1. Introduction

The method for assessing the trafficability of planetary rovers has garnered significant attention since the 1960s, when humans first began exploring the surface of the moon. After the successful landing of the Sojourner rover on Mars, trafficability assessment in complex terrain has emerged as a critical area of research in the field of deep space exploration.

Currently, image assessment serves as the primary source of information for trafficability assessment methods [

1,

2,

3], such as NASA’s JPL team developed the SPOC (Soil Property and Object Classifier) terrain classification system [

4], ESA developed the NOAH-H (Novelty or Anomaly Hunter—HiRISE) terrain classification system [

5]. While image-based assessment methods can circumvent most dangers during the rover’s journey, they are unable to prevent non-geometric hazards such as the sinking and slipping of the wheels when traversing the soft Martian soil [

6,

7], especially in the context of Mars’ distinctive crusty terrain [

8].

In such cases, to avoid non-geometric hazards for the planetary rover, one approach is to analyze the interaction between the soil and wheel [

9] or scoop [

10], then obtain the characteristic parameters of the Lunar/Mars soil, thereby assessing the ground’s ability to support the rover. However, due to equipment and environment limitations, this method can only provide a reference, a more accurate method is to use onboard sensor data such as slip ratio, wheel sinkage, and wheel drive motor current to infer the interaction between the wheel and the soil and assess the safety of the rover’s traversal.

The classic methods of using sensor information for non-geometric hazard trafficability assessment are relatively simple, such as using the average of motor encoder (drive) or potentiometer (steering) readings to determine when to switch off the motors of the Sojourner rover [

11]. The JPL team set the slip ratio thresholds for the Curiosity rover when driving on different Mars terrains based on ground simulation experiments [

12].

In recent times, numerous methods have been investigated and applied. From a theoretical perspective, advancements have been made in developing slip ratio models [

13,

14,

15,

16] and specialized simulation tools [

7,

17] for planetary rovers, building on classic terramechanics theory. On the technological front, techniques like Gaussian regression [

18,

19], convolutional neural networks [

20,

21,

22,

23], and data-driven [

24,

25,

26] methods are applied to predict slip ratio and enhance navigation ability [

27]. Furthermore, new sensor information such as wheel sinkage [

28], wheel vibration [

29], wheel-embedded resistance sensors [

30], and thermal inertia [

31] are being studied.

In the above studies, the slip ratio is a major indicator for the trafficability assessment of planetary rovers, while wheel drive motor current is primarily used as the basis for calculating wheel torque [

32,

33], wheel work [

9], and wheel slippage correction [

34]. The study of planetary rover wheel drive motor current can provide important evidence for trafficability assessment and the inversion of soil parameters.

It is now well established that there is a positive correlation between wheel drive motor current and the wheel torque of a planetary rover. However, the correlation between wheel drive motor current and other parameters remains unclear. These parameters include environmental factors, such as temperature and magnetic field; varying terrain conditions like sand, rock, and slope; soil characteristics such as cohesion, internal friction angle, and bulk density; and the aging and wear of motor parts. Some of these factors are the subjects of our research, while some factors would interfere with the result of the study. These factors collectively influence changes in motor current. Moreover, a change in one factor can lead to alterations in multiple related factors. This interplay of multiple factors and their interconnectedness make it difficult to study the interaction between a planetary rover’s wheel and the soil.

This study draws on the theoretical frameworks of terramechanics, links wheel drive motor current with soil characteristic parameters and slip ratio, and presents a wheel–soil interaction model based on wheel drive motor current for a planetary rover. The research data for setting and verifying the model in this thesis are drawn from two main sources: numerical simulation based on real rover parameters and Mars soil parameters and the data of the Zhurong rover mobility system test vehicle driving on Mars soil simulants. A combination of quantitative and qualitative approaches was used in the data analysis.

The remainder of this paper is organized as follows:

Section 2 introduces the experimental environment and equipment, with a focus on the mechanism of the mobility system of the Zhurong rover and the Mars soil simulants’ characteristic parameters, then the wheel–soil interaction model based on wheel drive motor current is constructed. In

Section 3, the relationships between wheel drive motor current and soil characteristic parameters and slip ratio are analyzed through MATLAB numerical simulation. In

Section 4, the results of model prediction in

Section 3 are verified through ground experiments using the Zhurong rover mobility test vehicle;

Section 5 is the discussion, and finally,

Section 6 is the conclusion.

2. Materials and Methods

2.1. Experiment Conditions and Environment

The experimental station is laid out with three types of Mars soil simulants that vary in terms of grain sizes, as shown in

Figure 1. According to the Curiosity rover’s Mars terrain classification criteria [

35], the experimental station is divided into five areas: Loose Sand, Sand, Bedrock, Loose Rock, and an additional slope of 28 degree (for the purpose of testing the Zhurong rover’s maximum climbing capability [

36,

37]). Additionally, based on rock distribution data around the Viking lander, this study arranged the quantity, spatial distribution, and embedment of both angular and rounded rocks. The environmental temperature at the experimental station corresponds to the temperature at ground level. Given the substantial size of the experimental station, no temperature regulation devices were employed. Based on monitoring data, the environmental temperature remained between 15 and 25 °C throughout the experiment.

The area covered with Mars soil simulant is 15 m long and 3 m wide. In the Loose Sand area, the Mars soil simulant attains a maximum thickness of 300 mm, whereas in other areas, the thickness is 200 mm, the disparity in thickness distinctly demarcates the Loose Sand area and the Sand area.

This experimental station was covered with Mars soil simulants JLU Mars 1–3, which are designed based on the known mechanical characteristics and chemical composition of Mars soil and the data from internationally utilized Mars soil simulants. These simulants belong to the category of mechanical property analogs and are used for engineering experiments. Their primary components are derived from volcanic ash found in the Jingyu area of Jilin Province, China. In the test of grain size distribution, this study first employed soil analysis sieves with varying mesh sizes to quantify the simulant for grain size exceeding 0.1 mm, then a laser grain size analyzer was utilized to quantify the simulant with grain sizes less than 0.1 mm; the distribution of JLU Mars 1–3 grain size curves and test equipment are shown in

Figure 2.

The pressure and shear characteristic parameters of each kind of simulant were measured using a Bevameter, which is widely used for soil parameter inversion. Its principle of operation involves obtaining a force–displacement curve through sensors when the contact component touches the soil, the curve is then fitted using empirical formulas to derive the soil’s pressure and shear parameters [

38,

39,

40]. The test equipment and test results are shown in

Table 1; each kind of simulant has three states, the loose state is the state after the soil is loosened, the medium state is the state of natural placement, the dense state is the state after compaction by vibration. The relative density of the loose state is between 5 and 10%, the medium state is between 20 and 40%, and the dense state is between 70 and 80%.

Figure 3 shows the results of soil parameter normalization. Firstly, it can be determined that with the increase in soil hardness, the trend of each parameter is the same (except

for JLU Mars 2); both the pressure capacity and shear resistance of the simulants have improved. In addition, with the increase in soil grain size, from JLU Mars 1 to JLU Mars 3, only the shear deformation modulus

maintains the same trend, while the other parameters fluctuate irregularly.

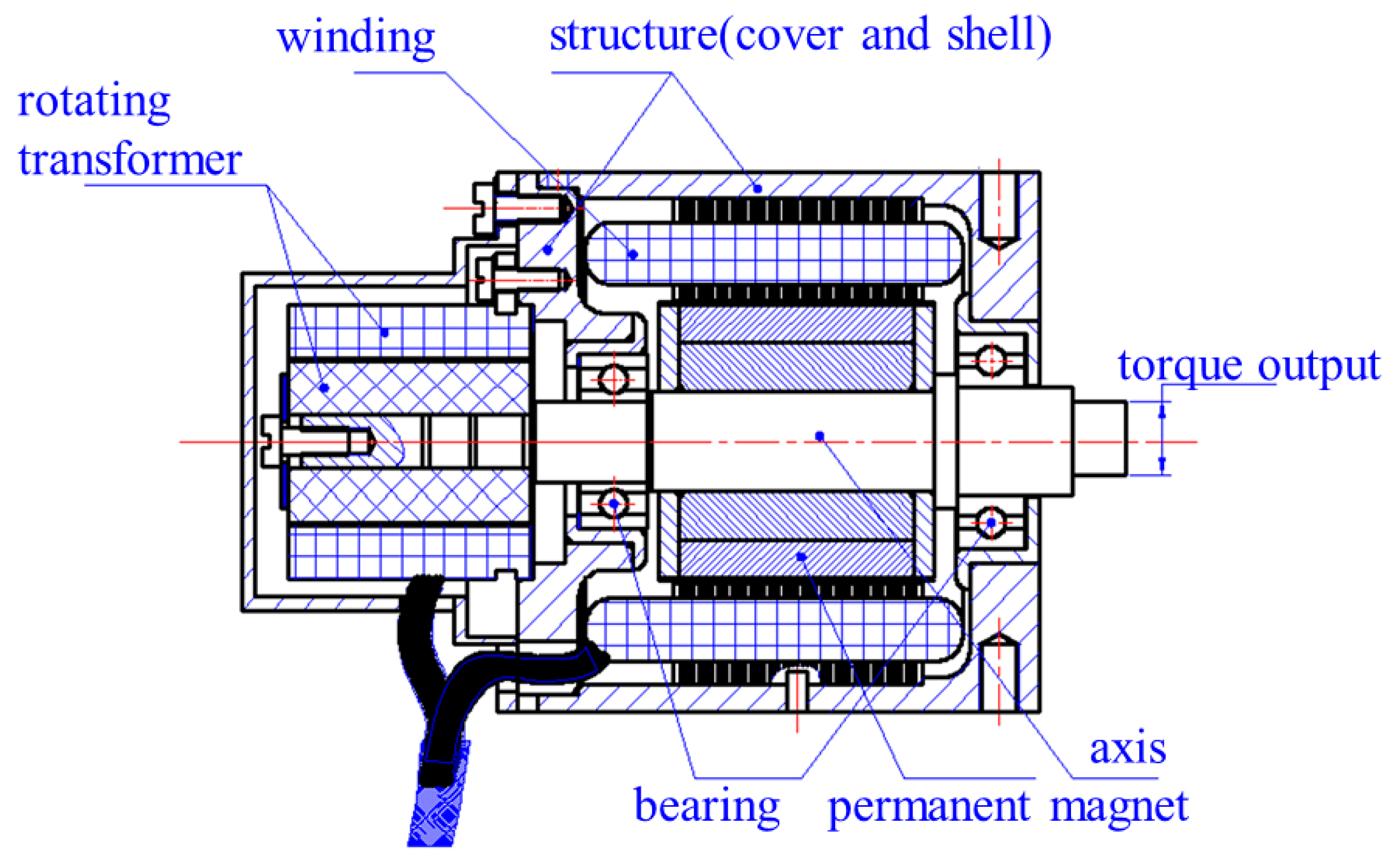

2.2. Mobility System of Zhurong Rover

The mobility system of the Zhurong rover test vehicle is composed of a suspension system (main rocker arm, deputy rocker arm, and steering arm), a differential mechanism, a clutch mechanism, an angle adjustment mechanism, and a wheel mechanism (drive motor assembly, steering motor assembly, and wheels), as shown in

Figure 4. The mobility system of the Zhurong rover was developed by the China Academy of Space Technology (Beijing, China). The rover adopts a main–deputy rocker arm active suspension and integrated shock absorbing wheels that can operate independently for driving and steering;

Table 2 displays the number of individual mechanisms within the test vehicle’s mobility system. The active suspension can support the functions of lifting and lowering the rover body and wheel lifting. The weight of the mobility system of the Zhurong rover test vehicle is 204.5 kg, with a single wheel load (

) of 34.08 kg, and wheels that are 20 cm wide (

). Considering the lug of the wheel, the maximum diameter is 300 mm, and the minimum diameter is 290 mm, due to the complexity of modeling curved wheel faces and lugs, the wheel diameter for simplified theoretical calculations is 295 mm and the wheel radius (

) is 147.5 mm.

The wheel drive motor of the test vehicle is a three-phase square wave driven permanent magnet brushless DC motor. The structure scheme of the drive motor is shown in

Figure 5; the motor weight does not exceed 210 g. During the ground experiment process, wheel drive motor current data under various conditions were sampled at 4 Hz (as maintained consistently by the Zhurong rover).

A thermal steady-state analysis of the motor components is shown in

Figure 6. The initial temperature of the motor components is 55 °C (the operating temperature range of the motor components is −60 °C to 55 °C, where the temperature of 55 °C represents the most adverse condition in thermal design). The heat generated by the motor components can be transmitted to the external environment via thermal radiation and can also be transferred to the gearbox via thermal conduction.

According to the simulation results, the highest temperature occurs in the motor winding section, reaching 78.4 °C; the temperature rise of 23.4 °C does not significantly reduce mechanical performance and is far from reaching the allowable temperature limit of the motor materials, and in actual conditions, within a finite running time, the motor temperature should not exceed the simulation data.

In addition, the reliability of the wheel drive motor is analyzed according to Equation (1), and the motor failure rate is calculated as 0.8 × 10

−6 /h.

where

: failure rate, = 1.6 × 10−6/h;

: environmental coefficient, = 1.0;

: quality coefficient, = 0.5.

Based on the above analysis, we assume that within the designed lifespan of the drive motor and under normal operating conditions, neither the external environmental temperature nor the internal motor parameters, such as the wear and tear of the motor components and mechanical degradation, will impact the electrical and mechanical performance of the motor. Then, through the testing of the motor, the relationships among the output torque, speed, and current of the drive motor can be obtained, as shown in

Figure 7.

The current–torque function relationship is shown in Equation (2), and the output torque of the wheel drive motor can be obtained from the current data.

where

: the torque constant scale factor, ;

: the correction factor, (ignored here).

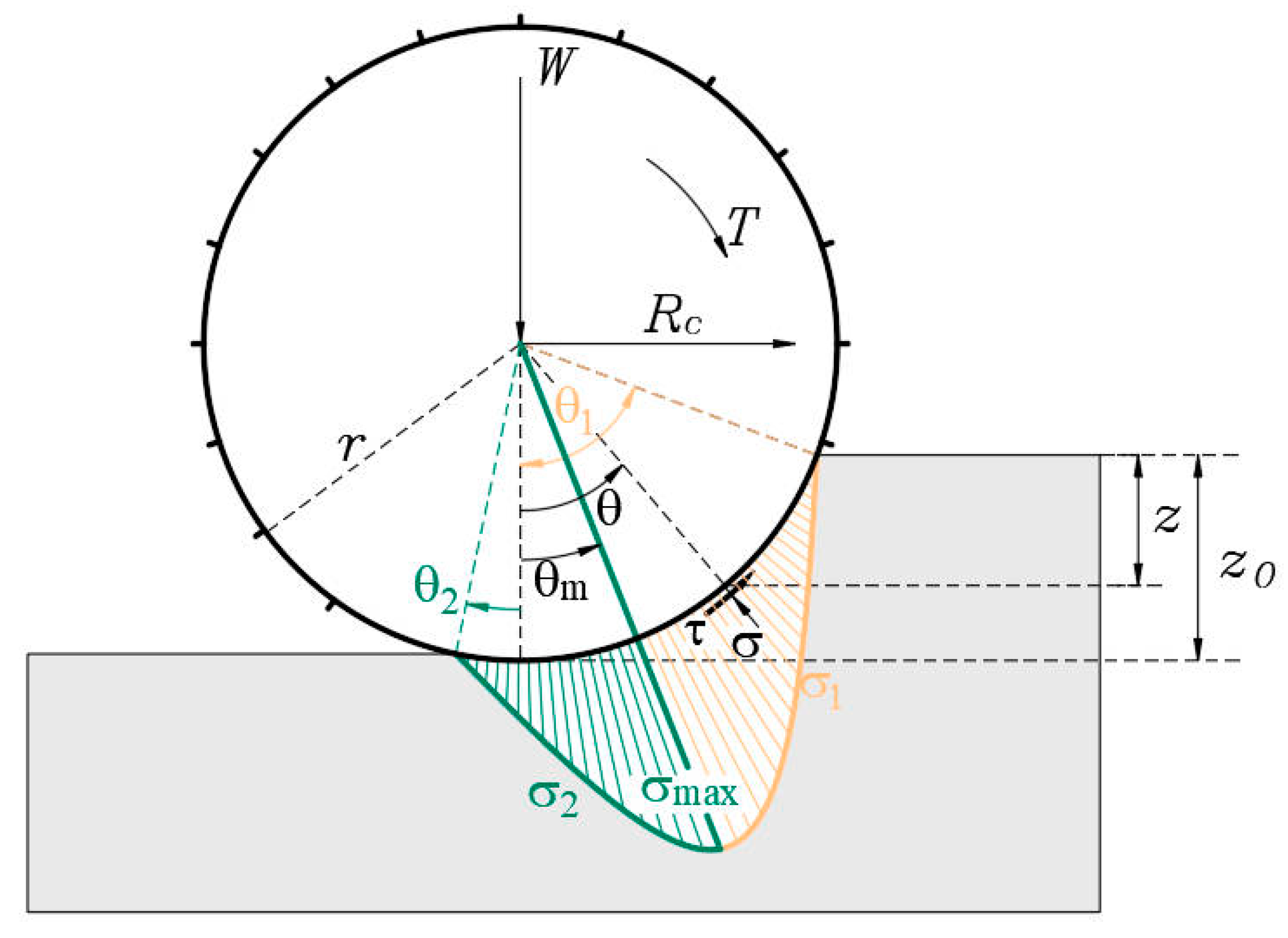

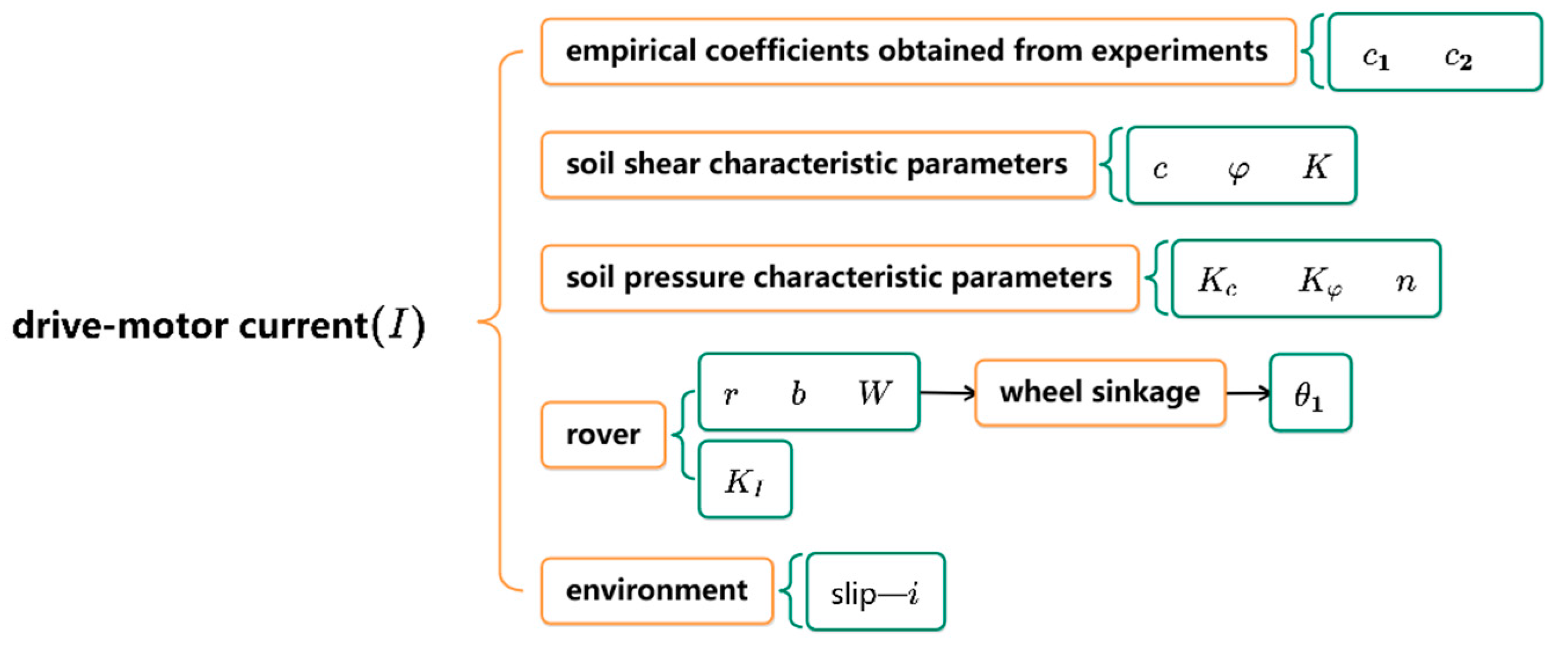

2.3. Construction of Model

The factors affecting the wheel drive motor current are categorized into two types in this study: The first category is the factors we hope to ignore, such as temperature and pressure. Due to the existence of these factors, the current fluctuates, and the trafficability of the rover based on current analysis is disturbed.

The second category is the factors that cause changes in the trafficability of the rover, such as variations in pressure and shear characteristic parameters of the soil lead to changes in compaction resistance and bulldozing resistance, variations in terrain angles result in changes in wheel loads, and variations in slip ratio lead to changes in wheel torque. These factors directly lead to changes in the interaction force between the wheel and the ground, thereby affecting the wheel drive motor current; the influence of various factors makes the current change sensitive. In this section, we standardize the relationship between the wheel drive motor current and these factors.

The wheel–soil interaction model proposed by M.G. Bekker [

41] is a widely used model at present. Based on the wheel–soil interaction model proposed by Bekker, the shear stress effect is considered [

42,

43]. Then, the wheel torque generated by the shear stress can be calculated, which serves as the link between current information and soil characteristic parameters or slip ratio, as shown in Equation (3); the derivation process of the model is shown in

Appendix A.

Among the factors affecting the change in wheel drive motor current, as shown in

Figure 8, the vehicle parameters are known as Zhurong rover parameters, and the empirical parameters

and

are specified according to

Table A1. Therefore, the varying parameters in the model are soil pressure parameters, shear parameters, and slip ratio.

3. Theoretical Calculation

3.1. Analysis of Slip Ratio

By inputting the soil and vehicle parameters from

Section 2 into Equation (3) for analysis, a quantifiable correlation between current and slip ratio during the test vehicle’s traversal in the Mars soil simulants was deduced, as shown in

Figure 9.

The nine curves exhibit a similar changing trend, characterized by an attenuating slope as the slip increases. When analyzing the curves based on soil hardness (different color curves), it is observed that the dense state curves have a smaller slope, while the slope is greater for the loose state curves. Furthermore, an analysis of the curve’s starting point reveals that the current value at the beginning of slipping gradually increases as soil hardness decreases.

From different hardness curves, we can find that when the wheel drive motor outputs the same torque (current), the slip ratio of the rover in loose soil is smaller than in dense soil. This is because the reduced soil hardness leads to greater wheel sinkage, requiring the wheels to overcome larger compaction resistance and bulldozing resistance during movement. Consequently, the ground’s reaction force on the wheels is larger. The increased sinkage enhances the wheel’s ground adhesion, resulting in higher efficiency (smaller slip) for the planetary rover; this seems different from the common view that we always want to avoid a planetary rover driving on soft soil to ensure safety. However, it is worth noting that driving efficiency and driving safety are not contradictory.

On the other hand, due to the irregularity of the simulant parameters with grain size changes clearly shown in

Figure 3, for the influence of soil grain size on the curve, no significant conclusions can be drawn, even at the same soil hardness, and the curve corresponding to JLU Mars 2 simulant always has the largest slope.

3.2. Analysis of Soil Pressure Characteristic Parameters

Based on the characteristic parameters of known Mars soil, Mars soil simulants, and some typical soils, this study determined the range of variation for soil characteristic parameters in the model, as shown in

Table 3.

According to the characteristic parameters in

Table 3, the analysis range of Mars soil pressure characteristic parameters is selected. The changed soil pressure characteristic parameters are

(1–20),

(60–7600), and

(0.7–1.4). Considering the structure of the mathematical model,

and

can be combined into a new variable:

According to the value of

and

, the value range of

is 60–7700. In fact,

is not a new variable, in the initial calculation of the relationship between radial stress and soil depth, it is called the Bernstein soil deformation modulus, and the unit is

; Equation (A10) is derived based on Equation (5)

Soil pressure parameters

and

are taken as independent variables, and the variation in slip

from 0.1 to 0.9 is additionally considered. To demonstrate the universality of the changing patterns, the soil shear parameters are altered for repeated calculations. The theoretical calculation results are shown in

Figure 10 where the three group graphs, respectively, represent the analytical results using different soil shear parameters (JLU Mars 1–3, loose state).

By analyzing the numerical difference between three group graphs in

Figure 10, it is obvious that the current values deduced from the JLU Mars 2 shear parameters invariably surpass those of JLU Mars 1 and JLU Mars 3, this is because the variation in shear parameters across the three soil types lacks any discernible regularity.

According the change trend of the curve, it is possible to analyze the effect of soil parameters and wheel slip on the current. In short, there is a negative correlation between and and and , while there is a positive correlation between and .

In detail, the change trends of each curve in the three group graphs are consistent; as

gradually increases, the current decreases, and the slope of the

-

curve gradually diminishes. Then, according to the analysis result of four curves with different shear deformation modulus in

Figure 10(a1,b1,c1), we can find that as

gradually decreases, the current decreases, the maximum slope of the

-

curve decreases, and the

-

curve approaches horizontal. Finally,

Figure 10(a2,b2,c2) present

-

curves with different slips; as the slip gradually decreases, the current decreases, the peak value of

-

curve significantly decreases, and the

-

curve approximates a vertical downward shift.

Based on the above numerical analysis, although it is limited in accuracy, we can find that, when conducting in situ Mars soil parameter inversion, if the parameters of and can be chosen as the maximum value within the estimated range, and can be chosen as the minimum value within the inversion range, that this will minimize the effects of fluctuations in the current data.

3.3. Analysis of Soil Shear Characteristic Parameters

According to the characteristic parameters in

Table 3, the analysis range of Mars soil shear characteristic parameters is selected. The changed soil shear characteristic parameters are

(0.1–15) and

(16–40), with additional consideration of slip

(0.1–0.9).

It is necessary to note that in the process of in situ Mars soil parameter inversion, the key soil shear characteristic parameters are cohesion (

) and internal friction angle (

); the modulus of shear deformation (

) is rarely obtained, which can also be seen in

Table 3, thereby in this section,

is set as the measured value of JLU Mars 1–3 and not analyzed.

Similarly to the previous analyses, the soil pressure parameters are altered for repeated calculations, the three group graphs, respectively, represent the analytical results using different soil pressure parameters, and the theoretical calculation results are shown in

Figure 11. It is obvious that there is a positive correlation between soil shear characteristic parameters and the wheel drive motor current; the current is linearly related to cohesion

, the change in slip alters the slope of the

line, while the change in the angle of internal friction

alters the line’s intercept. In addition, the slope of the

line decreases from JLU Mars 1 to JLU Mars 3.

4. Experiment Verification

The validation of the model prediction in

Section 4.1 was conducted in this section, the experimental conditions and environment were detailed in

Section 2, and the schematic diagram of the test process is shown in

Figure 12.

The drawbar pull comes from the friction resistance between the weight and the ground, it is measured by a pulling force sensor with a max range of 2000 N, with a resolution of 0.05 N, and a sensitivity of 2 Hz; the force is displayed in real time through an embedded LCD screen. Different weights were applied to obtain different drawbar pull and slip ratio. During the experiment, the control program set the wheel speed constant, a ruler was marked at intervals of 20 cm, and the time it took for the vehicle to pass each stage was recorded; these data were used to calculate the actual speed and, only when the vehicle maintained a stable speed over multiple consecutive stages, was the reading on the force sensor taken as the drawbar pull. The sampling frequency of the wheel drive motor current is 4 Hz, which is consistent with the Zhurong rover, and the vehicle power comes from a wired connection through a voltage regulator, ensuring the stability of the voltage of the whole vehicle.

The wheel slip formula is calculated as follows:

where

: slip;

: angular velocity;

: actual speed.

Before the experiment, we secured the connection point of the towing rope to the lowest part of the vehicle’s body and ensured that the rope remained horizontal. During the experiment, we locked the joint angle motors that control the rotation of the main and deputy rocker arms. After the experiment, we analyzed the joint angle data output by the control system to determine whether there was any relative movement between the main rocker arm and the deputy rocker arm, ensuring that the load on each wheel was not affected by the drawbar pull. In addition, the vehicle body was affixed to the central axis of the mobility system, and the forces applied to the vehicle body were initially directed to the central axis and then uniformly distributed to each wheel. Hence, even if the pulling force of the towing rope surpassed the maximum support force that the ground could provide, the vehicle could remain stable.

It should be noted that the area corresponding to JLU Mars 3 soil is relatively narrow, limiting the vehicle’s movement distance, as shown in

Figure 1. As a result, the data obtained from experiments in JLU Mars 2 soil were more detailed and abundant. In terms of soil hardness selection, the dense state is the most stable soil condition for vehicle travel. Therefore, to reduce the errors caused by the multi-slip experiments and improve the accuracy of the experiments, the soil hardness was uniformly maintained in the dense state.

4.1. Experimental Verification of Zero Slip

In order to verify the initial prediction accuracy of the model, an experiment with zero slip ratio was first performed. The experiment environment was JLU Mars 2 soil with a dense state, the corresponding theoretical calculation was the orange dotted line in

Figure 9; when the slip was 0, the predicted current value was 0.114 A, and this value was compared with the actual experimental data.

For the zero-slip experiment, the vehicle traveled a distance of 280 cm, totaling 413 current recordings.

Figure 13 displays the current data of the wheel drive motors.

Table 4 provides statistics on the errors between the predicted values and the actual current values of each drive motor. The mean relative error of the six motors is 3.64%, the mean error of three motors on the

side is 2.56%, and the mean error of the three motors on the

side is 8.57%.

The model uses the load averaging method to determine each wheel’s load when forecasting the motor current values. However, it is inevitable that the rear wheels will sink more than the front wheels, and the vibration of a rigidly constructed vehicle will lead to random shifts in the centroid, which results in the actual wheel load fluctuating under an ideal value, as is evident from the scatter of data points in

Figure 13. The motor current values of the

side are greater than the

side, and the values for

and

are greater than

, which indicates the unevenness of the load distribution of a single wheel. In cases where detailed single wheel loads are not available, taking the average current value of all of the motors is more consistent with the parameter conditions for the theoretical calculations, and this approach is also followed in multi-slip experiments.

4.2. Experimental Verification of Multi-Slip

There were two group multi-slip experiments, as shown in

Figure 14. For the first group in JLU Mars 2 soil with a dense state, there were a total of 13 successful experiments, with the measured drawbar pull range being 20~500 N, and the corresponding slip range being 0.04~0.91. For the second group in JLU Mars 3 soil with a dense state, there are a total of eight successful experiments, with the measured drawbar pull range being 200~490 N, and the corresponding slip range being 0.13~0.84.

The experimental

curves compared to the model predictions are shown in

Figure 15(a1,b1). The data points obtained by the experiments in two Mars soil simulants are closely distributed around the corresponding prediction curves.

For the first group of experiments in JLU Mars 2 soil, using a 10% threshold as a demarcation, the relative error in the initial four low-slip experiments notably exceeded this limit. Among these, when the slip was set at 0.05, the maximal relative error was 47.82%. In contrast, the relative errors of the subsequent nine experiments predominantly maintained relative errors within the 10% boundary; when the slip was set at 0.5, the minimal relative error was 2.26%. Across the thirteen experiments, the average relative error in current prediction was calculated to be 14.58%.

For the second group of experiments in JLU Mars 3 soil, as shown in

Figure 15(b2), using the same 10% threshold as a demarcation, the relative errors of all experiments also predominantly maintained within the 10% boundary. When the slip was set at 0.59, the maximal relative error was 11.51%, when the slip was set at 0.28, the minimal relative error was 0.99%. The average relative error in current prediction was calculated to be 8.40%.

Additionally, it can be distinctly observed from

Figure 14 that the errors in the four experiments, where the drawbar pull is below 180 N, were greater than the others. This is attributed to the fact that, in experiments involving low slip, only a small drawbar pull is required to meet the requirement. However, due to the methodology of the experiments, the control precision of the drawbar pull was compromised, and the testing error cannot be disregarded.

Across 21 experiments, the relative error in the model’s prediction of the wheel drive motor current was 12.23%. Excluding the four experiments with a drawbar pull below 180 N, the relative error in the remaining 17 experiments was reduced to 6.52%. The two group experiments indicate that the model exhibits smaller errors under conditions of medium and high slip ratios, with the prediction error being controllable within 10%, which can offer a valuable reference for the trafficability of rovers on practical missions.

5. Discussion and Future Work

In the process of establishing the current-based model, the quantitative description of motor current and torque is crucial to the model’s predictive accuracy. Through calculations and simulations, this study suggests that three factors—temperature variation, operational time, and reliability (aging and wear of motor parts)—can be disregarded. However, this conclusion should ideally be validated through experiments, by simulating extraterrestrial environmental factors, such as extreme temperatures, to test and calibrate the relationships between motor output torque, current, and other parameters. The relationships between various parameters of the Zhurong rover’s wheel motors were obtained only under standard terrestrial conditions, which presents a limitation of this research.

In

Section 3.2 and

Section 3.3, the relationship between the drive motor current and the characteristic parameters of Martian soil was analyzed based on the estimated range of Mars soil parameters. However, since soil pressure and shear parameters are empirical parameters rather than physical parameters like soil bulk density and moisture content, it is impossible to isolate and control the variation in a single soil characteristic parameter. As a result, the findings in

Section 3.2 and

Section 3.3 are challenging to validate through experimental methods. Furthermore, the model disregarded the influence of wheel rotation speed, though this omission aligns with standard practice in classical terramechanics theory.

In the next phase, we will analyze the effect of wheel rotation speed on the model’s predictive accuracy. Additionally, in

Section 4.1, the fluctuation in wheel load causes deviations in the current values from the model’s predictions over short time intervals. To address this, we will develop a kinematic model to examine the variation in wheel load, enhance the model’s predictive accuracy over short time scales, and optimize the utilization of motor current data.

In addition, the model we proposed was validated based on the data from the Mars rover and Martian soil simulants, while the model performs well in Mars-like environments, its applicability is limited; the model’s performance under different gravitational conditions, soil properties, and temperature variations has not yet been fully tested. Through systematic studies of various environmental factors, we aim to enhance the model’s practical value for extraterrestrial exploration missions.

_Zhu.png)