Experimental Investigation of Flameholding in Scramjet Combustor by Pylon with Plasma Actuator Based on Q-DC Discharge

Abstract

1. Introduction

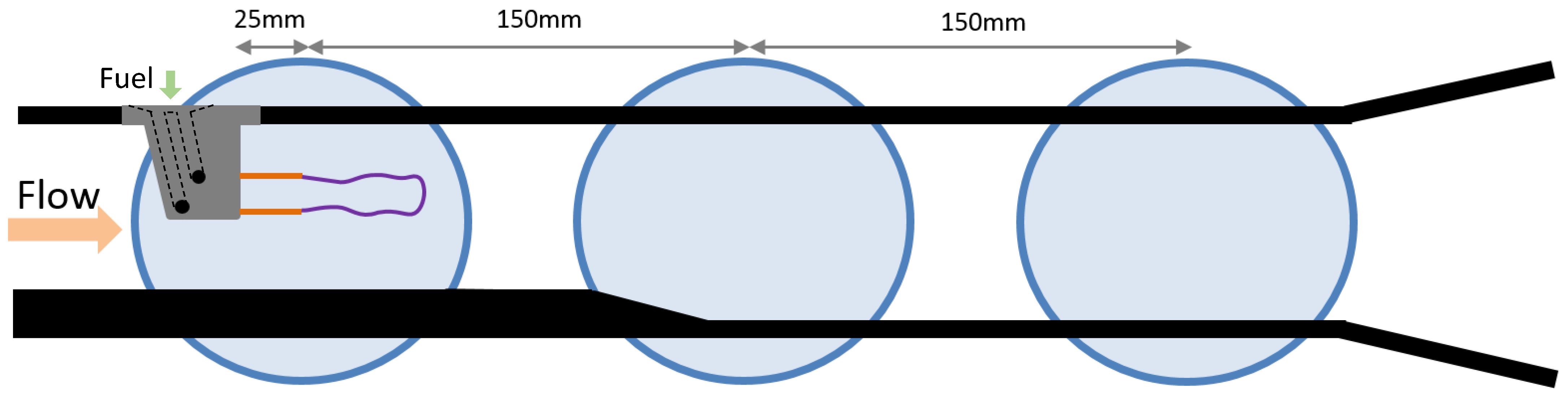

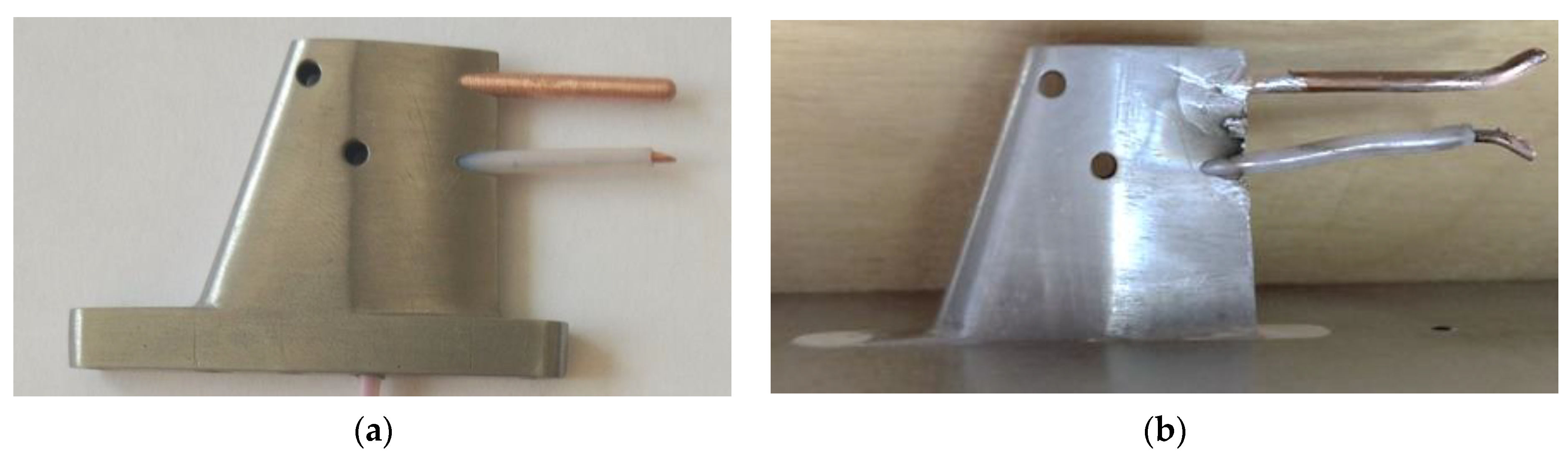

2. Experimental Setup and Diagnostics

3. Results

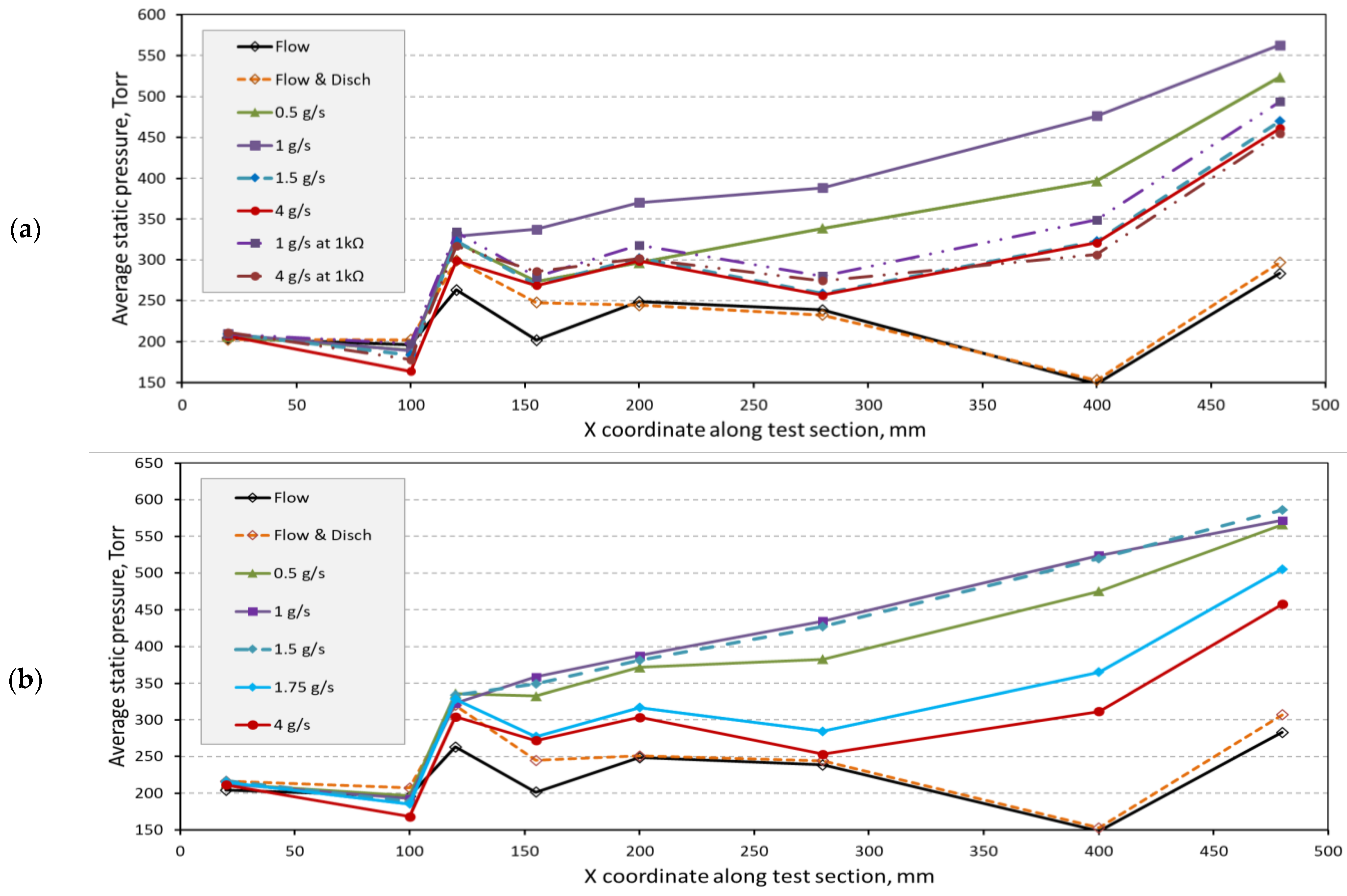

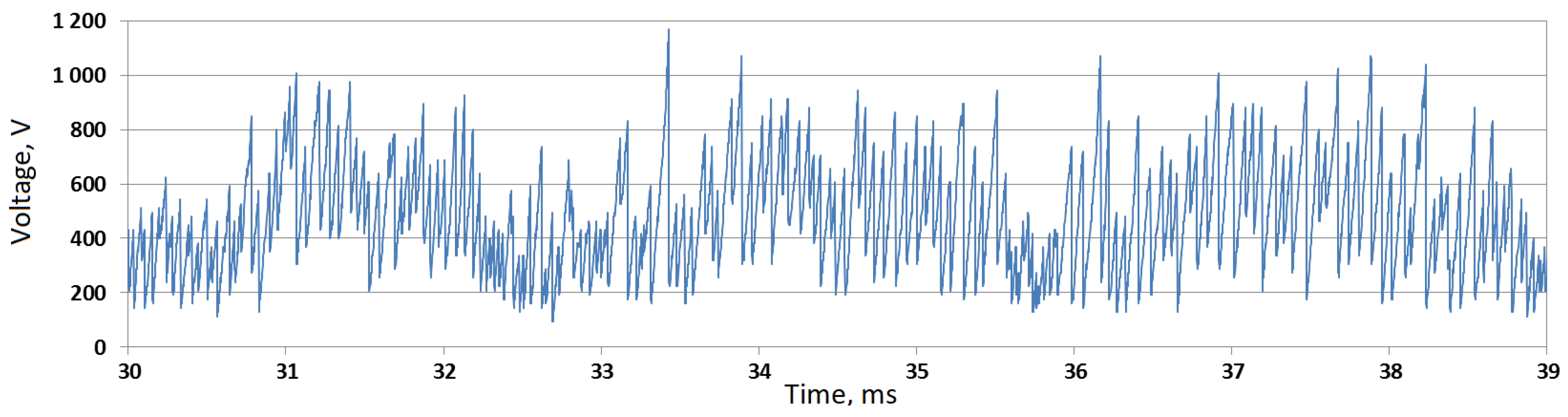

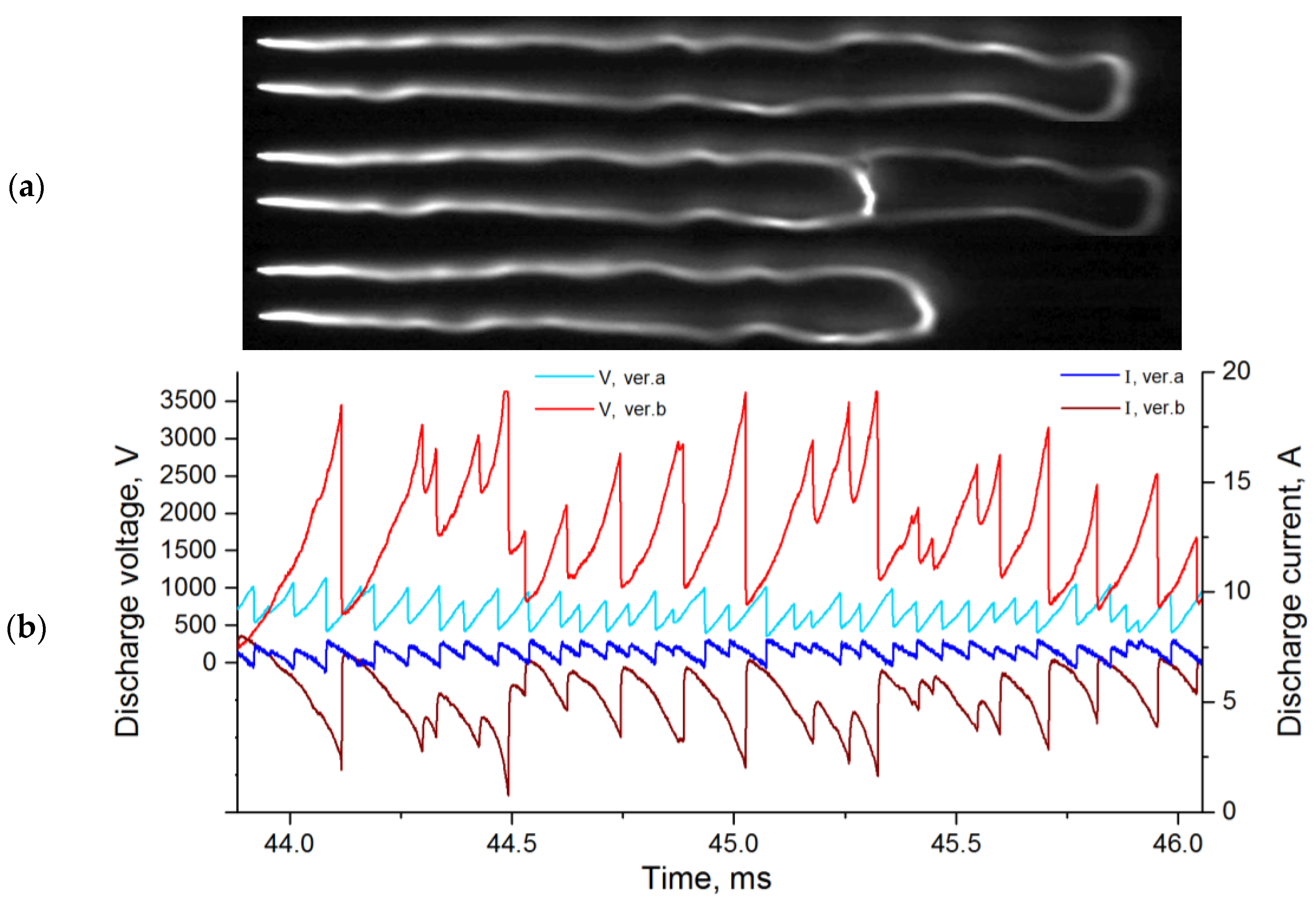

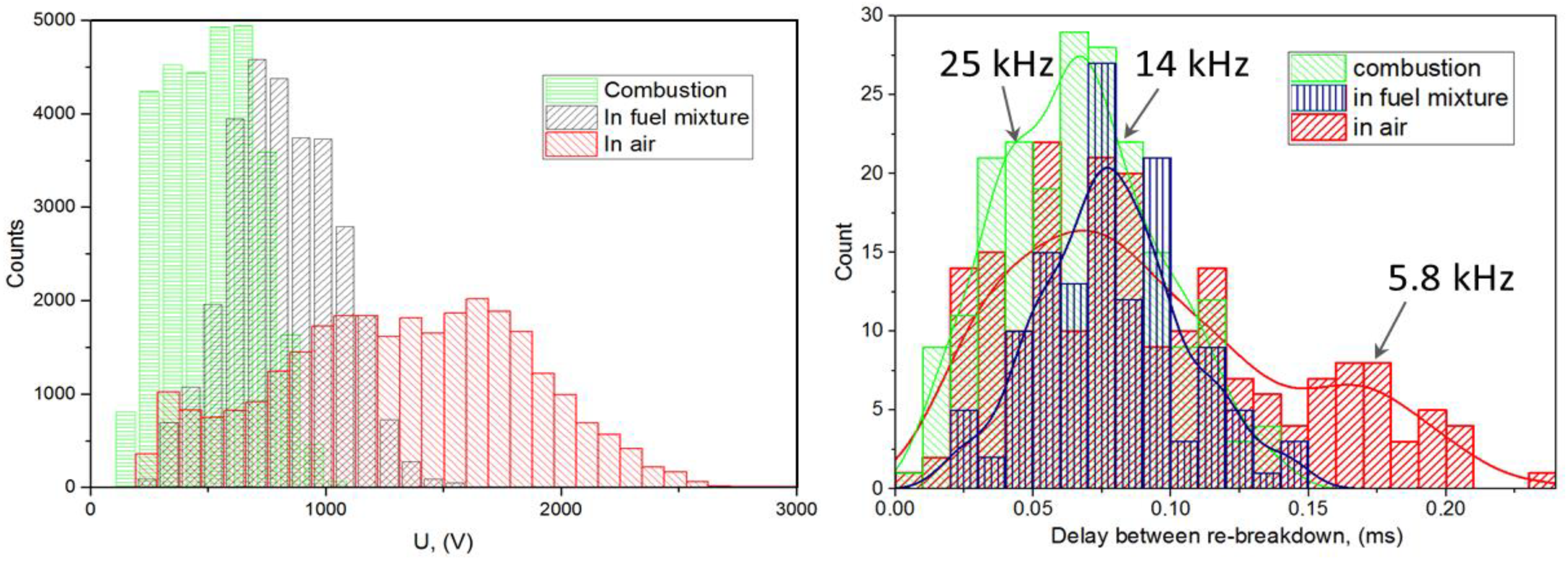

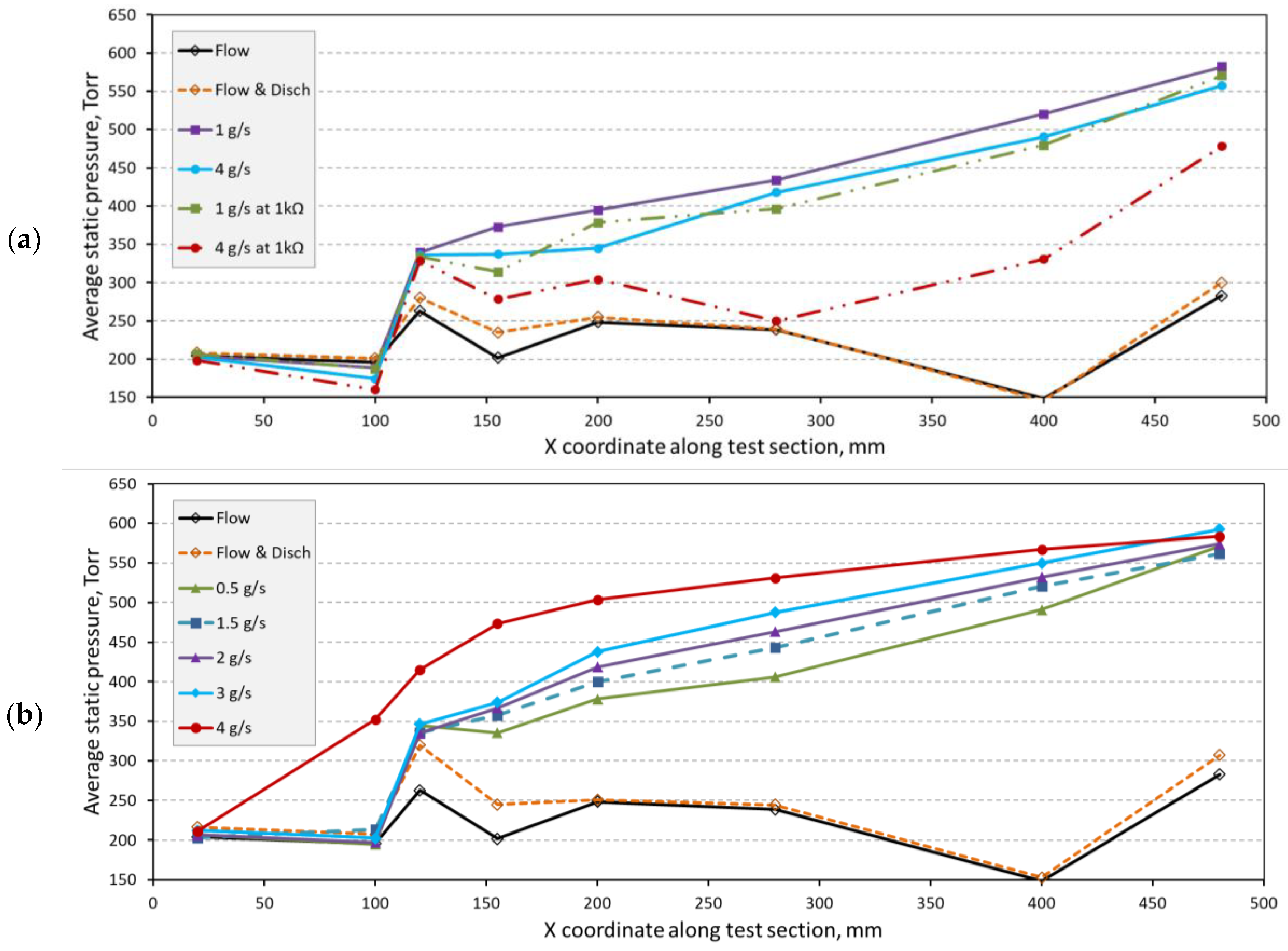

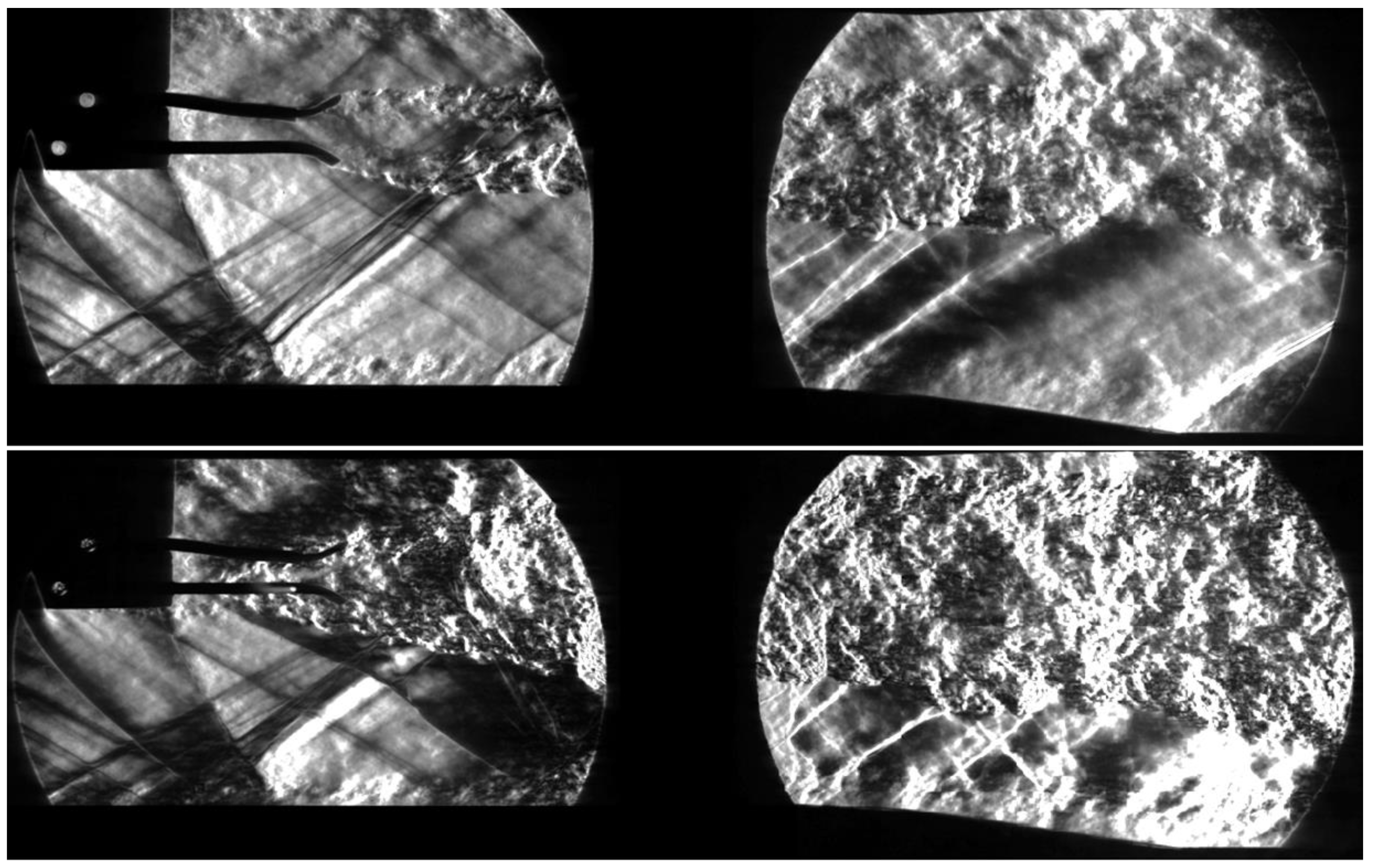

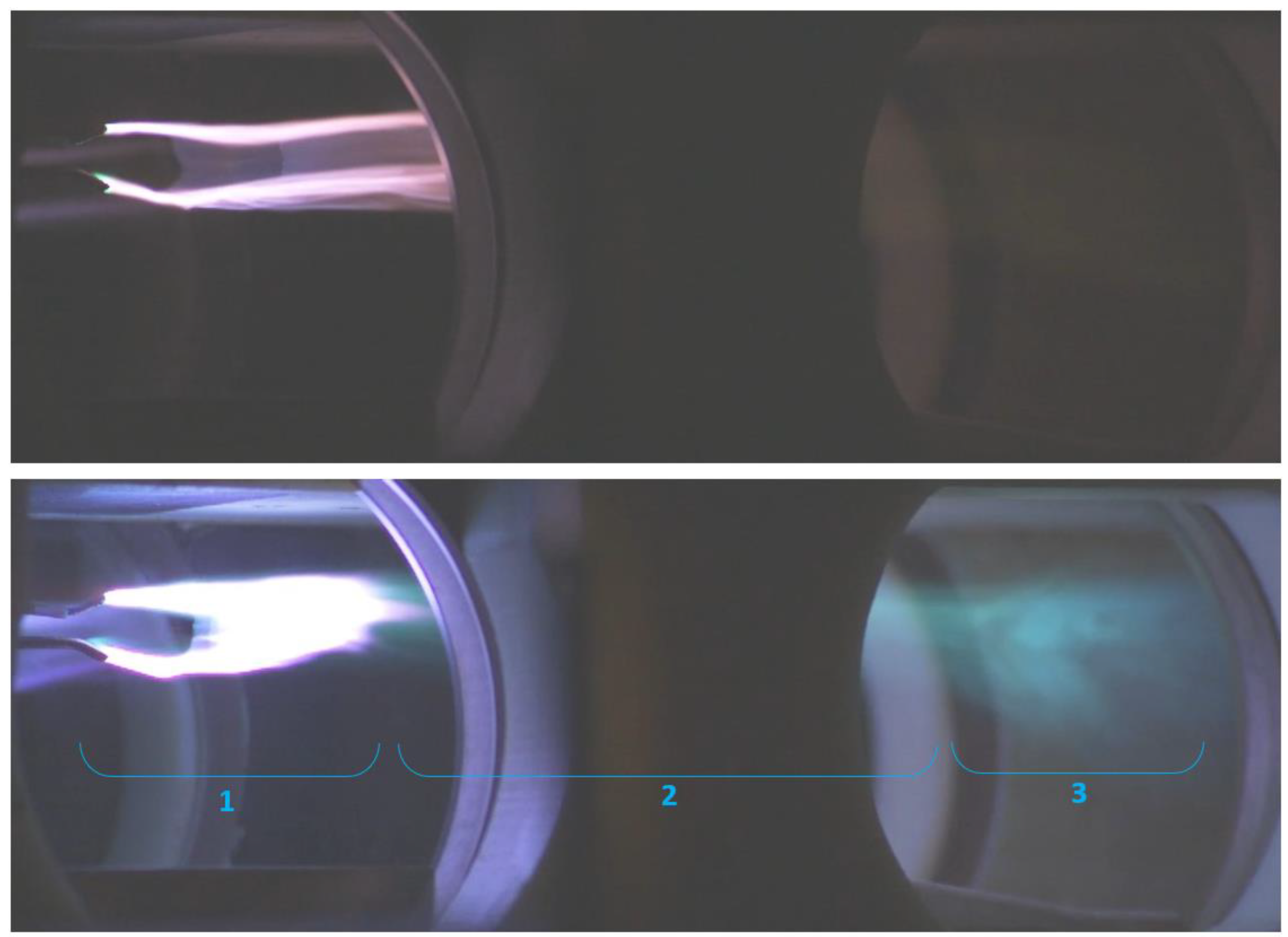

3.1. Experiments with Pylon Ver.a

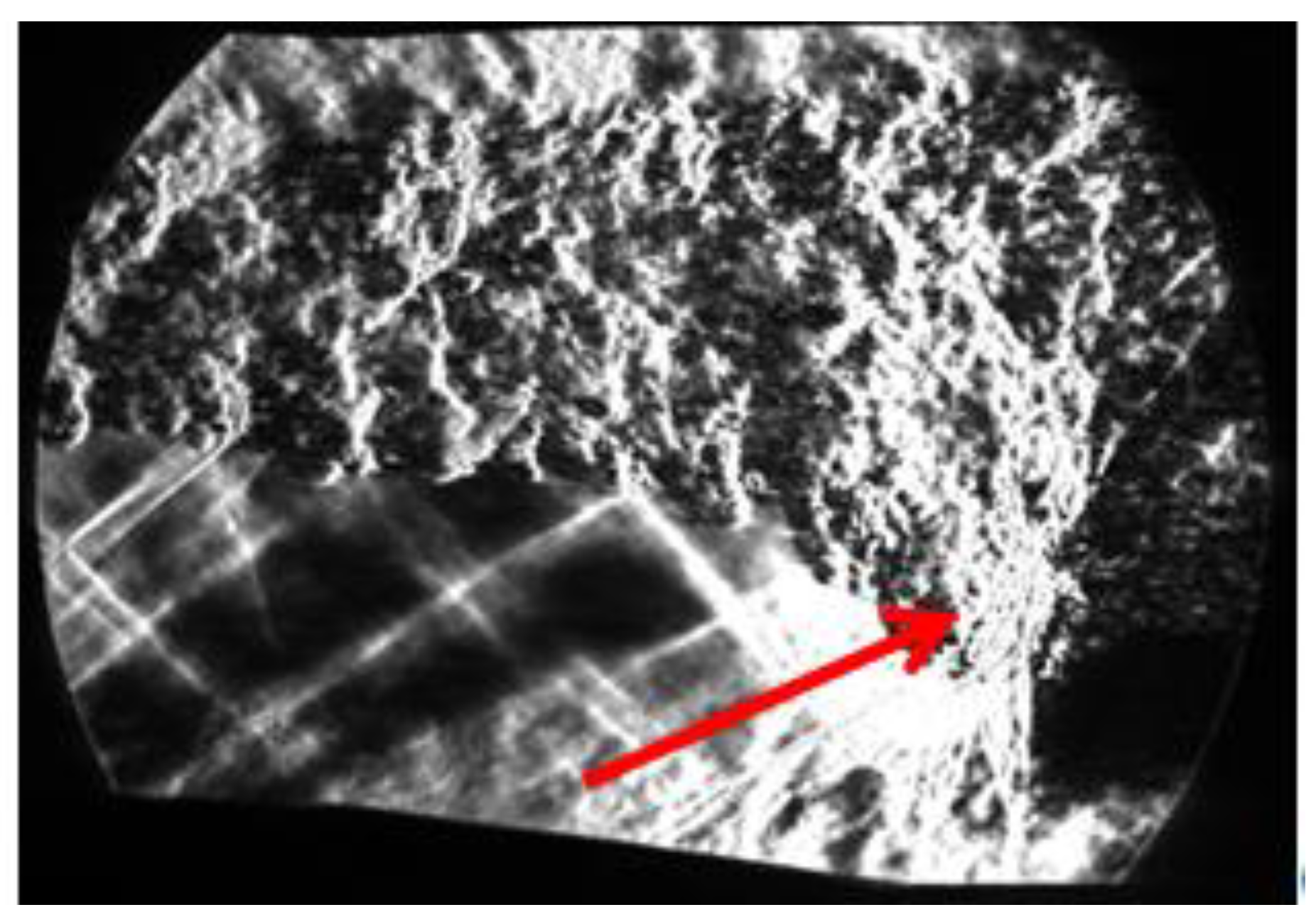

3.2. Experiments with Pylon Ver.b

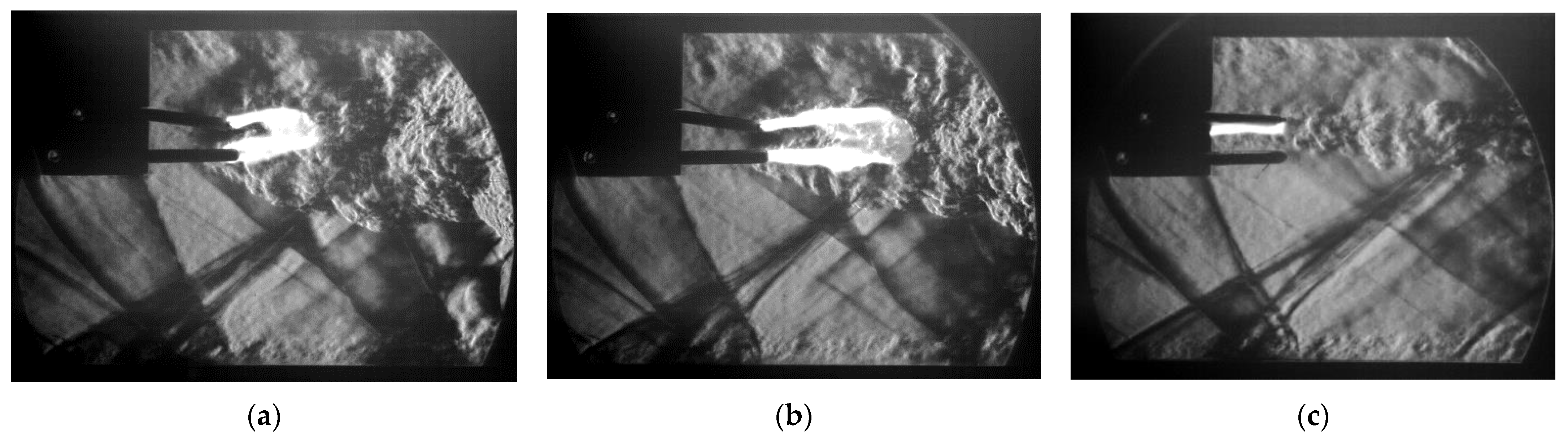

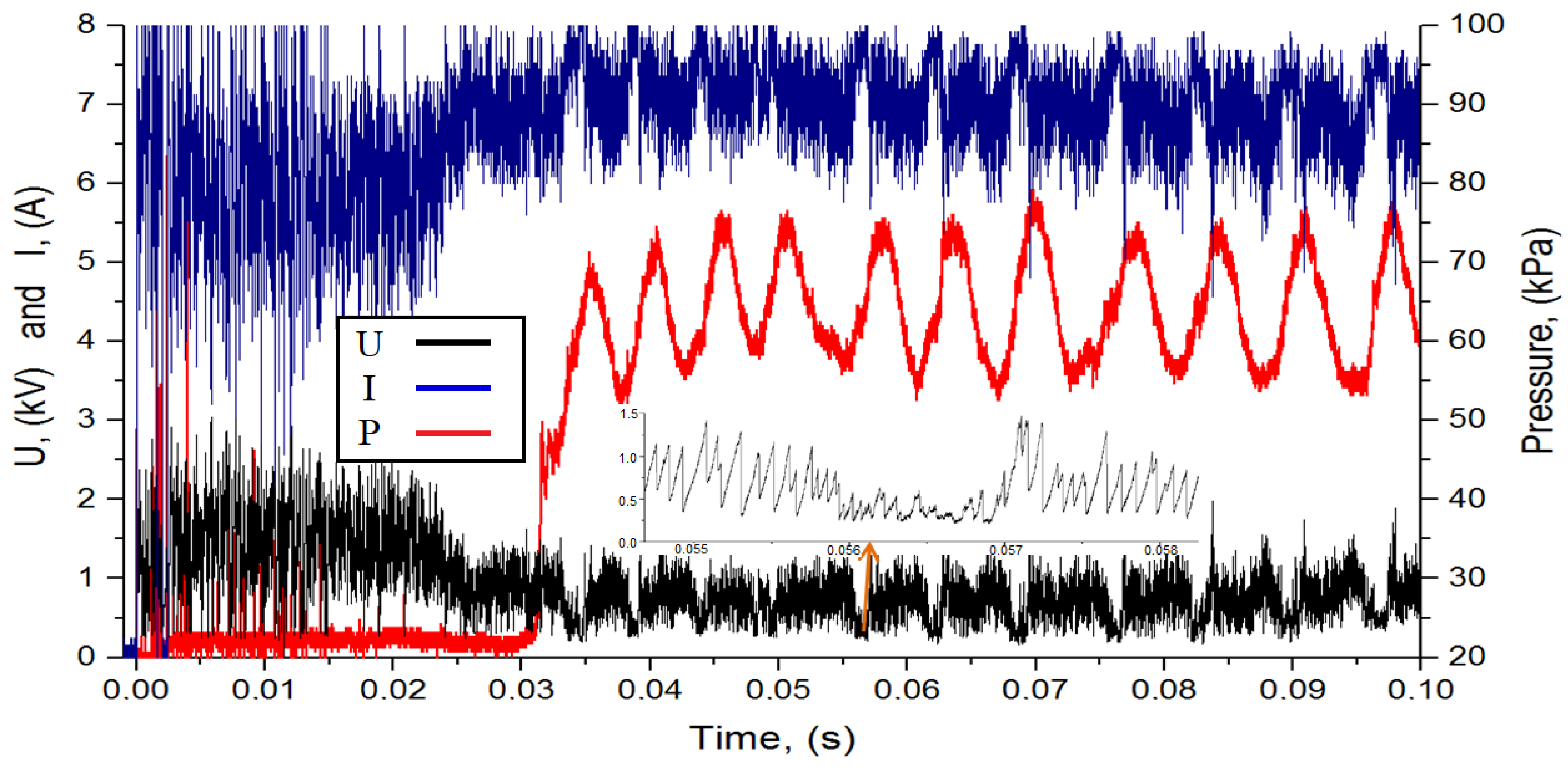

3.3. Dynamics of Ignition and Motion of the Flame Front

4. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Q.; Baccarella, D.; Lee, T. Review of Combustion Stabilization for Hypersonic Airbreathing Propulsion. Prog. Aerosp. Sci. 2020, 119, 100636. [Google Scholar] [CrossRef]

- Huang, W.; Du, Z.B.; Yan, L.; Xia, Z. xun Supersonic Mixing in Airbreathing Propulsion Systems for Hypersonic Flights. Prog. Aerosp. Sci. 2019, 109, 100545. [Google Scholar] [CrossRef]

- Cai, Z.; Wang, T.; Sun, M. Review of Cavity Ignition in Supersonic Flows. Acta Astronaut. 2019, 165, 268–286. [Google Scholar] [CrossRef]

- Leonov, S. Electrically Driven Supersonic Combustion. Energies 2018, 11, 1733. [Google Scholar] [CrossRef]

- Firsov, A.; Savelkin, K.V.; Yarantsev, D.A.; Leonov, S.B. Plasma-Enhanced Mixing and Flameholding in Supersonic Flow. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140337. [Google Scholar] [CrossRef]

- Shibkov, V.M.; Shibkova, L.V.; Kopyl, P.V.; Logunov, A.A. Stabilization of Supersonic Combustion of Propane in an Expanding Aerodynamic Channel with the Use of Low-Temperature Plasma. High Temp. 2019, 57, 164–176. [Google Scholar] [CrossRef]

- Goldfeld, M. The Heat Flux Research in Hydrogen Supersonic Combustor at Mach Number of 4. Int. J. Hydrogen Energy 2021, 46, 13365–13376. [Google Scholar] [CrossRef]

- Jia, D.; Pan, Y.; Wang, N.; Liu, C.; Yang, K. Combustion Modes and Unsteady Characteristics during the Condition Transition of a Scramjet Combustor. Energies 2021, 14, 2522. [Google Scholar] [CrossRef]

- He, Z.; Wang, H.; Li, F.; Tian, Y.; Wan, M.; Zhu, J. Effect of Fuel-Injection Distance and Cavity Rear-Wall Height on the Flameholding Characteristics in a Mach 2.52 Supersonic Flow. Aerospace 2022, 9, 566. [Google Scholar] [CrossRef]

- Goldfeld, M.A.; Starov, A.V. Determination of the Fuel Concentration Distribution in a Supersonic Combustion Chamber. Combust. Explos. Shock. Waves 2019, 55, 274–281. [Google Scholar] [CrossRef]

- Jin, Y.; Dou, S.; Yang, Q.; Xu, X.; Fu, Q.; Pan, L. Performance Characteristics of a Scramjet Engine Using JP-10 Fuel Containing Aluminum Nanoparticles. Acta Astronaut. 2021, 185, 70–77. [Google Scholar] [CrossRef]

- Yarantsev, D.A.; Fisov, A.A.; Dolgov, E.V.; Savelkin, K.V.; Talyzin, V.A.; Nikolaev, A.A.; Voloshenko, O.V. Ignition of Gaseous and Liquid Hydrocarbon Fuel in Supersonic Flow by Means of Plasma Generator. J. Phys. Conf. Ser. 2019, 1394, 012014. [Google Scholar] [CrossRef]

- Li, X.; Lei, Q.; Zhao, X.; Fan, W.; Chen, S.; Chen, L.; Tian, Y.; Zhou, Q. Combustion Characteristics of a Supersonic Combustor with a Large Cavity Length-to-Depth Ratio. Aerospace 2022, 9, 214. [Google Scholar] [CrossRef]

- Tang, T.; Zhao, G.; Wang, H.; Sun, M.; Wang, Z. Effects of Cavity Parameters on Flame Flashback Phenomenon in a Supersonic Crossflow with a Cavity Flameholder. J. Proc. Inst. Mech. Eng. G J. Aerosp. Eng. 2022. [Google Scholar] [CrossRef]

- Efimov, A.V.; Firsov, A.A.; Kolosov, N.S.; Leonov, S.B. Characterization of Electric Discharge Collocated with Gas Jet in Supersonic Airflow. Plasma Sources Sci. Technol. 2020, 29, 07LT01. [Google Scholar] [CrossRef]

- Shibkov, V.M.; Kornev, K.N.; Logunov, A.A.; Nesterenko, Y.K. Electron Density and Temperature in a Transverse–Longitudinal Discharge Plasma in High-Speed Airflows. Plasma Phys. Rep. 2022, 48, 806–811. [Google Scholar] [CrossRef]

- Firsov, A.; Bityurin, V.; Tarasov, D.; Dobrovolskaya, A.; Troshkin, R.; Bocharov, A. Longitudinal DC Discharge in a Supersonic Flow: Numerical Simulation and Experiment. Energies 2022, 15, 7015. [Google Scholar] [CrossRef]

- Andrews, P.; Lax, P.; Leonov, S. Triggering Shock Wave Positions by Patterned Energy Deposition. Energies 2022, 15, 7104. [Google Scholar] [CrossRef]

- Filimonova, E.A.; Dobrovolskaya, A.S.; Bocharov, A.N.; Bityurin, V.A.; Naidis, G.V. Formation of Combustion Wave in Lean Propane-Air Mixture with a Non-Uniform Chemical Reactivity Initiated by Nanosecond Streamer Discharges in the HCCI Engine. Combust. Flame 2020, 215, 401–416. [Google Scholar] [CrossRef]

- Leonov, S.B.; Elliott, S.; Carter, C.; Houpt, A.; Lax, P.; Ombrello, T. Modes of Plasma-Stabilized Combustion in Cavity-Based M = 2 Configuration. Exp. Therm. Fluid Sci. 2021, 124, 110355. [Google Scholar] [CrossRef]

- Feng, R.; Li, J.; Wu, Y.; Zhu, J.; Song, X.; Li, X. Experimental Investigation on Gliding Arc Discharge Plasma Ignition and Flame Stabilization in Scramjet Combustor. Aerosp. Sci. Technol. 2018, 79, 145–153. [Google Scholar] [CrossRef]

- Feng, R.; Sun, M.; Wang, H.; Huang, Y.; Tian, Y.; Wang, C.; Liu, X.; Zhu, J.; Wang, Z. Experimental Investigation of Flameholding in a Cavity-Based Scramjet Combustor by a Multi-Channel Gliding Arc. Aerosp. Sci. Technol. 2022, 121, 107381. [Google Scholar] [CrossRef]

- Kim, C.H.; Jeung, I.S. Forced Combustion Characteristics Related to Different Injection Locations in Unheated Supersonic Flow. Energies 2019, 12, 1746. [Google Scholar] [CrossRef]

- Leonov, S.; Houpt, A.; Elliott, S.; Hedlund, B. Ethylene Ignition and Flameholding by Electrical Discharge in Supersonic Combustor. J. Propuls. Power 2018, 34, 499–509. [Google Scholar] [CrossRef]

- Firsov, A.A.; Efimov, A.V.; Kolosov, N.S.; Moralev, I.A.; Leonov, S.B. Intensification of Mixing of Fuel with Supersonic Air Flow When Injection and Electric Discharge Are Combined. J. Phys. Conf. Ser. 2021, 2100, 012007. [Google Scholar] [CrossRef]

- Vishwakarma, M.; Vaidyanathan, A. Experimental Study of Mixing Enhancement Using Pylon in Supersonic Flow. Acta Astronaut. 2016, 118, 21–32. [Google Scholar] [CrossRef]

- Inshakov, S.I.; Skvortsov, V.V.; Rozhkov, A.F.; Shakhatov, V.A.; Inshakov, I.S.; Uspensky, A.A.; Urusov, A.Y. Spectroscopic Studies of Longitudinal Discharges in a Supersonic Air Flow during the Injection of Propane, Ethylene, and Oxygen into the Discharge Zone. High Temp. 2019, 57, 798–807. [Google Scholar] [CrossRef]

- Firsov, A.A.; Dolgov, E.V.; Kolosov, N.S.; Yarantsev, D.A. CFD Analysis of Pylon Equipped by Plasma Module for Combustion in Supersonic Airflow. J. Phys. Conf. Ser. 2020, 1698, 012014. [Google Scholar] [CrossRef]

- Firsov, A.A.; Kolosov, N.S. Combustion in a Supersonic Flow Using a Pylon Equipped with a Plasma Actuator. J. Phys. Conf. Ser. 2021, 2100, 012017. [Google Scholar] [CrossRef]

- Logunov, A.A.; Kornev, K.N.; Shibkova, L.V.; Shibkov, V.M. Influence of the Interelectrode Gap on the Main Characteristics of a Pulsating Transverse-Longitudinal Discharge in High-Velocity Multicomponent Gas Flows. High Temp. 2021, 59, 19–26. [Google Scholar] [CrossRef]

- Firsov, A.A.; Dolgov, E.V.; Leonov, S.B. Optimization of the Plasma System for the Ignition of Ethylene in a Supersonic Flow. Vestn. Obedin. Inst. Vysok. Temp. 2018, 1, 13–18. [Google Scholar] [CrossRef]

- Shibkov, V.M.; Shibkova, L.V.; Logunov, A.A. Effect of the Air Flow Velocity on the Characteristics of a Pulsating Discharge Produced by a DC Power Source. Plasma Phys. Rep. 2018, 44, 754–765. [Google Scholar] [CrossRef]

- Houpt, A.; Hedlund, B.; Leonov, S.; Ombrello, T.; Carter, C. Quasi-DC Electrical Discharge Characterization in a Supersonic Flow. Exp. Fluids 2017, 58, 25. [Google Scholar] [CrossRef]

- Savelkin, K.V.; Yarantsev, D.A.; Adamovich, I.V.; Leonov, S.B. Ignition and Flameholding in a Supersonic Combustor by an Electrical Discharge Combined with a Fuel Injector. Combust. Flame 2015, 162, 825–835. [Google Scholar] [CrossRef]

| Rbal, Ω | Average Current, A (Ver.a, No Fuel) | Average Current, A (Ver.b, No Fuel) |

|---|---|---|

| 1000 | 3.20 | 2.70 |

| 750 | 4.75 | 3.96 |

| 500 | 7.20 | 5.50 |

| Fuel MFR (g/s) | 0.5 | 0.75 | 1 | 1.5 | 2 | 3 | 4 | |

|---|---|---|---|---|---|---|---|---|

| Case | ||||||||

| 750 Ohm | - | - | 256 | 204 | 96 | 83 | 70 | |

| 500 Ohm | - | 400 | 345 | 313 | 294 | 182 | 188 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Firsov, A.A. Experimental Investigation of Flameholding in Scramjet Combustor by Pylon with Plasma Actuator Based on Q-DC Discharge. Aerospace 2023, 10, 204. https://doi.org/10.3390/aerospace10030204

Firsov AA. Experimental Investigation of Flameholding in Scramjet Combustor by Pylon with Plasma Actuator Based on Q-DC Discharge. Aerospace. 2023; 10(3):204. https://doi.org/10.3390/aerospace10030204

Chicago/Turabian StyleFirsov, Aleksandr A. 2023. "Experimental Investigation of Flameholding in Scramjet Combustor by Pylon with Plasma Actuator Based on Q-DC Discharge" Aerospace 10, no. 3: 204. https://doi.org/10.3390/aerospace10030204

APA StyleFirsov, A. A. (2023). Experimental Investigation of Flameholding in Scramjet Combustor by Pylon with Plasma Actuator Based on Q-DC Discharge. Aerospace, 10(3), 204. https://doi.org/10.3390/aerospace10030204