3.1. Technology Development History

In the 1960s and 1970s, the development of digital circuits, computer-aided testing, and digital signal analysis and processing technology promoted the development of online detection and fault diagnosis of machinery and equipment [

5].

The United States was the earliest country to carry out research on machinery condition monitoring and fault diagnosis technology. The United States began to implement the Apollo program in 1961 after a series of equipment failures; in 1967, under the initiative of the National Aeronautics and Space Administration, the U.S. Office of Naval Research hosted the establishment of the U.S. Machinery Fault Prevention Group, actively engaged in fault diagnosis technology research and development. In the late 1960s and early 1970s, the British Mechanical Health Monitoring Center, headed by Dr. R.A. Collacott, started the research and development of diagnostic technology, having the leading edge in the monitoring and diagnosis of friction and wear, automobiles, and internal combustion engines [

6]. The book named “Vibration Monitoring and Diagnosis” plays an important milestone role in the research of this field [

7].

China started to study engine testing technology in the early 1960s. In the 1970s, after the automobile nondisintegration testing technology was listed as the development and application project of the State Science and Technology Commission, the work of domestic researchers led to the development of the comprehensive testing table for automobile performance, the comprehensive engine testing instrument, and other equipment; however, the equipment in that era was not perfect and the quantity was limited. From the 1990s onwards, the relevant research includes the book “Vibration Monitoring and Fault Diagnosis of Rotating Machinery” by Zhang Zhengsong et al., which introduces the specific practice of this technology in a more comprehensive and basic way from a variety of application scenarios, and has a high academic status [

8]. With the continuous development of science and technology, China’s application needs in related fields have been increasing, especially in the field of military aero-engine technology and maintenance. The book “Aviation Engine Prediction and Health Management”, written by Xunkai Yu and others, explains the development of this field from the perspective of modern technology in a more comprehensive manner, and clearly proposes the important significance of fault prediction research and effective technical methods. The advancement of related technologies has directly promoted its development in the civil field. The book “Vibration Monitoring and Fault Diagnosis Technology for Wind Turbines” by Wenyi Liu introduces the more mature diagnostic analysis technologies in this field [

9].

Before the 1950s, the main method used for the analysis of vibration signals was the analog analysis method. After the 1950s, with the development of computer technology and digital signal processing, large, general-purpose digital computers began to be applied to the analysis of vibration signals [

10]. After the 1960s, with the deepening of the field of human exploration, aerospace, navigation, undersea exploration, military, and other fields proposed signal analysis and raised requirements for the higher resolution of vibration measuring equipment. J.W. Cooley and J.W. Tukey of the United States, in 1965, proposed a fast Fourier calculation method, which greatly saves calculation [

11]. With the development of digital signal processing technology, it has been very widely used.

It has been more than 50 years since vibration monitoring was proposed in China [

12]. Due to the domestic economic and social construction needs, the total number of power unit assemblers is large and the application demand is great; thus, the domestic researchers have unique insights into the research of vibration monitoring fault diagnosis methods and fault mechanisms [

13]. Although the start was lagging behind, after more than 50 years of practice in field fault diagnosis, we have accumulated rich knowledge and experience in unit vibration fault characteristics, and have produced long-term and in-depth research on the generation of these faults and the mechanism of generating vibration [

14].

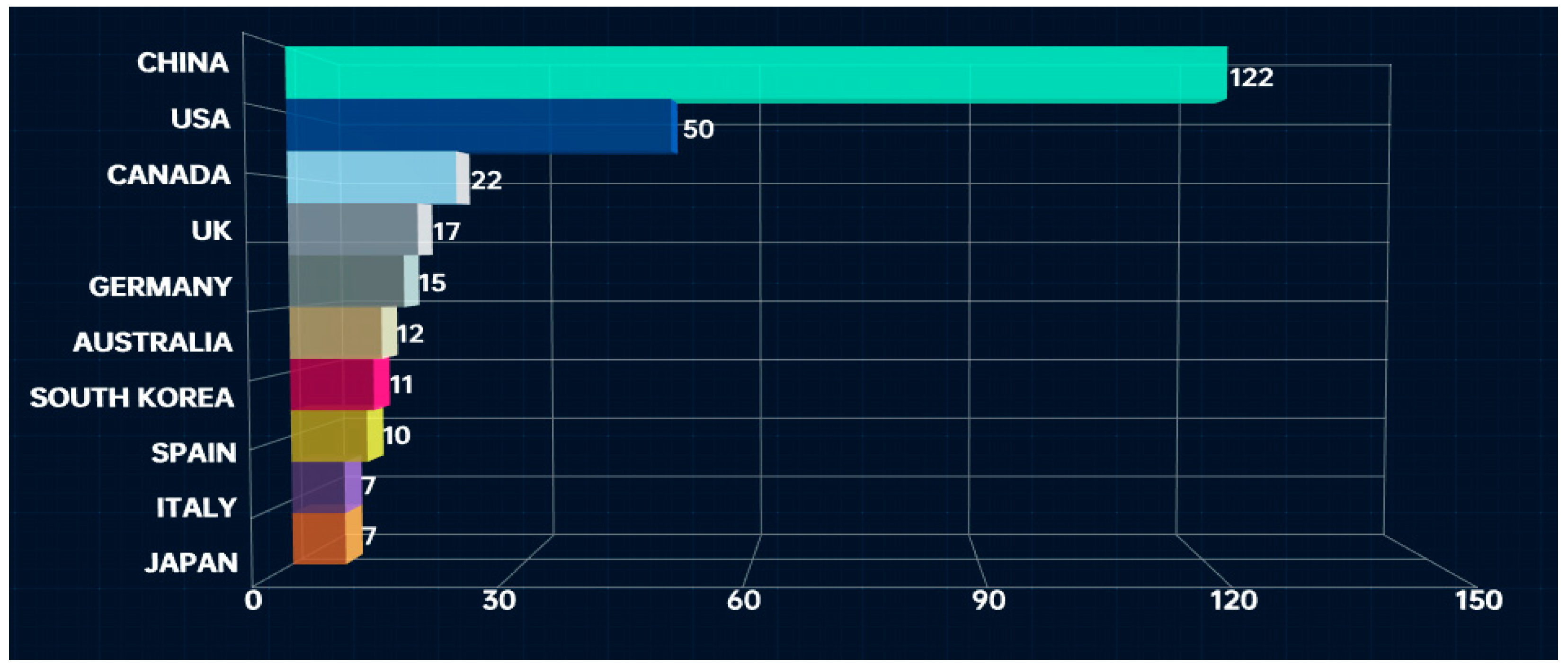

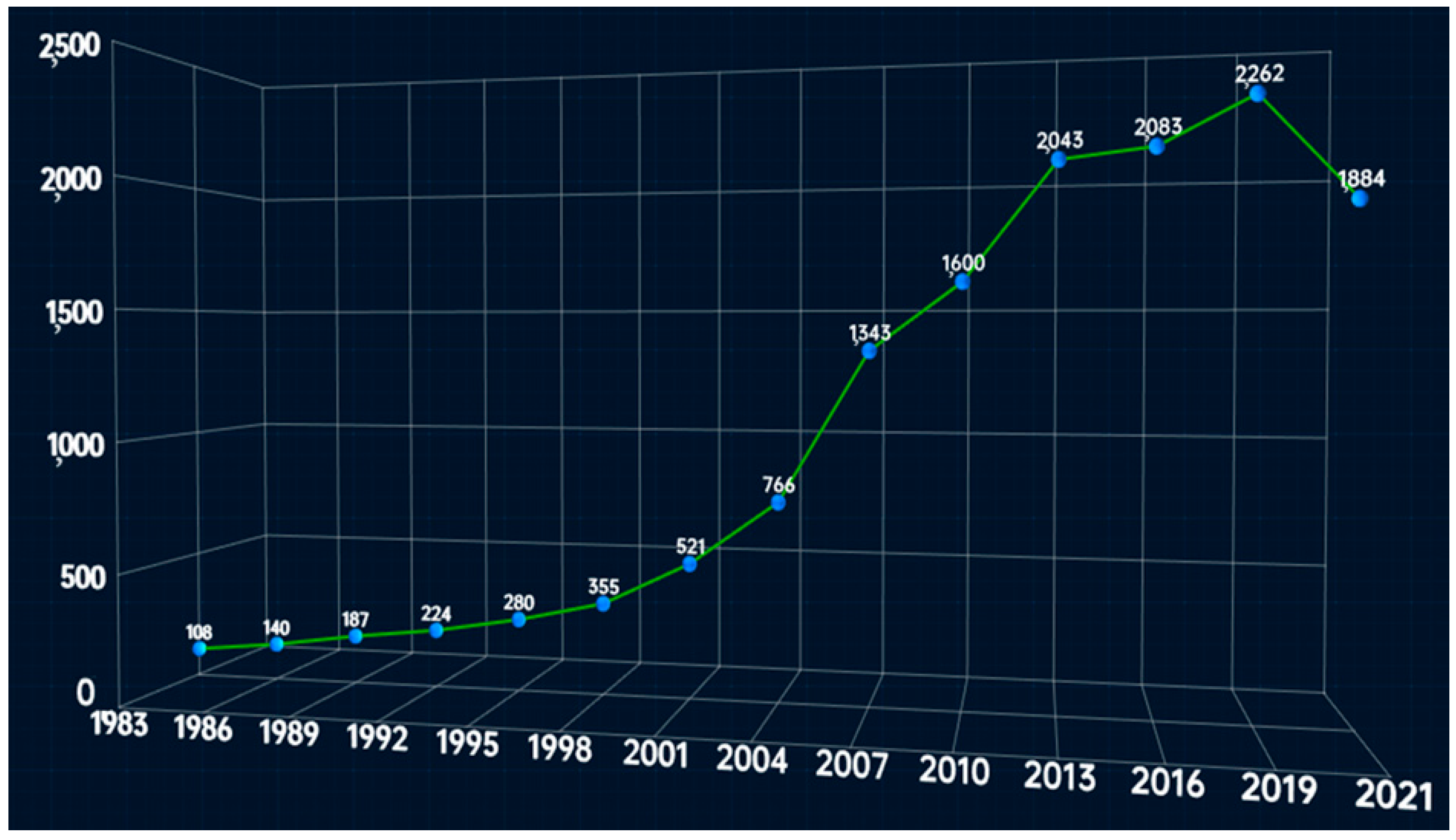

From

Figure 1, we can see that the number of domestic scientific papers in this field has taken an absolute advantage in the results of scientific papers from 1950 to 2022 by using “Vibration Detection” as the search term and searching the data in the platform “Web of Science”; in addition, using “cited” as the criterion for evaluating the quality and influence of papers, we analyzed 221 highly cited papers, and it can be seen from

Figure 2 that the domestic scientific research results in this field occupy a larger weight in this discipline, so the quality is also worth affirming. Based on the above, the achievements of China in this field are highlighted in terms of quantity and quality, so can it be considered that China has the leading advantage in this field? The answer is not affirmative. The classification of innovation is usually divided into three major categories, namely, basic innovation, applied innovation, and integrated innovation. The most significant manifestation is that the basic innovation results represented by relevant algorithms are fewer. Most of our scientific research achievements in this field are applied innovation and integrated innovation, which is specifically shown by the emergence of various supporting assistive technologies raised by China [

15,

16,

17].

3.2. Analysis of the Current State of Research

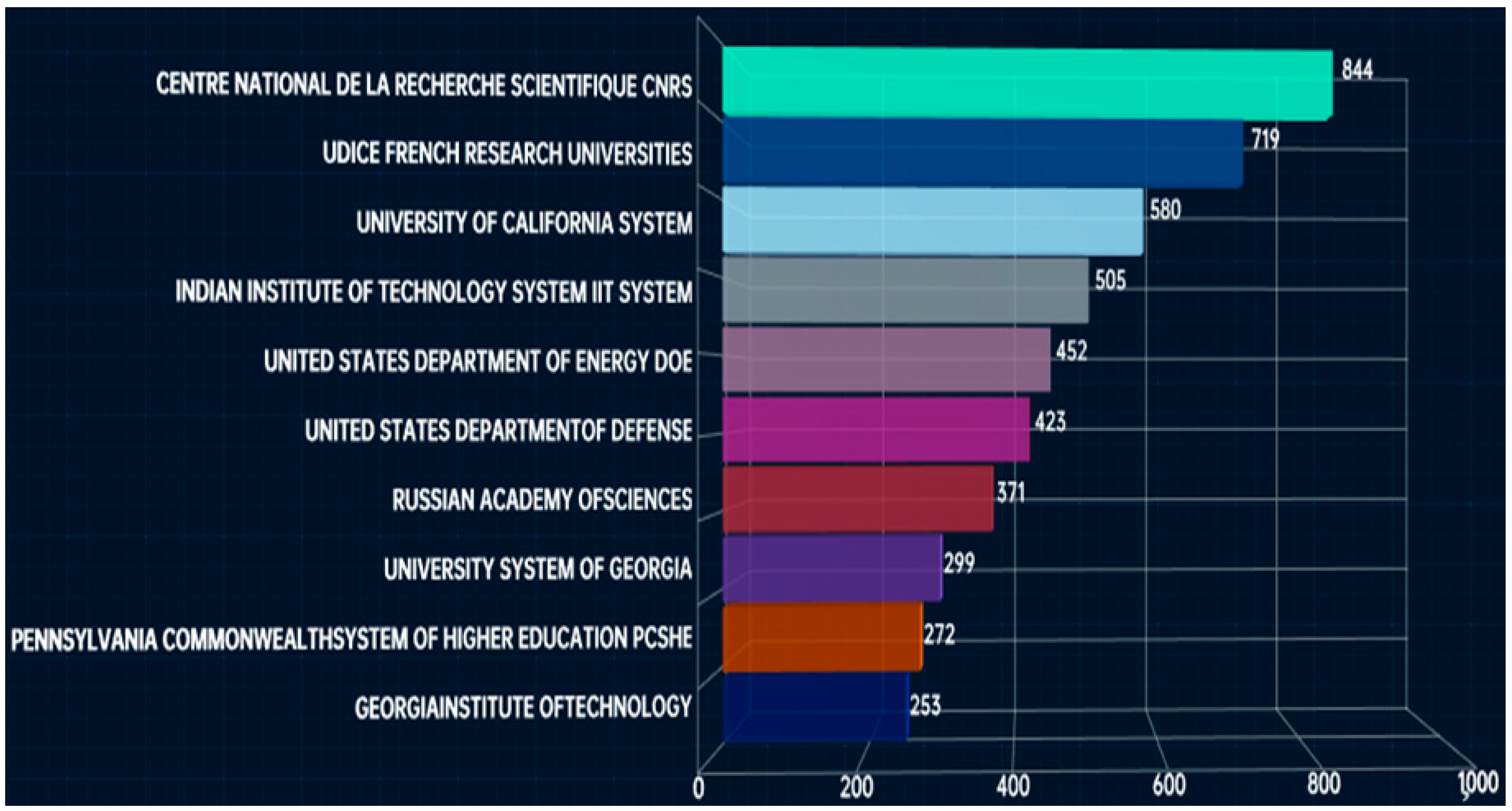

The interval of the research time was set from 1980 to 2022 and the data were extracted in June 2023. Using bibliometric techniques, the subject area of “engine vibration detection” was examined from a macroscopic perspective. From

Figure 3, it can be seen that internationally, the following institutions and organizations have a strong presence in their field: “Centre National de la Recherche Scientifique Cnrs”, “Udice French Research Universities”, “University of California System”, “Indian Institute of Technology system IIT System”, and “United States department of Energy Doe”.

In foreign countries, a large number of scholars in the field of engineering and technology have conducted in-depth research on the use of vibration signal analysis for power unit diagnosis. For example, BOHME.JF has an active contribution to the field of signal analysis, and the “Application of cyclostationary and time-frequency signal analysis to car engine diagnosis”, published in the ICASSP’94 conference, proposed an application based on the application of sensor information feedback for effective control of engine operating conditions. Tarassenko contributed to the integration of artificial intelligence and signal analysis by presenting “Novelty detection in jet engines” at the 1999 IEE Symposium on Condition Monitoring of Machinery, External Structures and Health, proposing the application of neural network algorithms to vibration monitoring. After a long period of effort, the teams and institutions of foreign researchers represented by the abovementioned people have become more influential in this field [

18].

From a technical aspect, the purpose of power unit vibration signal analysis is to extract the operation information of key rotating parts of machinery (e.g., gears, bearings, etc.), and effective signal processing and feature extraction are the keys to complete unit condition monitoring and fault diagnosis. Therefore, more accurate and comprehensive extraction of vibration signal features has been the pursuit of research workers in this field. The methods for vibration signal feature extraction mainly include fast Fourier transform, autoregressive sliding average model, Cohen-like distribution, short-time Fourier transform (STFT), wavelet transform, adaptive time–frequency analysis, etc. [

19,

20]. These methods provide fundamental guarantees for the development of mechanical fault diagnosis. According to the discipline system to which they belong, they can be broadly divided into three categories: control-model-based fault diagnosis, pattern-recognition-based fault diagnosis, and artificial-intelligence-based fault diagnosis.

In this field, newer international ideas and results are shown below. Dubravko Miljković’s paper “Cymatics for Visual Representation of Aircraft Engine Noise”, published in 2021, proposes the form of cymatic patterns as a form of signal representation. Scholars R. Talebitooti, M.R. Zarastvand, and M.R. Gheibi have carried out valuable work in the basic research of vibration signal transmission [

21,

22]. The paper “Two-level Signal Processing of Vibroacoustic Signals for Condition Monitoring of Complex Rotary System”, published by Olha Pazdrii in 2018, demonstrates the good applicability of the fractal dimensionality in this field of analysis. The paper “Wireless IoT Approach for Testing in Situ Motor’s Axis Vibration Monitoring”, published by Mohamed Hayouni in 2021, demonstrates the successful exploration of IoT technology for this field. The paper “Naturally induced Early Aviation Bearing Fault Test and Early Bearing Fault Detection”, published by Fan Feilong et al. in 2021, shows the use of this technology for fault prediction [

23]. The article “Application of Deep Learning Algorithm in Generator Fault Prediction”, by Xia Yun in 2020, shows the effective application of deep learning algorithms for signal studies. “Demonstration of a Speckle-Based Sensing with Pulse-Doppler Radar for Vibration Detection”, published by Nisan Ozana in 2018, successfully implements the study of vibration signals using pulse-Doppler radar [

24].

From the perspective of solving practical problems, this is seen at the level of applied innovation. As can be seen from

Figure 4, in the last 5 years (June 2017–June 2022), there have been mostly scientific research results in this field because of the rapid development of related industries in China and the high business demand. Thus, the study of the relevant domestic situations for innovative practice will be very meaningful and important.

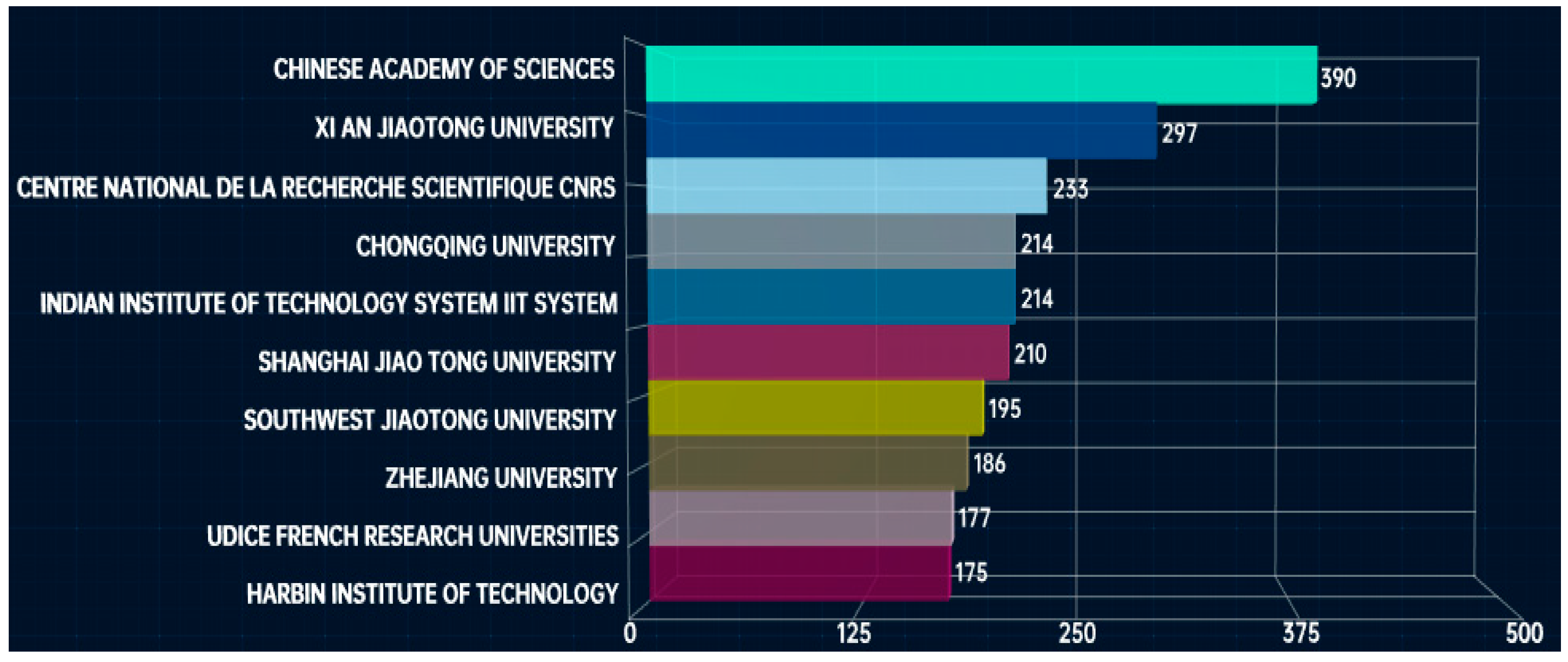

As can be seen from

Figure 5, in this field, domestic universities such as the University of Chinese Academy of Sciences, Xi’an Jiaotong University, Chongqing University, and Northwestern Polytechnic University have obvious competitiveness in the international arena. These institutions are the dominant institutions in areas such as gas turbine, aero-engine, automotive, and ship power specialties. It is worth noting that among the top 10 institutions in this table, institutions belonging to France and India have also made significant achievements.

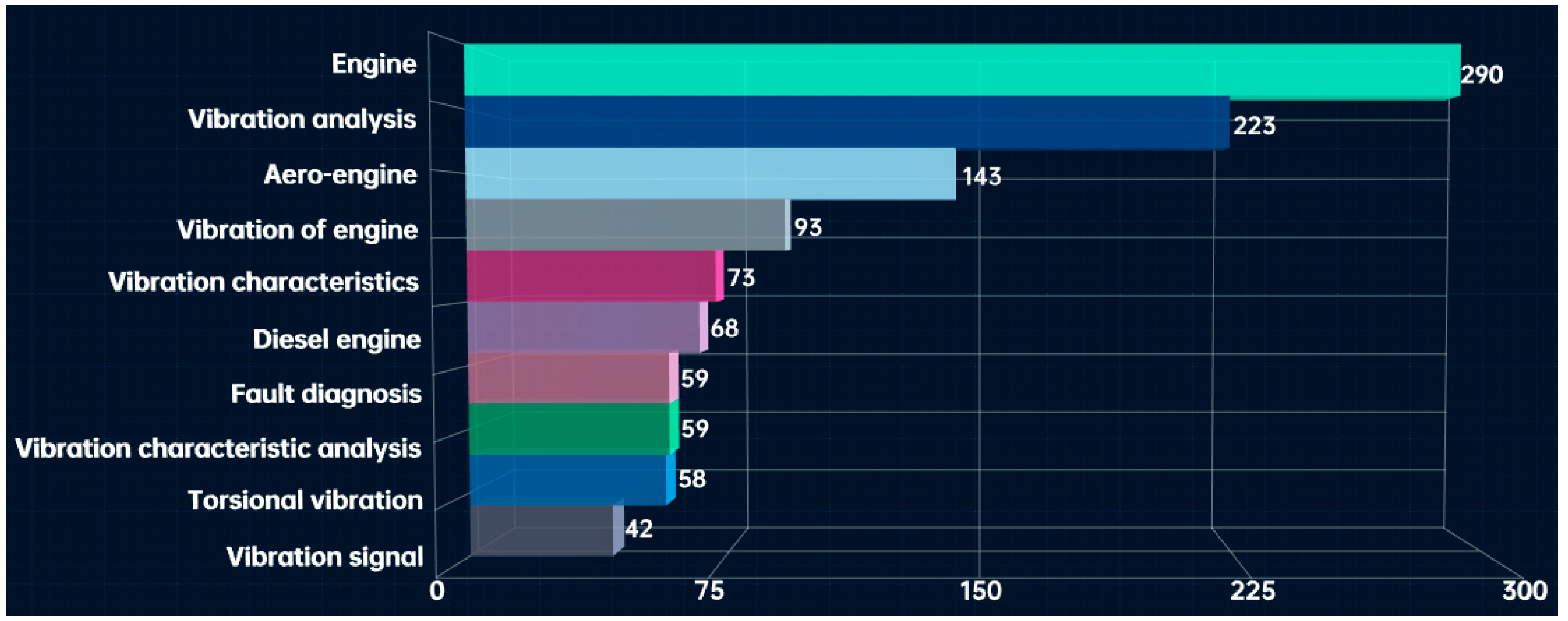

Focusing on domestic research in this field, a bibliometric study was conducted using the China Knowledge Network database, with “engine vibration”, “engine vibration detection”, and “vibration analysis” used as search terms. The interval of the research time was set from 1980 to 2022 and the data were extracted in June 2022. At the macro level, the main subject areas of the “engine vibration analysis” search are shown in

Figure 6. The main application of this technology is in the field of engine research. From

Figure 7, we can see that there are many research results and a strong demand for research in this field.

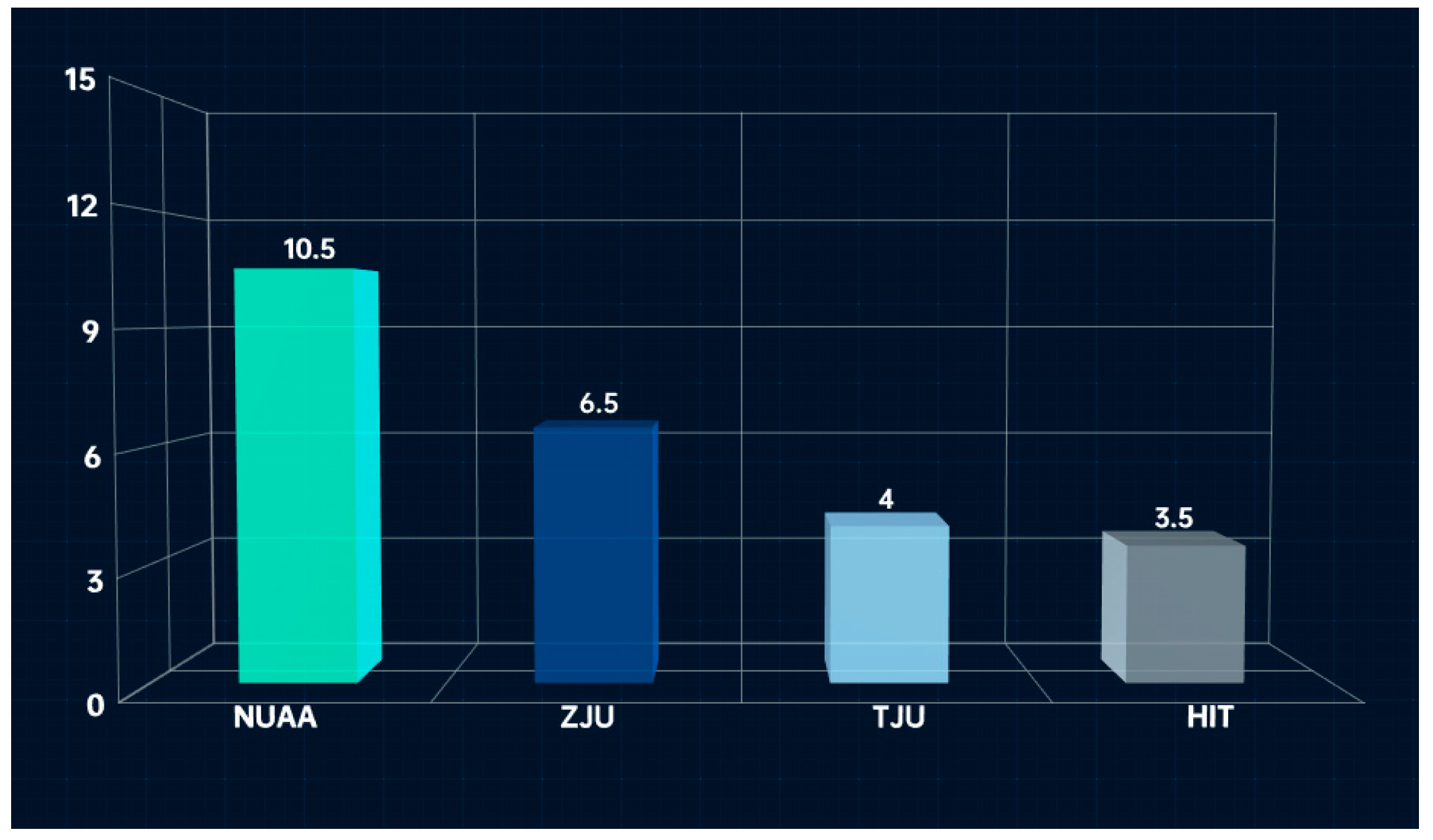

From the perspective of engine vibration detection, the main application area of this technology is engine fault diagnosis. With the search terms “engine-vibration-detection”, the papers with significant academic influence that have been cited more than 20 times in this field are selected for investigation and research. According to the distribution of sources,

Figure 8 shows that in China, Nanjing University of Aeronautics and Astronautics (NUAA), Zhejiang University (ZJU), Tianjin University (TJU), and Harbin Institute of Technology (HIT) are well represented in research results of the field. This also proves the influence of these universities.

We examine this from the perspective of literature cross-citation network analysis. In the form of a literature network map, it is visible which articles are the most cited or related in the field. Through the analysis, we can obtain the key literature, key laboratories, key scholars, and other information in the field. Based on the above work, we can effectively grasp the status of technological development in this field. As can be seen from

Figure 9, among the works that are cited with high frequency and in support of the discipline (large spheres in the figure) are Jiang Deming, “Combustion and emission of internal combustion engine”, 2001; “Review of academic research in Chinese automotive engineering”, 2017; Wang Yaonan, “Research status and the prospect of the electronic control system of automotive gasoline engine”, 2015; Chen Hong, “Research status and the prospect of automotive control”, 2013; “The empirical mode decomposition and the Hilbert spectrum for nonlinear and nonstationary time series analysis”, 1998; Yang Fusheng “Engineering analysis and application of wavelet transform”, 1999; Qu Liang-sheng “Mechanical Fault Diagnosis”, 1986; He Zhengjia, “Fault Principles and Applications of Non-smooth Signals in Mechanical Equipment”, 2001; Tao Chunhu, “Failure and Prevention of Rotating Components of Aero Engines”, 2000; Editorial office of Chinese Journal of Highway and Transportation, A Summary of Academic Research of China’s Auto Industry, 2017 (as shown in

Figure 9); Zaosheng Shun, Equipment Condition Monitoring and Fault Diagnosis Technology and Application, 2003 (as shown in

Figure 9), etc. [

25,

26,

27].

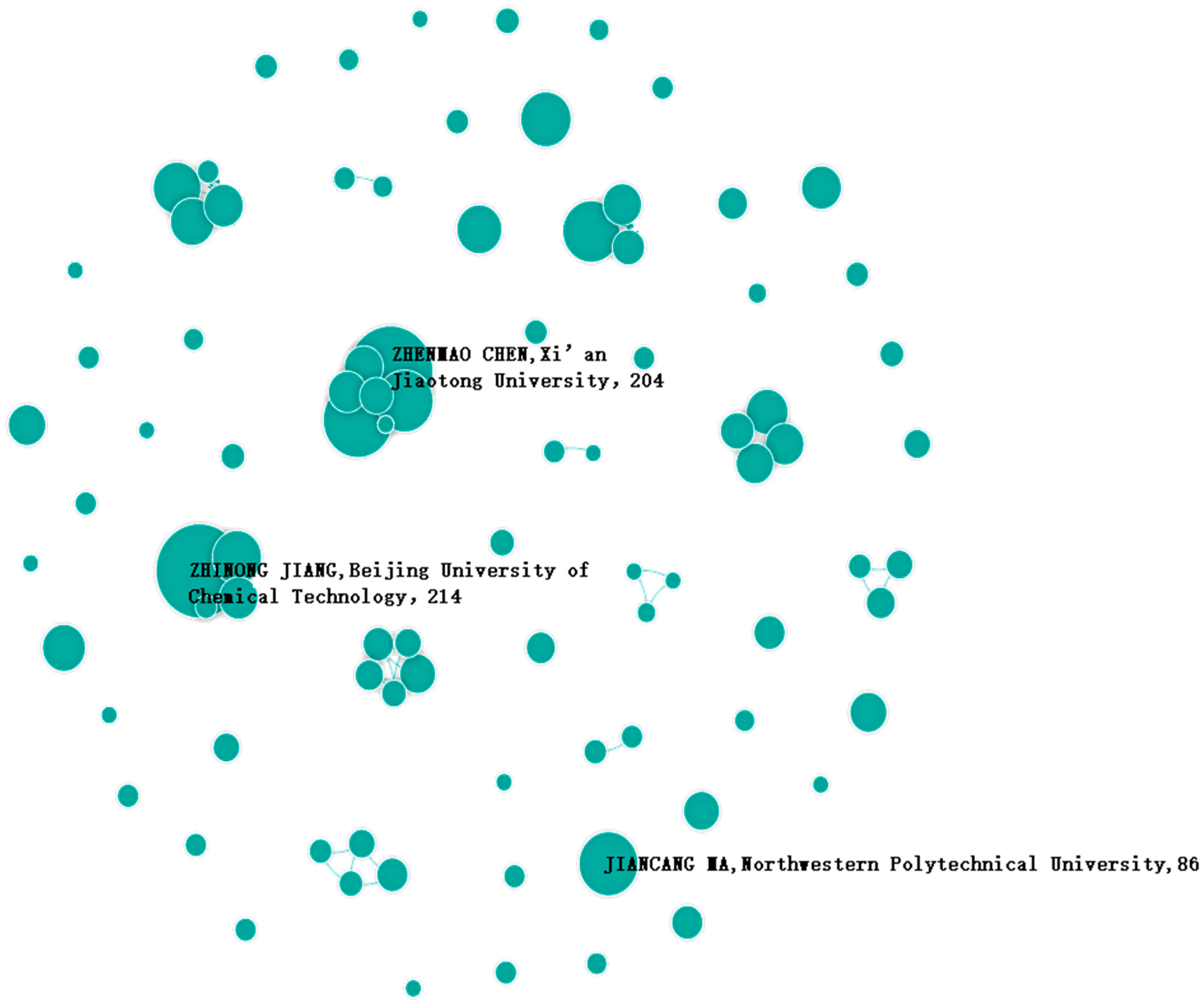

From the perspective of the relevance of researchers’ achievements, it can be seen from

Figure 10 that although domestic research teams are engaged in the same topic, they cooperate less and have a high dispersion of research resources in the same field. These scholars have a large number of academic research results. For example, Zhenmao Chen, who is from Xi’an Jiaotong University, has published 204 articles in this area of research. This results in a situation where the same subject is shown to be studied repeatedly, or even over and over again, which directly leads to a waste of various resources. From a national-level perspective, this is a loss of assets. From the macroscopic point of view of disciplinary research, it is a case of research resources not being effectively integrated and utilized; from the microscopic point of view, the various scattered research results are the soil for sprouting new research directions, which are conducive to the development of new knowledge and technology. The above inference has a dialectical meaning.

Combined with

Figure 11, it can be seen that in this field, scholars such as Wen Bangchun from Northeastern University, Zeng Qingyuan from Central South University, and Lei Xiaoyan from East China Jiaotong University have strong disciplinary influence. As can be seen from this figure, the units of the top ten authors ranking research results in this field are Northeastern University, Central South University, East China Jiaotong University, Sichuan Normal University, Southwest Jiaotong University, Zhaoqing University, Huazhong University of Science and Technology, Shanghai Jiaotong University, Beijing University of Technology, and Southeast University. The above institutions are mainly located in the economically relatively developed regions in the Middle East, which directly indicates that the economically developed regions have a higher research demand in this field and a broader application market. Therefore, the corresponding research institutions will receive sufficient funding to carry out research, and the research results will directly contribute to economic and industrial development, which can form a virtuous cycle of research and transformation development.

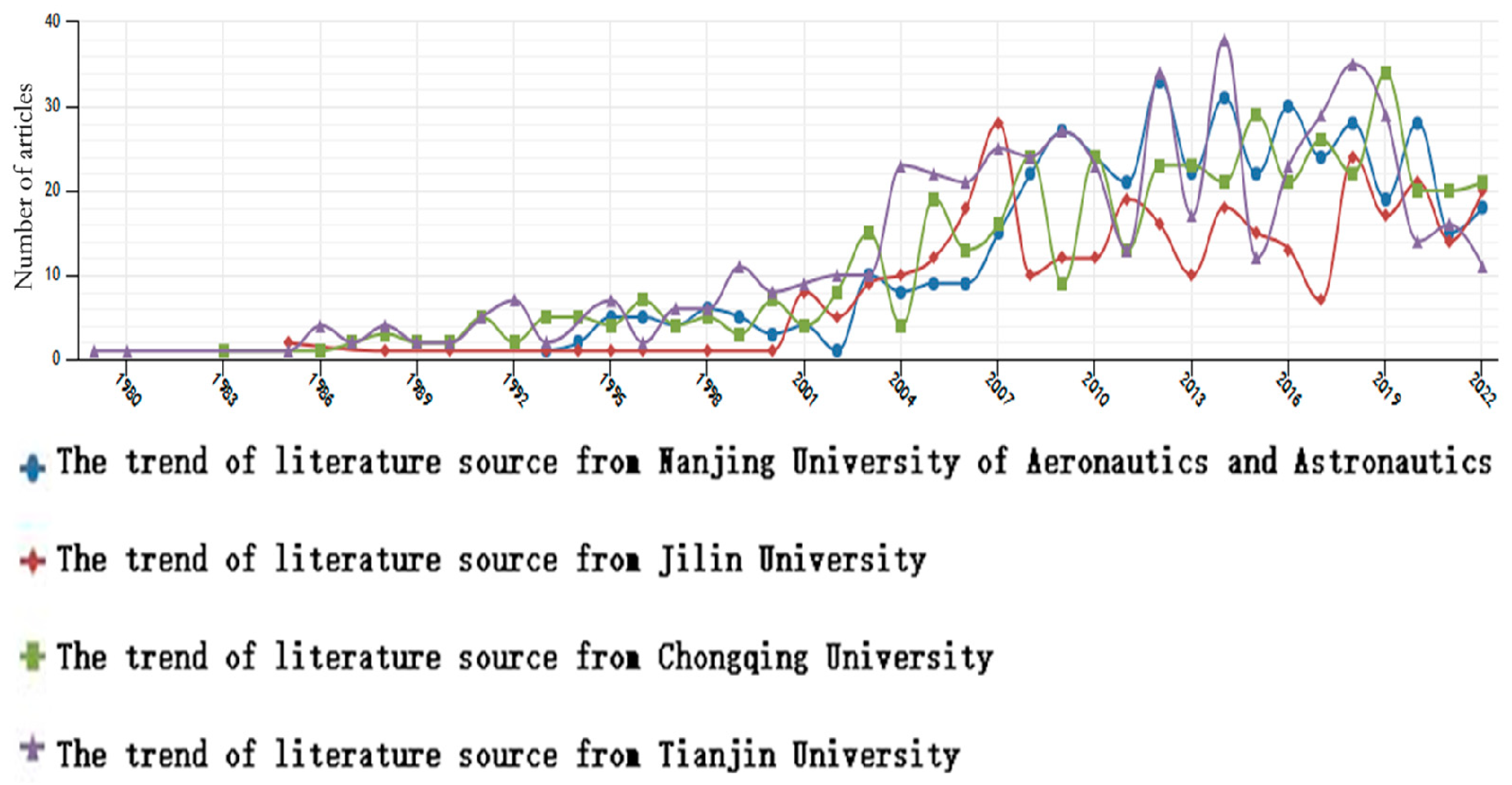

Through horizontal comparison, the research teams of Nanjing University of Aeronautics and Astronautics have maintained a strong development momentum in this field, as shown in

Figure 12. At the same time, Jilin University, Chongqing University, and Tianjin University have also achieved fruitful results in this field. By analysis, from the start, Jilin University, Chongqing University, and Tianjin University, three universities located in the early days of China’s major heavy industrial bases, with the development of production technology in the 1980s, gave birth to the research in this field, which has nearly 50 years of development. The development of Nanjing University of Aeronautics and Astronautics in this field started in the 1990s, and with the development of China’s aviation industry, especially engine technology, the nondestructive analysis technology of engines based on vibration detection has been developed tremendously. It can be seen from the figure that the development of the University in this field has shown strong vitality and vigor.

From the cross-sectional comparison, it is clear that domestic research is good at technology application. In fault diagnosis, domestic research technicians have developed expert systems, signal processing techniques based on blind source separation, fuzzy diagnosis techniques, bio-intelligent diagnosis techniques, and fractal and chaos techniques, in addition to carrying out applications of intelligent information processing methods such as fuzzy classification techniques, neural network techniques, expert systems, and support vector machines commonly used abroad. All these techniques have produced good application benefits in concrete application practice.

From the book “Theoretical Techniques of Engine Structural Vibration and Fault Diagnosis” by Yuxiu Yang, it is known that the methods based on wavelet analysis, matching tracking method, integrated methods based on Marxian distance, and BP neural network are more maturely applied for fault diagnosis of power units in China at present [

28,

29]. As the most deeply applied and actively researched aero-engine field in vibration analysis, the following types of methods are most representative: fault diagnosis methods based on the artificial neural network; fault diagnosis methods based on a support vector machine; fault diagnosis methods based on fuzzy set; new methods based on overlay machine learning; fault feature extraction methods based on genetic planning; fault diagnosis methods based on immune mechanism; methods based on rough set theory; methods based on multivariate unified analysis theory; nonlinear feature extraction methods based on kernel theory; combinatorial classification methods [

30,

31,

32].

In terms of analysis tools, with the development of technology, analysis tools are becoming more advanced and intelligent. From the complicated and functional single-entity instruments to the virtual instruments developed with tools such as Simulink, LABVIEW, MATLAB, etc., the functions are also more advanced [

33,

34,

35].

3.3. Technology Development Trend Forecast

Although the corresponding problems in this field can be largely solved by the various methods mentioned above [

36,

37], from the results of the previous bibliometric analysis, the research in this field is still lacking in the following three aspects: signal feature extraction, acquisition of fault samples, and acquisition of fault diagnosis knowledge. Specifically, there are few research results and no breakthrough progress, which directly restricts the further development of the research in this field and becomes a “roadblock”. The specific reasons and performance are described below.

Feature extraction. The power unit is a system; the information collected by the deployed sensors may be cluttered or inconspicuous, and the feature signals obtained by the corresponding processing methods may be distorted, which may affect the real-time diagnosis of faults.

Fault sample acquisition. For power units, the data reflecting normal working conditions are relatively easy to find, but the acquisition of fault data is relatively difficult. This makes it difficult to implement the fault diagnosis method that relies on a large number of sample data, which affects the development of fault diagnosis work. Determining how to make full use of the engine’s positive working state data and combine them with simulation technology to carry out research on abnormality detection and fault diagnosis is also an urgent problem to be solved.

Fault diagnosis knowledge acquisition. Knowledge acquisition is the bottleneck problem of building fault diagnosis expert systems, and the automatic acquisition of knowledge has been an especially difficult point in the research of expert systems. Adopting machine self-learning is an effective way to realize the automation of knowledge acquisition machine learning, which makes it possible to continuously summarize the lessons of success and failure in actual work, and automatically adjust and modify the knowledge in the knowledge base to enrich and improve the knowledge of the system. Determining how to use the machine learning methods to better solve the bottleneck problem of knowledge acquisition of fault diagnosis expert systems deserves further research.

Based on the effective analysis of bibliometrics, the three aspects mentioned above are exactly the directions that deserve to be deepened and broken down in the subsequent research. This provides guidance for both the selection of research topics and the development of projects.