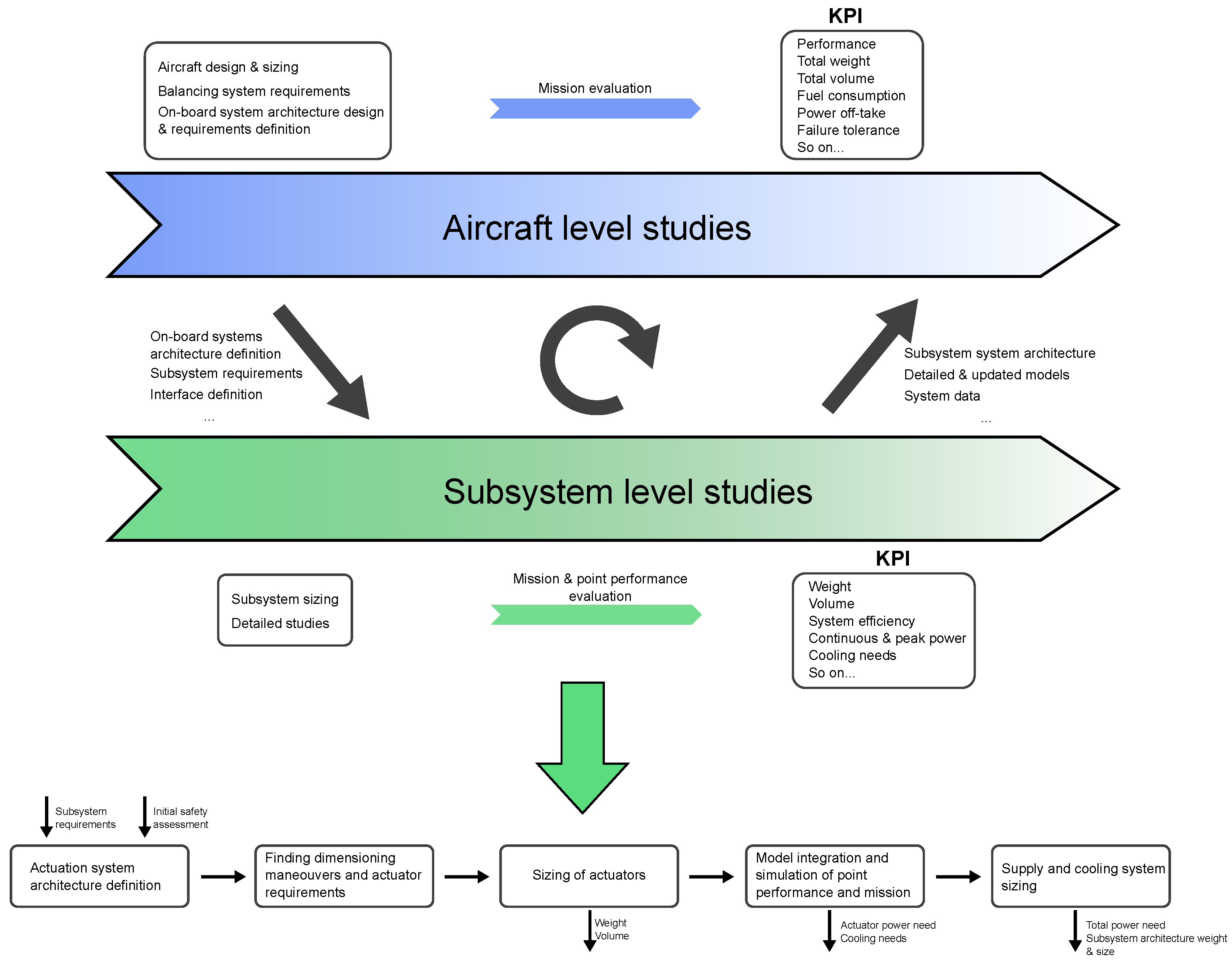

A case study that uses the proposed framework for comparing fly-by-wire servohydraulic, electromechanical, and electrohydrostatic actuation architectures for primary flight control actuation is presented here. The purpose is primarily to showcase the methodology that provides the weight and size distribution, power consumption, and cooling needs by integrating models in a full flight simulator environment containing more details than what is typically the case in the early aircraft conceptual design phase. This involves the definition of the architectures, development of proper models, and integration into the framework. The system boundary is defined from the engine power take-out shaft to the flight control surfaces.

The aircraft under consideration is fictive, and as such, the requirements are also fictive. Nevertheless, a realistic approach was taken when developing the architectures. The methodology and framework can therefore be adopted to similar studies where data are available. The results also give a sense of the difference between the technologies under consideration.

Since the modeling process is partially based on company data, no numbers can be disclosed and a relative comparison is provided. It is possible to conduct a similar study with any available data by following the same procedure.

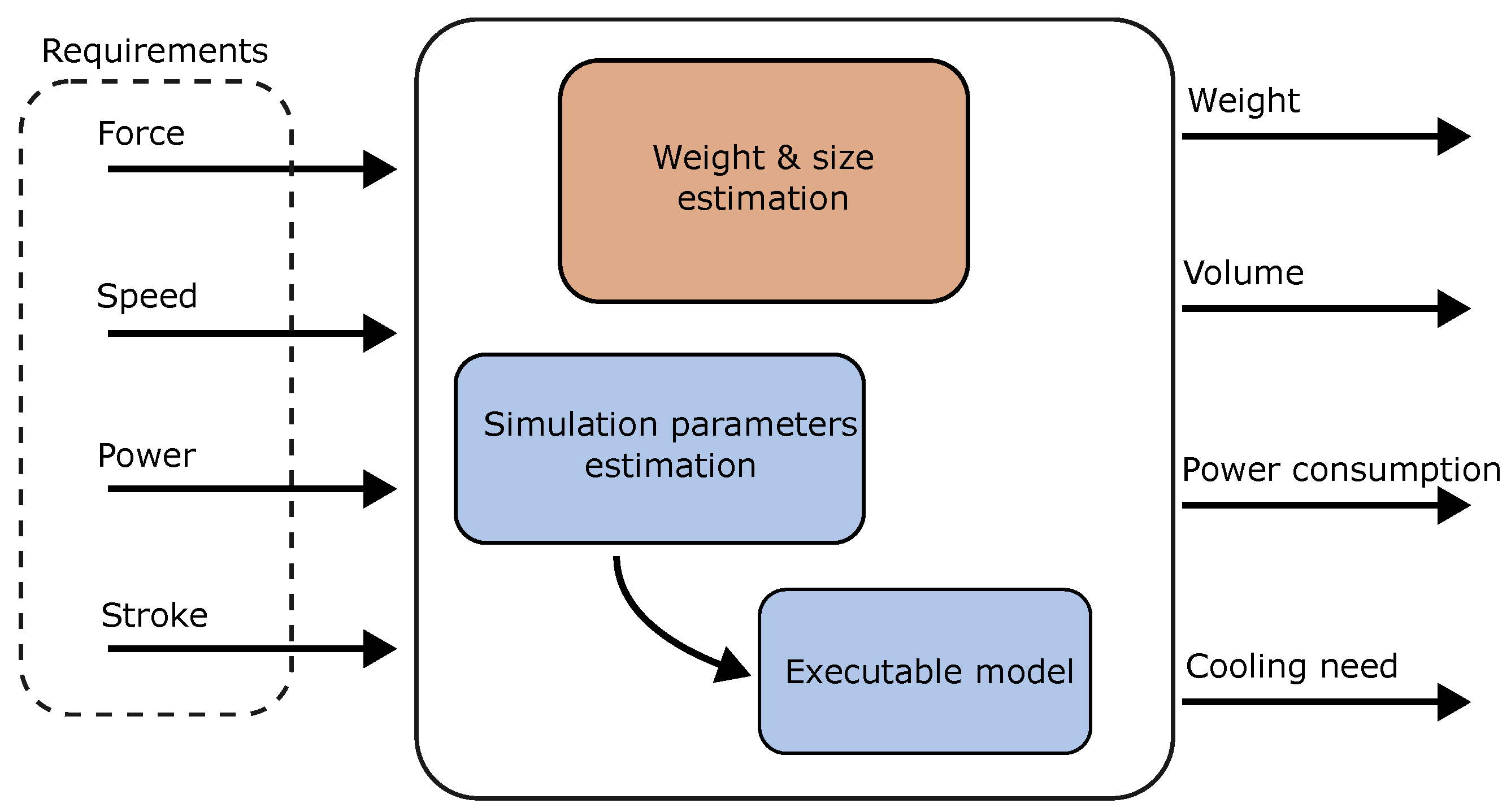

5.4. System Modeling

The system modeling is focused on modeling the actuation and vehicle systems, considering weight, size, power consumption, and cooling needs. The executable models are implemented in Matlab/Simulink (version 2022b) using the Simscape library.

Servohydraulic actuator

Weight and size

The weight and size estimation of the SHA is based on not publicly available aircraft data. Three different-sized duplex/tandem hydraulic primary actuators from an existing aircraft are used as input. A standard linear regression is applied and a relation was found between the actuator weight,

M, and size,

V, to stall force,

F, and stroke,

l, according to Equations (

1) and (

2). The coefficients

and

(

M and

V for mass and volume) are found from the linear regression:

The executable SHA model is defined in

Figure 7. It includes the nonlinear steady-state characteristic and the dynamic characteristic deemed necessary; that is, the integration from actuator movement. The important characteristic is the actuator position since it affects the flight dynamics and the actuator speed since it affects the power consumption and thermal properties. Any internal states, such as servo valve dynamics and pressure build-up, are excluded since they only concern the high-frequency spectrum and require more detailed design and modeling. The advantage of implementing the model as a closed-loop system is that both position and speed are calculated without any derivation.

The closed-loop response is defined by the proportional gain

, the hydraulic gain

, and cylinder size

. The valve opening

A is defined from the control signal as in Equation (

3):

where x is the actuator position. A saturation block limits the maximum allowed speed. The limit

can be defined according to Equation (

4):

The maximum allowed flow

is based on the defined maximum speed

, while the nominal load pressure

is based on the nominal load according to Equations (

5) and (

6):

The maximum speed is either defined at the no-load case, where the nominal load is set to zero, or at a continuous load value. The tank pressure, if any, could also be included but is neglected here for simplicity reasons. The hydraulic gain

defines the nonlinear steady-state characteristic based on the flow coefficient

, oil density

, and pressure difference over the servo valve as in Equation (

7):

with supply pressure

and load pressure

. Both

and

are user-defined and are here set to typical values of 0.7 and 850, respectively.

The block diagram in

Figure 7 can be turned into a first-order transfer function on the general form in Equation (

8), where

s is the Laplace operator and

the first-order response time:

The response varies with the load since the hydraulic system is nonlinear. The response is typically defined for the no-load case. The open loop gain is defined from the block diagram as in Equation (

9):

The closed-loop response can now be defined as in Equation (

10):

The closed-loop response is compared with the general form, which gives the controller gain as in Equation (

11):

A leakage term is added to account for the internal leakage of the system. A general model is adopted since no detailed data are available. The leakage is modeled using a variable orifice for each spool land of the servo valve (P for supply port, A and B for cylinder ports, and T for tank port): P-A, A-T, P-B, and B-T. The leakage is modeled according to the characteristics in

Figure 8, where the maximum leakage occurs when the spool is centered and gradually decreases as the spool closes the corresponding land. The leakage is kept constant when the spool land is fully opened, illustrated by the negative side in the figure, and will be part of the main flow. The total leakage flow can be set to a typical value; around 1 L/min is used here.

The estimation of the EMA’s characteristics is based on an SVD analysis. The EMA was reduced to include only the permanent magnet motor and ball screw since only a direct driven EMA is considered here. A more detailed modeling is possible using the same approach by including bearings and sensors as well, or a gearbox if such an actuator is considered. The process is illustrated in

Figure 9.

An SVD analysis is produced for both the ball screw and the permanent magnet motor. The ball screw model takes the required force, speed, and stroke as input, where the stroke is needed to estimate the ball screw weight. The SVD models can be used in different ways. Model parameters can be estimated directly or design rules can be defined that sets the relation between the inputs and ball screw characteristics. This can be seen in detail in [

32]. The pitch of the ball screw is estimated with the required actuator stall force as input, and it is used to transform the required force and linear speed to a motor torque and motor rotational speed.

An SVD model of the motor is produced, which estimates the size and weight, as well as all necessary parameters for the simulation model. The inputs to this model are the maximum torque, which is here derived from the actuator stall load through the ball screw; the maximum rotational speed derived from the actuator maximum speed; and the maximum power. The power is included since it gave a better estimation of the motor characteristics and can be motivated by the fact that motors with a similar torque and speed can have different power characteristics depending on certain design choices. The maximum power is here assumed to occur at 70% of the maximum torque–speed product. Of course, these are only assumptions, and without any detailed knowledge of the required torque–speed characteristics of the actuator, they serve as a good starting point. Based on these inputs, the model estimates the following parameters used for the weight and size estimation, as well as the simulation model: max allowed continuous current, torque constant, winding resistance, rotor inertia, thermal time constant, mass, and volume. The model is based on data from 64 different permanent magnet motors collected from [

35]. Seven motors were excluded from the dataset to serve as validation data. These motors are designed for typical industrial applications and require a 400 V supply, which is different from the 270 VDC assumed for this paper. However, the model is also tested for an available flight EMA designed for 270 VDC. The total weight and size of the actuator is the sum of the ball screw and motor. The specific tool for deriving the SVD model is implemented in Excel, and the approach can be studied more in detail in [

36].

An example of the validation of the SVD model is shown in

Figure 10. The model finds the statistical relation between all parameters in the left-side column. By applying an in-built optimization routine, the motor parameters are estimated by tuning the SVD variables in order to minimize the defined criteria, in this case, to minimize the motor weight. Only three SVD variables are included since it turns out that three inputs have the most dominant effect on the design. The relative error between each estimated parameter and the actual value from the validation set is calculated. There is a large spread in how accurately the different parameters are estimated for the validation set. The mass is at worst at 15% error, with a median at 7%. The volume is at 37%, but only for one sample, with a median error at 17%. The torque constant has a median error of 6% and a continuous current of 15%. The most difficult parameters to estimate are the winding resistance, rotor inertia, and the thermal time constant, with the respective median errors at 27%, 68%, and 36%. The only parameter with a very large spread in the estimated values is the rotor inertia. This is an indication that more input data are needed to have a better estimation; for example, a better knowledge of the operating envelope. The assumption is, however, that this information is not available in this phase of the conceptual design, and the model overall presents a valid approach to estimate the motor characteristics from only three input parameters. In all cases, the maximum speed is estimated higher. This is expected since the required value is low due to a direct drive EMA being investigated and electric motors typically working in a high speed range. This also affects the maximum power that is also estimated higher. This is not a problem, though, since the required speed and power are fulfilled.

A test sample is available from a current flight EMA. To have a better comparison, the maximum speed and power are scaled to a 400 V motor. The estimated total EMA weight differs only by 4%, the torque constant differs by 40%, the winding resistance by 46%, and the rotor inertia by 17%.

The actuator control unit’s weight and size are defined to scale linearly with stall load based on an available reference unit. This can differ depending on the control unit’s architecture, functionality, and whether it is integrated with the actuator or stand-alone equipment.

The executable EMA model is shown in

Figure 11. The model fidelity is balanced in such a way to include what is deemed necessary dynamic characteristic at a Level 2 model fidelity. Since a detailed design of the actuator is not available at the conceptual design stage, the modeling must also consider what data are available at this point. A typical electric motor model involves the electromagnetic and inertial effects. The electromagnetic effects are of very high frequency and are excluded. Furthermore, the model is implemented as a direct current (DC) equivalent since the alternating current components are not of interest. Thus, the model includes the speed and position control loops. The thermal characteristics account for the copper losses, and the whole motor is considered a homogeneous mass.

An initial rate limiter prevents the flight control system from commanding a too-high speed. The commanded actuator position is converted to motor angle through the ball screw lead. Since the model assumes the motor current control loop to be infinitely fast, only the static characteristic is included. The motor torque is assumed to be proportional to the motor current as in Equation (

12):

Both the motor torque

and the external load

act on the motor inertia

J together with friction. The external load is converted from the translational load through the ball screw as in Equation (

13), where

L is the ball screw lead:

The ball screw friction depends both on speed and temperature, which can be seen in [

37,

38], and can increase up to six times at very cold temperatures [

39]. The ball screw efficiency can reach up to 95% in low-speed conditions, ref. [

40], which is applied in this work. The viscous friction coefficient can be calculated based on assumptions of maximum efficiency and operating points, as shown in Equation (

14), where

and

are the nominal load and speed where the maximum efficiency

occurs. To include the temperature dependency, the coefficient is scaled with the factor

, which varies exponentially with temperature, being one at around 20 °C, as shown in [

39]. Finally, saturation limits the maximum allowed motor current:

The speed and position controllers are designed to give a first-order closed-loop system, and the respective controllers are identified using the same method as for the servhohydraulic actuator. The speed controller can be identified as in Equation (

15):

The time constant

is the desired speed control closed-loop response. The controller takes the form of a PI controller. The time response should be defined to be much faster than the position control loop, typically at least ten times faster. In this way, the speed control response can be neglected when designing the position control loop. The position control open loop now reduces to a pure integrator, and the position controller is defined as a proportional controller as in Equation (

16):

The constant

is the desired position closed-loop response. The output from the position controller is the speed control reference. Saturation prevents the controller from demanding a too-high motor speed.

The motor current is given directly from the motor model. The motor voltage

U is calculated from Equation (

17):

The motor coils’ resistance is denoted

R, and the back emf constant

is assumed to be the same as the motor torque constant. The input current from the DC power supply is calculated by assuming a constant efficiency for the converter (REU) and applying a constant power conversion as in Equation (

18):

The temperature characteristic is based on the assumption of a homogeneous thermal mass and that the dominating losses come from the copper resistance. The thermal behavior is defined by Equations (

19) and (

20):

The thermal mass is denoted

,

c is the specific heat,

T the equivalent motor temperature,

the motor losses,

the ambient temperature, and

the thermal resistance. The temperature transfer function can now be defined as in Equation (

21), with the thermal time constant

defined in Equation (

22). The copper losses are simply calculated from the squared motor current multiplied by the copper resistance:

The ambient temperature can either be set externally to a fixed value, or in this case, it is calculated as the bay temperature where the actuator is located. A detailed design is required to obtain a good estimate of the bay temperature, but a first approximation is to assume that the bay temperature follows the skin temperature with a 10 min delay. The bay temperature is calculated from Equation (

23), where

M is the Mach number, and the atmosphere temperature,

, is calculated from Equation (

24), where

h is the flight altitude. The first-order filter represents the time delay, where

s denotes the Laplace operator:

The estimation of the EHA weight and size follows the same process as for the SHA and EMA, shown in

Figure 12. The required force, speed, and stroke size the required cylinder. This is the same cylinder model used for the SHA. The cylinder is sized for a stall load at a maximum pressure of 28 MPa and converts the required speed into a flow

that the pumps must provide. The EHA pump typically runs at a very high speed. By assuming a speed

n, in this case, 10,000 rpm, the pump displacement

is given by Equation (

25).

The pump-sizing model is based on open data of bent-axis pumps. The same principle can be used for any type of pump with available data. Collecting data from [

41] on different pump sizes and their respective mass, size, and inertia and applying regression models gives the relations in Equations (

26), (

27) and (

28) between pump displacement (with unit m

3/rev) and pump characteristics (mass in kg, inertia in kgm

2, and size in m

3). The pump inertia is added to the motor inertia:

The pumps convert the cylinder pressure into a required motor torque through Equation (

29). A pump efficiency of 80% is applied. This of course varies over the working envelope but requires more detailed modeling of the pump losses. The chosen efficiency covers the interesting working region and is representative for sizing, even if higher efficiencies can be achieved in practice. The sizing of the motor then follows the same principle as for the EMA case by applying the SVD motor model:

The EHA also includes an accumulator to cover for possible oil leakage and volume change due to temperature. It is assumed that the accumulator size is equal to the cylinder oil volume. In a similar fashion to the pump, the weight and size of the accumulator can be estimated based on regression models from available data. Collecting data from [

42] gives the relation for mass and size based on the required accumulator volume

(unit liter) as in Equations (

30) and (

31):

The control unit follows the same model as for the EMA. The total mass and size is the sum of all components, number of pumps, number of motors, cylinder, accumulator, and controller.

Validation of the model can be performed by comparing it to the open data of existing electrohydrostatic actuators. Data of a dual tandem EHA tested on the F16 fighter aircraft is available in [

18], with a stall load of 15.5 kN. By applying the size estimation method, the total (actuator + control unit) weight is only 5% lower than the actual actuator.

Since the EMA and EHA are similar in terms of dominating dynamic characteristics, the same implementation can be used for the simulation model, as shown in

Figure 11. Although the pump contributes to the total inertia the motor has to overcome, the pump displacement and cylinder is considered as a ratio between the load and motor defined by the ratio in Equation (

32):

A viscous friction is applied for the motor with a nominal efficiency of 95%. The same model as for the EMA is used but without the temperature dependency. The pump is assumed to have a constant efficiency of 80%. The pump efficiency varies in reality with operating conditions and temperature but requires a far more detailed model than what is intended for this study. The assumed efficiency is conservative and sufficient for sizing purposes.

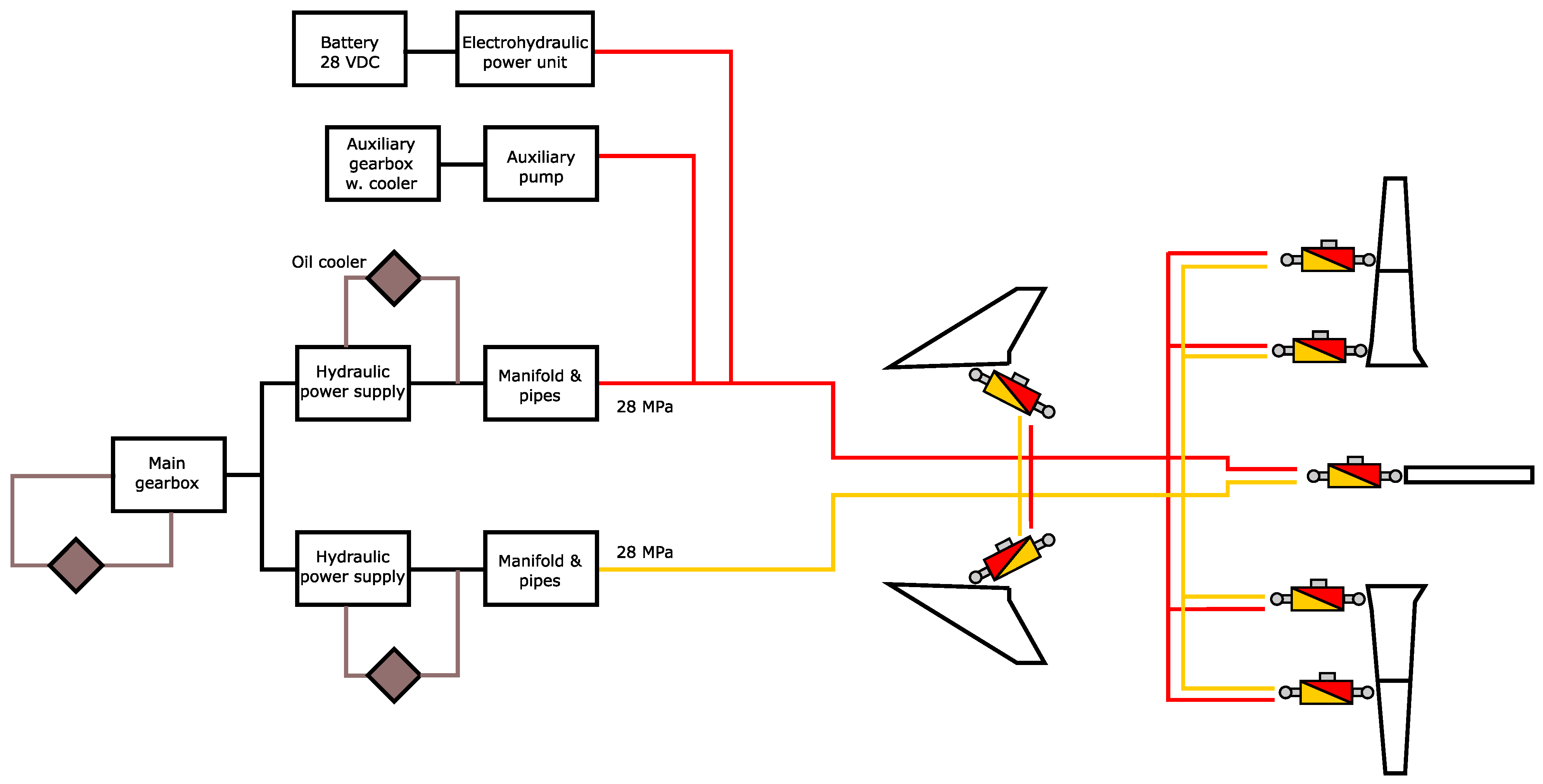

There are two approaches to estimate the weight and size of the supply and distribution systems. It is possible to follow the method used to estimate the EMA weight and size by collecting data and applying a linear regression or an SVD analysis. The challenge is to find appropriate data and detailed information on how components are interfaced. The other approach is to study an existing aircraft installation, which is available to the authors. The benefit is that actual installation effects and component interfaces are more easily covered, which improves the final estimation. The drawback is that just one sample was used in this study.

Since the weight and size estimation are based on company data, it cannot be revealed to the public. The models are divided into supply, distribution, and loads (power consumers), considering only the main components from the reference aircraft. The weight and size of the components are then scaled according to the reference aircraft.

The hydraulic supply system includes the main pumps, reservoirs, accumulators, connecting elements (related to the supply units), and the hydraulic oil cooler. Since the hydraulic supply pressure is assumed to be equal to the reference system, the weight and size scale proportionally to the required maximum oil flow. The oil cooler’s mass and volume scale with the total hydraulic system’s power losses.

The same gearbox model is used for both architectures. Its mass and volume scale linearly with the required maximum total power. It includes an oil cooler which scales linearly with the gearbox losses.

The hydraulic distribution includes the main manifolds and the hydraulic piping, including the hydraulic oil. The manifold scales linearly with the total maximum flow since a higher flow would require larger passages to avoid too-high pressure losses.

It is not straightforward to estimate the required piping length and size, and hence its mass, without a detailed design. There are many variables to consider. The approach is to compare with the reference aircraft and isolate the piping to the primary actuation system and scale it with the wing span, aircraft length, and total oil flow. The argument is that the piping extends across the aircraft and the wings, while a higher flow would require larger pipes to avoid a too-high pressure drop. The pipe’s mass is thus calculated as in Equation (

33), where

q is the oil flow,

S the wing span,

L the aircraft length, and the constants

and

are derived from the scaling:

The required pipe length follows the same approach but only scales with the wing span and aircraft length. The mass of the hydraulic oil follows the same principle as for the pipe mass.

The auxiliary pump is connected to one of the main hydraulic systems and shares the same reservoir. It is driven by the auxiliary gearbox, which in turn is driven by bleed air from the engine. The scale model therefore only considers the pump itself. The mass and volume scale linearly with the required oil flow. Since the auxiliary pump activates during a failure of the main system, only half of the total flow is required. The auxiliary gearbox is considered a complete package with an oil cooler and an air turbine to drive it. The mass and volume scale linearly with maximum power. The total mass and volume of the auxiliary system is the sum of these components.

The emergency hydraulic system consists of a pump driven by an integrated electric motor and connecting pipes. A 24 VDC battery supplies the motor. The system shares the same reservoir as the main system and is therefore excluded from the scale model. The pump and motor package mass and volume scale linearly with the maximum required oil flow in emergency mode. The battery’s mass and volume, on the other hand, scale with the required energy to drive the pump for 10 min. This time range was set arbitrarily for this case study. The battery weight and size are based on a single lithium-ion cell, for which data are available, for example, here [

43]. The required energy is used to calculated the amount of required cells. An actual battery pack weighs more than the total number of cells. There is the battery management system, the battery case, and installation equipment. Since no feasible data are available for the two battery packs in this work, comparing on the cell level at least gives a rough estimate of the relative weight difference for the two architectures.

The electric supply system consists of the electric generator, rectifier, and control unit. The total weight and size scale linearly with the power. The equipment shares a common oil cooler whose size and weight scale linearly with the internal power losses.

The electric power distribution system consists of solid-state power distribution units (the exact number is not considered here) and the electric wiring. The mass and volume of the distribution unit scale with the total power.

The estimation of the wiring mass is based on a reference cable from the reference aircraft, which is compared to pure copper of the same size. This gives a correction factor for the required insulation. The sizing of the wire follows the standard AWG tables, found for example here [

44], for the required maximum current. The wire mass estimates according to Equation (

34), where

l is the wire length,

A is the wire area (AWG size),

is the copper density, and

k is the correction factor:

The required wire length is set to be the same as the hydraulic pipe length. This is of course an assumption, but it ensures that the electric and hydraulic systems are compared on equal terms. The wire size is based on the assumption that the power distribution units are placed close to the actuators to avoid unnecessary cable routing. The assumption is that 20% of the total length is sized for the maximum power draw and the rest is sized for the mean power draw for one actuator.

The electric auxiliary system components are equal to what is already defined for the main system and run from a similar auxiliary gearbox as the hydraulic system. The electric emergency system relies on a 270 VDC battery. The mass and size scale linearly with the required energy content for 10 min of flight.

The simulation models of the vehicle systems are at a high fidelity steady-state level and include a gearbox, hydraulic pumps, and generator. The models are implemented to calculate the input power required to drive the actuation system by assuming constant efficiencies, as shown in Equation (

35). The energy efficiency is set to 90% for the gearbox and electric supply system (total efficiency) and 80% for the pumps:

5.5. System Sizing

Below follows the procedure for sizing all the involved systems. The above-defined framework and models are used to derive the requirements. The procedure is merely for illustrative purposes of the methodology and comparison of the two architectures. It is, however, chosen in order to have a realistic comparison.

The flight control actuators are sized by simulating the 6-DOF model in various envelope points performing doublet maneuvers; that is, performing a roll while pulling the pitch and then immediately rolling in the opposite direction. This is motivated by the operational requirements of such an aircraft. The highest loads occur at low altitudes at high subsonic speeds. This, in combination with past experience, results in actuator stall load requirements: 115 kN for the outer elevons, 85 kN for the inner elevons, 85 kN for canards, and 50 kN for the rudder. The maximum control surface deflection is set to 50°/s at no load with a response time of 50 ms, as is defined by the flight simulator in use.

The sizing of the SHA is straightforward by sizing the effective piston area according to the stall loads and assuming a supply pressure of 280 bars and a tank pressure of 6.5 bars. The maximum valve opening is calculated according to the model defined in

Section 5.4 based on the no-load speed requirements, the hydraulic gain is calculated with the defined supply and tank pressure at no-load, and finally, the controller gain is calculated with the defined actuator response. The response will of course vary due to the nonlinear actuator characteristic and will have its maximum at the no-load case. Any other requirements are possible by defining the required response for the desired load case.

The sizing of the supply and distribution system is conducted by again simulating the different maneuvers but with the integration of the actuation system which derives the total flow requirements. The flow requirements are driven by high actuator speed demands, which occur at a low speed and altitude for severe roll commands. With the flow and pressure defined, the required gearbox power is calculated and so is the required gearbox cooling by applying an assumed gearbox efficiency. The next step is to simulate the intended mission in order to estimate the required hydraulic oil cooling. During the mission, the hydraulic losses are only high during maneuvering, which only takes place for a short duration. The hydraulic oil cooler can therefore be sized to cover only the continuous losses due to servo valve leakage. The gearbox oil cooler is sized in the same way by only covering the gearbox losses providing the continuous power to drive the pump when covering the hydrau- lic leakage.

The size of the auxiliary system is sized to give the same total flow for one system. The emergency pump is sized to give 50% of the flow from one pump during 10 min of flight. This will also size the 24 VDC battery. The sizing of the battery is conservative but motivated since the required maneuvering during an emergency case is an unknown factor. This will ensure full maneuverability of the aircraft during 10 min.

The sizing and parameter estimation of the EMAs is developed using the SVD analysis approach described above. For the three different actuator sizes, all required model parameters are estimated based on the input’s stall load, max speed, max power, and stroke. The parameters are inertia, torque constant, winding resistance, screw lead, max motor current, continuous current, max motor speed, thermal time constant, weight, and size. The thermal resistance and thermal mass are then calculated according to the assumptions in

Section 5.4 and available data from the data sheet used for this work [

35], where the assumed temperature increase at continuous drive is 60°.

The sizing of the electric supply system follows the same procedure as for the hydraulic system. The same maneuver used for defining actuator stall loads is simulated again with the actuator models integrated. While the hydraulic supply system size is driven by the maximum flow requirements, the electric system is driven by the highest power requirements, which occur for the highest actuator loads and speed combination. This gives the maximum required power consumption of the actuation system, which together with the efficiency of the supply system and gearbox, size the respective system and its cooling requirements. In comparison to the hydraulic system, there are no continuous losses to cover. The supply system cooling would in practice be covered by the continuous power requirements from other on-board systems. In order to complete the actuation system comparison, however, the required supply system cooler is defined from a mean value of the supplied power during the maneuver. This is performed by studying the provided energy during the maneuver and dividing with the time to completion. This mean power is provided by the supply system (the gearbox and electric system), and their respective inefficiencies size the cooling requirements and the oil cooler size. The distribution units have channels for each actuator, and each channel must be scaled to handle the peak power from each actuator. The total actuator power is thus used to size the distribution unit. The electric wire, however, is sized to handle the maximum generator power for 20% of the total length, and the rest is sized to handle the mean actuator power.

It is assumed that no active cooling is required for the actuators since they typically only work for a short duration during maneuvering. Many different missions and maneuvers can be simulated with the developed framework where the temperature of the actuators is monitored to analyze if active cooling is required or to resize the actuators to handle higher temperatures. The amount of cooling is controlled by the thermal resistance parameter in the actuator model. Although thermal behavior is complex and requires detailed modeling, an initial estimation is provided with the outlined approach.

An example of a flight mission for investigating the power needs and the actuator’s thermal behavior is provided. The flight mission is defined in

Table 2 and includes take-off, climb, cruise, hard maneuvering, and descent, up to a 10 km flight altitude and a speed up to Mach 1.2. The results from the simulation are presented in

Section 5.6.

5.6. Results and Discussion

The implementation of all three actuator models is validated by comparing the respective step response against the ideal first-order transfer function. The results are shown in

Figure 13 where a linear spring load at 5 · 10

6 N/m is attached to each actuator. The actuators follow the ideal response curve, proving the validity of the method. The SHA will be most susceptible to high loads as the way it is designed in this case.

The simulation results from the double roll maneuver (the same used for sizing) are shown in

Figure 14, presenting the consumed power, power losses, load on the left inner elevon, and actuator speed for the left inner elevon. The consumed power by the respective actuation system is as expected where the hydraulic actuation consumes a lot of power as long as the actuator speed is high even if the output power is low. The electric actuation systems (EMAs and EHAs) only consume high power when the output power is high, therefore being much more efficient. A slightly higher number is seen for the EHA due to a slightly lower efficiency. Another difference is that the SHA also consumes power when the air loads are driving the actuator backward since the cylinder chambers need to be filled with oil, whereas the EMA and EHA actually allow for the recuperation of energy (not accounted for here). It is clear that the electric actuation system has the potential to downsize the whole supply chain with higher efficiency. Of course, this depends on the actual aircraft requirements, and there could exist cases that would drive the control surface loads much higher. What is also included is the power needed to accelerate the electric actuators, which adds to the total power consumption. Running the same test case without the inertial effects for the EMA results in about 10% lower peak consumption, but this varies of course with test cases and actuator design. Some cases might result in a higher power demand due to the inertial effects. The figure also shows the actuator movement, speed, and load, which verifies that all three systems are doing the same work.

Figure 15 shows a comparison of the hydraulic and electric architectures’ weight and size, relative to the hydraulic system. It is categorized as actuation, distribution, supply, and auxiliary/emergency. Due to confidentiality reasons, the actual weights and sizes can not be published, but the EMA system is around 60% heavier in total, and the EHA is 50% heavier. The total size of the systems is, however, very similar. The important difference is that the weight distribution and space allocation are very different between the hydraulic and electric architectures, where a much larger portion of the weight and size is concentrated to the actuators for the electric case, and vice versa for the hydraulic case.

Figure 16 shows the relative comparison of the weight and size of each component for both architectures.

As expected, the electric actuators themselves are the driving factor of weight and size. A direct driven EMA is assumed in this study, and the weight is expected to be much higher compared to an EMA with a gearbox. This would probably be a necessity for larger loads but comes at the expense of increased complexity and less reliability, a trade-off that the designer has to make. Other factors can also play in favor of reducing the weight further, like new technology such as an axial flux motor; iterating the aircraft requirements in order to reduce the hinge moments in the most severe operating point; finding different control surface configurations or command allocations to reduce the hinge moments; and increasing the hinge arm length, which reduces the load but would require more space for the hinge arm and a longer actuator. The key is to reduce the motor torque. The EHA configuration shows a lower weight than the EMA configuration. However, it is substantially larger than the SHA configuration. The use of the hydraulic pump works as a gearbox and reduces the motor torque. The motor is smaller than the direct driven EMA, but the additional components, pumps, and accumulator add to the weight and size. The actuator design is not optimized. The next design iteration would include more detailed models and could therefore result in a reduced weight. The results, however, give a clear indication of the challenge with electric actuation for this type of application.

Although the high power density of hydraulic systems is an advantage regarding the actuators, the supply system is far more bulkier and heavier than the electric counterpart. A big reason for this is not only the higher density of the power generation system, but also the higher efficiency of the electric actuators allows one to reduce the required supply power. The effect is further increased by the weight savings from the auxiliary/emergency system. A big unknown is the distribution system. The approach was to compare the installation of an existing aircraft and assume the same electric wire length as the hydraulic pipe length. This is probably not accurate but gives a good starting point for the analysis. Further studies would require a more detailed study. Hydraulic piping also requires clamping that further drives up the weight. The same is true for electric wires but probably not to the same extent. This further necessitates the need to develop a more accurate method for distribution weight and size estimation in the conceptual design phase.

The information from this study would be fed back to the aircraft level according to the work flow in

Figure 2 where the fuel burn, aircraft performance, installation effects, maintenance, safety, cost, and any other parameters can be evaluated. This process is iterated until a well-balanced design is found.

A flight mission is simulated, shown in

Figure 17, in order to demonstrate how the power extraction and thermal characteristics can be analyzed. It shows the flight altitude and Mach number in the two top figures, the actuator position and load in the two middle figures, and the different temperatures in the bottom figures. The bottom left shows the bay temperature, which is the actuator’s surrounding temperature, and the actuator temperature for the EMA canard and inner elevon and the EHA inner elevon. The right bottom figure shows the temperature for the EHA canard for two different design options.

The aircraft spends most of the time in high altitudes where the ambient temperature is cold. The elevon actuator only operates during maneuvering and remains close to being unloaded during the cruise segments. The temperature therefore remains nearly unchanged. The canard, on the other hand, is continuously loaded, and this affects the temperature. The difference in the design is clearly seen by comparing the EMA and EHA temperatures for the canard actuator. The EMA, being a direct driven configuration, has a much larger motor and is therefore not affected nearly as much as the EHA by the load. The first design option of the EHA has a high-speed pump and therefore a much smaller motor resulting in a too-high temperature. The framework quickly allows one to change the design. By doubling the pump displacement, a larger motor is used, which results in a much lower motor temperature. The total actuator weight only increased by around 10 %. By effectively iterating the design, the framework allows one to compare several solutions to changing missions and requirements until a satisfying design is found.

The next evolution of the model would include the thermal behavior around the coil windings and the internal thermal propagation. This would require a much more detailed design of the actuator, suitable when the overall design has matured and more information is available.