1. Introduction

Aircraft flight simulation is an essential element of modern aircraft design, flight control system design, certification process, and aircraft pilot training. The aerodynamic model forms the core of a flight simulator [

1]. The flight simulator needs a high-fidelity aerodynamic database to replicate the actual aircraft behaviour for the pilots. There are several methods for developing an aerodynamic database: semiempirical datasheet methods, linear flow solvers, nonlinear flow solvers, wind tunnel tests, and flight tests, in increasing order of fidelity [

2,

3,

4]. Semiempirical methods and linear flow approaches yield lower fidelity databases, and the accuracy notably decreases as the nonlinearity of the flow increases [

5]. Therefore, these approaches are commonly used in the early design or concept study phases [

6]. Nonlinear flow solvers are considered to be accurate within the low angle of attack sweeps (linear region) in subsonic–supersonic regions. On the other hand, the results in the transonic region, including shock-induced separations or at high angle of attack sweeps (nonlinear region), differ from the actual aerodynamic data due to highly unsteady flow characteristics. Additionally, it is difficult to analyse dynamic effects such as forced oscillations and spin conditions [

4]. In wind tunnels, there are problems such as scaling issues associated with the Reynolds number, aeroelastic characteristics, experimental system errors, the influence of the wind tunnel airflow quality, and interference of tunnel walls/supports [

3,

5]. Consequently, a flight test is the best alternative to correct errors in wind tunnel tests [

7]. A comprehensive system identification methodology using flight tests can be developed to generate the aerodynamic coefficients. This study explains the development of such a methodology.

There are four key features of system identification: manoeuvres, measurements, methods, and models [

8]. Other features are discussed in [

9,

10,

11,

12]. Jategaonkar [

8] focuses on time-domain applications, while Tischler and Remple [

10], and Morelli, Grauer, and Cooper [

11,

12] present frequency-domain approaches. An outline and theoretical foundations for both approaches are provided in Morelli and Klein [

9]. System identification in time and frequency domains are considered as competing methods. Both have advantages and disadvantages that generally complement each other [

13]. Time-domain methods tend to be more intuitive, and the parameters of the mathematical model have a clearer physical meaning [

13].

System identification in the time-domain can be implemented using several methods such as the equation error method (EEM) [

3,

8,

9,

14,

15,

16,

17], the output error method [

8,

9,

14], the filter error method [

8,

18], and artificial neural networks [

3,

19,

20]. Computational software tools such as FVSysID [

8] and SIDPAC [

9], running under MATLAB, are available for system identification [

21]. The EEM calculates the aerodynamic parameter estimates that minimize the sum of squared differences between the values of the nondimensional force and moment coefficients obtained from measured flight data and those obtained from estimated model values [

22] and is the least computationally expensive technique since no state integration is necessary.

A modification of the EEM in the time domain is implemented in this study. First, the thrust body-axis forces and moments were determined from the propulsion model. To achieve this, the propulsion model was run independently with all relevant inputs from flight-test data [

14,

17]. After applying the thrust body-axis forces and moments, i.e., subtracting from the total forces and moments acting on the aircraft, the nondimensional aerodynamic force and moment coefficients were obtained. Then, the EEM was employed to determine all the aerodynamic forces and moment coefficients as linear/nonlinear combinations of the parameters (aircraft motion and control variables). If no propulsion model or thrust data are available, then it is not possible to isolate the nondimensional aerodynamic force and moment coefficients. To overcome this, the thrust was calculated using assumptions based on steady-state flight tests and a preliminary simplified turbofan engine thrust model was developed. Afterward, an iterative EEM (IEEM) was employed to determine the nonlinear aerodynamic and engine thrust models.

The objective of this study was to develop a novel application of nonlinear isolated aerodynamic identification for fixed aircraft in the absence of engine manufacturer data. Previous studies in this field used propulsion models from the manufacturer which were run independently with all relevant inputs from flight-test data and were assumed to be correct. In this study, no manufacturer propulsion model was available. Furthermore, lift, drag, and thrust values were calculated, i.e., approximated using assumptions from steady-state flight tests.

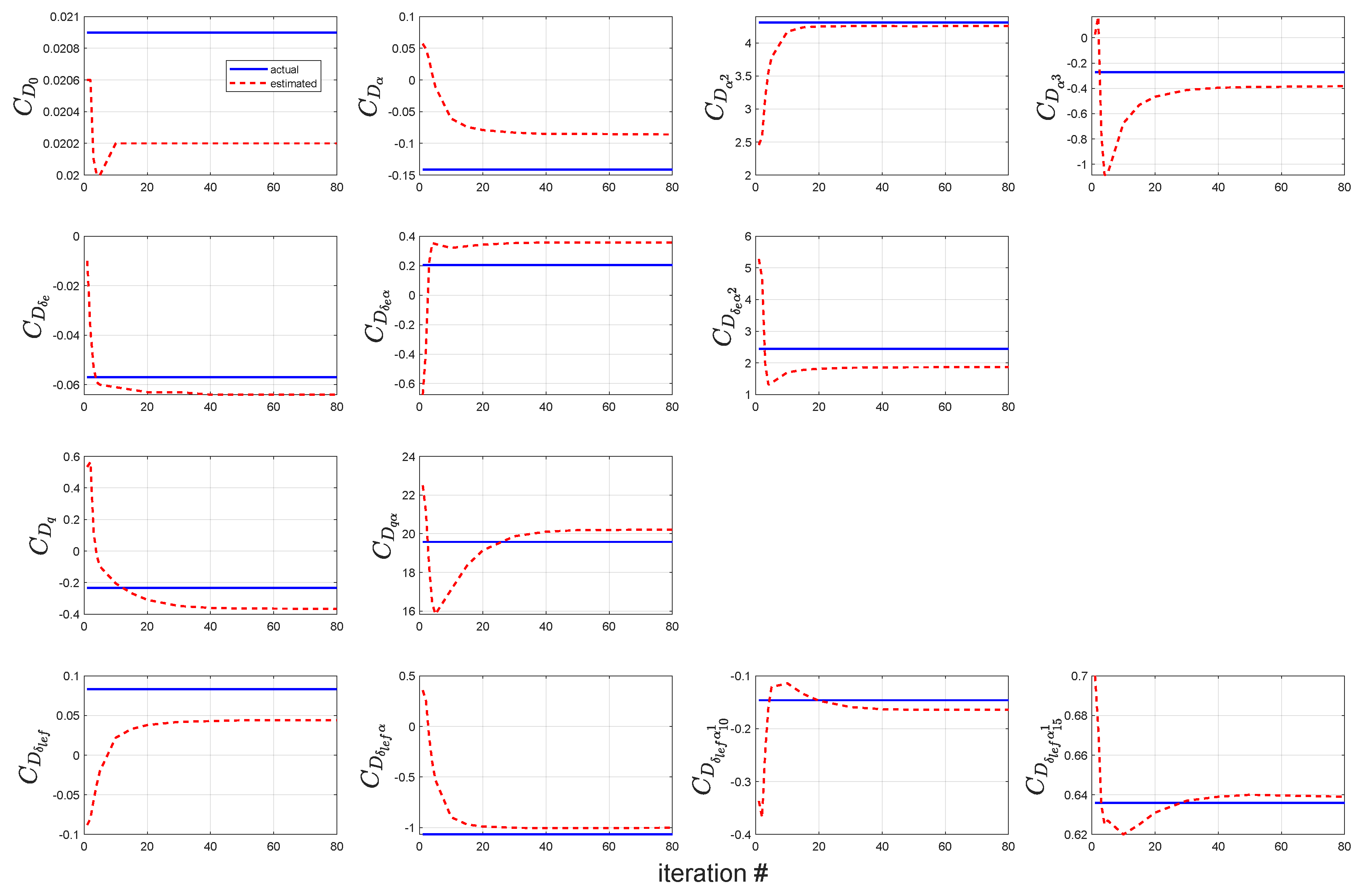

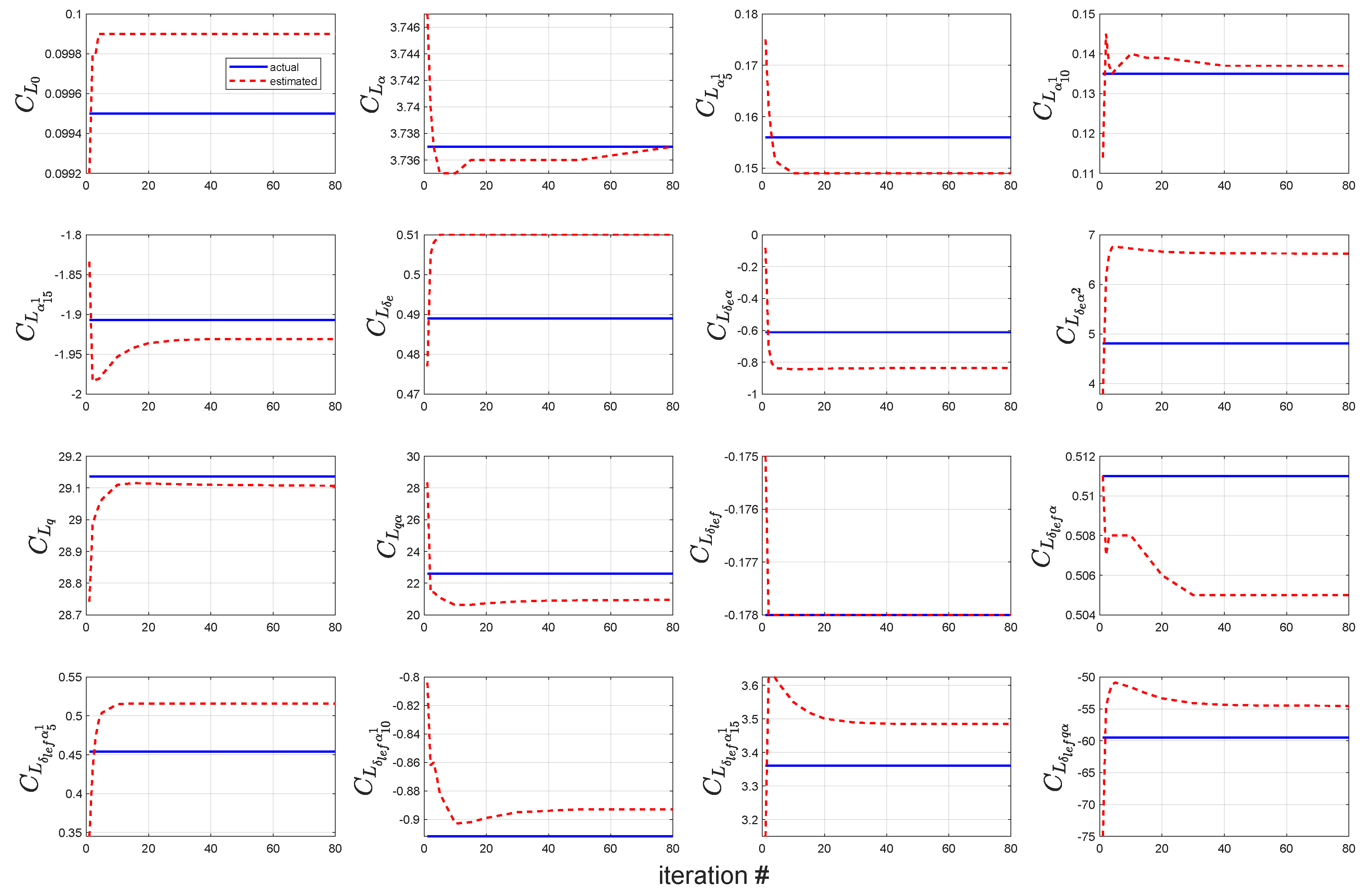

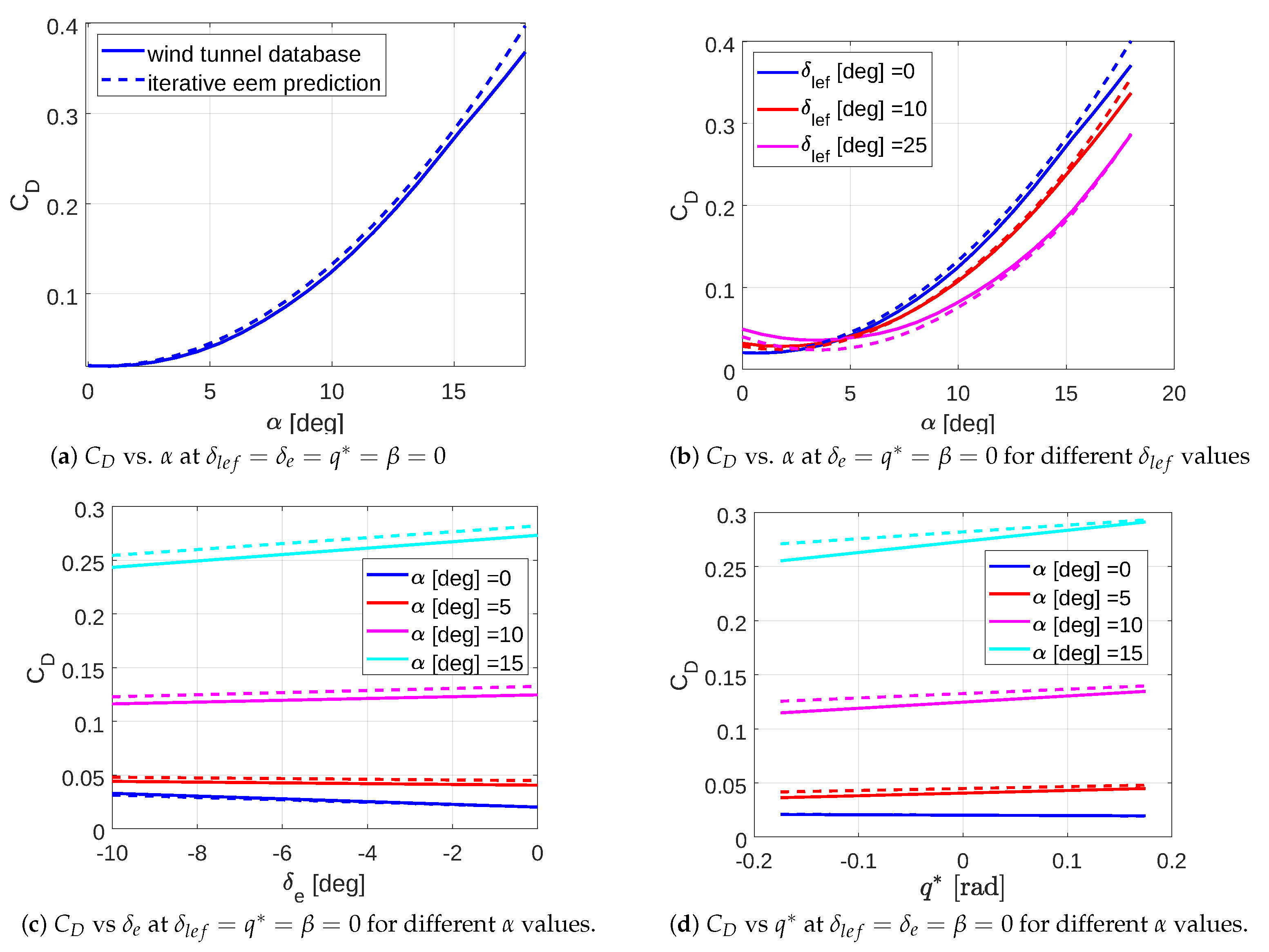

Moreover, a preliminary simplified turbofan thrust model was developed for any flight condition using the approximated thrust values. Based on this model, the EEM was used to find the aerodynamic force and moment coefficients. Finally, the application of the IEEM was introduced, which is a sequential process in which each coefficient is estimated at each iteration to solve the collinearity problem. It also proved to be insensitive to the propulsion model uncertainty.

Thus, the main contribution of this study is the estimation of the nonlinear aerodynamic coefficients using the IEEM when there is no engine database. The motivation for using the IEEM is as follows. Since drag and thrust coefficient parameters are nearly collinear or linearly dependent, classical methods cannot distinguish between the parameters. Therefore, the resulting parameter estimates are biased with large uncertainties and subsequent poor regression results. With the IEEM, the unknown parameter vector is divided into estimated and fixed vectors, thus solving the collinearity problem between thrust and drag coefficient parameters. In this study, simulated flight test data were used rather than actual flight test data because using the known aerodynamic coefficients within the flight simulator provided a reliable benchmark for the evaluation of the developed methodology effectiveness. This approach allowed us to use the aerodynamic database as a test bed to assess the efficiency of the developed method. Furthermore, as part of the study, a mathematical model of the F-16 fighter aircraft was also developed based on [

21].

The paper is organized as follows.

Section 2 presents the air vehicle flight simulation and data acquisition.

Section 3 explains the developed methodology. The results and discussions are presented in

Section 4, followed by the conclusions in

Section 5. There is a nomenclature at the end of the paper that lists abbreviations and well-known aeronautics parameters that are not explicitly defined in the text.

3. Methodology

The methodology developed for the preliminary thrust model from steady-state flight tests and for the parameter estimation using the IEEM are described below.

3.1. Development of the Preliminary Thrust Model from Steady-State Flight Tests

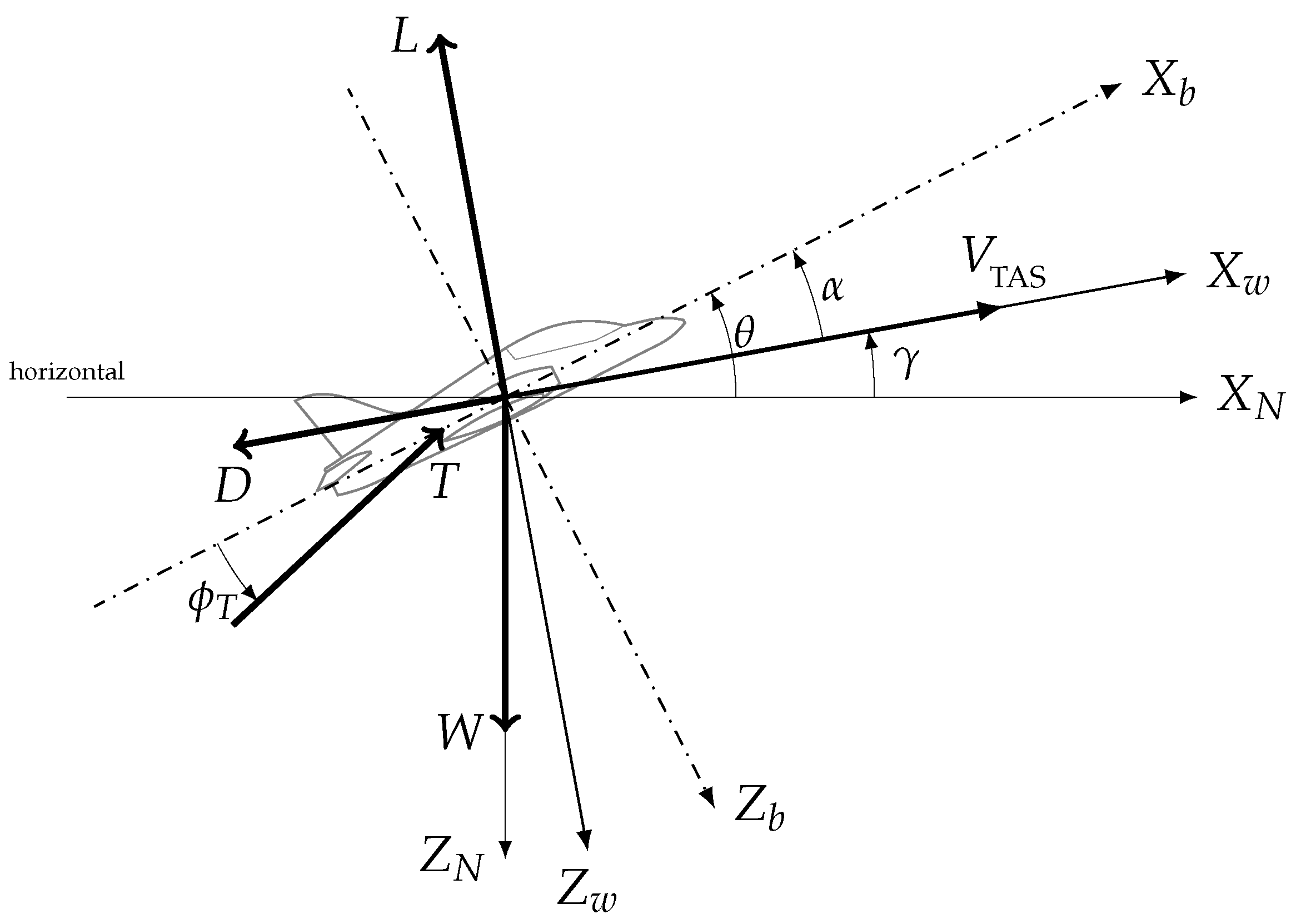

The flight geometry and the applied forces on the air vehicle are shown in

Figure 2. The flight path angle

is the angle between the horizontal

and the

x-wind axis,

, and

is the pitch angle. Summing forces in the

and

directions yields:

where

T is the thrust force,

D is the drag force,

L is the lift force,

W is the weight,

is the angle of attack, and

is the thrust incidence angle. It is assumed that the thrust axis is parallel to the wind axis, i.e.,

, and that

is small compared to the weight. Hence, if the aircraft is flying at trim, the sum of the forces must be equal to zero, which leads to the translational equations of motion:

where the drag force,

D, and lift force,

L, are:

where

is the dynamic pressure and

S is the reference area.

The relationship between the drag and lift coefficients

and

is given by [

6,

21,

23]:

where

is the drag coefficient at a zero angle of attack,

e is the Oswald efficiency factor, and

🜇 is the aspect ratio. For swept-wing aircraft,

e is assumed to be [

37]

where

is the leading-edge sweep angle. For an F-16 aircraft,

and

, which yields

. Note that a clean configuration is assumed even though the F16 will often have added equipment. However, this expression is adequate for the preliminary estimation.

During flight, the aircraft weight is known, the angle of attack , flight path angle , and true airspeed are measured, and the air density is calculated using the standard atmosphere model.

In gliding flight,

and the sum of forces must be equal to zero, so

, which leads to:

From Equations (

11), (

12), (

15), and (

16), we obtain

Using Equation (

13),

is calculated as:

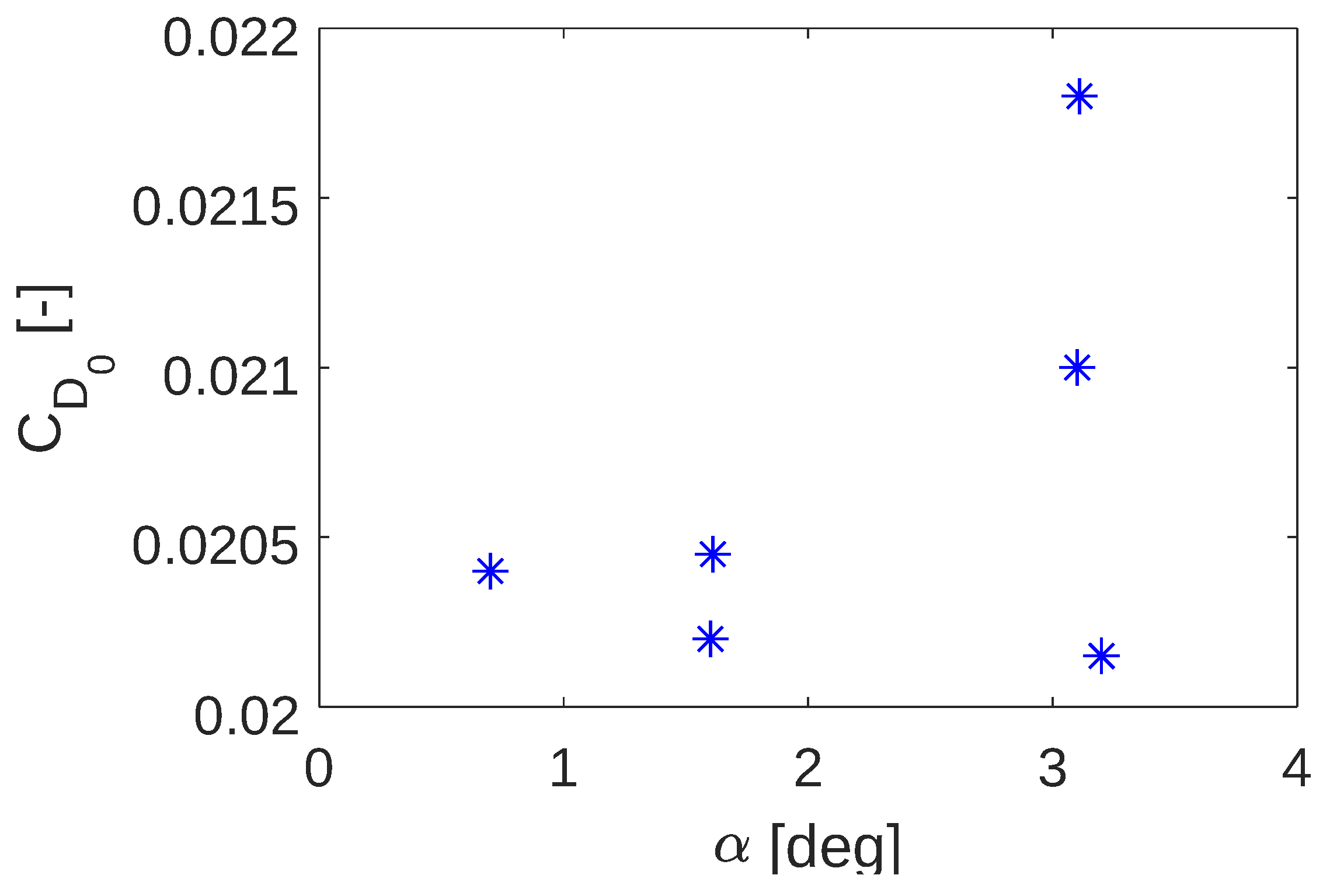

Trim data in gliding flight for different altitudes and speeds were collected, and the results are presented in

Figure 3. The averaged

value for the flight is

, which is very close to the actual value of 0.0202.

Approximate thrust values for each trim point were calculated using the following formulas. The vector-valued function

was constructed using the Newton–Raphson algorithm [

23]. Using Equations (

9), (

10) and (

13), the following system equations with two unknowns were obtained:

where

and

. After calculating the approximate thrust values for different altitudes, airspeeds, and throttle levers using Equation (

15), a preliminary engine propulsion (thrust) model was obtained using Equation (

6). The order of the polynomials for throttle position

and Mach number (

n) were set as 2 and 3, respectively.

3.2. Parameter Estimation

The mathematical model of the dynamic system (process) in a nonlinear state space form is given by the system:

where

is the vector of state variables,

is the control input vector,

the system output vector,

is the unknown parameter vector,

,

,

, and

are the system dimensions, and

,

are general nonlinear functions. Furthermore, the output

y is measured periodically and so the measured output is given by

where

is the system measurement vector,

is the measurement noise vector,

is the additive measurement noise distribution matrix,

is the measurement noise dimension, and

k is the discrete-time index.

The objective (cost) function

J can be calculated from the difference between the measured and estimated responses:

The unknown coefficient values can be determined using any minimization method. The Gauss–Newton method is one of the most widely used minimization algorithms and was selected for this study. The parameter estimation process is frequently unstable, i.e., a small change in measurement might result in a significant change in the estimated model. Inverse problems that develop because of this scenario are referred to as ill-conditioned problems. Regularization is the process of enhancing the stability of the inversion process by introducing extra constraints that bias the result. The Tikhonov regularization is the most often used approach for regularization. Another possibility is to employ the bounds’ constraint technique. There are lower and upper bounds for the model parameters [

38]. To account for simple lower and upper limits on the estimated parameters, the unconstrained optimization problem may be modified to include them. This leads to a linearly constrained optimization problem, formulated as [

39]:

which, in standard form, is

Barrier methods [

40] offer an elegant approach to this constrained optimization problem. The constrained optimization problem is recast as an unconstrained problem in which the objective function is extended with logarithmic barrier terms. The unconstrained problem (combined objective/barrier function) is given by

3.3. Equation Error Method (EEM)

The EEM is used to determine nonstate parameters such as force and moment coefficients, which are not integrated during simulation. By using the equation error form, there is no need to integrate the equations of motion to achieve model outputs since the matching is performed in the equations of motion (hence the term “equation error” [

14]). Furthermore, by minimizing the differences in the least-square sense between measured and model (estimated) responses, the equation error approach estimates the unknown parameter vector (aerodynamic stability and control derivatives).

A wide range of information is needed to derive total aerodynamic force and moment coefficients from flight data, such as the angular rates and accelerations, linear accelerations, thrust-induced forces and moments on the body axis, dynamic pressure, and aircraft mass and inertia data. The location of the accelerometer and air data system is often used to transfer air data and accelerations to the CM. In addition, for each manoeuvre, the centre of gravity location must be determined to transfer total moments to the aerodynamic moment centre (MC) around which an aerodynamic model can be constructed. The coefficients of the nondimensional force and moment are obtained by substituting measured and known quantities. The EEM is used to model the functional dependence of aerodynamic forces and moments on aircraft motion and control variables since propulsive forces and moments are generally obtained from ground tests. The process is illustrated in

Figure 4.

The engine model was based on static thrust look-up tables derived from data provided by the engine manufacturer. Engine dynamics were modelled by applying lag filters to the static engine model. Throughout each manoeuvre, the throttles were held in the trim position.

A preprocessing step was required for the aerodynamic forces and moments since they were not directly measured but could be obtained from the measurements of the related variables, linear accelerations, angular rates, mass properties, and other external forces and moments, as shown in

Figure 4.

The computation of the nondimensional force and moment coefficients were performed using the following equations. The body-fixed specific accelerations at the CM were computed from measured accelerations at the accelerometer sensor position using the following transformation:

Having obtained the specific linear accelerations at the CM, the body-axes aerodynamic force coefficients were obtained as

The nondimensional force components resolved in the wind axis can be obtained using the transformation matrix and written as:

The aerodynamic body-axes’ moments at the CM were computed as

The body-axes’ rolling, pitching, and yawing coefficients referred to CM were obtained from:

The moment coefficients referred to MC on the vehicle were obtained from:

For the EEM estimation, the control input, state variables, observation variables, and unknown (estimated) variables are listed in

Table 2.

Determination and Validation of the Aerodynamic Model Structure

In the process of evaluating the identified model’s correctness, accuracy, and applicability, each coefficient was assigned a unique model structure, which represents a multi-input, single-output subspace. This approach allowed for a greater flexibility and simplified the training task. The initial goal of aerodynamic model development is to determine a good model structure. The model should be as simple as possible while being sufficiently complex to capture the necessary dynamics. Although restricting the number of terms used simplifies computing, it is essential to use the correct terms to ensure a high degree of accuracy. Choosing which terms to include in each coefficient model is a tedious process and is known as “feature selection”.

There are numerous well-known methods for feature selection, including stepwise regression, multivariate orthogonal functions, and generalized additive models. The aerodynamic model structure used in this study was based on that developed by Grauer and Morelli [

41]. They developed a generic, precise, and simple nonlinear aerodynamics model using multivariate orthogonal function modelling to investigate measured wind tunnel aerodynamic databases for eight aircraft over a wide range of flight regimes. The most critical modelling terms (the number of selected instances was high) for each coefficient were selected as frozen model terms. The remaining model terms for longitudinal coefficients were selected using a correlation-based stepwise regression method. The algorithm started by generating a set of candidate model terms based on a set of base regressors and a maximum term order. Then, the pairwise correlation among model terms was compared, and some terms were removed. Finally, a binary particle swarm optimization was utilized to generate the best subset of the remaining terms. Certain additions and rejections to the structure of the underlying aerodynamic model were made using the statistical and qualitative graphical findings analysed by Jategaonkar and Thielecke [

33] and the resampling methods analysed by Millidere et al. [

19].

To evaluate the statistical accuracy of the results, first a check was performed to find out whether the expected value was reasonable. The magnitude should be close to the real value. Next, values of standard deviation, coefficient of variation (COV), and correlation matrix were checked. The COV of any term should not exceed 50% since a significant uncertainty level indicates low information in the derivative estimate. None of the correlations among the two independent terms should exceed 0.95 because the existence of data collinearity compromises the parameter estimation results.

Comparing the time histories of flight-measured and model-estimated responses is a widespread method for the qualitative evaluation of the model’s fidelity. Some inconsistencies in matching the two responses often offer critical information for improving the model fidelity. The residuals test (the difference between the predicted and measured response), also known as cross-plots of residuals, is a good indicator of the reliability of the assumptions made about measurement noise on the system. Ideally, the residual distribution should be flat and centred near zero.

Rather than evaluating the model on the training data, the trained model was evaluated for the data in the testing dataset not used in the training model. The k-fold cross-validation method was used as the resampling method.

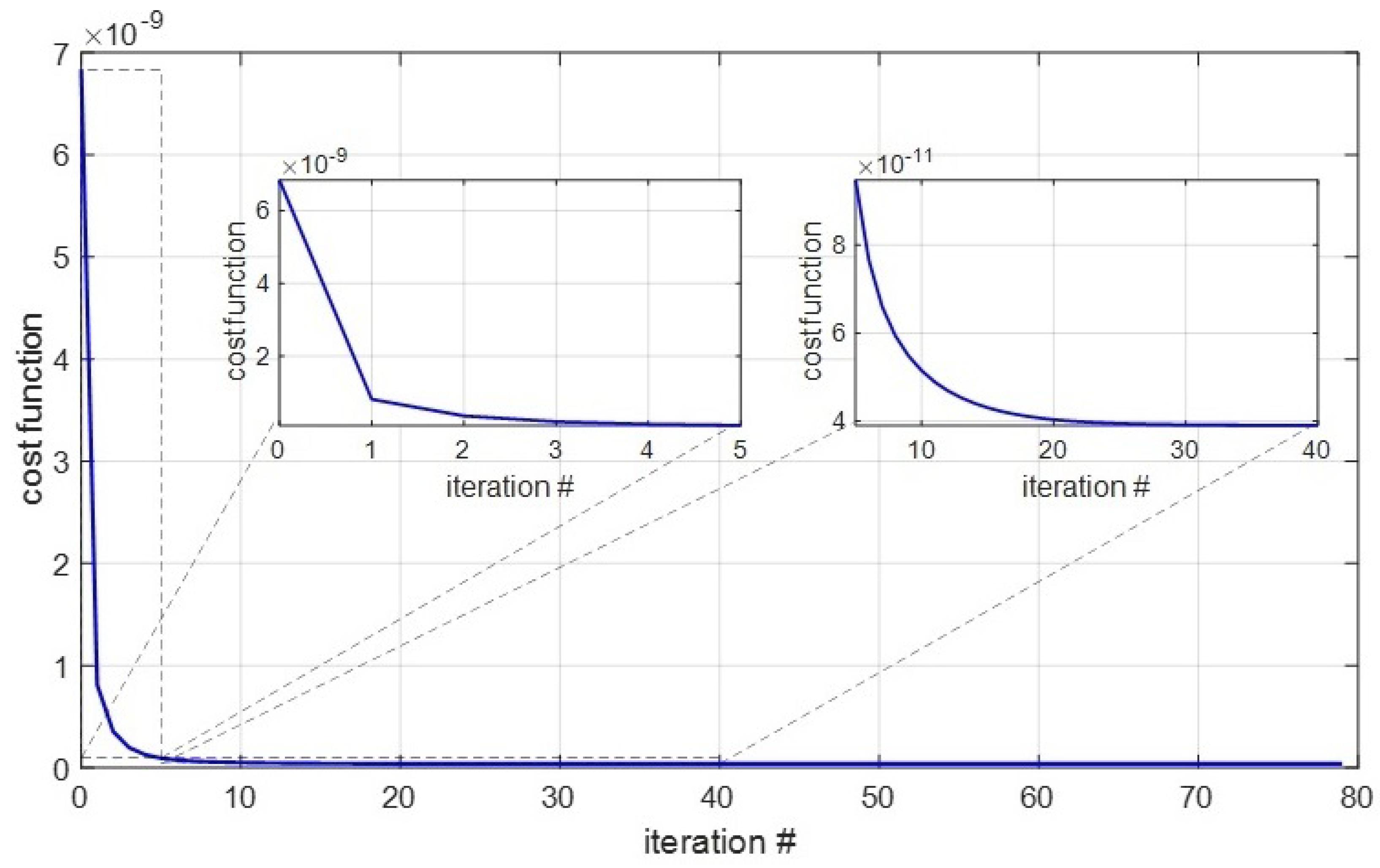

3.4. Iterative Equation Error Method (IEEM)

When the thrust force is known, the EEM is used to find the aerodynamic force and moment coefficients. However, when thrust data are not available, thrust is calculated using the assumptions from steady-state flight tests, and a preliminary simplified turbofan engine thrust model is developed. A good preliminary design is needed as a starting point for all optimization-based design methods. Otherwise, there is no guarantee that the search engine will find a satisfactory solution. The preliminary design is usually accomplished by applying classical methods and employing the IEEM. Since the thrust force does not produce any moment and the angle of sideslip is relatively small in longitudinal manoeuvres, the problem is reduced to identifying aerodynamic drag and lift force coefficients.

The IEEM consists of a starting point and then using a systematic method to obtain a refined estimate of the solution. In the end, it is expected to obtain a solution that simultaneously satisfies the given output vector. The process starts by choosing a reasonable starting point for an unknown parameter vector . If the starting point is far from the optimum, estimations may not lead to a converged solution. The unknown parameter vector is split into two sub-vectors, and . Vector contains the fixed coefficients, and contains the parameters to be estimated. The starting point can be substituted into the cost function, which can be used to calculate a new estimate for coefficient parameters. The fixed parameters, the new estimates of the coefficient parameters along with the previous estimates for are then substituted into the cost function to compute a new estimate for the coefficient parameters. This process is repeated to calculate a new estimate for the coefficient. Then, the entire procedure is repeated until the relative error, falls below a prespecified stopping criterion, , or until the maximum number of iterations is reached.

For the IEEM estimation, the control input, state variables, measured/model output vectors, and unknown (estimated) variables are listed in

Table 3.

The equations that describe the IEEM can be expressed as:

By inserting Equation (

4) into Equation (

39), we obtain

To eliminate the sideslip dependency, only longitudinal manoeuvres are employed, where it is assumed that

, so that Equation (

40) becomes:

5. Conclusions

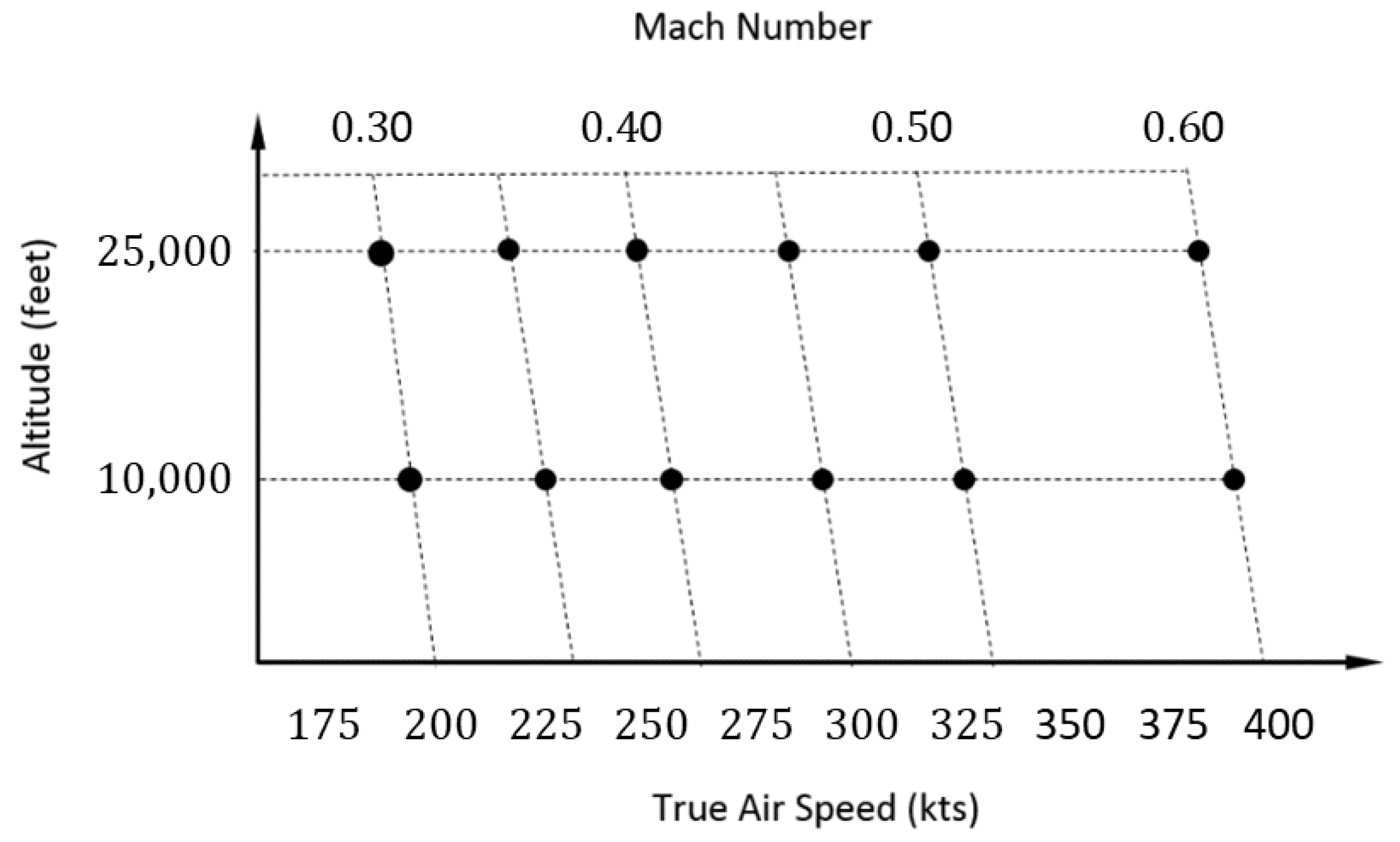

A methodology was developed based on the iterative equation error method (IEEM) to determine nonlinear aerodynamic and engine thrust models in the absence of engine manufacturer data. The study was based on simulated flight test data from a nonlinear simulation of the F-16 aircraft with realistic noise included. With two different altitudes and six different speed configurations, manoeuvres were carried out for twelve different trim points. Control inputs of the pilot were configured for short-period, phugoid, Dutch roll, and bank-to-bank manoeuvres. Trim data for a set of discrete flight conditions with Mach number ranging from

to

, altitude from

ft to

h = 40,000 ft, and flight path angle from

to

were collected to develop a generic engine thrust model. Ideally the method should have been tested for a larger range of Mach numbers, but the F-16 model of [

21] is limited to a maximum Mach number of 0.6.

The IEEM is a sequential process in which the flight data remain the same and only an estimated variable is modified at each iterative step. The simulation results indicated that the proposed algorithm was effective and could produce a satisfactory estimation accuracy. Furthermore, the parameter separation technique introduced herein can be applied to identify large-scale systems by reducing the number of parameters to be identified, thereby greatly simplifying the system identification process.

The engine model is assumed to be true for the EEM application. Clearly, the more accurate the engine model, the more accurate the drag coefficient estimation. Any error in the engine propulsion model propagates into errors in the measured (constructed) aerodynamic force and moment coefficients and thus leads to changes in the identified model parameters. Therefore, to improve the accuracy of the engine model, the IEEM can be utilized.