1. Introduction

The aviation industry is more vulnerable to weather than other transport sectors. The aircraft structure, which is made of a variety of materials of different types, moves through the atmosphere at high speed and interacts with the environment through physical or chemical reactions. These have a major impact on the operation of the aircraft and subsequent maintenance. Some parts of the aircraft need to be treated with special additives or methods to ensure safe and comfortable flight in all possible conditions [

1]. One such method to ensure safety is the selection of the correct aircraft upholstery material and paint finish. These must withstand the effects of the external environment at a variety of temperatures, speeds, loads and more [

2]. Among other things, they must also ensure ease of maintenance and easy assembly and disassembly. The parameters of the chosen materials must meet strict requirements and the cost of their use is based on their properties. The goal of airlines is to use materials that meet these strict requirements at the lowest possible cost [

3].

One of the most dangerous factors of atmospheric conditions during flight is lightning. Lightning is one of the most destructive phenomena in nature. The electric current averages 30,000 amperes, and the electric potential reaches several million kilovolts at intervals of about 100 microseconds [

4]. Current data suggest that most lightning occurs at altitudes between 8000 and 14,000 feet, below cruising altitude [

5]. The probability of lightning occurring increases rapidly in clouds or rain. Considering the safety risk posed by lightning strikes and the accidents that have occurred in the past, researchers have developed various solutions [

6,

7].

Lightning strikes can cause two basic types of damage. Physical damage, which manifests itself at the point of impact, and indirect damage, which is caused by electromagnetic coupling. Mechanical damage is caused by the lightning striking the structure, which can cause the material to break, spall or puncture. The first component is the overpressure created by the explosion of the lightning channel, which causes the propagation of a strong shock wave in the radial direction. The temperature can rise to 30,000 K in a time interval of a few microseconds. Due to the current circulation, a strong magnetic field is also generated, which contributes to mechanical constraints. The internal pressure can rise to 50 bar in a few microseconds. The current flowing through the coating causes additional mechanical constraints. Finally, temperature causes thermal expansion, which contributes to additional mechanical stress [

8]. Thermal damage that occurs can lead to melting or piercing of the material [

9]. The safety risk on this occasion is of great concern and the materials used are the subject of serious debate.

The simplest and most effective way to deal with the problem of lightning strikes is prevention, which led to the development of weather radar to avoid this undesirable flight condition [

10]. Nowadays, more advanced technologies such as Deep Learning- based identification or end-to-end prediction from geostationary satellites are used [

11,

12]. Another solution for prevention is slowing of the airspeed, which allows stabilisation of the static rise to a lower maximum value. Many other flight procedures have been developed to avoid lightning strikes. Another option is to provide adequate distance between the metal material and the lightning protection system [

13]. In addition to preventive lightning protection, active solutions have also been investigated. Some metal parts of aircraft, such as ribs, spars and stringers, can be used as safe lightning rods. New technological approaches have enabled the development of non-metallic materials that do not transmit electricity. The disadvantage of these materials is that the connection between glass fibers and plastics do not tolerate voltage stress and charge mobility well. For this reason, external arresters must be fitted to aircraft to attract and then dissipate lightning [

14]. Furthermore, lightning not only causes voltage stress, but also extreme thermal shock. This can manifest itself by burning the paintwork or even damaging the aircraft fairing; thus, a special treatment of the material should be used to improve thermal shock resistance [

15]. Due to the electro-magnetic field, other electronic devices may be damaged or the signal may be disturbed if the protection is inadequate, resulting in interruptions, errors or loss of signal. It is therefore necessary to protect such equipment in a suitable manner [

16,

17]. In addition to electromagnetic fields, high voltages also pose a risk. Today, there are many solutions, some of which are fully automatic [

18,

19].

The method of studying the effects of a lightning strike on material can vary. The most common method involves experiments in laboratories where the generation of lightning is simulated by using an electrode to generate a high-voltage pulse. For such lightning generation, a thin conducting wire is used to help break the air gap between the conducting wire and the sample [

8]. Another method is computer simulations, which can provide a set of complex conditions for generating a wide range of variations [

20]. The biggest advantage is the data output, which is clear and comprehensive.

A salt chamber is used to create an environment that models, in terms of conditions, an environment that simulates the degradation of the material due to the exposure of the material to certain elements of the atmosphere over a period of several years in a much shorter time. All aspects of the salt chamber simulation were subject to the STN standard.

The development of experiments to model the situation after a lightning strike followed by the insertion of a material sample into the salt chamber is carried out to analyze the damage to the material that can occur during real aircraft operation. The analysis of the materials, which was carried out in a partial way, i.e., after the lightning strike and subsequently, and after the salt chamber test, shows that the damage to the coating and paint depends on the surface and material treatment used. Choosing the appropriate material that can best withstand lightning strikes and environmental influences can save considerable funds associated with aircraft maintenance and ensure the privilege of aviation safety [

21,

22].

2. Materials and Methods

2.1. General Information

In order to create the best possible laboratory conditions, keeping in mind the safety of the participants of the experiment, parameters were chosen for the construction of a device to create an electrical discharge simulating a lightning strike [

23]. The stand on which all the components were placed to create the electrical discharge needed to be properly grounded. The pedestal on which the samples were placed was made of metal and wired into the ground. A metal electrode was chosen to induce an electrical discharge, which was used to direct the discharge into the sample material. The electrode featured a final tip-shaped section before achieving the most accurate strike to the sample. An electrode of a different shape, e.g., rounded, could cause the discharge to be directed away from the test sample.

2.1.1. Electrical Discharge and Propagation

The method of current propagation in the material has certain sequences in which certain peaks are reached. The way the current passes through the material in time can be divided into different phases (1,2,3,4). Group 1 is the first one in time, when an electric discharge hits the sample and there is a sharp increase in the current in the sample. This current then rapidly decreases and propagates further through the sample. Phase 2 is specific in that the decrease in current magnitude is smaller in time scale than for phase 1. Subsequently, the current transitions to phase 3, where the current flows through the sample at a constant value. In the last part, phase 4, there is a short-term re-increase in current, which reaches a certain peak and then drops to zero value [

8].

2.1.2. Air Gap

Another subject to investigate for the generation of an electrical discharge is the air gap between the electrode tip and the sample. There are several variations of the generated electrical discharge that depend on the size of this air gap along correlated with the magnitude of the electrical voltage. Four basic types of generated discharge include: streamer breakdown, electric arc, streamer waves and glove corona. Depending on the amount of voltage and the size of the gap between the electrode tip and the sample, the basic differences can be defined into: short gap and large gap. For short gaps, if a high voltage is applied, either a streamer breakdown or an electric arc is formed. At low voltages, streamer waves or glove corona are formed. If the gap between the electrode and the sample is large, streamer waves or glove corona are formed at low voltage. At high voltages there are more variations, namely corona streamer, electric arc, leader or leader breakdown [

24,

25,

26,

27].

2.1.3. Material

Aluminum alloys are a conventional type of aircraft coverage compared to composite materials, which are currently used in aerospace due to their excellent strength-to-weight ratio. The disadvantage of composite materials is their electrical conductivity, which is low, and a possible lightning strike on the aircraft surface could cause serious damage to the material.

When lightning strikes an aircraft coating, various forces are propagated that cause a change in the structure of the material, namely: Current streamline, Vaporization flux, Dielectric breakdown, Joule heating, Thermal flux, Radiative flux, Acoustic force, Magnetic force [

8].

2.2. Coating

Among the basic parameters that an aircraft coating must meet are: corrosion protection, reduced adhesion of dirt and other contaminants, reduced drag and low weight, what improves fuel consumption. Other preferred requirements also include good cleanability, excellent gloss and light reflection, resistance to chemicals, ease of application and a host of others. Nowadays, composite materials are used as aircraft coatings, which provide a number of advantages that are significant compared to conventional metal coatings. Composite materials are made up of two or more materials that have distinctly different chemical and physical properties. Their correct combination results in appropriate coating properties that provide a lightweight material with high strength and stiffness values. The disadvantage of this composite material is the low electrical conductivity, which is compensated for by the coating material [

28,

29,

30,

31,

32].

Aircraft coatings consist of two basic parts. The first is the primer, which may consist of various elements that provide adhesion, durability and provide corrosion protection. Such primers may be, for example: zinc phosphate or zinc chromate. However, tests have shown that they are highly toxic and have caused the development of cancer in animal tests. Therefore, it is important to observe strict safety precautions during application and the topic of coatings has become a concern, inspiring the development of non-toxic coatings [

33,

34].

The second part of the coating is called the topcoat. Like the primer, the topcoat meets certain requirements. This part is exposed to the weather and must provide UV protection, chemical resistance and impact resistance [

33]. Since metallic materials are capable of conducting current, it is possible to divert a large amount of this current in the event of a lightning strike so that the safety of flight is maintained. In the case of non-conductive materials such as composite, the lightning protection solution is different. One such solution is to add metal particles to the paint, like silver or copper [

35,

36].

2.3. Samples

For the experiments, 12 coating samples of real aircraft were used. Each of these samples was made of aluminum material, covered with primer and topcoat. The samples are square in shape, 15 × 15 cm with thickness of 1.9 mm. All samples are made up of one type of material. These samples were provided by (ATB) Austrian Technik Bratislava, an aircraft maintenance company, and supplied samples of the material used on real aircraft together with a primer that complies with aviation legislation. Each sample differed from the other in the type of primer and topcoat and their combinations. These primers were of 3 types: 10-P4-2/EC-117, PR143, AW2001. Each of these coatings varies in its composition and properties, based on which they are used for a specific operation. The topcoats which were analyzed can be distinguished depending on composition. The metallic topcoats which were used are: Deco color acryl metallic, Primalex metallic spray matte, Primalex silver metallic gloss. The non-metallic topcoats are: Eclipse 080,775 red Bac 1023, CA8800-P064C-Kaho-blue, AVIOX 77,702 041,537 white FSBI17875. The following

Table 1 is used to describe the primers,

Table 2 is used to describe the topcoats and

Table 3 explores the individual samples for the specified paint combinations.

2.4. Set Up

The measurements are provided for the setup shown in

Figure 1, experimental stand is shown in

Figure 2, while

Figure 3 captures the electrodes in detail with dimensions. The air gap above the tested sample was set to 50 mm. The small gap shown between the steel gauge (serial no. C0298) and the tip electrode in

Figure 1 is the thickness of tested sample.

As the source of lightning impulse, a symmetrical 10-stage impulse generator with the maximum output voltage of 2500 kVmax was used, with a total energy of 100 kJ from TuR Dresden (serial no: 0-1656). During the experiment, only two stages of impulse generator were connected. For measuring purposes, an impulse voltage divider from Haefely-Trench RCR 400 (serial no. 554381-2), digital measuring instrument DMI 551 (serial no. 081 393-03), digital oscilloscope Tektronix TDS3052C (serial no. TDS3052C C011754) and a notebook computer with Tektronix SignalExpert software installed were used.

To every sample, a set of 10 negative lightning impulses with a shape of 1.2/50 µs at maximum voltage level of 100 kVmax were applied.

2.5. Results Evaluation

The results were evaluated in three ways. The first was to observe the results of the sample damage with the naked eye. The second was to use a microscope to observe more thoroughly, and the third was to use laser scanning confocal microscopy.

2.5.1. Naked Eye Observation

Naked eye observation is carried out after the electric discharge tests by looking to evaluate the results of the damage. It also includes the use of feel to detect mechanical damage to the coverage and coating. By simply comparing samples, preliminary damage results can be quickly determined. However, a more detailed evaluation of the results is required.

2.5.2. Microscope Observation

The use of a microscope allows a more detailed view of the samples themselves. The advantage of the method used is the connection with a computer, which displays the results on a monitor screen. This method provides the possibility of storing individual images of the views for further use. In addition, it is possible to change and adjust display conditions such as scale or color resolution using programs. The microscope provides a significant zoom-in to view touch areas of electrical discharge.

The microscope used was an Olympus SZX9 and a Leica DFC295 objective.

2.5.3. Laser Scanning Confocal Microscopy

This is a method of examining samples using 2D and 3D imaging. In a confocal microscope, a selected plane of the sample is imaged point-by-point, allowing light scattered by the surroundings of the currently imaged point to be filtered out. The confocal microscope, therefore, has higher contrast and higher spatial resolution.

The laser scanning confocal microscopy used was ZEISS Axio Observer Z1 with confocal head LSM 700.

2.6. Salt Chamber

After all observations of coating damage after lightning strike were made, all specimens were tested in a salt chamber. This chamber serves as a simulation tool to model the real aircraft situation. In the event that the aircraft is not treated with the right methods to repair the damage after a lightning strike, the impact of the environment can have a catastrophic effect on the aircraft coating and subsequent flight safety. The salt chamber can model the impact of external environmental conditions over a period of months to years for a relatively short period of time [

47].

2.6.1. Description of Salt Chamber

Corrosion tests under artificial conditions, in the form of neutral salt spray, were carried out according to ISO 9227:2017 using 5% wt. NaCl solution for the period of 336h. The standard describes the procedures for using the chamber to investigate the effects of corrosion on metal coverage applied with coatings. It uses reagents and test procedures for this in neutral salt spray, acetic acid acidified salt spray and in salt spray acidified with acetic acid accelerated with copper. The tests are mainly used to detect integrity defects, such as pores, and other flaws in metallic materials or coatings [

36]. Samples were placed on a plastic holder with a tilt of 20° to the vertical line of the corrosion chamber Vötsch VSC KWT 1000.

2.6.2. Effects of Salt Chamber

Depending on the material used, the effects of the salt chamber can vary. It is proven that the increased load of salt reacting with the aluminum alloy clearly increases the amount of corrosion formed [

48]. Many factors influence the way aluminum alloys corrode, such as macrosegregation, cooling rate during its solidification, type of alloy and more [

49]. However, during a study on carbon steels using electrochemical impedance spectroscopy and linear polarization resistance, it was found that a higher NaCl content in the CO

2 solution causes a lower corrosion rate [

50]. The multitude of variables influencing the development of corrosion proves that it is necessary to define very specifically the type of material, its surface treatment, the method of production and the chemical composition of the external influence to correctly predict the development of corrosion.

Other effects than corrosion, caused by the action of the salt chamber on the aluminum alloy, together with defined surface treatments under specific conditions, are evaluated in the Results section.

2.6.3. Set Up

The test chamber must ensure the homogeneity of the environment and the uniform dispersion of the mist. The solution must meet the exact composition requirements and must not be sprayed directly onto the samples. The ISO 9227:2017 also recommends time intervals according to which the tests should be carried out, and any interruptions, such as for the purpose of visual inspection, have their sequence. Example of testing chamber set up is seen in

Figure 4 [

47].

1. Dispersion Tower, 2. Sprayer, 3. Cover, 4. Testing Chamber, 5. Testing sample, 6. Collection Facility, 7. Chamber, 8. Air Saturation, 9. Air Compressor, 10. Electromagnetic valve, 11. Pressure Gauge, 12. Test Solution Reservoir, 13. Temperature Control.

2.6.4. Salt Chamber Results

Photodocumentation of each specimen was carried out according to the recommendations of the standard, i.e., after 24, 48, 168 and 336 h. The results of the impact of the salt chamber were observed under a microscope by examining the lightning strike points. Subsequently, the results were compared with the damage results before the use of the salt chamber. Based on the data obtained, it is possible to determine how the damage was extended after the lightning strike and the subsequent exposure of the simulated exterior.

3. Results

The results can be summed up by three points:

Observing lightning damage under a microscope;

Observation of lightning damage by confocal microscopy;

Observation of lightning damage exposed to a salt chamber under a microscope.

It is important to note that the samples were hit by several discharges, with only one single hit shown and compared. The measured values after the discharge were not very different from each other and because of the large number of samples, the values were averaged. In three cases, there was a deviation in the measured magnitude of the volts of the electrical discharge, which may have caused the deviation in the measured values. In case of high bias, some hits are ignored and evaluated as error.

Observed parameters after electric discharge are summarized in

Table 4. To understand the issue, the observed parts were divided into: Largest Average Diameter, Burned Average Diameter, Crater Average Diameter, Average Wide Spread Homogeinity Changes.

Largest Average Diameter indicates the diameter of the crater along with the area where the greatest damage to the top coating occurred. In this area, the top coat was completely destroyed.

Burned Area Diameter indicates the area that is identifiable as damaged by the high generated heat.

Crater Average Diameter is the area that is affected by the electric discharge and caused damage to the coatings and also the material.

Average Wide Spread Homogeneity Changes is a difficult area to measure, due to the irregular shape. It is an area where there has been slight damage to the topcoat due to the passage of current. The bottom coating, or the material, is minimally affected.

Sample numbers with * symbol are non-metallic.

3.1. Observing by Naked Eye

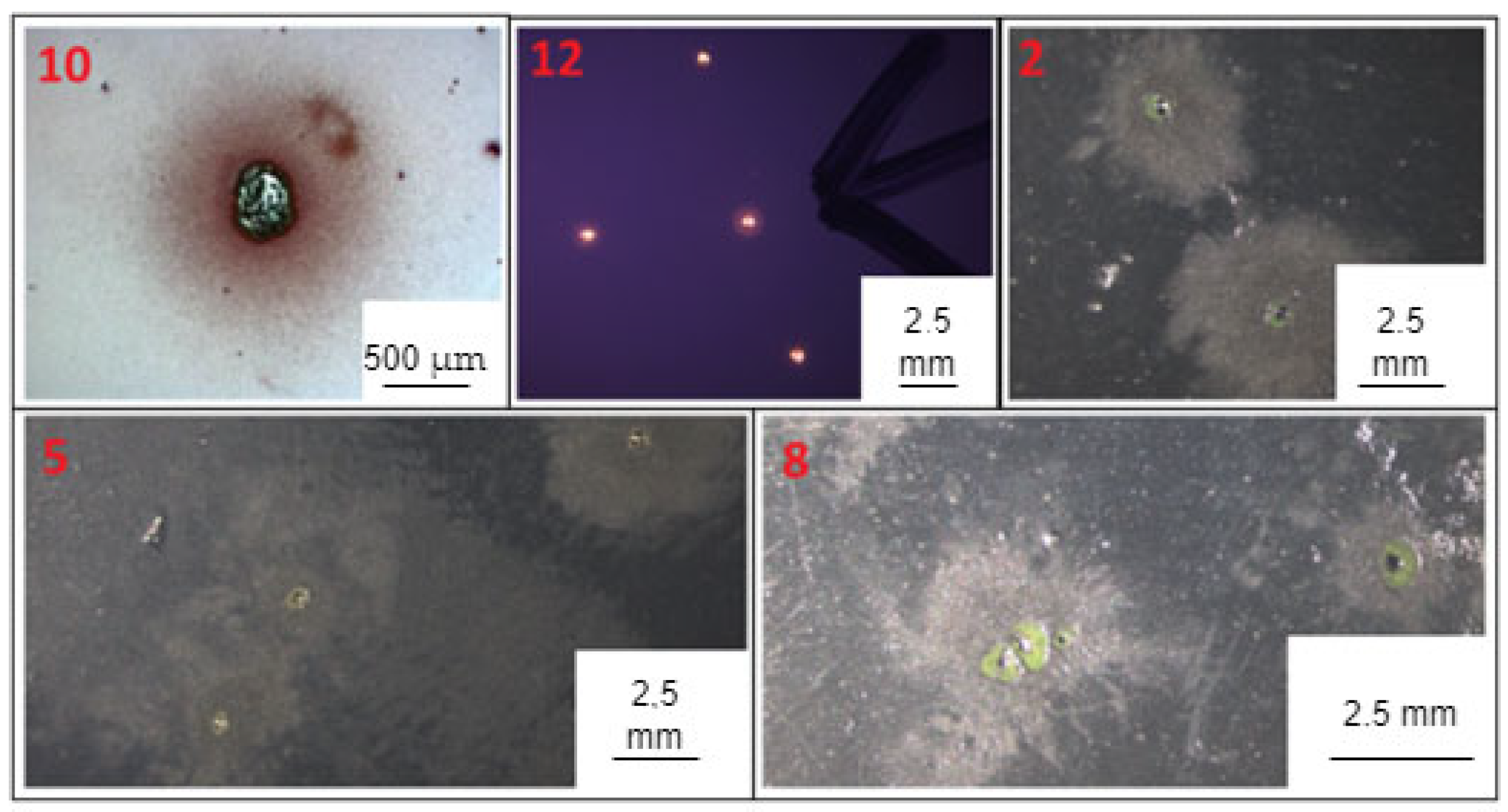

This method for observing the effect of lightning on the sample allows the extent of the damage to be determined very quickly and from a broader perspective. The samples themselves were browsed chronologically based on the sample numbering shown in

Table 4. Some samples showed significant damage to the upper coat over a very wide diameter. The most severe damage was sustained by sample 2, where the upper structure was altered by up to 5 cm on average. In one case in this sample, an electrical discharge even penetrated through the entire sample. The remaining structure changes are recorded in

Table 4 as Average Wide Spread Homogeneity Changes, which are observable by the naked eye. These changes are visible in

Figure 5, where few of samples were chosen for visualization.

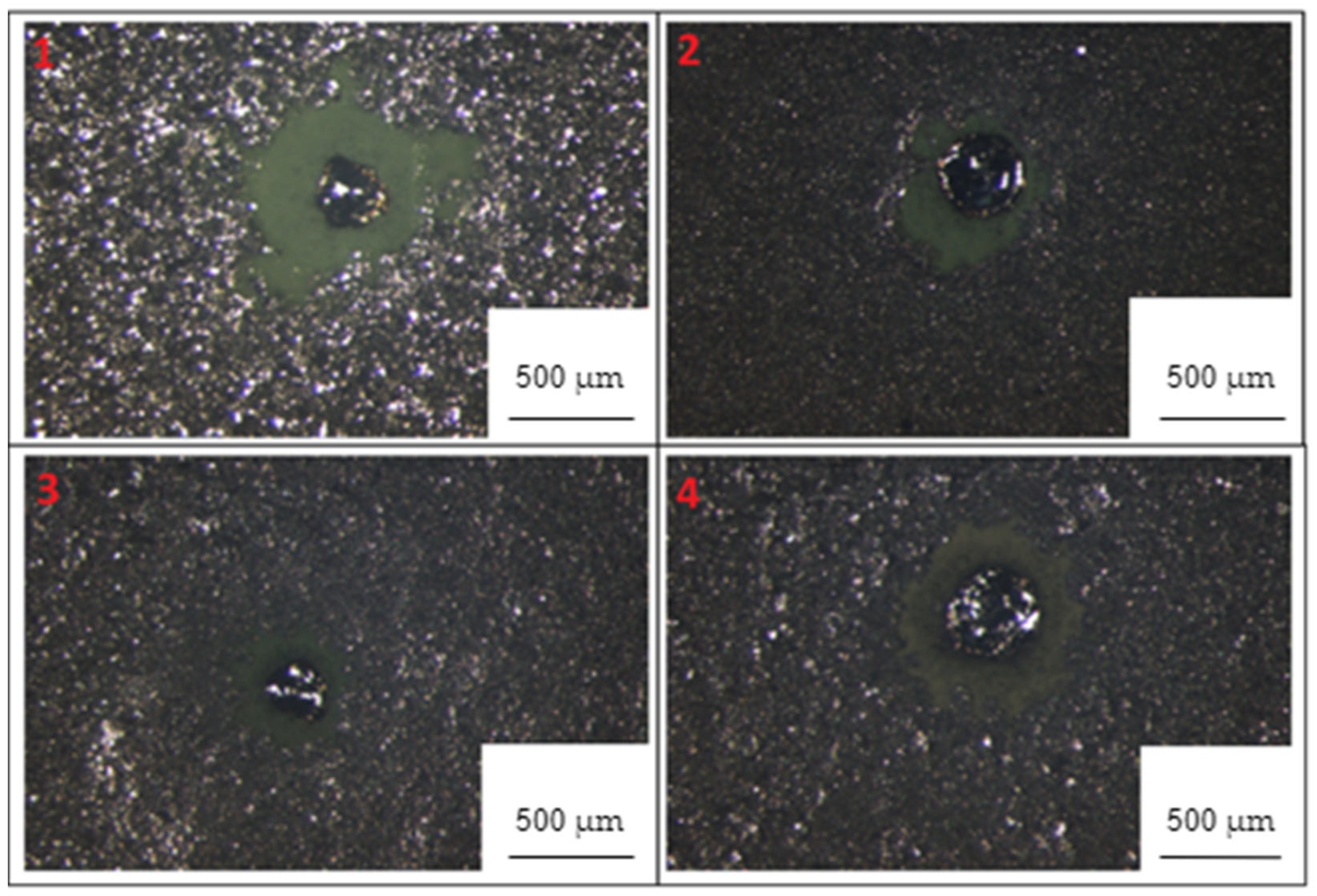

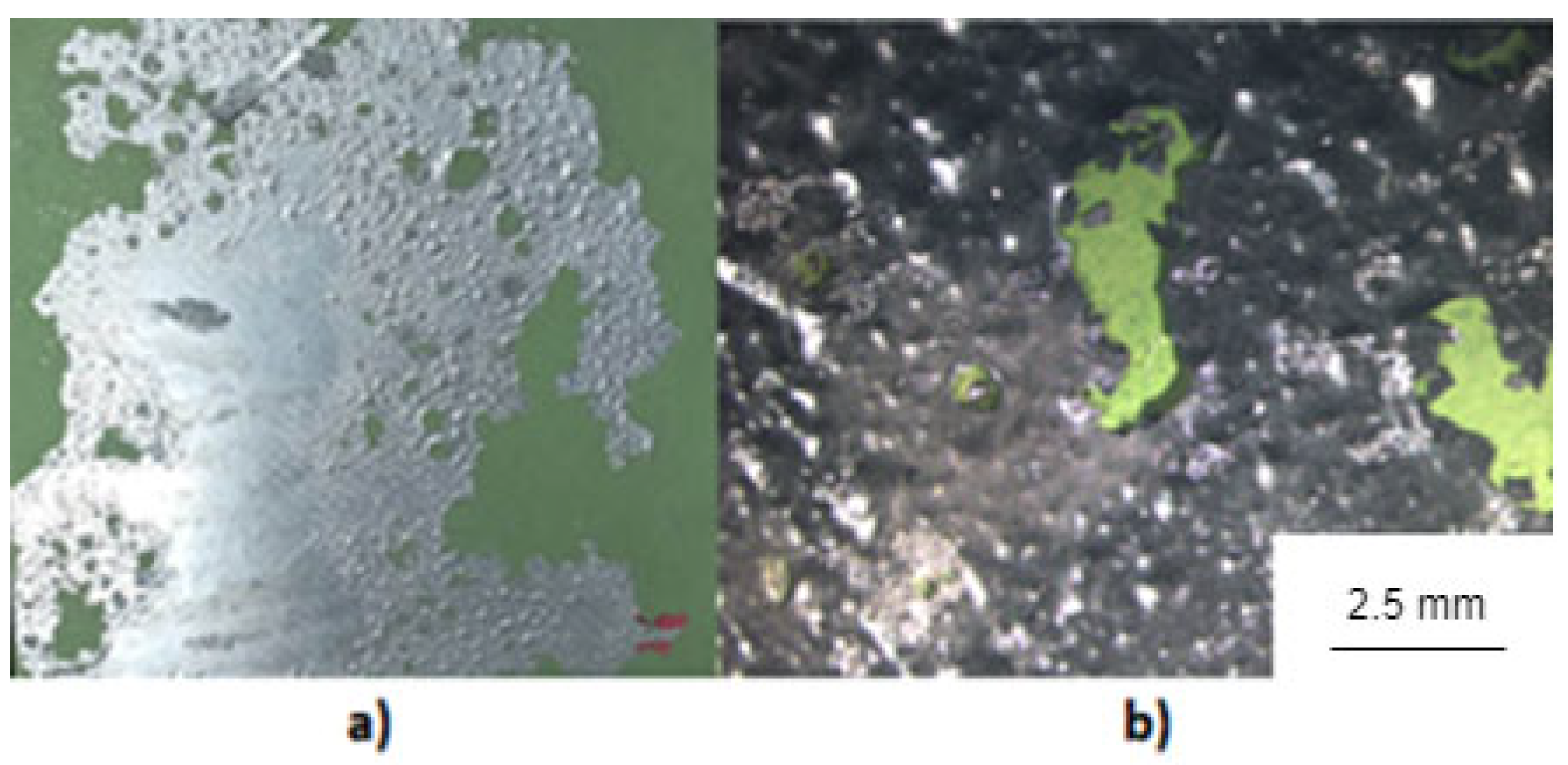

3.2. Observing Lightning Damage under a Microscope

Electric discharge damage has an impact on the structure of the aircraft covering, depending on the material and surface treatments used. The following figures (

Figure 6,

Figure 7 and

Figure 8) show detailed photographs together with scales of one hit in each sample to determine the extent of damage in the lateral direction.

The basic three parameters, observable with a microscope in the lateral direction, are described. These parameters are: the largest average diameter, the average diameter of the burned area and the average diameter of the crater. The individual parameters are described as follows. The largest average diameter consists of the areas that are significantly affected by the lightning strike. This area is significant for destruction of the upper mantle, while the primer may also be affected. The burned area is very specific in some cases. It describes an area where there are signs of scorch marks. This area has been blasted at a very high temperature causing significant damage to the material. It is usually smaller than the area of damage to the topcoat but in some extreme cases this rule does not apply. The value of the crater diameter determines the extent of the direct hit of the electrical discharge that passed through the top coat, primer and also damaged the coating. Such a crater is also characterized by its depth, which is described in the following section on confocal microscopy.

From the data of

Table 4, it can be seen to determine the effects of electrical discharge on different types of coating surfaces. The metallic Deco color surfaces had the greatest damage to the upper coats. When comparing the impact on metallic and non-metallic surfaces, it is evident that the metallic surfaces suffered more severe damage where there was more destruction in terms of diameter. This means that such a surface, when struck by lightning, exposes a larger area of the aircraft covering, which is subsequently exposed to atmospheric effects.

Greater damage to metallic upper coats is attributed to the ability to conduct electric current. Thus, the affected sample causes the energy to be dissipated in the lateral direction. Therefore, the aircraft coverage itself is less damaged. Non-metallic upper coats cannot conduct electric current, causing a huge amount of energy to be dissipated to a relatively small point that can cause fatal damage to the aircraft covering. A more detailed description of the damage in the vertical direction is available in the section on confocal microscopy.

The amount of damage also depends on the primer used, which affects the upper coat by its properties. This dependence can be seen by comparing the obtained parameters for the same upper coats but different primers. An example is the Primalex Gloss top coat, which represents samples 3, 4 and 6. Depending on the primer used, the amount of damage varies significantly.

The diameter of the burned area indicates the thermal effect of the electric discharge on the sample. Combinations of primers and upper coats cause a different thermal effect that damages the aircraft coating. Most samples are characterized by the burned area being smaller than the damage to the upper coats. In some cases, however, there were differences. Some samples showed very small areas affected by thermal damage. A significant difference is the non-metallic upper coats, specifically sample 10 and 12, which bear signs of open fire, as can be seen in

Figure 9. Non-metallic sample 11 differs from the metallics in that the area of burn damage is higher than the area of damage to the upper coats. In this case, it is evident that while the other forces acting in the electrical discharge concentrated their direction in the vertical direction, the thermal effect propagated in the lateral direction.

The diameter of the crater points to several facts. The force exerted by a lightning strike is significantly influenced by the top coat and primer. Depending on their properties, a certain amount of energy is subsequently transferred to the aircraft coating itself. Using a microscope, it is only possible to observe damage in the lateral direction. Damage observed in this way indicates the size of the area that is exposed to atmospheric conditions without any surface protection. The shape and size of the craters vary on the samples themselves, indicating the unpredictability of the impact.

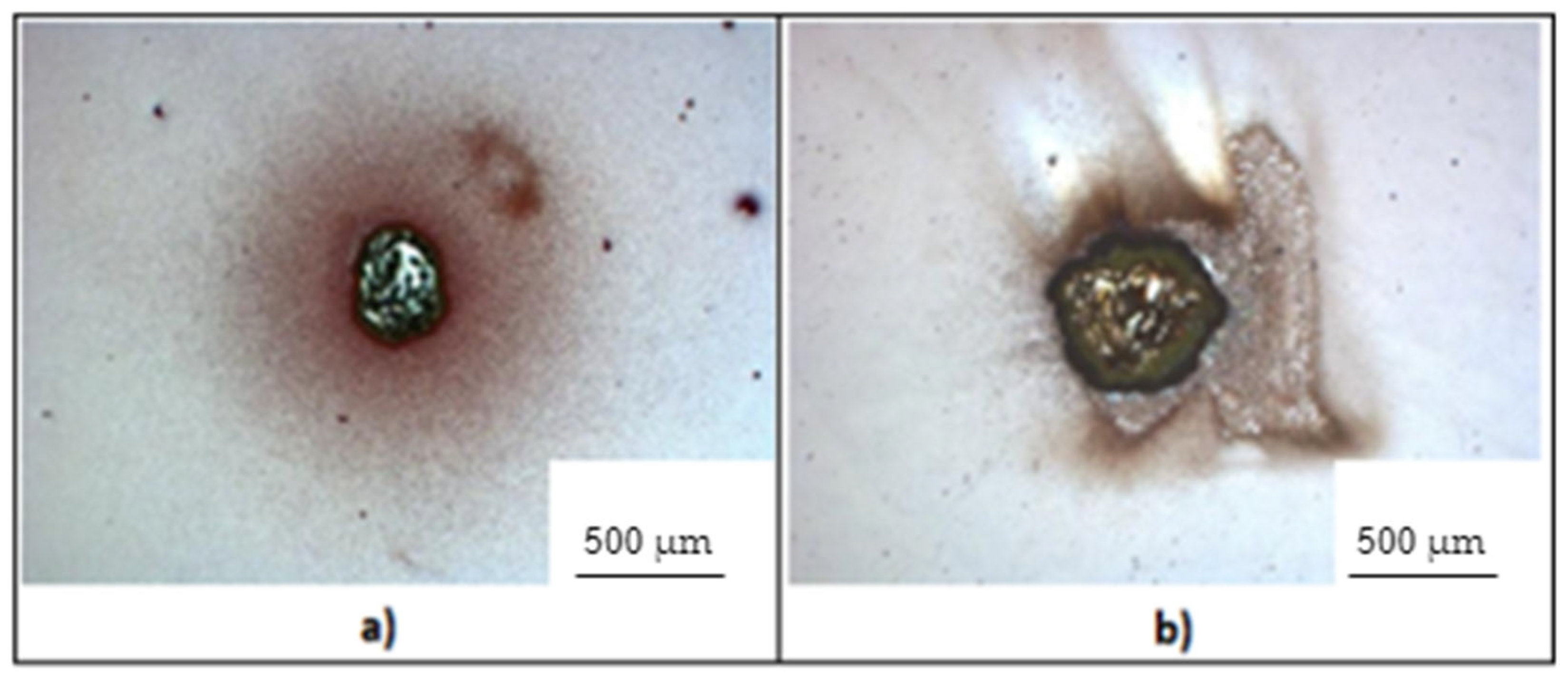

3.3. Observation of Lightning Damage by Confocal Microscopy

Confocal microscopy provides a closer look at lightning damage. Using it, 2D and 3D schematics were created, showing the damage in both lateral and vertical directions.

The 2D schematic zoomed the observation to such an extent that it was possible to observe micro-damages. It can be seen in

Figure 10, which represents general view of samples, that small cracks inside the crater have formed, which are exposed to external conditions after damage to the primer and topcoat, which, with the mechanical damage itself, weakens the strength of the material and thus reduces the safety of operation.

Using 3D visualization, the vertical damage of the sample was detected. The mode of sample damage was similar for all metallic and for all non-metallic samples. While the non-metallic samples absorbed a large amount of energy in the vertical direction, causing relatively deep damage, the energy propagation pattern in the metallic samples has a pattern identical to defined propagation in

Section 2.1.1. In

Figure 11, the difference of damage in the vertical direction can be seen, clearly showing that the non-metallic samples, which do not conduct current, concentrate a large amount of energy to a relatively small point, leading to more severe coating damage. On the other hand, metallic samples can conduct electric current and thus distribute the energy of a lightning strike, resulting in less damage. In the case of sample 2, where an electrical discharge was passed through the entire sample, a fault can be noted.

A detailed view of the metallic sample demonstrates a defined flow pattern through the sample. Area “1” defines the crater that was formed after the lightning strike, with subsequent sections showing a reduced waveform. In the outer region of the 3D visualization, the amount of current increases again and causes additional damage, visible in 3D and color spectra. The color differentiation shows the proportional differences in the height profile of the surface, shown in

Figure 12.

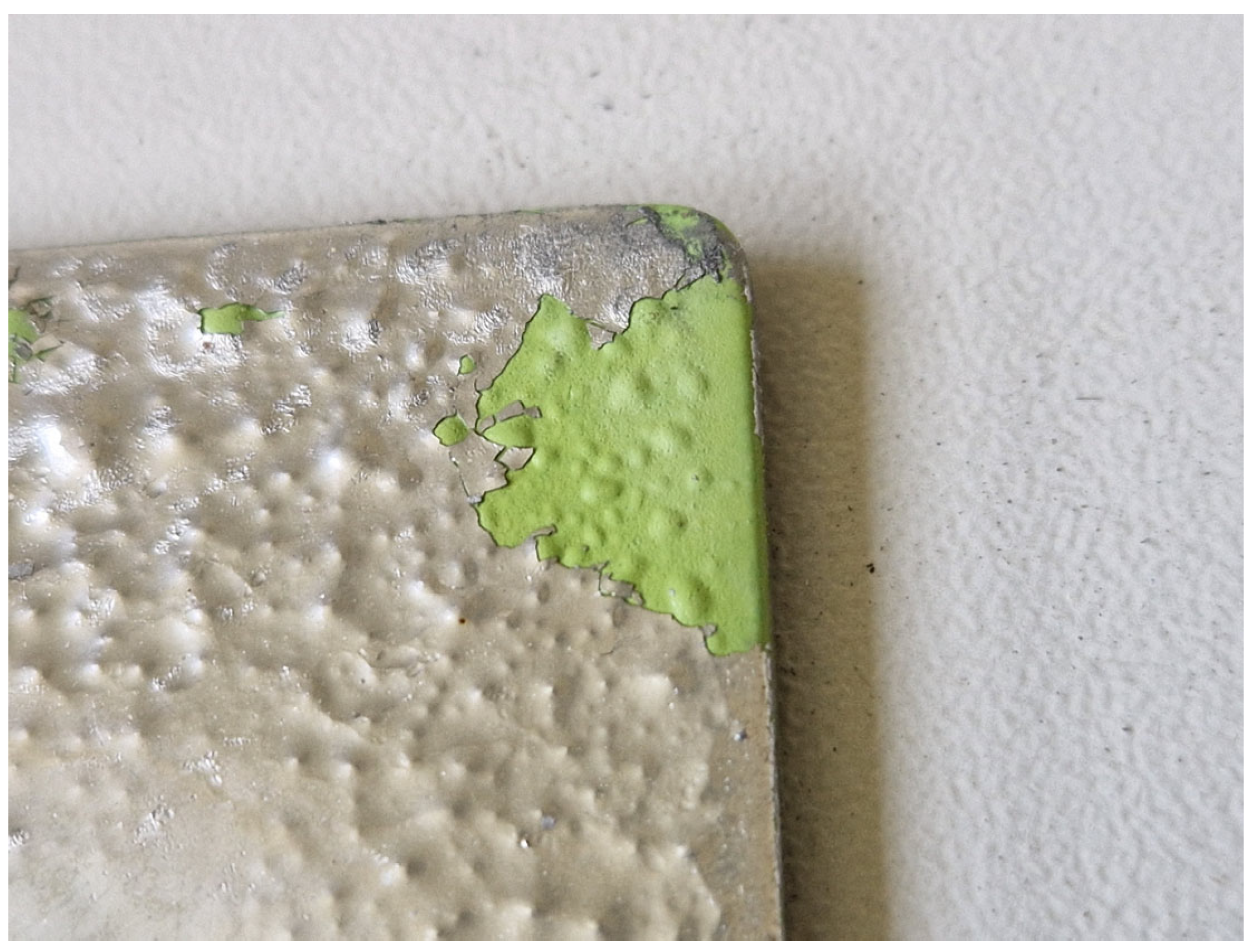

3.4. Observation of Lightning Damage Exposed to a Salt Chamber by Naked Eye

Photodocumentation of individual samples followed a defined sequence. After the first phase, which lasted 24 h, the non-metallic samples started to show signs of hydrophobicity. This phenomenon was observed around the lightning strike sites. This feature was maintained on the non-metallic samples during all phases of the photo-documentation and was preserved permanently. Real photo-documentation of these hydrophobic samples is shown in

Figure 13. Along with hydrophobicity, sample 8 began to show destructive damage to the topcoat and primer, as it seems in

Figure 14.

Individual observations after defined time intervals did not yield any significant changes. The only exception is sample 8, whose upper coat and primer suffered severe damage that expanded with each salt chamber interval. Evaluation of the results under the microscope was performed after the last stage, i.e., after 2 weeks in the salt chamber.

3.5. Observation of Lightning Damage Exposed to a Salt Chamber under a Microscope

Samples that were exposed to the salt chamber were examined individually under a microscope. Their evaluation was carried out chronologically according to

Table 3. At first glance, signs of salt chamber exposure could be observed. However, these marks were only superficial and no major damage was visible on the surface of the samples after washing. The exception is sample No 8, whose upper coat suffered destructive damage. However, these damages were not limited to the areas where the electrical discharge had hit, but extended to the surface of the entire sample. This concludes the fact that the action of the salt chamber on a given combination of top coat and primer is devastating and the use of this combination is totally inappropriate, apart from the damage caused by the lightning.

Closer examination under the microscope clarified that the salt chamber, similar to the naked eye observation, did not cause any damage that would significantly affect the difference between lightning strike damage and subsequent exposure to external conditions. The only exception is the aforementioned sample 8, the microscope view of which is shown in

Figure 15.

In

Figure 16, a visual comparison of some of the samples can be seen, capturing the same hit point on the sample before and after the salt chamber. At first glance, some differences can be seen that represent different lighting effects. In the case of more significant differences, these are salt residues from the salt chamber that could not be washed away without causing mechanical damage to the sample, which could lead to misrepresentation of the results.

4. Discussion

The data collected from the lightning strike simulation experiment produced an extensive set of values, which are described in the Results section, where is a comparison of the individual samples damage based on their combination of primer and topcoat.

In order to confirm the data on the reduction of mechanical properties, and its specific values, stress experiments need to be performed to evaluate these properties of the samples before and after the lightning strike. It would then be possible to determine how the subsequent non-treatment of the surface had an effect on the safety of flight operations.

Tests in the salt chamber did not show a major effect on damage extension. However, the evaluation of the results was carried out only under a microscope. The use of confocal microscopy would perhaps have revealed more severe damage. Given the fact of increasing corrosivity, a method designed to identify such damage could yield better results. An interesting result is the appearance of hydrophobicity on non-metallic samples in the vicinity of a lightning strike. Due to the fact that the samples were not subjected to water exposure prior to the use of the salt chamber, it is not possible to determine the exact reason for this phenomenon. This task will be under investigation in future research.

By using composite materials as the basis of the aircraft covering, which are currently a frequently used aircraft covering material, lightning resistance tests can be carried out by the described experiment. Under the assumption that has been found, namely, that a material which does not conduct current is prone to greater damage, it is necessary to define the surface treatment so that it contains metal particles which would dissipate some of the energy to a larger area, and thus, prevent significant damage. The use of composites with some metal particle content is also a possible solution to prevent severe damage.

5. Conclusions

The experimental tests carried out have clearly demonstrated the fact that the use of non-metallic surface treatment on the aircraft covering causes higher damage, which is concentrated in a smaller point, and thus, largely disturbs the mechanical properties of the aircraft covering. This is in contrast to the use of metallic surface treatments, which, due to their ability to conduct electric current, allow the distribution of the forces applied after the electric discharge has hit the aircraft.

The biggest difference between conductive and non-conductive materials was the proximity of the impact area after the discharge, where, in the case of non-conductive materials, an area was observed where an open fire was created, as well as damage that was caused by the concentration of forces into a smaller area than for conductive materials, resulting in damage extending into a greater depth of the aircraft covering material. Damage of this kind, which has a small area on the surface but goes deeper into the material, possess a high risk to aviation safety.

The combination of primers and top coats used also significantly influences the mode of damage to the specimen. This statement is based on the assumption of different macroscopic and chemical compositions of colors, which affects the distribution of the energy of the impact of electric discharges. The combination of the top and bottom coating can cause a reaction of the mutual composition of the coatings, when they can interact with each other as a catalyst. Such an experiment is the object of further study. With the exception of the single case after the salt chamber, where total destruction of the coating occurred, it can be concluded that metallic surface treatment are more suitable for use under possible lightning circumstances.

Nevertheless, it was found that even metallic specimens suffered damage that would affect the mechanical properties of the material, and thus, the safety of flight would be affected. Any damage caused by a lightning strike should be treated appropriately to avoid gradual degradation of the material strength and fatal consequences. In aviation practice, the occurrence of lightning and damage after electrical discharge occurs in a common sense [

51]. Depending on the severity and extent, these damages are usually treated and repaired in an adequate way and with a certified procedure [

52]. If such damage is not repaired, the occurrence of cracks and fissures could cause fatal crashes, as was the case with Aloha Flight 243 in 1988 [

53].