Manufacturing Technology of Lightweight Fiber-Reinforced Composite Structures in Aerospace: Current Situation and toward Intellectualization

Abstract

1. Introduction

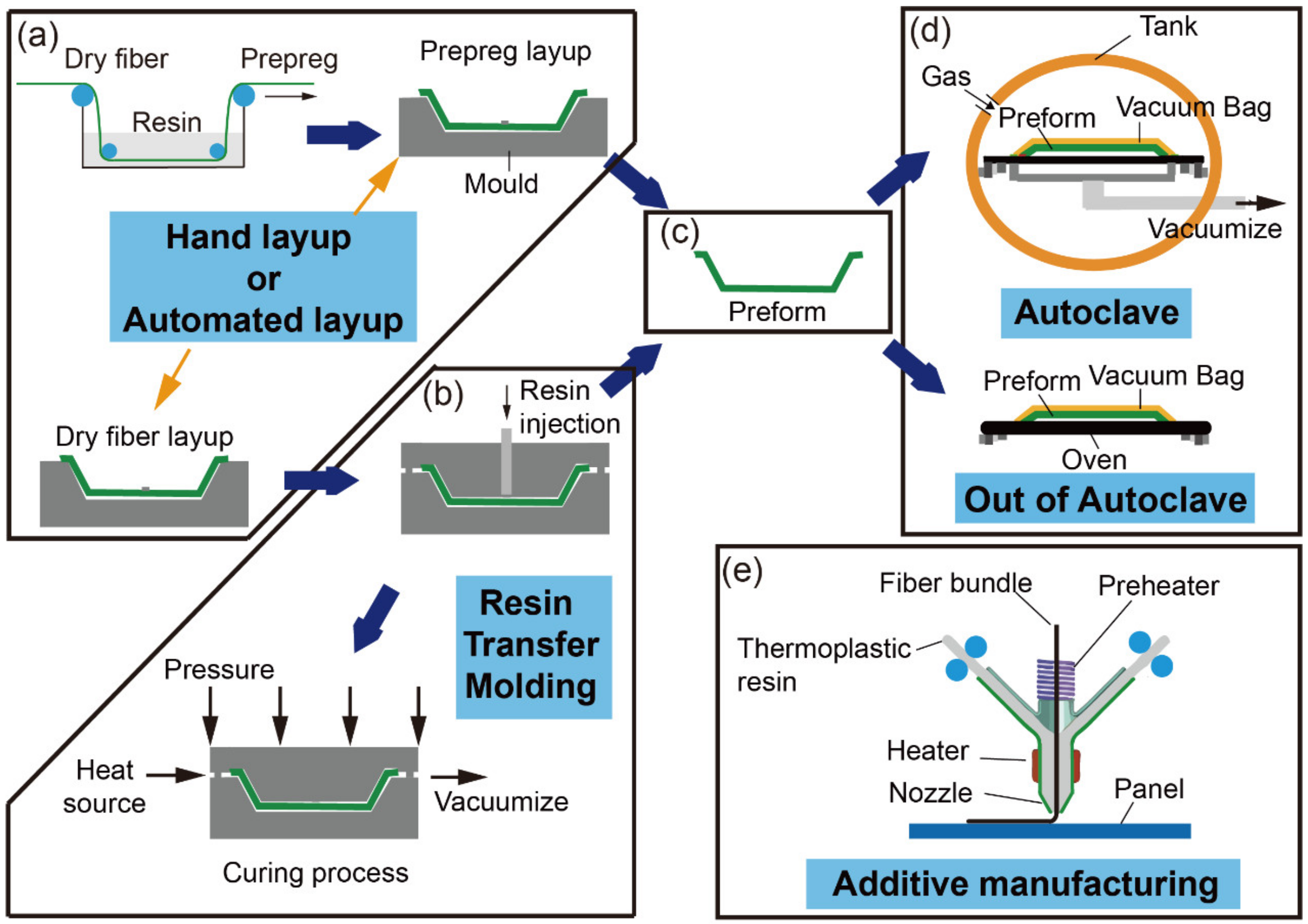

2. Traditional Molding Technology

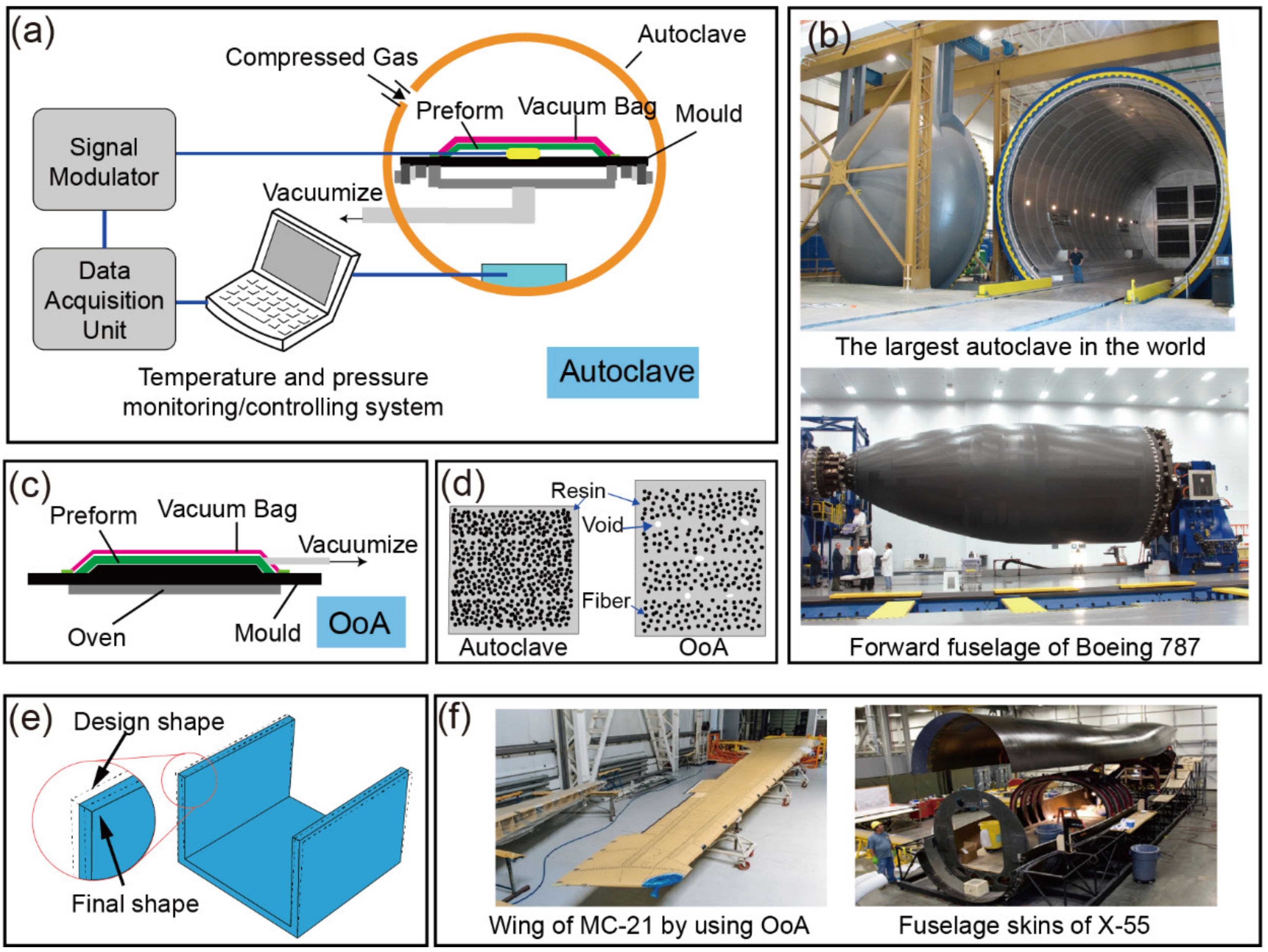

2.1. Autoclave

2.1.1. Curing Process

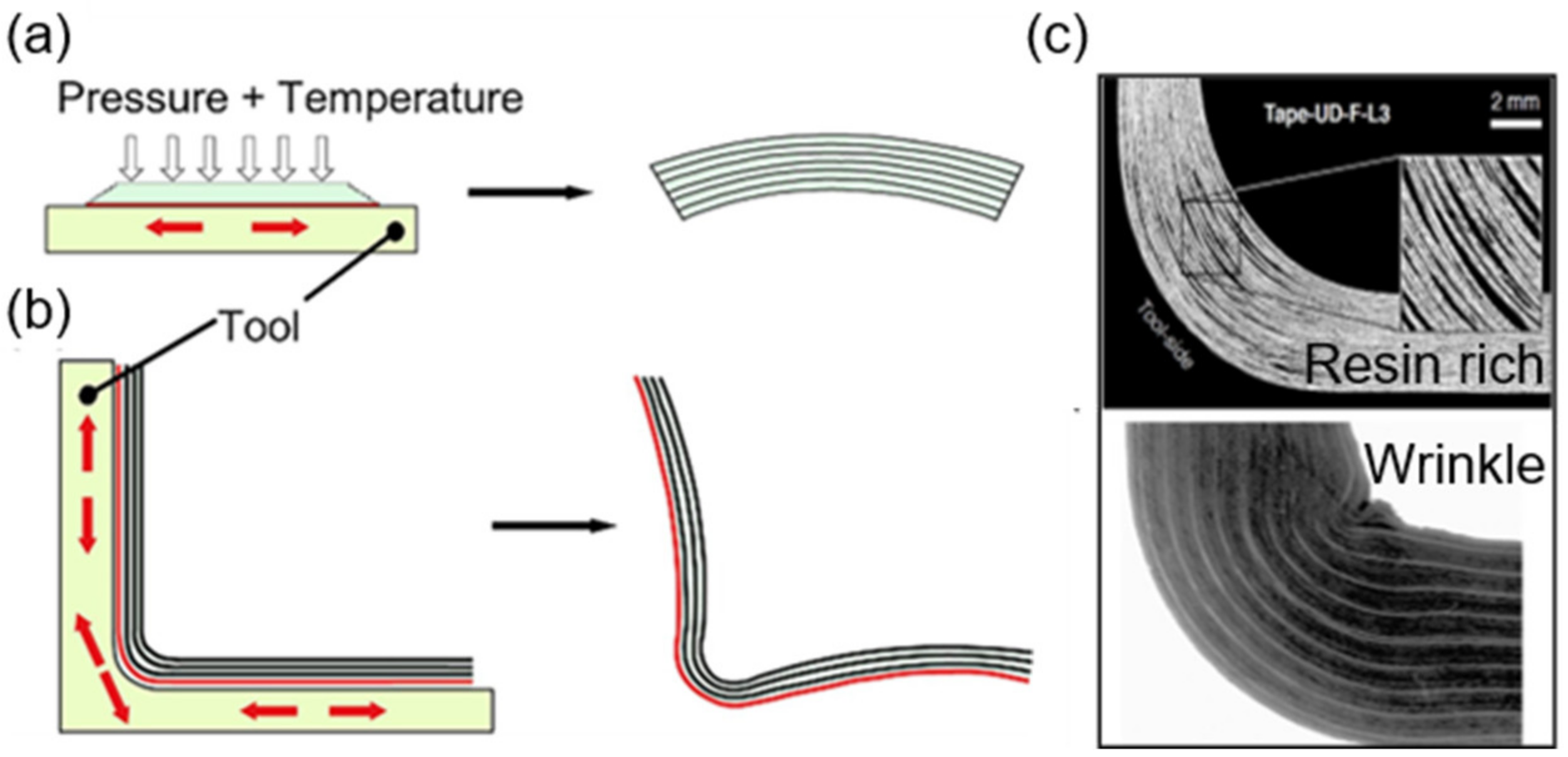

2.1.2. Curing Process-Induced Deformation

2.2. Out of Autoclave

Porosity and Fiber Volume Fraction

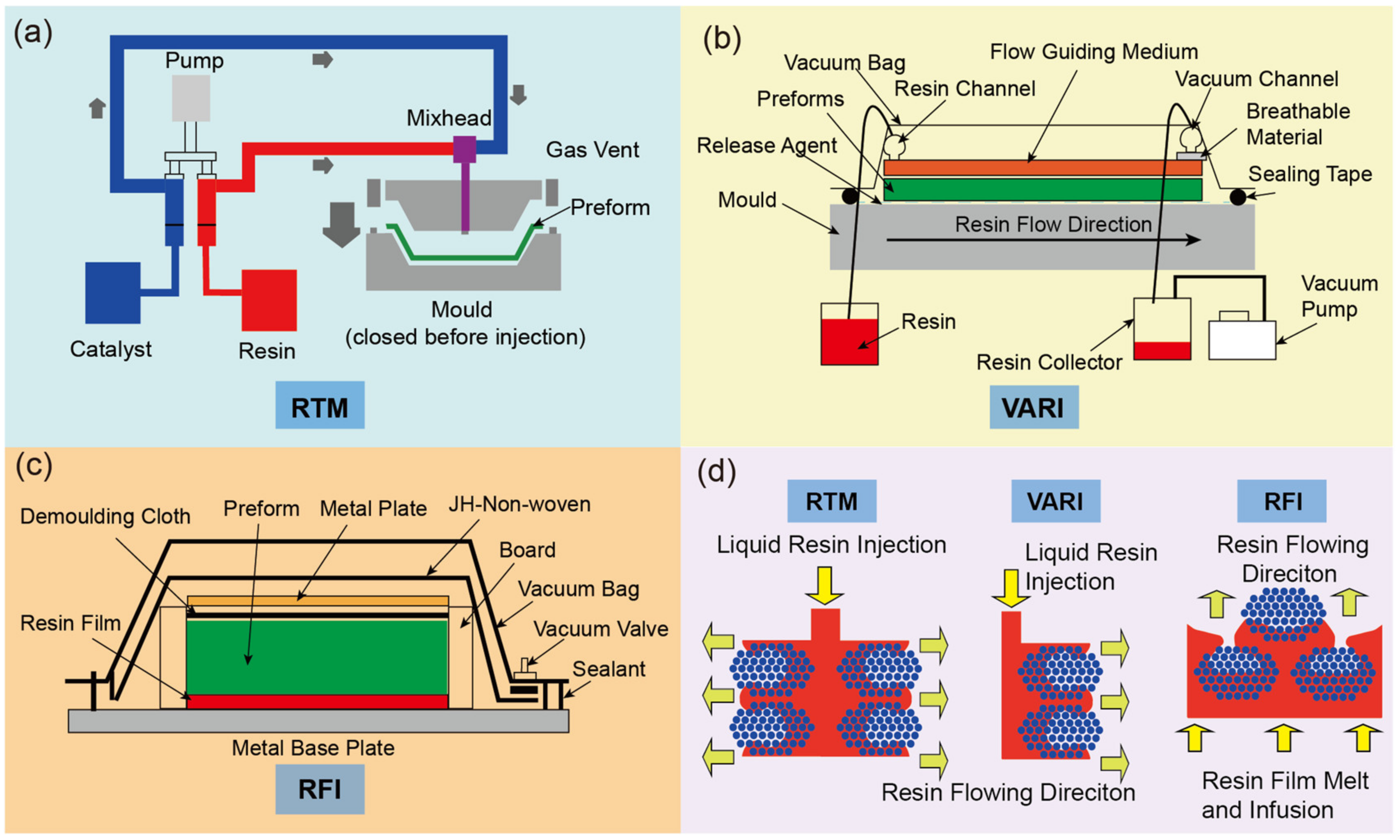

3. Liquid Composite Molding

3.1. Resin Transfer Molding

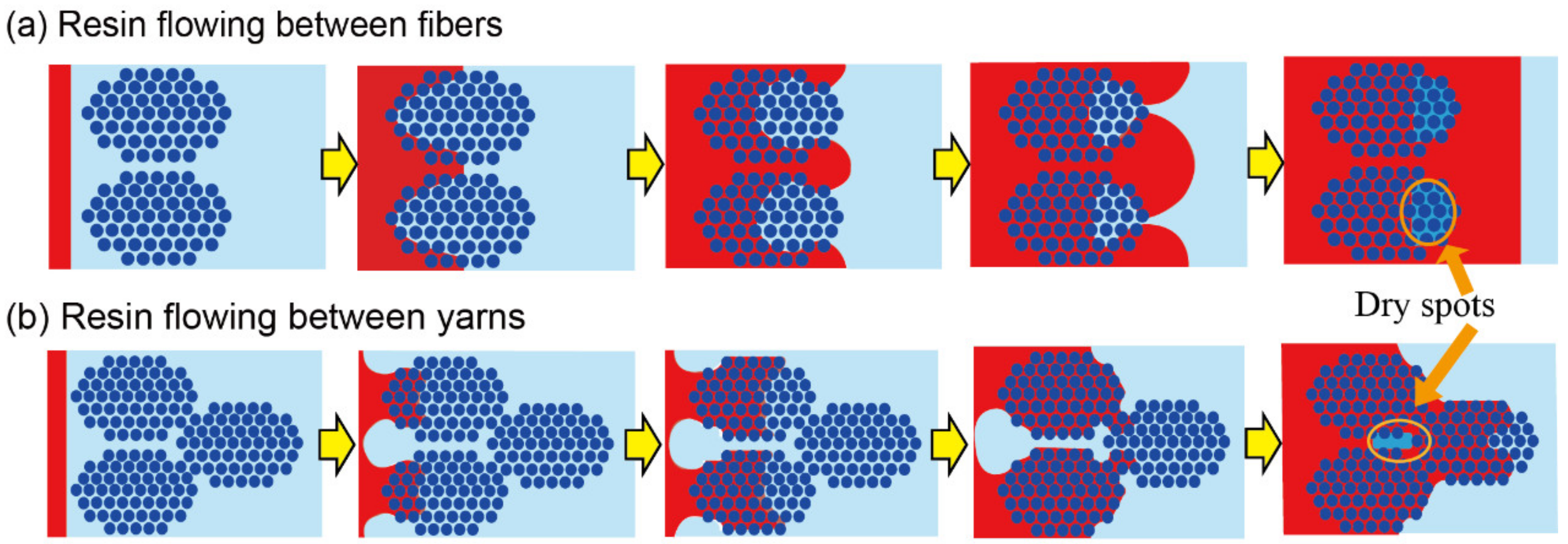

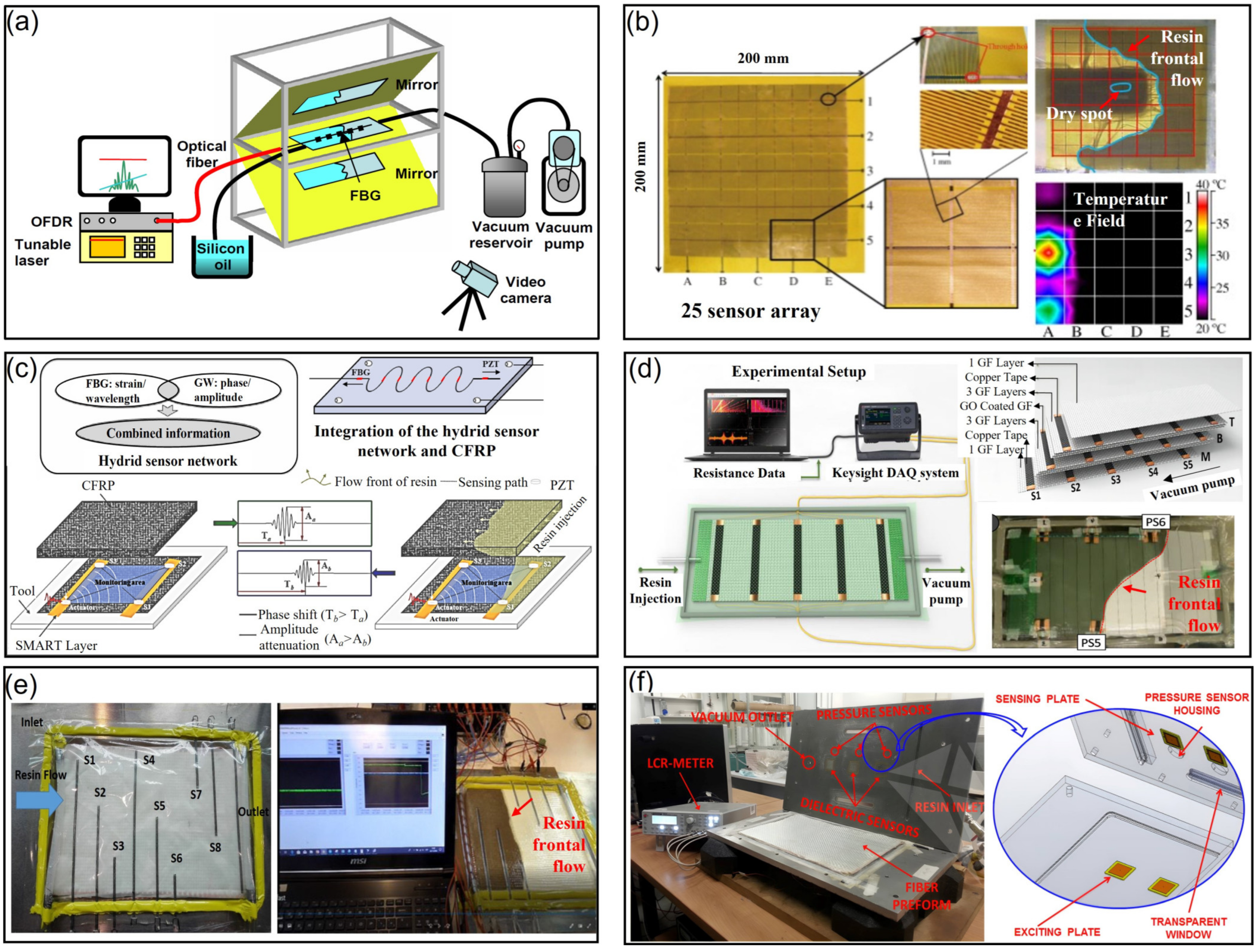

Resin Flow

- The fiber volume fraction of components is low.

- Resin is poorly impregnated with fibers, resulting in many dry spots inside the components.

- Components with a complex internal structure cannot be molded integrally.

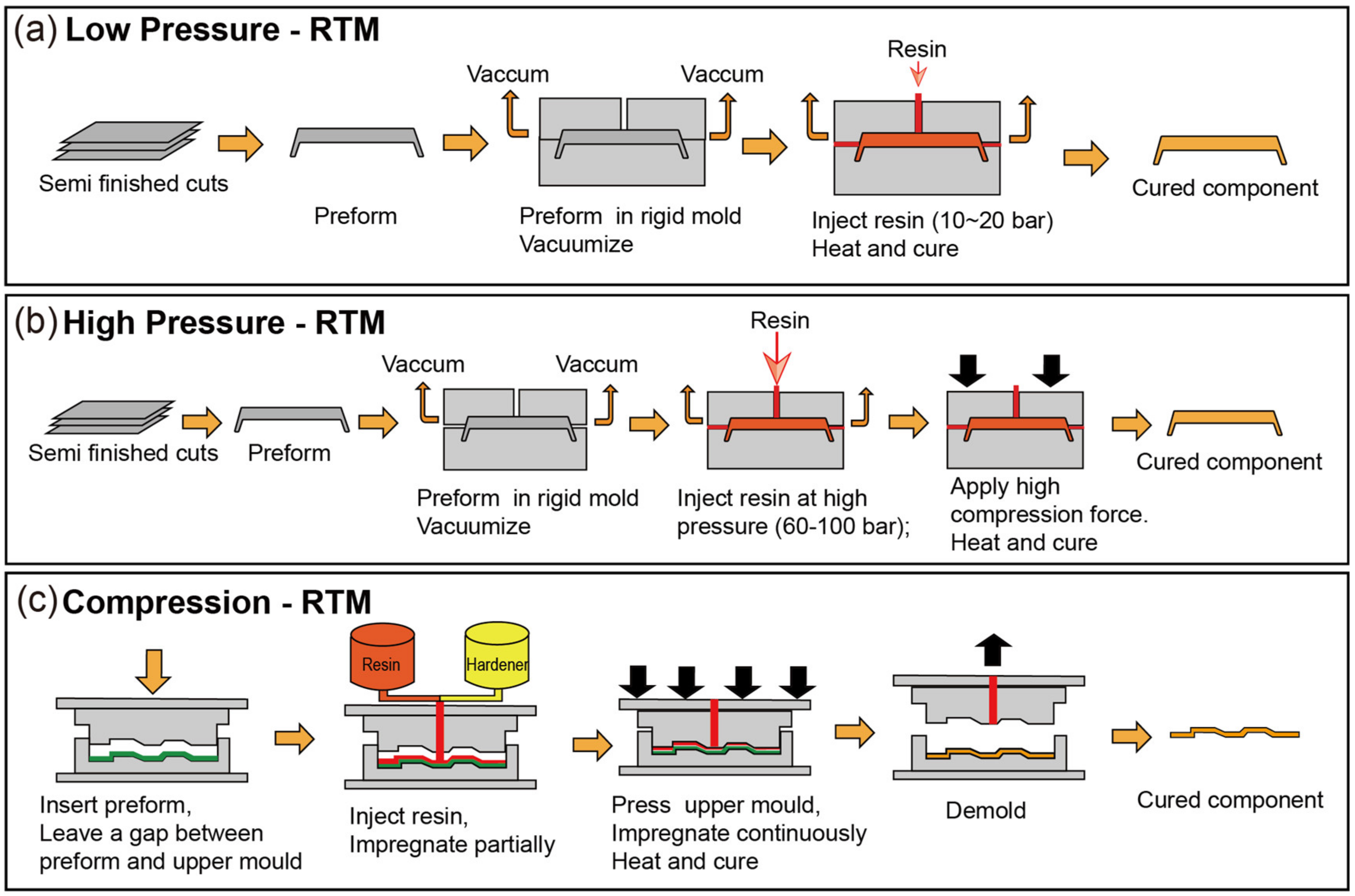

3.2. Variants of RTM

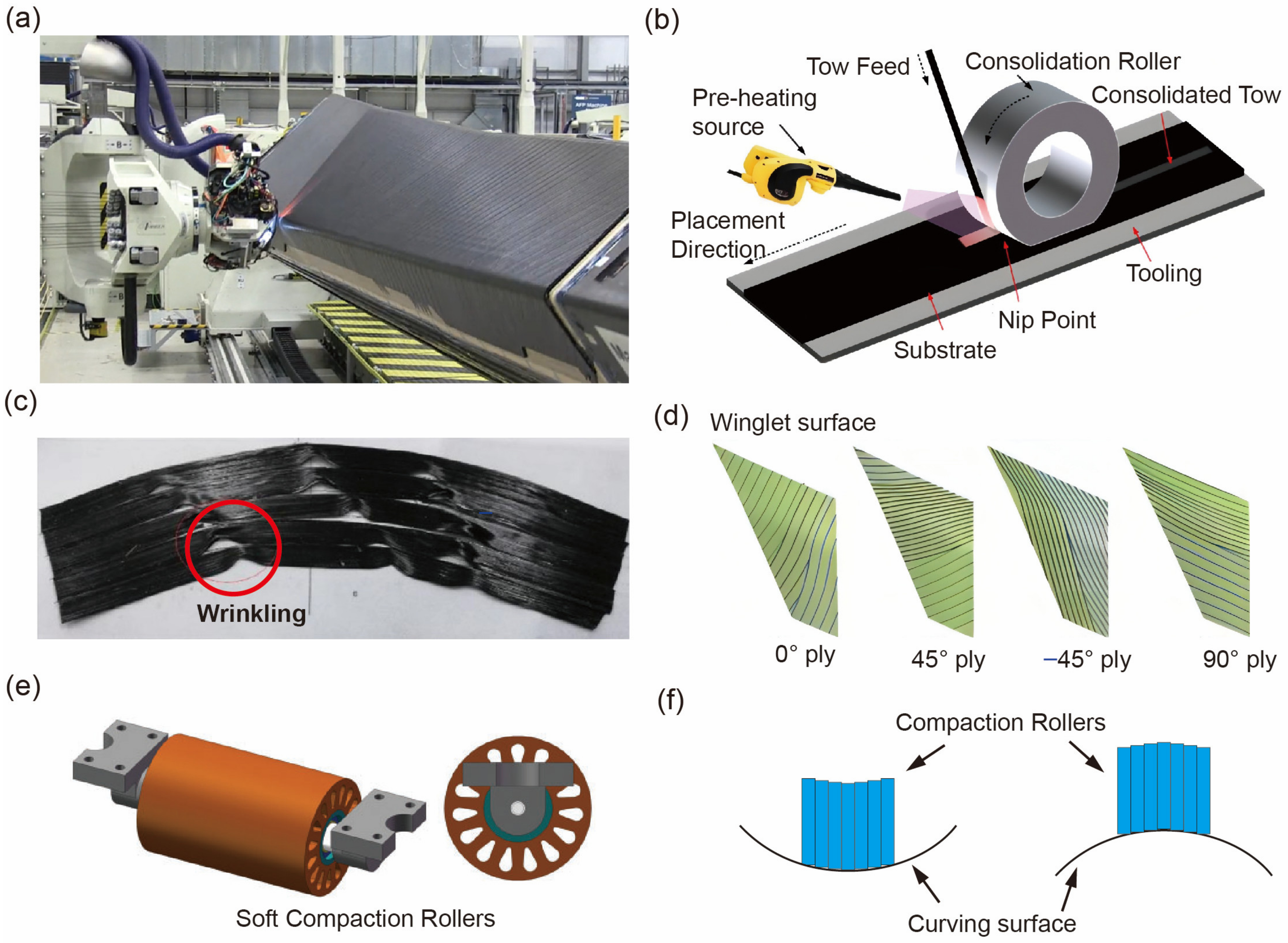

4. Automated Layup Technology

4.1. Layup Path Planning

4.2. In situ Consolidation Process Parameters

4.3. In situ Inspection and Defect Detection

4.4. Characteristic Prediction

4.5. Advanced Placed Ply

5. Additive Manufacturing

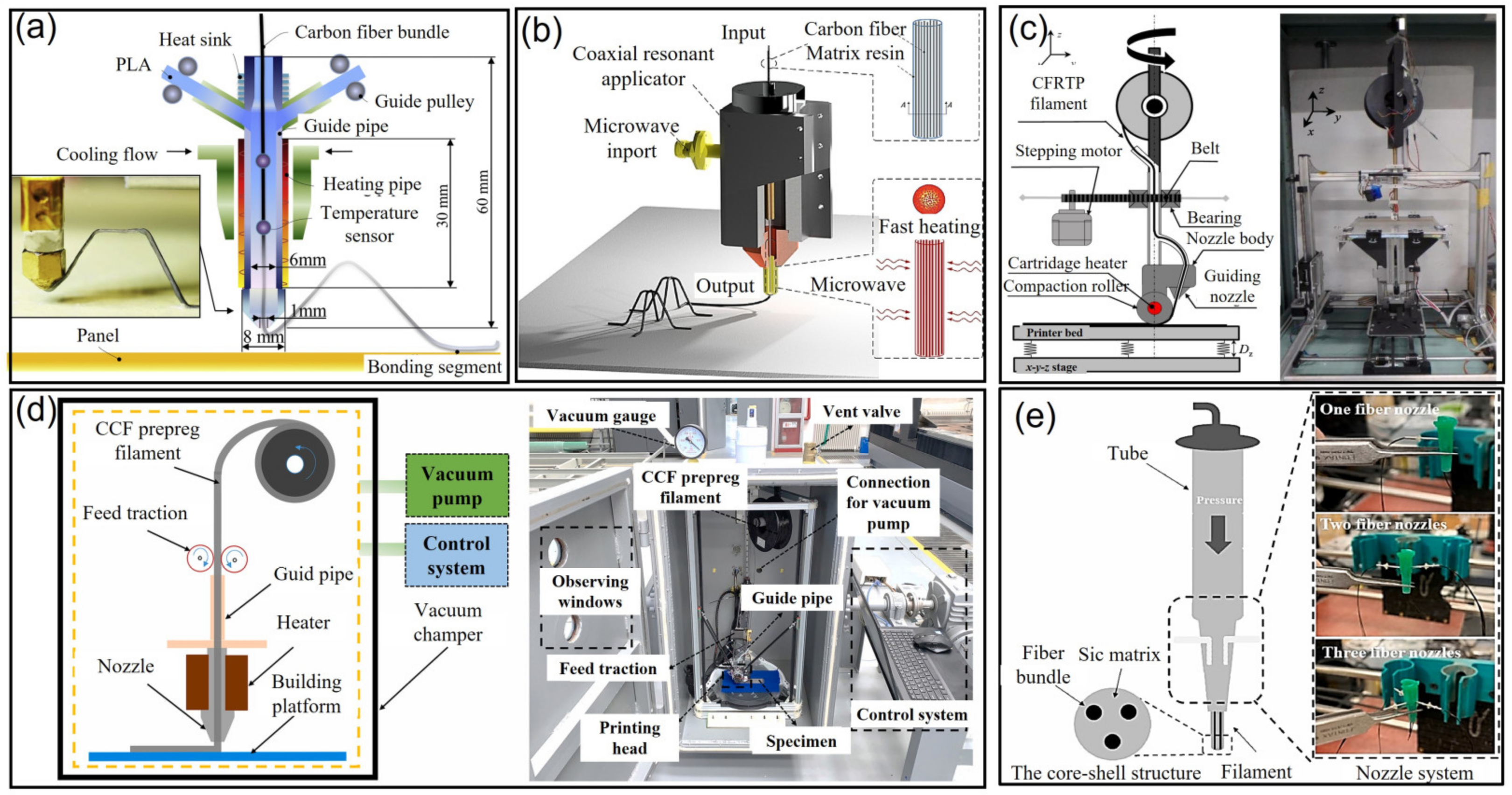

5.1. Traditional Additive Manufacturing

5.1.1. Path Planning

5.1.2. Interface Properties

5.1.3. Topology Optimization

5.1.4. Vacuum Printing

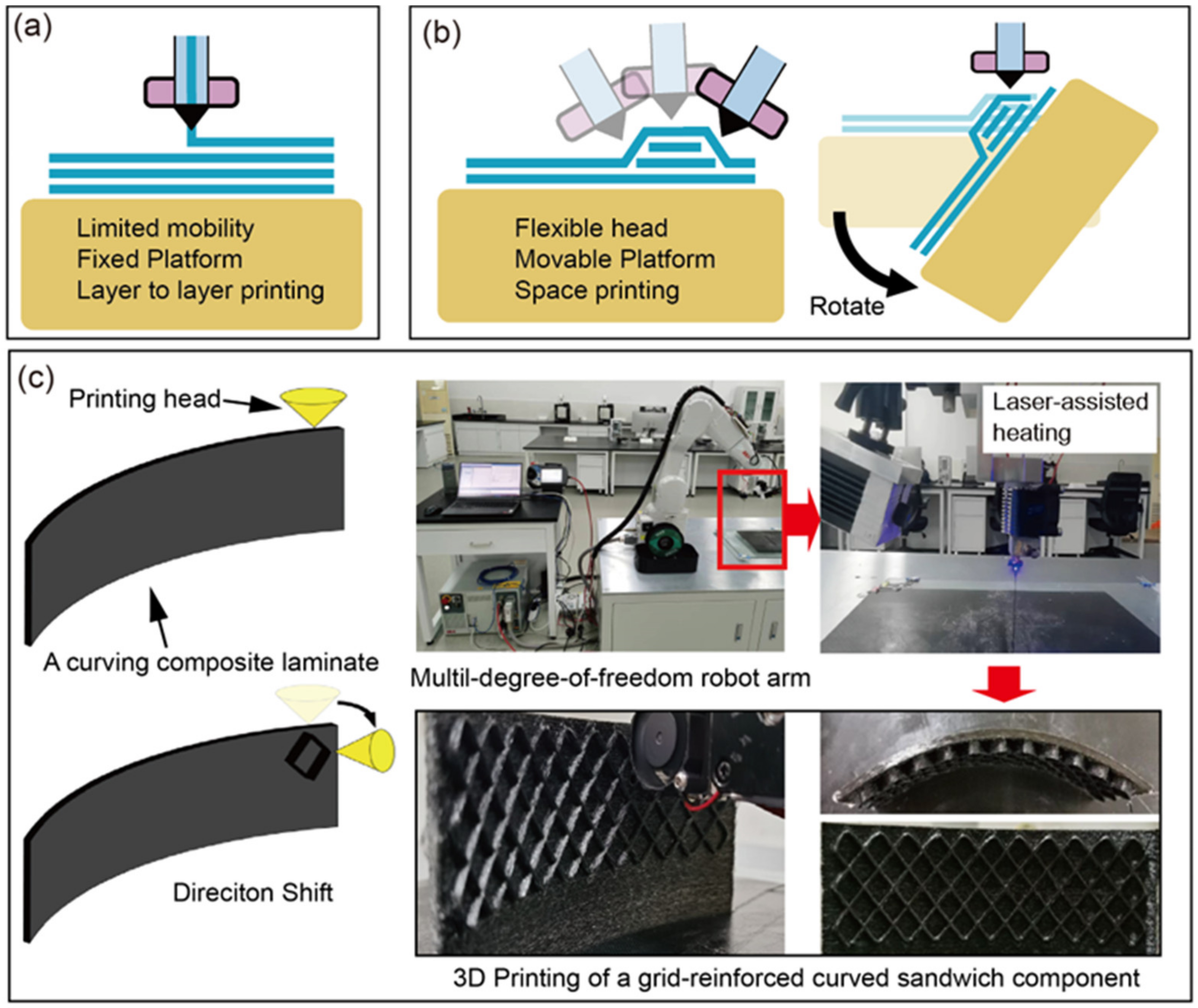

5.2. Muti-Degree of Freedom Additive Manufacturing

Intellectualization Development

6. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, S.; Han, Z.; Fu, H.; Jin, H.; Dhupia, J.S.; Wang, Y. Defect Characteristics and Online Detection Techniques During Manufacturing of FRPs Usiang Automated Fiber Placement: A Review. Polymers 2020, 12, 1337. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Liu, H.; Zhao, Y. Advance in Automated Fiber Placement Technology on Continuous Fiber Reinforced Thermoplastic Resin Matrix Composites. Aeronaut. Manuf. Technol. 2021, 64, 41–49. [Google Scholar] [CrossRef]

- Wang, F.; Wang, G.; Ning, F.; Zhang, Z. Fiber–matrix impregnation behavior during additive manufacturing of continuous carbon fiber reinforced polylactic acid composites. Addit. Manuf. 2021, 37, 101661. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, H.; Li, Z. Manufacturing Technology and Its Application of Aerospace Advanced Polymer Matrix Composites. Aerosp. Mater. Technol. 2016, 46, 1–7. [Google Scholar]

- Xie, L.; Jonathan, D.; Garth, M.P. Automation of tow wise modelling for automated fibre placement and filament wound composites. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106449. [Google Scholar]

- Van Grootel, A.; Chang, J.; Wardle, B.L.; Olivetti, E. Manufacturing variability drives significant environmental and economic impact: The case of carbon fiber reinforced polymer composites in the aerospace industry. J. Clean. Prod. 2020, 261, 121087. [Google Scholar] [CrossRef]

- Parmar, H.; Khan, T.; Tucci, F.; Umer, R.; Carlone, P. Advanced robotics and additive manufacturing of composites: Towards a new era in Industry 4.0. Mater. Manuf. Process. 2022, 37, 483–517. [Google Scholar] [CrossRef]

- Composites World. Compression RTM for Production of Future Aerostructures. 2020. Available online: https://www.compositesworld.com/articles/compression-rtm-for-production-of-future-aerostructures (accessed on 11 June 2022).

- Lukaszewicz, D.H.J.A.; Ward, C.; Potter, K.D. The engineering aspects of automated prepreg layup: History, present and future. Compos. Part B Eng. 2012, 43, 997–1009. [Google Scholar] [CrossRef]

- Boon, Y.D.; Joshi, S.C.; Bhudolia, S.K. Review: Filament Winding and Automated Fiber Placemeant with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers 2021, 13, 1951. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, J.; Wen, L.; Qi, J.; Dang, X. Research Progress of Automated Tape-laying Technology. J. Mater. Eng. 2010, 42, 87–91. [Google Scholar]

- Brasington, A.; Sacco, C.; Halbritter, J.; Wehbe, R.; Harik, R. Automated fiber placement: A review of history, current technologies, and future paths forward. Compos. Part C Open Access 2021, 6, 100182. [Google Scholar] [CrossRef]

- Rana, K.I.; Sajid, Z.; Tao, J.; Khan, L.A. Effect of vacuum manipulation on inter laminar shear strength and flexural strength in double bag vacuum infusion moulding. Polym. Polym. Compos. 2021, 29 (Suppl. 9), S432–S440. [Google Scholar] [CrossRef]

- Ermanni, P.; Fratta, C.D.; Trochu, F. Molding: Liquid Composite Molding (LCM). In Wiley Encyclopedia of Composites; Nicolais, L., Borzacchiello, A., Eds.; Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Harshe, R. A Review on Advanced Out-of-Autoclave Composites Processing. J. Indian Inst. Sci. 2015, 95, 207–220. [Google Scholar]

- Joanna, B. The MC-21 Wing—Why It’s A World’s First. 2021. Available online: https://simpleflying.com/mc-21-wing-world-first (accessed on 20 May 2022).

- Aleksendrić, D.; Carlone, P. Soft Computing in the Design and Manufacturing of Composite Materials; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Martin, I.; Saenz Del Castillo, D.; Fernandez, A.; Guemes, A. Advanced Thermoplastic Composite Manufacturing by In-Situ Consolidation: A Review. J. Compos. Sci. 2020, 4, 149. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, W.; Li, Y. Application of artificial intelligence in composite materials. Adv. Mech. 2021, 51, 865–900. [Google Scholar]

- Seyhan, A.T.R.; Tayfur, G.; Karakurt, M.; TanoğLu, M. Artificial neural network (ANN) prediction of compressive strength of VARTM processed polymer composites. Comput. Mater. Sci. 2005, 34, 99–105. [Google Scholar] [CrossRef]

- Lichtenwalner, P.F. Neural network-based control for the fiber placement composite manufacturing process. J. Mater. Eng. Perform. 1993, 2, 687–691. [Google Scholar] [CrossRef]

- Sacco, C.; Baz Radwan, A.; Anderson, A.; Harik, R.; Gregory, E. Machine learning in composites manufacturing: A case study of Automated Fiber Placement inspection. Compos. Struct. 2020, 250, 112514. [Google Scholar] [CrossRef]

- Brüning, J.; Denkena, B.; Dittrich, M.A.; Hocke, T. Machine Learning Approach for Optimization of Automated Fiber Placement Processes. Procedia CIRP 2017, 66, 74–78. [Google Scholar] [CrossRef]

- Wanigasekara, C.; Oromiehie, E.; Swain, A.; Prusty, B.G.; Nguang, S.K. Machine learning-based inverse predictive model for AFP based thermoplastic composites. J. Ind. Inf. Integr. 2021, 22, 100197. [Google Scholar] [CrossRef]

- Bi, F.Y.; Jin, T.G.; Peng, G.I. A Rapid Design and Design Knowledge Management System for Mould of Aetoclave Forming Resin Matrix Composite Components. Polym. Polym. Compos. 2012, 20, 183–190. [Google Scholar]

- Miracle, D.B.; Donaldson, S.L. ASM Handbook Volume 21: Composites; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- ASC Process Systems. ASC Completes the Largest Autoclave in the World. 2012. Available online: http://www.aschome.com/index.php/zh/asc-completes-worlds-largest-autoclave (accessed on 11 May 2022).

- TESLARATI. Forward Fuselage of the 787 on a Mandrel. 2018. Available online: https://www.teslarati.com/spacex-bfr-tent-spy-shot-mars-rocket-tooling-molds/forward-fuselage-of-the-787-on-a-mandrel-credit-boeing/ (accessed on 20 May 2022).

- RobotPig.net. X-55 (ACCA). 2009. Available online: https://robotpig.net/aerospace-news/x-55-acca-_1546 (accessed on 21 May 2022).

- Loos, A.C.; Springer, G.S. Curing of Epoxy Matrix Composites. J. Compos. Mater. 1983, 17, 135–169. [Google Scholar] [CrossRef]

- Guo, H.; Xiao, G.; Mrad, N.; Yao, J. Fiber optic sensors for structural health monitoring of air platforms. Sensors 2011, 11, 3687–3705. [Google Scholar] [CrossRef]

- Güemes, A.; Fernández-López, A.; Díaz-Maroto, P.F.; Lozano, A.; Sierra-Perez, J. Structural Health Monitoring in Composite Structures by Fiber-Optic Sensors. Sensors 2018, 18, 1094. [Google Scholar] [CrossRef] [PubMed]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Sonnenfeld, C.; Luyckx, G.; Collombet, F.; Grunevald, Y.-H.; Douchin, B.; Crouzeix, L.; Torres, M.; Geernaert, T.; Sulejmani, S.; Chah, K.; et al. Cure cycle monitoring of laminated carbon fiber-reinforced plastic by fiber Bragg gratings in microstructured optical fiber. In Proceedings of the 19th International Conference on Composite Materials, Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Sonnenfeld, C.; Luyckx, G.; Collombet, F.; Grunevald, Y.H.; Douchin, B.; Crouzeix, L.; Torres, M.; Geernaert, T.; Sulejmani, S.; Eve, S.; et al. Embedded Fiber Bragg Gratings in Photonic Crystal Fiber for Cure Cycle Monitoring of Carbon Fiber-Reinforced Polymer Materials. In Micro-Structured and Specialty Optical Fibres II; SPIE Digital Library: Bellingham, WA, USA, 2013. [Google Scholar]

- Ding, G.; Cao, H.; Xie, C. Multipoint cure monitoring of temperature and strain of carbon fibre-reinforced plastic shafts using fibre Bragg grating sensors. Nondestruct. Test. Eval. 2019, 34, 117–134. [Google Scholar] [CrossRef]

- Cable, D. Imbedded Fiber Optic Pressure and Temperature Sensors Enable Cure Monitoring of Pultruded Composite Materials. In Proceedings of the Society of Manufacturing Engineers, Conference on Effective Manufacturing Methods of Pultrusion, Manhattan Beach, CA, USA, 9–10 May 1990. [Google Scholar]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Small-diameter optical fibre sensor embedment for ambient temperature cure monitoring and residual strain evaluation of CFRP composite laminates produced by vacuum-assisted resin infusion. CEAS Space J. 2021, 13, 353–367. [Google Scholar] [CrossRef]

- Lynch, K.; Hubert, P.; Poursartip, A. Use of a simple, inexpensive pressure sensor to measure hydrostatic resin pressure during processing of composite laminates. Polym. Compos. 1999, 20, 581–593. [Google Scholar] [CrossRef]

- Xin, C.; Gu, Y.; Li, M.; Li, Y.; Zhang, Z. Online monitoring and analysis of resin pressure inside composite laminate during zero-bleeding autoclave process. Polym. Compos. 2011, 32, 314–323. [Google Scholar] [CrossRef]

- Wang, B.; Fan, S.; Chen, J.; Yang, W.; Liu, W.; Li, Y. A review on prediction and control of curing process-induced deformation of acontinuous fiber-reinforced thermosetting composite structures. Compos. Part A 2023, 165, 107321. [Google Scholar] [CrossRef]

- Benavente, M.; Marcin, L.; Courtois, A.; Lévesque, M.; Ruiz, E. Numerical analysis of viscoelastic process-induced residual distortions during manufacturing and post-curing. Compos. Part A 2018, 107, 205–216. [Google Scholar] [CrossRef]

- Benavente, M.; Marcin, L.; Courtois, A.; Lévesque, M.; Ruiz, E. Viscoelastic distortion in asymmetric plates during post curing. Compos. Part A 2017, 103, 122–130. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, D. A micromechanics-based processing model for predicting residual stress in fiber-reinforced polymer matrix composites. Compos. Struct. 2018, 204, 153–166. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Dai, J. Process Modelling of Curing Process-Induced Internal Stress and Deformation of Composite Laminate Structure with Elastic and Viscoelastic Models. Appl. Compos. Mater. 2018, 25, 527–544. [Google Scholar] [CrossRef]

- Bailleul, J.L.; Sobotka, V.; Delaunay, D.; Jarny, Y. Inverse algorithm for optimal processing of composite materials. Compos. Part A 2003, 34, 695–708. [Google Scholar] [CrossRef]

- Zobeiry, N.; Humfeld, K.D. A physics-informed machine learning approach for solving heat transfer equation in advanced manufacturing and engineering applications. Eng. Appl. Artif. Intell. 2021, 101, 104232. [Google Scholar] [CrossRef]

- Liang, Q.; Feng, X.-P.; Zhang, K.; Hui, X.-M.; Hou, X.; Ye, J.-R. Effect of curing pressure on the curing behavior of an epoxy system: Curing kinetics and simulation verification. Polymer 2022, 256, 125162. [Google Scholar] [CrossRef]

- Šesták, J.; Berggren, G. Study of the kinetics of the mechanism of solid-state reactions at increasing temperatures. Thermochim. Acta 1971, 3, 1–12. [Google Scholar] [CrossRef]

- Maji, P.; Neogi, S. Development of kinetics sub-model of cyanate ester-based prepregs for autoclave molding process simulation. High Temp. Mater. Process. 2018, 37, 769–776. [Google Scholar] [CrossRef]

- Bheemreddy, V.; Huo, Z.; Chandrashekhara, K.; Brack, R.A. Modeling and Simulation of Cure Kinetics and Flow in Cavity-Molded Composites. J. Am. Helicopter Soc. 2016, 61, 022004. [Google Scholar] [CrossRef]

- Davé, R. A Unified Approach to Modeling Resin Flow During Composite Processing. J. Compos. Mater. 1990, 24, 22–41. [Google Scholar] [CrossRef]

- Hill, R.R., Jr.; Muzumdar, S.V.; Lee, L.J. Analysis of volumetric changes of unsaturated polyester resins during curing. Polym. Eng. Sci. 1995, 35, 852–859. [Google Scholar] [CrossRef]

- Klingler, A.; Gilberg, M.; Wetzel, B.; Krüger, J.K. Simultaneous access to different types of volume changes and the degree of cure during isothermal polymerization of polymer networks. Express Polym. Lett. 2022, 16, 1193–1207. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, G.; Xu, J.; Shi, X.P.; Wang, X. Review of curing deformation control methods for carbon fiber reinforced resin composites. Polym. Compos. 2022, 43, 3350–3370. [Google Scholar] [CrossRef]

- Kravchenko, O.G.; Kravchenko, S.G.; Pipes, R.B. Cure history dependence of residual deformation in a thermosetting laminate. Compos. Part A 2017, 99, 186–197. [Google Scholar] [CrossRef]

- Fernlund, G.; Rahman, N.; Courdji, R.; Bresslauer, M.; Nelson, K. Experimental and numerical study of the effect of cure cycle, tool surface, geometry, and lay-up on the dimensional fidelity of autoclave-processed composite parts. Compos. Part A Appl. Sci. Manuf. 2002, 33, 341–351. [Google Scholar] [CrossRef]

- Dai, J.; Xi, S.; Li, D. Numerical Analysis of Curing Residual Stress and Deformation in Thermosetting Composite Laminates with Comparison between Different Constitutive Models. Materials 2019, 12, 572. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, J.; Wang, B.; Chen, J.; Yang, W.; Liu, W.; Li, Y. A deep learning method for fast predicting curing process-induced deformation of aeronautical composite structures. Compos. Sci. Technol. 2023, 232, 109844. [Google Scholar] [CrossRef]

- Krumenacker, N. Experimental Study of Variability and Defects in Vacuum-Bag-Only Corner Laminates; McGill University: Montreal, QC, Canada, 2018; p. 303. [Google Scholar]

- Kappel, E.; Stefaniak, D.; Hühne, C. Process distortions in prepreg manufacturing—An experimental study on CFRP L-profiles. Compos. Struct. 2013, 106, 615–625. [Google Scholar] [CrossRef]

- Radford, D.W.; Rennick, T.S. Separating Sources of Manufacturing Distortion in Laminated Composites. J. Reinf. Plast. Compos. 2000, 19, 621–641. [Google Scholar] [CrossRef]

- Mostafa, H.E.; El-Dakhakhni, W.W.; Mekky, W.F. Use of reinforced rigid polyurethane foam for blast hazard mitigation. J. Reinf. Plast. Compos. 2010, 29, 3048–3057. [Google Scholar] [CrossRef]

- Gajjar, T.; Shah, D.B.; Joshi, S.J.; Patel, K.M. Experimental and simulation investigation on spring-in deformation for L-shape component. Curved Layered Struct. 2019, 6, 169–180. [Google Scholar] [CrossRef]

- Çınar, K.; Ersoy, N. Effect of fibre wrinkling to the spring-in behaviour of L-shaped composite materials. Compos. Part A 2015, 69, 105–114. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Huan, D.; Wang, W.; Jiao, Y. Influence of resin curing cycle on the deformation of filament wound composites by in situ strain monitoring. High Perform. Polym. 2021, 33, 1141–1152. [Google Scholar] [CrossRef]

- Feng, Y.; Han, Z.; Li, R.; Zhang, W. Numerical modeling for curing of unidirectional carbon fiber reinforced polymer based on micromechanics in Laplace domain. Compos. Sci. Technol. 2022, 228, 109637. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, L.; Zhou, J. Curing multidirectional carbon fiber reinforced polymer composites with indirect microwave heating. Int. J. Adv. Manuf. Technol. 2018, 97, 1137–1147. [Google Scholar] [CrossRef]

- Li, Y.; Li, N.; Zhou, J.; Cheng, Q. Microwave curing of multidirectional carbon fiber reinforced polymer composites. Compos. Struct. 2019, 212, 83–93. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Li, N.; Liu, S.; Cheng, L.; Sui, S.; Gao, J. A multi-pattern compensation method to ensure even temperature in composite materials during microwave curing process. Compos. Part A 2018, 107, 10–20. [Google Scholar] [CrossRef]

- Nawab, Y.; Tardif, X.; Boyard, N.; Sobotka, V.; Casari, P.; Jacquemin, F. Determination and modelling of the cure shrinkage of epoxy vinylester resin and associated composites by considering thermal gradients. Compos. Sci. Technol. 2012, 73, 81–87. [Google Scholar] [CrossRef]

- Nawab, Y.; Jaquemin, F.; Casari, P.; Boyard, N.; Sobotka, V. Evolution of chemical and thermal curvatures in thermoset-laminated composite plates during the fabrication process. J. Compos. Mater. 2013, 47, 327–339. [Google Scholar] [CrossRef]

- Ahmad, F.N.; Jaafar, M.; Palaniandy, S.; Azizli, K.A.M. Effect of particle shape of silica mineral on the properties of epoxy composites. Compos. Sci. Technol. 2008, 68, 346–353. [Google Scholar] [CrossRef]

- Khan, L.A.; Khan, W.A.; Ahmed, S. Out-of-Autoclave (OOA) Manufacturing Technologies for Composite Sandwich Structures. In Handbook of Research on Manufacturing Process Modeling and Optimization Strategies; Khan, A.K.W.A., Ahmed, S., Eds.; IGI Global: Hershey, PA, USA, 2017; pp. 292–317. [Google Scholar]

- Tooling up for Larger Launch Vehicles. 2013. Available online: https://www.compositesworld.com/articles/tooling-up-for-larger-launch-vehicles. (accessed on 8 June 2022).

- Grunenfelder, L.K.; Nutt, S.R. Void formation in composite prepregs—Effect of dissolved moisture. Compos. Sci. Technol. 2010, 70, 2304–2309. [Google Scholar] [CrossRef]

- Centea, T.; Grunenfelder, L.K.; Nutt, S.R. A review of out-of-autoclave prepregs–Material properties, process phenomena, and manufacturing considerations. Compos. Part A 2015, 70, 132–154. [Google Scholar] [CrossRef]

- Hou, T.H.; Jensen, B.J. Evaluation of Double-Vacuum-Bag Process for Composite Fabrication. In Proceedings of the International SAMPE Symposium and Exhibition, SAMPE 2004, Long Beach, CA, USA, 16–20 May 2004. [Google Scholar]

- Hou, T.H.; Jensen, B.J. Double-vacuum-bag technology for volatile management in composite fabrication. Polym. Compos. 2008, 29, 906–914. [Google Scholar] [CrossRef]

- Gardiner, G. Out-of-Autoclave Prepregs: Hype or Revolution? High Perform. Compos. 2011, 19. [Google Scholar]

- Fratta, C.D.; Sun, Y.; Causse, P.; Trochu, F. A Dimensionless Characteristic Number for Process Selection and Mold Design in Composites Manufacturing: Part II—Applications. J. Compos. Sci. 2020, 4, 10. [Google Scholar] [CrossRef]

- Parnas, R.S. Liquid Composite Molding; Hanser Publications: Cincinnati, OH, USA, 2000. [Google Scholar]

- Jungang, G.U.O.; Xinjuan, Z.; Yiyao, T.; Chao, Y.a.N.; Junjun, J.; Yujun, L.I. Development and Application of Liquid Composite Molding Technique on Aircraft. Aerosp. Mater. Technol. 2022, 52, 85–91. [Google Scholar]

- Abdellaoui, H.; Echaabi, J. Rheological models for modeling the viscoelastic behavior in liquid composite molding processes (LCM) review. J. Reinf. Plast. Compos. 2014, 33, 714–732. [Google Scholar] [CrossRef]

- Sozer, M.; Simacek, P.; Advani, G. Resin transfer molding (RTM) in polymer matrix composites. In Manufacturing Techniques for Polymer Matrix Composites (PMCs); Advani, S.G., Hsiao, K.T., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2012; pp. 245–309. [Google Scholar]

- Vita, A.; Castorani, V.; Germani, M.; Marconi, M. Comparative life cycle assessment of low-pressure RTM, compression RTM and high-pressure RTM manufacturing processes to produce CFRP car hoods. Procedia CIRP 2019, 80, 352–357. [Google Scholar] [CrossRef]

- Kranbuehl, D.; Kingsley, P.; Hart, S.; Loos, A.; Dexter, B. Sensor-model prediction, monitoring and in-situ control of liquid RTM advanced fiber architecture composite processing. In Proceedings of the 37th International SAMPE Symposium & Exhibition, Anaheim, CA, USA, 9–12 March 1992. [Google Scholar]

- Hasko, G.; Dexter, H.B.; Loos, A.; Kranbuehl, D. Application of science-based RTM for fabricating primary aircraft structural elements. J. Adv. Mater. 1994, 26, 9–15. [Google Scholar]

- Rutt, M.; Lekakou, C.; Smith, P.A.; Sordon, A.; Santoni, C.; Meeks, G.; Hamerton, I. Methods for process-related resin selection and optimisation in high-pressure resin transfer moulding. Mater. Sci. Technol. 2019, 35, 327–335. [Google Scholar] [CrossRef]

- The European Space Agency. Ariane 5. 2022. Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Launch_vehicles/Ariane_5. (accessed on 6 June 2022).

- Avila, S.J.; Oliveira, R.L.A.; Campos, A.S.; Coelho, V.J.V. A numerical investigation of the resin flow front tracking applied to the RTM process. Mater. Res. 2011, 14, 345–354. [Google Scholar]

- Lin, J.L.; Young, W.B. The Effect of Preheater on the Resin Transfer Molding. J. Optoelectron. Adv. Mater. 1999, 18, 954–965. [Google Scholar] [CrossRef]

- Trochu, F.; Gauvin, R.; Gao, D. Numerical analysis of the resin transfer molding process by the finite element method. Adv. Polym. Technol. 2010, 12, 329–342. [Google Scholar] [CrossRef]

- Chang, C.Y. Modeling and evaluation of the filling process of vacuum-assisted compression resin transfer molding. J. Polym. Eng. 2013, 33, 211–219. [Google Scholar] [CrossRef]

- Kardos, J.L.; Duduković, M.; Dave, R. Void growth and resin transport during processing of thermosetting—Matrix composites. In Epoxy Resins and Composites IV; Springer: Berlin/Heidelberg, Germany, 1986. [Google Scholar]

- Kang, M.K.; Lee, W.I.; Hahn, H.T. Formation of microvoids during resin-transfer molding process. Compos. Sci. Technol. 2000, 60, 2427–2434. [Google Scholar] [CrossRef]

- Lee, D.H.; Lee, W.I.; Kang, M.K. Analysis and minimization of void formation during resin transfer molding process. Compos. Sci. Technol. 2006, 66, 3281–3289. [Google Scholar] [CrossRef]

- Gu, Y.; Li, M.; Zhang, Z.; Sun, Z. Void formation model and measuring method of void formation condition during hot pressing process. Polym. Compos. 2010, 31, 1562–1571. [Google Scholar] [CrossRef]

- Li, Y.; Li, Q.; Ma, H. The voids formation mechanisms and their effects on the mechanical properties of flax fiber reinforced epoxy composites. Compos. Part A 2015, 72, 40–48. [Google Scholar] [CrossRef]

- Cai, Z. Simplified Mold Filling Simulation in Resin Transfer Molding. J. Compos. Mater. 1992, 26, 2606–2630. [Google Scholar]

- Ito, T.; Yamagishi, K.; Okumura, I.; Kitade, S.; Shigegaki, Y. Smart manufacturing of low-cost integrated panel by resin-transfer molding. Adv. Compos. Mater 2004, 13, 57–66. [Google Scholar] [CrossRef]

- Bickerton, S.; Stadtfeld, H.C.; Steiner, K.V.; Advani, S.G. Design and application of actively controlled injection schemes for resin-transfer molding. Compos. Sci. Technol. 2001, 61, 1625–1637. [Google Scholar] [CrossRef]

- Kang, M.K.; Jung, J.J.; Lee, W.I. Analysis of resin transfer moulding process with controlled multiple gates resin injection. Compos. Part A Appl. Sci. Manuf. 2000, 31, 407–422. [Google Scholar] [CrossRef]

- Yu, B.; Chiu, H.T.; Ding, Z.; Lee, L.J. Analysis of Flow and Heat Transfer in Liquid Composite Molding. Int. Polym. Process. J. Polym. Process. Soc. 2013, 15, 273–283. [Google Scholar] [CrossRef]

- Eum, S.; Kageyama, K.; Murayama, H.; Ohsawa, I.; Uzawa, K.; Kanai, M.; Igawa, H. Resin flow monitoring in vacuum assisted resin transfer molding using optical fiber distributed sensor. In Proceedings of the Conference on Behavior and Mechanics of Multifunctional and Composite Materials, San Diego, CA, USA, 18–22 March 2007. [Google Scholar]

- Yildiz, M.; Ozdemir, N.G.; Bektas, G.; Keulen, C.J.; Boz, T.; Sengun, E.F.; Ozturk, C.; Menceloglu, Y.Z.; Suleman, A. An Experimental Study on the Process Monitoring of Resin Transfer Molded Composite Structures Using Fiber Optic Sensors. J. Manuf. Sci. Eng.-Trans. ASME 2012, 134, 044502. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Kobayashi, S.; Todoroki, A.; Mizutani, Y. Full-field monitoring of resin flow using an area-sensor array in a VaRTM process. Compos. Part A Appl. Sci. Manuf. 2011, 42, 550–559. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Kobayashi, S.; Todoroki, A.; Mizutani, Y. Control of resin flow/temperature using multifunctional interdigital electrode array film during a VaRTM process. Compos. Part A Appl. Sci. Manuf. 2011, 42, 782–793. [Google Scholar] [CrossRef]

- Khan, T.; Ali, M.A.; Irfan, M.S.; Khan, K.A.; Liao, K.; Umer, R. Resin infusion process monitoring using graphene coated glass fabric sensors and infusible thermoplastic and thermoset matrices. Polym. Compos. 2022, 43, 2924–2940. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Zhu, J.; Wang, Y.; Qing, X. Monitoring of resin flow front and degree of cure in vacuum-assisted resin infusion process using multifunctional piezoelectric sensor network. Polym. Compos. 2021, 42, 113–125. [Google Scholar] [CrossRef]

- Yu, Y.; Cui, X.; Liang, Z.; Qing, X.; Yan, W. Monitoring of three-dimensional resin flow front using hybrid piezoelectric-fiber sensor network in a liquid composite molding process. Compos. Sci. Technol. 2022, 229, 109712. [Google Scholar] [CrossRef]

- Del Rio, J.S.; Pascual-Gonzalez, C.; Martinez, V.; Jimenez, J.L.; Gonzalez, C. 3D-printed resistive carbon-fiber-reinforced sensors for monitoring the resin frontal flow during composite manufacturing. Sens. Actuators A Phys. 2021, 317, 112422. [Google Scholar] [CrossRef]

- Carlone, P.; Rubino, F.; Paradiso, V.; Tucci, F. Multi-scale modeling and online monitoring of resin flow through dual-scale textiles in liquid composite molding processes. Int. J. Adv. Manuf. Technol. 2018, 96, 2215–2230. [Google Scholar] [CrossRef]

- Cristovao, C.; Bodaghi, M.; Correia, N.; Gomes, R. Experimental characterization of voids in high fibre volume fraction composites processed by high injection pressure RTM. Compos. Part A Appl. Sci. Manuf. 2016, 82, 88–99. [Google Scholar]

- Pham, X.; Trochu, F. Simulation of compression resin transfer molding to manufacture thin composite shells. Polym. Compos. 1999, 20, 436–459. [Google Scholar] [CrossRef]

- Simacek, P.; Advani, S.G.; Iobst, S.A. Modeling Flow in Compression Resin Transfer Molding for Manufacturing of Complex Lightweight High-Performance Automotive Parts. J. Compos. Mater. 2008, 42, 2523–2545. [Google Scholar] [CrossRef]

- Davenport, D.E.; Petrovich, R.; Sutton, G. Low Pressure Resin Transfer Molding for Cost Effective Aircraft Quality Structures; North Coast Composites: Cleveland, OH, USA, 2014. [Google Scholar]

- Chaudhari, R.; Rosenberg, P.; Karcher, M.; Schmidhuber, S.; Elsner, P.; Henning, F. High-Pressure RTM Process Variants for Manufacturing of Carbon Fiber Reinforced Composites. In Proceedings of the International Conference on Composite Materials (ICCM-19), Montreal, QC, Canada, 28 July–2 August 2013; pp. 1–9. [Google Scholar]

- Rosenberg, P.; Chaudhari, R.; Karcher, M.; Henning, F.; Elsner, P. Investigating Cavity Pressure Behavior in High-Pressure RTM Process Variants. In Proceedings of the AIP Conference, Surakarta, Indonesia, 12 May 2014. [Google Scholar]

- Bhat, P.; Merotte, J.; Simacek, P.; Advani, S.G. Process analysis of compression resin transfer molding. Compos. Part A Appl. Sci. Manuf. 2009, 40, 431–441. [Google Scholar] [CrossRef]

- Grone, R.; Grimshaw, M. Composite Tape Laying Machine with Pivoting Presser Member. U.S. Patent EP0250673A1, 9 December 1986. [Google Scholar]

- Goldsworthy, W.; Estates, P.; Karlson, H.; Monica, S.; Hardesty, E. Geodesic Path Length Compensator for Composite-Tape Placement Method. U.S. Patent 3810805, 14 April 1974. [Google Scholar]

- Clancy, G.; Peeters, D.; O’higgins, R.M.; Weaver, P.M. In-line variable spreading of carbon fibre/thermoplastic pre-preg tapes for application in automatic tape placement. Mater. Des. 2020, 194, 108967. [Google Scholar] [CrossRef]

- Rizzolo, R.H.; Walczyk, D.F. Ultrasonic consolidation of thermoplastic composite prepreg for automated fiber placement. J. Thermoplast. Compos. Mater. 2016, 29, 1480–1497. [Google Scholar] [CrossRef]

- Kontis, K.; Romano, F.; Barile, M.; Cacciapuoti, G.; Godard, J.-L.; Vollaro, P.; Barabinot, P.; Pantelakis, S. Advanced OoA and Automated Technologies for the Manufacturing of a Composite Outer Wing Box. MATEC Web Conf. 2018, 233, 00005. [Google Scholar]

- GKN Aerospace. Advanced Automated Fibre Placement Machine. Available online: https://www.gknaerospace.com/en/newsroom/video-library/ (accessed on 12 June 2022).

- Han, Z.; Sun, S.; Fu, H.; Fu, Y. Multi-Scale Low-Entropy Method for Optimizing the Processing Parameters during Automated Fiber Placement. Materials 2017, 10, 1024. [Google Scholar] [CrossRef]

- Niu, X.; Liu, Y.; Wu, J.; Yang, T. Curvature-controlled trajectory planning for variable stiffness composite laminates. Compos. Struct. 2020, 238, 111986. [Google Scholar] [CrossRef]

- Zhao, A. Automatic paving path planning method on complex surfaces. J. Beijing Univ. Aeronaut. Astronaut. 2022, 48, 595–601. [Google Scholar]

- Jiang, J.; He, Y.; Ke, Y. Pressure distribution for automated fiber placement; design optimization of compaction rollers. J. Reinf. Plast. Compos. 2019, 38, 860–870. [Google Scholar] [CrossRef]

- Qu, W.; Gao, J.; Yang, D.; He, R.; Yang, Q.; Cheng, L.; Ke, Y. Automated fiber placement path generation method based on prospective analysis of path performance under multiple constraints. Compos. Struct. 2021, 255, 112940. [Google Scholar] [CrossRef]

- Shirinzadeh, B.; Cassidy, G.; Oetomo, D.; Alici, G.; Ang, M.H., Jr. Trajectory generation for open-contoured structures in robotic fibre placement. Rob. Comput. Integr. Manuf. 2007, 23, 380–394. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, B.; Xiao, J. Macroscopic characterization of fiber micro-buckling and its influence on composites tensile performance. J. Reinf. Plast. Compos. 2017, 36, 196–205. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Bittrich, L.; Jansen, E.; Tita, V.; Spickenheuer, A. Buckling optimization of composite cylinders for axial compression: A design methodology considering a variable-axial fiber layout. Compos. Struct. 2019, 222, 110928. [Google Scholar] [CrossRef]

- Bittrich, L.; Spickenheuer, A.; Almeida, J.H.S.; Müller, S.; Kroll, L.; Heinrich, G. Optimizing Variable-Axial Fiber-Reinforced Composite Laminates: The Direct Fiber Path Optimization Concept. Math. Probl. Eng. 2019, 2019, 8260563. [Google Scholar] [CrossRef]

- Arhant, M.; Davies, P. Thermoplastic Matrix Composites for Marine Applications. In Marine Composites; Pemberton, R., Summerscales, J., Graham-Jones, J., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 31–53. [Google Scholar]

- Chen, J.; Wang, K.; Dong, A.; Li, X.; Fan, X.; Zhao, Y. A comprehensive study on controlling the porosity of CCF 300/PEEK composites by optimizing the impregnation parameters. Polym. Compos. 2018, 39, 3765–3779. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Li, N.; Zhao, X.; Han, X.; Li, S.; Lu, W.; Wang, K.; Du, S. Enhanced interfacial strength of carbon fiber/PEEK composites using a facile approach via PEI&ZIF-67 synergistic modification. J. Mater. Res. Technol. 2019, 8, 6289–6300. [Google Scholar]

- August, Z.; Ostrander, G.; Michasiow, J.; Hauber, D. Recent Developments in Automated Fiber Placement of Thermoplastic Composites. SAMPE J. 2014, 50, 30–37. [Google Scholar]

- Song, Q.; Xiao, J.; Wen, L.; Wang, X.; Zhao, C.; Chu, Q. Non-isothermal Crystallization Kinetics of Thermoplastic Composite for Automated Fiber Placement. J. Mater. Eng. 2018, 46, 120–126. [Google Scholar]

- Song, Q.; Liu, W.; Xiao, J.; Chen, P.; Yang, Y.; Chen, J. Infrared heating system based on automated fiber placement for thermoplastic composites. J. Mater. Eng. 2019, 47, 77–83. [Google Scholar]

- Danezis, A.; Williams, D.; Edwards, M.; Skordos, A.A. Heat transfer modelling of flashlamp heating for automated tape placement of thermoplastic composites. Compos. Part A 2021, 145, 106381. [Google Scholar] [CrossRef]

- Jiang, J.; He, Y.; Wang, H.; Ke, Y. Modeling and experimental validation of compaction pressure distribution for automated fiber placement. Compos. Struct. 2021, 256, 113101. [Google Scholar] [CrossRef]

- Bakhshi, N.; Hojjati, M. Effect of compaction roller on layup quality and defects formation in automated fiber placement. J. Reinf. Plast. Compos. 2020, 39, 3–20. [Google Scholar] [CrossRef]

- Denkena, B.; Schmidt, C.; Weber, P. Automated Fiber Placement Head for Manufacturing of Innovative Aerospace Stiffening Structures. In Proceedings of the 16th Machining Innovations Conference for Aerospace Industry (MIC), Garbsen, Germany, 23–24 November 2016. [Google Scholar]

- Zacchia, T.T.; Shadmehri, F.; Fortin-Simpson, J.; Hoa, S.V. Design of hard compaction rollers for automated fiber placement on complex mandrel geometries. In Proceedings of the Canadian Society for Mechanical Engineering International Congress, Toronto, ON, Canada, 27–30 May 2018. [Google Scholar]

- Heider, D.; Piovoso, M.J.; Gillespie, J.W. Intelligent Control of the Thermoplastic Composite Tow-Placement Process. J. Thermoplast. Compos. Mater. 1998, 11, 573–595. [Google Scholar] [CrossRef]

- Maass, D. Progress in automated ply inspection of AFP layups. Reinf. Plast. 2015, 59, 242–245. [Google Scholar] [CrossRef]

- Halbritter, A.; Harper, R. Big parts demand big changes to the fiber placement status quo. SME Compos. Manuf. 2012, 2012. [Google Scholar]

- Peters, K.; Pattis, P.; Botsis, J.; Giaccari, P. Experimental verification of response of embedded optical fiber Bragg grating sensors in non-homogeneous strain fields. Opt. Lasers Eng. 2000, 33, 107–119. [Google Scholar] [CrossRef]

- Oromiehie, E.; Prusty, B.G.; Compston, P.; Rajan, G. In situ process monitoring for automated fibre placement using fibre Bragg grating sensors. Struct. Health Monit. Int. J. 2016, 15, 706–714. [Google Scholar] [CrossRef]

- Croft, K.; Lessard, L.; Pasini, D.; Hojjati, M.; Chen, J.; Yousefpour, A. Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Compos. Part A Appl. Sci. Manuf. 2011, 42, 484–491. [Google Scholar] [CrossRef]

- Woigk, W.; Hallett, S.R.; Jones, M.I.; Kuhtz, M.; Hornig, A.; Gude, M. Experimental investigation of the effect of defects in Automated Fibre Placement produced composite laminates. Compos. Struct. 2018, 201, 1004–1017. [Google Scholar] [CrossRef]

- Oromiehie, E.; Prusty, B.G.; Compston, P.; Rajan, G. Characterization of process-induced defects in automated fiber placement manufacturing of composites using fiber Bragg grating sensors. Struct. Health Monit. Int. J. 2018, 17, 108–117. [Google Scholar] [CrossRef]

- Denkena, B.; Schmidt, C.; Voeltzer, K.; Hocke, T. Thermographic online monitoring system for Automated Fiber Placement processes. Compos. Part B Eng. 2016, 97, 239–243. [Google Scholar] [CrossRef]

- Schmidt, C.; Hocke, T.; Denkena, B. Artificial intelligence for non-destructive testing of CFRP prepreg materials. Prod. Eng. 2019, 13, 617–626. [Google Scholar] [CrossRef]

- Han, Z.; Sun, S.; Li, W.; Zhao, Y.; Shao, Z. Experimental study of the effect of internal defects on stress waves during automated fiber placement. Polymers 2018, 10, 413. [Google Scholar] [CrossRef]

- Wanigasekara, C.; Oromiehie, E.; Swain, A.; Prusty, B.G.; Nguang, S.K. Machine Learning Based Predictive Model for AFP-Based Unidirectional Composite Laminates. IEEE Trans. Ind. Inf. 2020, 16, 2315–2324. [Google Scholar] [CrossRef]

- Nagelsmit, M.H.; Kassapoglou, C.; Gürdal, Z. A New Fibre Placement Architecture for Improved Damage Tolerance; NLR-TP-2010-626; National Aerospace Laboratory NLR: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Li, X.; Hallett, S.R.; Wisnom, M.R. Modelling the effect of gaps; overlaps in automated fibre placement (AFP)-manufactured laminates. Sci. Eng. Compos. Mater. 2015, 22, 115–129. [Google Scholar] [CrossRef]

- Nagelsmit, M.H. Fibre Placement Architectures for Improved Damage Tolerance. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2013. [Google Scholar]

- Vakili Rad, C.; Thomas, F.D.; Seay, B.; Van Tooren, M.J.L.; Sockalingam, S. Manufacturing and characterization of novel clutch non-conventional fiber-reinforced composite laminates. Compos. Struct. 2019, 215, 454–470. [Google Scholar] [CrossRef]

- Tooren, M.V.; Sockalingam, S. Non-conventional Composite Laminates—Clutch Laminates. In Proceedings of the American Society for Composites 2017—32th Technical Conference, West Lafayette, IN, USA, 23–25 October 2017. [Google Scholar]

- Rutger, K.; Marco, P.; Francisca, M.-H.; Antonio, P. Dynamic response of Advanced Placed Ply composites. Compos. Part B 2023, 248, 110347. [Google Scholar]

- Drach, B.; Drach, A.; Tsukrov, I.; Penverne, M.; Lapusta, Y. Finite element models of 3D woven composites based on numerically generated micro-geometry of reinforcement. In Proceedings of the American Society for Composites 2014—29th Technical Conference on Composite Materials, La Jolla, CA, USA, 8–10 September 2014. [Google Scholar]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fibre reinforced t hermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar]

- Saeed, K.; Mcilhagger, A.; Harkin-Jones, E.; Kelly, J.; Archer, E. Predication of the in-plane mechanical properties of continuous carbon fibre reinforced 3D printed polymer composites using classical laminated-plate theory. Compos. Struct. 2021, 259, 113226. [Google Scholar] [CrossRef]

- Thomas, A.J.; Barocio, E.; Pipes, R.B. A machine learning approach to determine the elastic properties of printed fiber-reinforced polymers. Compos. Sci. Technol. 2022, 220, 109293. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, K.; Neto, V.; Peng, Y.; Valente, R.; Ahzi, S. Interfacial behaviors of continuous carbon fiber reinforced polymers manufactured by fused filament fabrication: A review and prospect. Int. J. Mater. Form. 2022, 15, 18. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive manufacturing of structural materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, X.; Zhao, W.; Wang, G.; Liu, B. An Overview of Research on FDM 3D Printing Process of Continuous Fiber Reinforced Composites. J. Phys. Conf. Ser. 2019, 1213, 052037. [Google Scholar] [CrossRef]

- Rakhshbahar, M.; Sinapius, M. A Novel Approach: Combination of Automated Fiber Placement (AFP) and Additive Layer Manufacturing (ALM). J. Compos. Sci. 2018, 2, 42. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Li, N. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures. Mater. Des. 2018, 137, 235–244. [Google Scholar] [CrossRef]

- Li, N.; Link, G.; Jelonnek, J. Rapid 3D microwave printing of continuous carbon fiber reinforced plastics. CIRP Ann. 2020, 69, 221–224. [Google Scholar] [CrossRef]

- Ueda, M.; Kishimoto, S.; Yamawaki, M.; Matsuzaki, R.; Todoroki, A.; Hirano, Y.; Le Duigou, A. 3D compaction printing of a continuous carbon fiber reinforced thermoplastic. Compos. Part A 2020, 137, 105985. [Google Scholar] [CrossRef]

- Li, H.; Liu, B.; Ge, L.; Chen, Y.; Zheng, H.; Fang, D. Mechanical performances of continuous carbon fiber reinforced PLA composites printed in vacuum. Compos. Part B 2021, 225, 109277. [Google Scholar] [CrossRef]

- Chen, R.; Bratten, A.; Rittenhouse, J.; Leu, M.C.; Wen, H. Additive manufacturing of continuous carbon fiber-reinforced SiC ceramic composite with multiple fiber bundles by an extrusion-based technique. Ceram. Int. 2022, 49, 9839–9847. [Google Scholar] [CrossRef]

- Dong, K.; Ke, H.; Panahi-Sarmad, M.; Yang, T.; Huang, X.; Xiao, X. Mechanical properties and shape memory effect of 4D printed cellular structure composite with a novel continuous fiber-reinforced printing path. Mater. Des. 2021, 198, 109303. [Google Scholar] [CrossRef]

- Chen, X.; Fang, G.; Liao, W.-H.; Wang, C.C.L. Field-Based Toolpath Generation for 3D Printing Continuous Fibre Reinforced Thermoplastic Composites. Addit. Manuf. 2022, 49, 102470. [Google Scholar] [CrossRef]

- Bi, M.; Xia, L.; Tran, P.; Li, Z.; Wan, Q.; Wang, L.; Shen, W.; Ma, G.; Xie, Y.M. Continuous contour-zigzag hybrid toolpath for large format additive manufacturing. Addit. Manuf. 2022, 55, 102822. [Google Scholar] [CrossRef]

- Sayam, A.; Rahman, A.N.M.M.; Rahman, M.S.; Smriti, S.A.; Ahmed, F.; Rabbi, M.F.; Hossain, M.; Faruque, M.O. A review on carbon fiber-reinforced hierarchical composites: Mechanical performance, manufacturing process, structural applications and allied challenges. Carbon Lett. 2022, 32, 1173–1205. [Google Scholar] [CrossRef]

- Fan, C.; Shan, Z.; Zou, G.; Zhan, L.; Yan, D. Interfacial Bonding Mechanism and Mechanical Performance of Continuous Fiber Reinforced Composites in Additive Manufacturing. Chin. J. Mech. Eng. 2021, 34, 21. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, J.; Zhang, G.; Li, Y.; Li, L. Prediction of deformation and failure behavior of continuous fiber reinforced composite fabricated by additive manufacturing. Compos. Struct. 2021, 265, 113738. [Google Scholar] [CrossRef]

- Fasel, U.; Keidel, D.; Baumann, L.; Cavolina, G.; Eichenhofer, M.; Ermanni, P. Composite additive manufacturing of morphing aerospace structures. Manuf. Lett. 2020, 23, 85–88. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Zocca, A.; Wilbig, J.; Waske, A.; Günster, J.; Widjaja, M.P.; Neumann, C.; Clozel, M.; Meyer, A.; Ding, J.; Zhou, Z.; et al. Challenges in the Technology Development for Additive Manufacturing in Space. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100018. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Zou, M.; Zhang, L.; Song, Y. Suppressing the Step Effect of 3D Printing for Constructing Contact Lenses. Adv. Mater. 2022, 34, 2107249. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J.; Yang, W.; Li, Y. Simulation and optimization of continuous fiber reinforced composite curved sandwich structure fabricated by Multi-DOF 3D printing. Addit. Manuf. 2022; submitted for publication. [Google Scholar]

- Bin Ishak, I.; Fisher, J.; Larochelle, P. Robot Arm Platform for Additive Manufacturing using Multi-Plane Toolpaths. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016. [Google Scholar]

- Eichenhofer, M.; Wong, J.C.H.; Ermanni, P. Continuous lattice fabrication of ultra-lightweight composite structures. Addit. Manuf. 2017, 18, 48–57. [Google Scholar] [CrossRef]

- Tian, X.; Todoroki, A.; Liu, T.; Wu, L.; Hou, Z.; Ueda, M.; Hirano, Y.; Matsuzaki, R.; Mizukami, K.; Iizuka, K.; et al. 3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Application, and Prospective. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100016. [Google Scholar] [CrossRef]

- Yang, T.; Yi, X.; Lu, S.; Johansson, K.H.; Chai, T. Intelligent Manufacturing for the Process Industry Driven by Industrial Artificial Intelligence. Engineering 2021, 7, 1224–1230. [Google Scholar] [CrossRef]

- Su, H.B.; Fan, L.T.; Schlup, J.R. Monitoring the process of curing of epoxy/graphite fiber composites with a recurrent neural network as a soft sensor. Eng. Appl. Artif. Intell. 1998, 11, 293–306. [Google Scholar] [CrossRef]

- Pillai, V.; Beris, A.N.; Dhurjati, P. Intelligent Curing of Thick Composites Using a Knowledge-Based System. J. Compos. Mater. 1997, 31, 22–51. [Google Scholar] [CrossRef]

- Rai, N.; Pitchumani, R. Optimal cure cycles for the fabrication of thermosetting-matrix composites. Polym. Compos. 1997, 18, 566–581. [Google Scholar] [CrossRef]

- Oh, J.H.; Lee, D.G. Cure Cycle for Thick Glass/Epoxy Composite Laminates. J. Compos. Mater. 2002, 36, 19–45. [Google Scholar] [CrossRef]

- Michaud, D.J.; Beris, A.N.; Dhurjati, P.S. Thick-Sectioned RTM Composite Manufacturing, Part II. Robust Cure Cycle Optimization. Control. J. Compos. Mater. 2002, 36, 1201–1231. [Google Scholar]

- Ruiz, E.; Trochu, F. Comprehensive thermal optimization of liquid composite molding to reduce cycle time and processing stresses. Polym. Compos. 2005, 26, 209–230. [Google Scholar] [CrossRef]

- Kopparthi, P.K.; Kundavarapu, V.R.; Dasari, V.R.; Kaki, V.R.; Pathakokila, B.R. Modeling of glass fiber reinforced composites for optimal mechanical properties using teaching learning based optimization and artificial neural networks. SN Appl. Sci. 2019, 2, 131. [Google Scholar] [CrossRef]

- Meister, S.; Wermes, M.; Stüve, J.; Groves, R.M. Investigations on Explainable Artificial Intelligence methods for the deep learning classification of fibre layup defect in the automated composite manufacturing. Compos. Part B 2021, 224, 109160. [Google Scholar] [CrossRef]

| Technology | Advantage | References |

|---|---|---|

| Free-hanging 3D printing (2018) |

| [175] |

| 3D microwave printing (2020) |

| [176] |

| 3D compaction printing (2020) |

| [177] |

| Vacuum 3D printing (2021) |

| [178] |

| Multiple fiber bundles 3D printing (2022) |

| [179] |

| Project | Traditional Additive Manufacturing | Multi-Degree-of-Freedom Additive Manufacturing |

|---|---|---|

| Print trajectory | Line in the horizontal plane | Space line or curve |

| Calibration difficulty | Easy | Difficult |

| Print flexibility | Low | High |

| Step effect | Obvious | Not obvious |

| Supporting material | Much | Few or none |

| Manufacturing Technology | Advantage | Disadvantage | Challenge |

|---|---|---|---|

| Autoclave |

|

|

|

| OoA |

|

|

|

| LCM |

|

|

|

| ALT |

|

|

|

| Additive Manufacturing |

|

|

|

| Manufacturing Technology | Process Monitoring | Process Controlling | Property and PID Prediction |

|---|---|---|---|

| Autoclave & OoA |

| ||

| LCM |

| ||

| ALT |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhang, J.; Li, Z.; Zhang, H.; Chen, J.; Yang, W.; Yu, T.; Liu, W.; Li, Y. Manufacturing Technology of Lightweight Fiber-Reinforced Composite Structures in Aerospace: Current Situation and toward Intellectualization. Aerospace 2023, 10, 206. https://doi.org/10.3390/aerospace10030206

Chen Y, Zhang J, Li Z, Zhang H, Chen J, Yang W, Yu T, Liu W, Li Y. Manufacturing Technology of Lightweight Fiber-Reinforced Composite Structures in Aerospace: Current Situation and toward Intellectualization. Aerospace. 2023; 10(3):206. https://doi.org/10.3390/aerospace10030206

Chicago/Turabian StyleChen, Yonglin, Junming Zhang, Zefu Li, Huliang Zhang, Jiping Chen, Weidong Yang, Tao Yu, Weiping Liu, and Yan Li. 2023. "Manufacturing Technology of Lightweight Fiber-Reinforced Composite Structures in Aerospace: Current Situation and toward Intellectualization" Aerospace 10, no. 3: 206. https://doi.org/10.3390/aerospace10030206

APA StyleChen, Y., Zhang, J., Li, Z., Zhang, H., Chen, J., Yang, W., Yu, T., Liu, W., & Li, Y. (2023). Manufacturing Technology of Lightweight Fiber-Reinforced Composite Structures in Aerospace: Current Situation and toward Intellectualization. Aerospace, 10(3), 206. https://doi.org/10.3390/aerospace10030206