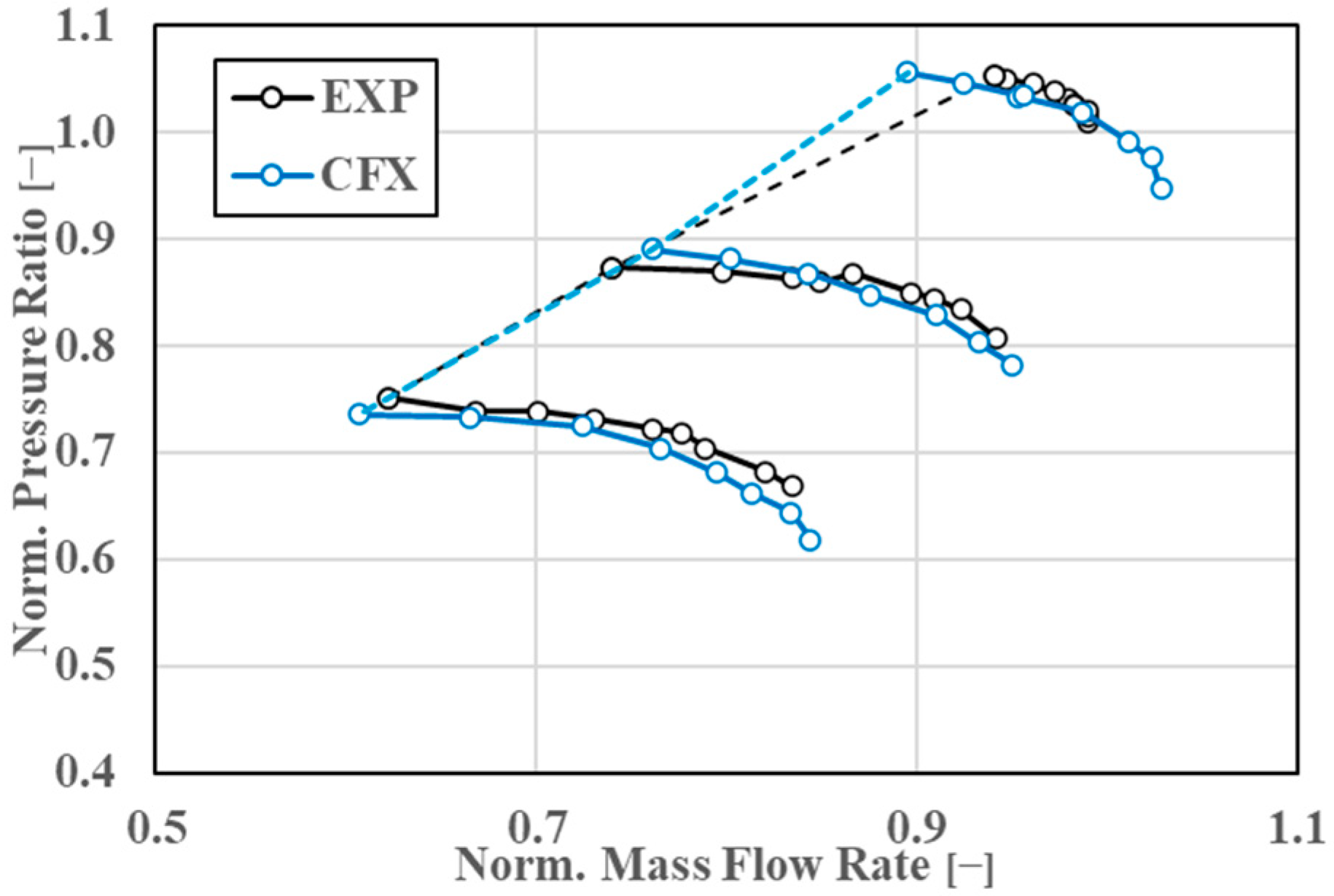

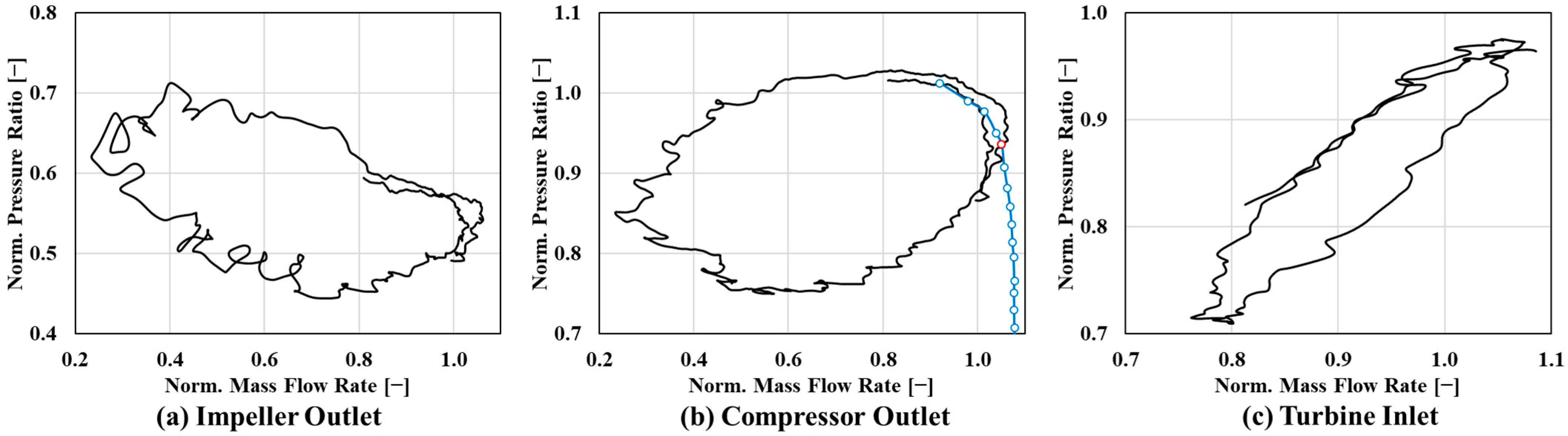

3.2. Surge Boundary in Full-Engine Environment

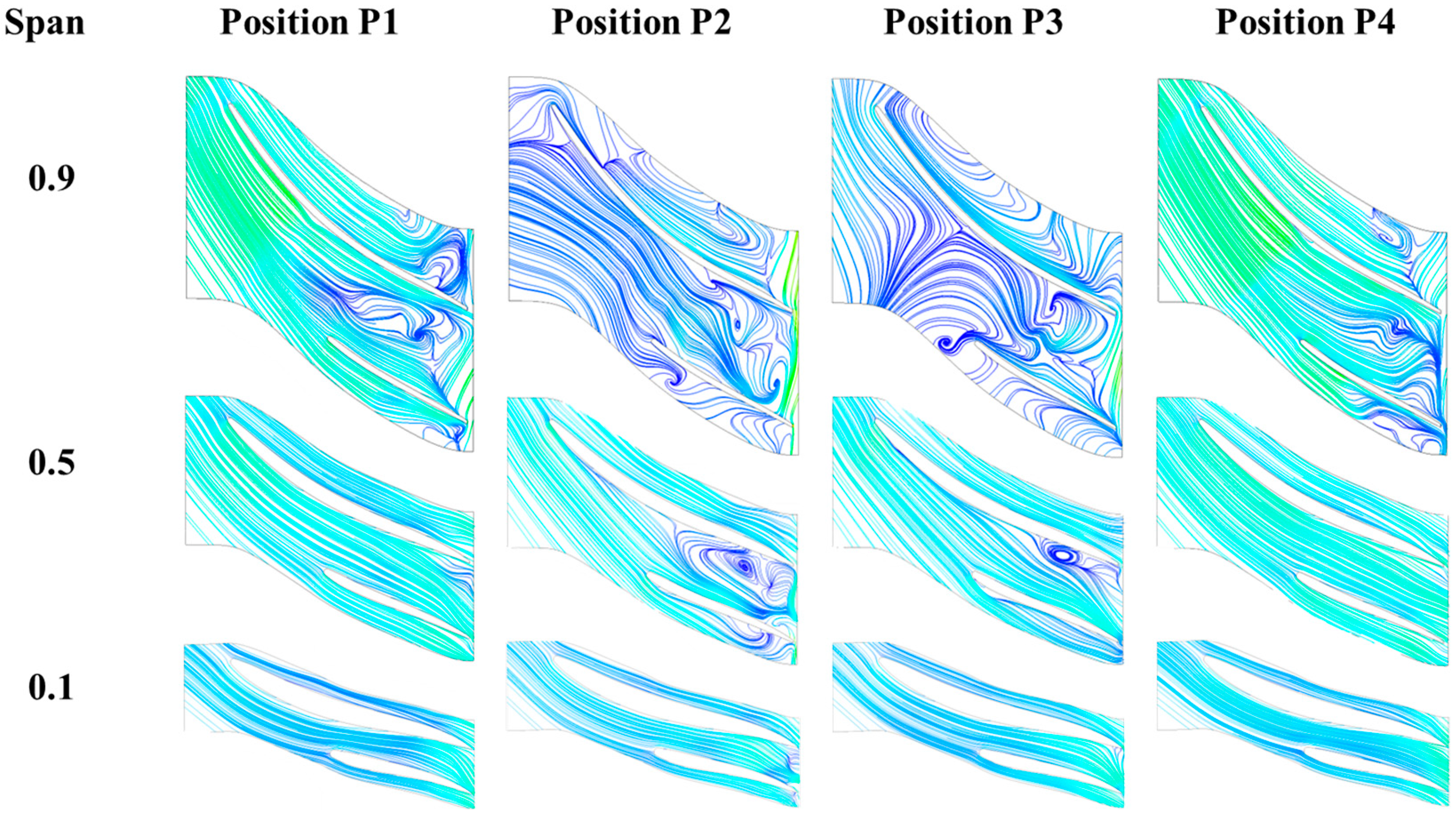

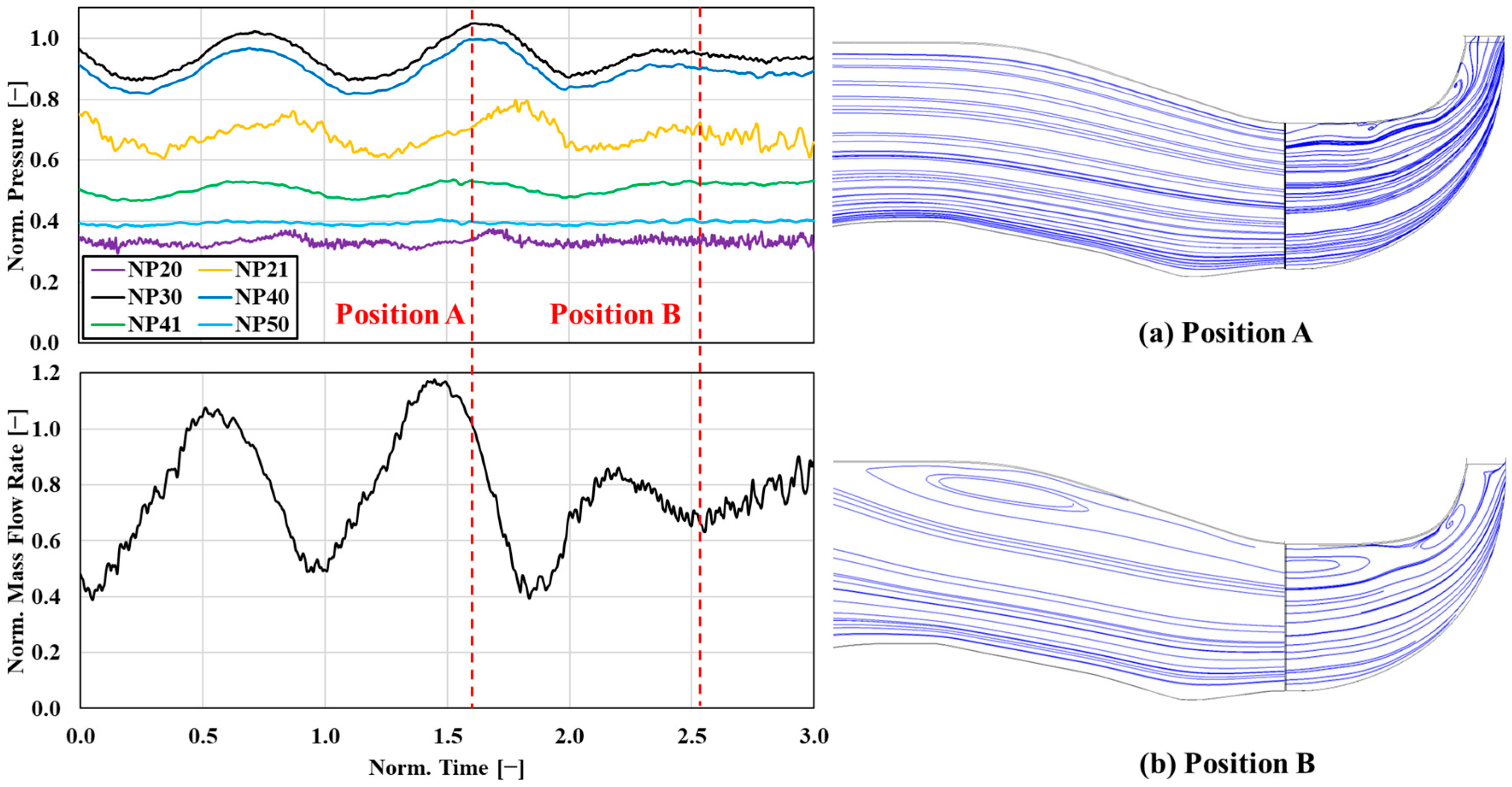

3.3. Surge Cycle

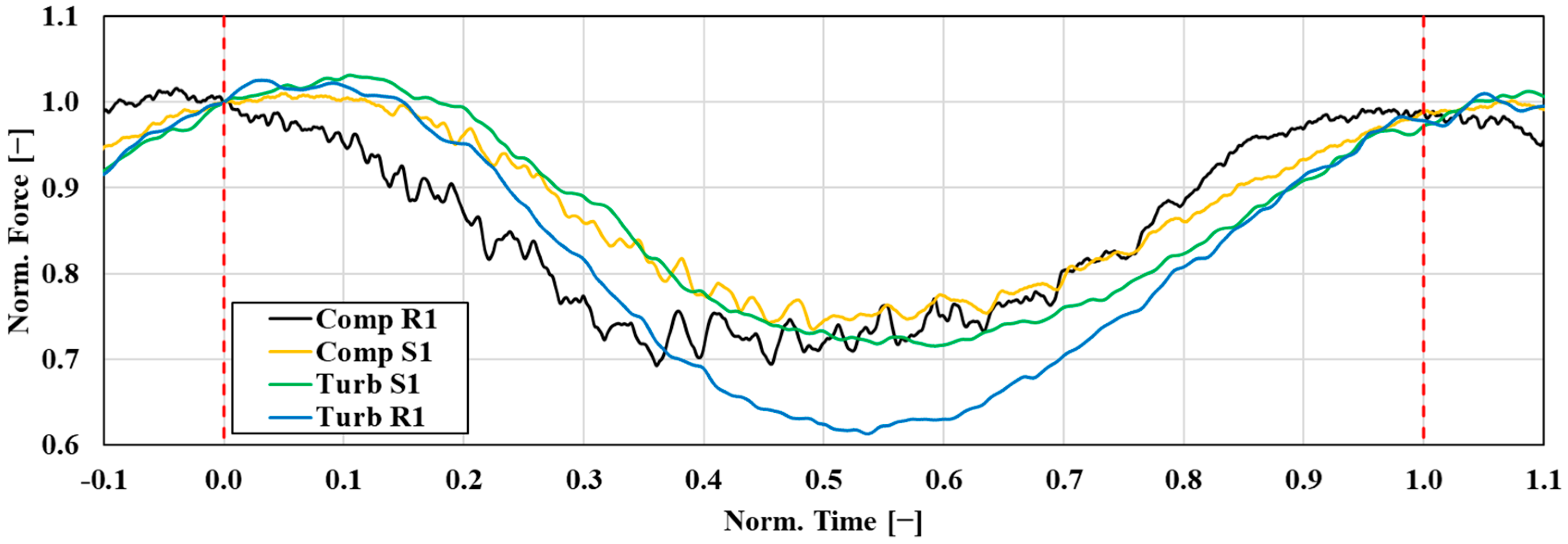

3.4. Axial Force Evaluation

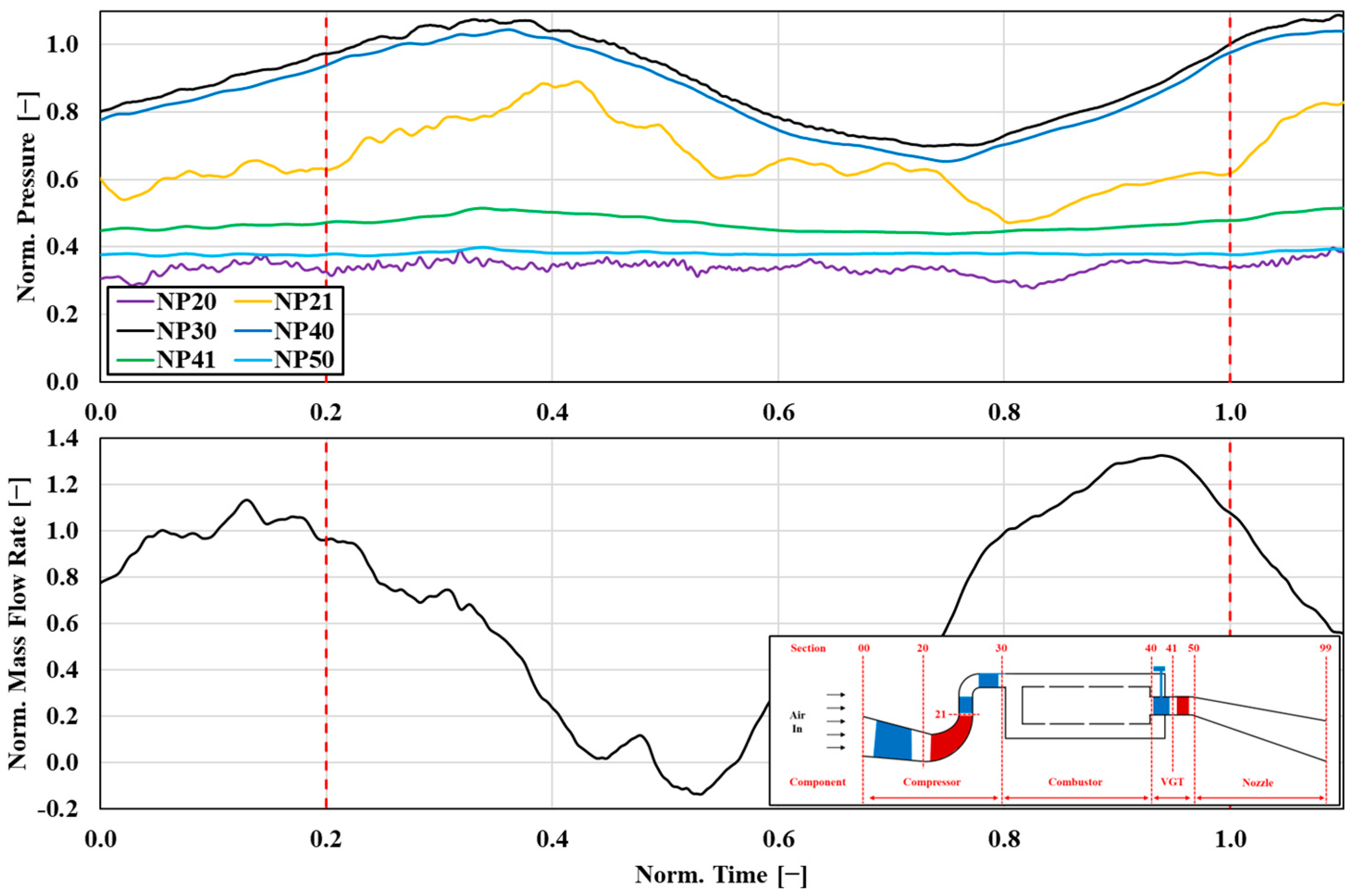

3.5. Two-Regime Surge

4. Conclusions

- (1)

- Through analysis of experimental and simulation results, it is concluded that the full-engine three-dimensional URANS method used in this study can capture the performance changes, surge boundaries, and main flow parameters during surge across the whole engine speed range. For engines with size configurations similar to the engine studied in this paper, the prediction accuracy of this method for surge frequency, pressure fluctuation amplitude, and surge boundary is on the order of 6%. This method can be used to obtain engine surge characteristics in the early design stage accurately, does not rely on additional empirical parameter calibration, and can replace part of the engine surge tests, reducing research costs.

- (2)

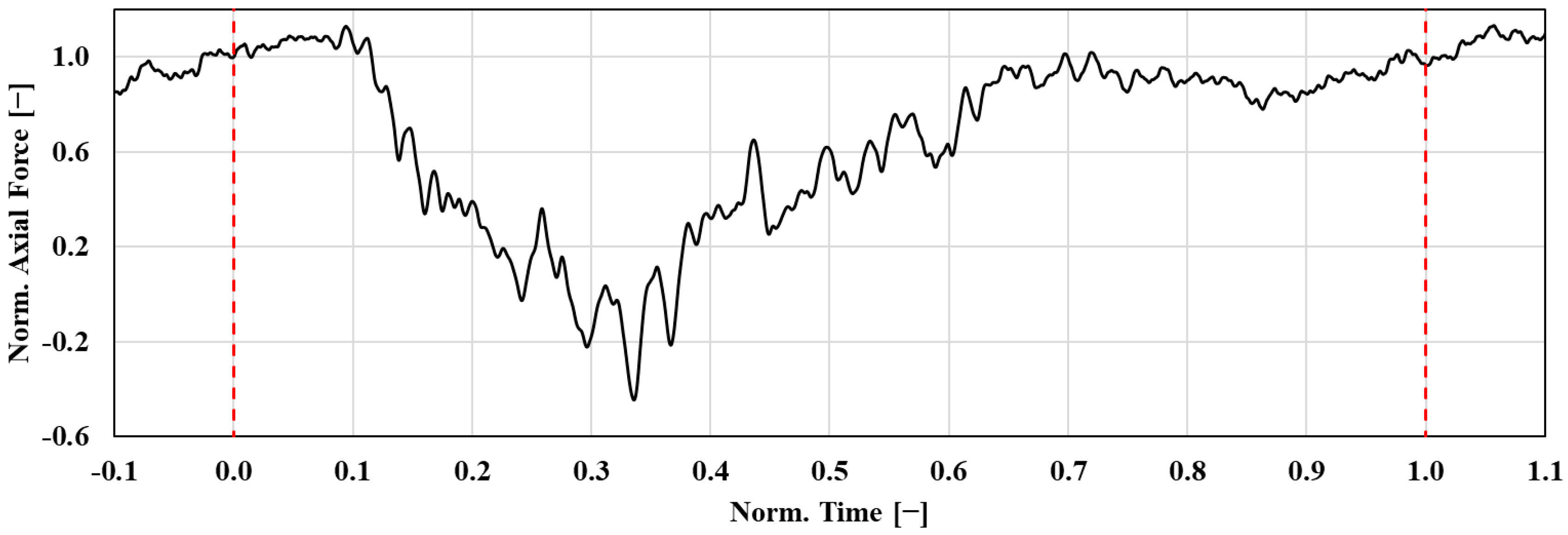

- The engine surge characteristics are obtained through the adjustment of the variable geometry turbine in the simulation results. During the surge, compressor inlet and outlet pressures exhibit periodic changes, but the minimum flow rate does not reach a negative value in the inlet passage. The engine studied in this paper enters a mild surge state. During the surge, the changes in aerodynamic forces on all blade rows are not significant. However, the axial aerodynamic forces on the engine rotor system reverse their directions. The maximum reverse axial force exerted on the rotor system is 0.6 times the axial force before the surge inception.

- (3)

- In the engine environment, the centrifugal compressor still exhibits the evolution trend of two-regime surge previously reported in component-level studies. In the small turbojet engine studied in this paper, when gradually closing VGTS vanes, the compressor sequentially enters mild surge and then recovers from it. If the exhaust temperature limits are lifted in simulations, the engine then progresses into a deep surge. In the practical applications, the engine becomes inoperable beyond the mild surge state; thus, the mild surge inception point should be defined as the engine’s stability boundary.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ECU | Engine Control Unit |

| EGT | Exit Gas Temperature |

| FFT | Fast Fourier Transform |

| FSO | Full-Scale Output |

| Norm. | Normalized |

| NP | Normalized Pressure |

| PR | Pressure Ratio |

| PID | Proportional Integral Derivative |

| RANS | Reynolds-averaged Navier–Stokes |

| SST | Shear Stress Transport |

| URANS | Unsteady Reynolds-averaged Navier–Stokes |

| VGT | Variable Geometry Turbine |

| VGTS | Variable Geometry Turbine Stator |

| π | Pressure Ratio |

| ṁ | Mass Flow Rate |

References

- Day, I.J. Stall, Surge, and 75 Years of Research. J. Turbomach. 2016, 138, 011001. [Google Scholar] [CrossRef]

- Cumpsty, N.A. Compressor Aerodynamics; Longman Scientific & Technical: Harlow, UK; J. Wiley: New York, NY, USA, 1989; p. 509. [Google Scholar]

- Emmons, H.W.; Pearson, C.E.; Grant, H.P. Compressor Surge and Stall Propagation. Trans. ASME 1955, 77, 455–467. [Google Scholar] [CrossRef]

- McDougall, N.M.; Cumpsty, N.A.; Hynes, T.P. Stall Inception in Axial Compressors. J. Turbomach. 1990, 112, 116–123. [Google Scholar] [CrossRef]

- Day, I.J. Stall Inception in Axial Flow Compressors. J. Turbomach. 1993, 115, 1–9. [Google Scholar] [CrossRef]

- Greitzer, E.M. Surge and Rotating Stall in Axial Flow Compressors—Part I: Theoretical Compression System Model. J. Eng. Power 1976, 98, 190–198. [Google Scholar] [CrossRef]

- Moore, F.K. A Theory of Rotating Stall of Multistage Axial Compressors: Part I—Small Disturbances. J. Eng. Gas Turbines Power 1984, 106, 313–320. [Google Scholar] [CrossRef]

- Fink, D.A.; Cumpsty, N.A.; Greitzer, E.M. Surge Dynamics in a Free-Spool Centrifugal Compressor System. J. Turbomach. 1992, 114, 321–332. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, A. Experimental Investigation of Surge and Stall in a High-Speed Centrifugal Compressor. J. Propuls. Power 2015, 31, 815–825. [Google Scholar] [CrossRef]

- Sun, Z.; Zheng, X.; Kawakubo, T. Experimental investigation of instability inducement and mechanism of centrifugal compressors with vaned diffuser. Appl. Therm. Eng. 2018, 133, 464–471. [Google Scholar] [CrossRef]

- Zheng, X.; Sun, Z.; Kawakubo, T.; Tamaki, H. Experimental investigation of surge and stall in a turbocharger centrifugal compressor with a vaned diffuser. Exp. Therm. Fluid Sci. 2017, 82, 493–506. [Google Scholar] [CrossRef]

- Lin, Y.; Niu, Z.; Zheng, X. Two-Regime Surge Mechanism in Centrifugal Compressors. J. Propuls. Power 2023, 39, 190–201. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, A. Phenomenon and Mechanism of Two-Regime-Surge in a Centrifugal Compressor. J. Turbomach. 2015, 137, 081007. [Google Scholar] [CrossRef]

- Burwell, A.; Patterson, G. Dynamic engine behavior during post surge operation of a turbofan engine. In Proceedings of the 21st Joint Propulsion Conference, Monterey, CA, USA, 8–10 July 1985. Paper AIAA-1985-1288. [Google Scholar]

- Lorenzo, C.F.; Chiaramonte, F.P.; Mehalic, C.M. Determination of compressor stall characteristics from engine surge transients. J. Propuls. Power 1988, 4, 133–143. [Google Scholar] [CrossRef][Green Version]

- Höss, B.; Leinhos, D.; Fottner, L. Stall Inception in the Compressor System of a Turbofan Engine. J. Turbomach. 2000, 122, 32–44. [Google Scholar] [CrossRef]

- Wilson, A.G.; Freeman, C. Stall Inception and Development in an Axial Flow Aeroengine. J. Turbomach. 1994, 116, 216–225. [Google Scholar] [CrossRef]

- Bae, J.W. An Experimental Study of Surge Control in a Helicopter Gas Turbine Engine. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Greitzer, E.M. Surge and Rotating Stall in Axial Flow Compressors—Part II: Experimental Results and Comparison with Theory. J. Eng. Power 1976, 98, 199–211. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, M.; Zheng, X. Compressor surge based on a 1D-3D coupled method—Part 1: Method establishment. Aerosp. Sci. Technol. 2019, 90, 342–356. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, M.; Zheng, X. Compressor surge based on a 1D-3D coupled method—Part 2: Surge investigation. Aerosp. Sci. Technol. 2019, 90, 289–298. [Google Scholar] [CrossRef]

- Andrew, G. Three-Dimensional Rotating Stall Inception and Effects of Rotating Tip Clearance Asymmetry in Axial Compressors. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Aeronautics and Astronautics, Cambridge, MA, USA, 1999. [Google Scholar]

- Sun, X.; Liu, X.; Hou, R.; Sun, D. A General Theory of Flow-Instability Inception in Turbomachinery. AIAA J. 2013, 51, 1675–1687. [Google Scholar] [CrossRef]

- You, D.; Kalitzin, G.; Herrmann, M.; Ham, F.; Pitsch, H.; van der Weide, E.; Alonso, J. Integrated Computations of an Entire Jet Engine. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; Volume 6: Turbo Expo 2007, Parts A and B, Paper GT2007-27094. pp. 299–308. [Google Scholar] [CrossRef]

- Turner, M.; Ryder, R.; Celestina, M.; Moder, J.; Liu, N.-S.; Adamczyk, J.; Veres, J. High Fidelity 3D Turbofan Engine Simulation with Emphasis on Turbomachinery-Combustor Coupling. In Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Indianapolis, IN, USA, 7–10 July 2002. Paper AIAA 2002-4067. [Google Scholar]

- Turner, M. Lessons Learned from the GE90 3-D Full Engine Simulations. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010. Paper AIAA 2010-962. [Google Scholar]

- Romagnosi, L.; Mezine, M.; Baux, Y.; Anker, J.; Claramunt, K.; Hirsch, C. A Methodology for Fully-Coupled CFD Engine Simulations, Applied to a Micro Gas Turbine Engine. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018; Volume 2C: Turbomachinery, Paper V02CT42A047. [Google Scholar] [CrossRef]

- Li, Y.; Mezine, M.; Teixeira, M.; Vilmin, S.; Anker, J.E.; Claramunt, K.; Baux, Y.; Hirsch, C. A Methodology for Steady and Unsteady Full-Engine Simulations. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019; Volume 2C: Turbomachinery, Paper V02CT41A002. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Piao, Y. Analysis of discrepancies between 3-D coupled and uncoupled schemes based on CFD in full engine simulation. Aerosp. Sci. Technol. 2022, 131, 107978. [Google Scholar] [CrossRef]

- Wei, J.; Wen, M.; Yang, H.; Wang, X.; Zheng, X. Full Three-Dimensional Fluid-Thermal-Structural Coupling Modeling Method for Turbojet Engines. J. Aerosp. Power 2025, 40, 79–87. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Zheng, X.; Wang, Z.; Zheng, X. Experimental Investigation on the Aerodynamic Instability Process of a High-Speed Axial-Centrifugal Compressor. J. Eng. Gas Turbines Power 2024, 146, 081018. [Google Scholar] [CrossRef]

- Erario, M.L.; De Giorgi, M.G.; Przysowa, R. Model-Based Dynamic Performance Simulation of a Microturbine Using Flight Test Data. Aerospace 2022, 9, 60. [Google Scholar] [CrossRef]

- Akhlaghi, M.; Azizi, Y. Investigation of Vaned-Recessed Casing Treatment in a Low-Speed Axial-Flow Compressor, Part II: Unsteady Results. Aerospace 2023, 10, 763. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Zeng, H.; Zheng, X. Investigation of the mild surge in an axial–centrifugal compressor. Phys. Fluids 2024, 36, 066113. [Google Scholar] [CrossRef]

- Zhao, B.; Huang, C.; Zhang, Z.; Cui, W.; Zhou, T. Experimental study on the effects of compressor rotational speed on surge characteristics: Spatial and temporal frequencies. Aerosp. Sci. Technol. 2025, 157, 109854. [Google Scholar] [CrossRef]

- Magnussen, B.F.; Hjertager, B.H. On mathematical modeling of turbulent combustion with special emphasis on soot formation and combustion. Symp. (Int.) Combust. 1977, 16, 719–729. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Diameter of the impeller | 0.12 m |

| Diameter of the engine | 0.18 m |

| Design spool speed | 90,000 rpm |

| Design rotor tip speed | 565 m/s |

| Number of impeller blades | 7 |

| Number of diffuser blades | 15 |

| Number of vaporizer tubes in the combustor | 12 |

| Number of turbine stator blades | 15 |

| Number of turbine rotor blades | 23 |

| Max thrust of the engine | 539 N |

| Design Turbine Inlet Temperature | 1200 K |

| Max pressure ratio of the engine | 4.5 |

| Characteristics | XTE-190(M)-40A | XTEH-10L-190 |

|---|---|---|

| Range of Pressure | 275 kPa ± 0.1% FSO | 1379 kPa ± 0.1% FSO |

| Natural Frequency | 300 kHz | 500 kHz |

| Range of Temperature | 25–232 °C | 25–454 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, M.; Yang, H.; Zheng, X.; Kong, W.; Ding, Z.; Li, R.; Jin, L.; Wang, B.; Zheng, X. Numerical Analyses of Surge Process in a Small-Scale Turbojet Engine by Three-Dimensional Full-Engine Simulation. Aerospace 2025, 12, 878. https://doi.org/10.3390/aerospace12100878

Wen M, Yang H, Zheng X, Kong W, Ding Z, Li R, Jin L, Wang B, Zheng X. Numerical Analyses of Surge Process in a Small-Scale Turbojet Engine by Three-Dimensional Full-Engine Simulation. Aerospace. 2025; 12(10):878. https://doi.org/10.3390/aerospace12100878

Chicago/Turabian StyleWen, Mengyang, Heli Yang, Xuedong Zheng, Weihan Kong, Zechen Ding, Rusheng Li, Lei Jin, Baotong Wang, and Xinqian Zheng. 2025. "Numerical Analyses of Surge Process in a Small-Scale Turbojet Engine by Three-Dimensional Full-Engine Simulation" Aerospace 12, no. 10: 878. https://doi.org/10.3390/aerospace12100878

APA StyleWen, M., Yang, H., Zheng, X., Kong, W., Ding, Z., Li, R., Jin, L., Wang, B., & Zheng, X. (2025). Numerical Analyses of Surge Process in a Small-Scale Turbojet Engine by Three-Dimensional Full-Engine Simulation. Aerospace, 12(10), 878. https://doi.org/10.3390/aerospace12100878