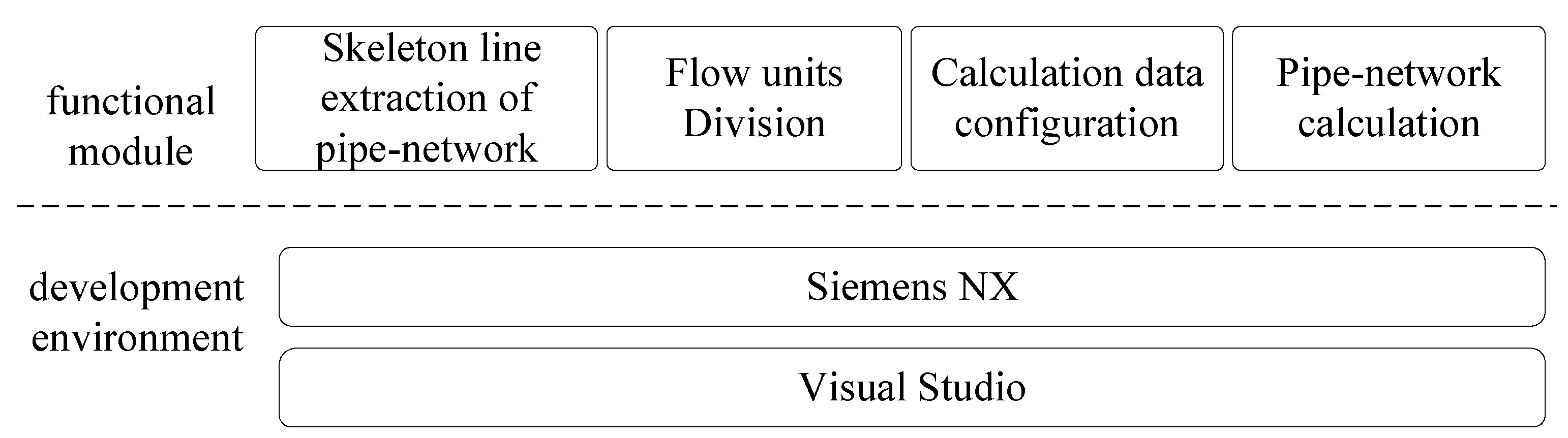

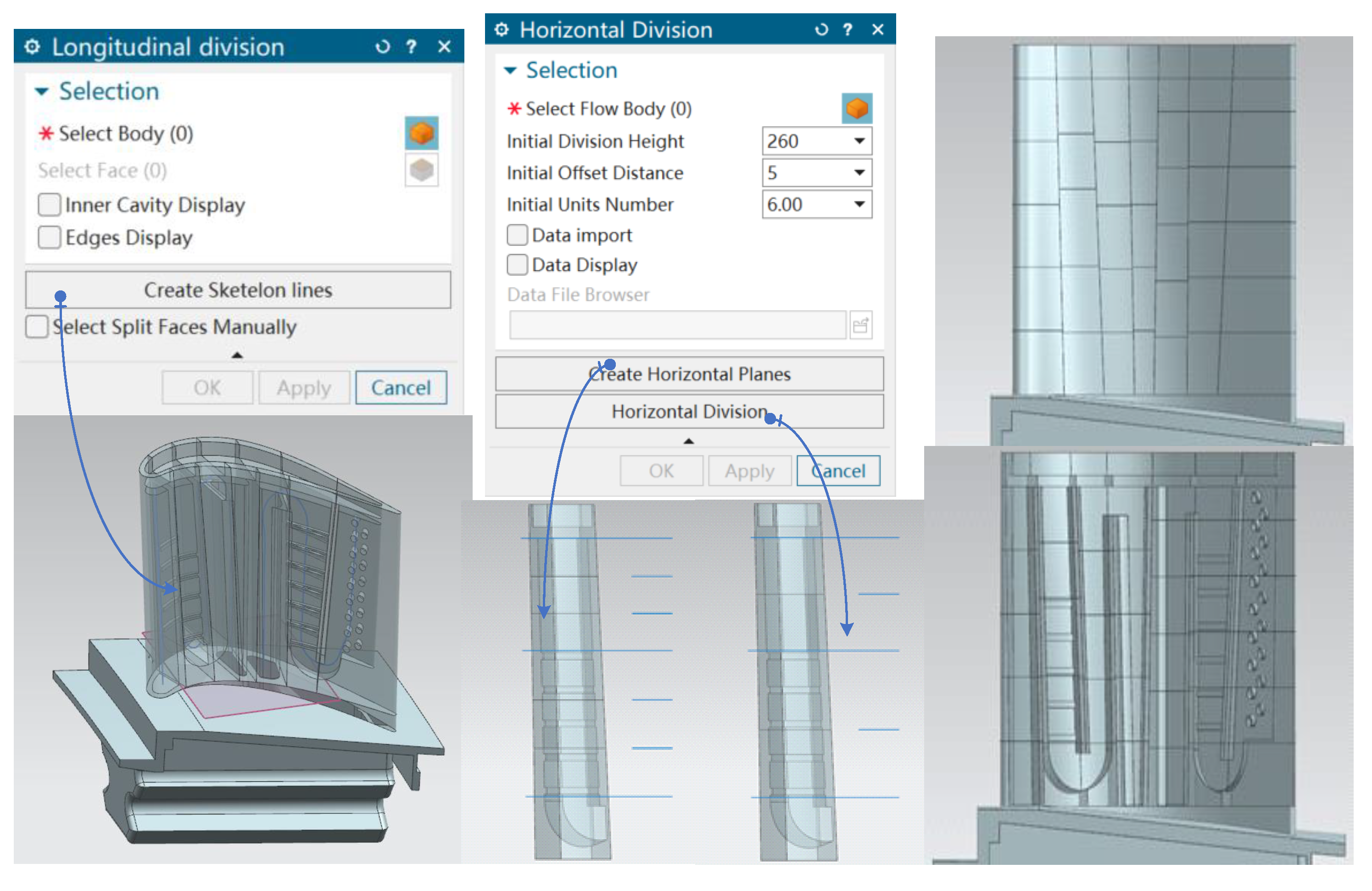

The traditional flow unit division based on manual operation has low efficiency and inconsistent standards, which cannot meet the requirements of automatic data extraction and data iteration. Therefore, an adaptive flow unit division method is presented, which is based on the skeleton lines of the pipe-network. The division plane of the longitudinal flow channel can be identified with the help of the skeleton lines. Then, according to the vertical flow channel obtained by cutting and the standardized input parameters, the boundary plane of the cooling structure is constructed. Finally, according to the marked division plane of the blade model, the flow units are divided adaptively.

3.2.1. Longitudinal Flow Channel Division Based on Skeleton Lines

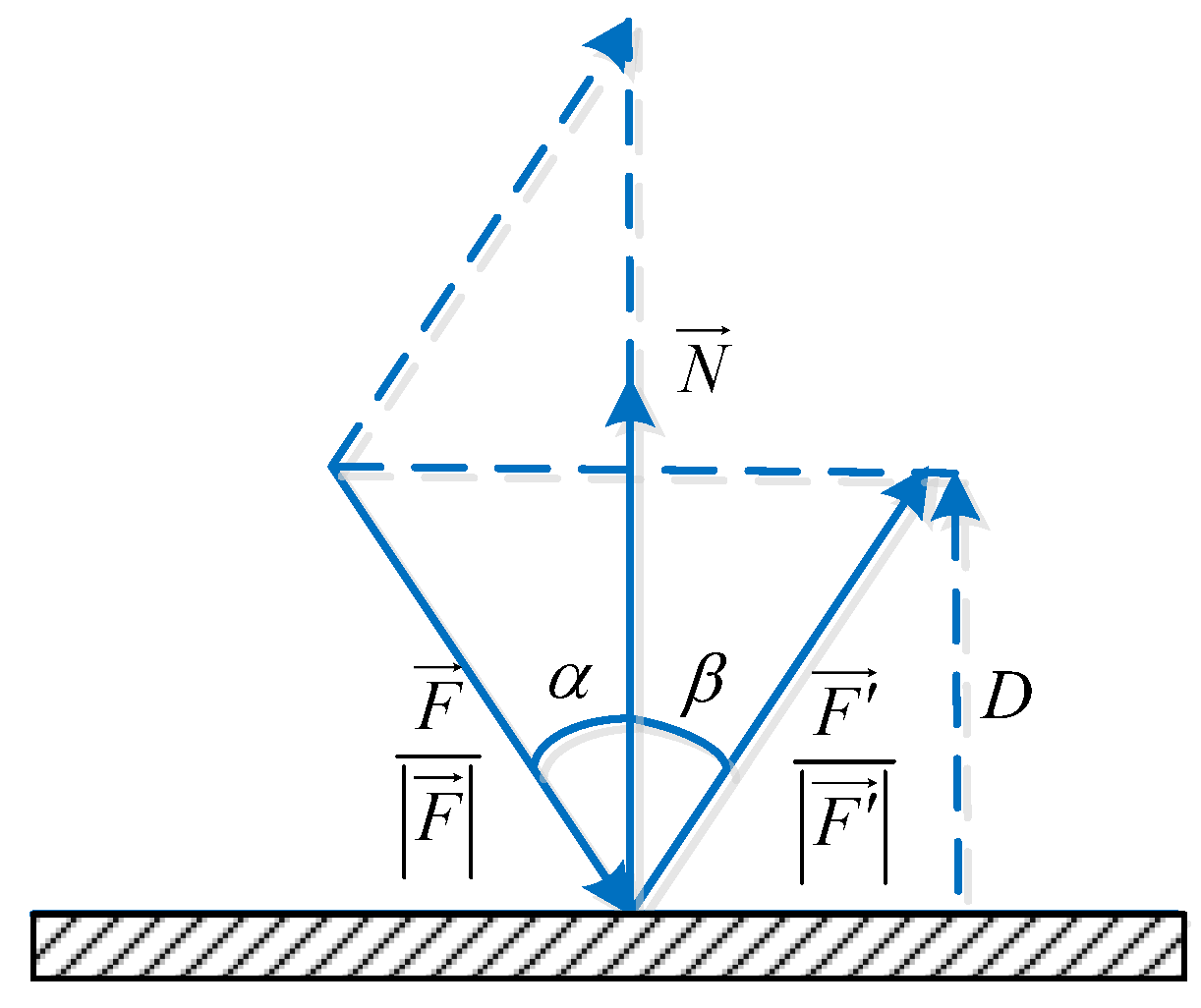

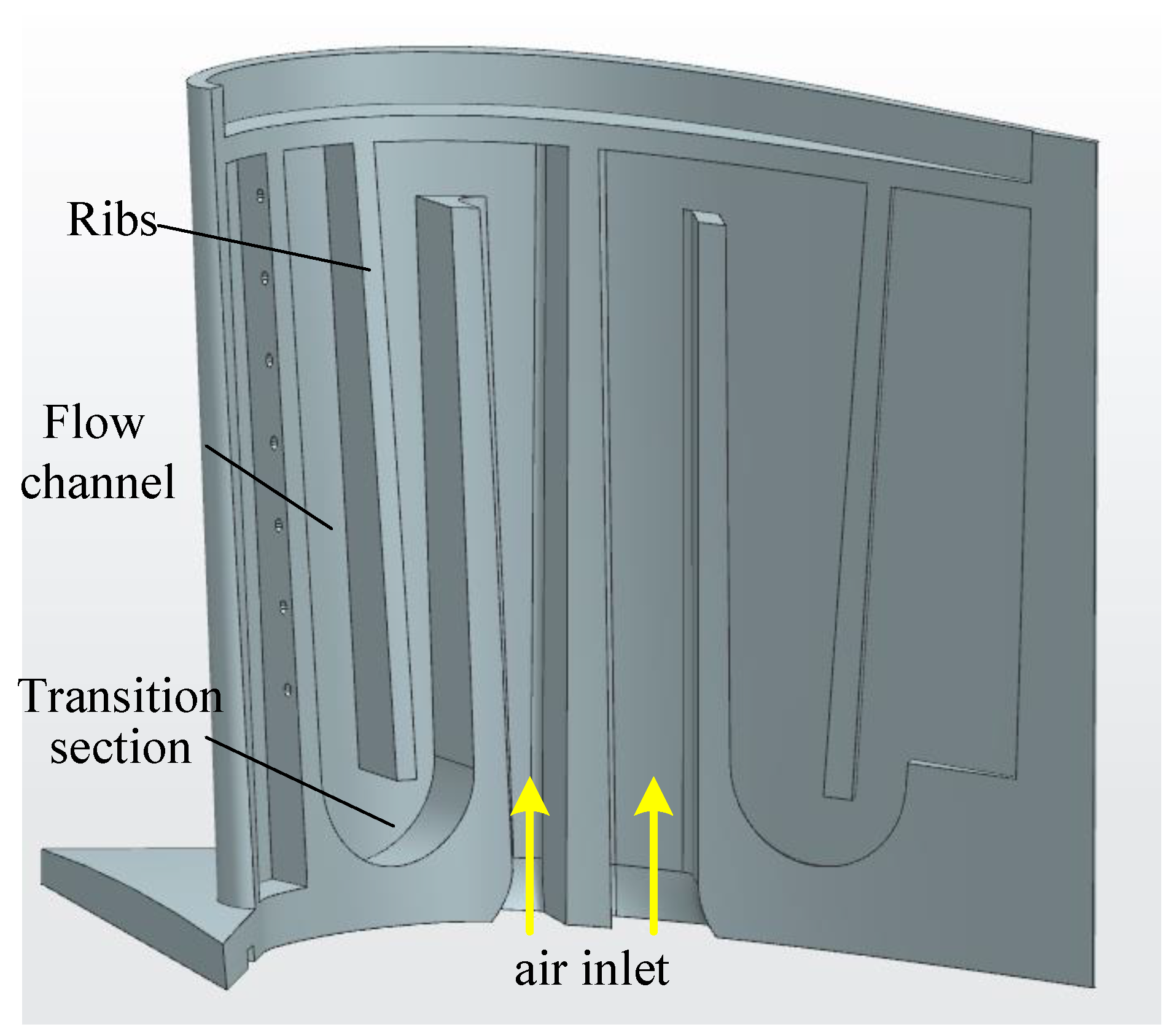

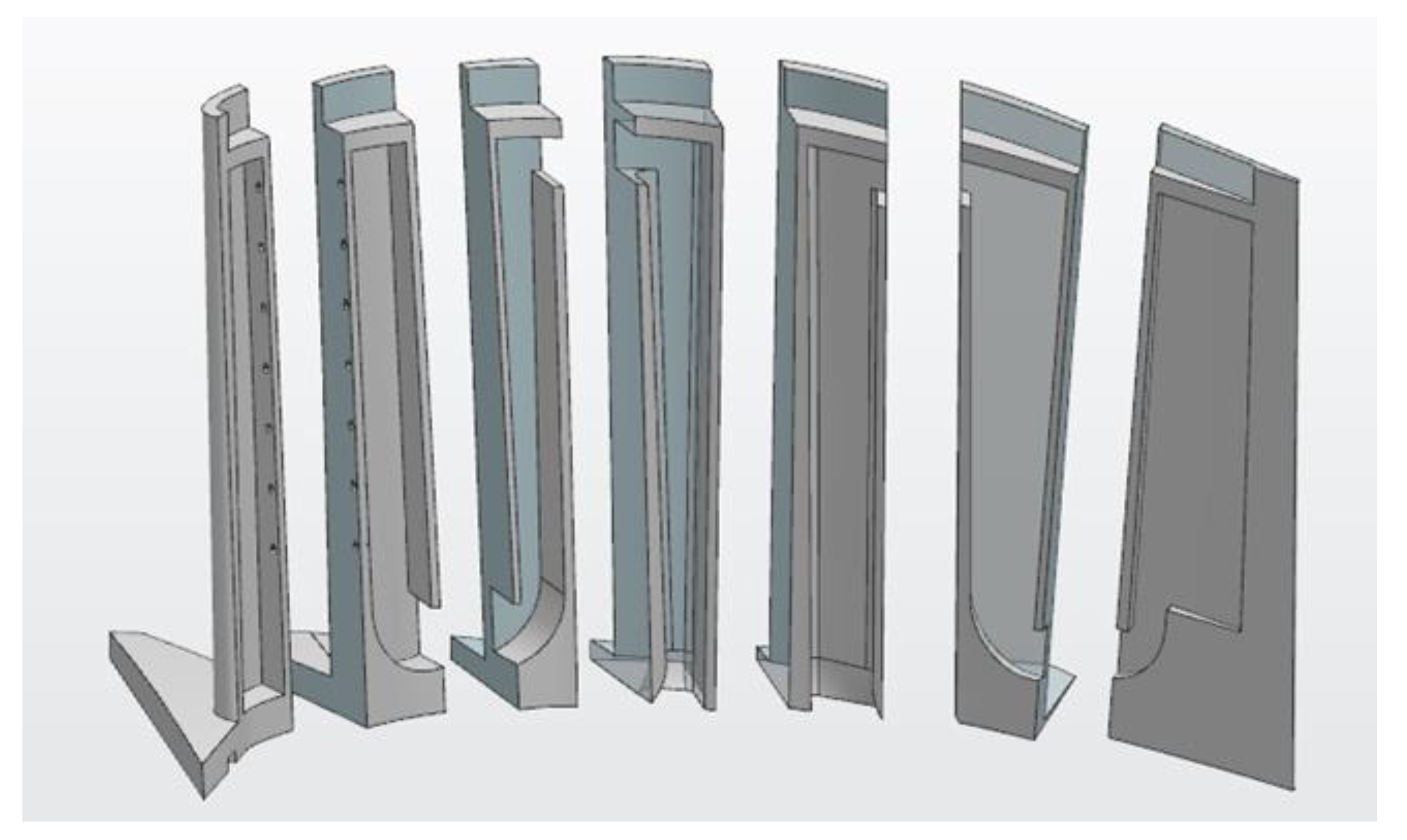

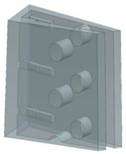

The flow channel of the turbine blade is mainly divided by the spacer ribs to form a plurality of flow cavities. Each flow cavity is connected by a transition section. Therefore, the spacer rib is an important reference for the longitudinal flow channel division of the turbine blade. The division reference planes are formed using the middle surface of the spacer rib and the two sides of the existing spacer rib. For better procedural expression, it is necessary to analyze the characteristics of spacer ribs. Turbine blade spacer ribs are illustrated in

Figure 9.

(1) Geometric characteristics.

Generally, the rib’s side faces are geometrically ruled surfaces. They appear in pairs, although the paired side faces are not necessarily parallel.

(2) Location characteristics.

The transition section connects the side faces of the rib and is the starting point or end point of the flow channel and turning. Therefore, one of the side faces of the rib must be the interval between two adjacent flow paths or the turning position of a single flow path.

The skeleton line is an abstract expression of the three-dimensional fluid flow path. Therefore, the skeleton lines of the flow channels of the turbine blade are used to help to identify the position of the longitudinal division datum planes automatically. The basic idea of generating the longitudinal division planes is as follows. Firstly, the detail features such as spoiler ribs and air film holes on the blade are suppressed, because the detail features interfere with the extraction of the skeleton line and affect the extraction of the reference surfaces of the ribs. Then, all the surfaces of the blade are cycled and stored. All the side faces of the bending and torsion spacer ribs are identified and paired according to the two characteristics. Finally, the middle surface of the spacer rib is generated using the paired side faces, which are the longitudinal split surface. Hence, the longitudinal flow channel division steps based on the skeleton line are as follows.

Step 1. Solid geometry model preprocessing—feature suppression.

The blade geometric model

is cycled to obtain the detailed feature set, such as air film holes, impact holes, tail seams, etc. The detailed features are suppressed.

Figure 10 shows the blade models before and after detail features suppression.

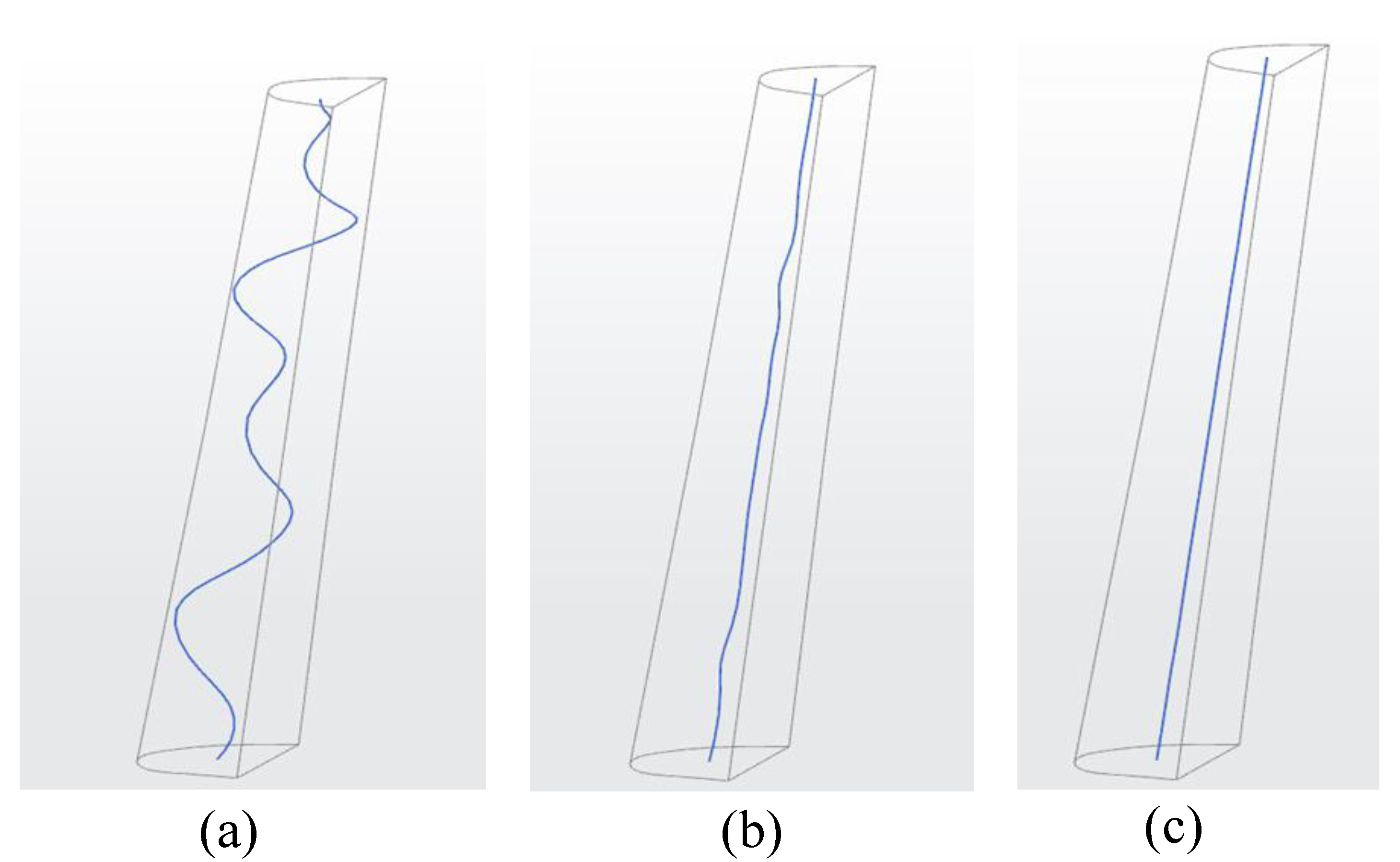

Step 2. Extraction and division of skeleton lines

The flow channel’s skeleton lines

are generated using the method described in

Section 2. Each skeleton line of every flow channel is divided into discrete points

. The sequence of skeleton lines is obtained by sorting each starting point’s

x coordinate of each skeleton line.

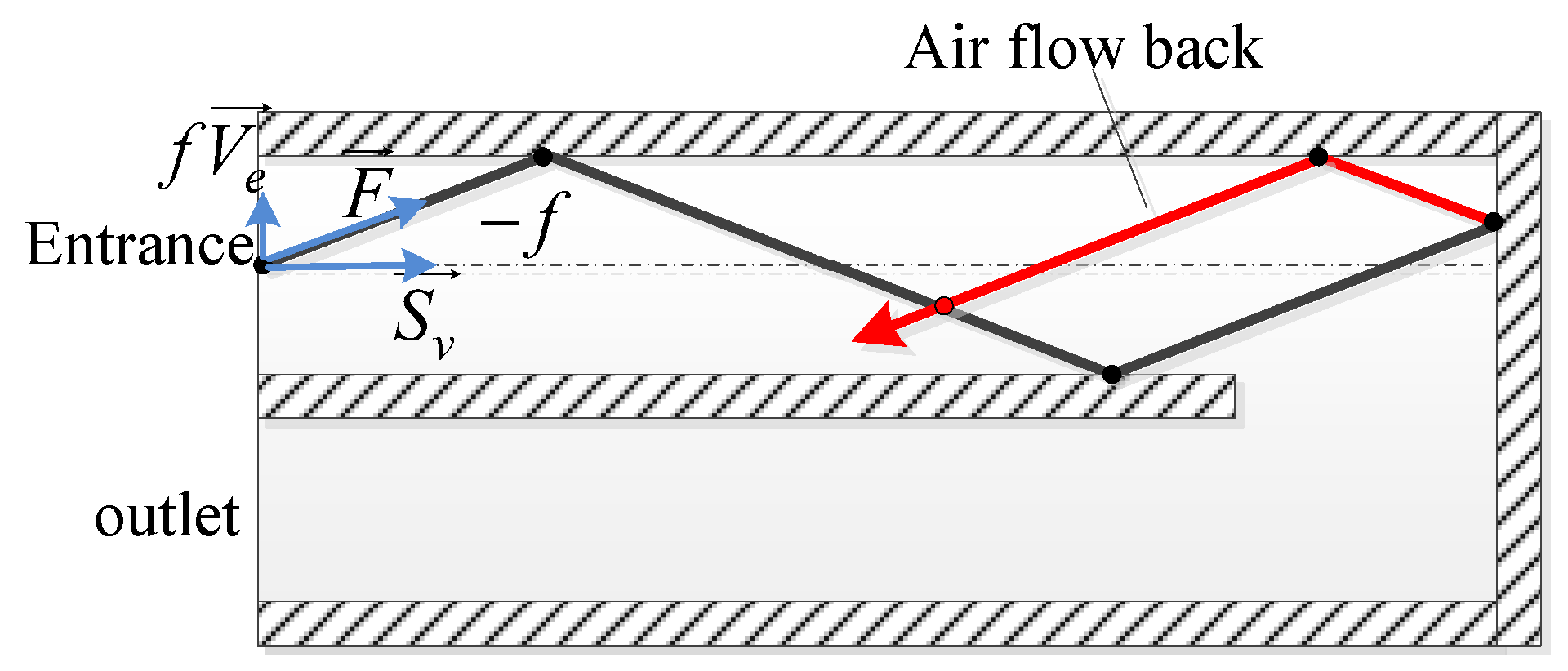

Step 3. Adaptive division of skeleton lines

The turning of the skeleton line depends on the transition section, which is adapted to the spacer ribs. Taking the radial

z direction of blade model

as the reference direction, the points in

, which are the discrete points of each skeleton line, with maximum or minimum

z value are calculated. To exclude possible error interference in skeleton line extraction, it is necessary to set the minimum radial spacing tolerance

of adjacent extreme points as a reference, exclude the extreme point between the tolerances

, and store the extreme point with the larger radial z value, which is the appropriate turning point

after the tolerance judgment. As shown in the

Figure 11, at the four extreme points of

∼

, the initial skeleton line

is divided into seven segments. According to the abscissa of the starting point of the blade spanwise coordinate, the adaptive segmented skeleton lines are recorded as

.

Step 4. Division faces filtering

All the face elements of the blade model are cycled. All the face types and normal vectors are stored as the criterion. The criteria of judgment: (1) type filtering, , design reference planes are excluded; and (2) direction judgment, , the bottom faces of the spacer rib are excluded. An initial face set can be obtained.

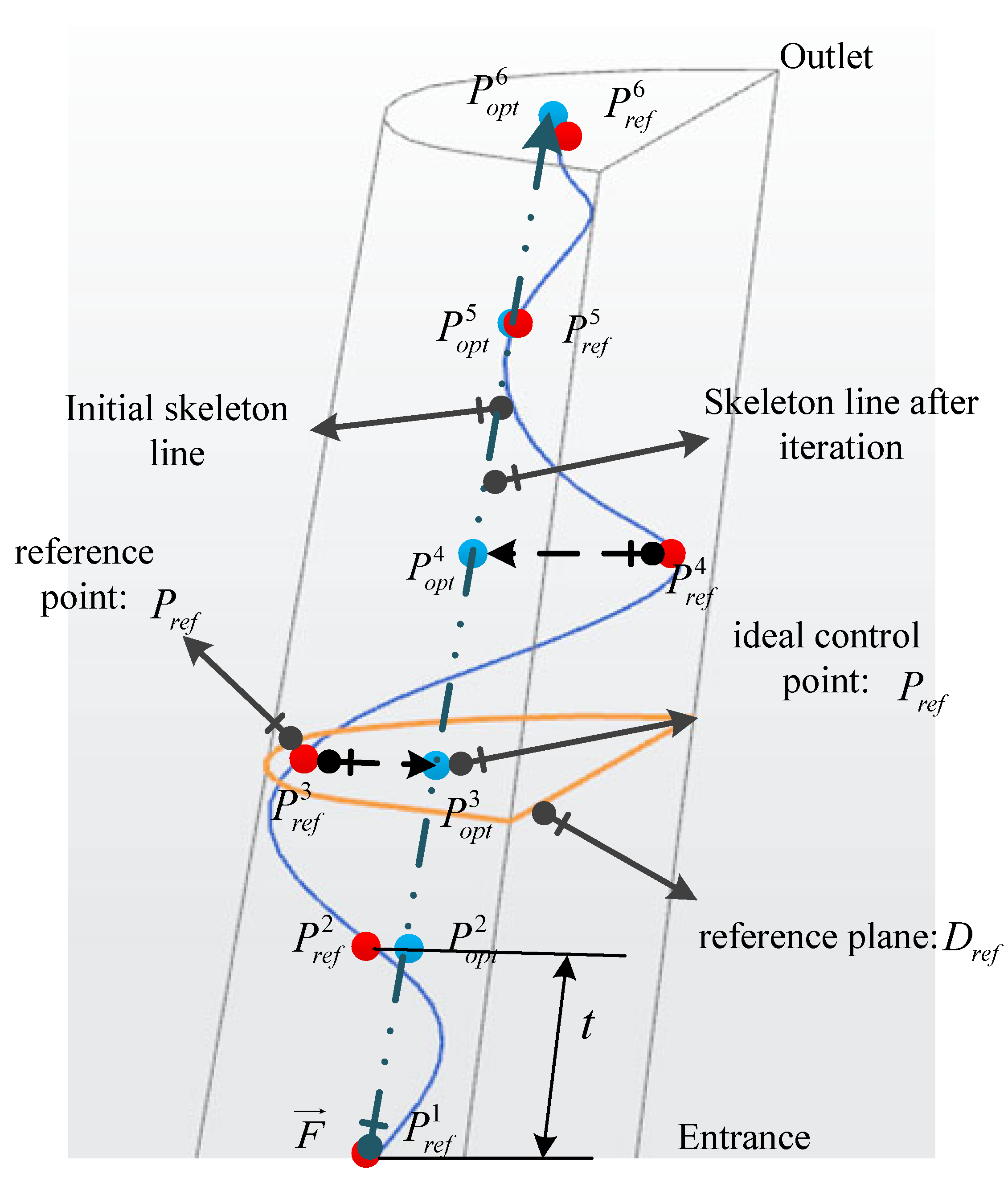

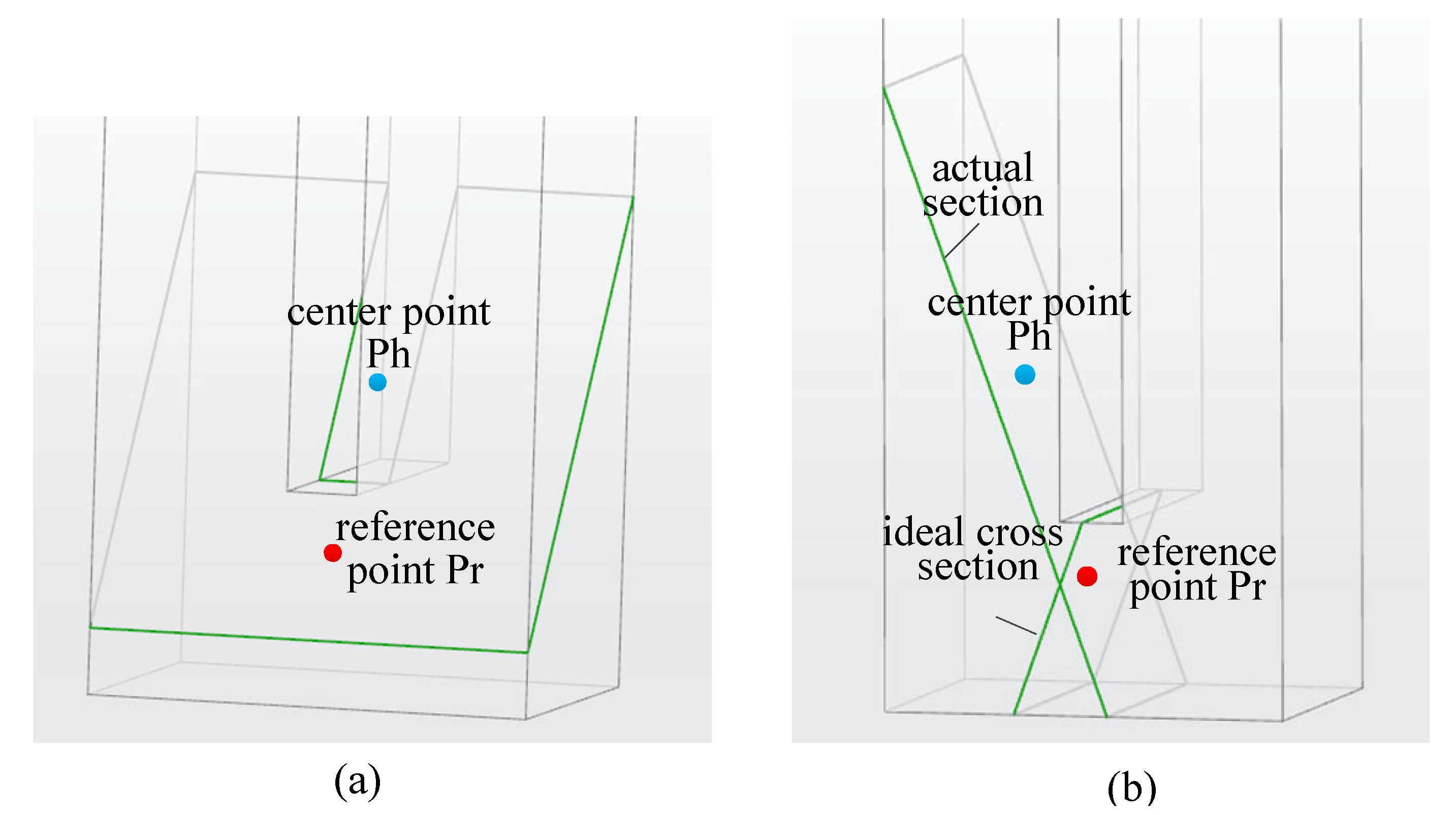

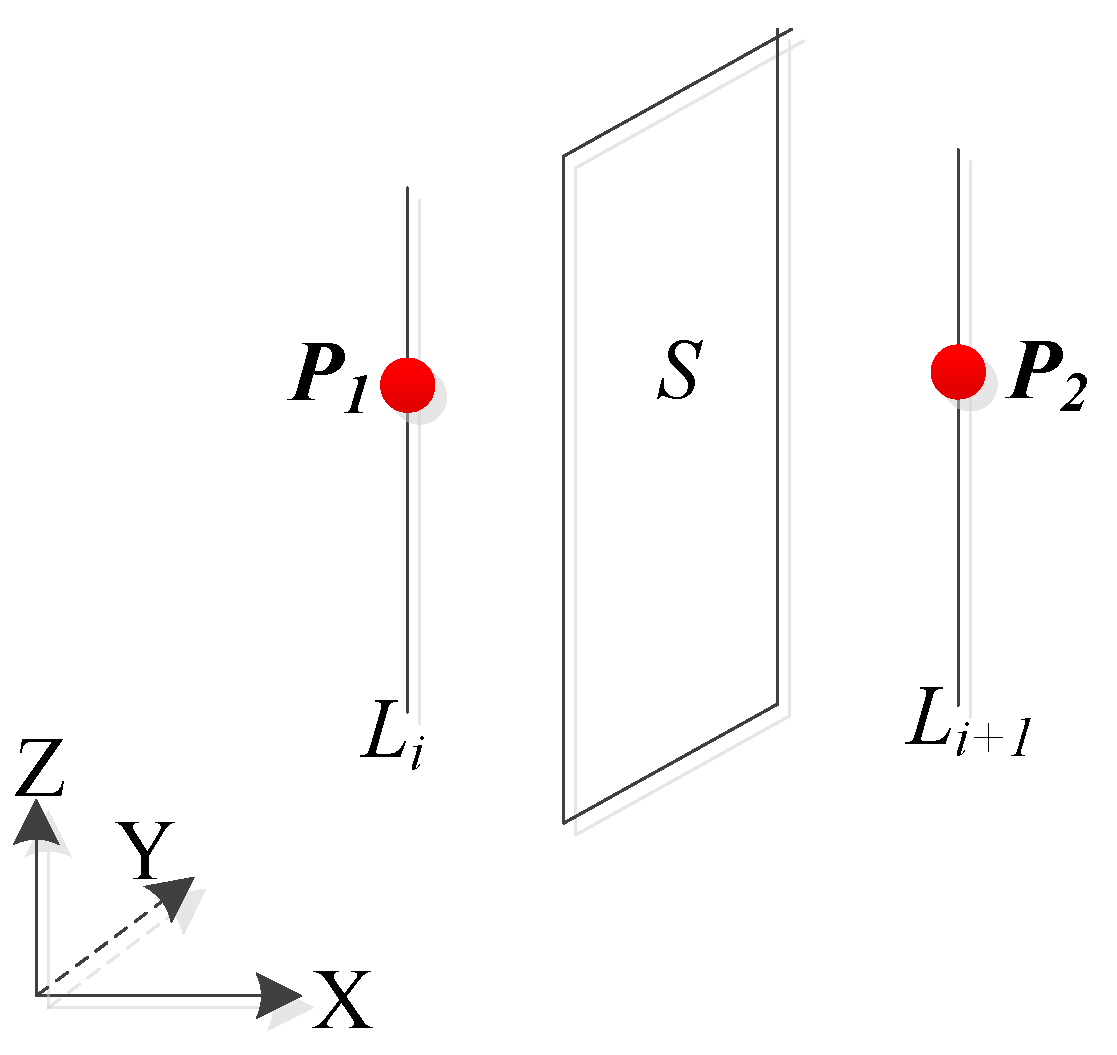

Step 5. Judgment of the relative position of the flow channel wall

If

in

is the wall of the flow channel, then there is

. When

, the points on the skeleton line

are all on the left side of the

, and when

, the points on

are on the right side of

. Due to the existence of errors and the complexity of discreteness, the efficiency will be affected and the robustness will be poor if all discrete points participate in the above judgment. Therefore, two trisection points are selected for each skeleton line as reference points for judging the skeleton line according to the minimum point judgment criterion, as shown in

Figure 12.

Judging the relationship between point and face: If the face

is the flow channel wall face, the points

and

are on the divided skeleton line, and

is satisfied. Equation (

2) must be satisfied.

All the flow channel walls faces

, which are screened out in step 4, are cycled. For

and normal vetcor

of a plane (

), the following Formula (

3) can be obtained.

Substitute Equation (

2) into Equation (

3). If the face is a flow channel wall face, then

, the reference point

satisfies Equation (

4).

Finally, all the flow channel wall faces are found. They are classified and saved according to the value of m.

Step 6. Adaptive division

To further ensure the robustness of the algorithm and prevent the interference of some non-flow channel wall faces, the flow channel wall faces are screened and paired. For paired faces with more than 2 elements, they will be paired again under the consideration of the normal direction of faces. Then, the longitudinal split faces of the turbine blade are generated by creating the mid-face of the paired face.

According to the above algorithm, the blade model is divided into longitudinal fluid units adapted to the skeleton line of the flow channel, as shown in

Figure 13.

3.2.2. Feature Recognition of Flow Unit

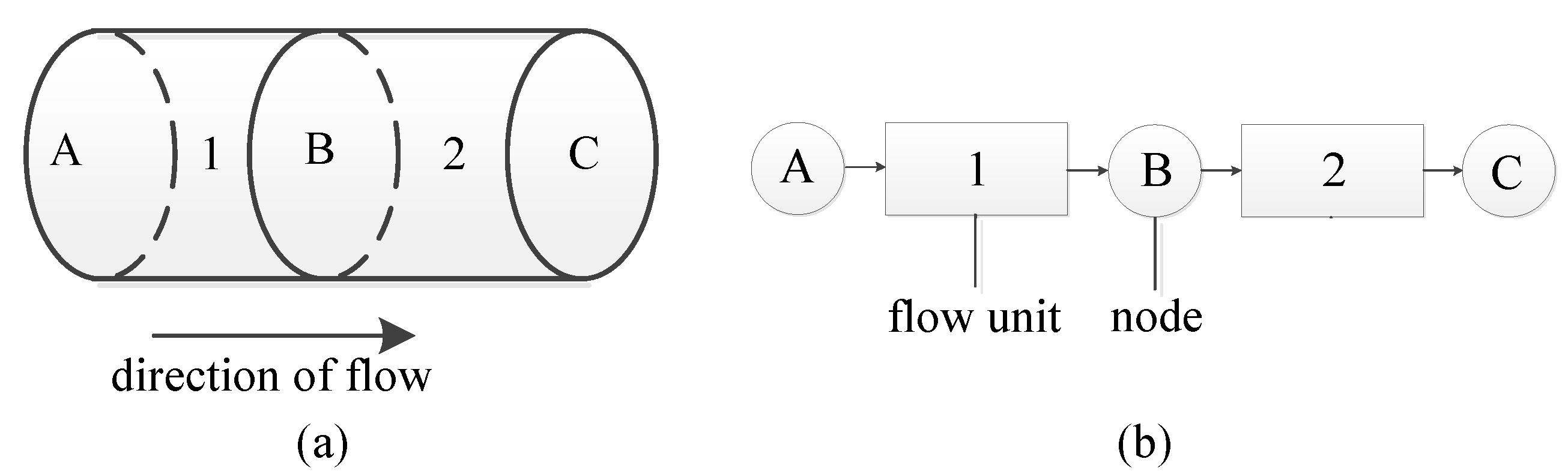

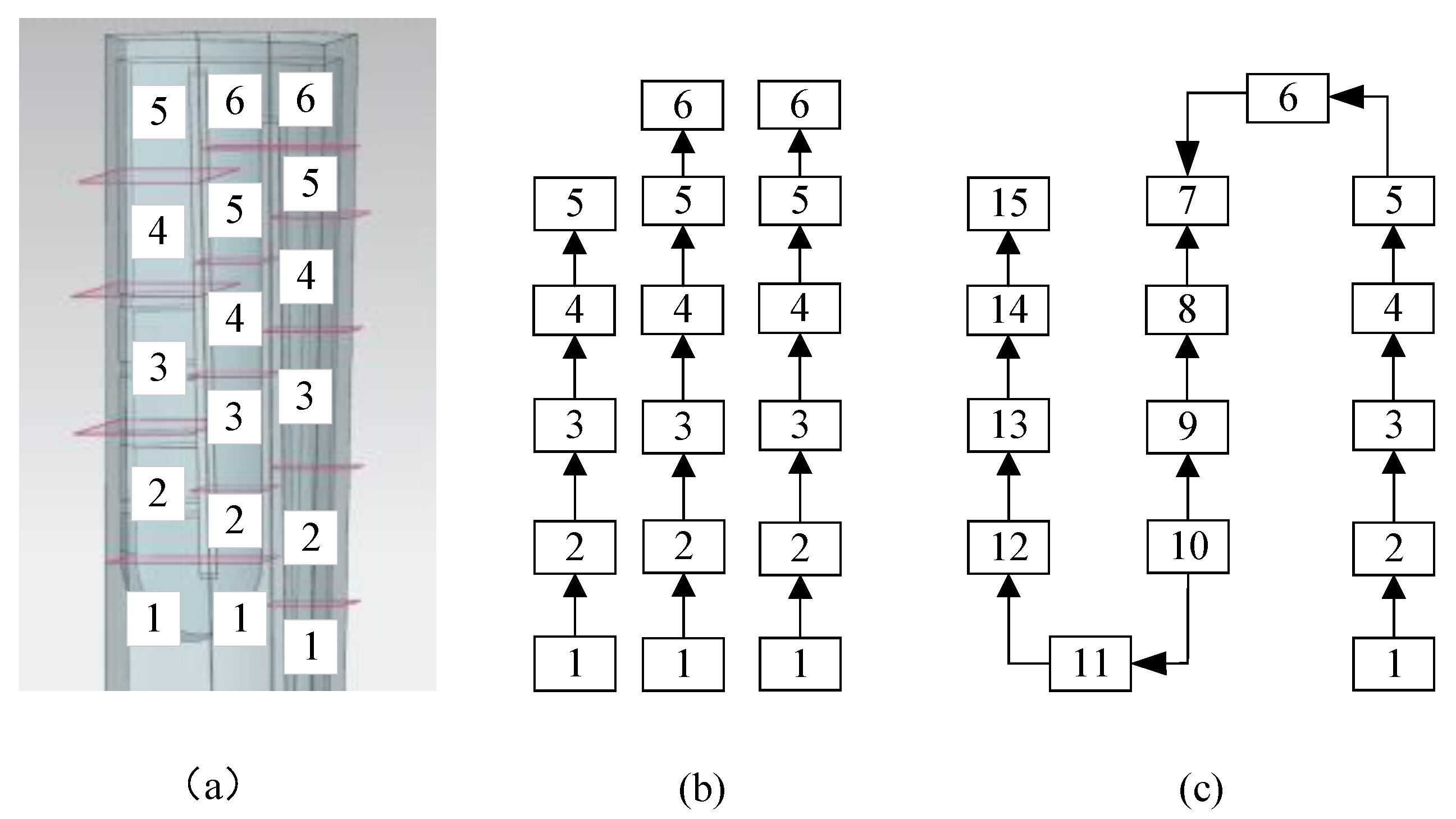

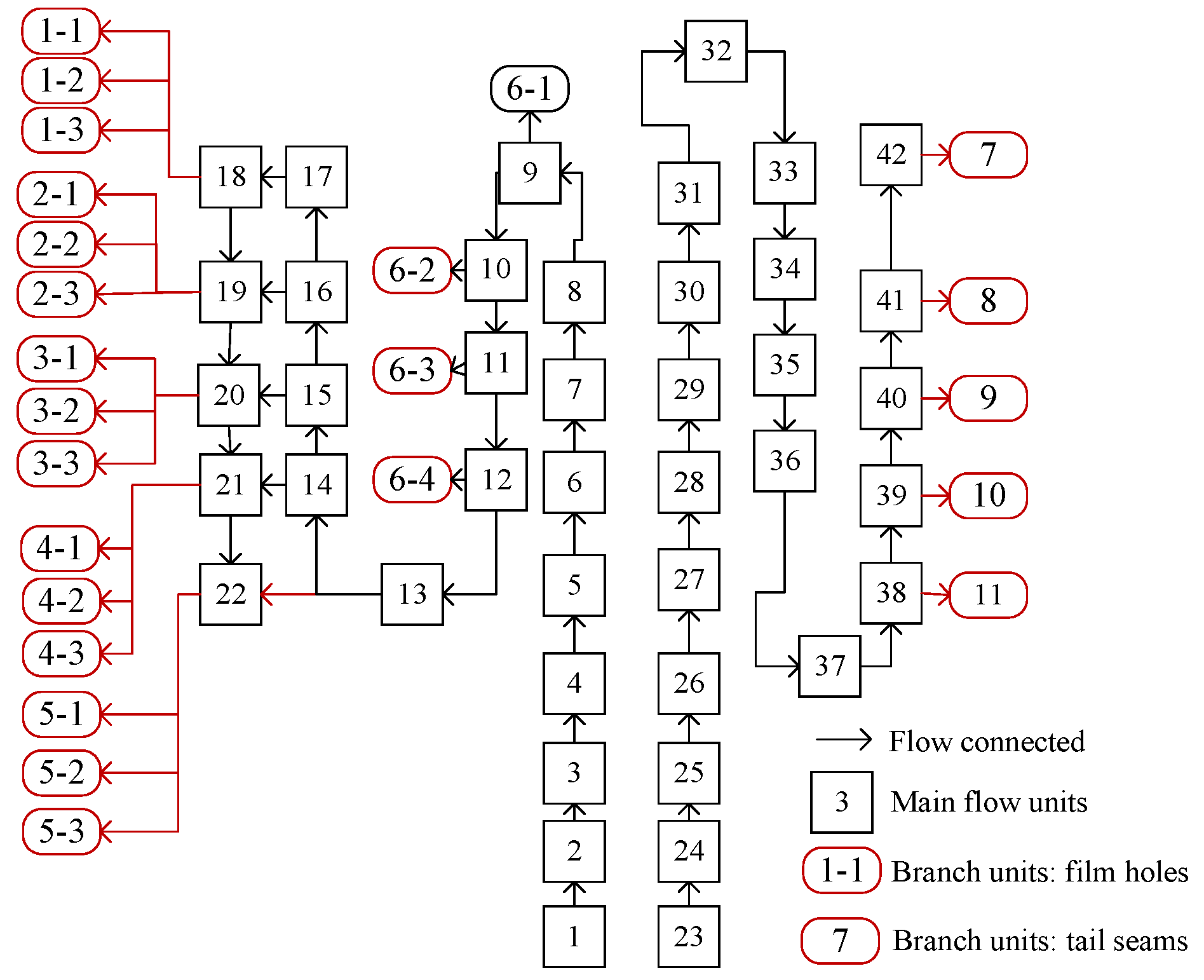

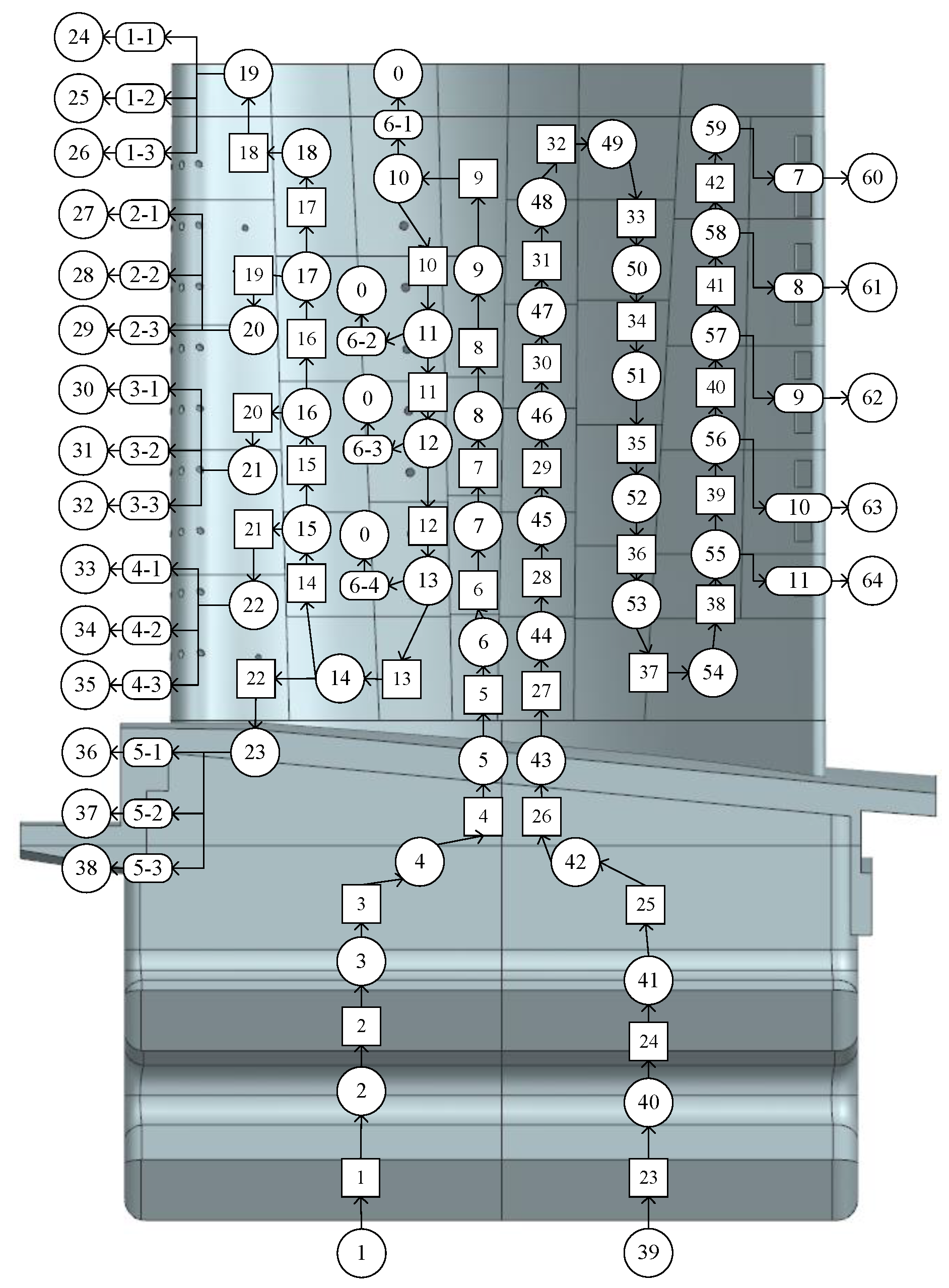

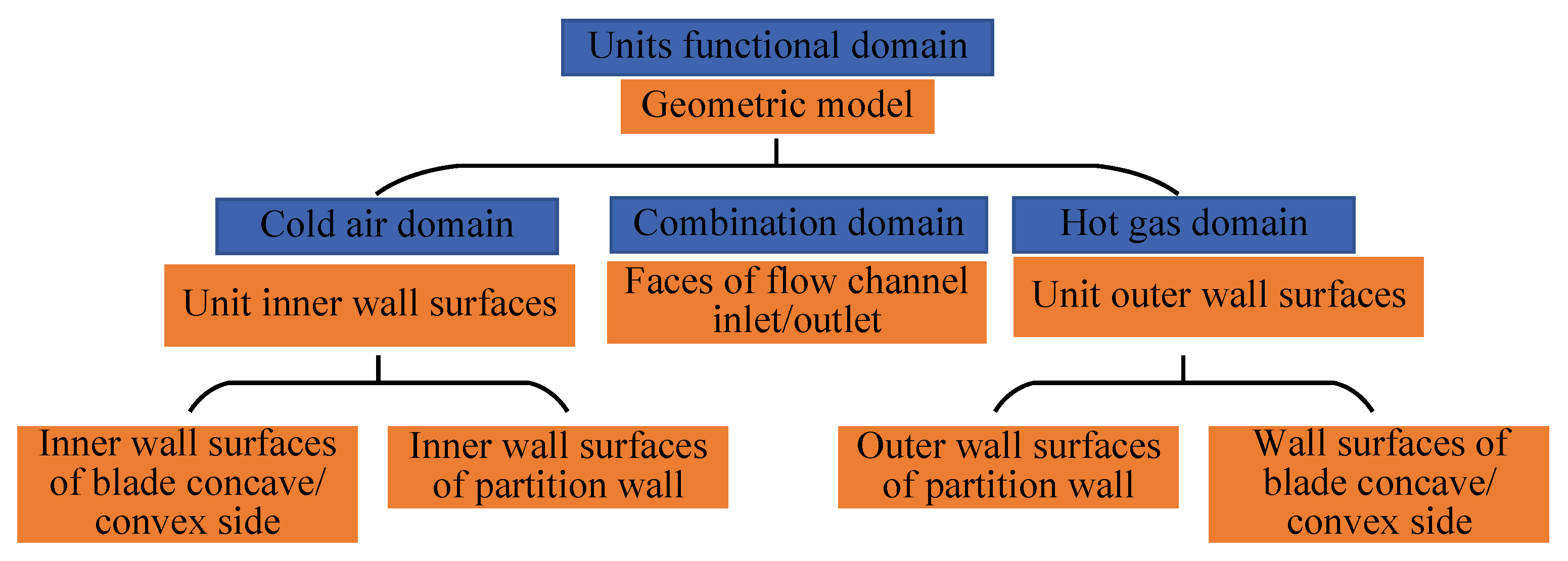

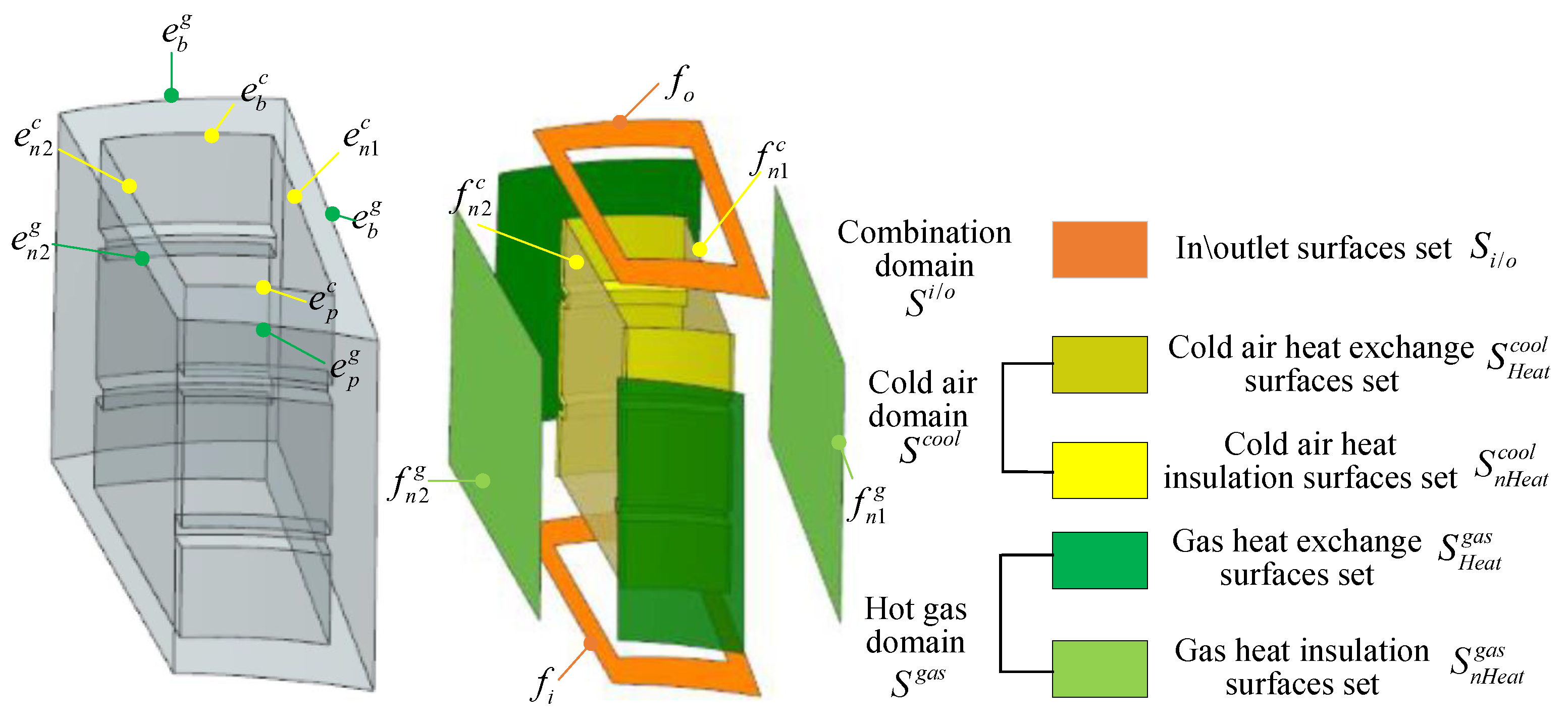

For each longitudinally divided flow channel, it can be abstracted into units that can be calculated one by one. The basic calculation logic principle is shown in

Figure 14. Therefore, it is necessary to build a logical feature library of typical flowing units to facilitate feature recognition, data extraction, and data configuration. The logical features of flowing units are constructed and classified according to their heat transfer characteristics, as shown in

Table 1, which covers most flowing structures of turbine air-cooled blades.

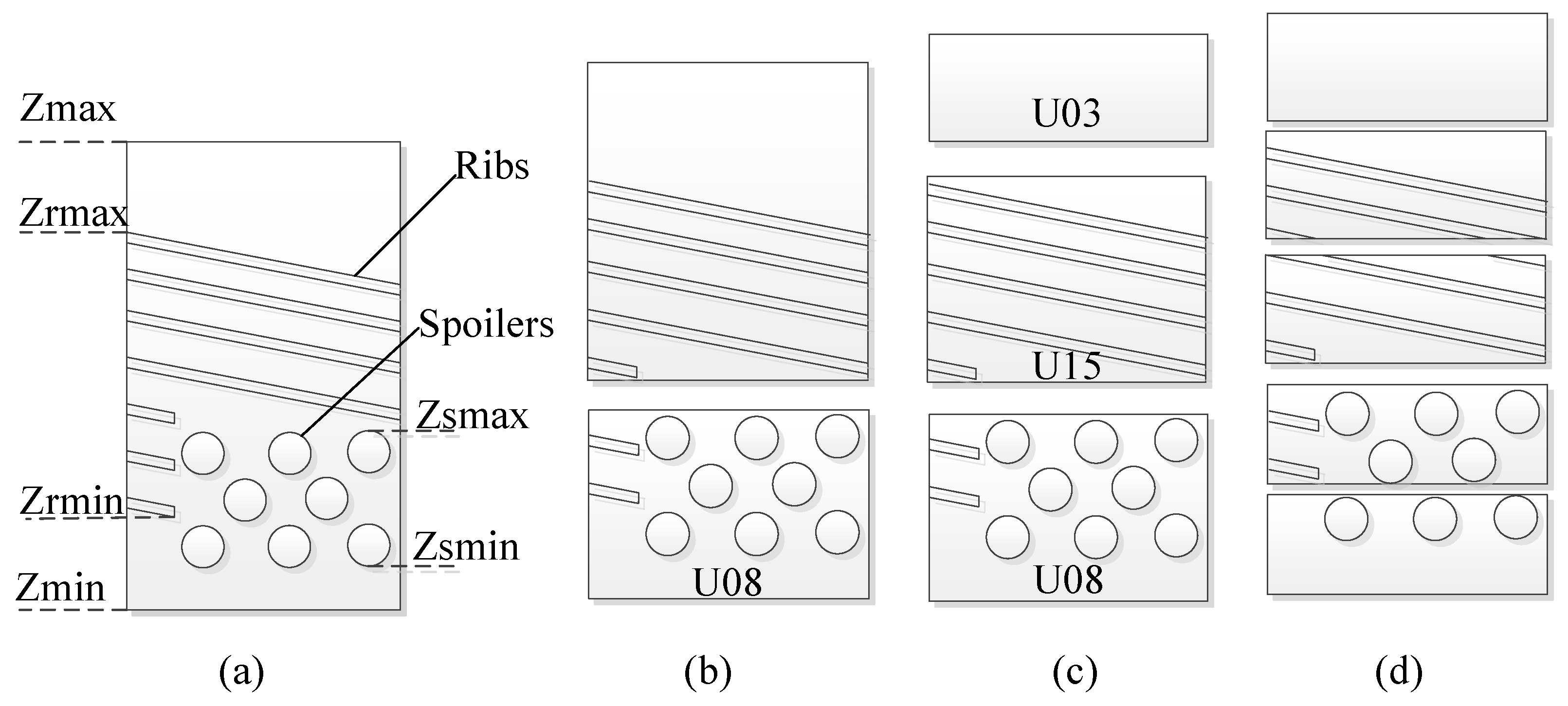

According to the position of the flowing units in the flow channel, it can be divided into two categories: main flowing unit and additional structural unit. The typical flowing units are shown in

Table 1. The main operations of the main flow unit are as follows: flow unit determination, parameter extraction, and unit calculations. The basic calculation process of main flowing units is shown in

Figure 15. The additional structural unit is calculated after the main flow unit calculation. Because they include detailed features such as air film holes, tail seams, impact holes, etc, the detailed features are feature-suppressed during the adaptive division of the flowing channels.

The main channel unit is characterized in turn according to the order of the elbow unit and the straight channel unit.

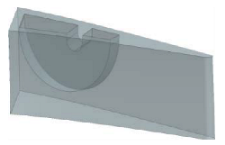

(1) Feature recognition of elbow unit

Such flow unit features are mainly distributed at the turn of the flow channel, which can be divided into

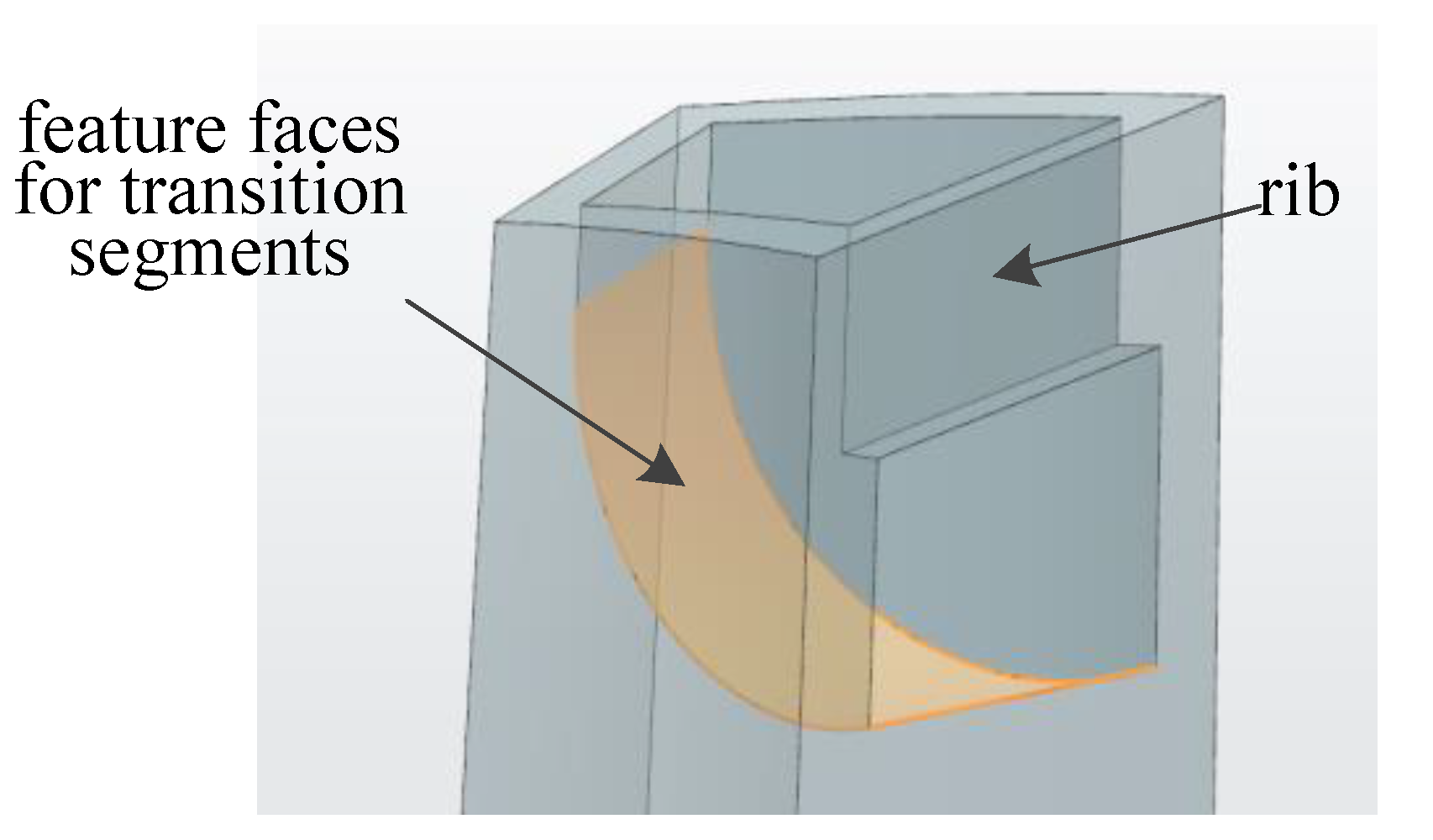

-shaped elbow units and circular elbow units. The main features identified are position and structure. In terms of position recognition, the position distribution can be judged according to the turning pole of the skeleton line. In the previous section, the extreme point of the skeleton line was calculated and discriminated, so the division points of the skeleton line can be selected as the layout feature points of the elbow unit feature. If the structure is completely recognized and extracted, it is necessary to ensure the integrity of the internal cooling structure: (1) feature surface of the transition section, and (2) part of the wall of the partition rib. As shown in

Figure 16, these two features contain heat transfer data such as turning radius, inlet/outlet section width, etc.

Hence, the recognition Algorithm 2 of elbow unit features is as follows.

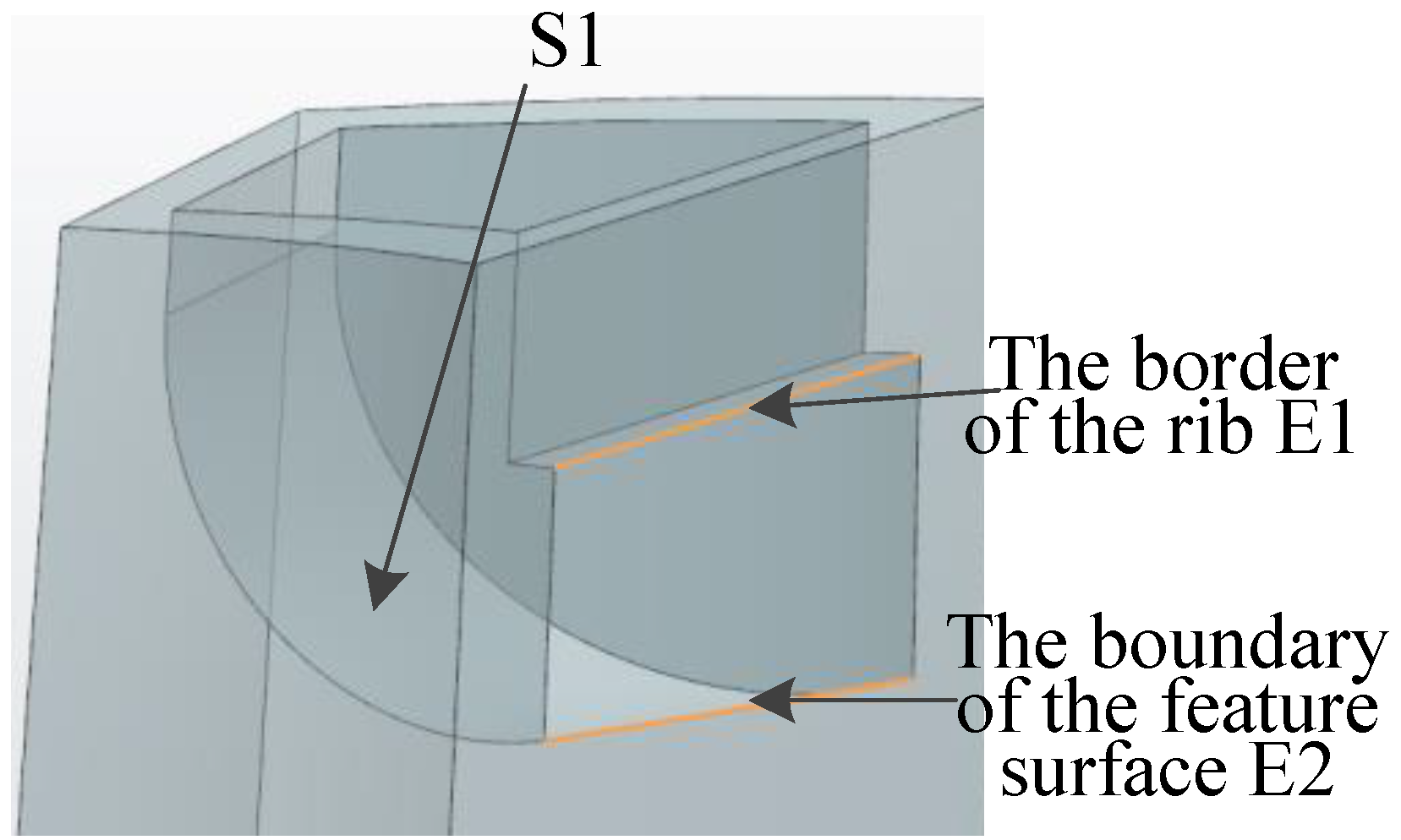

The faces of the longitudinally divided unit are cycled to find the elbow feature face S1, one of whose edges is connected to E1. S1 is set as the elbow unit feature classification surface, which is used to identify and classify the type of elbow units. The main judgment criteria are the characteristic surface type. (1) If the surface’s type is a plane, the unit is denoted as U04, a feature of the -shaped elbow unit. (2) If it is not a plane, it is a U09 unit, a feature of a circular elbow unit.

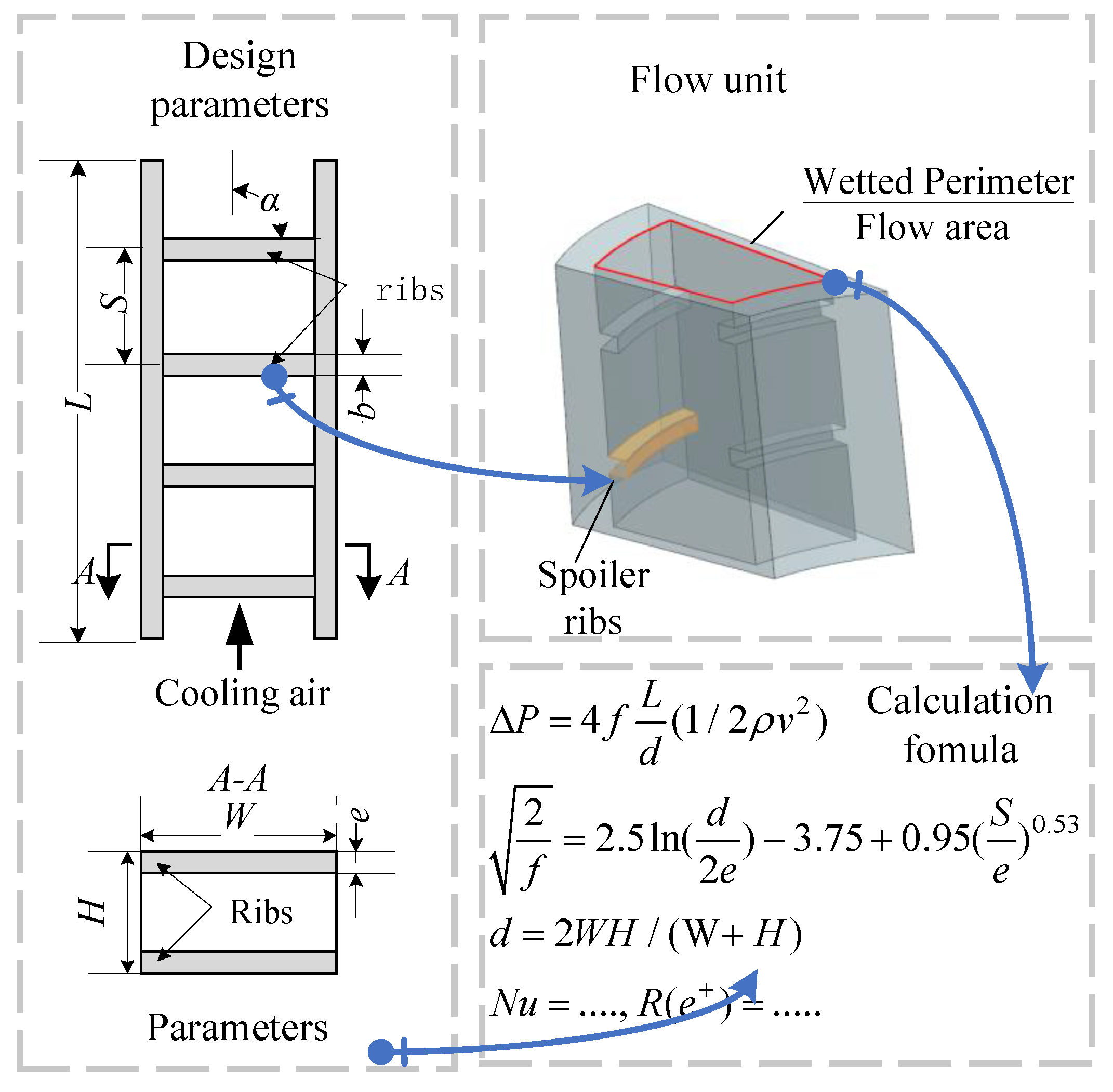

(2) Feature recognition of straight flow channel units

After the elbow units in the longitudinally divided unit are recognized, the rest of the units are composed of straight-flow channel units. The straight units include a smooth straight pipe unit U03, an impact cooling unit U05, a unit with a spoiler column U08 and a unit with a rough spoiler rib U15. The classification of these types of units is based on features such as spoiler columns and spoiler ribs. Therefore, the key to this step lies in the recognition of two types of cooling features. The recognition steps are: All face elements of the blade model are cycled. The faces of the Z-direction bounding box within the Z-direction bounding box of the skeleton line are stored. In the face set, according to the characteristics of each cooling feature, the spoiler column and spoiler rib are recognized in turn. The two types of cooling features are recognized as follows.

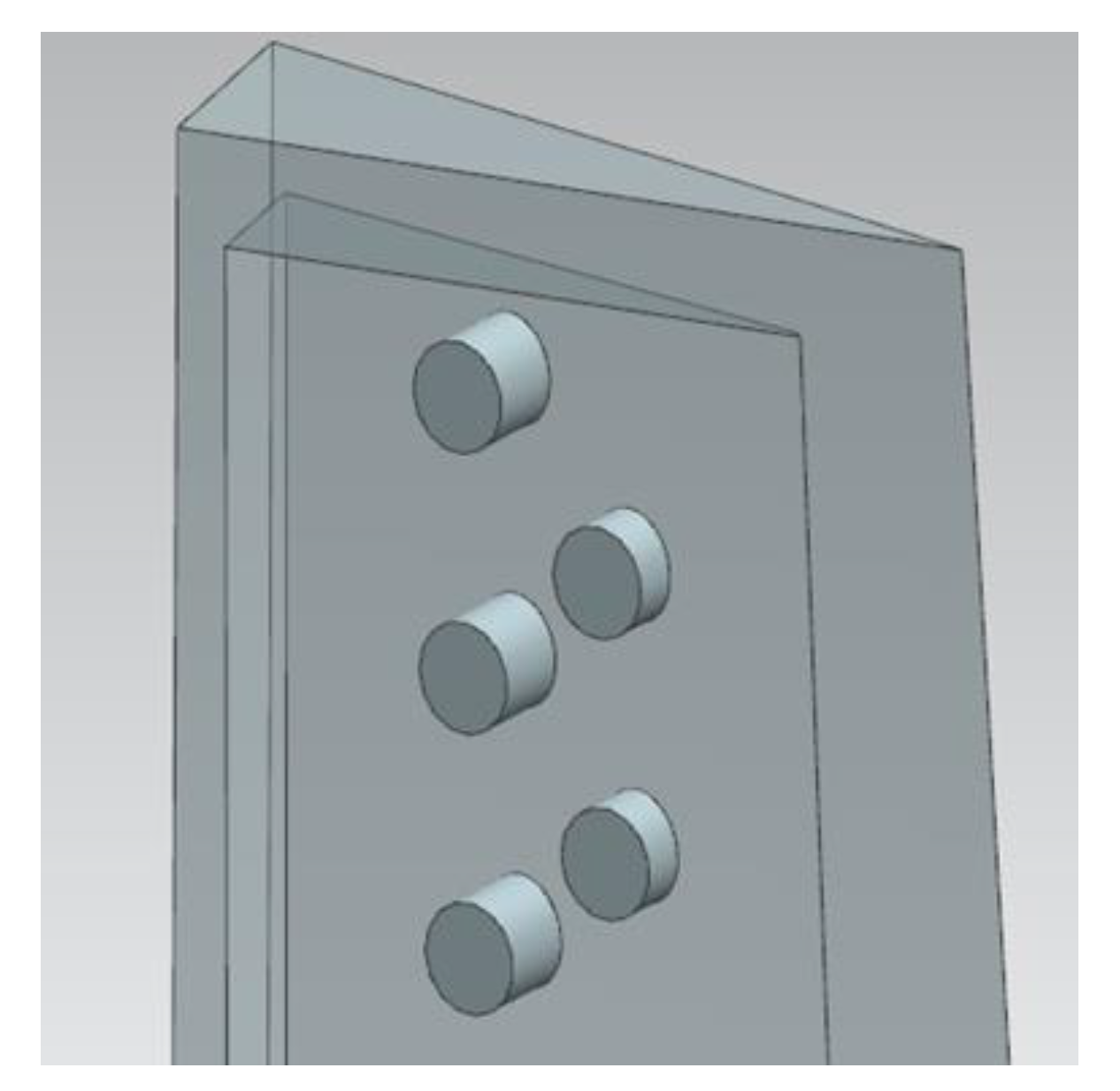

Spoiler column: The spoiler column is usually designed at the trailing edge of the airfoil cavity, as shown in

Figure 18. The section is mainly circular, and its characteristic surface is cylindrical. The cylinder surface in the solid has fillets in addition to the spoiler column. However, the coverage of the fillets is a sector area, while the spoiler column is a complete circle and the number of boundaries of the two is different. Therefore, all the faces are cycled in the face set to find the faces whose type is cylinder

. The edge elements associated with the cylinder are obtained. The face with two edges is the spoiler column. The Z average value of each spoiler column bounding box is recorded. It is arranged in the array

in ascending order.

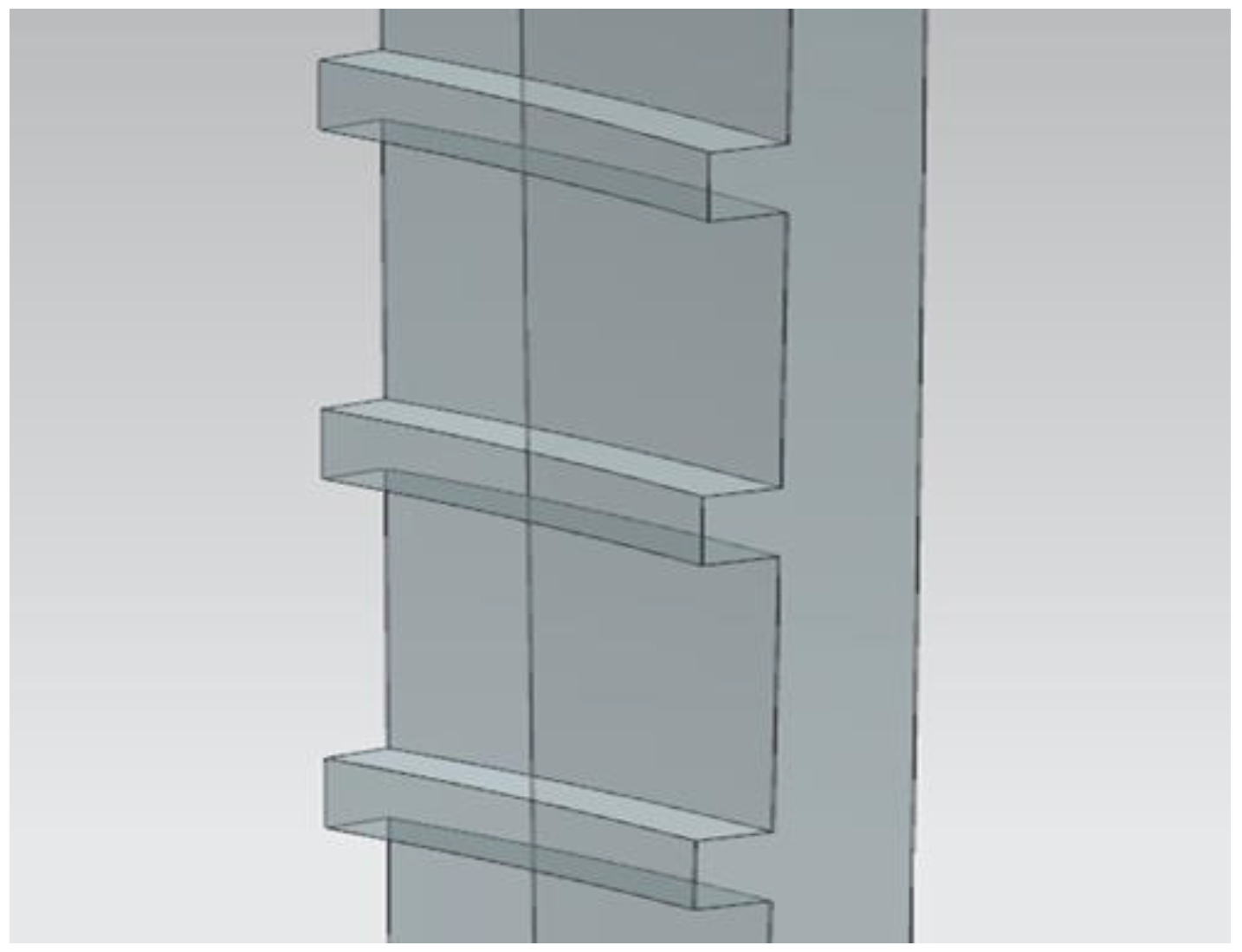

Spoiler rib: The spoiler ribs usually exist in the form of an array on the back of the blade or the blade basin. The top and bottom surfaces of each spoiler rib are a set of planes that are parallel to each other and are parallel to the top and bottom surfaces of other spoiler ribs on the same row, as shown in

Figure 19. Therefore, the planes in the face set can be grouped by the normal direction, and the number of group elements that is more than 4 is the spoiler rib surface. Since the directions of each row of spoiler ribs are not necessarily the same, there may be multiple groups of spoiler rib planes obtained. We record the Z mean value of each plane and arrange it in the array rib in ascending order.

The longitudinal unit that does not contain spoiler ribs and spoiler columns is a smooth straight pipe unit or an impingement cooling unit. Next, it is necessary to generate the diameter division faces according to the position information of the spoiler columns and the spoiler ribs. In the process, a unit height

H needs to be set to ensure that the height of each unit is in a suitable range. The diameter division faces generated method is as follows. Firstly, the spoiler column array

and the spoiler rib array

are traversed, whether there are elements whose adjacent coordinate value spacing is greater than

H. If it exists, it means that there are other types of straight flow units between them. The array is divided again based on this. Since spoiler ribs are allowed to be included in the unit with spoiler column

, the divided face for each group of spoiler columns according to the

Z-coordinate range is

∼

of each group of spoiler columns. It is necessary to judge whether the distance between

and the boundary

of the whole longitudinal partition block is greater than the reference value

H of unit height. If so, a divided face is generated in

, otherwise the part between

and

will be incorporated into the spoiler column unit. After the spoiler column unit is divided, the interface between the spoiler rib and the smooth straight pipe unit is planned in the same way. After all the interface settings are completed, the flow unit is divided in sequence from the bottom to the top. The flow of the scheme is shown in

Figure 20.

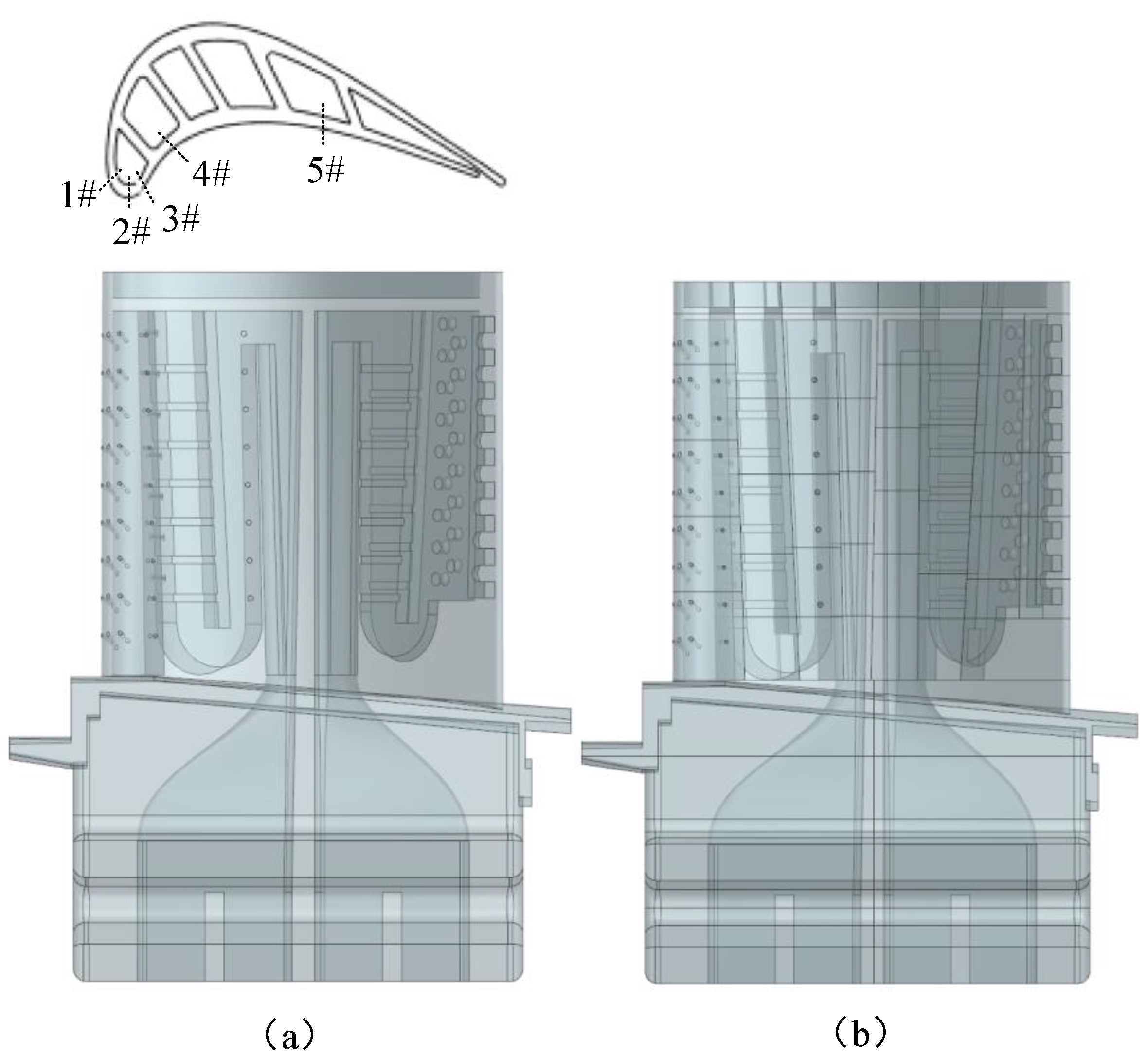

Based on the above diameter steps, in the order from left to right, the cooling structure is recognized and divided for each longitudinal flow channel in turn. A blade model adaptive division result is shown in

Figure 21.