Abstract

In this paper, a multidisciplinary optimization design method and its verification of low-noise aircraft propellers considering aerodynamics, noise, and structural strength were carried out to further reduce the aerodynamic noise of the aircraft propellers. The Vortex Lattice Method-based Lift Surface Method and the Frequency-Domain-based Hanson Method were deployed to evaluate the aerodynamic performance and far-field noise of the propeller with validation by benchmark test result comparison, respectively. Integrating both of the aforementioned methods, the constraints, and a genetic algorithm with coding, a joint program was successfully proposed so that the aircraft propeller performance could be optimized comprehensively. In this program, the design variables contain blade structural strength-constrained distribution patterns of the chord length, twist angle, and dihedral angle along the blade radius. A maximum amount of noise reduction was settled as an optimization target. Meanwhile, it ensured no penalty for aerodynamic thrust and efficiency. The optimized propeller was successfully delivered by performing the developed program. Its structure examined strength tests such as static load and dynamic response, and its aerodynamic and aeroacoustic performances were tested at an aeroacoustic wind tunnel. As a result, the optimized propeller reduced its far-field noise emission peak by 2.7 dB at the first BPF under typical conditions and performed a maximum noise reduction of 4 dB for lower-thrust operations compared with the baseline propeller. For the latter operation, noise reduction at the second BPF was also obviously observed.

1. Introduction

Taking advantage of a high propulsion efficiency and an excellent takeoff and landing performance, propellers are still one of the most important military and civilian aircraft power units and are widely used in large-, medium-, and small-transport aircrafts, unmanned aerial vehicles (UAVs), and electric aircrafts. At present, decent progress in propeller technologies has been observed; yet, this has focused on its excessive noise level. For civil applications, the external noise airworthiness standard needed to be satisfied, and the riding quality was affected by noise transmitted into the cabin. For military applications, acoustic stealth performance was also affected by its excessive noise. Nowadays, the continuous growth of UAV and general aviation markets and the increasing attention paid to environmental issues have been promoting the development of low-noise propeller design technology.

Unlike the noise reduction of turbofans, which can be commonly achieved at the sound transmission stage, i.e., the installation of a nacelle acoustic liner, the noise reduction of propellers has to be accomplished by lowering its sound source intensity through the formation of the blade structure and shape. This leads to a strong correlation between the design of a low-noise propeller and its aerodynamic design and strength design. However, the aerodynamic performance, strength, and noise are naturally conflicted. Therefore, the low-noise design of the propeller usually requires multidisciplinary optimization methods.

The multidisciplinary optimization algorithm can achieve a good compromise between a propeller’s aerodynamic performance, strength, and noise, and it has been applied to the optimization design of the propeller. Burger considered the two disciplines of aerodynamics and noise, in which a lifting surface is applied to calculate the aerodynamic performance, and the empirical model developed by Smith is applied to calculate the acoustic performance [1,2]. Later, many scholars carried out optimization design by comprehensively considering aerodynamics, noise, and structural strength. Pagano et al. carried out research on low-noise propeller design for P180 aircraft and calculated aerodynamic performance using a full potential flow model, and the FW-H method was used to calculate noise [3,4,5]. Marinus carried out a lot of low-noise design work for propellers. In his previous research, he mainly considered two disciplines: aerodynamics and noise [6]. Later, he also took structural strength into account [7]. He used computational fluid dynamics (CFD) to calculate aerodynamic performance and the Farasset 1A equation [8] to calculate aeroacoustic performance. Ohad carried out a low-noise multidisciplinary design for small UAV propellers, applied the blade element method to calculate the propeller aerodynamic performance, and applied the FW-H equation to calculate the aeroacoustic performance [9,10]. At present, it is only the ANIBAL propeller that was formed through multidisciplinary optimization and finally manufactured and tested. The lifting surface method and FW-H equation are used to calculate aerodynamic and acoustic performance.

At present, there are two deficiencies in the multidisciplinary optimization of low-noise propellers: (1) An insufficient consideration of structural strength. The low-noise propeller that has been verified is a straight-blade propeller, which is designed for light propeller aircraft. The low-noise propeller designed by Marinus et al. has not been manufactured and tested [7]. (2) The method of calculating the propeller aerodynamic performance has a low accuracy or efficiency, which is not suitable for low-noise propeller optimization. The blade element method cannot consider the airflow movement along the blade radial direction, and the lift line cannot consider the twist angle change along the blade radial direction, while the CFD combined agent model method leads to low optimization efficiency.

In this paper, aerodynamic, acoustic, and structural strength will be fully considered in the low-noise design of the propeller. Previous studies have shown that the lift surface method has a very high accuracy for predicting the aerodynamic performance of a propeller, with a tip Mach number less than 0.7 Ma [11]. This method belongs to the analytical method and has a high optimization efficiency. Kotwicz et al. studied the acoustic prediction accuracy of different computational models by comparing them with several experimental results [12,13]. The results show that the Hanson model has a higher accuracy than those of other models used for predicting pure noise. In this paper, Hanson’s method will be used to calculate propeller noise [14]. The strength of the blade structure is considered by adding constraints to the design variables. At the same time, the sweep and the large deformation of the blade under a 50% radius were avoided.

This paper includes the following four parts: First, the calculation method of propeller aerodynamics and noise is briefly presented, and the code is verified. Second, blade parameterization, constraint determination, optimization strategy, method determination, optimization design, and discussion are carried out, respectively. Third, propeller strength, aerodynamic, and noise verification is carried out. Finally, a summary is given.

2. Calculation Method of Propeller Aerodynamics and Acoustics

2.1. Calculation Method of Propeller Aerodynamic Performance

In this paper, the lift surface theory based on the vortex lattice method is used to calculate the aerodynamic performance of the propeller. Then, the aerodynamic force distribution on the surface of the propeller blade is obtained.

The induced velocity of the quadrilateral vortex ring and the spiral horseshoe vortex can be calculated according to a similar formula in the lifting line theory. For example, the induced velocity of the vortex ring with a serial number (I, J) at the control point with a serial number (m, n) is given by the following formula:

in which , , and are the induced velocity in three directions, is the incoming velocity, R is the radius, is the circulation, and , , and are the influence coefficients of the vortex lattice (I, J) on control point (m, n).

The boundary condition that the velocity component that is normal in relation to the chord plane is always zero is satisfied at the control points at the center of each quadrilateral vortex element. Thus,

in which is the angular frequency, is the normalized radius at the vortex lattice (I, J), and is the phase angle.

The system of linear equations is composed of Equation (2) of each control point, and the circulation on each control point can be obtained. From this, the induced velocity at the control point can be obtained, and the total velocity can be obtained by adding the incoming velocity and the rotation velocity. The aerodynamic performance of the propeller can be obtained by using the Kutta–Joukowski relation to calculate the force acting on each vortex element and considering the drag coefficient Cd and lift coefficient Cl of the airfoil with compressibility.

2.2. Verification of the Calculation Method for Propeller Aerodynamic Performance

The NACA6623-A propeller is a straight-blade propeller. NASA has conducted a series of aerodynamic performance tests in the last century, which can be used to verify the aerodynamic performance calculation method applied in this paper [15].

In the analysis of the lift surface, the blade is divided into 20 equal parts along the span (hub to tip). Conformal transformation processing is carried out along the chord direction, that is, the leading and trailing edges are encrypted, which are divided into 15 pieces. Thus, 300 quadrilateral vortex lattices are formed on the blade surface. The integral spacing of the wake is 0.0222 radians, and the integral length is 8 π radians.

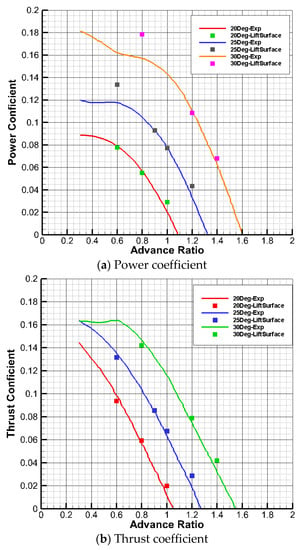

Figure 1 shows the comparison between the calculation results and the test results of the propeller power coefficient and the thrust coefficient under different twist angles and different advance ratios. Table 1 compares the detailed values. The calculated values agree with the experimental values in terms of the thrust coefficient and power coefficient variation trend with the advance ratio. Under the condition of the twist angle being 20° and the advance ratio being 0.6, the calculation accuracy is the highest (the absolute error of the absolute value is 0.005; the relative error is 5%). With the increase in the twist angle and the advance ratio, the error increases. This is mainly due to the increasing influence of air separation on the aerodynamic performance of the propeller at high angles of attack and a high incoming velocity, which is not fully considered in the analytical algorithm.

Figure 1.

Calculation accuracy of aerodynamic performance. (The experimental results are derived from the paper of David Biermann et al. [15].)

Table 1.

Error analysis of propeller aerodynamic performance calculation.

2.3. Calculation Method of Propeller Acoustics

The sound pressure disturbance generated by the propeller can be expressed as the sum of thickness noise, load noise, and quadrupole noise:

According to the Hanson frequency domain noise calculation method, thickness noise can be written as:

The load noise is expressed as:

in which is the sound speed, B is the number of blades, m is the harmonic number, γ is the specific heat ratio, the sound source coordinate is y = (y1, y2, y3), is the environmental density, represents the normal velocity of the object surface relative to the fluid, and represents the volume displacement of the area element dA within the time increment. G is Green’s function. . . According to the lifting surface method for solving the propeller aerodynamic performance, the blade load on the area element required by Formula (5) can be given.

Therefore, the aerodynamic and aeroacoustic characteristics of a propeller with a given aerodynamic profile can be obtained by combining the aerodynamic performance and the aeroacoustic performance of the propeller.

The quadrupole noise is not the main noise source of the air propeller and is ignored here.

2.4. Verification of the Calculation Method for Propeller Aeroacoustics

The accuracy of the aeroacoustic prediction method developed in the current project was validated via the employment of a series of two-blade aeroacoustic test data carried out in the German-Dutch wind tunnel [16].

Table 2 shows the comparison between the test results and the calculated results of the sound pressure level at the microphone measuring point at the propeller rotating plane under three working conditions. The two are generally in good agreement, with a maximum difference of 3 dB, and the numerical results are relatively small.

Table 2.

Comparison between the test results and the calculated results of the SPL.

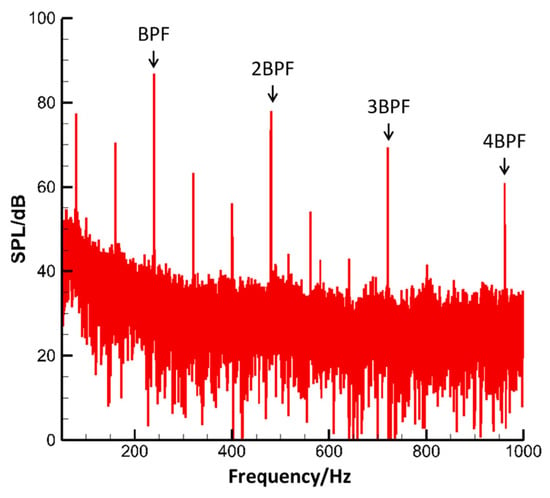

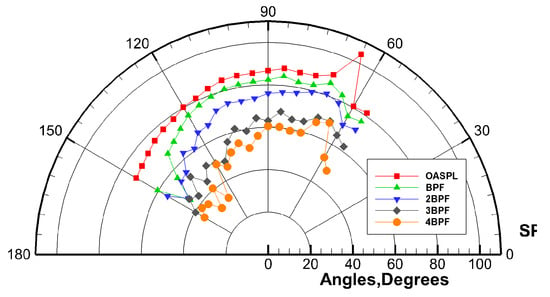

3. Multidisciplinary Optimization

The selected basic propeller is a wind tunnel test three-blade propeller with a diameter of 800 mm. The rotational speed is 4811 rpm, the inflow speed is 50 m/s, and the blade angle is 22°. The spectrum of the measuring point of the far field directivity peak of the propeller is shown in Figure 2. The propeller noise spectrum is dominated by four pure tones on the blade passing frequency (the first BPF is 240.5 Hz), of which the sound pressure level of 1 BPF is about 9 dB higher than that of 2 BPF. As the order increases, the corresponding SPL decreases. Figure 3 shows the far-field directivity, which shows a similar trend. The maximum SPL is around 75°. Several measuring points near the rotating plane have similar SPL values.

Figure 2.

SPL spectrum at the far-field directivity peak.

Figure 3.

Far-field directivity.

3.1. Propeller Parameterization and Selection of Design Variables

The parameterization of blade geometry is a key step in the low-noise design of the propeller. It is necessary to reduce the number of design variables as much as possible. At the same time, it needs to ensure that the propeller deformation space is large enough.

In this paper, optimization design and experimental verification are carried out for existing aircraft propellers. To ensure that the optimized propeller matches the aircraft, engine, and transmission mechanism, the number of engines, the number of blades, the speed and radius of the propeller, and other general parameters are not used as design variables.

Generally, the geometry of propeller blades is described completely in terms of two aspects. The first kind is the distribution of airfoils along the radius. The second kind is the sweep, the dihedral angle, the twist angle, the chord length, the thickness, and the distribution of the aerodynamic stacking center along the radius. The pitch angle is the twist angle at 0.7 r. The airfoils at different radii engage in dihedral angle and twist angle conversion around the quarter-chord point to stack as the blade. ARA-D airfoils at different radii are scaled to the chord and rotated around the quarter-chord point.

The propeller blade of the aircraft is very thin, the thickness of the blade has little influence on the thickness noise, and the thickness noise has a low proportion to the total propeller noise. Therefore, the thickness of the blade is not used as a design variable, and the thickness distribution of the basic blade is used. As pointed out by Gur et al., the selection of an airfoil has little effect on the aerodynamic performance of the propeller [17,18]. In terms of describing the geometric parameters of the airfoil, the ARA-D airfoil, like the basic propeller, is selected as the airfoil family. For the variation in airfoil parameters along the radius, the distribution law along the radius defined by the ARA-D airfoil itself is adopted. In addition, the selected aerodynamic stack center is the 1/4 chord length position of the airfoil. At present, the sweep seriously affects its structural strength performance. Mainstream propeller aircraft have no sweep, so this paper does not take the sweep as a design variable.

The design variables selected in this paper are three categories: twist angle, chord length, and dihedral angle. There are four control points distributed from the root to the tip of the propeller, and the Bezier curve [3,4,5] is selected as the fitting curve, which can effectively avoid the strength problem caused by a sudden change in design parameters. In this way, 12 design variables are shared.

3.2. Constraints and Optimization Objectives

It needs to ensure that the optimized propeller will not be damaged during the experiment. Specifically, when the optimized propeller is subjected to twice the working aerodynamic load and centrifugal load, the test piece will not be damaged, and the dynamic characteristic frequency of the optimized propeller does not coincide with the working frequency of the propeller.

In this paper, the consideration of the structural strength discipline is mainly realized through the constraint of design variables and strength test verification. The constraints on design variables shall be fully communicated with the manufacturer and the tester, mainly in terms of the following two aspects:

- (a)

- Constraints on large deformation regions. To ensure sufficient structural strength at the blade root, no obvious deformation is allowed in the area below 0.5 r, according to the manufacturer’s communication.

- (b)

- Dihedral angle. An excessive dihedral angle affects the strength of the propeller. According to the communication with the manufacturer, the maximum dihedral angle is limited to 2.86°.

Therefore, the constraints of each design variable are:

- (a)

- Chord. Strength needs to be considered. The minimum chord length is located at the propeller tip, and the minimum chord length is 5% of the propeller rotation radius.

- (b)

- Twist angle. The maximum twist angle of the aerodynamic performance is at the blade tip, and the attack angle at the blade tip is positive.

- (c)

- Dihedral angle. Strength is mainly considered. The maximum dihedral angle is 2.86°.

The objective of the optimization design in this paper is to reduce the far-field radiated noise of the propeller without reducing the aerodynamic performance of the propeller. This leads to one optimization objective and two constraints:

- (a)

- Efficiency. The reduction in the propeller efficiency is less than 0.2%.

- (b)

- Thrust. Considering the optimization design of the existing propeller under specific working conditions, the thrust under this working condition cannot be reduced, and the reduction in propeller thrust is set to be less than 0.1%.

- (c)

- Far-field radiated noise (at the first blade passage frequency). The noise observation point is the far-field measurement point on the rotation plane. Find the maximum value of noise reduction.

The linear weighted sum method is used to deal with the relationship between multiple optimization objectives. The weighting factors need to be tried repeatedly so that the aeroacoustics of the blade can be reduced and the aerodynamic performance and strength of the propeller can be guaranteed.

Take its optimal solution x * as the “optimal solution” of the objective function in the sense of a linear weighted sum, wherein is the weighting factor.

3.3. Design Method and Strategy

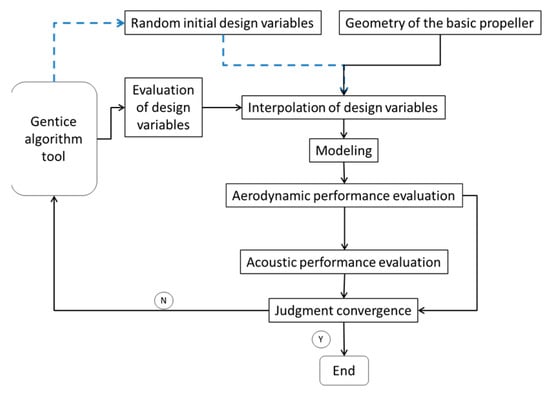

In this paper, a genetic algorithm is selected as the optimization design tool. The genetic algorithm has the advantage of global optimization, while its disadvantage is that the blade sawtooth problem is caused by the discontinuity between design variables, which is solved by Bezier curve fitting. To speed up the iteration, a parallel algorithm is used to synchronously calculate different individuals of the same population with 12 cores.

The optimization design framework of this paper is shown in Figure 4.

Figure 4.

Optimization flow chart.

3.4. Optimization Results

The contrast of the thrust, efficiency, and noise of the propeller before/after optimization is shown in Table 3. The aerodynamic performance of the propeller has not changed, while the far field noise is reduced by 5 dB.

Table 3.

The difference in the aerodynamics and noise (calculation results).

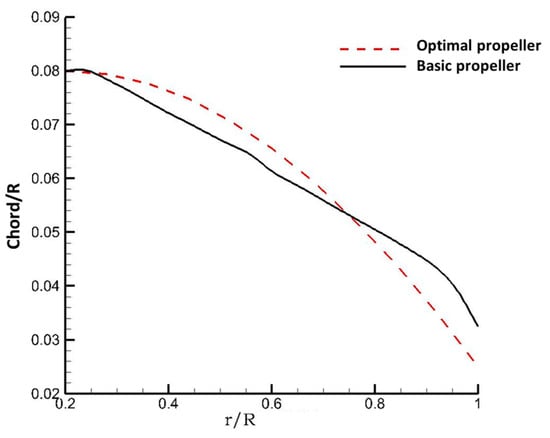

The optimized chord distribution is shown in Figure 5 (where r is the dimensional radial coordinate and R is the propeller radius). The chord of the optimized propeller is larger in an area below 0.75 r. In the tip area, the chord length of the optimized propeller is smaller. The tip area is the main propeller noise source. Reducing the chord length of the propeller tip is helpful in reducing the load on the propeller tip. The thrust loss of the propeller tip is compensated by increasing the chord length of the blade below 0.75 r. The increase in the chord length below 0.75 r is also helpful in maintaining the propeller strength.

Figure 5.

Chord distribution.

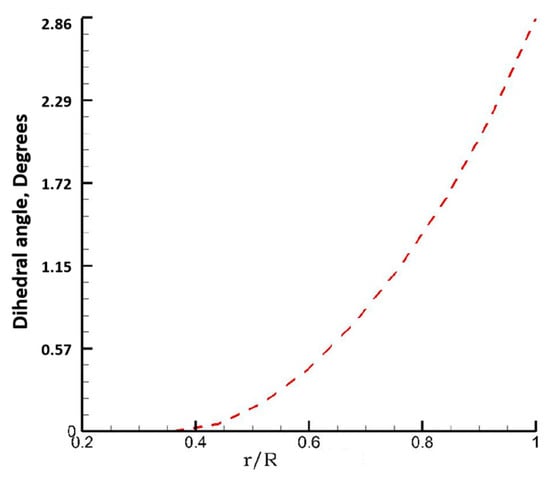

The optimized dihedral angle distribution is shown in Figure 6. The original blade is straight, so there is no dihedral angle. At the propeller rotating radius below 50%, the dihedral angle of the optimized propeller is very small to ensure strength. In more than 50% of the area, the dihedral angle of the propeller increases exponentially. By changing the phase of the aeroacoustic load at different radii along the blade, far-field noise cancellation is achieved.

Figure 6.

Dihedral angle distribution.

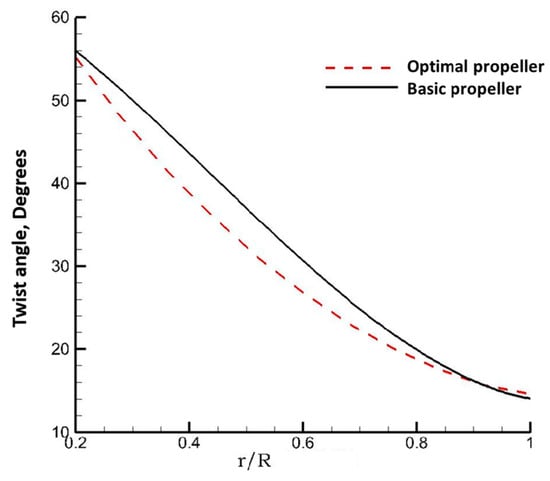

The optimized twist angle distribution is shown in Figure 7. Compared with the original propeller, the twist angle of the optimized propeller is smaller at the blade tip.

Figure 7.

Twist angle distribution.

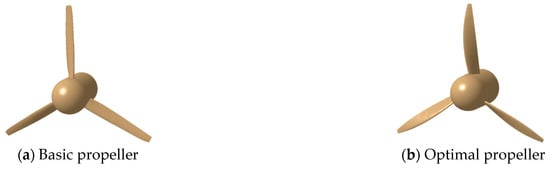

The geometry of the optimized propeller and the original propeller is shown in Figure 8. Compared with the original propeller, the chord length of the optimized propeller increases significantly in the middle and bottom of the rotation radius; In addition, the optimized propeller has obvious dihedral angle characteristics.

Figure 8.

Comparison of geometry between original and optimal propellers.

4. Test Verification

4.1. Strength Verification

The purpose of propeller strength test verification is to ensure that the propeller can withstand centrifugal force and aerodynamic force and ensure that its structural dynamic characteristic frequency does not coincide with the working frequency of the propeller. The strength tests carried out mainly provide structural strength proof for the subsequent tests in the wind tunnel.

The design variables include the chord, twist angle, and dihedral angle. Therefore, the blade mass and center of gravity have changed, and a centrifugal load test is required to assess the carrying capacity of the blade root. The results show that the connection between the blade and the blade root meets the requirements of bearing twice the centrifugal force load. There is no crack in the connection part and no sudden displacement change during the test.

Under the action of an aerodynamic load, the blade bears the force on the rotating plane and the torsion around the pitch axis. The torque generated by the force on the rotating plane to the blade root and the force acted by the force on the rotating plane to the blade is the main load. The results show that, under 2.4 times the aerodynamic load, the blade is normal.

To further analyze the feasibility of optimal design, the dynamic characteristics of the propeller blade are tested, including the first-order mode and the frequency of the propeller blade waving, shimmy, and torsion. The method of knock excitation is adopted to identify the corresponding vibration frequency and mode of the blade according to the excitation force and response acting on the blade. The test shows that the structural frequency does not coincide with the operating condition of the blade.

4.2. Aerodynamic and Aeroacoustic Verification

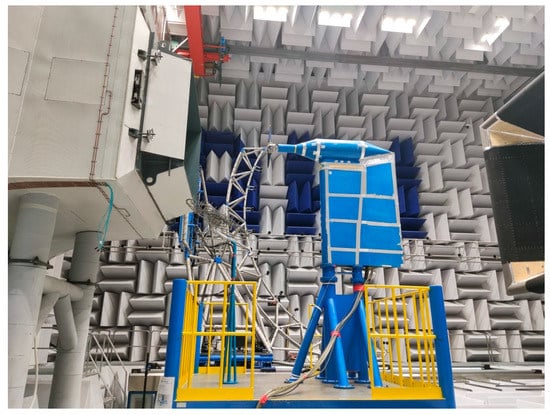

The aerodynamic and noise characteristics of the prototype propeller and the optimized propeller were tested in the aeroacoustic wind tunnel(Figure 9). The thrust and torque of the propeller are measured by the balance, and the aerodynamic characteristics of the propeller, such as the thrust coefficient, power coefficient, and efficiency, are obtained by conversion. The noise characteristics of the propeller are obtained through the microphone array.

Figure 9.

The aeroacoustic wind tunnel and test platform.

The size of the anechoic chamber is 13 m wide, 9.05 m high, and has a fetch length of 12.5 m. The wind tunnel test section size is 2.0 m wide, 1.5 m high, and has a fetch length of 6.3 m. The background noise is below 80 dBA (80 m/s). The linear array composed of 20-channel microphones is used to measure the far-field noise, which is 6.3 m away from the propeller axis and is arranged at an equal angle along the direction of the flow field. The angle measurement range is 50°, −145°, and 0° and is located upstream of the flow.

4.2.1. Comparison and Verification of Aerodynamic Performance

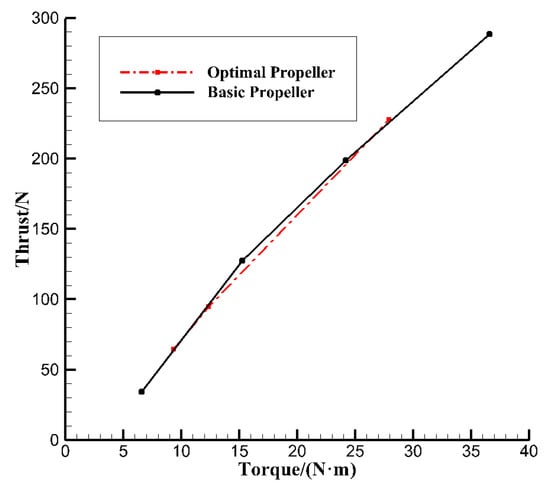

The curves of thrust versus torque at different incoming velocities and different pitch angles are given. As the operating conditions of the optimized propeller are different from those of the original propeller, the torque thrust diagram can better reflect the aerodynamic characteristics of the propeller. That is to compare and analyze the input torque of two sets of propellers under the same thrust.

Figure 10 shows the torque curves corresponding to different thrusts under design conditions (flow velocity of 50 m/s, rotation speed of 4811 r/min). The curve corresponding to the optimized propeller coincides with the curve corresponding to the original propeller. The specific numerical comparison between the two is shown in Table 4. Under the optimized design condition, the efficiency of the optimized propeller decreases slightly (the thrust decreases by 6 N, and the efficiency decreases by 0.035). However, under the two working conditions deviating from the design, the aerodynamic performance of the propeller is improved (the thrust is increased by 1 N~2 N, and the efficiency is increased by 0.01). Therefore, their aerodynamic performance is equivalent and consistent with the optimization goal. The results of the optimization design meet the requirement of no reduction in aerodynamic performance in the optimization goal.

Figure 10.

Comparison of thrust between basic and optimal propellers at 50 m/s.

Table 4.

The difference in the aerodynamics at 50 m/s (Experimental results).

In the design condition, the computation of optimization results shows that (Table 3) the thrust of the optimized propeller is reduced by 1 N, while the efficiency is reduced by 0.0013. The test of the optimized propeller (Figure 11 and Table 4) shows that the thrust decreases by 6 N and the efficiency decrease by 0.035. It shows that the thrust prediction error is 5 N (the thrust coefficient error is 0.0015), while the efficiency prediction error is 0.0337. The calculation result is relatively accurate and consistent with the conclusion of calculation accuracy in Section 2.2.

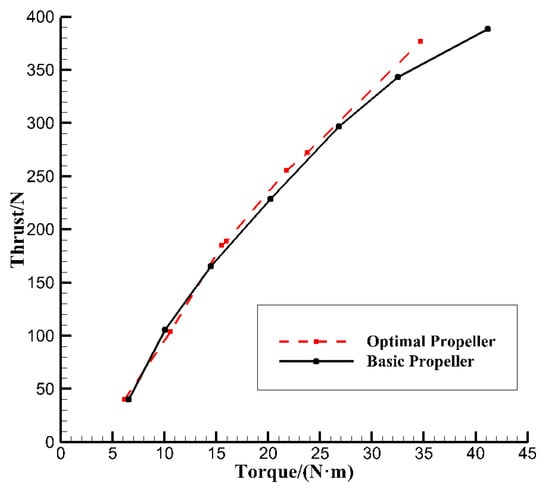

Figure 11.

Comparison of thrust between basic and optimal propellers at 30 m/s.

For a constant-speed propeller, under takeoff conditions, the speed of the propeller remains unchanged, and the flight speed is low. Here, the aerodynamic characteristics of the two sets of propellers under this working condition are further compared and analyzed. Figure 10 shows the torque curve corresponding to different pitch angles/thrust when the inflow speed is 30 m/s. The torque required by the optimized propeller is lower when a large thrust is required above 150 N, that is, the efficiency of the optimized propeller is slightly higher than that of the original propeller. The specific numerical comparison between the two is shown in Table 5. Under the given three working conditions (the original propeller thrust is 43 N, 230 N, and 350 N, in turn), the thrust and efficiency of the optimized propeller are improved (the thrust is increased by 6 N~12 N, and the efficiency is increased by 0.028~0.051). Thus, the aerodynamic performance of the optimized propeller is significantly higher than that of the original propeller.

Table 5.

The difference in the aerodynamics at 30 m/s (Experimental results).

4.2.2. Comparison and Verification of Acoustic Performance

The jet shear layer correction, atmospheric attenuation correction, measurement distance correction, and measurement direction angle correction are carried out for aeroacoustic data.

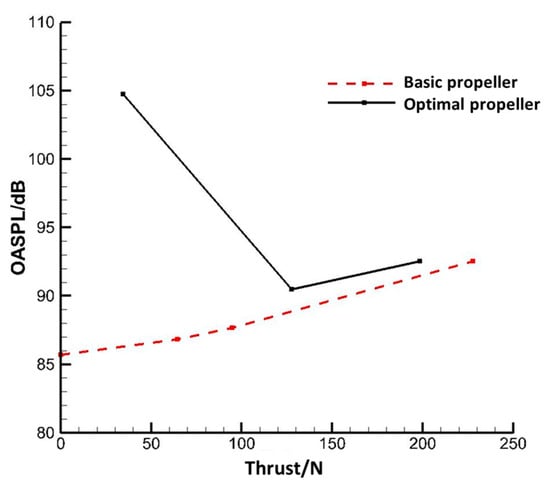

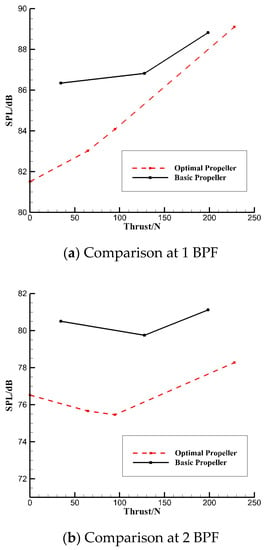

Here, the aeroacoustic characteristics of the two sets of propellers at different pitch angles are also compared and analyzed, with thrust as the variable. Figure 12 shows the comparison of the total sound pressure level (OASPL) at the far field at a propeller speed of 4811 r/min and an inflow speed of 50 m/s. The noise reduction characteristics are like those under 1 BPF because the dominant amount of the propeller’s spectrum is the noise of 1 BPF. Compared with the original propeller, the optimized propeller reduces the noise by 3 dB at the design condition, with a thrust of about 120 N. The noise reduction effect is more obvious with a lower thrust, and the maximum is 18 dB (thrust 35.4 N). The amount of noise reduction decreases with the increase in thrust, with a minimum of 1 dB (thrust 198 N).

Figure 12.

Comparison of thrust–OASPL between the basic and optimal propeller.

Figure 13a shows the comparison of far-field pointing peak values under design conditions (propeller speed 4811 r/min, inflow speed 50 m/s, 1 BPF). Compared with the original propeller, the noise of the optimized propeller is significantly reduced. The noise is reduced by 2.7 dB at the optimal operating point, with a thrust of about 120 N. The noise reduction effect is more obvious in the area with a lower thrust, up to 4 dB. The noise reduction decreases with the increase in thrust, with a minimum of 1 dB. Under the design condition, the optimization results show that (Table 3) the noise of the optimized propeller is reduced by 5 dB. The actual test of the optimized propeller shows that the noise of the optimized propeller is reduced by 2.7 dB. It shows that the noise prediction error of 1 BPF is 2.3 dB. The calculation result is relatively accurate and consistent with the calculation accuracy conclusion in Section 2.4.

Figure 13.

Comparison of thrust–SPL between the basic and optimal propeller.

Figure 13b shows the comparison of the far-field point SPL at a propeller speed of 4811 r/min, an incoming flow speed of 50 m/s, and 2 BPF. Compared with the original propeller, the noise of the optimized propeller is still significantly reduced. Compared with the noise reduction at 1 BPF, the noise reduction at 2 BPF is better, and the noise reduction amount under different pitch angles is more than 3.5 dB. The noise reduction effect under 2 BPF does not show the trend of the noise reduction amount decreasing with the increase in thrust under 1 BPF.

Therefore, the optimized propeller can effectively reduce the aeroacoustic performance of the propeller without reducing or even slightly improving the aerodynamic characteristics.

5. Conclusions

The main conclusions are as follows:

- (a)

- The aerodynamic performance of the propeller was calculated based on lifting surface theory, and the aeroacoustic performance of the propeller was calculated based on the Hanson frequency domain method. The propeller aeroacoustic calculation method formed by the combination of the two methods was verified and feasible.

- (b)

- The strength of the propeller was fully considered. The optimized propeller has passed the strength verification of the centrifugal load test, aerodynamic load test, and dynamic characteristic test. The structural strength constraint of design variables is feasible.

- (c)

- The aerodynamic and acoustic verification of the optimized blade was completed in the aeroacoustic wind tunnel. Under the design condition, the aerodynamic performance of the optimized propeller is unchanged compared with the basic propeller, and the noise reduction of the optimized propeller reaches 2.7 dB. The noise reduction under low-thrust conditions can reach 4 dB at most. Under off-design conditions, the optimized propeller also has better aerodynamic and acoustic characteristics.

- (d)

- The proposed multidisciplinary design method for propellers with low noise took noise as the optimization objective and aerodynamics as a constraint and fully considered the structural strength. The optimized blades were verified by aerodynamic, noise, and strength tests, and the propeller noise was reduced to meet the structural strength requirements and unchanged aerodynamic performance.

Author Contributions

Conceptualization, D.X. and Q.Y.; methodology, D.X.; software, D.X.; validation, D.X., Z.L. and K.W.; formal analysis, D.X.; investigation, D.X.; resources, Q.Y.; data curation, D.X.; writing—original draft preparation, D.X.; writing—review and editing, D.X.; visualization, D.X.; supervision, D.X.; project administration, Q.Y.; funding acquisition, Q.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Burger, C.; Hartfield, R.; Burkhalter, J. Performance and Noise Optimization of a Propeller using the Vortex Lattice Method and a Genetic Algorithm. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007. [Google Scholar]

- Burger, C.; Hartfield, R.; Burkhalter, J. Propeller Performance Optimization using Vortex Lattice Theory and a Genetic Algorithm. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006. [Google Scholar]

- Pagano, A.; Barbarino, M.; Casalino, D.; Federico, L. Tonal and Broadband Noise Calculations for Aeroacoustic Optimization of a Pusher Propeller. J. Aircr. 2010, 47, 835–848. [Google Scholar] [CrossRef]

- Pagano, A.; Luigi, F.; Mattia, B. Multi-objective Aeroacoustic Optimization of an Aircraft Propeller. In Proceedings of the 12th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Victoria, BC, Canada, 10–12 September 2008. [Google Scholar]

- Marinus, B.G.; Roger, M. Aeroacoustic and Aerodynamic Optimization of Aircraft Propeller Blades. In Proceedings of the 16th AIAA/CEAS Aeroacoustics Conference, Stockholm, Sweden, 7–9 June 2010. [Google Scholar]

- Marinus, B.G.; Roger, M. Multidisciplinary Optimization of Propeller Blades: Focus on the aeroacoustic results. In Proceedings of the 17th AIAA/CEAS Aeroacoustics Conference (32nd AIAA Aeroacoustics Conference), Portland, OR, USA, 5–8 June 2011. [Google Scholar]

- Farassat, F. Derivation of Formulations 1 and 1A of Farassat; Technical Memorandum TM-2007-214853; NASA Technical Reports Server: Washington, DC, USA, 2007. [Google Scholar]

- Gur, O. Multidisciplinary Design Optimization of a Quiet Propeller. In Proceedings of the 14th AIAA/CEAS Aeroacoustics Conference (29th AIAA Aeroacoustics Conference), Vancouver, BC, Canada, 5–7 May 2008. [Google Scholar]

- Gur, O.; Rosen, A. Optimization of Propeller Based Propulsion System. J. Aircr. 2009, 46, 95–106. [Google Scholar] [CrossRef]

- Canard-Caruana, S.; Le Tallec, C.; Beaumier, P.; Lefebvre, T. ANIBAL A New Aero-Acoustic Optimized Propeller for Light Aircraft Applications. In Proceedings of the 16th AIAA/CEAS Aeroacoustics Conference, Stockholm, Sweden, 7–9 June 2010. [Google Scholar]

- Kobayakawa, M.; Onuma, H. Propeller Aerodynamic Performance by Vortex-Lattice Method. J. Aircr. 1985, 22, 649–654. [Google Scholar] [CrossRef]

- Kotwicz Herniczek, M.T.; Feszty, D.; Meslioui, S.A.; Park, J. Applicability of Early Acoustic Theory for Modern Propeller Design. In Proceedings of the 23rd AIAA/CEAS Aeroacoustics Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Kotwicz Herniczek, M.T.; Feszty, D.; Meslioui, S.A.; Park, J.; Nitzsche, F. Evaluation of Acoustic Frequency Prediction of Propeller Noise. AIAA J. 2019, 57, 2465–2478. [Google Scholar] [CrossRef]

- Hanson, D.B.; Parzych, D.J. Theory for Noise of Propellers in Angular Inflow with Parametric Studies and Experimental Verification; NASA Contractor Report No. 4499; NASA: Washington, DC, USA, 1993. [Google Scholar]

- Biermann, D.; Hartman, E.P. The Aerodynamic Characteristics of Six Full-Scale Propellers Having Different Airfoil Sections; NACA Report No. 650; NASA: Washington, DC, USA, 1939. [Google Scholar]

- Dobrzynski, W.M.; Heller, H.H.; Densmore, J.E. DFVLR/FAA Propeller Noise Test in the German-Dutch Wind Tunnel DNW; FAA Report AEE 86-3; Berlin, German, 1986. [Google Scholar]

- Gur, O. Does Propeller Performance Depend on Airfoil Design? In Proceedings of the 61st Israel Annual Conference on Aerospace Sciences, Technion, Haifa, Israel, 9–10 March 2022.

- Bergmann, O.; Götten, F.; Braun, C.; Janser, F. Comparison and evaluation of blade element methods against RANS simulations and test data. CEAS Aeronaut J. 2022, 13, 535–557. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).