Numerical Investigation of Bio-Aviation Fuel: Dubai’s Future Perspective

Abstract

1. Introduction

2. Methods

2.1. Reference Design

2.2. PUGH Matrix

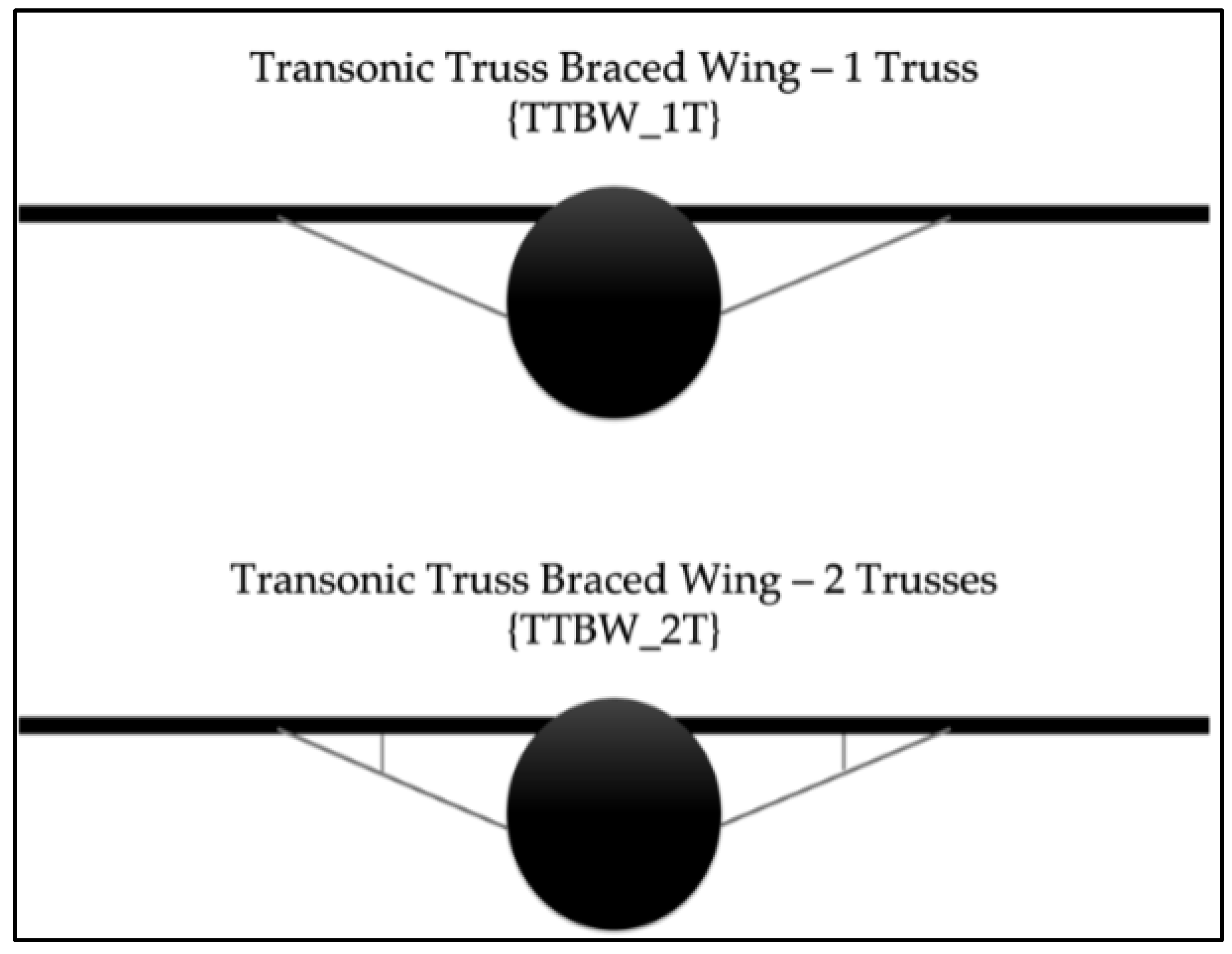

2.2.1. Wing Configuration

2.2.2. Tail Configuration

2.2.3. Engine and Engine Number

2.2.4. Environmental Impact and Fuel

2.2.5. Aerodynamic Performance

2.3. Final Design

2.4. Aircraft Design Methodology—Weight Estimation

2.5. Aircraft Design Methodology—Constraint Sizing

2.6. ICAO Landing and Take-Off (LTO) Cycle

- Take-off: the first stage of the LTO cycle that matches the thrust setting from the aircraft’s take-off until the main throttle back segment;

- Climb: the thrust setting corresponds to the throttle back instant until the maximum altitude of 3000 ft is reached in the LTO cycle;

- Approach: occupies the thrust setting from the maximum altitude up until the touchdown along with the roll-out at the end of the runway;

- Taxi: corresponds to the thrust setting for two divisions; one from the engine warming period until the take-off brake release point for taxi out, and two from the end of the landing and parking phase until the engine shutdown for taxi out.

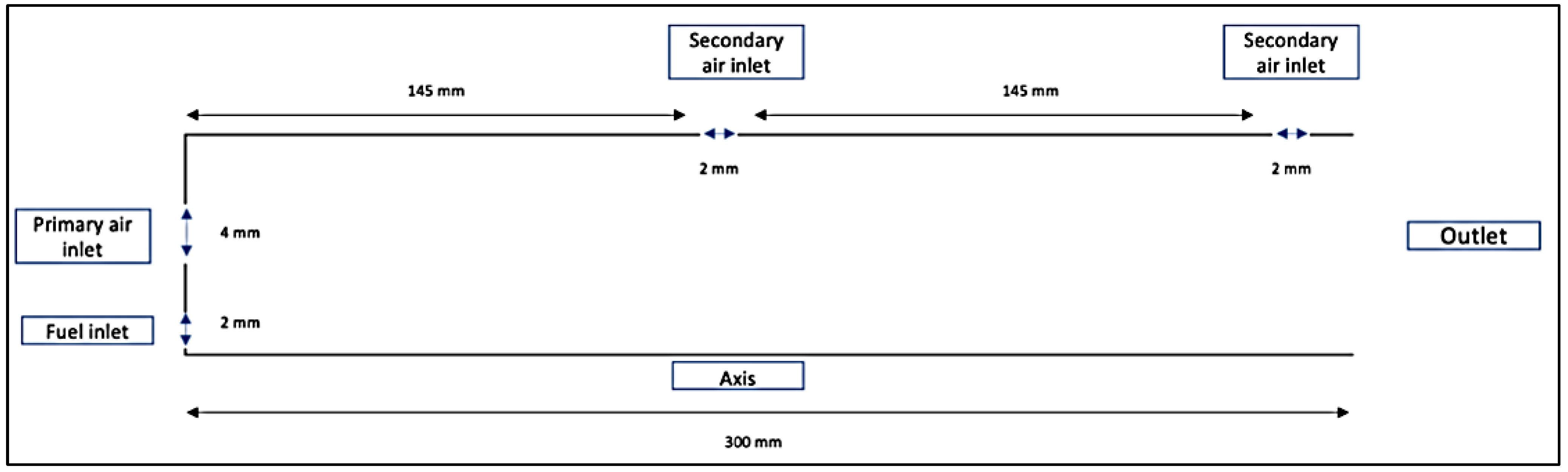

2.7. CFD Analysis of Fuel Combustion

- Energy: this model was selected to account for the energy change due to the temperature change and heat transfer in the process;

- Radiation: to produce a more accurate solution, the discrete ordinates (DO) model was selected;

- Viscous: the selected model was SST k-omega with the default constant values;

- Species: this model was the most significant since it sets the combustion characteristics. The model was set as non-premixed, and inlet diffusion, and eddy dissipation were selected. Chemical equilibrium was chosen for the state relation, besides the non-adiabatic energy treatment.

3. Results

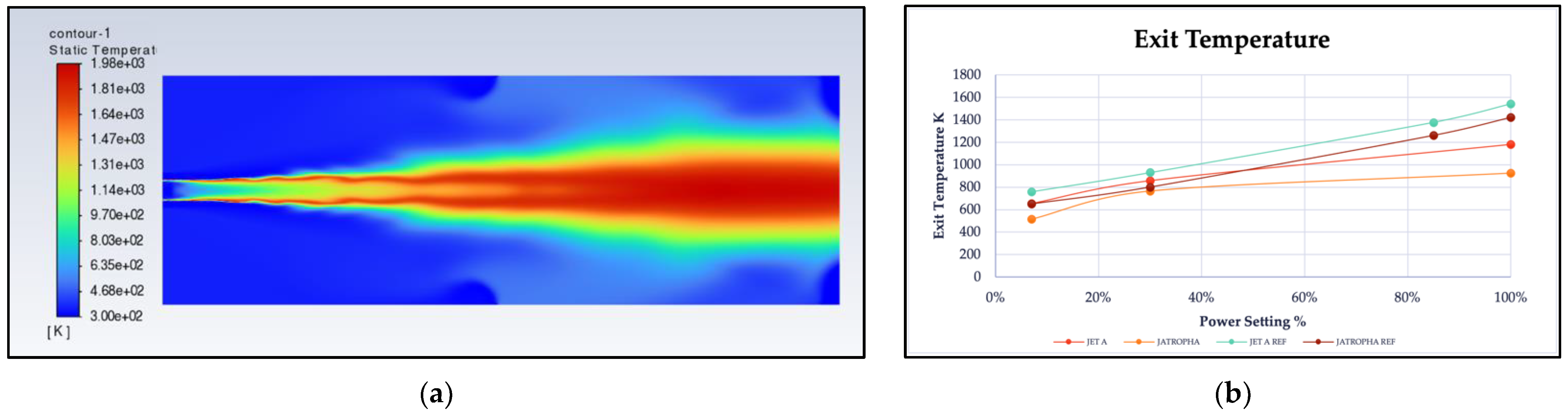

3.1. Numerical Simulation Results

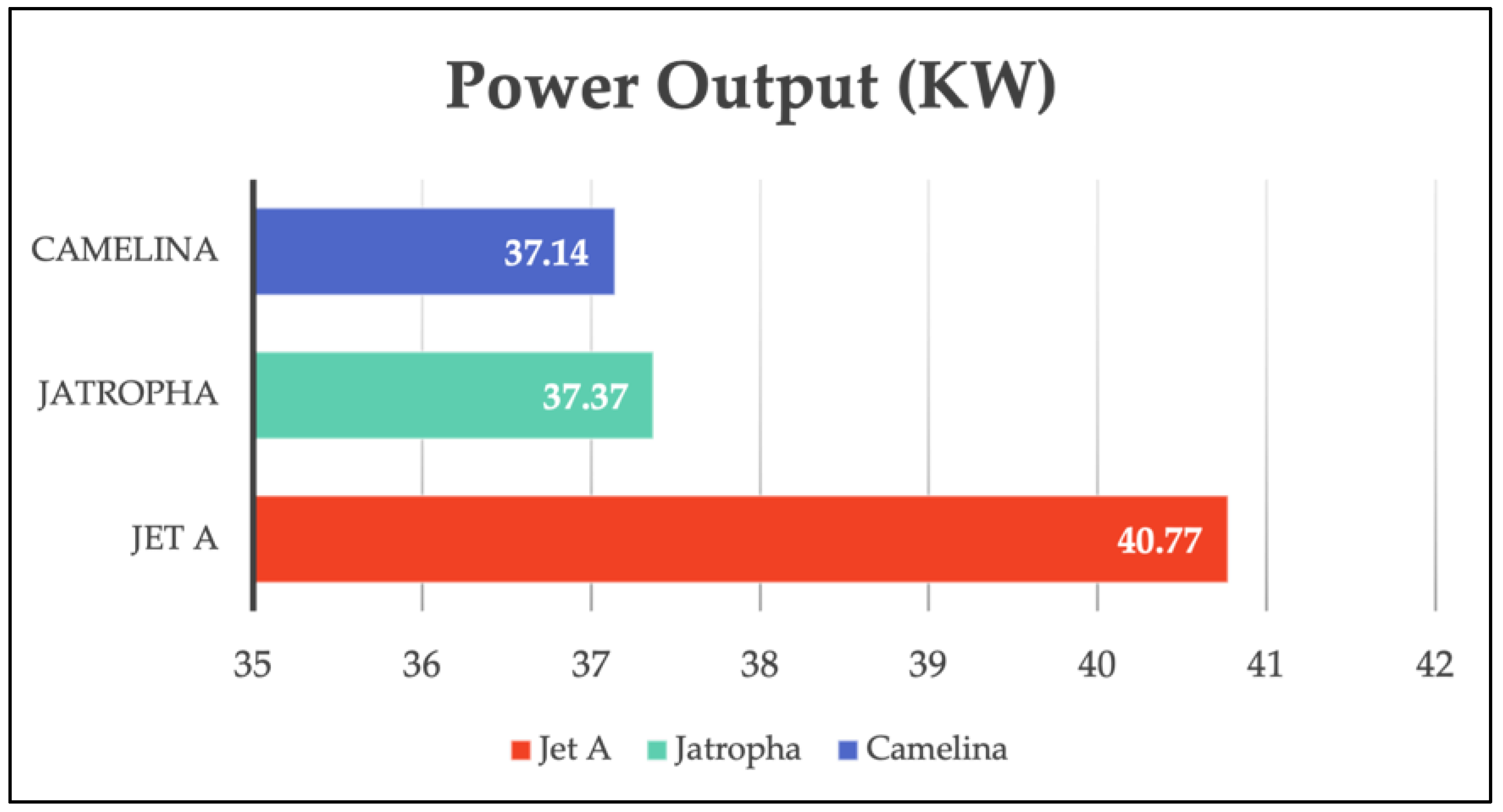

3.1.1. Power Output

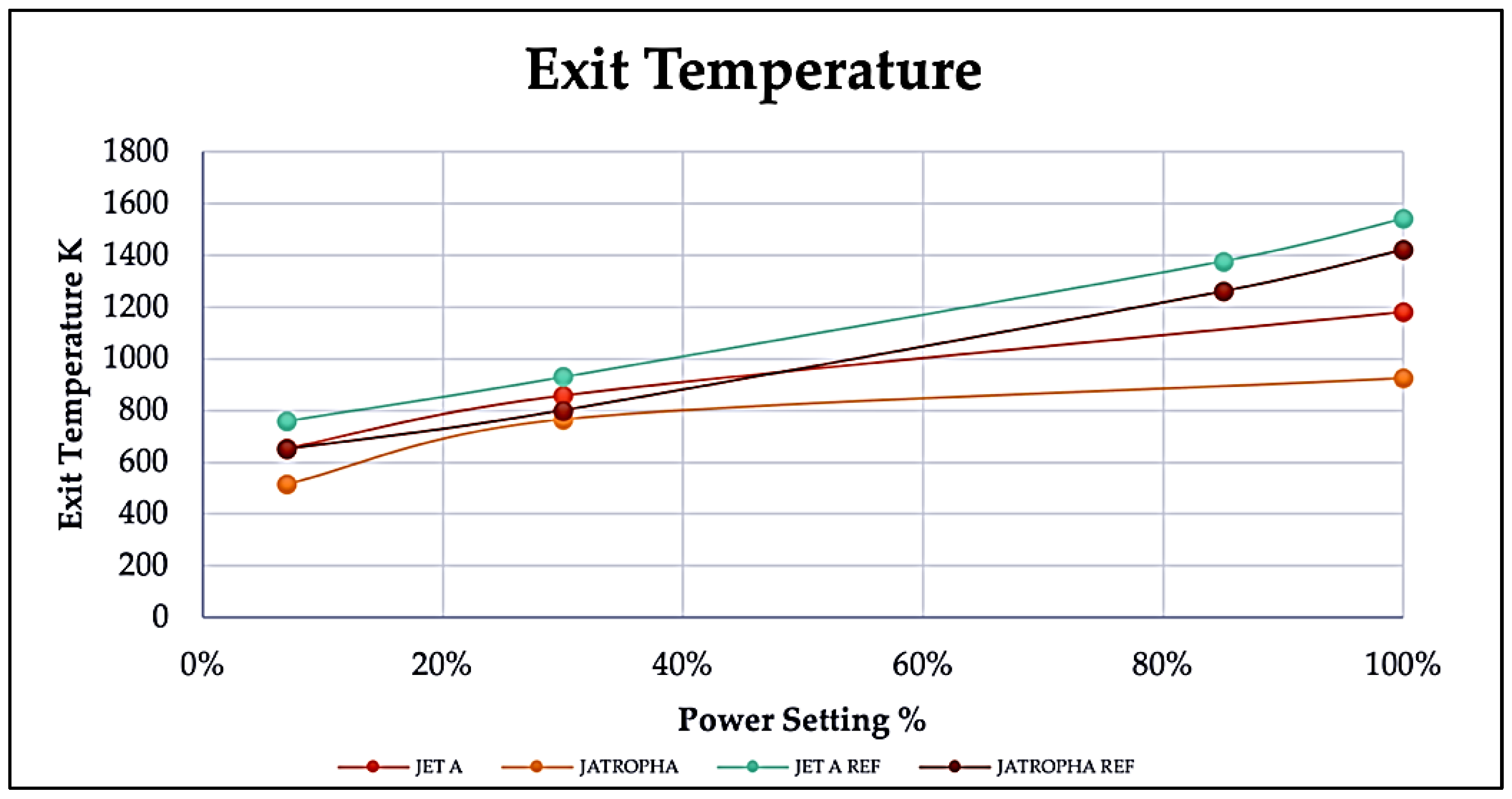

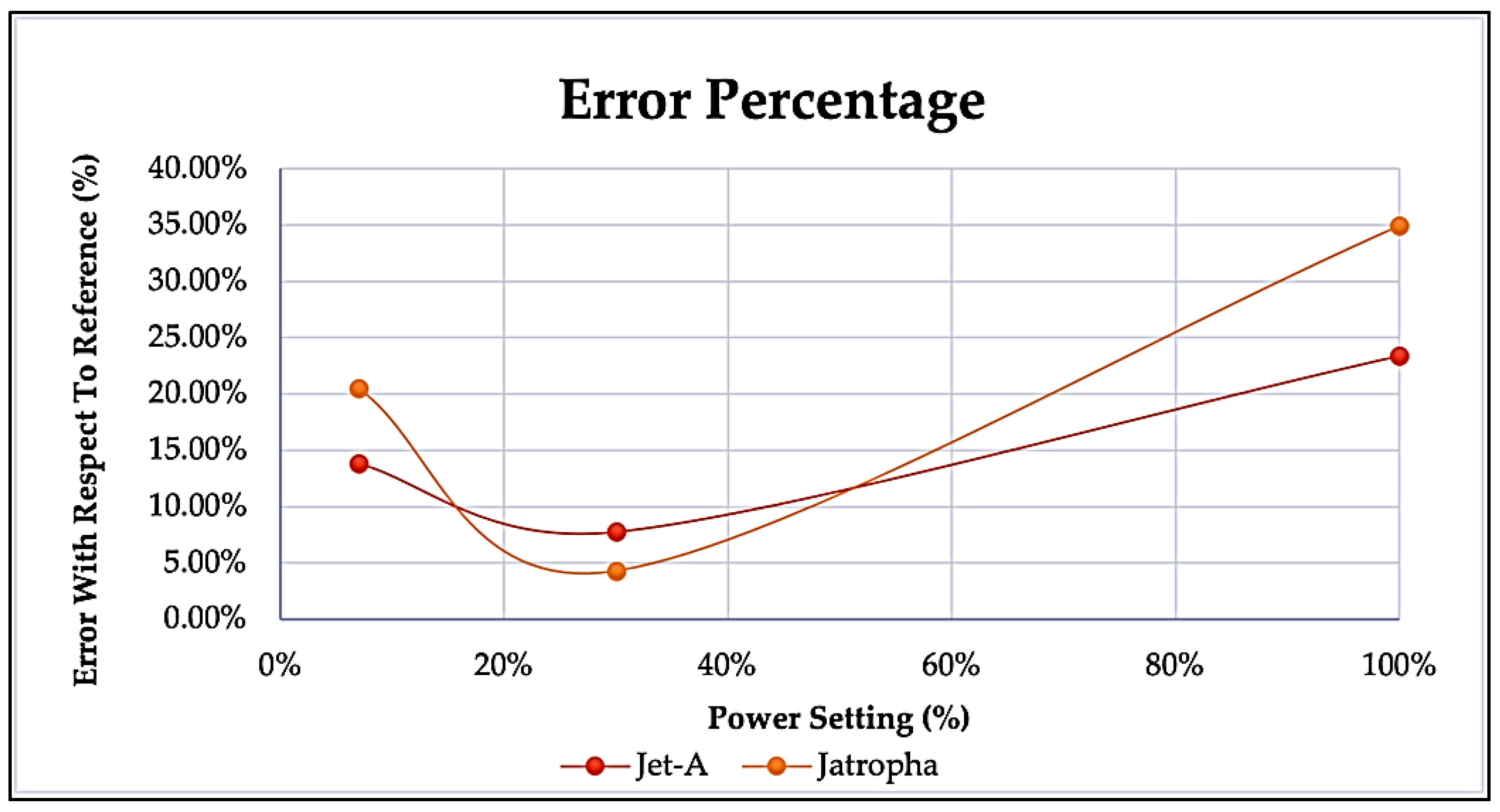

3.1.2. Combustor Exit Temperatures

3.1.3. Emissions

- Emission Index CO:

- Emission Index CO2:

3.2. Final Designs’ Analysis

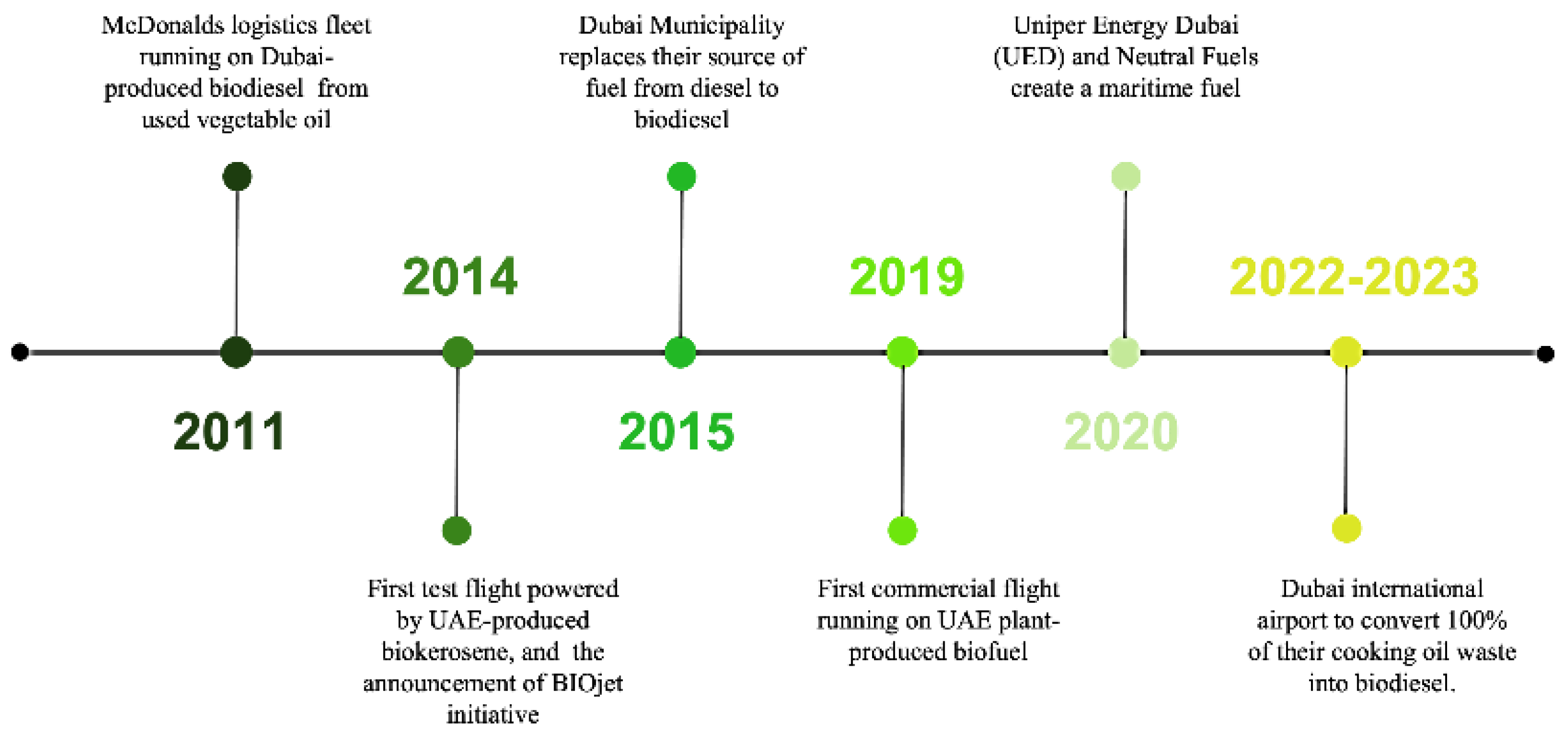

3.3. UAE and Biofuel

3.4. Ticket Cost Analysis

4. Discussion

5. Conclusions

- Through a PUGH analysis, it was concluded that the optimum aircraft design had a transonic truss-braced wing configuration and was powered by a 60% biofuel blend.

- By researching and comparing different biofuels, camelina was selected to power the optimum design as it was found to be the best plant for oil extraction and biofuel production in the UAE.

- A numerical simulation was conducted to confirm and study the effects of camelina biofuel on emissions. The results showed a decrease of 50% and 24% in CO and CO2 emissions, respectively, owing to its chemical composition that yielded fewer particulates than jet fuel when burned, in return emitting less greenhouse gases.

- It was also found from the simulation that while a higher mass flow rate is needed for biofuels, they are capable of producing the same energy as Jet-A with a reduction in the combustor’s exit temperature.

- From the design analysis it was concluded that an aircraft design with a TTBW configuration running on a 60% camelina biofuel blend is expected to increase the take-off weight by 1.34% and reduce the emission and fuel consumption by 30% and 10%, respectively, compared with the conventional aircraft design.

- Lastly, through a cost investigation, it was established that flying on board a 100%-biofuel-powered aircraft would increase the ticket cost by 453 USD (1653.18 AED) per passenger.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AR | Aspect Ratio |

| CFD | Computational Fluid Dynamics |

| Maximum required Take-off Lift coefficient with flaps up | |

| Maximum required Lift coefficient for Take-off | |

| Maximum required Take-off Lift coefficient for landing | |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| EI | Emission Index |

| GHG | Greenhouse Gases |

| HEFA | Hydro process asters and fatty acids |

| IATA | International Air Transport Association |

| ICAO | International Civil Aviation Organization |

| LHV | Lower heating value |

| LTO | Landing and Take-off |

| L/D | Lift to drag ratio |

| Air Mass flow rate | |

| Fuel Mass flow rate | |

| Mass flow rate of water | |

| NOx | Nitrogen Oxides |

| SUGAR | Subsonic Ultra-Green Aircraft Research |

| S/W | Wing loading |

| TTBW | Transonic Truss-braced Wing |

| T/W | Thrust-to-weight ratio |

| Wcrew | Crew weight |

| WE | Empty weight |

| WF | Fuel weight |

| WPL | Payload weight |

| Wtfo | Trapped fuel oil weight |

| WTO | Take-off weight |

| Actual heat release | |

| Theoretical heat release | |

| Burner efficiency |

References

- Masson-Delmotte, V.; Zhai, P.; Pörtner, H.O.; Roberts, D.; Skea, J.; Shukla, P.R.; Pirani, A.; Moufouma-Okia, W.; Pöan, C.; Pidcock, R.; et al. Global Warming of 1.5 °C. In An IPCC Special Report on the Impacts of Global Warming of 1.5 °C; IPCC: Geneva Switzerland, 2018; Volume 1. [Google Scholar]

- Change, P.C. Global warming of 1.5 °C; World Meteorological Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Yoro, K.O.; Daramola, M.O. CO2 emission sources, greenhouse gases, and the global warming effect. In Advances in Carbon Capture; Woodhead Publishing: Sawston, UK, 2020; pp. 3–28. [Google Scholar]

- Mikhaylov, A.; Moiseev, N.; Aleshin, K.; Burkhardt, T. Global climate change and greenhouse effect. Entrep. Sustain. Issues 2020, 7, 2897–2913. [Google Scholar] [CrossRef] [PubMed]

- International Civil Aviation Organization: CO2 Emission from Commercial Aviation. 2018. Available online: https://www.icao.int/Meetings/a40/Documents/WP/wp_560_rev1_en.pdf (accessed on 29 December 2022).

- Lee, D.S.; Fahey, D.W.; Forster, P.M.; Newton, P.J.; Wit, R.C.N.; Lim, L.L.; Owen, B.; Sausen, R. Aviation and global climate change in the 21st century. Atmos. Environ. 2009, 43, 3520–3537. [Google Scholar] [CrossRef]

- Airbus: Global Market Forecast. Available online: https://www.airbus.com/en/products-services/commercial-aircraft/market/global-market-forecast (accessed on 14 December 2022).

- Boeing: Commercial Market Outlook. Available online: https://www.boeing.com/commercial/market/commercial-market-outlook/index.page (accessed on 14 December 2022).

- Solomon, S.C. Effects of Carbon Dioxide on the Upper Atmosphere. In McGraw-Hill Yearbook of Science and Technology; McGraw-Hill: New York, NY, USA, 2008. [Google Scholar]

- Emmert, J.T.; Picone, J.M.; Lean, J.L.; Knowles, S.H. Global change in the thermosphere: Compelling evidence of a secular decrease in density. J. Geophys. Res. 2004, 109, A02301. [Google Scholar] [CrossRef]

- Lewis, H.G.; Swinerd, G.G.; Ellis, C.S.; Martin, C.E. Response of the space debris environment to greenhouse cooling. In Proceedings of the Fourth European Conference on Space Debris, Darmstadt, Germany, 18–20 April 2005; pp. 243–248. [Google Scholar]

- Arockiam, N.J.; Jawaid, M.; Saba, N. Sustainable bio composites for aircraft components. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Sawston, UK, 2018; pp. 109–123. [Google Scholar]

- Sharma, G.; Isanaka, B.R.; Kushvaha, V. Engineering applications of biofibers. In The Textile Institute Book Series: Advances in Bio-Based Fiber; Woodhead Publishing: Sawston, UK, 2022; pp. 619–643. [Google Scholar]

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Kokorikou, A.; Vink, P.; De Pauw, I.C.; Braca, A. Exploring the design of a lightweight, sustainable and comfortable aircraft seat. Work 2016, 54, 941–954. [Google Scholar] [CrossRef]

- Markatos, D.N.; Pantelakis, S.G. Assessment of the Impact of Material Selection on Aviation Sustainability, from a Circular Economy Perspective. Aerospace 2022, 9, 52. [Google Scholar] [CrossRef]

- Bachmann, J.; Yi, X.; Tserpes, K.; Sguazzo, C.; Barbu, L.G.; Tse, B.; Soutis, S.; Ramón, E.; Linuesa, H.; Bechtel, S. Towards a circular economy in the aviation sector using eco-composites for interior and secondary structures. Results and recommendations from the EU/China project ECO-COMPASS. Aerospace 2021, 8, 131. [Google Scholar] [CrossRef]

- Sebastian, R.M.; Louis, J. Understanding waste management at airports: A study on current practices and challenges based on literature review. Renew. Sustain. Energy Rev. 2021, 147, 111229. [Google Scholar] [CrossRef]

- Maldonado, D.; Viken, S.A.; Housman, J.A.; Hunter, C.A.; Duensing, J.C.; Frink, N.T.; Jensen, J.C.; McMillin, S.N.; Kiris, C.C. Computational Simulations of a Mach 0.745 Transonic Truss-Braced Wing Design. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- NASA Aims for Climate-Friendly Aviation. Available online: https://www.nasa.gov/aeroresearch/nasa-aims-for-climate-friendly-aviation (accessed on 15 September 2022).

- How Sweet the Future of Aviation—Boeing Multimedia by Bradley, M. Available online: https://www.boeing.com/features/innovation-quarterly/aug2017/feature-technical-sugar.page (accessed on 12 August 2022).

- Droney, C.; Harrison, N.; Gatlin, G. Subsonic Ultra-Green Aircraft Research: Transonic Truss-Braced Wing Technical Maturation. In Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences, Belo Horizon, Brazil, 9–14 September 2018. [Google Scholar]

- Gur, O.; Bhatia, M.; Schetz, J.; Mason, W. Design Optimization of a Truss-Braced-Wing Transonic Transport Aircraft. J. Aircr. 2010, 46, 1907–1917. [Google Scholar] [CrossRef]

- Patel, N. Design of Medium Size Blended Wing Body Subsonic Transport Aircraft; San José State University: San Jose, CA, USA, 2018. [Google Scholar]

- Leifsson, L.; Ko, A.; Mason, W.H.; Schetz, J.A.; Grossman, B.; Haftka, R.T. Multidisciplinary design optimization of blended-wing-body transport aircraft with distributed propulsion. Aerosp. Sci. Technol. 2013, 25, 16–28. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, M.; Chen, Y.; Sang, W.; Tan, Z.; Li, D.; Zhang, B. Assessment on critical technologies for conceptual design of blended-wing-body civil aircraft. Chin. J. Aeronaut. 2019, 32, 1797–1827. [Google Scholar] [CrossRef]

- Jemitola, P.O.; Fielding, J.P. Box Wing Aircraft Conceptual Design. Available online: https://www.icas.org/ICAS_ARCHIVE/ICAS2012/PAPERS/213.PDF (accessed on 1 October 2021).

- Jemitola, P.O.; Okonkwo, P.P. An Analysis of Aerodynamic Design Issues of Box Wing Aircraft. Available online: https://globaljournals.org/GJRE_Volume22/4-An-Analysis-of-Aerodynamic-Design.pdf (accessed on 27 January 2022).

- International Air Transport Association (IATA): Annual Review. 2022. Available online: https://www.iata.org/contentassets/c81222d96c9a4e0bb4ff6ced0126f0bb/annual-review-2022.pdf (accessed on 14 December 2022).

- Panbudi, N.; Itaoka, K.; Kurosawa, A.; Yamakawa, N. Impact of hydrogen fuel for CO2 emission reduction in power generation sector in Japan. In Proceedings of the 8th International Conference on Applied Energy—ICAE, Beijing, China, 8–11 October 2016. [Google Scholar]

- International Air Transport Association (IATA): Developing Sustainable Aviation Fuel (SAF). Available online: https://www.iata.org/en/programs/environment/sustainable-aviation-fuels/ (accessed on 26 September 2022).

- Strategic Research and Innovation Agenda (SRIA), Clean Aviation. Available online: https://www.clean-aviation.eu/strategic-research-and-innovation-agenda-sria (accessed on 7 February 2023).

- Office of Energy Efficiency & Renewable Energy: Biofuel Basics. Available online: https://www.energy.gov/eere/bioenergy/biofuel-basics (accessed on 24 December 2022).

- Cabrera, E.; de Sousa, J.M.M. Use of Sustainable Fuels in Aviation—A Review. Energies 2022, 15, 2440. [Google Scholar] [CrossRef]

- IEA Bioenergy: Drop-In Biofuels: The Key Role That Co-Processing Will Likely Play in Its Production. Available online: https://www.ieabioenergy.com/wpcontent/uploads/2019/09/Task-39-Drop-in-Biofuels-Full-Report-January-2019.pdf (accessed on 24 November 2021).

- European Technology and Innovation Platform: Aviation Biofuels. Available online: https://www.etipbioenergy.eu/images/ETIP_Bioenergy_Factsheet_Aviation_Biofuels.pdf (accessed on 24 December 2022).

- Boomadevi, P.; Paulson, V.; Samlal, S.; Varatharajan, M.; Sekar, M.; Alsehli, M.; Elfasakhany, A.; Tola, S. Impact of microalgae biofuel on microgas turbine aviation engine: A combustion and emission study. Fuel 2021, 302, 121155. [Google Scholar] [CrossRef]

- Olivera, J.; Brojo, F. Simulation of the combustion of bio-derived fuels in a CFM56-3 combustor. In Proceedings of the 2017 2nd International Conference Sustainable and Renewable Energy Engineering (ICSREE), Hiroshema, Japan, 10–12 May 2017. [Google Scholar]

- Kilic, G.; Sungur, B.; Topaloglu, B.; Ozcan, H. Experimental analysis on the performance and emissions of diesel/butanol/biodiesel blended fuels in a flame tube boiler. Appl. Therm. Eng. 2018, 130, 195–202. [Google Scholar] [CrossRef]

- Sharma, P.; Le, M.P.; Chhillar, A.; Said, Z.; Deepanraj, B.; Cao, D.N.; Bandh, S.A.; Hoang, A.T. Using response surface methodology approach for optimizing performance and emission parameters of diesel engine powered with ternary blend of Solketal-biodiesel-diesel. Sustain. Energy Technol. Assess. 2022, 52, 102343. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, Z.; Wang, Z. Numerical study of influence of biofuels on the combustion characteristics and performance of aircraft engine system. Appl. Therm. Eng. 2015, 91, 399–407. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T.; Janicka, A.; Suchocki, T. Combustion and Emissions Characteristics of the Turbine Engine Fueled with HEFA Blends from Different Feedstocks. Energies 2020, 13, 1277. [Google Scholar] [CrossRef]

- Azami, M.; Savill, M. Comparative study of alternative biofuels on aircraft engine performance. J. Aerosp. Eng. 2017, 231, 1509–1521. [Google Scholar] [CrossRef]

- Burge Hughes Walsh. Pugh Decision Matrix. Available online: https://www.burgehugheswalsh.co.uk/uploaded/1/documents/pugh-matrix-v1.1.pdf (accessed on 20 December 2022).

- Ghatak, A. Blended Wing Body (BWB)—Future of Aviation. 2021, Online Slides (Submitted). Available online: https://www.slideshare.net/AsimGhatak/blended-wing-body-bwb-future-of-aviation (accessed on 12 December 2021).

- Boeing: Spreading Our Wings: Boeing Unveils New Transonic Truss-Braced Wing. Available online: https://www.boeing.com/features/2019/01/spreading-our-wings-01-19.page (accessed on 10 September 2021).

- Allen, B. Blended Wing Body—A Potential New Aircraft Design; NASA: Washington, DC, USA, 2008. Available online: https://www.nasa.gov/centers/langley/news/factsheets/FS-2003-11-81-LaRC.html (accessed on 12 November 2021).

- Sadraey, M. Chapter 6. Tail Design. In Lecture Notes from Daniel Webster College. Available online: http://aero.us.es/adesign/Slides/Extra/Stability/Design_Tail/Chapter%206.%20Tail%20Design.pdf (accessed on 25 January 2023).

- Texas Space Grant Consortium. Available online: https://www.tsgc.utexas.edu/archive/general/ethics/vtail.html (accessed on 15 November 2021).

- The Vertical Stabilizer. Available online: https://www.aeroclass.org/vertical-stabilizer/#:~:text=Cruciform%20tails%20have%20disadvantages%3A%20They,the%20same%20amount%20of%20stability (accessed on 25 January 2023).

- Engine Failure after TakeOff—Light Twin Engine Aircraft. Available online: https://skybrary.aero/articles/engine-failure-after-takeoff-light-twin-engine-aircraft (accessed on 25 January 2023).

- Mazlan, N.M.; Savill, M.; Kipouros, T. Effects of biofuels properties on aircraft engine performance. Aircr. Eng. Aerosp. Technol. 2015, 87, 437–442. [Google Scholar] [CrossRef]

- Orban, A. Airbus Blended Wing Prototype Prioritizes Fuel Efficiency; Aviation24: Zemst, Belgium, 2020; Available online: https://www.aviation24.be/manufacturers/airbus/analysis-airbus-blended-wing-prototype-prioritises-fuel-efficiency/ (accessed on 17 November 2021).

- Air bp: What Is Sustainable Aviation Fuel (SAF)? Available online: https://www.bp.com/en/global/air-bp/news-and-744views/views/what-is-sustainable-aviation-fuel-saf-and-why-is-it-important.html (accessed on 14 November 2021).

- Marino, M.; Siddique, O.; Sabatini, R. Benefits of the Blended Wing Body Aircraft Compared to Current Airliners. In Proceedings of the First International Symposium on Sustainable Aviation, Istanbul, Turkey; 2015. [Google Scholar]

- Aviation Benefits Beyond Borders. Available online: https://aviationbenefits.org/media/166152/beginners-guide-to-saf_web.pdf (accessed on 23 November 2021).

- Baisden, T. Climate Explained: Could Biofuels Replace All Fossil Fuels in New Zealand? The Conversation 2021. Available online: https://theconversation.com/climate-explained-could-biofuels-replace-all-fossil-fuels-in-new-zealand-162502 (accessed on 20 November 2021).

- Carbon Brief. Available online: https://www.carbonbrief.org/thinktank-biofuels-are-too-expensive-and-they-dont-always-reduce-emissions/ (accessed on 20 November 2021).

- Energy Education. Available online: https://energyeducation.ca/encyclopedia/Energy_density (accessed on 20 November 2021).

- Bradley, M.K.; Droney, C.K. Subsonic Ultra Green Aircraft Research: Phase I Final Report; NASA: Washington, DC, USA, 2011; 207p. Available online: https://ntrs.nasa.gov/api/citations/20110011321/downloads/20110011321.pdf (accessed on 19 October 2021).

- Ikeda, T. Aerodynamic Analysis of a Blended-Wing-Body Aircraft Configuration. In A Thesis Submitted in Fulfilment of the Requirement for the Degree of Master of Engineering by Research; RMIT University: Melbourne, Australia, 2006; Available online: https://core.ac.uk/download/pdf/15615098.pdf (accessed on 20 October 2021).

- NASA: Blended-Wing-Body Transonic Aerodynamics: Summary of Ground Tests and Sample Results (Invited). Available online: https://ntrs.nasa.gov/api/citations/20090007702/downloads/20090007702.pdf (accessed on 21 October 2021).

- Roskam, J. Airplane Design Part I-VIII; DARcorporation: Lawrence, KS, USA, 1985. [Google Scholar]

- International Civil Aviation Organization: ICAO and Environmental Protection. Available online: https://www.icao.int/environmental-protection/Pages/LAQ_TechnologyStandards.aspx (accessed on 31 May 2022).

- Ribeiro, P. Análise de Performance da Família de Motores de Avião CFM56. Master’s Thesis, Instituto Superior de Engenharia de Lisboa, Lisboa, Portugal, 2012. [Google Scholar]

- Burcat, A.; Ruscic, C. Third Millennium Ideal Gas and Condensed Phase Thermochemical Database for Combustion with Updates from Active Thermochemical Tables. Available online: https://publications.anl.gov/anlpubs/2005/07/53802.pdf (accessed on 9 June 2022).

- Llamas, A.; Al-Lal, A.M.; Hernandez, M.; Lapuerta, M.; Canoira, L. Biokerosene from Babassu and Camelina Oils: Production and Properties of Their Blends with Fossil Kerosene. Energy Fuels 2012, 26, 5968–5976. [Google Scholar] [CrossRef]

- Stamenković, O.S.; Gautam, K.; Singla-Pareek, S.L.; Dhankher, O.P.; Djalović, I.G.; Kostić, M.D.; Mitrović, P.M.; Pareek, A.; Veljković, V.B. Biodiesel production from camelina oil: Present status and future perspectives. Food Energy Secur. 2023, 12, e340. [Google Scholar] [CrossRef]

- Bamerni, F. Plant-Based (Camelina sativa) Biodiesel Manufacturing Using the Technology of Instant Controlled Pressure Drop (DIC): Process Performance and Biofuel Quality. Ph.D. Thesis, University of La Rochelle, La Rochelle, France, 2018. [Google Scholar]

- Moser, B. Camelina (Camelina sativa L.) oil as a biofuel’s feedstock: Golden opportunity or false hope? Lipid Technol. 2010, 22, 270–273. [Google Scholar] [CrossRef]

- Frank, J.H.; Barlow, R.S. Non-Premixed Turbulent Combustion. Available online: https://www.osti.gov/biblio/1714512 (accessed on 1 June 2022).

- The European Commission. Available online: https://cordis.europa.eu/project/id/251798/reporting (accessed on 9 June 2022).

- Wang, Z.; Feser, J.S.; Lei, T.; Gupta, A.K. Performance and emissions of camelina oil derived jet fuel blends under distributed combustion condition. Fuel 2020, 271, 117685. [Google Scholar] [CrossRef]

- Etihad Airways News: Etihad Airways Flies the World’s First Flight Using Fuel Made in the UAE from Plants Grown in Saltwater by Khalifa Uni. Available online: https://www.etihad.com/en-ae/news/Etihad-airways-flies-the-worlds-first-flight-using-fuel-made-in-t (accessed on 22 December 2022).

- Hemighaus, G.; Boval, T.; Bacha, J.; Barnes, F.; Franklin, M.; Gibbs, L.; Hogue, N.; Jones, J.; Lesnini, D.; Lind, J.; et al. Aviation Fuels Technical Review; Chevron Products Company: San Ramon, CA, USA, 2007; pp. 1–94. [Google Scholar]

- Helsel, Z.R. Camelina for Biofuel Production. Farm Energy. 2019. Available online: https://farm-energy.extension.org/camelina-for-biofuel-production/ (accessed on 21 October 2021).

- Aslam, M.M.; Khan, A.A.; Cheema, H.M.N.; Hanif, M.A.; Azeem, M.W.; Azmat, M.A. Novel mutant camelina and jatropha as valuable feedstocks for biodiesel production. Sci. Rep. 2020, 10, 21868. Available online: https://www.nature.com/articles/s41598-020-78680-w#citeas (accessed on 26 October 2021). [CrossRef]

- Ghilvacs, M.; Carlanescu, R.; Paraschiv, M.; Prisecaru, M. Analysis of energy potential of biofuels obtained from camelina sativa. Renew. Energy 2020, 180, 02005. [Google Scholar] [CrossRef]

- Sankpal, S.T.; Naikwade, P.V. Important Bio-fuel Crops: Advantages and Disadvantages. Int. J. Sci. Eng. Res. 2013, 4, 1–5. [Google Scholar]

- Green, L. Jatropha as Biofuel: An Analysis of the Possible Implications for Food Security in Mali. Bachelor’s Thesis, Dalhousie University, Halifax, NS, Canada, 2009. [Google Scholar]

- Travel and Leisure: This Is Where Every Dollar of Your Airfare Goes Do You Know Where Your Airfare Dollars Go? By Garcia, M. Travel and Leisure. Available online: https://www.travelandleisure.com/airlines-airports/airfare-dollars-breakdown (accessed on 22 December 2022).

- Bankrate: How Much Does a Private Jet Cost? By Rivelli, E. Available online: https://www.bankrate.com/loans/personal-loans/how-much-does-a-private-jet-cost/ (accessed on 22 December 2022).

- IATA: Jet Fuel Price Monitor. Available online: https://www.iata.org/en/publications/economics/fuel-monitor/ (accessed on 22 December 2022).

- IRENA. Reaching Zero with Renewables: Biojet fuels; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

| Design Option | Wing | Engine Placement and Number | Tail | Landing Gear |

|---|---|---|---|---|

| 60% Biofuel | Cantilever conventional wing | 2 Rear fuselage | T-tail | Retractable tricycle |

| TTBW_1 + Jet Fuel | TTBW_1 | 2 Under the wing | Cruciform | Retractable tricycle |

| TTBW_2 + Jet Fuel | TTBW_2 | 2 Under the wing | V-tail | Retractable tricycle |

| TTBW_1 + 60% Biofuel | TTBW_1 | 2 Under the wing | T-tail | Retractable tricycle |

| BWB + Jet Fuel | Blended wing | 2 toward the trailing edge of the fuselage | No tail | Retractable tricycle |

| Criteria | Weighting | 60% Biofuel | TTBW_1 + Jet Fuel | TTBW_2 + Jet Fuel | TTBW_1 + 60% Biofuel | BWB + Jet Fuel |

|---|---|---|---|---|---|---|

| Wing configuration | 30% | 66.35 | 76.25 | 80.1 | 79.35 | 37.45 |

| Tail configuration | 5% | 76 | 74 | 71.5 | 76 | 0 |

| Engine | 15% | 71 | 82 | 77.5 | 81 | 71 |

| Engine number | 5% | 80 | 82.25 | 86.25 | 88.75 | 82.75 |

| Environmental impact and fuel | 40% | 66.75 | 67.5 | 70 | 82.75 | 70.5 |

| Aerodynamic performance | 5% | 71 | 71.5 | 81.5 | 77.5 | 83.5 |

| Total | 100% | 68.6 | 73.56 | 75.61 | 81.16 | 58.4 |

| Power | 7% | 30% | 85% | 100% |

|---|---|---|---|---|

| Operating Pressure (pa) | 101,325 | 655,804 | 1,981,730 | 2,343,346 |

| Oxidizer temperature (K) | 311.15 | 418.82 | 674.25 | 743.91 |

| Fuel | Jet-A [38] | Jatropha [38] | Camelina [67,68,69] |

|---|---|---|---|

| Stoichiometric Air-to-Fuel Ratio | 14.7 | 13.3 | 12.5 |

| Stoichiometric Fuel-to-Air Ratio | 0.0680 | 0.0751 | 0.0799 |

| Fuel Flammability | 0.0748 | 0.08261 | 0.0879 |

| Flash point (K) | 312 | 445 | 317.6 |

| Lower Heating Value (MJ/kg) | 43.1 | 39.5 | 39.26 |

| Fuel | Jatropha | Camelina |

|---|---|---|

| C16:0 | 16.2 | 5 |

| C18:0 | 8.2 | 2.2 |

| C18:1 | 38.4 | 17.7 |

| C18:2 | 36.8 | 18 |

| C18:3 | 0.4 | 37.9 |

| C20:0 | - | 1.4 |

| C20:1 | - | 9.8 |

| C20:2 | - | 1.6 |

| C20:3 | - | 1 |

| C22:0 | - | 0.4 |

| C22:1 | - | 4.5 |

| C24:0 | - | 0.3 |

| C24:1 | - | 0.2 |

| Fuel | Power % | 7% | 30% | 85% | 100% |

|---|---|---|---|---|---|

| Jet-A | primary | 0.96045 | 2.07676 | 3.3363 | 3.4765 |

| secondary | 1.88955 | 4.08573 | 6.5637 | 6.8327 | |

| total | 2.85 | 6.1625 | 9.9 | 10.3092 | |

| 0.0285 | 0.0725 | 0.198 | 0.2365 | ||

| Air-to-Fuel Ratio | 100 | 85 | 50 | 43.6 | |

| Jatropha | primary | 0.5973325 | 2.17557 | 3.62595 | 3.71899 |

| secondary | 1.1751675 | 4.2801291 | 7.1335 | 7.3166 | |

| total | 1.7725 | 6.4557 | 10.7595 | 11.0356 | |

| 0.0177 | 0.0759 | 0.2152 | 0.2532 | ||

| Air-to-Fuel Ratio | 100 | 85 | 50 | 43.6 | |

| Camelina | primary | 0.6007 | 2.1888 | 3.648 | 3.7427 |

| secondary | 1.18 | 4.306 | 7.177 | 7.3626 | |

| total | 1.7825 | 6.495 | 10.825 | 11.105 | |

| 0.0178 | 0.0764 | 0.2165 | 0.2547 | ||

| Air-to-Fuel Ratio | 100 | 85 | 50 | 43.6 |

| Baseline Conventional Business Jet | Conventional Business Jet with 60% Camelina Biofuel | TTBW_1T Business Jet with Conventional Fuel | TTB_1T Business Jet with 60% Camelina Biofuel | |

|---|---|---|---|---|

| Gross Take-Off Weight (WTO) | 15,000 lb | 18,000 lb | 12,600 lb | 15,200 lb |

| Wing Loading (W/S) | 75 psf | 75 psf | 87 psf | 87 psf |

| Thrust-to-Weight Ratio (T/W) | 0.48 | 0.48 | 0.55 | 0.55 |

| Fuel | Advantages | Disadvantages |

|---|---|---|

| Jet-A fuel [75] | ● Low melting point ● Proven effectiveness ● Well-established market ● Relatively cheaper | ● Non-renewable energy source ● Source of greenhouse gases ● High carbon emission |

| Camelina biofuel [76,77,78,79] | ● Renewable energy source ● Easy production ● No threat to the food supply ● Competitive calorific power | ● Expensive ● Extensive extraction process ● No well-established market |

| Jatropha biofuel [79,80] | ● Renewable energy source ● Can be grown in harsh conditions ● Low production cost ● No threat to the food supply | ● Lower yield through extraction ● High viscosity ● High density |

| Fuel Blends | Fuel Cost (USD/nm) | Ticket Price /Pax (USD) | Fuel Price /Pax (USD) | Price Increase /Pax (USD) | Price Increase /Pax (AED) |

|---|---|---|---|---|---|

| 40% BIO + 60% JET | 0.554 | 19,530.38 | 2929.55 | 179.60 | 659.69 |

| 50% BIO + 50% JET | 0.567 | 19,829.60 | 2974.44 | 224.49 | 824.57 |

| 60% BIO + 40% JET | 0.580 | 20,133.50 | 3020.02 | 270.07 | 991.99 |

| 70% BIO + 30% JET | 0.593 | 20,428.01 | 3064.20 | 314.25 | 1154.27 |

| 100% BIO | 0.631 | 21,333.53 | 3200.03 | 450.08 | 1653.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aldarrai, H.; Alsuwaidi, D.; Khan, B.; Xu, H.; Tolouei, E. Numerical Investigation of Bio-Aviation Fuel: Dubai’s Future Perspective. Aerospace 2023, 10, 338. https://doi.org/10.3390/aerospace10040338

Aldarrai H, Alsuwaidi D, Khan B, Xu H, Tolouei E. Numerical Investigation of Bio-Aviation Fuel: Dubai’s Future Perspective. Aerospace. 2023; 10(4):338. https://doi.org/10.3390/aerospace10040338

Chicago/Turabian StyleAldarrai, Houreya, Dhabya Alsuwaidi, Beenish Khan, Haoyang Xu, and Elham Tolouei. 2023. "Numerical Investigation of Bio-Aviation Fuel: Dubai’s Future Perspective" Aerospace 10, no. 4: 338. https://doi.org/10.3390/aerospace10040338

APA StyleAldarrai, H., Alsuwaidi, D., Khan, B., Xu, H., & Tolouei, E. (2023). Numerical Investigation of Bio-Aviation Fuel: Dubai’s Future Perspective. Aerospace, 10(4), 338. https://doi.org/10.3390/aerospace10040338