Recent Advances in Airfoil Self-Noise Passive Reduction

Abstract

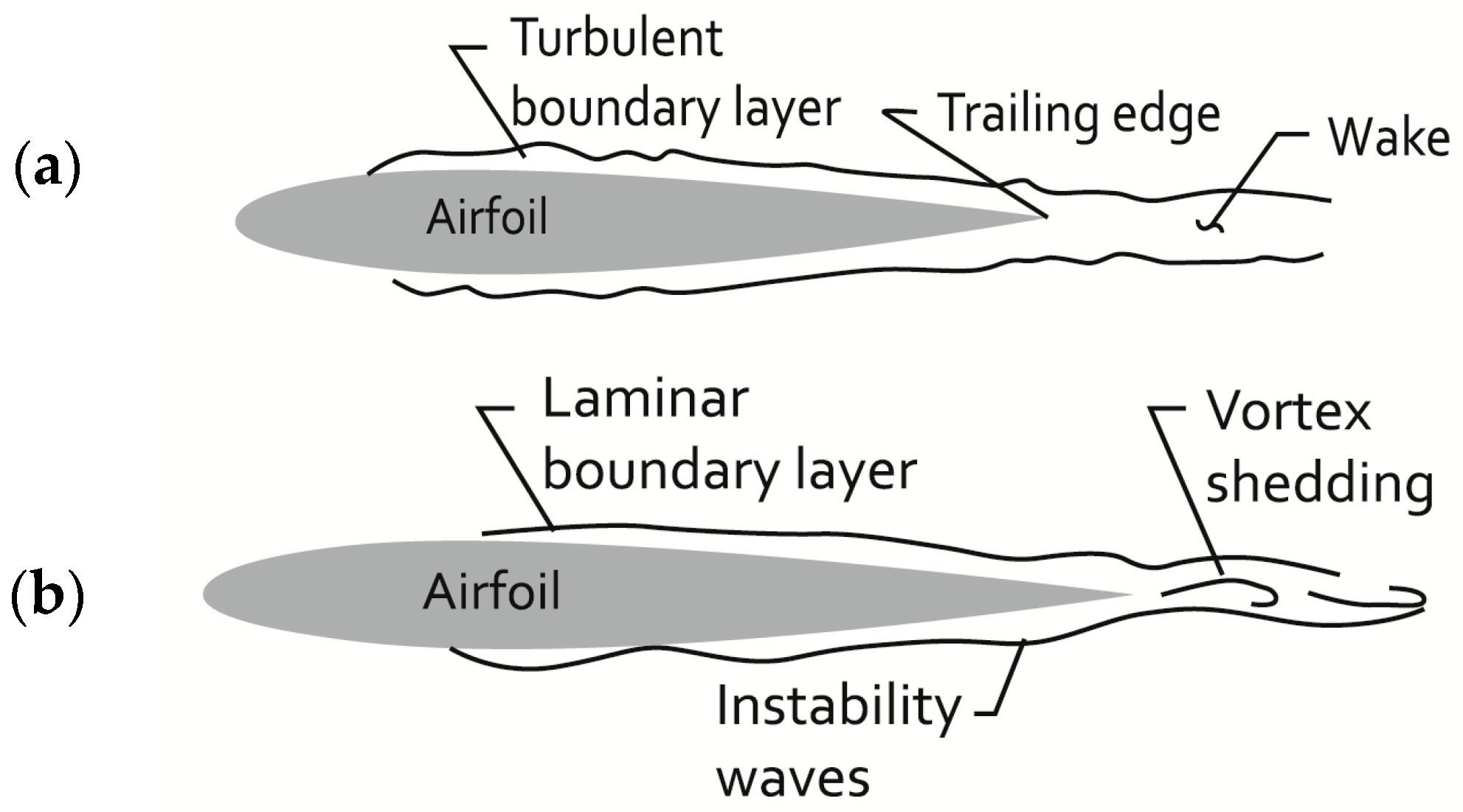

1. Introduction

2. Aeroacoustic Methods

2.1. Analytical Methods

2.2. Computational/Numerical/Scale-Resolving Approaches

2.3. Empirical/Semi-Empirical Approaches

3. Supplementary Methods

3.1. Optimization Algorithms

3.2. Metamodeling Algorithms

4. Passive Noise Reduction Mechanisms

4.1. Edge Treatment Methods

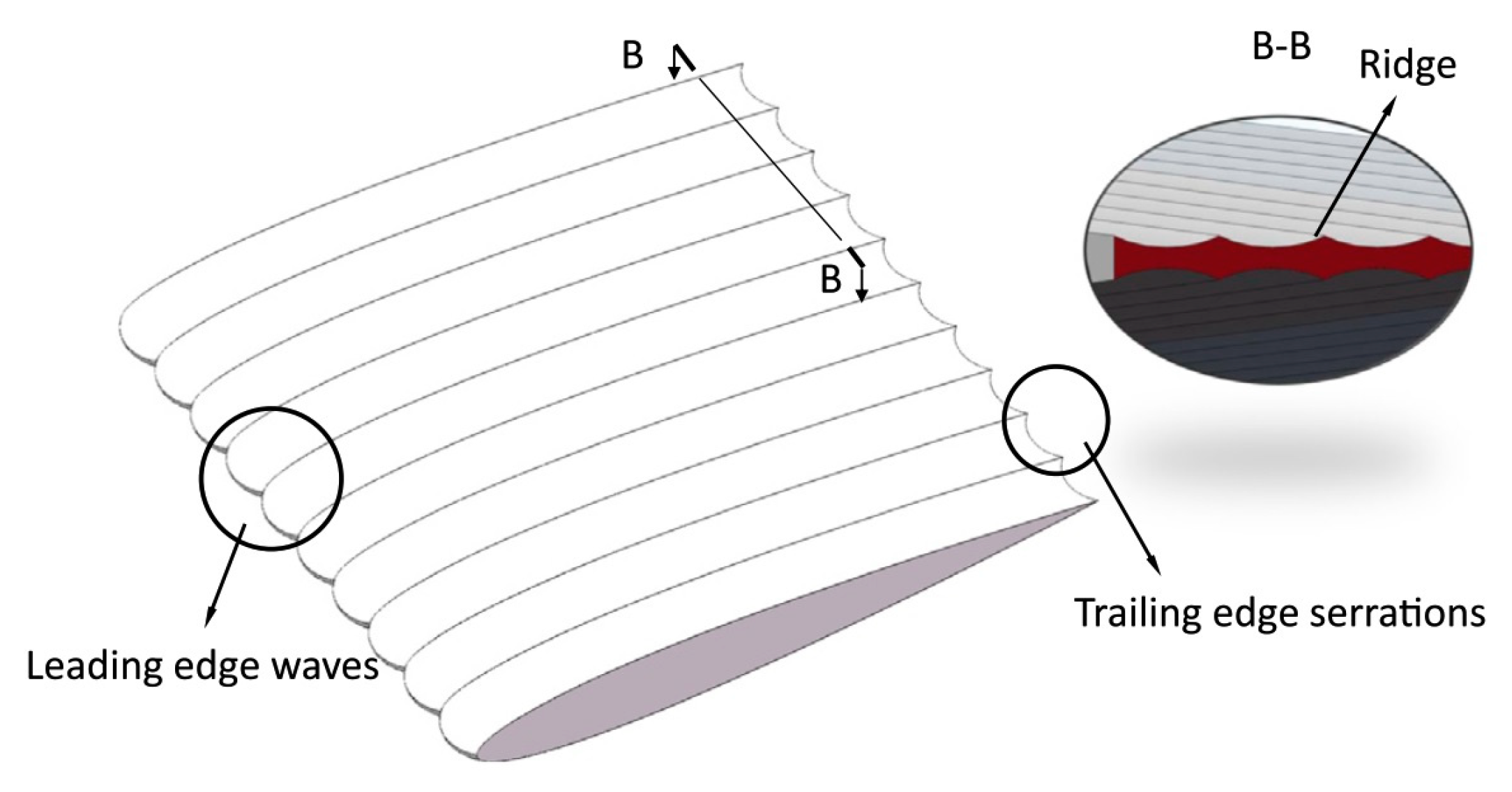

4.1.1. Leading Edge Treatments

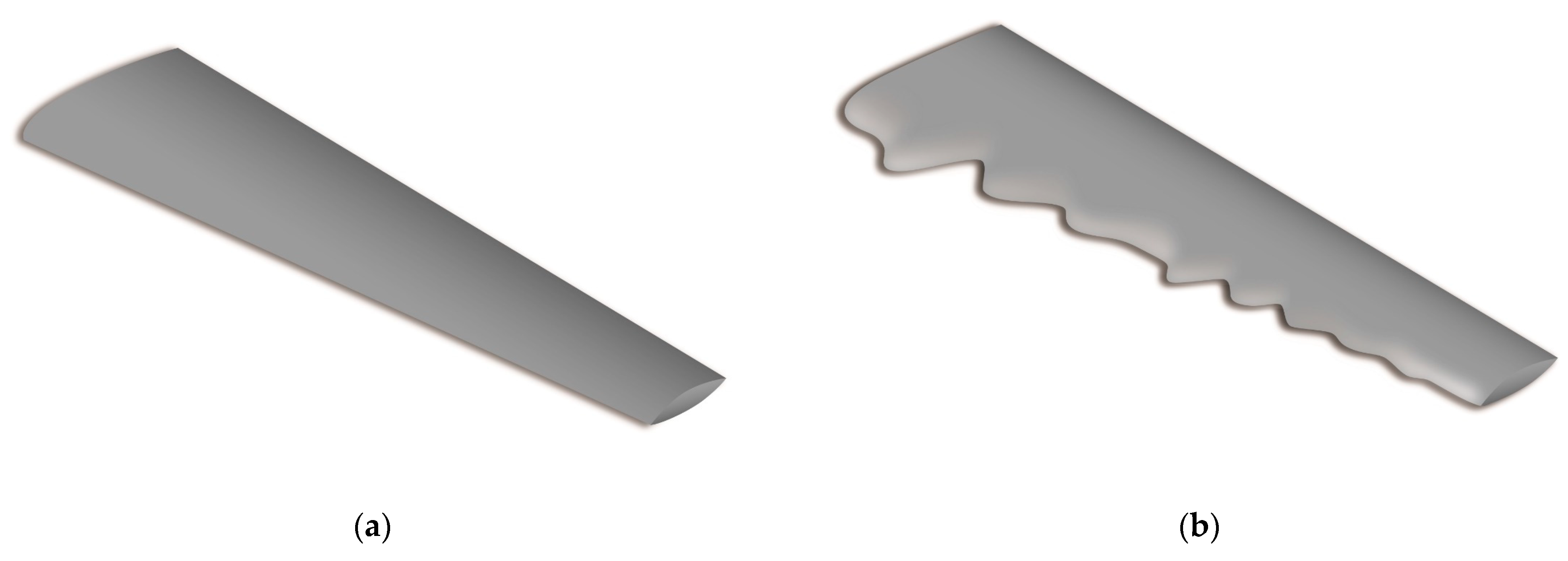

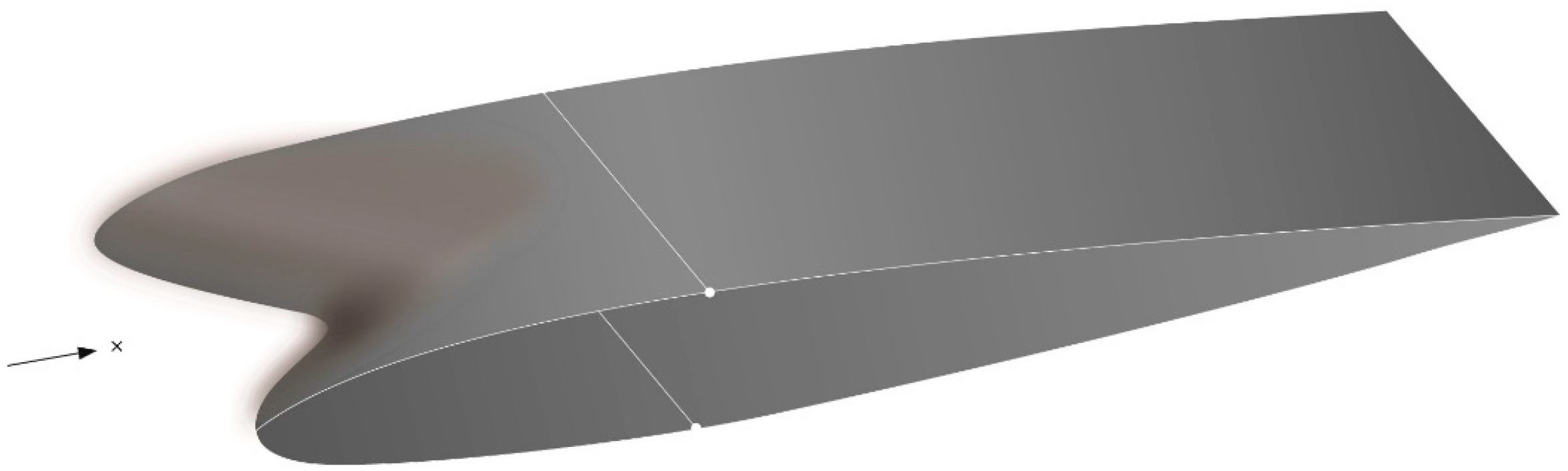

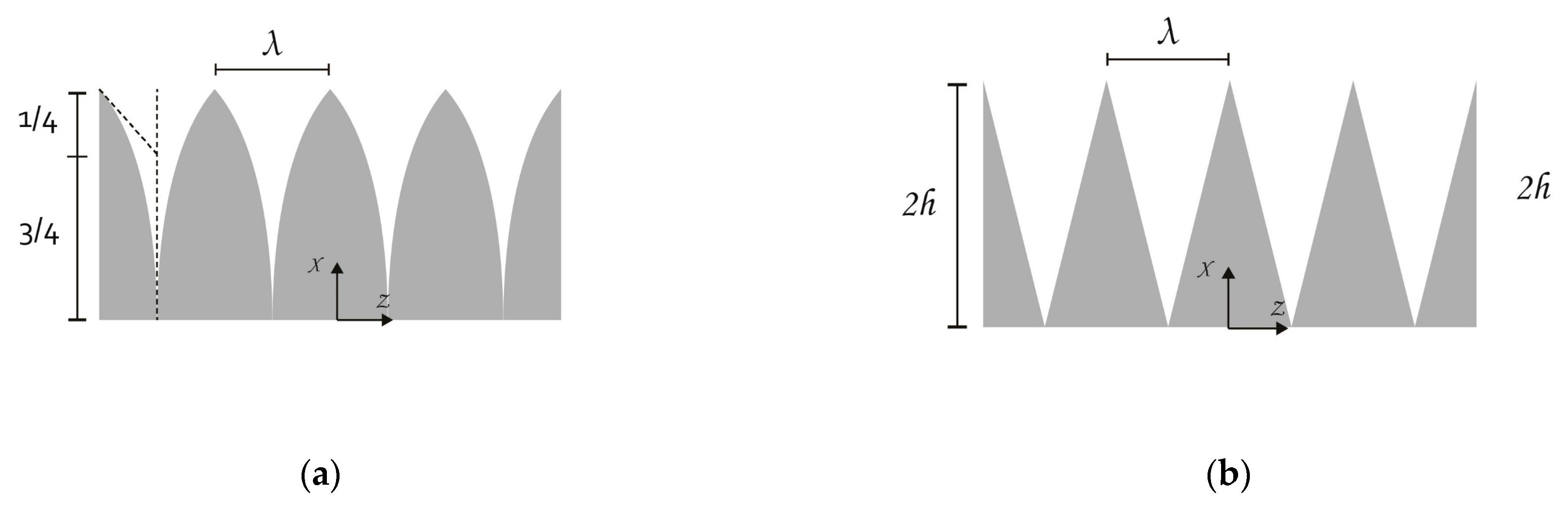

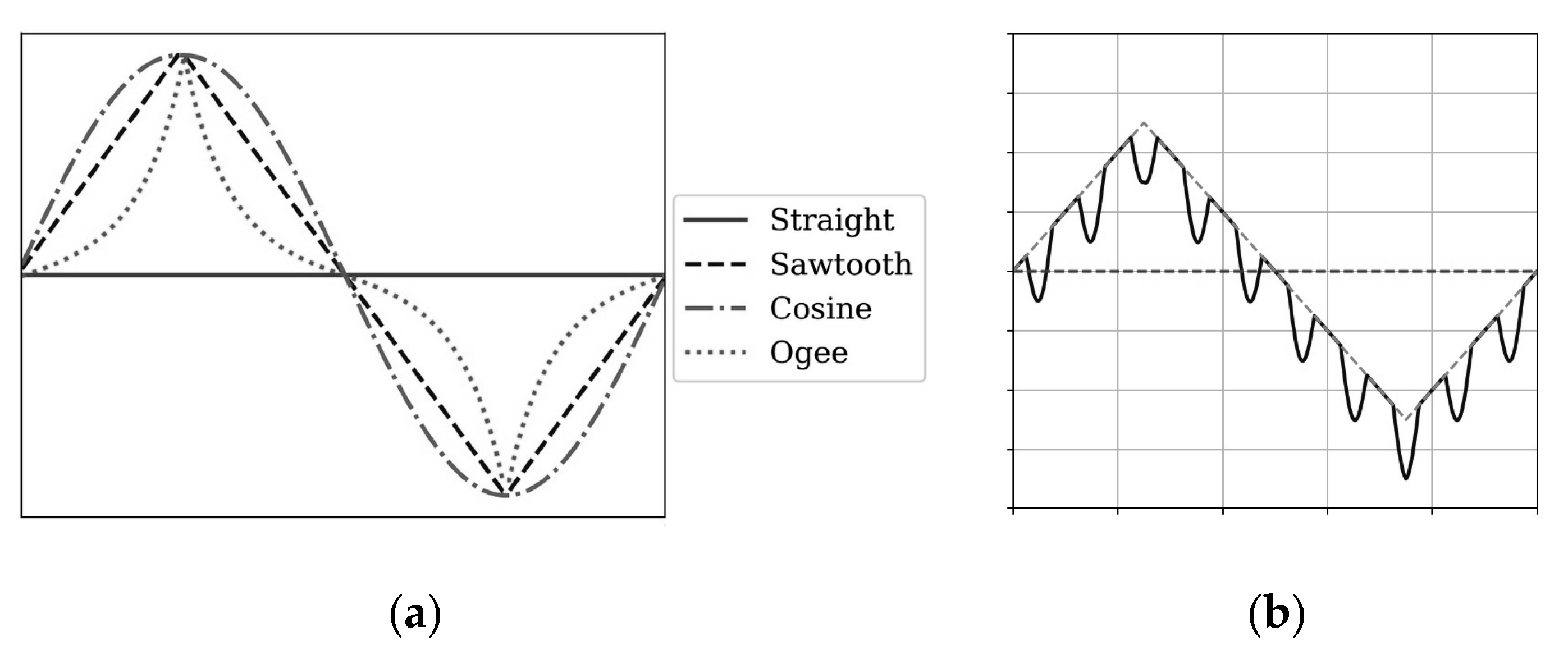

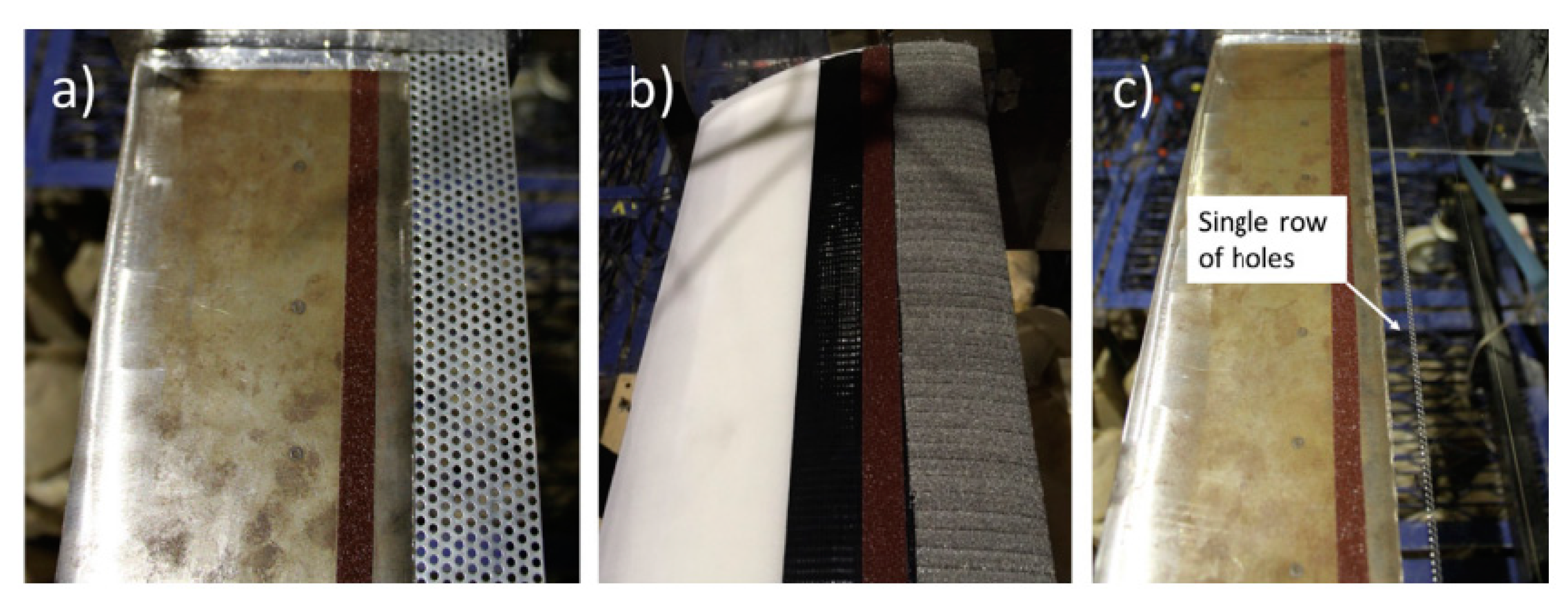

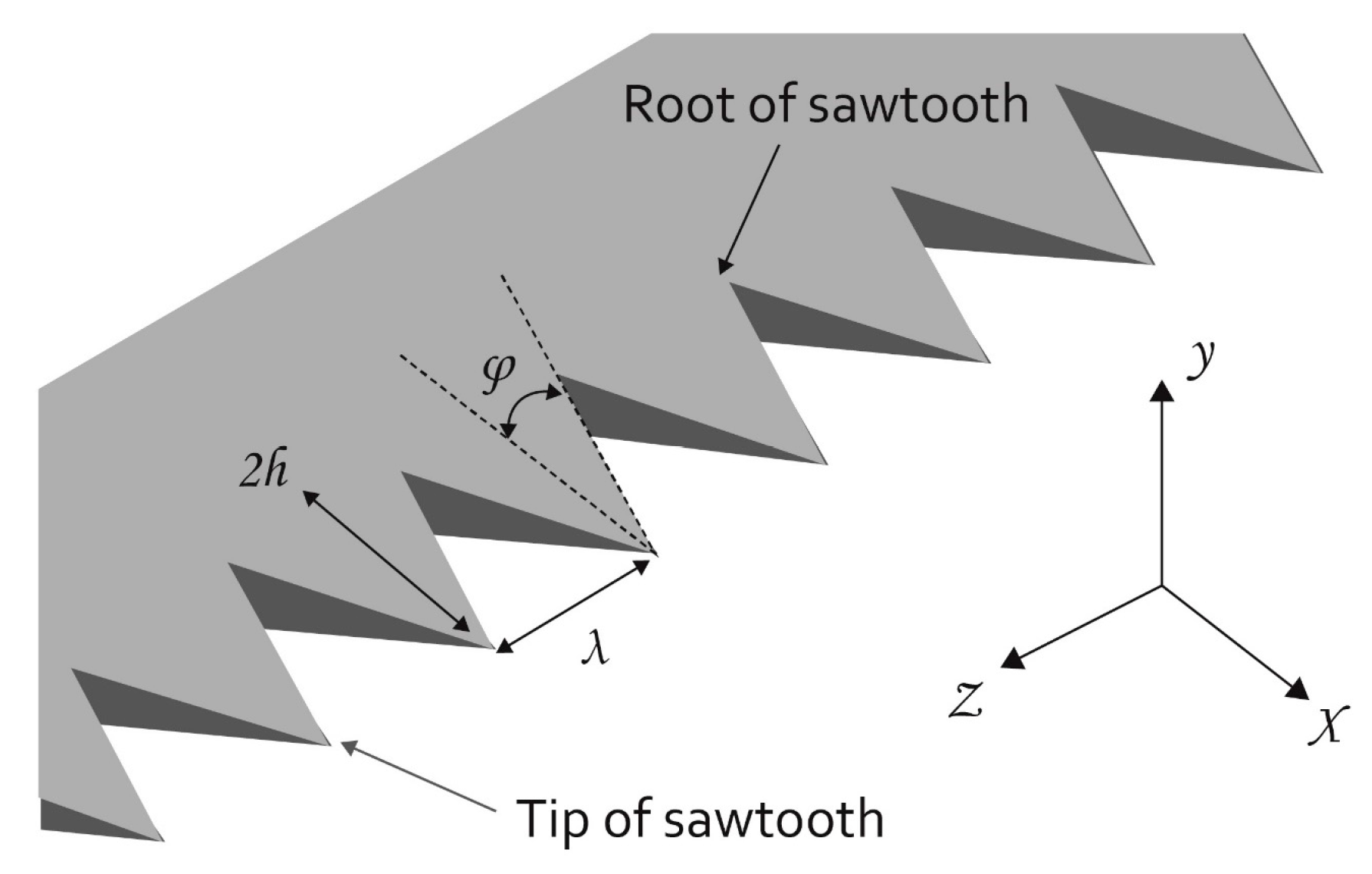

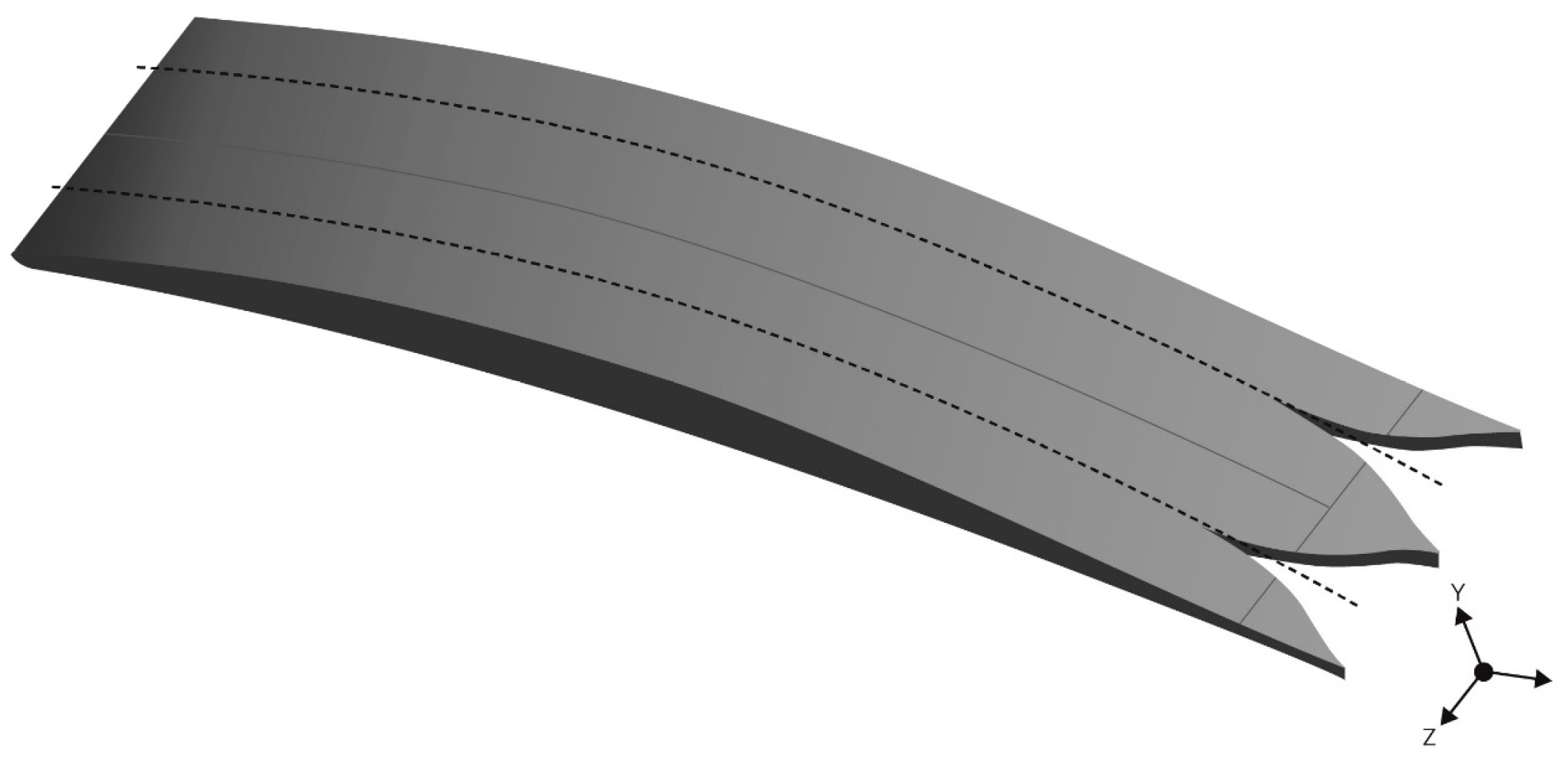

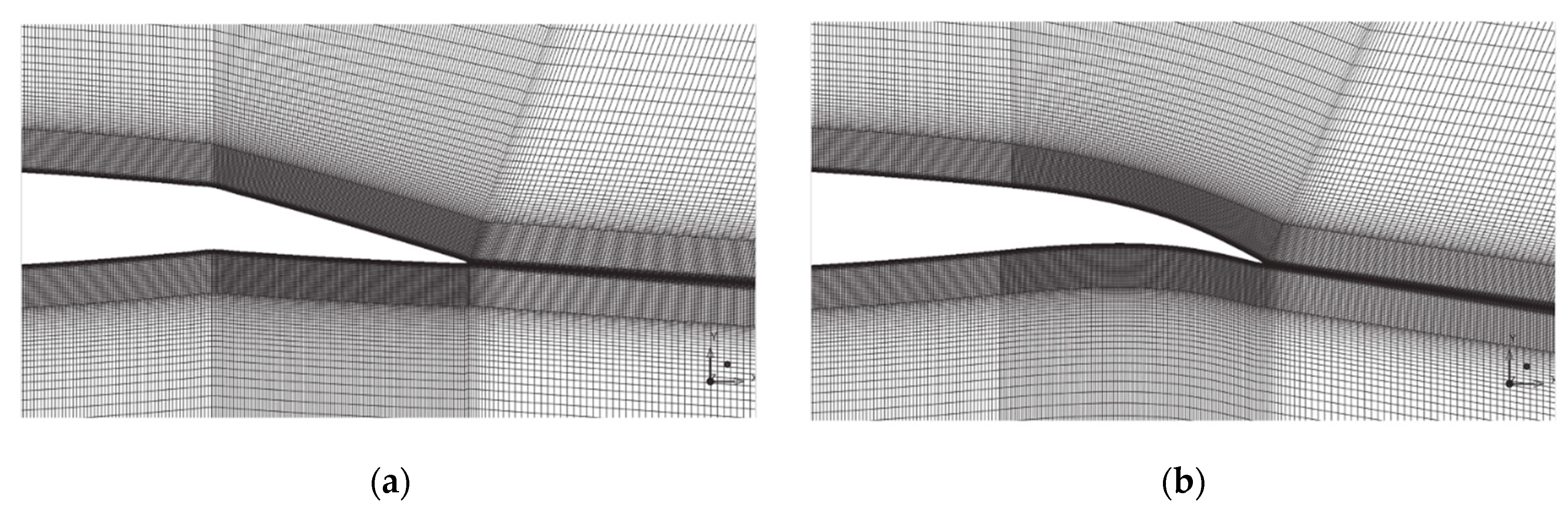

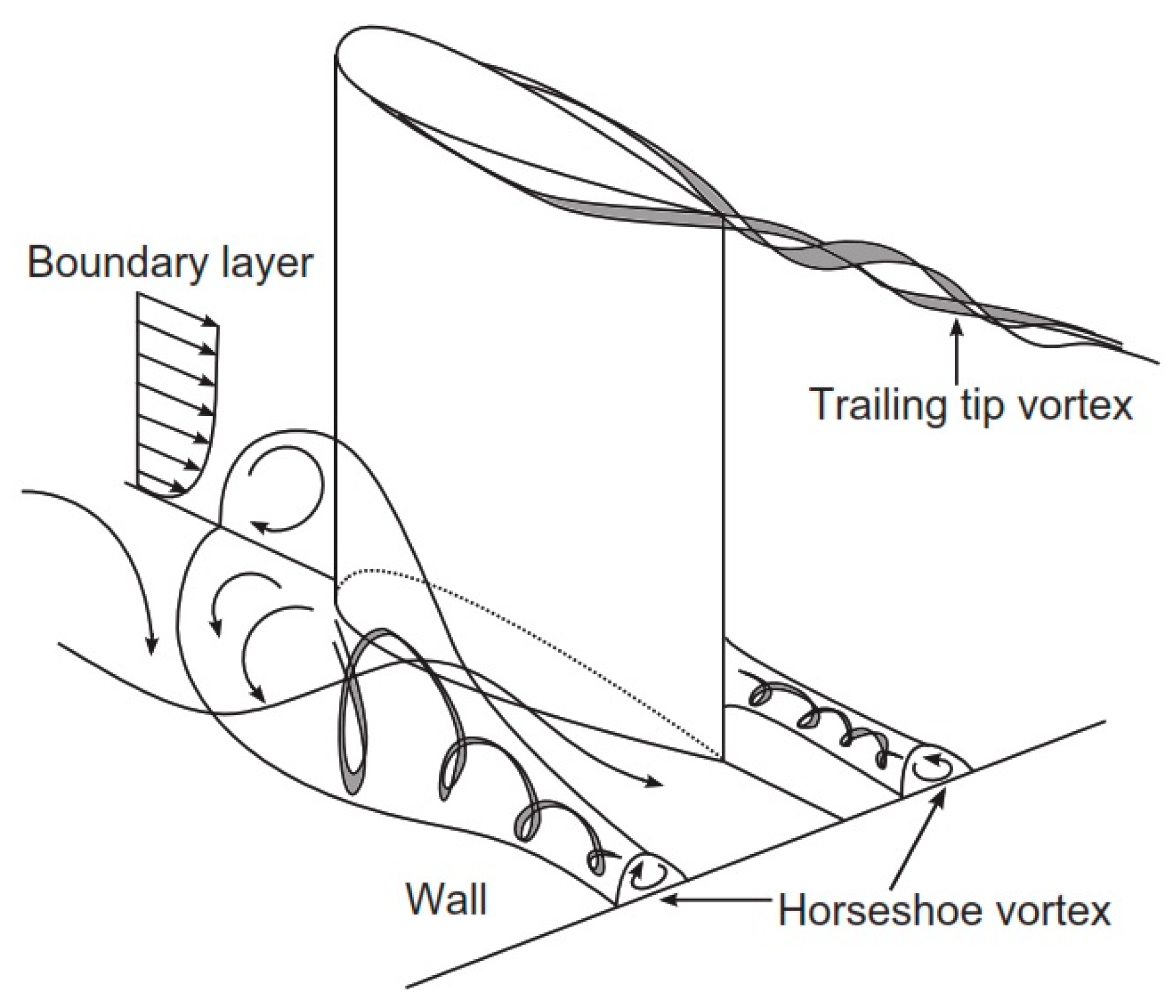

4.1.2. Trailing Edge Treatments

- Vortex-Shedding Suppression: TE serrations can limit the VS process by breaking up the coherent vortex structures into smaller eddies that disrupt the periodic shedding of vortices and reduce tonal noise [213].

- Boundary Layer Stability: The TBL tends to be more stable and less prone to separation and associated noise generation [214]. Serrations can alter the airflow BL characteristics and trip the BL over the length of the serrations, which leads to a transition from laminar to turbulent flow closer to the TE [215].

- Noise Diffusion: The serrations create multiple smaller flow features along the TE instead of larger ones on a single sharp edge. This multiplicity of smaller eddies causes the sound waves generated by the airflow to diffract and scatter more, resulting in noise diffusion. The diffused noise is spread across a wider frequency spectrum, often leading to a reduction in overall noise levels [216].

- Flat-plate trailing edge

- Non-flat trailing edge

4.2. Porous Materials

4.3. Controlled Diffusion Airfoils

4.4. Morphing Wings

4.5. Other Design Techniques

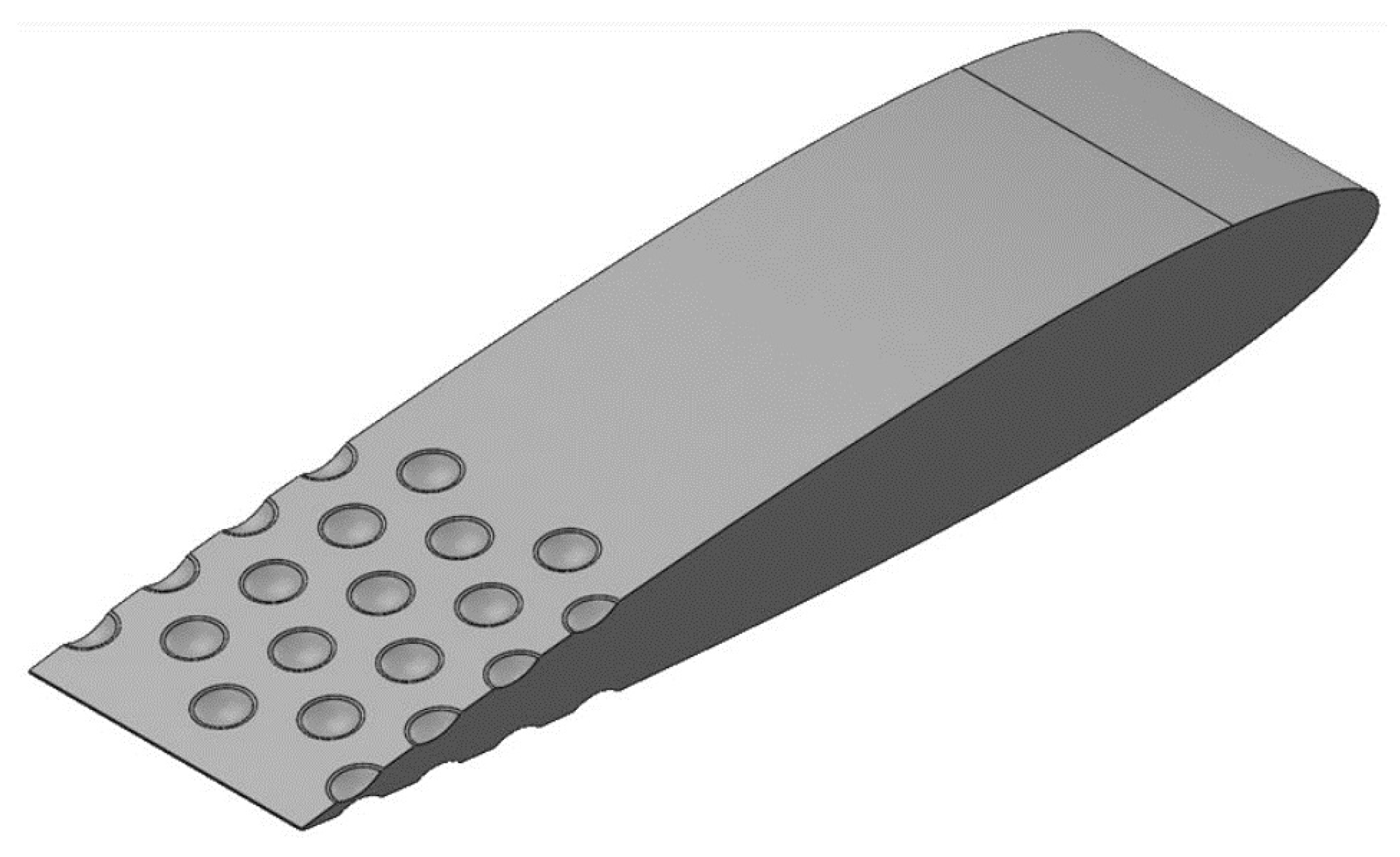

4.6. Surface Treatments

5. Conclusions

Funding

Conflicts of Interest

References

- Chong, T.P.; Dubois, E. Optimization of the poro-serrated trailing edges for airfoil broadband noise reduction. J. Acoust. Soc. Am. 2016, 140, 1361–1373. [Google Scholar] [CrossRef] [PubMed]

- Rocha, J.; Suleman, A.; Lau, F. Prediction of turbulent boundary layer induced noise in the cabin of a BWB aircraft. Shock Vib. 2012, 19, 693–705. [Google Scholar] [CrossRef][Green Version]

- Dull, C.; Tai, J.C.; Mavris, D.N. Surrogate-Based Multi-Objective Optimization of Commercial Aircraft for the Minimization of Noise and Emissions. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 1358. [Google Scholar] [CrossRef]

- Palma, G.; Meloni, S.; Camussi, R.; Iemma, U.; Bogey, C. Data-Driven Multiobjective Optimization of Wave-Packets for Near-Field Subsonic Jet Noise. AIAA J. 2023, 61, 2179–2188. [Google Scholar] [CrossRef]

- Sinha, S.; Cerizza, D.; Schuster, W. Multiple Pure Tone Noise Predictions of a Propulsion Engine Fan with PowerFLOW. In Proceedings of the AIAA AVIATION 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 4296. [Google Scholar] [CrossRef]

- Bull, M. Wall-pressure fluctuations associated with subsonic turbulent boundary layer flow. J. Fluid Mech. 1967, 28, 719–754. [Google Scholar] [CrossRef]

- Al-Am, J.; Clair, V.; Giauque, A.; Boudet, J.; Gea-Aguilera, F. On the effects of a separation bubble on fan noise. J. Sound Vib. 2022, 537, 117180. [Google Scholar] [CrossRef]

- Pröbsting, S.; Yarusevych, S. Laminar separation bubble development on an airfoil emitting tonal noise. J. Fluid Mech. 2015, 780, 167–191. [Google Scholar] [CrossRef]

- Dos Santos, F.L.; Botero-Bolívar, L.; Venner, C.H.; de Santana, L.D. Inflow turbulence distortion for airfoil leading-edge noise prediction for large turbulence length scales for zero-mean loading. J. Acoust. Soc. Am. 2023, 153, 1811–1822. [Google Scholar] [CrossRef] [PubMed]

- Anderson, J.M.; Hickling, C.; Manar, F. Effects of Rotor Blade Wavy Leading Edge Wavelength on Turbulence Ingestion Sound. In Proceedings of the AIAA AVIATION 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 3657. [Google Scholar] [CrossRef]

- Zamponi, R.; Satcunanathan, S.; Moreau, S.; Ragni, D.; Meinke, M.; Schröder, W.; Schram, C. On the role of turbulence distortion on leading-edge noise reduction by means of porosity. J. Sound Vib. 2020, 485, 115561. [Google Scholar] [CrossRef]

- Casalino, D.; Romani, G.; Zhang, R.; Chen, H. Lattice-Boltzmann calculations of rotor aeroacoustics in transitional boundary layer regime. Aerosp. Sci. Technol. 2022, 130, 107953. [Google Scholar] [CrossRef]

- Brooks, T.F.; Pope, D.S.; Marcolini, M.A. Airfoil Self-Noise and Prediction; NASA Reference Publication1218 (RP-1218); NASA: Washington, DC, USA, 1989. [Google Scholar]

- Hornung, C.; Lutz, T.; Krämer, E. A model to include turbulence-turbulence interaction in the prediction of trailing edge far field noise for high angles of attack or slightly separated flow. Renew. Energy 2019, 136, 945–954. [Google Scholar] [CrossRef]

- Kojima, Y.; Skene, C.S.; Yeh, C.-A.; Taira, K.; Kameda, M. On the origin of quadrupole sound from a two-dimensional aerofoil trailing edge. J. Fluid Mech. 2023, 958, A3. [Google Scholar] [CrossRef]

- Manoha, E.; Troff, B.; Sagaut, P. Trailing-edge noise prediction using large-eddy simulation and acoustic analogy. AIAA J. 2000, 38, 575–583. [Google Scholar] [CrossRef]

- Arcondoulis, E.; Doolan, C.; Zander, A.; Brooks, L. A review of trailing edge noise generated by airfoils at low to moderate Reynolds number. Acoust. Aust. 2010, 38, 129–133. [Google Scholar]

- Xue, W.; Yang, B. Experimental Investigation of Airfoil Trailing Edge Noise Reduction by using TE Serrations. arXiv preprint 2023, arXiv:2307.12188. [Google Scholar] [CrossRef]

- Brito, P.P.; Morra, P.; Cavalieri, A.V.; Araújo, T.B.; Henningson, D.S.; Hanifi, A. Experimental control of Tollmien–Schlichting waves using pressure sensors and plasma actuators. Exp. Fluids 2021, 62, 1–13. [Google Scholar] [CrossRef]

- Placidi, M.; Gaster, M.; Atkin, C.J. Acoustic excitation of Tollmien–Schlichting waves due to localised surface roughness. J. Fluid Mech. 2020, 895, R5. [Google Scholar] [CrossRef]

- Rouviere, A.; Méry, F.; Methel, J.; Vermeersch, O.; Forte, M. Experimental and numerical study on wall impedance effects on Tollmien–Schlichting Waves. AIAA J. 2022, 60, 508–519. [Google Scholar] [CrossRef]

- Zang, B.; Mayer, Y.; Azarpeyvand, M. An experimental investigation on the mechanism of Tollmien-Schlichting waves for a NACA 0012 aerofoil. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2609. [Google Scholar] [CrossRef]

- Chong, T.; Juknevicius, A. Reconstruction of the deterministic turbulent boundary layer for the study of aerofoil self-noise mechanisms. Exp. Fluids 2022, 63, 139. [Google Scholar] [CrossRef]

- Yao, H.-D.; Huang, Z.; Davidson, L.; Niu, J.; Chen, Z.-W. Blade-Tip Vortex Noise Mitigation Traded-Off against Aerodynamic Design for Propellers of Future Electric Aircraft. Aerospace 2022, 9, 825. [Google Scholar] [CrossRef]

- Smith, T.A. Numerical modelling of fluid-induced noise from lifting surfaces at moderate Reynolds numbers. Doctoral Thesis, University College London (UCL), London, UK, 2021. [Google Scholar]

- Kapoor, R.; Kloet, N.; Gardi, A.; Mohamed, A.; Sabatini, R. Sound propagation modelling for manned and unmanned aircraft noise assessment and mitigation: A review. Atmosphere 2021, 12, 1424. [Google Scholar] [CrossRef]

- Lee, S.; Ayton, L.; Bertagnolio, F.; Moreau, S.; Chong, T.P.; Joseph, P. Turbulent boundary layer trailing-edge noise: Theory, computation, experiment, and application. Prog. Aerosp. Sci. 2021, 126, 100737. [Google Scholar] [CrossRef]

- Lyrintzis, A.; Uzun, A. Integral techniques for jet aeroacoustics calculations. In Proceedings of the 7th AIAA/CEAS Aeroacoustics Conference and Exhibit, Maastricht, The Netherlands, 28–30 May 2001; p. 2253. [Google Scholar] [CrossRef]

- Prieur, J.; Rahier, G. Aeroacoustic integral methods, formulation and efficient numerical implementation. Aerosp. Sci. Technol. 2001, 5, 457–468. [Google Scholar] [CrossRef]

- Kurbatskii, K.A.; Mankbadi, R.R. Review of computational aeroacoustics algorithms. Int. J. Comput. Fluid Dyn. 2004, 18, 533–546. [Google Scholar] [CrossRef]

- Farassat, F. Acoustic radiation from rotating blades—The Kirchhoff method in aeroacoustics. J. Sound Vib. 2001, 239, 785–800. [Google Scholar] [CrossRef]

- Lighthill, M.J. On sound generated aerodynamically I. General theory. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1952, 211, 564–587. [Google Scholar] [CrossRef]

- Ffowcs Williams, J.E.; Hawkings, D.L. Sound generation by turbulence and surfaces in arbitrary motion. Philos. Trans. R. Soc. London Ser. A Math. Phys. Sci. 1969, 264, 321–342. [Google Scholar] [CrossRef]

- Brentner, K.S.; Farassat, F. Modeling aerodynamically generated sound of helicopter rotors. Prog. Aerosp. Sci. 2003, 39, 83–120. [Google Scholar] [CrossRef]

- Yang, T.; Chen, X.; Zhao, Q.; Ding, Y. Numerical analysis on the high-speed impulsive noise propagation characteristic of helicopter rotor in the presence of strong shear flow. Appl. Acoust. 2023, 203, 109213. [Google Scholar] [CrossRef]

- Williams, J.F.; Hall, L. Aerodynamic sound generation by turbulent flow in the vicinity of a scattering half plane. J. Fluid Mech. 1970, 40, 657–670. [Google Scholar] [CrossRef]

- Yao, H.-D. Special Issue “Aeroacoustics and Noise Mitigation”. Aerospace 2023, 10, 594. [Google Scholar] [CrossRef]

- Parry, A.; Crighton, D. Asymptotic theory of propeller noise. I-Subsonic single-rotation propeller. AIAA J. 1989, 27, 1184–1190. [Google Scholar] [CrossRef]

- Wang, Z.-N.; Tyacke, J.; Tucker, P.; Boehning, P. Parallel computation of aeroacoustics of industrially relevant complex-geometry aeroengine jets. Comput. Fluids 2019, 178, 166–178. [Google Scholar] [CrossRef]

- Sabra, K.G.; Roux, P.; Kuperman, W. Emergence rate of the time-domain Green’s function from the ambient noise cross-correlation function. J. Acoust. Soc. Am. 2005, 118, 3524–3531. [Google Scholar] [CrossRef]

- Vér, I.L.; Beranek, L.L. Noise and Vibration Control Engineering: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Sabra, K.G.; Gerstoft, P.; Roux, P.; Kuperman, W.; Fehler, M.C. Extracting time-domain Green’s function estimates from ambient seismic noise. Geophys. Res. Lett. 2005, 32, L03310. [Google Scholar] [CrossRef]

- Howe, M.S. Edge-source acoustic Green’s function for an airfoil of arbitrary chord, with application to trailing-edge noise. Q. J. Mech. Appl. Math. 2001, 54, 139–155. [Google Scholar] [CrossRef]

- Snieder, R. Extracting the Green’s function of attenuating heterogeneous acoustic media from uncorrelated waves. J. Acoust. Soc. Am. 2007, 121, 2637–2643. [Google Scholar] [CrossRef] [PubMed]

- Amiet, R.K. High frequency thin-airfoil theory for subsonic flow. AIAA J. 1976, 14, 1076–1082. [Google Scholar] [CrossRef]

- Amiet, R.K. Acoustic radiation from an airfoil in a turbulent stream. J. Sound Vib. 1975, 41, 407–420. [Google Scholar] [CrossRef]

- Amiet, R.K. Noise due to turbulent flow past a trailing edge. J. Sound Vib. 1976, 47, 387–393. [Google Scholar] [CrossRef]

- Howe, M.S. Noise produced by a sawtooth trailing edge. J. Acoust. Soc. Am. 1991, 90, 482–487. [Google Scholar] [CrossRef]

- Howe, M.S. Acoustics of Fluid-Structure Interactions; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Grasso, G.; Jaiswal, P.; Wu, H.; Moreau, S.; Roger, M. Analytical models of the wall-pressure spectrum under a turbulent boundary layer with adverse pressure gradient. J. Fluid Mech. 2019, 877, 1007–1062. [Google Scholar] [CrossRef]

- Moin, P.; Mahesh, K. Direct numerical simulation: A tool in turbulence research. Annu. Rev. Fluid Mech. 1998, 30, 539–578. [Google Scholar] [CrossRef]

- Serrin, J. Asymptotic behaviour of velocity profiles in the Prandtl boundary layer theory. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1967, 299, 491–507. [Google Scholar] [CrossRef]

- Lighthill, M.J. On sound generated aerodynamically II. Turbulence as a source of sound. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1954, 222, 1–32. [Google Scholar] [CrossRef]

- Schoder, S.; Kaltenbacher, M. Hybrid aeroacoustic computations: State of art and new achievements. J. Theor. Comput. Acoust. 2019, 27, 1950020. [Google Scholar] [CrossRef]

- Deng, G.C.; Baba, S.; Lavoie, P.; Moreau, S.; Stalnov, O. Large Eddy Simulation and Noise Prediction of a Supercritical Airfoil at Moderate Angle of Attack. In Proceedings of the AIAA AVIATION 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 4481. [Google Scholar] [CrossRef]

- Jiang, H.; Zhong, S.; Zhang, X.; Huang, X. Boundary element analysis on the fuselage scattering of drone noise. Int. J. Aeroacoustics 2022, 21, 43–56. [Google Scholar] [CrossRef]

- Qian, L.; Hanru, L.; Jiahui, L.; Shang, X.; Nanshu, C.; Yangang, W. Research on aerodynamics and aeroacoustics of propeller based on panel-vortex particle method. Xibei Gongye Daxue Xuebao/J. Northwestern Polytech. Univ. 2022, 40, 778–786. [Google Scholar] [CrossRef]

- Zhu, W.; Morandini, M.; Li, S. Viscous vortex particle method coupling with computational structural dynamics for rotor comprehensive analysis. Appl. Sci. 2021, 11, 3149. [Google Scholar] [CrossRef]

- Artoni, A.; Antonietti, P.F.; Mazzieri, I.; Parolini, N.; Rocchi, D. A segregated finite volume-spectral element method for aeroacoustic problems. arXiv preprint 2023, arXiv:2302.03370. [Google Scholar] [CrossRef]

- Falone, M.; Delorme, Y.; Edri, Y.; Amouyal, S.; Wasserman, M.; Ding, Z.; D’Alessandro, V. Libfastmesh: An Optimized Finite-Volume Framework for Computational Aeroacoustics (Preprint). Compu. Phys. Commun. 2022. [Google Scholar] [CrossRef]

- Guasch, O.; Pont, A.; Baiges, J.; Codina, R. Finite element hybrid and direct computational aeroacoustics at low Mach numbers in slow time-dependent domains. Comput. Fluids 2022, 239, 105394. [Google Scholar] [CrossRef]

- Cerretani, J.; Dmitruk, P. Coexistence of acoustic waves and turbulence in low Mach number compressible flows. Phys. Fluids 2019, 31, 045102. [Google Scholar] [CrossRef]

- Ewert, R.; Schröder, W. Acoustic perturbation equations based on flow decomposition via source filtering. J. Comput. Phys. 2003, 188, 365–398. [Google Scholar] [CrossRef]

- Smith, T.A.; Ventikos, Y. A hybrid computational aeroacoustic model with application to turbulent flows over foil and bluff bodies. J. Sound Vib. 2022, 526, 116773. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, W.; Zhang, W.; Xia, Z. Analysis on numerical stability and convergence of Reynolds averaged Navier–Stokes simulations from the perspective of coupling modes. Phys. Fluids 2022, 34. [Google Scholar] [CrossRef]

- Altland, S.; Xu, H.H.; Yang, X.I.; Kunz, R. Modeling of cube array roughness: RANS, large eddy simulation, and direct numerical simulation. J. Fluids Eng. 2022, 144, 061106. [Google Scholar] [CrossRef]

- Ricks, N.; Tsirikoglou, P.; Contino, F.; Ghorbaniasl, G. A CFD-based methodology for aerodynamic-aeroacoustic shape optimization of airfoils. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 1729. [Google Scholar] [CrossRef]

- Martínez-Lera, P.; Christophe, J.; Schram, C. Computation of the self-noise of a controlled-diffusion airfoil based on the acoustic analogy. Int. J. Aeroacoustics 2017, 16, 44–64. [Google Scholar] [CrossRef]

- Tamaki, Y.; Kawai, S. Wall-Resolved Large-Eddy Simulation of Near-Stall Airfoil Flow at R ec= 10 7. AIAA J. 2023, 61, 698–711. [Google Scholar] [CrossRef]

- van Noordt, W.; Ganju, S.; di Mare, L.; Brehm, C. Modelling Errors in Wall-Modelled Large-Eddy Simulations of High-Speed Channel Flows. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 0284. [Google Scholar] [CrossRef]

- Deck, S.; Gand, F.; Brunet, V.; Ben Khelil, S. High-fidelity simulations of unsteady civil aircraft aerodynamics: Stakes and perspectives. Application of zonal detached eddy simulation. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130325. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Wang, K.; Wang, M. Aeroacoustic prediction of a multi-element airfoil using wall-modeled large-eddy simulation. AIAA J. 2017, 55, 4219–4233. [Google Scholar] [CrossRef]

- Zhai, L.; Chen, H.; Ma, Z. A Delayed Detached Eddy Simulation Model for the Simulation of Complex Turbulent Flow. J. Appl. Fluid Mech. 2022, 15, 1111–1124. [Google Scholar] [CrossRef]

- Pindi Nataraj, P. Airfoil self-noise predictions using DDES and the FWH analogy. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2022. [Google Scholar]

- Lyrintzis, A.S.; Coderoni, M. Overview of the use of large-eddy simulations in jet aeroacoustics. AIAA J. 2020, 58, 1620–1638. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, Y.; Liu, R.; Chen, H. Aeroacoustic prediction based on large-eddy simulation and the Ffowcs Williams–Hawkings equation. Adv. Aerodyn. 2022, 4, 1–18. [Google Scholar] [CrossRef]

- Cheng, Z.; Lien, F.-S.; Yee, E.; Meng, H. A unified framework for aeroacoustics simulation of wind turbines. Renew. Energy 2022, 188, 299–319. [Google Scholar] [CrossRef]

- Zhu, W.J.; Heilskov, N.; Shen, W.Z.; Sørensen, J.N. Modeling of aerodynamically generated noise from wind turbines. J. Sol. Energy Eng. 2005, 517–528. [Google Scholar] [CrossRef]

- Chase, D.M. Modeling the wavevector-frequency spectrum of turbulent boundary layer wall pressure. J. Sound Vib. 1980, 70, 29–67. [Google Scholar] [CrossRef]

- Goody, M. Empirical spectral model of surface pressure fluctuations. AIAA J. 2004, 42, 1788–1794. [Google Scholar] [CrossRef]

- March, A.; Willcox, K. Provably convergent multifidelity optimization algorithm not requiring high-fidelity derivatives. AIAA J. 2012, 50, 1079–1089. [Google Scholar] [CrossRef]

- Rozenberg, Y.; Robert, G.; Moreau, S. Wall-pressure spectral model including the adverse pressure gradient effects. AIAA J. 2012, 50, 2168–2179. [Google Scholar] [CrossRef]

- Arce León, C.; Merino-Martínez, R.; Ragni, D.; Avallone, F.; Snellen, M. Boundary layer characterization and acoustic measurements of flow-aligned trailing edge serrations. Exp. Fluids 2016, 57, 1–22. [Google Scholar] [CrossRef]

- Kingan, M.J.; Pearse, J.R. Laminar boundary layer instability noise produced by an aerofoil. J. Sound Vib. 2009, 322, 808–828. [Google Scholar] [CrossRef]

- Li, S.; Lee, S. Extensions and Applications of Lyu and Ayton’s Serrated Trailing-Edge Noise Model to Rotorcraft. In Proceedings of the 28th AIAA/CEAS Aeroacoustics 2022 Conference, Southampton, UK, 14–17 June 2022; p. 2916. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Bekiropoulos, D.; Lutz, T.; Würz, W.; Krämer, E. A semi-empirical surface pressure spectrum model for airfoil trailing-edge noise prediction. Int. J. Aeroacoustics 2015, 14, 833–882. [Google Scholar] [CrossRef]

- Howe, M.S. A review of the theory of trailing edge noise. J. Sound Vib. 1978, 61, 437–465. [Google Scholar] [CrossRef]

- Liu, C.; Lee, S. Parametric airfoil design for trailing-edge noise reduction. In Proceedings of the AIAA AVIATION 2020 FORUM, Online, 15–19 June 2020; p. 2536. [Google Scholar] [CrossRef]

- Lee, S. Empirical wall-pressure spectral modeling for zero and adverse pressure gradient flows. AIAA J. 2018, 56, 1818–1829. [Google Scholar] [CrossRef]

- Morris, M.D. Factorial sampling plans for preliminary computational experiments. Technometrics 1991, 33, 161–174. [Google Scholar] [CrossRef]

- Guidati, G.; Ostertag, J.; Wagner, S. Prediction and reduction of wind turbine noise-An overview of research activities in Europe. In Proceedings of the 2000 ASME Wind Energy Symposium, Reno, NV, USA, 10–13 January 2000; p. 42. [Google Scholar] [CrossRef]

- Parchen, R.R. Progress Report DRAW: A Prediction Scheme for Trailing Edge Noise Based on Detailed Boundary Layer Characteristics; TNO Institute of Applied Physics: Delft, The Netherlands, 1998. [Google Scholar]

- Bertagnolio, F.; Fischer, A.; Zhu, W.J. Tuning of turbulent boundary layer anisotropy for improved surface pressure and trailing-edge noise modeling. J. Sound Vib. 2014, 333, 991–1010. [Google Scholar] [CrossRef]

- Kou, J.; Botero-Bolívar, L.; Ballano, R.; Marino, O.; de Santana, L.; Valero, E.; Ferrer, E. Aeroacoustic airfoil shape optimization enhanced by autoencoders. Expert Syst. Appl. 2023, 119513. [Google Scholar] [CrossRef]

- Casalino, D.; van der Velden, W.C.; Romani, G. A Framework for Multi-Fidelity Wind-Turbine Aeroacoustic Simulations. In Proceedings of the 28th AIAA/CEAS Aeroacoustics 2022 Conference, Southampton, UK, 14–17 June 2022; p. 2892. [Google Scholar] [CrossRef]

- Wyngaard, J.; Clifford, S. Taylor’s hypothesis and high–frequency turbulence spectra. J. Atmos. Sci. 1977, 34, 922–929. [Google Scholar] [CrossRef]

- Moin, P. Revisiting Taylor’s hypothesis. J. Fluid Mech. 2009, 640, 1–4. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Bekiropoulos, D.; Wolf, A.; Lutz, T.; Kraemer, E. Rnoise: A RANS based airfoil trailing-edge noise prediction model. In Proceedings of the 20th AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 16–20 June 2014; p. 3305. [Google Scholar] [CrossRef]

- Stalnov, O.; Chaitanya, P.; Joseph, P.F. Towards a non-empirical trailing edge noise prediction model. J. Sound Vib. 2016, 372, 50–68. [Google Scholar] [CrossRef]

- Ferret Gasch, O.; Oerlemans, S.; Bertagnolio, F.; Fischer, A.; Arnold, B.; Lutz, T.; Fassmann, B.W.; Herr, M. Trailing edge noise prediction of wind turbine airfoils: A benchmark exercise. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2675. [Google Scholar] [CrossRef]

- Fischer, A.; Bertagnolio, F.; Madsen, H.A. Improvement of TNO type trailing edge noise models. Eur. J. Mech. -B/Fluids 2017, 61, 255–262. [Google Scholar] [CrossRef]

- Blake, W.K. Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure Interactions; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Lynch III, D.A.; Blake, W.K.; Mueller, T.J. Turbulence correlation length-scale relationships for the prediction of aeroacoustic response. AIAA J. 2005, 43, 1187–1197. [Google Scholar] [CrossRef]

- Allen, C.S.; Blake, W.K.; Dougherty, R.P.; Lynch, D.; Soderman, P.T.; Underbrink, J.R.; Underbrink, J.R. Aeroacoustic phased array testing in low speed wind tunnels. In Aeroacoustic Measurements; Springer: Berlin/Heidelberg, Germany, 2002; pp. 98–217. [Google Scholar] [CrossRef]

- Abid, H.A.; Stalnov, O.; Karabasov, S.A. Comparative Analysis of Low Order Wall Pressure Spectrum Models for Trailing Edge Noise Based in Amiet Theory. In Proceedings of the AIAA AVIATION 2021 FORUM, Virtual Event, 2–6 August 2021; p. 2231. [Google Scholar] [CrossRef]

- Blake, W.K. Mechanics of flow-induced sound and vibration. Volume 1 General concepts and elementary source. Volume 2-Complex flow-structure interactions. Apl. Mat. Appl. Math. 1986, 1, 457. [Google Scholar]

- Wilcox, D.C. Turbulence Modeling for CFD; DCW Industries: La Canada, CA, USA, 1998; Volume 2. [Google Scholar] [CrossRef]

- Abid, H.A.; Markesteijn, A.P.; Karabasov, S.A. Trailing Edge Noise Modelling of Flow over NACA Airfoils Informed by LES. In Proceedings of the AIAA AVIATION 2021 FORUM, Virtual Event, 2–6 August 2021; p. 2233. [Google Scholar] [CrossRef]

- Mukha, T.; Rezaeiravesh, S.; Liefvendahl, M. A library for wall-modelled large-eddy simulation based on OpenFOAM technology. Comput. Phys. Commun. 2019, 239, 204–224. [Google Scholar] [CrossRef]

- Larsson, J.; Kawai, S.; Bodart, J.; Bermejo-Moreno, I. Large eddy simulation with modeled wall-stress: Recent progress and future directions. Mech. Eng. Rev. 2016, 3, 15-00418. [Google Scholar] [CrossRef]

- Mason, P.J. Large-eddy simulation: A critical review of the technique. Q. J. R. Meteorol. Soc. 1994, 120, 1–26. [Google Scholar] [CrossRef]

- Piomelli, U. Large-eddy simulation: Achievements and challenges. Prog. Aerosp. Sci. 1999, 35, 335–362. [Google Scholar] [CrossRef]

- Herr, M.; Ewert, R.; Rautmann, C.; Kamruzzaman, M.; Bekiropoulos, D.; Arina, R.; Iob, A.; Batten, P.; Chakravarthy, S.; Bertagnolio, F. Broadband trailing-edge noise predictions—Overview of BANC-III results. In Proceedings of the 21st AIAA/CEAS Aeroacoustics Conference, Dallas, TX, USA, 22–26 June 2015; p. 2847. [Google Scholar] [CrossRef]

- Tian, Y.; Cotté, B. Wind turbine noise modeling based on Amiet’s theory: Effects of wind shear and atmospheric turbulence. Acta Acust. United Acust. 2016, 102, 626–639. [Google Scholar] [CrossRef]

- Foken, T. 50 years of the Monin–Obukhov similarity theory. Bound. -Layer Meteorol. 2006, 119, 431–447. [Google Scholar] [CrossRef]

- Salesky, S.T.; Chamecki, M. Random errors in turbulence measurements in the atmospheric surface layer: Implications for Monin–Obukhov similarity theory. J. Atmos. Sci. 2012, 69, 3700–3714. [Google Scholar] [CrossRef]

- Yu, J.; Chen, W.; Zhou, T.; Lee, C.; Huang, X. Transient analysis of trailing edge noise assisted by wavelet-based beamforming and flow visualisation. J. Sound Vib. 2022, 526, 116751. [Google Scholar] [CrossRef]

- Catlett, M.R.; Anderson, J.M.; Forest, J.B.; Stewart, D.O. Empirical modeling of pressure spectra in adverse pressure gradient turbulent boundary layers. AIAA J. 2016, 54, 569–587. [Google Scholar] [CrossRef]

- Schepers, J.; Curvers, A.; Oerlemans, S.; Braun, K.; Lutz, T.; Herrig, A.; Wuerz, W.; Mantesanz, A.; Garcillan, L.; Fischer, M. Sirocco: Silent rotors by acoustic optimisation. In Proceedings of the 2nd International Meeting on Wind Turbine Noise, Lyon, France, 20–21 September 2007. [Google Scholar]

- Al Tlua, B.; Rocha, J. Development and testing of an aeroacoustic wind tunnel test section. Can. Acoust. 2019, 47, 64–65. [Google Scholar]

- Sarradj, E.; Herold, G.; Sijtsma, P.; Merino Martinez, R.; Geyer, T.F.; Bahr, C.J.; Porteous, R.; Moreau, D.; Doolan, C.J. A microphone array method benchmarking exercise using synthesized input data. In Proceedings of the 23rd AIAA/CEAS Aeroacoustics Conference, Denver, CO, USA, 5–9 June 2017; p. 3719. [Google Scholar] [CrossRef]

- Tam, C.K. Computational aeroacoustics: An overview of computational challenges and applications. Int. J. Comput. Fluid Dyn. 2004, 18, 547–567. [Google Scholar] [CrossRef]

- Chow, F.K.; Moin, P. A further study of numerical errors in large-eddy simulations. J. Comput. Phys. 2003, 184, 366–380. [Google Scholar] [CrossRef]

- Bernicke, P.; Ananthan, V.B.; Akkermans, R.A.; Dierke, J.; Ewert, R. Scale-Resolving Simulation of Aeroacoustic Sound from Coanda Flaps. In Fundamentals of High Lift for Future Civil Aircraft: Contributions to the Final Symposium of the Collaborative Research Center 880, 17–18 December 2019, Braunschweig, Germany; Springer: Berlin/Heidelberg, Germany, 2020; pp. 529–543. [Google Scholar] [CrossRef]

- Iemma, U.; Poggi, C.; Rossetti, M.; Bernardini, G. Techniques for adaptive metamodelling of propeller arrays far-field noise. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Washington, DC, USA, 1–5 August 2021; pp. 2674–2686. [Google Scholar] [CrossRef]

- Marsden, A.L.; Wang, M.; Dennis, J.E.; Moin, P. Optimal aeroacoustic shape design using the surrogate management framework. Optim. Eng. 2004, 5, 235–262. [Google Scholar] [CrossRef]

- Lele, S.K.; Nichols, J.W. A second golden age of aeroacoustics? Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130321. [Google Scholar] [CrossRef]

- Zhao, M.; Cao, H.; Zhang, M.; Liao, C.; Zhou, T. Optimal design of aeroacoustic airfoils with owl-inspired trailing-edge serrations. Bioinspiration Biomim. 2021, 16, 056004. [Google Scholar] [CrossRef]

- Brezina, M. Aeroacoustic Optimization of Flat-Plate Serrated Trailing Edge Extensions for Broadband Noise Reduction. Master’s Thesis, Carleton University, Ottawa, ON, Canada, 2017. [Google Scholar] [CrossRef]

- de Haan, W. Impact of Blade Sweep on Aerodynamic and Aeroacoustic Performance Optimization of Isolated Propellers. Master’s Thesis, TU Delft, Delft, The Netherlands, 2021. [Google Scholar]

- Pullin, S.F.; Ghiglino, A.; Zhou, B.Y.; Azarpeyvand, M. Rapid Optimisation of Propellers with Tonal and Broadband Aeroacoustic Constraints. In Proceedings of the AIAA AVIATION 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 3834. [Google Scholar] [CrossRef]

- Pinto, O.L.; Bossotto, G.; Afonso, F.; Lau, F. On Rotor Aeroacoustic Optimization for Urban Air Mobility. In Proceedings of the 28th AIAA/CEAS Aeroacoustics 2022 Conference, Southampton, UK, 14–17 June 2022; p. 2946. [Google Scholar] [CrossRef]

- Stirrat, S.; Afsar, M.Z.; Minisci, E. Assessment of optimization methods for aeroacoustic prediction of trailing-edge interaction noise in axisymmetric jets. Mathematics 2021, 9, 998. [Google Scholar] [CrossRef]

- Gen, M.; Cheng, R. Genetic Algorithms and Engineering Optimization; John Wiley & Sons: Hoboken, NJ, USA, 1999; Volume 7. [Google Scholar]

- Huang, X.; Sheng, L.; Wang, Y. Propeller synchrophase angle optimization of turboprop-driven aircraft—An experimental investigation. J. Eng. Gas Turbines Power 2014, 136, 112606. [Google Scholar] [CrossRef]

- Özkan, R.; Genç, M.S. Aerodynamic design and optimization of a small-scale wind turbine blade using a novel artificial bee colony algorithm based on blade element momentum (ABC-BEM) theory. Energy Convers. Manag. 2023, 283, 116937. [Google Scholar] [CrossRef]

- Kaviani, H.; Nejat, A. Aeroacoustic and aerodynamic optimization of a MW class HAWT using MOPSO algorithm. Energy 2017, 140, 1198–1215. [Google Scholar] [CrossRef]

- Hao, X.; Zhang, W.; Liu, X.; Liu, J. Aerodynamic and aeroacoustic optimization of wind turbine blade by a genetic algorithm. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; p. 1331. [Google Scholar] [CrossRef]

- Bai, B.; Li, X.; Chen, H. Aerodynamic and aeroacoustics optimization design of multi-element airfoil by a genetic algorithm. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2762. [Google Scholar] [CrossRef]

- Volkmer, K.; Carolus, T. Aeroacoustic airfoil shape optimization utilizing semi-empirical models for trailing edge noise prediction. In Proceedings of the 2018 AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 25–29 June 2018; p. 3130. [Google Scholar] [CrossRef]

- Lim, S.; Garbo, A.; Bekemeyer, P.; Appel, C.; Ewert, R.; Delfs, J. High-fidelity Aerodynamic and Aeroacoustic Multi-Objective Bayesian Optimization. In Proceedings of the AIAA Aviation 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022; p. 3354. [Google Scholar] [CrossRef]

- Liu, C.; Lee, S. Surrogate-based optimization for airfoil trailing-edge noise reduction using morphed trailing-edge shapes. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Seoul, Republic of Korea, 23–26 August 2020; pp. 2457–2466. [Google Scholar]

- Jim, T.M.; Faza, G.A.; Palar, P.S.; Shimoyama, K. Bayesian optimization of a low-boom supersonic wing planform. AIAA J. 2021, 59, 4514–4529. [Google Scholar] [CrossRef]

- Burgers, J.M. A mathematical model illustrating the theory of turbulence. Adv. Appl. Mech. 1948, 1, 171–199. [Google Scholar] [CrossRef]

- Rallabhandi, S.K. Advanced sonic boom prediction using the augmented Burgers equation. J. Aircr. 2011, 48, 1245–1253. [Google Scholar] [CrossRef]

- Wang, L.; Wang, T.-g.; Luo, Y. Improved non-dominated sorting genetic algorithm (NSGA)-II in multi-objective optimization studies of wind turbine blades. Appl. Math. Mech. 2011, 32, 739–748. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar] [CrossRef]

- da Silva Pinto, W.J.G.; Margnat, F. Shape optimization for the noise induced by the flow over compact bluff bodies. Comput. Fluids 2020, 198, 104400. [Google Scholar] [CrossRef]

- Li, Y.; Wei, K.; Yang, W.; Wang, Q. Improving wind turbine blade based on multi-objective particle swarm optimization. Renew. Energy 2020, 161, 525–542. [Google Scholar] [CrossRef]

- Ju, S.; Sun, Z.; Guo, D.; Yang, G.; Wang, Y.; Yan, C. Aerodynamic-Aeroacoustic Optimization of a Baseline Wing and Flap Configuration. Appl. Sci. 2022, 12, 1063. [Google Scholar] [CrossRef]

- Smagorinsky, J. General circulation experiments with the primitive equations: I. The basic experiment. Mon. Weather Rev. 1963, 91, 99–164. [Google Scholar] [CrossRef]

- Biedermann, T.; Reich, M.; Kameier, F.; Adam, M.; Paschereit, C. Assessment of statistical sampling methods and approximation models applied to aeroacoustic and vibroacoustic problems. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Chicago, IL, USA, 26–29 August 2018; pp. 13–24. [Google Scholar] [CrossRef]

- Fabiano, E.; Mavriplis, D. Adjoint-based aeroacoustic design-optimization of flexible rotors in forward flight. J. Am. Helicopter Soc. 2017, 62, 1–17. [Google Scholar] [CrossRef]

- Zhou, B.Y.; Albring, T.A.; Gauger, N.R.; Economon, T.D.; Palacios, F.; Alonso, J.J. A discrete adjoint framework for unsteady aerodynamic and aeroacoustic optimization. In Proceedings of the 16th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Dallas, TX, USA, 22–26 June 2015; p. 3355. [Google Scholar] [CrossRef]

- Zhou, B.Y.; Albring, T.A.; Gauger, N.R.; Economon, T.D.; Alonso, J.J. An efficient unsteady aerodynamic and aeroacoustic design framework using discrete adjoint. In Proceedings of the 17th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Washington, DC, USA, 13–17 June 2016; p. 3369. [Google Scholar] [CrossRef]

- Içke, R.Ö.; Baysal, O.; Lopes, L.V.; Zhou, B.Y.; Diskin, B.; Moy, A. Toward adjoint-based aeroacoustic optimization for propeller and rotorcraft applications. In Proceedings of the AIAA Aviation 2020 Forum, Online, 15–19 June 2020; p. 3140. [Google Scholar] [CrossRef]

- Vishnampet, R.; Bodony, D.J.; Freund, J.B. A practical discrete-adjoint method for high-fidelity compressible turbulence simulations. J. Comput. Phys. 2015, 285, 173–192. [Google Scholar] [CrossRef]

- Yuepeng, B.; Wenping, S.; Zhonghua, H.; Zhang, Y.; Zhang, L. Aerodynamic/aeroacoustic variable-fidelity optimization of helicopter rotor based on hierarchical Kriging model. Chin. J. Aeronaut. 2020, 33, 476–492. [Google Scholar] [CrossRef]

- Bu, Y.-P.; Song, W.-P.; Han, Z.-H.; Zhang, Y. Efficient aerostructural optimization of helicopter rotors toward aeroacoustic noise reduction using multilevel hierarchical kriging model. Aerosp. Sci. Technol. 2022, 127, 107683. [Google Scholar] [CrossRef]

- Zhou, B.Y.; Albring, T.; Gauger, N.R.; da Silva, C.R.; Economon, T.D.; Alonso, J.J. Efficient airframe noise reduction framework via adjoint-based shape optimization. AIAA J. 2021, 59, 580–595. [Google Scholar] [CrossRef]

- Suss, A.; Mary, I.; Le Garrec, T.; Marié, S. A hybrid lattice Boltzmann-Navier-Stokes method for unsteady aerodynamic and aeroacoustic computations. J. Comput. Phys. 2023, 485, 112098. [Google Scholar] [CrossRef]

- Poggi, C.; Rossetti, M.; Bernardini, G.; Iemma, U.; Andolfi, C.; Milano, C.; Gennaretti, M. Surrogate models for predicting noise emission and aerodynamic performance of propellers. Aerosp. Sci. Technol. 2022, 125, 107016. [Google Scholar] [CrossRef]

- Kim, J.-H.; Ovgor, B.; Cha, K.-H.; Kim, J.-H.; Lee, S.; Kim, K.-Y. Optimization of the aerodynamic and aeroacoustic performance of an axial-flow fan. AIAA J. 2014, 52, 2032–2044. [Google Scholar] [CrossRef]

- Jouhaud, J.-C.; Sagaut, P.; Montagnac, M.; Laurenceau, J. A surrogate-model based multidisciplinary shape optimization method with application to a 2D subsonic airfoil. Comput. Fluids 2007, 36, 520–529. [Google Scholar] [CrossRef]

- Marsden, A.L.; Wang, M.; Koumoutsakos, P.; Moin, P. Optimal aeroacoustic shape design using approximation modeling. Cent. Turb. Res. Briefs 2002, 201, 213. [Google Scholar]

- Liu, H.; Lu, Y.; Li, Y.; Wang, X. A bionic noise reduction strategy on the trailing edge of NACA0018 based on the central composite design method. Int. J. Aeroacoustics 2021, 20, 317–344. [Google Scholar] [CrossRef]

- Qiu, S.; Song, W.; Liu, H. Multi-objective optimization of airfoil trailing edge noise with three different measures. In Proceedings of the 18th AIAA/CEAS Aeroacoustics Conference (33rd AIAA Aeroacoustics Conference), Colorado Springs, CO, USA, 4–6 June 2012; p. 2182. [Google Scholar] [CrossRef]

- Vaezi, E.; Madani, S.A.S. A Novel Use of Artificial Intelligence for the Modeling of Wing Aeroacoustics: An Investigation on the Efficacy of Winglet Cant Angle; Sharif University of Technology: Tehran, Iran, 2021. [Google Scholar] [CrossRef]

- Traylor, C.; DiPaola, M.; Willis, D.J.; Inalpolat, M. A computational investigation of airfoil aeroacoustics for structural health monitoring of wind turbine blades. Wind Energy 2020, 23, 795–809. [Google Scholar] [CrossRef]

- Errasquin, L. Airfoil self-noise prediction using neural networks for wind turbines. Master’s Thesis, Virginia Tech, Blacksburg, VA, USA, 2009. [Google Scholar]

- Thurman, C.S.; Zawodny, N.S. Aeroacoustic characterization of optimum hovering rotors using artificial neural networks. In Proceedings of the The Vertical Flight Society’s 77th Annual Forum & Technology Display, Online, 10–14 May 2021. [Google Scholar]

- Kapteyn, M.G.; Knezevic, D.J.; Huynh, D.; Tran, M.; Willcox, K.E. Data-driven physics-based digital twins via a library of component-based reduced-order models. Int. J. Numer. Methods Eng. 2022, 123, 2986–3003. [Google Scholar] [CrossRef]

- Zarri, A.; Christophe, J.; Schram, C.F. Low-order aeroacoustic prediction of low-speed axial fan noise. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2760. [Google Scholar] [CrossRef]

- Li, J.; Zhang, M. Data-based approach for wing shape design optimization. Aerosp. Sci. Technol. 2021, 112, 106639. [Google Scholar] [CrossRef]

- Brown, K.; Fleming, J.; Langford, M.; Walton, W.; Ng, W.; Schwartz, K.; Wisda, D.; Burdisso, R. Reduced-Order Prediction of Unsteady Propeller Loading and Noise from Pylon Wake Ingestion. AIAA J. 2021, 59, 3304–3316. [Google Scholar] [CrossRef]

- Lopes, L.; Burley, C. Design of the next generation aircraft noise prediction program: ANOPP2. In Proceedings of the 17th AIAA/CEAS Aeroacoustics Conference (32nd AIAA Aeroacoustics Conference), Portland, OR, USA, 5–8 June 2011; p. 2854. [Google Scholar] [CrossRef]

- Dominique, J.; Van den Berghe, J.; Schram, C.; Mendez, M. Artificial neural networks modeling of wall pressure spectra beneath turbulent boundary layers. Phys. Fluids 2022, 34. [Google Scholar] [CrossRef]

- Nagata, T.; Nakai, K.; Yamada, K.; Saito, Y.; Nonomura, T.; Kano, M.; Ito, S.-i.; Nagao, H. Seismic wavefield reconstruction based on compressed sensing using data-driven reduced-order model. Geophys. J. Int. 2023, 233, 33–50. [Google Scholar] [CrossRef]

- Le Clainche, S.; Ferrer, E.; Gibson, S.; Cross, E.; Parente, A.; Vinuesa, R. Improving aircraft performance using machine learning: A review. Aerosp. Sci. Technol. 2023, 108354. [Google Scholar] [CrossRef]

- Li, J.; Zhang, M. On deep-learning-based geometric filtering in aerodynamic shape optimization. Aerosp. Sci. Technol. 2021, 112, 106603. [Google Scholar] [CrossRef]

- Peixun, Y.; Jiahui, P.; Junqiang, B.; Xiao, H.; Xiang, S. Aeroacoustic and aerodynamic optimization of propeller blades. Chin. J. Aeronaut. 2020, 33, 826–839. [Google Scholar] [CrossRef]

- Lui, H.F.; Wolf, W.R. Construction of reduced-order models for fluid flows using deep feedforward neural networks. J. Fluid Mech. 2019, 872, 963–994. [Google Scholar] [CrossRef]

- Rastgoo, A.; Khajavi, H. A novel study on forecasting the Airfoil self-noise, using a hybrid model based on the combination of CatBoost and Arithmetic Optimization Algorithm. Expert Syst. Appl. 2023, 120576. [Google Scholar] [CrossRef]

- Tam, C.; Kurbatskii, K. An optimized extrapolation and interpolation method for computational aeroacoustics. In Proceedings of the 38th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–12 January 2001; p. 218. [Google Scholar] [CrossRef]

- Shubham, S.; Wright, N.; Ianakiev, A. Application of Richardson extrapolation method to aerodynamic and aeroacoustic characteristics of low Reynolds number vertical axis wind turbines. In Proceedings of the 28th AIAA/CEAS Aeroacoustics 2022 Conference, Southampton, UK, 14–17 June 2022; p. 3022. [Google Scholar] [CrossRef]

- Seid, K.-H.; Gilka, G.; Leung, R.; Thiele, F. A Comparison Study of Reduced Order Models for Aeroacoustic Applications. In Proceedings of the 18th AIAA/CEAS Aeroacoustics Conference (33rd AIAA Aeroacoustics Conference), Colorado Springs, CO, USA, 4–6 June 2012; p. 2072. [Google Scholar] [CrossRef]

- Arina, R.; Pinti, O. Aeroacoustic Reduced-Order Models Based on a priori/posteriori Data Analysis. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2680. [Google Scholar] [CrossRef]

- González, A.E. Overview of Noise Control Techniques and Methods; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Pendar, M.-R.; Páscoa, J.C. Numerical investigation of plasma actuator effects on flow control over a three-dimensional airfoil with a sinusoidal leading edge. J. Fluids Eng. 2022, 144, 081208. [Google Scholar] [CrossRef]

- Fink, M.; Bailey, D. Airframe Noise Reduction Studies and Clean-Airframe Noise Investigation; Contractor Report (CR); NASA: Washington, DC, USA, 1980. [Google Scholar]

- Deuse, M.; Sandberg, R.D. Parametric study of multiple aerofoil self-noise sources using direct noise computation. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2681. [Google Scholar] [CrossRef]

- Lee, D.-J.; Heo, D.N.; Lee, I.C.; Kim, J.W. CAA application for the feedback mechanism in cavity and jet. In Proceedings of the Acoustical Society of Japan, Kyoto, Japan, 4–9 April 2004; pp. 1307–1310. [Google Scholar]

- Zhang, Y.; Cao, H.; Liu, X.; Qi, L. Effect of the leading-edge protuberances on the aeroacoustic and aerodynamic performances of the wind turbine airfoil. Ocean. Eng. 2022, 266, 113153. [Google Scholar] [CrossRef]

- Trembois, N.P.; Jacobellis, G. Broadband Noise Prediction from Leading Edge Turbulence Quantities. J. Test Eval. 2023, 44, 1–9. [Google Scholar]

- dos Santos, F.L.; Botero-Bolívar, L.; Venner, C.; de Santana, L.D. Modeling the turbulence spectrum dissipation range for leading-edge noise prediction. AIAA J. 2022, 60, 3581–3592. [Google Scholar] [CrossRef]

- Jabbari, H.; Ali, E.; Djavareshkian, M.H. Acoustic and phase portrait analysis of leading-edge roughness element on laminar separation bubbles at low Reynolds number flow. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2022, 236, 1782–1798. [Google Scholar] [CrossRef]

- Wang, J.; Ishibashi, K.; Ikeda, T.; Fujii, T.; Nakata, T.; Liu, H. Morphological effects of leading-edge serrations on the acoustic signatures of mixed flow fan. Phys. Fluids 2022, 34. [Google Scholar] [CrossRef]

- Kim, J.-H.; Choi, K.-S.; Lacagnina, G.; Chaitanya, P.; Joseph, P.; Hasheminejad, S.; Pei Chong, T.; Shahab, M.; Omidyeganeh, M.; Pinelli, A. Aerodynamic and Aeroacoustic Optimization of Leading-Edge Undulation of a NACA 65 (12)-10 Airfoil. AIAA J. 2022, 60, 2342–2353. [Google Scholar] [CrossRef]

- Lu, Y.; Li, Z.; Chang, X.; Chuang, Z.; Xing, J. An aerodynamic optimization design study on the bio-inspired airfoil with leading-edge tubercles. Eng. Appl. Comput. Fluid Mech. 2021, 15, 292–312. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Lyu, B.; Ayton, L.J.; Chaitanya, P. On the acoustic optimality of leading-edge serration profiles. J. Sound Vib. 2019, 462, 114923. [Google Scholar] [CrossRef]

- Jacob, M.C.; Boudet, J.; Casalino, D.; Michard, M. A rod-airfoil experiment as a benchmark for broadband noise modeling. Theor. Comput. Fluid Dyn. 2005, 19, 171–196. [Google Scholar] [CrossRef]

- Jacob, M.; Ciardi, M.; Gamet, L.; Greschner, B.; Moon, Y.; Vallet, I. Assessment of CFD broadband noise predictions on a rod-airfoil benchmark computation. In Proceedings of the 14th AIAA/CEAS Aeroacoustics Conference (29th AIAA Aeroacoustics Conference), Vancouver, BC, Canada, 5–7 May 2008; p. 2899. [Google Scholar] [CrossRef]

- Agrawal, B.R.; Sharma, A. Numerical analysis of aerodynamic noise mitigation via leading edge serrations for a rod–airfoil configuration. Int. J. Aeroacoustics 2016, 15, 734–756. [Google Scholar] [CrossRef]

- Hatakeyama, N.; Inoue, O. A novel application of Curle’s acoustic analogy to aeolian tones in two dimensions. Phys. Fluids 2004, 16, 1297–1304. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, F.; Jin, F.; Xiao, R.; Tao, R. Influence of the hydrofoil trailing-edge shape on the temporal-spatial features of vortex shedding. Ocean Eng. 2022, 246, 110645. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X. Aeroacoustic investigation of asymmetric oblique trailing-edge serrations enlighted by owl wings. Phys. Fluids 2022, 34, 015113. [Google Scholar] [CrossRef]

- Liu, H.; Hu, Z.; Chen, N.; Liu, Y.; Fan, H. Structured porous blunt trailing edge with uniform and non-uniform parameters for vortex shedding noise reduction. Appl. Acoust. 2023, 206, 109302. [Google Scholar] [CrossRef]

- Feng, W.; Chen, K.; Gui, H.; Zhao, P.; Gao, R.; Li, Y. Aerodynamic Noise Reduction Based on Bionic Blades with Non-Smooth Leading Edges and Curved Serrated Trailing Edges. J. Appl. Fluid Mech. 2023, 16, 1402–1413. [Google Scholar] [CrossRef]

- Song, B.; Xu, L.; Zhang, K.; Cai, J. Numerical study of trailing-edge noise reduction mechanism of wind turbine with a novel trailing-edge serration. Phys. Scr. 2023, 98, 065209. [Google Scholar] [CrossRef]

- Ji, X.; Wang, L.; Ravi, S.; Tian, F.-B.; Young, J.; Lai, J. Influences of serrated trailing edge on the aerodynamic and aeroacoustic performance of a flapping wing during hovering flight. Phys. Fluids 2022, 34, 011902. [Google Scholar] [CrossRef]

- Tian, H.; Lyu, B. Prediction of broadband noise from rotating blade elements with serrated trailing edges. Phys. Fluids 2022, 34, 085109. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Wu, L.; Li, D. Effect of the asymmetric bio-inspired trailing-edge serrations on sound suppression in a coupled owl-based airfoil. Appl. Acoust. 2022, 191, 108667. [Google Scholar] [CrossRef]

- Jiang, C.; Fischer, J.R.; Moreau, D.; Doolan, C.J. Experimental investigation of novel porous-serrated treatments on airfoil trailing edge noise reduction. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2435. [Google Scholar] [CrossRef]

- Hasheminejad, S.M.; Chong, T.P.; Lacagnina, G.; Joseph, P.; Kim, J.-H.; Choi, K.-S.; Omidyeganeh, M.; Pinelli, A.; Stalnov, O. On the manipulation of flow and acoustic fields of a blunt trailing edge aerofoil by serrated leading edges. J. Acoust. Soc. Am. 2020, 147, 3932–3947. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, W.; Li, T.-y. Numerical investigation on noise reduction mechanism of serrated trailing edge installed on a pump-jet duct. Ocean Eng. 2019, 191, 106489. [Google Scholar] [CrossRef]

- Luesutthiviboon, S.; Lima Pereira, L.T.; Ragni, D.; Avallone, F.; Snellen, M. Aeroacoustic Benchmarking of Trailing-Edge Noise from NACA 63 3–018 Airfoil with Trailing-Edge Serrations. AIAA J. 2023, 61, 329–354. [Google Scholar] [CrossRef]

- Herr, M.; Dobrzynski, W. Experimental Investigations in Low-Noise Trailing Edge Design. AIAA J. 2005, 43, 1167–1175. [Google Scholar] [CrossRef]

- Moreau, D.; Doolan, C. The generation of tonal noise from sawtooth trailing-edge serrations at low Reynolds numbers. Aeronaut. J. 2016, 120, 971–983. [Google Scholar] [CrossRef]

- Singh, S.K.; Narayanan, S. Control of airfoil broadband noise through non-uniform sinusoidal trailing-edge serrations. Phys. Fluids 2023, 35, 025139. [Google Scholar] [CrossRef]

- Arif, I.; Leung, R.C.; Naseer, M.R. A computational study of trailing edge noise suppression with embedded structural compliance. JASA Express Lett. 2023, 3, 023602. [Google Scholar] [CrossRef]

- Vathylakis, A.; Paruchuri, C.C.; Chong, T.P.; Joseph, P. Sensitivity of aerofoil self-noise reductions to serration flap angles. In Proceedings of the 22nd AIAA/CEAS Aeroacoustics Conference, Lyon, France, 30 May–1 June 2016; p. 2837. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Abbasi Parizad, F. Effects of splitter geometry as a passive control method on sound pressure level, a mathematical modeling. Int. J. Mod. Phys. C 2023, 34, 2350139. [Google Scholar] [CrossRef]

- Jones, L.; Sandberg, R. Numerical investigation of airfoil self-noise reduction by addition of trailing-edge serrations. In Proceedings of the 16th AIAA/CEAS Aeroacoustics Conference, Stockholm, Sweden, 7–9 June 2010; p. 3703. [Google Scholar] [CrossRef]

- Song, K. Numerical Investigation of Flatback Airfoils Drag and Noise Reduction by a Splitter Plate. IOP Conf. Ser. Earth Environ. Sci. 2020, 495, 012081. [Google Scholar] [CrossRef]

- Zuo, Z.; Huang, Q.; Liu, S. An analysis on the flow field structures and the aerodynamic noise of airfoils with serrated trailing edges based on embedded large eddy flow simulations. J. Appl. Fluid Mech. 2019, 12, 327–339. [Google Scholar] [CrossRef]

- Tehranizadeh, F.; Koca, R.; Budak, E. Investigating effects of serration geometry on milling forces and chatter stability for their optimal selection. Int. J. Mach. Tools Manuf. 2019, 144, 103425. [Google Scholar] [CrossRef]

- Hu, Y.-S.; Zhang, P.-J.-Y.; Wan, Z.-H.; Liu, N.-S.; Sun, D.-J.; Lu, X.-Y. Effects of trailing-edge serration shape on airfoil noise reduction with zero incidence angle. Phys. Fluids 2022, 34, 105108. [Google Scholar] [CrossRef]

- Gelot, M.B.; Kim, J.W. Effect of serrated trailing edges on aerofoil tonal noise. J. Fluid Mech. 2020, 904, A30. [Google Scholar] [CrossRef]

- Gelot, M.B.; Kim, J.W. Aerofoil tonal noise reduction using serrated trailing edges. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Seoul, Republic of Korea, 23–26 August 2020; pp. 2500–2508. [Google Scholar]

- Lyu, B.; Azarpeyvand, M.; Sinayoko, S. Prediction of noise from serrated trailing edges. J. Fluid Mech. 2016, 793, 556–588. [Google Scholar] [CrossRef]

- Llorente, E.; Ragni, D. Trailing-edge serrations effect on the performance of a wind turbine. Renew. Energy 2020, 147, 437–446. [Google Scholar] [CrossRef]

- Chong, T.P.; Vathylakis, A. On the aeroacoustic and flow structures developed on a flat plate with a serrated sawtooth trailing edge. J. Sound Vib. 2015, 354, 65–90. [Google Scholar] [CrossRef]

- Tang, H.; Lei, Y.; Fu, Y. Noise reduction mechanisms of an airfoil with trailing edge serrations at low Mach number. Appl. Sci. 2019, 9, 3784. [Google Scholar] [CrossRef]

- Pan, Y. Perturbation solution of the Navier–Stokes equations and its relation to the Lighthill–Curle solution of aerodynamic sound. J. Acoust. Soc. Am. 1975, 58, 794–799. [Google Scholar] [CrossRef]

- Gruber, M.; Joseph, P.; Chong, T. On the mechanisms of serrated airfoil trailing edge noise reduction. In Proceedings of the 17th AIAA/CEAS Aeroacoustics Conference (32nd AIAA Aeroacoustics Conference), Portland, OR, USA, 5–8 June 2011; p. 2781. [Google Scholar] [CrossRef]

- Avallone, F.; Van der Velden, W.; Ragni, D. Benefits of curved serrations on broadband trailing-edge noise reduction. J. Sound Vib. 2017, 400, 167–177. [Google Scholar] [CrossRef]

- Lu, J.; Lei, H.; Dai, C.; Yang, L.; Shu, C. Analyses and reconstruction of the lattice Boltzmann flux solver. J. Comput. Phys. 2022, 453, 110923. [Google Scholar] [CrossRef]

- Woodhead, P.; Chong, T.; Joseph, P.; Vathylakis, A. Aerofoil self-noise radiations subjected to serration flap angles. Exp. Fluids 2021, 62, 1–22. [Google Scholar] [CrossRef]

- Woodhead, P.C.; Chong, T.P.; Wissink, J. Exploiting the misalignment of the serrated trailing edge for improved aerofoil broadband noise reduction. In Proceedings of the 23rd AIAA/CEAS Aeroacoustics Conference, Denver, CO, USA, 5–9 June 2017; p. 4175. [Google Scholar] [CrossRef]

- Kholodov, P.; Moreau, S. Optimization of trailing-edge serrations with and without slits for broadband noise reduction. J. Sound Vib. 2021, 490, 115736. [Google Scholar] [CrossRef]

- Ayton, J. A new method for the prediction of industrial noise. Appl. Acoust. 1979, 12, 245–257. [Google Scholar]

- Ayton, L.J. Analytic solution for aerodynamic noise generated by plates with spanwise-varying trailing edges. J. Fluid Mech. 2018, 849, 448–466. [Google Scholar] [CrossRef]

- Noble, B.; Weiss, G. Methods based on the Wiener-Hopf technique for the solution of partial differential equations. Phys. Today 1959, 12, 50. [Google Scholar] [CrossRef]

- Lawrie, J.B.; Abrahams, I.D. A brief historical perspective of the Wiener–Hopf technique. J. Eng. Math. 2007, 59, 351–358. [Google Scholar] [CrossRef]

- Daniele, V. On the solution of two coupled Wiener–Hopf equations. SIAM J. Appl. Math. 1984, 44, 667–680. [Google Scholar] [CrossRef]

- Masujima, M. Applied Mathematical Methods in Theoretical Physics; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Roger, M.; Schram, C.; De Santana, L. Reduction of airfoil turbulence-impingement noise by means of leading-edge serrations and/or porous material. In Proceedings of the 19th AIAA/CEAS Aeroacoustics Conference, Berlin, Germany, 27–29 May 2013; p. 2108. [Google Scholar] [CrossRef]

- Zhou, T.; Cao, H.; Zhang, M.; Liao, C. Performance simulation of wind turbine with optimal designed trailing-edge serrations. Energy 2022, 243, 122998. [Google Scholar] [CrossRef]

- Gruber, M. Airfoil noise reduction by edge treatments. Doctoral Thesis, University of Southampton, Southampton, UK, 2012. [Google Scholar]

- Oerlemans, S.; Fisher, M.; Maeder, T.; Kögler, K. Reduction of wind turbine noise using optimized airfoils and trailing-edge serrations. AIAA J. 2009, 47, 1470–1481. [Google Scholar] [CrossRef]

- Chen, E.; Ma, Y.; Yang, A.; Zhao, G. Experimental investigation on noise emissions of an airfoil with non-flat plate trailing edge serrations. J. Mech. Sci. Technol. 2019, 33, 3069–3074. [Google Scholar] [CrossRef]

- Chong, T.P.; Vathylakis, A.; Joseph, P.F.; Gruber, M. Self-noise produced by an airfoil with nonflat plate trailing-edge serrations. AIAA J. 2013, 51, 2665–2677. [Google Scholar] [CrossRef]

- Chong, T.; Joseph, P.; Gruber, M. Airfoil self noise reduction by non-flat plate type trailing edge serrations. Appl. Acoust. 2013, 74, 607–613. [Google Scholar] [CrossRef]

- Zhou, P.; Liu, Q.; Zhong, S.; Fang, Y.; Zhang, X. A study of the effect of serration shape and flexibility on trailing edge noise. Phys. Fluids 2020, 32, 127114. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, P.; Guo, H.; Hu, T.; Zhang, J. Experimental study of far-field aerodynamic noise characteristics of serrated slat. J. Aerosp. Eng. 2023, 36, 04022104. [Google Scholar] [CrossRef]

- Al Tlua, B.; Rocha, J. On the Effect of Trailing-Edge Bluntness on Airfoil Noise. Can. Acoust. 2022, 50, 5–10. [Google Scholar]

- Al Tlua, B.; Joana, R. Optimization and testing of flat-plate trailing-edge serration geometry for reducing airfoil self-noise. Can. Acoust. 2020, 48, 7–18. [Google Scholar]

- Van Blitterswyk, J.; Rocha, J. An experimental study of the wall-pressure fluctuations beneath low Reynolds number turbulent boundary layers. J. Acoust. Soc. Am. 2017, 141, 1257–1268. [Google Scholar] [CrossRef]

- Maddula, S.P.; Nukala, V.B.; Neigapula, V.S.N. Trailing Edge Thickness Effect on Tonal Noise Emission Characteristics from Wind Turbine Blades. INCAS Bull. 2021, 13, 99–111. [Google Scholar] [CrossRef]

- Zhu, W.J.; Shen, W.Z.; Sørensen, J.N.; Leloudas, G. Improvement of airfoil trailing edge bluntness noise model. Adv. Mech. Eng. 2016, 8, 1687814016629343. [Google Scholar] [CrossRef]

- Michelsen, J.A. Basis3D-a platform for development of multiblock PDE solvers. Rep. AFM 1992, 92, 5. [Google Scholar]

- Sørensen, N.N. General purpose flow solver applied to flow over hills. Doctoral Thesis, Danmarks Tekniske University (DTU), Kongens Lyngby, Denmark, 1995. [Google Scholar]

- Tu, J.; Yeoh, G.H.; Liu, C. Computational Fluid Dynamics: A Practical Approach; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Boyer, F.; Fabrie, P. Mathematical Tools for the Study of the Incompressible Navier-Stokes Equations andRelated Models; Springer Science & Business Media: Berlin, Germany, 2012; Volume 183. [Google Scholar]

- Franca, L.P.; Frey, S.L. Stabilized finite element methods: II. The incompressible Navier-Stokes equations. Comput. Methods Appl. Mech. Eng. 1992, 99, 209–233. [Google Scholar] [CrossRef]

- Feng, D.; Li, Y.; Pan, W.; Li, M.; Wei, L. Nonflat-Plate Transition-Serrated Trailing Edge for Airfoil Self-Noise Reduction. AIAA J. 2022, 1–11. [Google Scholar] [CrossRef]

- Herr, M.; Rossignol, K.-S.; Delfs, J.; Lippitz, N.; Mößner, M. Specification of porous materials for low-noise trailing-edge applications. In Proceedings of the 20th AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 16–20 June 2014; p. 3041. [Google Scholar] [CrossRef]

- Jaworski, J.W.; Peake, N. Aerodynamic noise from a poroelastic edge with implications for the silent flight of owls. J. Fluid Mech. 2013, 723, 456–479. [Google Scholar] [CrossRef]

- Teruna, C.; Avallone, F.; Casalino, D.; Ragni, D. Numerical investigation of leading edge noise reduction on a rod-airfoil configuration using porous materials and serrations. J. Sound Vib. 2021, 494, 115880. [Google Scholar] [CrossRef]

- Zamponi, R.; Van de Wyer, N.; Schram, C.F. Experimental investigation of airfoil turbulence-impingement noise reduction using porous treatment. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2649. [Google Scholar] [CrossRef]

- Ananthan, V.B.; Bernicke, P.; Akkermans, R.; Hu, T.; Liu, P. Effect of porous material on trailing edge sound sources of a lifting airfoil by zonal overset-LES. J. Sound Vib. 2020, 480, 115386. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, J.; Sun, Z.; Cao, J.; Guo, G.; Shen, W. Numerical Study on Flow and Noise Characteristics of an NACA0018 Airfoil with a Porous Trailing Edge. Sustainability 2022, 15, 275. [Google Scholar] [CrossRef]

- Ikami, T.; Fujita, K.; Nagai, H. Unsteady Flow Field on Wing Surface in Propeller Slipstream at Low Reynolds Number. In Proceedings of the AIAA AVIATION 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022; p. 3983. [Google Scholar] [CrossRef]

- Go, S.T.; Kingan, M.J.; McKay, R.S.; Sharma, R.N. Turbulent inflow noise produced by a shrouded propeller. J. Sound Vib. 2023, 542, 117366. [Google Scholar] [CrossRef]

- Hunt, J.C.; Carruthers, D.J. Rapid distortion theory and the ‘problems’ of turbulence. J. Fluid Mech. 1990, 212, 497–532. [Google Scholar] [CrossRef]

- Carpio, A.R.; Merino Martinez, R.; Avallone, F.; Ragni, D.; Snellen, M.; van der Zwaag, S. Broadband trailing edge noise reduction using permeable metal foams. In Proceedings of the Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Hong Kong, China, 27–30 August 2017; p. 2755. [Google Scholar]

- Chaitanya, P.; Joseph, P.; Chong, T.P.; Priddin, M.; Ayton, L. On the noise reduction mechanisms of porous aerofoil leading edges. J. Sound Vib. 2020, 485, 115574. [Google Scholar] [CrossRef]

- Teruna, C.; Avallone, F.; Ragni, D.; Casalino, D. On the noise reduction of a porous trailing edge applied to an airfoil at lifting condition. Phys. Fluids 2021, 33, 055132. [Google Scholar] [CrossRef]

- Carpio, A.R.; Martínez, R.M.; Avallone, F.; Ragni, D.; Snellen, M.; van der Zwaag, S. Experimental characterization of the turbulent boundary layer over a porous trailing edge for noise abatement. J. Sound Vib. 2019, 443, 537–558. [Google Scholar] [CrossRef]

- Ayton, L.J.; Colbrook, M.J.; Geyer, T.F.; Chaitanya, P.; Sarradj, E. Reducing aerofoil–turbulence interaction noise through chordwise-varying porosity. J. Fluid Mech. 2021, 906. [Google Scholar] [CrossRef]

- Colbrook, M.J.; Kisil, A.V. A Mathieu function boundary spectral method for scattering by multiple variable poro-elastic plates, with applications to metamaterials and acoustics. Proc. R. Soc. A 2020, 476, 20200184. [Google Scholar] [CrossRef]

- Colbrook, M.J.; Priddin, M.J. Fast and spectrally accurate numerical methods for perforated screens (with applications to Robin boundary conditions). IMA J. Appl. Math. 2020, 85, 790–821. [Google Scholar] [CrossRef]

- Vathylakis, A.; Chong, T.P.; Joseph, P.F. Poro-serrated trailing-edge devices for airfoil self-noise reduction. AIAA J. 2015, 53, 3379–3394. [Google Scholar] [CrossRef]

- Jaiswal, P.; Rendón, J.; Moreau, S. Aeroacoustic investigation of airfoil at near stall conditions. arXiv preprint 2023, arXiv:2307.02109. [Google Scholar] [CrossRef]

- Kalyani, S.K.; Moreau, S.; Ragni, D. Flow-field and Noise Characterization of a Controlled-Diffusion Airfoil subject to flow separation and stall. In Proceedings of the 8th AIAA/CEAS Aeroacoustics 2022 Conference, Southampton, UK, 14–17 June 2022. [Google Scholar] [CrossRef]

- Sanjose, M.; Méon, C.; Moreau, S.; Idier, A.; Laffay, P. Direct numerical simulation of acoustic reduction using serrated trailing-edge on an isolated airfoil. In Proceedings of the 20th AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 16–20 June 2014; p. 2324. [Google Scholar]

- Moreau, S.; Sanjosé, M.; Lyu, B.; Ayton, L.J. Analytical, numerical and experimental investigation of trailing-edge noise reduction on a Controlled Diffusion airfoil with serrations. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2450. [Google Scholar] [CrossRef]

- Lyu, B.; Ayton, L.J. Rapid noise prediction models for serrated leading and trailing edges. J. Sound Vib. 2020, 469, 115136. [Google Scholar] [CrossRef]

- Sanjose, M.; Towne, A.; Jaiswal, P.; Moreau, S.; Lele, S.; Mann, A. Modal analysis of the laminar boundary layer instability and tonal noise of an airfoil at Reynolds number 150,000. Int. J. Aeroacoustics 2019, 18, 317–350. [Google Scholar] [CrossRef]

- Kholodov, P.; Moreau, S. Optimization of serrations for broadband trailing-edge noise reduction using an analytical model. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2655. [Google Scholar] [CrossRef]

- Kholodov, P.; Moreau, S. Numerical study of optimized airfoil trailing-edge serrations for broadband noise reduction. In Proceedings of the AIAA AVIATION 2020 FORUM, Online, 15–19 June 2020; p. 2541. [Google Scholar] [CrossRef]

- Harbi Monfared, R.; Taeibi Rahni, M.; Zareh, M.; Ahmadi, G.; Etemadi Haghighi, S. Aerodynamic and Aeroacoustic Performance of a Wing with Structured Surface Inspired by Owl’s Wings. J. Appl. Fluid Mech. 2022, 15, 1243–1253. [Google Scholar] [CrossRef]

- Jawahar, H.K.; Vemuri, S.S.; Azarpeyvand, M. Aerodynamic noise characteristics of airfoils with morphed trailing edges. Int. J. Heat Fluid Flow 2022, 93, 108892. [Google Scholar] [CrossRef]

- Harbi Monfared, R.; Taeibi Rahni, M.; Zareh, M. Aerodynamic/Aeroacoustic Numerical Simulation and Manufaturing of a Sample Morphing Wing in Twisted Mode. Technol. Aerosp. Eng. 2023, 7, 1–9. [Google Scholar] [CrossRef]

- Ameduri, S.; Concilio, A.; Visingardi, A.; Federico, L.; Barbarino, M.; Vitagliano, P.L. Aeroacoustic and Structural Achievements for a Morphing Blade Twist System Developed for the European Project “Shape Adaptive Blades for Rotorcraft Efficiency”. In Proceedings of the Smart Materials, Adaptive Structures and Intelligent Systems, Dearborn, MI, USA, 12–14 September 2022; p. V001T004A009. [Google Scholar] [CrossRef]

- Bashir, M.; Longtin-Martel, S.; Botez, R.M.; Wong, T. Aerodynamic Design Optimization of a Morphing Leading Edge and Trailing Edge Airfoil–Application on the UAS-S45. Appl. Sci. 2021, 11, 1664. [Google Scholar] [CrossRef]

- Kharal, A.; Saleem, A. Neural networks based airfoil generation for a given Cp using Bezier–PARSEC parameterization. Aerosp. Sci. Technol. 2012, 23, 330–344. [Google Scholar] [CrossRef]

- Bashir, M.; Longtin Martel, S.; Botez, R.M.; Wong, T. Aerodynamic shape optimization of camber morphing airfoil based on black widow optimization. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022; p. 2575. [Google Scholar] [CrossRef]

- Bashir, M.; Longtin-Martel, S.; Botez, R.M.; Wong, T. Aerodynamic Design and Shape Optimization of the UAS-S45 Camber Adaptive Winglet. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022. [Google Scholar] [CrossRef]

- Kammegne, M.J.T.; Botez, R.M.; Grigorie, L.T.; Mamou, M.; Mébarki, Y. Proportional fuzzy feed-forward architecture control validation by wind tunnel tests of a morphing wing. Chin. J. Aeronaut. 2017, 30, 561–576. [Google Scholar] [CrossRef]

- Valldosera Martinez, R.; Afonso, F.; Lau, F. Aerodynamic Shape Optimisation of a Camber Morphing Airfoil and Noise Estimation. Aerospace 2022, 9, 43. [Google Scholar] [CrossRef]

- Spalart, P.; Allmaras, S. A one-equation turbulence model for aerodynamic flows. In Proceedings of the 30th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1992; p. 439. [Google Scholar] [CrossRef]

- Farassat, F. Theory of Noise Generation from Moving Bodies with an Application to Helicopter Rotors; Technical Report (TR); NASA: Washington, DC, USA, 1975. [Google Scholar]

- Schweikert, M.; Patel, K.; Kanistras, K. Development of an Optimization Framework for a Circulation Control Morphing Wing. In Proceedings of the AIAA AVIATION 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022; p. 3355. [Google Scholar] [CrossRef]

- Bao, N.; Peng, Y.; Feng, H.; Yang, C. Multi-objective aerodynamic optimization design of variable camber leading and trailing edge of airfoil. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 4748–4765. [Google Scholar] [CrossRef]

- Lotov, A.V.; Miettinen, K. Visualizing the Pareto Frontier. Multiobjective Optim. 2008, 5252, 213–243. [Google Scholar]

- Curle, N. The influence of solid boundaries upon aerodynamic sound. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1955, 231, 505–514. [Google Scholar] [CrossRef]

- Marouf, A.; Simiriotis, N.; Tô, J.; Carvalho, M.; Bmegaptche, Y.; Kitouni, A.; Hoarau, Y.; Rouchon, J.; Braza, M. Smart Morphing and Sensing for the Wings of the Future. In Advances in Computational Methods and Technologies in Aeronautics and Industry; Springer: Berlin/Heidelberg, Germany, 2022; pp. 17–36. [Google Scholar] [CrossRef]

- Bodling, A.; Agrawal, B.R.; Sharma, A.; Clark, I.; Alexander, W.N.; Devenport, W.J. Numerical investigation of bio-inspired blade designs at high reynolds numbers for ultra-quiet aircraft and wind turbines. In Proceedings of the 23rd AIAA/CEAS Aeroacoustics Conference, Denver, CO, USA, 5–9 June 2017; p. 3502. [Google Scholar] [CrossRef]

- Gstrein, F.; Zang, N.; Azarpeyvand, M. Application of Finlets for Trailing Edge Noise Reduction of a NACA 0012 Airfoil. In Proceedings of the AIAA Aviation 2020 Forum, Online, 15–19 June 2020; p. 2502. [Google Scholar] [CrossRef]

- Salama, Y.; Rocha, J. Aeroacustic and aerodynamic investigating of a new airfoil trailing-edge noise-suppressing design. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Washington, DC, USA, 1–5 August 2021; pp. 1652–1663. [Google Scholar] [CrossRef]

- Liu, J.; Khine, Y.Y.; Saleem, M.; Lopez Rodriguez, O.; Gutmark, E. Supersonic jet noise reduction using micro vortex generators. In Proceedings of the AIAA Aviation 2021 Forum, Virtual Event, 2–6 August 2021; p. 2183. [Google Scholar] [CrossRef]

- Liu, J.; Khine, Y.Y.; Saleem, M.; Lopez Rodriguez, O.; Gutmark, E.J. Effect of axial location of micro vortex generators on supersonic jet noise reduction. In Proceedings of the AIAA Scitech 2022 Forum, San Diego, CA, USA, 3–7 January 2022; p. 1791. [Google Scholar] [CrossRef]

- Murayama, M.; Yamamoto, K.; Takaishi, T.; Ito, Y.; Ura, H.; Yokokawa, Y.; Tanaka, K.; Hirai, T. Airframe noise reduction of flap side-edge using vortex generators. In Proceedings of the 23rd AIAA/CEAS Aeroacoustics Conference, Denver, CO, USA, 5–9 June 2017; p. 4030. [Google Scholar] [CrossRef]

- Cene, A.; Manolesos, M.; Grasso, F. Aerodynamic and Aeroacoustic Measurements of the Flow Past a Very Thick Flatback Airfoil with Passive Flow Control Devices. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022; p. 0279. [Google Scholar] [CrossRef]

- Sundeep, S.; Zhou, P.; Zheng, C.; Jiang, H.; Zhong, S.; Zhang, X. Enhancing the noise reduction capability of serrations usinglow-profile vortex generators. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Grand Rapids, MI, USA, 15–18 May 2023; pp. 4006–4017. [Google Scholar] [CrossRef]

- Smith, T.; Klettner, C. Airfoil trailing-edge noise and drag reduction at a moderate Reynolds number using wavy geometries. Phys. Fluids 2022, 34, 117107. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Wu, Z.; Wharton, J.; Ren, L. Numerical study on reduction of aerodynamic noise around an airfoil with biomimetic structures. J. Sound Vib. 2017, 394, 46–58. [Google Scholar] [CrossRef]

- Ananthan, V.B.; Akkermans, R.A.; Hu, T.; Liu, P.Q.; Rathje, N. Trailing-edge noise reduction potential of a locally applied shallow dimpled surface. J. Sound Vib. 2022, 525, 116745. [Google Scholar] [CrossRef]

- Perry, C.L. Mitigation of Aeroacoustic Noise of a Fixed Wing Using Passive Flow Control. Master’s, Thesis, Georgia Southern University, Statesboro, GA, USA, 2023. [Google Scholar]

- Zhang, C.; Cheng, W.; Du, T.; Sun, X.; Shen, C.; Chen, Z.; Liang, D. Experimental and numerical study on noise reduction of airfoil with the bioinspired ridge-like structure. Appl. Acoust. 2023, 203, 109190. [Google Scholar] [CrossRef]

- Muhammad, C.; Chong, T.P. A Feasibility Study of Riblet for Aeroacoustics Applications. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Grand Rapids, MI, USA, 15–18 May 2023; pp. 3638–3649. [Google Scholar] [CrossRef]

- Sadraey, M.H. Aircraft Design: A Systems Engineering Approach; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Piliouras, N.; Kalatzis, I.; Dimitropoulos, N.; Cavouras, D. Development of the cubic least squares mapping linear-kernel support vector machine classifier for improving the characterization of breast lesions on ultrasound. Comput. Med. Imaging Graph. 2004, 28, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016; Available online: https://mitpress.mit.edu/9780262035613/deep-learning/ (accessed on 10 June 2023).

- Smith, T.; Ventikos, Y. Wing-tip vortex dynamics at moderate Reynolds numbers. Phys. Fluids 2021, 33. [Google Scholar] [CrossRef]

- Moreau, D.J.; Doolan, C.J. Tonal noise production from a wall-mounted finite airfoil. J. Sound Vib. 2016, 363, 199–224. [Google Scholar] [CrossRef]

- Fleig, O.; Iida, M.; Arakawa, C. Wind turbine blade tip flow and noise prediction by large-eddy simulation. J. Sol. Energy Eng. 2004, 126, 1017–1024. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Zhang, D. Control strategies for aircraft airframe noise reduction. Chin. J. Aeronaut. 2013, 26, 249–260. [Google Scholar] [CrossRef]

- Yamamoto, K.; Murayama, M.; Isotani, K.; Ueno, Y.; Hayashi, K.; Hirai, T. Slat Noise Reduction Based on Turbulence Attenuation Downstream of Shear-layer Reattachment. In Proceedings of the 28th AIAA/CEAS Aeroacoustics 2022 Conference, Southampton, UK, 14–17 June 2022; p. 2954. [Google Scholar] [CrossRef]

- Burghignoli, L.; Di Marco, A.; Centracchio, F.; Camussi, R.; Ahlefeldt, T.; Henning, A.; Adden, S.; Di Giulio, M. Evaluation of the noise impact of flap-tip fences installed on laminar wings. CEAS Aeronaut. J. 2020, 11, 849–872. [Google Scholar] [CrossRef]

- Sijtsma, P. CLEAN based on spatial source coherence. Int. J. Aeroacoustics 2007, 6, 357–374. [Google Scholar] [CrossRef]

- Grasso, G.; Roger, M.; Moreau, S. Effect of sweep angle and of wall-pressure statistics on the free-field directivity of airfoil trailing-edge noise. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019; p. 2612. [Google Scholar] [CrossRef]

- Schwarzschild, K. Die beugung und polarisation des lichts durch einen spalt. i. Math. Ann. 1901, 55, 177–247. [Google Scholar] [CrossRef]

- Corcos, G. The structure of the turbulent pressure field in boundary-layer flows. J. Fluid Mech. 1964, 18, 353–378. [Google Scholar] [CrossRef]

- Michelis, T.; Putranto, A.; Kotsonis, M. Attenuation of Tollmien–Schlichting waves using resonating surface-embedded phononic crystals. Phys. Fluids 2023, 35. [Google Scholar] [CrossRef]

- Crouch, J.; Kosorygin, V. Surface step effects on boundary-layer transition dominated by Tollmien–Schlichting instability. AIAA J. 2020, 58, 2943–2950. [Google Scholar] [CrossRef]

- Jaworski, J.W.; Peake, N. Aeroacoustics of silent owl flight. Annu. Rev. Fluid Mech. 2020, 52, 395–420. [Google Scholar] [CrossRef]

- Zhou, P.; Zhong, S.; Zhang, X. On the effect of velvet structures on trailing edge noise: Experimental investigation and theoretical analysis. J. Fluid Mech. 2021, 919, A11. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Li, D. Noise reduction mechanism of airfoils with leading-edge serrations and surface ridges inspired by owl wings. Phys. Fluids 2021, 33, 015123. [Google Scholar] [CrossRef]

- Ibren, M.; Andan, A.D.; Asrar, W.; Sulaeman, E. A Review on Generation and Mitigation of Airfoil Self-Induced Noise. J. Adv. Res. Fluid Mech. Therm. Sci. 2022, 90, 163–178. [Google Scholar] [CrossRef]

- Thurman, C.S. Computational study of boundary layer effects on stochastic rotor blade vortex shedding noise. Aerosp. Sci. Technol. 2022, 131, 107983. [Google Scholar] [CrossRef]

- Kang, D.H.; Lee, S. On the Effect of Boundary-layer Tripping for Trailing-edge Noise Predictions. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 0972. [Google Scholar] [CrossRef]

- Winkler, J.; Wu, H.; Moreau, S.; Carolus, T.; Sandberg, R.D. Trailing-edge broadband noise prediction of an airfoil with boundary-layer tripping. J. Sound Vib. 2020, 482, 115450. [Google Scholar] [CrossRef]

- Dos Santos, F.L.; Botero-Bolívar, L.; Venner, C.; de Santana, L.D. Influence of roughness trips on near-and far-field trailing-edge noise. AIAA J. 2022, 60, 5880–5889. [Google Scholar] [CrossRef]

- Volkmer, K.; Kaufmann, N.; Carolus, T.H. Mitigation of the aerodynamic noise of small axial wind turbines-methods and experimental validation. J. Sound Vib. 2021, 500, 116027. [Google Scholar] [CrossRef]

- Oerlemans, S.; Sijtsma, P.; López, B.M. Location and quantification of noise sources on a wind turbine. J. Sound Vib. 2007, 299, 869–883. [Google Scholar] [CrossRef]

| Method | Mechanism | Frequency Range | Reynolds Number |

|---|---|---|---|

| Leading-Edge Serrations | Disrupt the formation of LE vortices. Delay separation | Low-to-mid frequency range | Low to moderate Reynolds numbers |

| Trailing-Edge Serrations | Disrupting the formation of turbulent VS, Breaking large vortices into smaller-scale ones | A wide frequency range, especially tonal noise in the mid-frequency range | Moderate to high Reynolds numbers |

| Porous Materials | Flow Reshaping and Wake Interaction | Low-to-mid frequency range | A wide range of Reynolds numbers |

| Controlled Diffusion Airfoils | Controlling the flow separation and preventing the formation of noise-inducing vortices | A wide frequency range, including both low and high-frequency components | Moderate to high Reynolds numbers |

| Morphing Airfoil | Smooth Shape Transitions and BL control | A wide frequency range, mostly effective on low-frequency components | The applicability of morphing airfoils depends on their structural design and the targeted Reynolds number range |

| Surface Treatments | Control BL behavior and trip the laminar flow | High-frequency components, particularly those associated with BL turbulence | A wide range of Reynolds numbers |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amirsalari, B.; Rocha, J. Recent Advances in Airfoil Self-Noise Passive Reduction. Aerospace 2023, 10, 791. https://doi.org/10.3390/aerospace10090791

Amirsalari B, Rocha J. Recent Advances in Airfoil Self-Noise Passive Reduction. Aerospace. 2023; 10(9):791. https://doi.org/10.3390/aerospace10090791

Chicago/Turabian StyleAmirsalari, Behzad, and Joana Rocha. 2023. "Recent Advances in Airfoil Self-Noise Passive Reduction" Aerospace 10, no. 9: 791. https://doi.org/10.3390/aerospace10090791

APA StyleAmirsalari, B., & Rocha, J. (2023). Recent Advances in Airfoil Self-Noise Passive Reduction. Aerospace, 10(9), 791. https://doi.org/10.3390/aerospace10090791