Decision Science-Driven Assessment of Ti Alloys for Aircraft Landing Gear Beams

Abstract

1. Introduction and Background

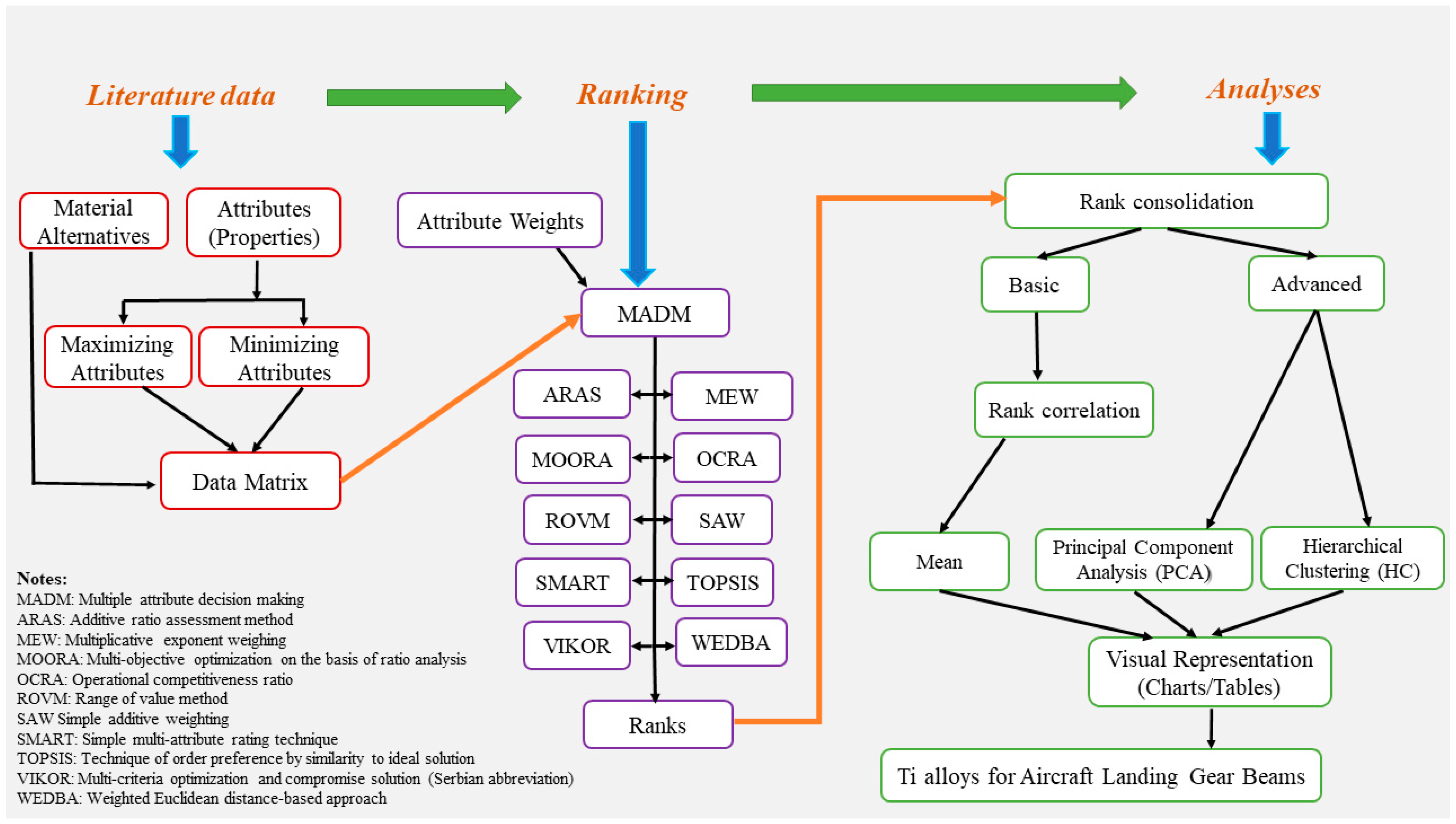

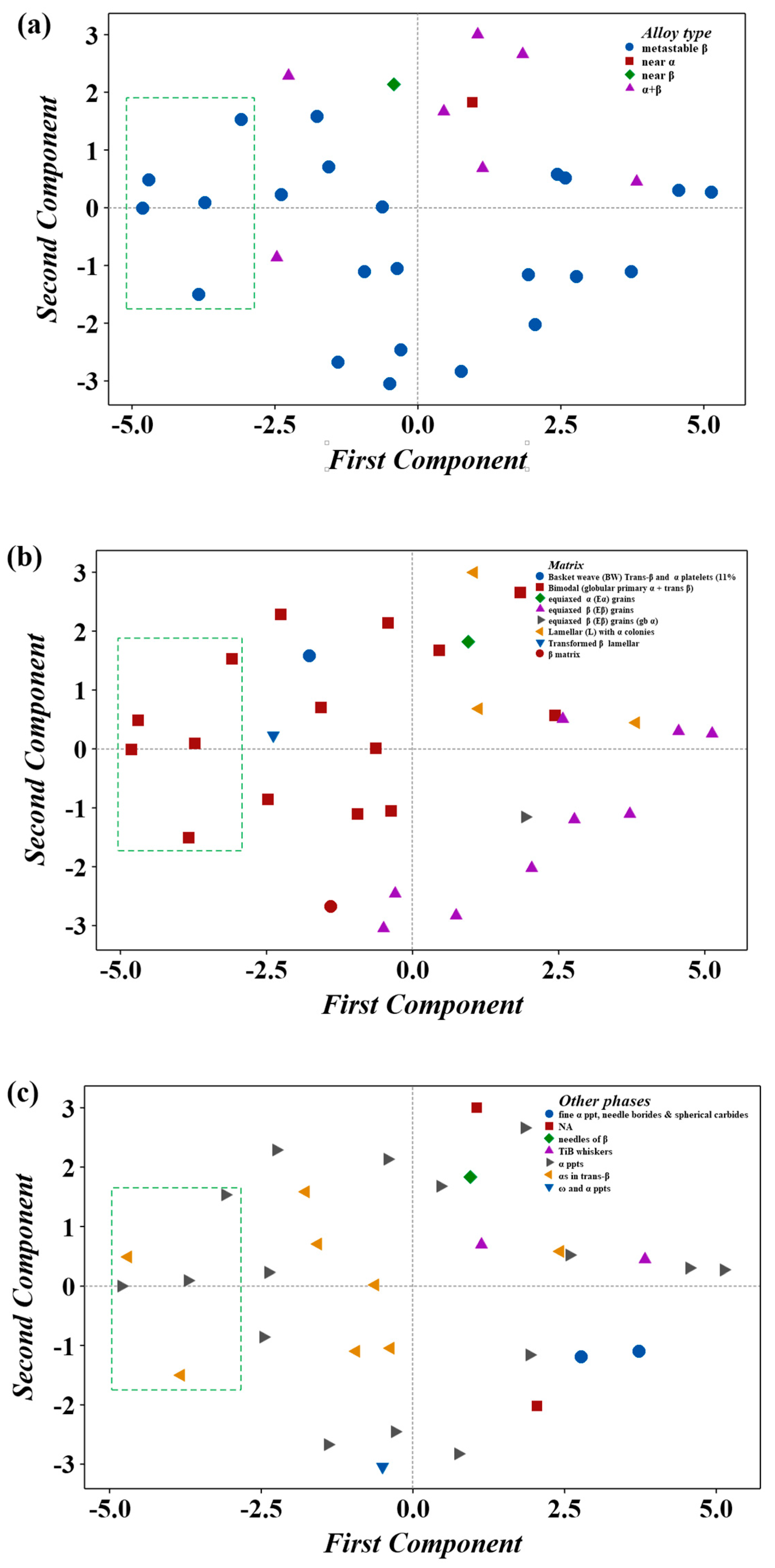

2. Assessment Methodology

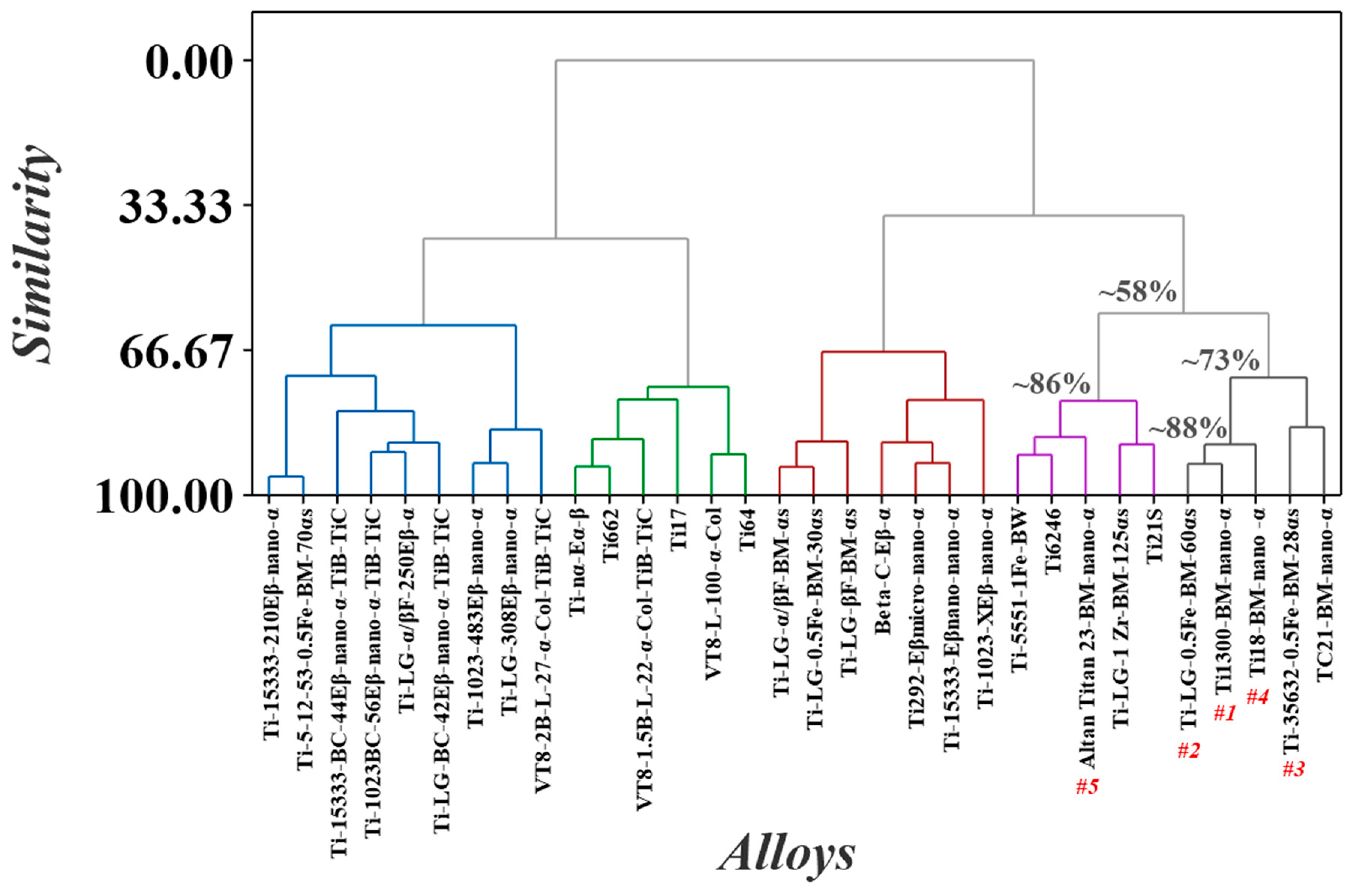

3. Results and Discussion

4. Summary and Conclusions

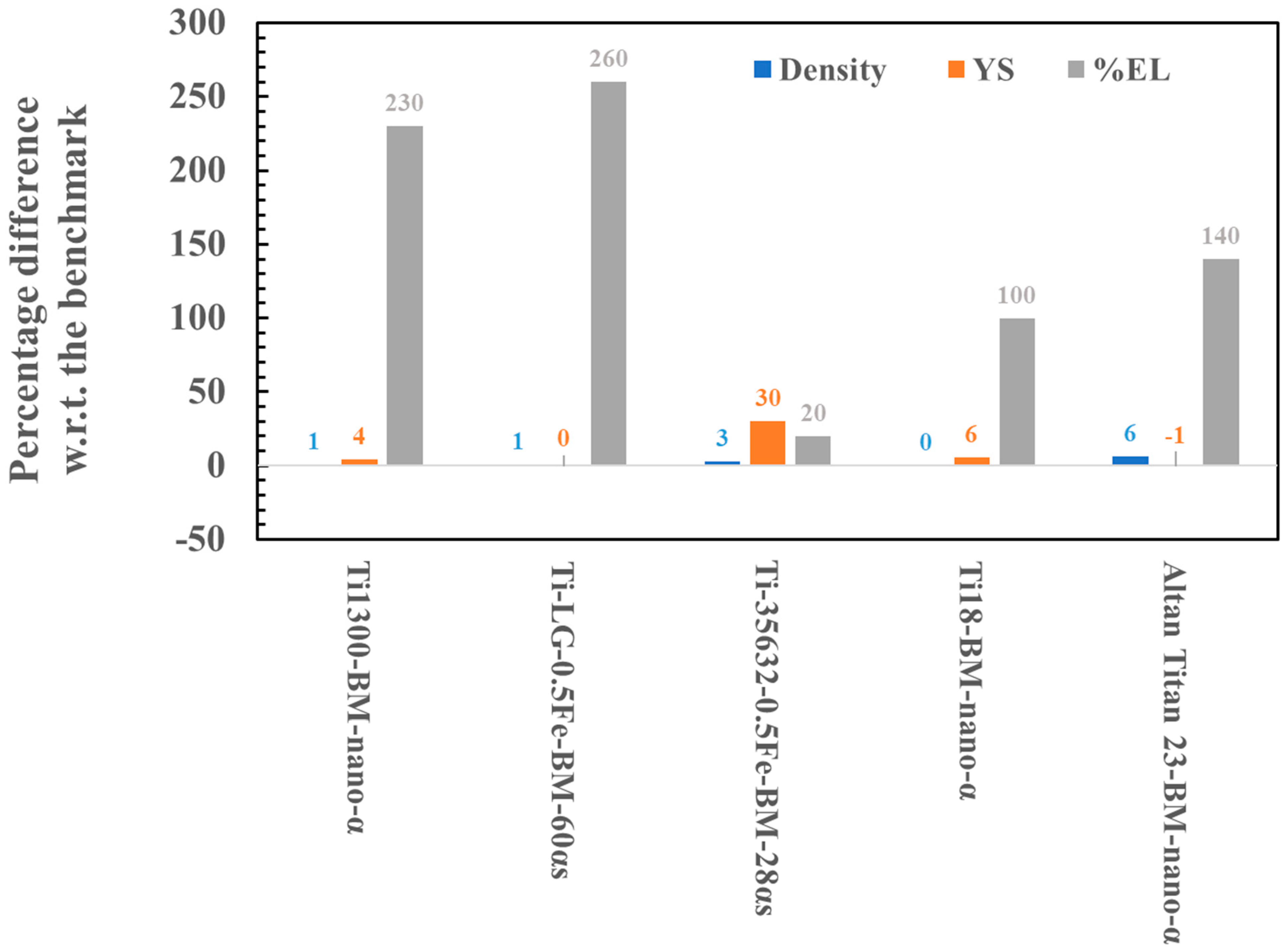

- The methodology identifies the five top-ranked Ti alloys—Ti-5Al-4V-4Mo-3Zr-4Cr (Ti1300-BM-nano-α), Ti-5Al-5V-5Mo-3Cr-0.5Fe (Ti-LG-0.5Fe-BM-60αs), Ti-3.5Al-5Mo–6V-3Cr-2Sn-0.5Fe (Ti-35632-0.5Fe-BM-28αs), Ti-5.5Al-5V-5Mo-2.3Cr-0.8Fe-0.15O (Ti18-BM-nano-α), and Ti-3.5Al-9V-2.5Mo-5Sn-3Zr-0.2O (Altan Titan 23-BM-nano-α)—in that order.

- The data and analyses suggest that the top-ranked alloys could be refined further to adjust the properties by appropriate thermomechanical processing.

- The novel decision science-driven methodology verifies the guidelines for alloy design and makes metallurgical sense: metastable β Ti alloys comprising a globular primary α + trans β matrix coupled with α precipitates in trans β seem to be the optimum microstructure for these Ti alloys for aircraft landing gear applications.

- Ranking helps focus on the top-ranked alloys to generate all the needed data for the intended application expeditiously and cost-effectively and also helps in further improvements to optimize the microstructural features to balance the desired attributes are possible through variations in thermomechanical processing (TMP).

- Hierarchical clustering analysis seems to bring out similarities between alloy grades that follow the materials science tetrahedron approach.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Distribution Statement

Disclaimer/Authors’ Note

References

- IATA/Global Outlook for Air Transport- Highly Resilient, Less Robust. Semi Annual Report, June 2023. Available online: https://www.iata.org/en/iata-repository/publications/economic-reports/global-outlook-for-air-transport----june-2023/ (accessed on 26 December 2023).

- Airbus. Global Market Forecast. 2023. Available online: https://www.airbus.com/sites/g/files/jlcbta136/files/2023-06/GMF%202023-2042%20Presentation_0.pdf (accessed on 26 December 2023).

- Bickers, C.; Bergman, P. Boeing Forecasts $8.7 Trillion Aerospace and Defense Market through 2028. Boeing 2019. Available online: https://boeing.mediaroom.com/2019-06-17-Boeing-Forecasts-8-7-Trillion-Aerospace-and-Defense-Market-through-2028 (accessed on 26 December 2023).

- Ulhmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F. Additive manufacturing of titanium alloy for aircraft components. Procedia CIRP 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Chatterjee, B.; Bhowmick, S. Evolution of material selection in commercial aviation industry. In Sustainable Engineering Products and Manufacturing Technologies; Academic Press: Cambridge, MA, USA, 2019; pp. 199–219. [Google Scholar]

- Wang, M.; Li, H.; Chen, H.; Fang, X.; Zhu, E.; Huang, P.; Wei, X.; Nie, H. Structural optimization of AeroMet100 Steel Torsion Spring Based on Strain Fatigue. Aerospace 2023, 10, 828. [Google Scholar] [CrossRef]

- Philip, T.V.; McCaffrey, T.J. Ultrahigh-Strength Steels, in ASM Handook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys; ASM International: Almere, The Netherlands, 1990; Volume 1, pp. 431–448. [Google Scholar]

- Buscher, M.; Terlinde, G.; Wegmann, G.; Thoben, C.; Millet, Y.; Lutjering, G.; Albrecht, J. Forgings from Ti5Al-5V-5Mo-3Cr with Optimized Fracture Toughness; Ninomi, M., Akiyama, S., Ikeda, M., Hagiwara, M., Maruyama, K., Eds.; The Japan Institute of Metals: Kyoto, Japan, 2007; pp. 885–888. [Google Scholar]

- Serey, J.P. Trends in landing gear material. Aerosp. Eng. 2005, 25, 46, (SAE International, Warrendale, PA, USA). Available online: https://www.42volt.sae.org/aeromag/features/futurelook/09-2005/2-25-8-46.pdf (accessed on 2 April 2021).

- Commercial Aircraft Landing Gear Market: Study, Opportunities, and Forecast (2023–2031). Available online: https://straitsresearch.com/report/commercial-aircraft-landing-gear-market (accessed on 26 December 2023).

- Ashby, M.F. Materials and the Environment Eco-Informed Material Choice, 1st ed.; Butterworth Heinemann: Oxford, UK; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Jahan, A.; Ismail, M.Y.; Sapuan, S.M.; Mustapha, F. Materials screening and choosing methods—A review. Mater. Des. 2010, 31, 696–705. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 5th ed.; Butterworth Heinemann: Oxford, UK; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Polmear, I.J. Light Alloys—Metallurgy of Light Alloys, 3rd ed.; Butterworth Heinemann: Oxford, UK, 1995. [Google Scholar]

- Ji, Z.; Yang, H. Microstrucural design of two-phase tianium alloys by microscale strain determination. Mater. Lett. 2016, 184, 157–161. [Google Scholar] [CrossRef]

- Wang, H.B.; Wang, S.S.; Gao, P.Y.; Jiang, T.; Lu, X.G.; Li, C.H. Microstructure, and mechanical properties of a novel near-α titanium alloy Ti6.0Al4.5Cr1.5Mn. Mater. Sci. Eng. A 2016, 672, 170–174. [Google Scholar] [CrossRef]

- Correa, D.R.; Kuroda, P.A.; Grandini, C.R.; Rocha, L.A.; Olieira, F.G.; Alves, A.C. Tribocorrosion behavior of β-type Ti-15Zr-based alloys. Mater. Lett. 2016, 179, 118–121. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities, and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Canumalla, R. On the low tensile ductility at room temperature in high temperature titanium alloys. SCIREA J. Metall. Eng. 2020, 4, 16–51. [Google Scholar]

- Kolli, R.P.; Devaraj, A. A review of metastable beta titanium alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Kang, L.M.; Yang, C. A review on high-strength titanium alloys: Microstructure, Strengthening, and Properties. Adv. Eng. Mater. 2019, 21, 1801357. [Google Scholar] [CrossRef]

- Huda, Z.; Edi, P. Materials selection in design of structures and engines of supersonic aircrafts: A review. Mater. Des. 2013, 46, 552–560. [Google Scholar] [CrossRef]

- Inagaki, I.; Shirai, Y.; Takechi, T.; Ariyasu, N. Application and Features of Titanium for the Aerospace Industry. Nippon Steel & Sumitomo Metal Technical Report No. 106 July 2014, Osaka City, Japan. pp. 22–27. Available online: https://www.nipponsteel.com/en/tech/report/nssmc/pdf/106-05.pdf (accessed on 2 April 2021).

- Santos, C.V.; Leiva, D.R.; Costa, F.R.; Gregolin, J.A. Materials Selection for Sustainable Executive Aircraft Interior. Mater. Res. 2016, 19, 339–352. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in aerospace industry. Mater. Sci. Eng. 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium Alloys for Aerospace Applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandala, S.; Russo, P.; Shchetnikov, N.; Fanning, J.C. State of the art beta titanium alloys for airframe applications. JOM 2015, 67, 1281–1303. [Google Scholar] [CrossRef]

- Renato, A.A.; Salvador, C.A.; de Oliviera, M.C. Materials selection of optimized alloys for Aircraft Applications. Mater. Res. 2018, 21, e20170979. [Google Scholar]

- Jayaraman, T.V.; Canumalla, R. Competitor Ti-Comprising Refractory High Entropy Alloys to Superalloy 718 for Aeroengine Applications. In Proceedings of the 10th International Symposium on Superalloy 718 and Derivatives, Pittsburgh, PA, USA, 14–17 May 2023. [Google Scholar]

- Canumalla, R.; Jayaraman, T.V. Decision Science Driven Selection of High-Temperature Conventional Ti Alloys for Aeroengines. Aerospace 2023, 10, 211. [Google Scholar] [CrossRef]

- Jayaraman, T.V.; Canumalla, R. Data-driven Search and Selection of Ti-containing Multi-principal Element Alloys for Aeroengine Parts. In Proceedings of the TMS 2023 152nd Annual Meeting & Exhibition Supplemental Proceedings, San Diego, CA, USA, 19–23 March 2023. [Google Scholar]

- Canumalla, R.; Jayaraman, T.V. Ti-containing High-Entropy Alloys for Aeroengine Turbine Applications. Mater. Res. 2023, 26, e20220213. [Google Scholar] [CrossRef]

- Jayaraman, T.V.; Canumalla, R. Strategic selection of refractory high-entropy alloy coatings for hot-forging dies by applying decision science. Coatings 2024, 14, 19. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Kildiene, S. State of art surveys of overviews on MCDM/MADM methods. Technol. Econo. Dev. Econ. 2014, 20, 165–179. [Google Scholar] [CrossRef]

- Zakeri, S.; Chatterjee, P.; Konstantas, D.; Ecer, F. A decision analysis model for material selection using simple ranking process. Sci. Rep. 2023, 13, 8631. [Google Scholar] [CrossRef] [PubMed]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making Methods, and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Rao, R.V. Decision Making in the Manufacturing Environment, Using Graph Theory and Fuzzy Multiple Attribute Decision Making Methods; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Cadima, J.; Jolliffle, I.T. Principal Component Analysis: A review and recent developments. Phil. Trans. R. Soc. A 2016, 374, 20150202. [Google Scholar]

- Rajan, K.; Sun, C.; Mendez, P.F. Principal component analysis and dimensional analysis as materials informatics tools to reduce dimensionality in materials science and engineering. Stat. Anal. Data Min. 2009, 1, 361–371. [Google Scholar] [CrossRef]

- Banoth, R.; Sarkar, R.; Bhattacharjee, A.; Nandy, T.K.; Rao, G.V. Effect of boron and carbon addition on microstructure and mechanical properties of metastable beta titanium alloys. Mater. Des. 2015, 67, 50–63. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, W.; Xue, S.; Jia, Z. The crack initiation behavior and the fatigue limit of Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy with basket-weave microstructure. J. Alloys Compd. 2015, 631, 340–349. [Google Scholar] [CrossRef]

- Imayev, V.M.; Gaisin, R.A.; Imayev, R.M. Effect of boron additions and processing on microstructure and mechanical properties of a titanium alloy Ti-6.5Al-3.3Mo-0.3Si. Mater. Sci. Eng. A 2015, 641, 71–83. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Z.; Xue, K. Cyclic deformation response and micromechanisms of Ti alloy Ti-5Al-5V-5Mo-3Cr-0.5Fe. Mater. Sci. Eng. A 2011, 528, 8723–8732. [Google Scholar] [CrossRef]

- Opini, V.C.; Salvador, C.A.; Campo, K.N.; Lopes, E.S.; Chaves, R.R.; Caram, R. α phase precipitation and mechanical properties of Nb-modified Ti-5553 alloy. Mater. Sci. Eng. A 2016, 670, 112–121. [Google Scholar] [CrossRef]

- Berg, A.; Kiese, J.; Wagner, L. Microstructural gradients in Ti-3Al-8V-6Cr-4Zr-4Mo for excellent HCF strength and toughness. Mater. Sci. Eng. A 1998, 243, 146–149. [Google Scholar] [CrossRef]

- Du, Z.; Xiao, S.; Xu, L.; Tian, J.; Kong, F.; Chan, Y. Effect of heat treatment on microstructure and mechanical properties of a new β high strength titanium alloy. Mater. Des. 2014, 55, 183–190. [Google Scholar]

- Huang, C.; Zhao, Y.; Xin, S.; Tan, C.; Zhou, W.; Li, Q. Effect of microstructure on high cycle fatigue behavior of Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy. Int. J. Fatigue 2017, 94, 30–40. [Google Scholar] [CrossRef]

- Li, C.L.; Mi, X.J.; Ye, W.J.; Hui, S.X.; Lee, D.G.; Lee, Y.T. Microstructural evolution, and age hardening behavior of a new metastable beta Ti-2Al-9.2Mo-2Fe alloy. Mater. Sci. Eng. A 2015, 645, 225–231. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, Q.; Sun, D.L.; Han, X.L.; Wu, G.H. Formation of nanostructure and mechanical properties of cold-rolled Ti-15V-3Sn-3Al-3Cr alloy. Mater. Sci. Eng. A 2010, 527, 4229–4232. [Google Scholar]

- Srinivasu, G.; Natraj, Y.; Bhattacharjee, A.; Nandy, T.K.; Nageswara Rao, G.V. Tensile and fracture toughness of high strength Beta Ti Tanium alloy, Ti-10V-2Fe-3Al, as a function of rolling and solution treatment temperatures. Mater. Des. 2013, 47, 323–330. [Google Scholar] [CrossRef]

- Fanning, J. Recent developments in High Strength Near Beta Ti alloy. In Proceedings of the Titanium 2011 Conference, San Diego, CA, USA, October 2011; Available online: https://cdn.ymaws.com/titanium.org/resource/resmgr/2010_2014_papers/FanningJohn_2011.pdf (accessed on 26 December 2023).

- Wilwert, L.P. A New High Strength Titanium Alloy with Improved Fatigue Life. in ATI Titan 23. 2019. Available online: https://srehsv.com/wp-content/uploads/2019/11/D6a-Wilwert-ATI-Titan-23%E2%84%A2.pdf (accessed on 26 December 2023).

- Lu, L.; Ge, P.; Li, Q.; Zhang, W.; Huo, W.; Hu, J.; Zhang, Y.; Zhao, Y. Effect of microstructure characteristic on mechanical properties and corrosion behavious of new high strength Ti1300 beta titanium alloy. J. Alloys Compd. 2017, 727, 1126–1135. [Google Scholar] [CrossRef]

- Ibrahim, K.M.; Barakat, A.F.; Elshaer, R.N.; Abbas, R.R. Effect of Cooling rate and aging on microstructure and tensile properties of TC21 Ti Alloy. TIMS Bull. 2018, 107, 1–11. [Google Scholar]

- TIMETAL 21S; High Strength, Oxidation Resistant Strip Alloy. Titanium Metals Corporation: Dallas, TX, USA, 2000.

- TIMETAL 17; High Strength Forging Alloy. Titanium Metals Corporation: Dallas, TX, USA, 2000.

- TIMETAL 6-2-4-6; High-Strength Intermediate Temperature Alloy. Titanium Metals Corporation: Dallas, TX, USA, 2000.

- Titanium Alloys; Titanium Metals Corporation: Dallas, TX, USA, 1997.

- Properties and Processing of TIMETAL 6-4 (TMC-0131); Titanium Metals Corporation: Dallas, TX, USA, 1998.

- Zavadskas, E.K.; Turskis, Z. A new additive ratio assessment (ARAS) method in multicriterial decision making. Technol. Econ. Dev. Econ. 2010, 16, 159–172. [Google Scholar] [CrossRef]

- Stanujic, S.; Jovanovic, R. Measuring a quality of faculty website using ARAS method. Contemp. Issues Bus. Manag. Educ. 2012, 2012, 545–554. [Google Scholar]

- Jahan, A.; Edwards, K.L.; Bahraminasab, M. Multi-Criteria Decision Analysis—For Supporting the Selection of Engineering Materials in Product Design, 2nd ed.; Butterworth-Heinemann; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Chakraborty, S. Applications of the MOORA method for decision making in manufacturing environment. Int. J. Adv. Manuf. Technol. 2011, 4, 1155–1166. [Google Scholar] [CrossRef]

- Dominguez, L.P.; Mojica, K.Y.S.; Pabon, L.C.O.; Diaz, M.C.C. Application of the MOORA method for the evaluation of the industrial maintenance system. J. Phys. Conf. Ser. 2018, 1126, 012018. [Google Scholar] [CrossRef]

- Erdogan, S.; Aydin, S.; Balki, M.K.; Sayin, C. Operational evaluation of thermal barrier coated diesel engine fueled with biodiesel/diesel blend by using MCDM method base on engine performance, emission, and combustion characteristics. Renew. Energy 2020, 151, 698–706. [Google Scholar] [CrossRef]

- Darji, V.P.; Rao, R.V. Intelligent multi-criteria decision making methods for material selection in sugar industry. Procedia Mater. Sci. 2014, 5, 2585–2594. [Google Scholar] [CrossRef]

- Madic, M.; Radovanovic, M.; Manic, M. Application of the ROV method of selection of cutting fluids. Decis. Sci. Lett. 2016, 5, 245–254. [Google Scholar] [CrossRef]

- Jha, G.K.; Chatterjee, P.; Chatterjee, R.; Chakraborty, S. Suppliers selection in a manufacturing environment using a range of value method. J. Mech. Eng. 2013, 3, 1–15. [Google Scholar] [CrossRef]

- Siregar, D.; Arisandi, D.; Usman, A.; Irwan, D.; Rahim, R. Research of simple multi-attribute rating technique for decision support. J. Phys. Conf. Ser. 2017, 930, 012015. [Google Scholar] [CrossRef]

- Deng, H.; Yeh, C.H.; Willis, R.J. Inter-company comparison using modified TOPSIS with objective weights. Comput. Oper. Res. 2000, 27, 963–973. [Google Scholar] [CrossRef]

- Gul, M.; Celik, E.; Aydin, N.; Gumus, A.T.; Guneri, A.F. A state-of-the-art literature review of VIKOR and its fuzzy extensions on applications. App. Soft Comput. 2016, 46, 60–89. [Google Scholar] [CrossRef]

- Sayadi, M.M.; Heydari, M.; Shahanaghi, K. Extension of VIKOR method for decision making problem with interval numbers. App. Math. Model. 2009, 33, 2257–2262. [Google Scholar] [CrossRef]

- Rao, R.V.; Singh, D. Evaluating flexible manufacturing systems using Euclidean distance-based integrated approach. Int. J. Risk. Manag. 2012, 3, 32–53. [Google Scholar] [CrossRef]

- Levine, D.M.; Ramsey, P.P.; Smidt, R.K. Applied Statistics for Engineers and Scientists; Prentice-Hall: Upper Saddle, NJ, USA, 2001. [Google Scholar]

- Navidi, W. Statistics for Engineers and Scientists, 3rd ed.; McGraw-Hill Science/Engineering: New York, NY, USA, 2010. [Google Scholar]

- Rajan, K. Materials Informatics. Mater. Today 2015, 8, 38–45. [Google Scholar] [CrossRef]

- George, L.; Hrubiak, R.; Rajan, K.; Saxena, S.K. Principal component analysis on properties of binary and ternary hydrides and a comparison of metal versus metal hydride properties. J. Alloys Compd. 2009, 478, 731–735. [Google Scholar] [CrossRef]

- Arabie, P.; Hubert, L.J.; De Soete, G. Clustering and Classification; World Scientific: River Edge, NJ, USA, 1999. [Google Scholar]

- Shannon, M.E. A mathematical theory of communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Mukaka, M.M. Statistics Corner: A guide to appropriate use of correlation coefficient in medical research. Malawi Med. J. 2012, 24, 69–71. [Google Scholar] [PubMed]

- Hinkle, D.E.; Wiersma, W.; Jurs, S.G. Applied Statistics for the Behavioral Sciences; Houghton Mifflin: Boston, MA, USA, 2003. [Google Scholar]

- Zhang, Z.Y.; Liu, D.R.; Pu, Z.P. Effect of microstructure on high-speed tensile mechanical properties of Ti-1300 alloy. Materials 2023, 16, 4725. [Google Scholar] [CrossRef] [PubMed]

- Li, C.C.; Xin, C.; Wang, Q.; Ren, J.Q.; Zhao, B.; Wu, J.P.; Pan, X.L.; Lu, X.F. A novel low-cost high-strength β titanium alloy: Microstructure evolution and mechanical behavior. J. Alloys Compd. 2023, 959, 170497. [Google Scholar] [CrossRef]

- Bai, C.; Lan, L.; Xin, R.; Gao, S.; He, B. Microstructure evolution and cyclic deformation behavior of Ti-6Al-4V alloy wia electron beam melting during low cycle fatigue. Int. J. Fatigue 2022, 159, 106784. [Google Scholar] [CrossRef]

- Canumalla, R.; Jayaraman, T.V. Tensile ductility at room temperature in high temperature titanium alloys used for aeroengine applications. In Proceedings of the 15th World Conference on Titanium (Ti-2023), Edinburgh, UK, 12–16 June 2023. [Google Scholar]

- Pilchak, A.; Gram, M. Cold dwell fatigue of titanium alloys. JOM 2022, 74, 3691–3692. [Google Scholar] [CrossRef]

| Sl# | Alloy Chemistry (wt.%) (Alloy Type) | Mo-Eq | Solution Treatment | Aging | Matrix | Other Phases | Alloy Designation | Ref. |

|---|---|---|---|---|---|---|---|---|

| 1 | Ti-15V-3Cr-3Al-3Sn (metastable β) | 11.85 | 900 °C forged- ST810 °C-1 h-WQ (i.e., ST above βtr) | 500 °C–8 h–AC | Equiaxed β (Eβ) grains | α ppts | Ti-15333-210Eβ-nano-α | [40] |

| 2 | Ti-15V-3Cr-3Al-3Sn-C-B (metastable β) | 11.85 | 900 °C forged–ST810 °C-1 h-WQ (i.e., ST above βtr) | 500 °C–8 h–AC | Equiaxed β (Eβ) grains | fine α ppt, needle borides and spherical carbides | Ti-15333-BC-44Eβ-nano-α-TiB-TiC | [40] |

| 3 | Ti-10V-2Fe-3Al (metastable β) | 9.5 | 950 °C forged–ST850 °C-1 h–WQ (i.e., ST above βtr) | 500 °C–8 h–AC | Equiaxed β (Eβ) grains | α ppts | Ti-1023-483Eβ-nano-α | [40] |

| 4 | Ti-10V-2Fe-3Al-C-B (metastable β) | 9.5 | 950 °C forged–ST850 °C-1 h–WQ (i.e., ST above βtr) | 500 °C–8 h–AC | Equiaxed β (Eβ) grains | fine α ppt, needle borides and spherical carbides | Ti-1023BC-56Eβ-nano-α-TiB-TiC | [40] |

| 5 | Ti-5Al-5V-5Mo-3Cr (metastable β) | 8.2 | 1000 °C forged-ST900 °C-1 h-WQ (i.e., ST above βtr) | 500 °C–8 h–AC | Equiaxed β (Eβ) grains | α ppts | Ti-LG-308Eβ-nano-α | [40] |

| 6 | Ti-5Al-5V-5Mo-3Cr-C-B (metastable β) | 8.2 | 1000 °C forged-ST900 °C-1 h-WQ (i.e., ST above βtr) | 500 °C–8 h–AC | Equiaxed β (Eβ) grains | NA | Ti-LG-BC-42Eβ-nano-α-TiB-TiC | [40] |

| 7 | Ti-5Al-5V-5Mo-3Cr (metastable β) | 8.2 | (α/β) hand forged-(α/β)ST-aging (α/β route) (i.e., ST below βtr) | “done aging”-parameters NA | Bimodal (globular primary α + trans β) | α in trans-β | Ti-LG-α/βF-BM-αs | [8] |

| 8 | Ti-5Al-5V-5Mo-3Cr (metastable β) | 8.2 | (α/β) hand forged-(β)ST-Aging (β-annealed route) (i.e., ST above βtr) | “done aging”-parameters NA | Equiaxed β (Eβ) grains (gb α) | α ppts | Ti-LG-α/βF-250Eβ-α | [8] |

| 9 | Ti-5Al-5V-5Mo-3Cr (metastable β) | 8.2 | (β) hand forged-(α/β) ST-aging (β-forged route) (i.e., ST above βtr) | “done aging”-parameters NA. | Bimodal (globular primary α + trans β) | α in trans-β | Ti-LG-βF-BM-αs | [8] |

| 10 | Ti-6Al-4.5Cr-1.5Mn (near-α) | 3.75 | Rolling at 770 °C (in the α + β phase field; α/α + β transition is 720 °C)/ST750 °C-1.5 h-AC (Vac) | None | Equiaxed α (Eα) grains | needles of β | Ti-nα-Eα-β | [16] |

| 11 | Ti-5Al-5V-5Mo-1Cr-1Fe (VT-22) (metastable β) | 7.85 | 850 °C-2 h-FC, 750 °C-2 h-AC | 500 °C-4 h-AC | Basket weave (BW) trans-β and α platelets (11% Vf) | α in trans-β | Ti-5551-1Fe-BW | [41] |

| 12 | Ti-6.5Al-3.3Mo-0.3Si (α + β) | -3.2 | Hot 2D forging at 950 °C; ST1030 °C-0.5 h-FC (i.e., ST above βtr) | NA | Lamellar (L) with α colonies | NA | VT8-L-100-α-Col | [42] |

| 13 | Ti-6.5Al-3.3Mo-0.3Si-1.5B (α + β) | -3.2 | Hot 2D forging at 950 °C; ST1030 °C–0.5 h-FC (i.e., ST above βtr) | NA | Lamellar (L) with α colonies | TiB whiskers | VT8-1.5B-L-22-α-Col-TiB-TiC | [42] |

| 14 | Ti-6.5Al-3.3Mo-0.3Si-2B (α + β) | -3.2 | Hot 2D forging at 950 °C; ST1030 °C–0.5 h-FC (i.e., ST above βtr) | NA | Lamellar (L) with α colonies | TiB whiskers | VT8-2B-L-27-α-Col-TiB-TiC | [42] |

| 15 | Ti-5Al-5V-5Mo-3Cr-0.5Fe (metastable β) | 9.6 | ST821 °C-3 h-fan cooling (i.e., ST below βtr) | 621 °C-6 h-AC | Bimodal (globular primary α + trans β) | α in trans-β | Ti-LG-0.5Fe-BM-60αs | [43] |

| 16 | Ti-5Al-5V-5Mo-3Cr-0.5Fe (metastable β) | 9.6 | ST830 °C-AC (i.e., ST below βtr) | 600 °C-10 h-FC | Bimodal (globular primary α + trans β) | α in trans-β | Ti-LG-0.5Fe-BM-30αs | [44] |

| 17 | Ti-5Al-12Nb-5Mo-3Cr-0.5Fe (metastable β) | 9.6 | ST830 °C-AC (i.e., ST below βtr) | 600 °C-10 h-FC | Bimodal (globular primary α + trans β)) | α in trans-β | Ti-5-12-53-0.5Fe-BM-70αs | [44] |

| 18 | Ti-3Al-8V-6Cr-4Zr-4Mo (Beta C) (metastable β) | 16 | ST927 °C-AC–40% deep rolling followed by aging (i.e., ST above βtr) | 400 °C–4 h | β matrix | α ppts | Beta-C-Eβ-α | [45] |

| 19 | Ti-3.5Al-5Mo-6V-3Cr-2Sn-0.5Fe (metastable β) | 11.8 | ST775 °C-1 h-AC (i.e., ST below βtr) | 440 °C–8 h–AC | Bimodal (globular primary α + trans β) | α in trans-β | Ti-35632-0.5Fe-BM-28αs | [46] |

| 20 | Ti-5Al-5V-5Mo-3Cr-1Zr (metastable β) | 8.2 | ST 790 °C (2 h)-(i.e., below βtr); AC | 600 °C–6 h-AC | Bimodal (globular primary α + trans β) | α in trans-β | Ti-LG-1 Zr-BM-125αs | [47] |

| 21 | Ti-2Al-9.2Mo-2Fe (metastable β) | 13.0 | ST850 °C-1 h-WQ (i.e., ST above βtr) | 500 °C–2 h–WQ. | Equiaxed β (Eβ) grains | ω and α ppts | Ti292-Eβmicro-nano-α | [48] |

| 22 | Ti-15V-3Sn-3Al-3Cr (metastable β) | 11.9 | ST800 °C-20 min.-WQ to RT (200 to 300 µm grain size)/cold rolling (80% thickness reduction; three passes)—above β transus produces nanosize β | 450 °C–4 h | Equiaxed β (Eβ) grains | α ppts | Ti-15333-Eβnano-nano-α | [49] |

| 23 | Ti-10V-2Fe-3Al (metastable β) | 9.5 | 860 °C rolling-ST830 °C-1 h–WQ (i.e., ST above βtr) | 500 °C–4 h–AC | Equiaxed β (Eβ) grains | α ppts | Ti-1023-Xeβ-nano-α | [50] |

| 24 | Ti-5.5Al-5V-5Mo-2.3Cr-0.8Fe-0.15O (metastable β) | 8.9 | ST820 °C–2 h–AC (i.e., ST below βtr) | 593 °C–8 h-AC | Bimodal (globular primary α + trans β) | α ppts | Ti18-BM-nano–α | [51] |

| 25 | Ti-3.5Al-9V-2.5Mo-5Sn-3Zr-0.2O (metastable β) | 8.5 | ST760 °C–2 h–AC (i.e., ST below βtr) | 538 °C–8 h-AC | Bimodal (globular primary α + trans β) | α ppts | Altan Titan 23-BM-nano-α | [52] |

| 26 | Ti-5Al-4V-4Mo-3Zr-4Cr (metastable β) | 8.1 | ST800 °C–1 h–AC (i.e., ST below βtr) | 500 °C–4 h-AC | Bimodal (globular primary α + trans β) | α ppts | Ti1300-BM-nano-α | [53] |

| 27 | Ti–6Al–2Sn–2Zr–3Mo–1Cr–2Nb (α + β) | -0.8 | β forging followed by Water quenching and the α/β ST at 900 °C–1 h-WQ | 575 °C–4 h-AC | Bimodal (globular primary α + trans β) | α ppts | TC21-BM-nano-α | [54] |

| 28 | Ti-15Mo-3Nb-3Al-0.2Si (metastable β) | 12.8 | β ST-AC (i.e., ST above βtr) | 538 °C–8 h-AC | Transformed β lamellar | α ppts | Ti21S | [55] |

| 29 | Ti-5Al-2Sn-4Mo-2Zr-4Cr (near-β) | 5.4 | α/β 800 °C ST-AC (i.e., ST below βtr) | 635 °C–8 h-AC | Bimodal (globular primary α + trans β) | α ppts | Ti17 | [56] |

| 30 | Ti-6Al-2Sn-4Zr-6Mo (α + β) | 0 | α/β 885 °C ST-AC (i.e., ST below βtr) | 595 °C–8 h-AC | Bimodal (globular primary α + trans β) | α ppts | Ti6246 | [57] |

| 31 | Ti-6Al-6V-2Sn-0.5Fe-0.5Cu (α + β) | -0.5 | α/β 871 °C ST-WQ (i.e., ST below βtr) | 538 °C–4 h-AC | Bimodal (globular primary α + trans β) | α ppts | Ti662 | [58] |

| 32 | Ti-6Al-4V (α + β) | -3.32 | α/β 955 °C–ST-WQ (i.e., ST below βtr) | 538 °C–4 h-AC | Bimodal (globular primary α + trans β) | α ppts | Ti64 | [59] |

| Alloy Designation | d (g/cm3) | YS (MPa) | UTS (MPa) | %El. | %RA | Ref. |

|---|---|---|---|---|---|---|

| Ti-15333-210Eβ-nano-α | 4.67 | 1179 | 1240 | 4.3 | NA | [40] |

| Ti-15333-BC-44Eβ-nano-α-TiB-TiC | 4.68 | 1278 | 1277 | 0.3 | NA | [40] |

| Ti-1023-483Eβ-nano-α | 4.57 | 932 | 1306 | 0.73 | NA | [40] |

| Ti-1023BC-56Eβ-nano-α-TiB-TiC | 4.55 | 1305 | 1385 | 0.98 | NA | [40] |

| Ti-LG-308Eβ-nano-α | 4.57 | 1107 | 1267 | 1.2 | NA | [40] |

| Ti-LG-BC-42Eβ-nano-α-TiB-TiC | 4.58 | 1400 | 1463 | 0.5 | NA | [40] |

| Ti-LG-α/βF-BM-αs | 4.57 | 1350 | 1412 | 4.6 | NA | [8] |

| Ti-LG-α/βF-250Eβ-α | 4.57 | 1332 | 1373 | 2.1 | NA | [8] |

| Ti-LG-βF-BM-αs | 4.57 | 1288 | 1365 | 6.1 | NA | [8] |

| Ti-nα-Eα-β | 4.43 | 1052 | 1091 | 8.3 | NA | [16] |

| Ti-5551-1Fe-BW | 4.64 | 1196 | 1286 | 10 | 21.8 | [41] |

| VT8-L-100-α-Col | 4.40 | 870 | 925 | 11 | 22 | [42] |

| VT8-1.5B-L-22-α-Col-TiB-TiC | 4.35 | 1125 | 1240 | 6.5 | 16 | [42] |

| VT8-2B-L-27-α-Col-TiB-TiC | 4.33 | 1025 | 1175 | 3.3 | 6 | [42] |

| Ti-LG-0.5Fe-BM-60αs | 4.61 | 1245 | 1316 | 18 | NA | [43] |

| Ti-LG-0.5Fe-BM-30αs | 4.64 | 1369 | 1440 | 4.7 | NA | [44] |

| Ti-5-12-53-0.5Fe-BM-70αs | 4.84 | 1220 | 1293 | 4 | NA | [44] |

| Beta-C-Eβ-α | 4.78 | 1580 | NA | 2 | NA | [45] |

| Ti-35632-0.5Fe-BM-28αs | 4.70 | 1624 | 1720 | 6 | 11 | [46] |

| Ti-LG-1 Zr-BM-125αs | 4.61 | 1248 | 1293 | 8.5 | 15 | [47] |

| Ti292-Eβmicro-nano-α | 4.72 | 1543 | NA | 1 | NA | [48] |

| Ti-15333-Eβnano-nano-α | 4.70 | 1483 | 1562 | 2 | NA | [49] |

| Ti-1023-Xeβ-nano-α | 4.57 | 1461 | NA | 0.5 | NA | [50] |

| Ti18-BM-nano-α | 4.58 | 1322 | 1435 | 10 | 19 | [51] |

| Altan Titan 23-BM-nano-α | 4.85 | 1240 | 1288 | 12 | 49 | [52] |

| Ti1300-BM-nano-α | 4.61 | 1300 | 1400 | 16.5 | 21 | [53] |

| TC21-BM-nano-α | 4.65 | 1375 | 1480 | 7 | 20.5 | [54] |

| Ti21S | 4.94 | 1350 | 1450 | 8 | NA | [55] |

| Ti17 | 4.65 | 1100 | 1180 | 10 | 25 | [56] |

| Ti6246 | 4.64 | 1118 | 1214 | 13 | 37 | [57] |

| Ti662 | 4.53 | 1105 | 1205 | 8 | NA | [58] |

| Ti64 | 4.43 | 895 | 965 | 10 | 20 | [59] |

| Attribute | N | Minimum | Maximum | Mean ± st.dev. | Benchmark |

|---|---|---|---|---|---|

| d (g/cm3) | 32 | 4.3 | 4.9 | 4.6 ± 0.1 | 4.57 |

| YS (MPa) | 32 | 870.0 | 1624.0 | 1250.5 ± 187.8 | 1250 |

| UTS (MPa) | 29 | 925.0 | 1720.0 | 1311.9 ± 163.9 | 1300 |

| %El. | 32 | 0.3 | 18.0 | 6.3 ± 4.8 | 5 |

| %RA | 13 | 6.0 | 49.0 | 21.8 ± 11.0 | NA |

| SAW | SMART | MEW | TOPSIS | WEDBA | MOOA | OCRA | VIKOR | ARAS | |

|---|---|---|---|---|---|---|---|---|---|

| SMART | 0.857 | ||||||||

| MEW | 0.820 | 0.465 | |||||||

| TOPSIS | 0.808 | 0.464 | 0.926 | ||||||

| WEDBA | 0.706 | 0.944 | 0.237 | 0.233 | |||||

| MOORA | 0.888 | 0.571 | 0.968 | 0.970 | 0.351 | ||||

| OCRA | 0.623 | 0.208 | 0.910 | 0.933 | 0.048 | 0.889 | |||

| VIKOR | 0.857 | 1.000 | 0.465 | 0.464 | 0.944 | 0.571 | 0.208 | ||

| ARAS | 0.841 | 0.499 | 0.968 | 0.984 | 0.268 | 0.988 | 0.927 | 0.499 | |

| ROVM | 0.857 | 1.000 | 0.465 | 0.464 | 0.944 | 0.571 | 0.208 | 1.000 | 0.499 |

| PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 | PC8 | PC9 | PC10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Eigenvalue | 7.1278 | 2.6828 | 0.0815 | 0.0480 | 0.0303 | 0.0186 | 0.0067 | 0.0042 | 0.0000 | 0.0000 |

| Proportion | 0.713 | 0.268 | 0.008 | 0.005 | 0.003 | 0.002 | 0.001 | 0.000 | 0.000 | 0.000 |

| Cumulative | 0.713 | 0.981 | 0.989 | 0.994 | 0.997 | 0.999 | 1.000 | 1.000 | 1.000 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canumalla, R.; Jayaraman, T.V. Decision Science-Driven Assessment of Ti Alloys for Aircraft Landing Gear Beams. Aerospace 2024, 11, 51. https://doi.org/10.3390/aerospace11010051

Canumalla R, Jayaraman TV. Decision Science-Driven Assessment of Ti Alloys for Aircraft Landing Gear Beams. Aerospace. 2024; 11(1):51. https://doi.org/10.3390/aerospace11010051

Chicago/Turabian StyleCanumalla, Ramachandra, and Tanjore V. Jayaraman. 2024. "Decision Science-Driven Assessment of Ti Alloys for Aircraft Landing Gear Beams" Aerospace 11, no. 1: 51. https://doi.org/10.3390/aerospace11010051

APA StyleCanumalla, R., & Jayaraman, T. V. (2024). Decision Science-Driven Assessment of Ti Alloys for Aircraft Landing Gear Beams. Aerospace, 11(1), 51. https://doi.org/10.3390/aerospace11010051