Predictive Model of a Mole-Type Burrowing Robot for Lunar Subsurface Exploration

Abstract

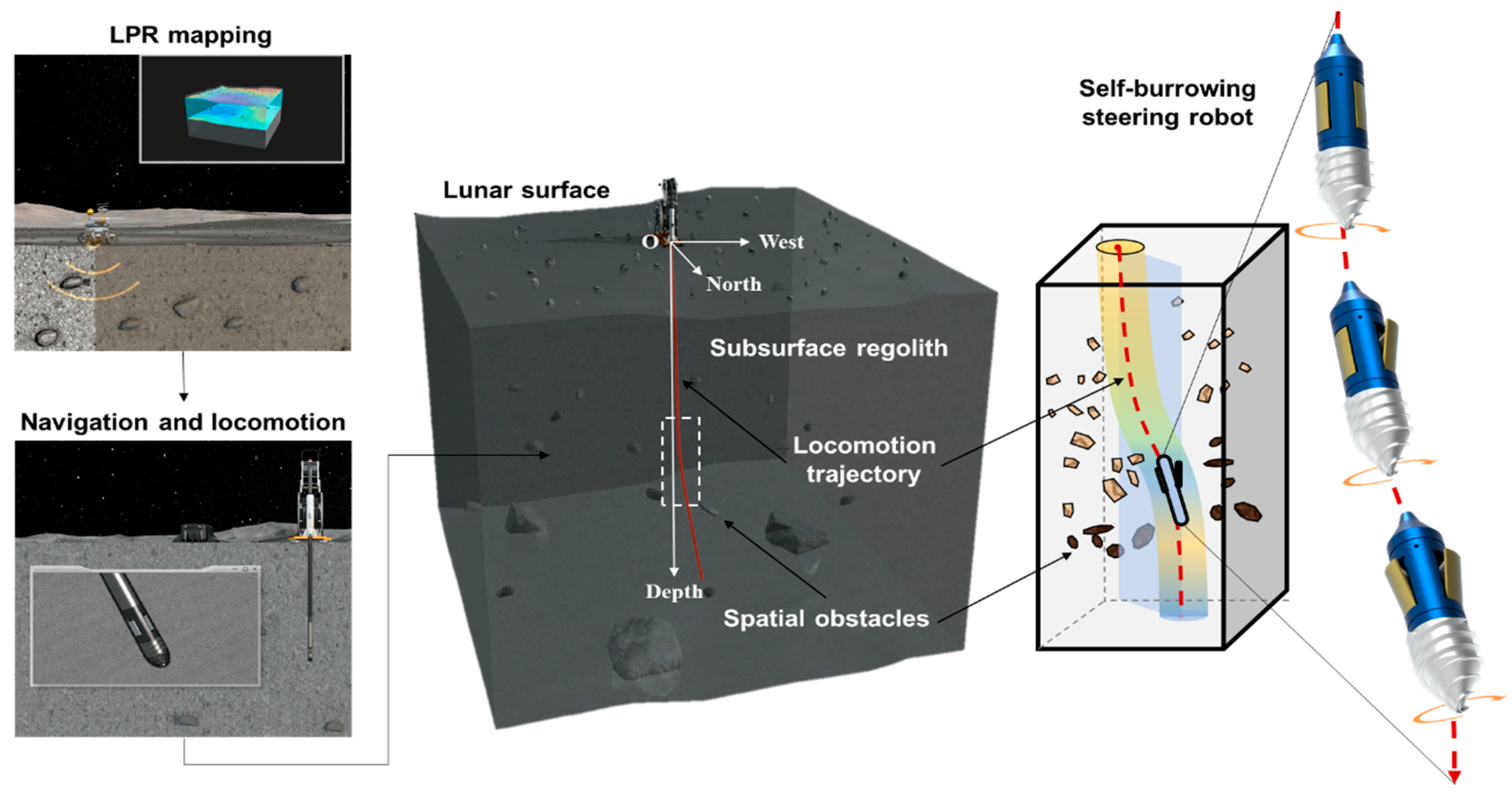

1. Introduction

2. Modeling Methods

2.1. Model Description

2.2. Dynamic Equations

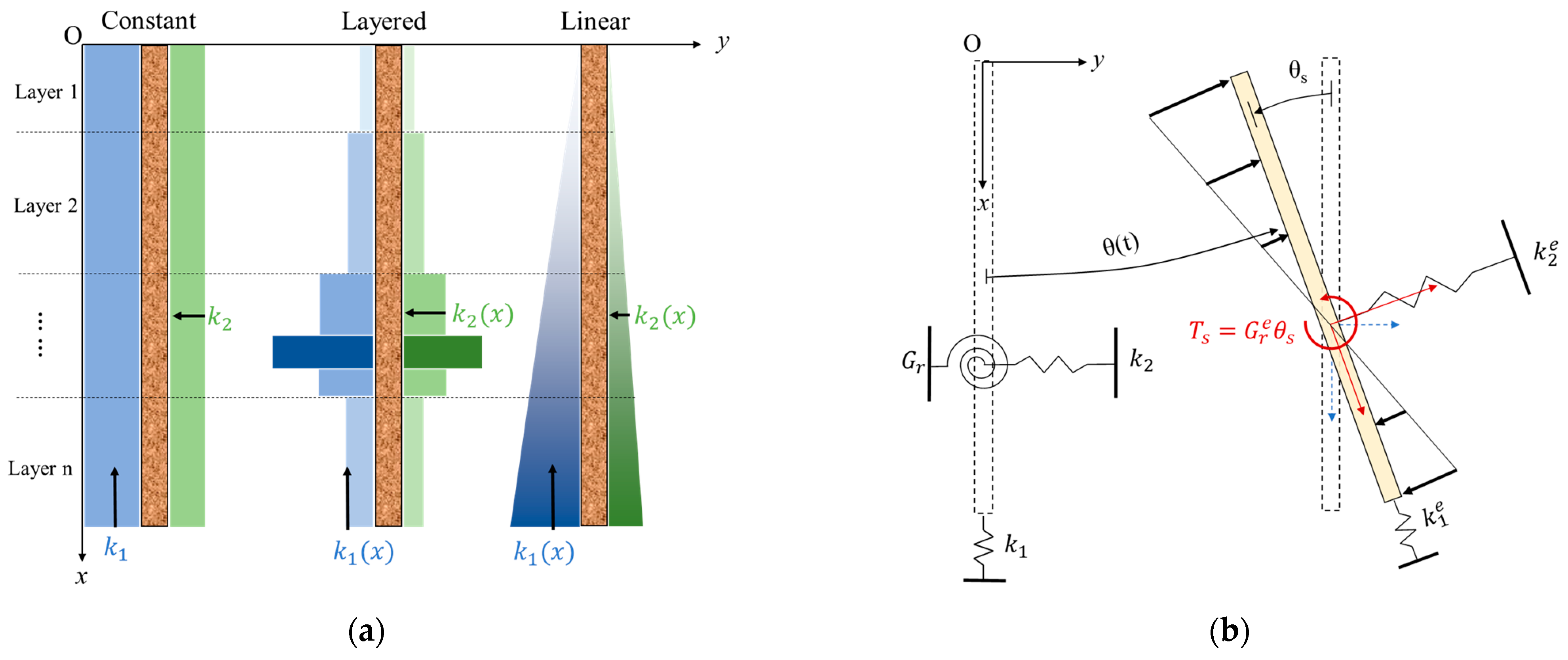

2.3. Soil Interaction Model

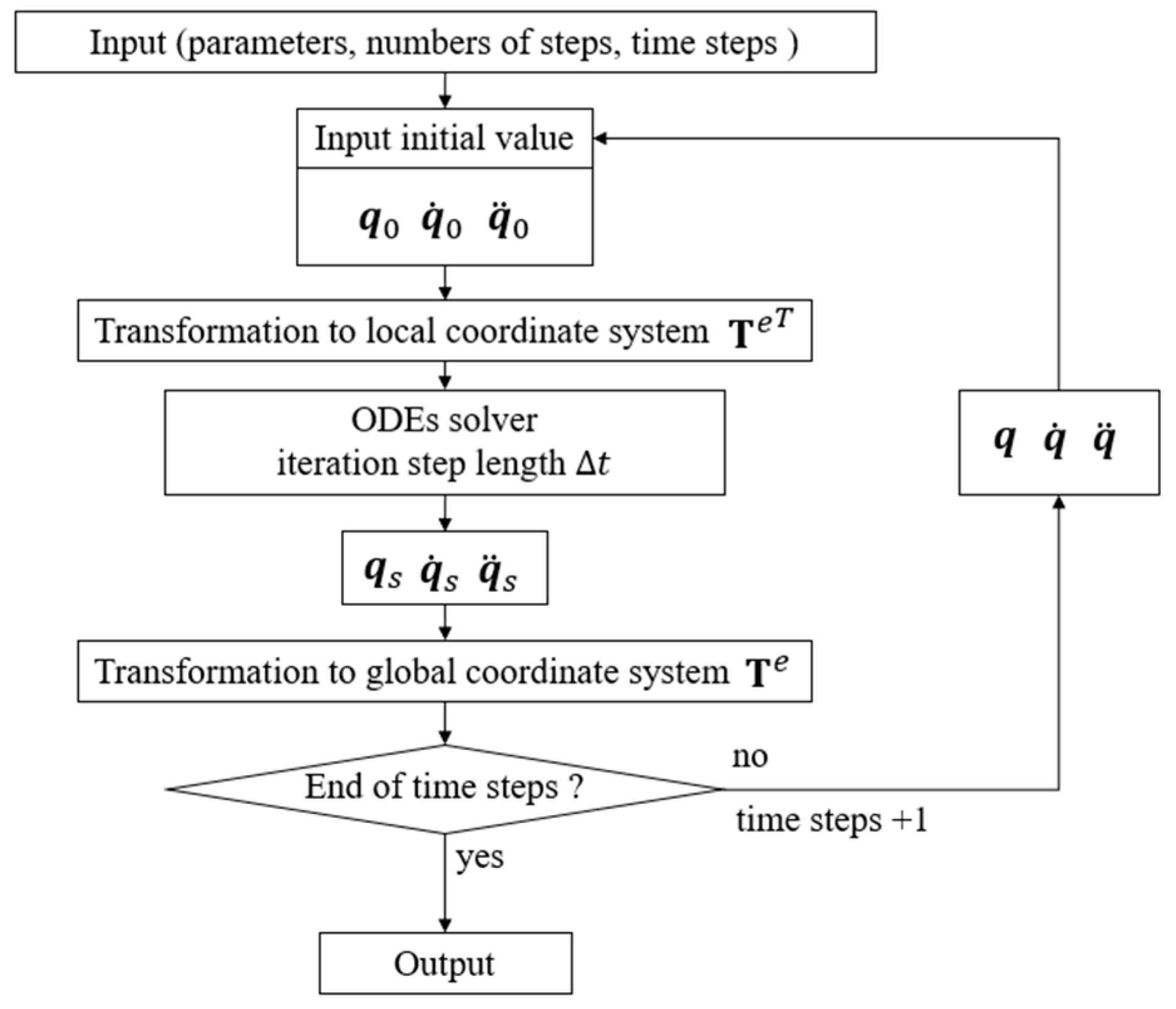

2.4. Numerical Scheme and Nondimensionalized Treatment

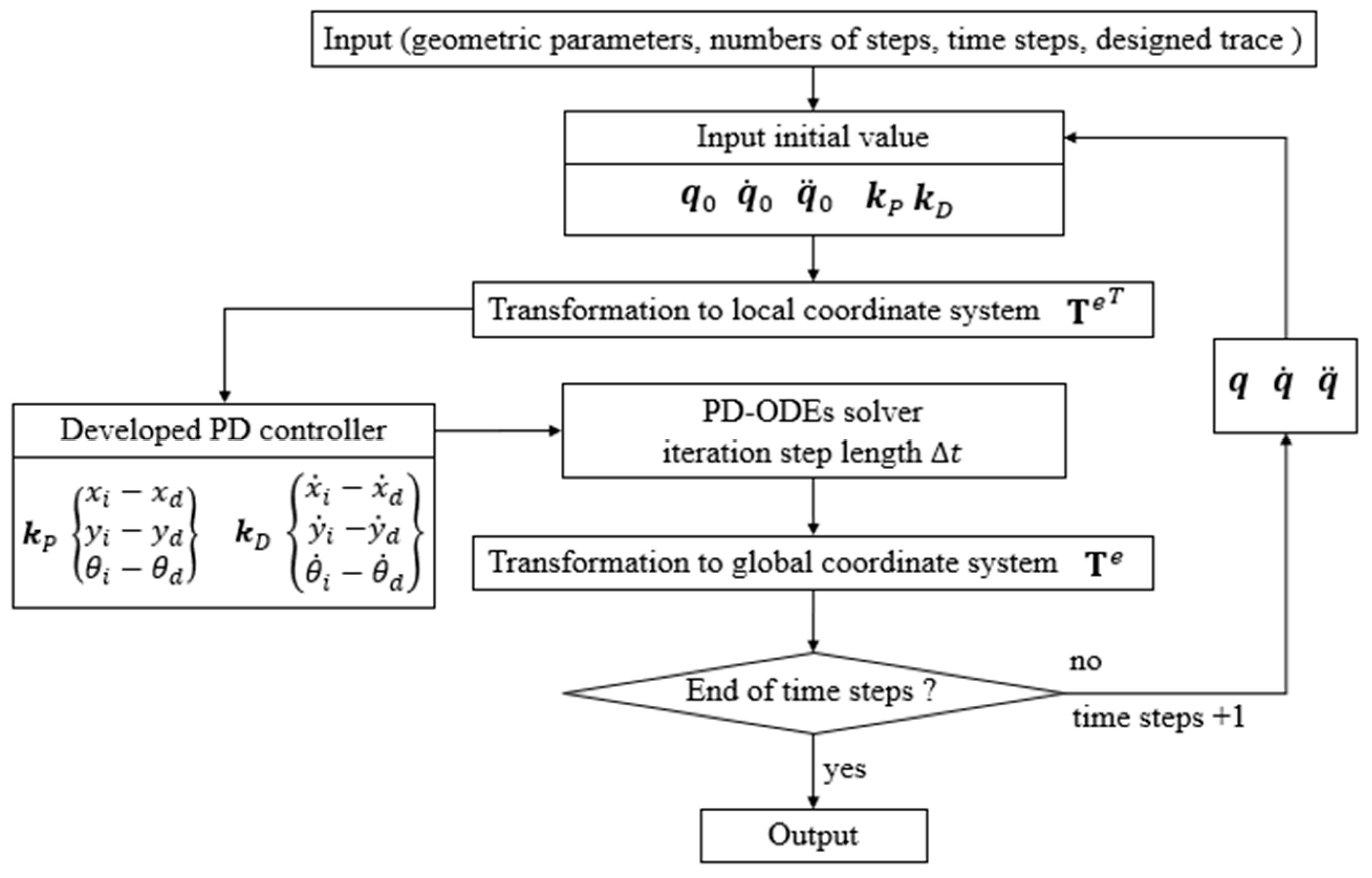

2.5. Implementation of PD Tracking Control Strategies

3. Studies of Numerical Procedures

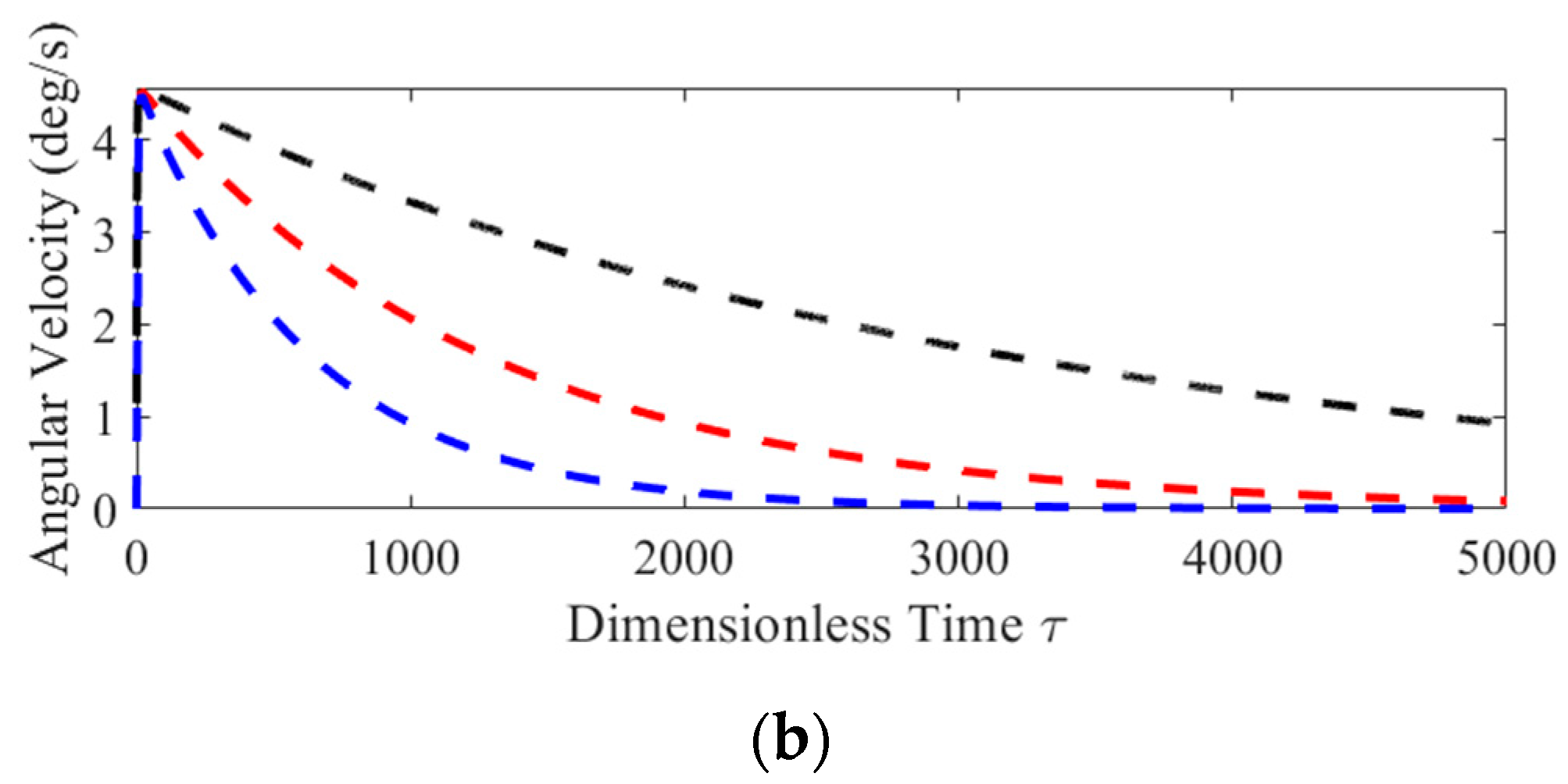

3.1. Numerical Damping

3.2. Time Step Size

4. Numerical Experiments

4.1. 1-DOF Movement in a Uniform Formation: Earth vs. Moon

4.1.1. Case I of Penetration

4.1.2. Case II of Deflection

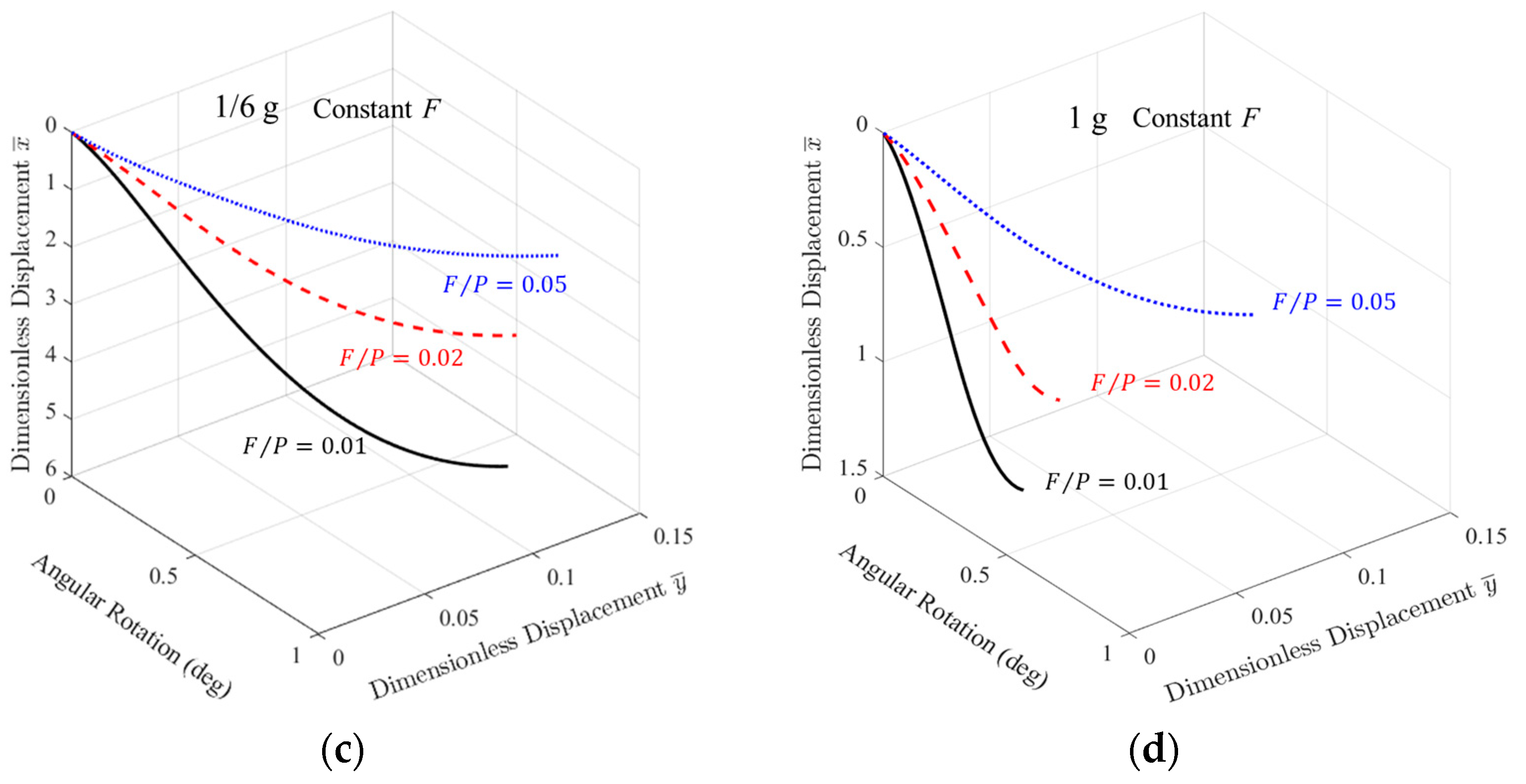

4.1.3. Case III of in-Plane Directional Movement

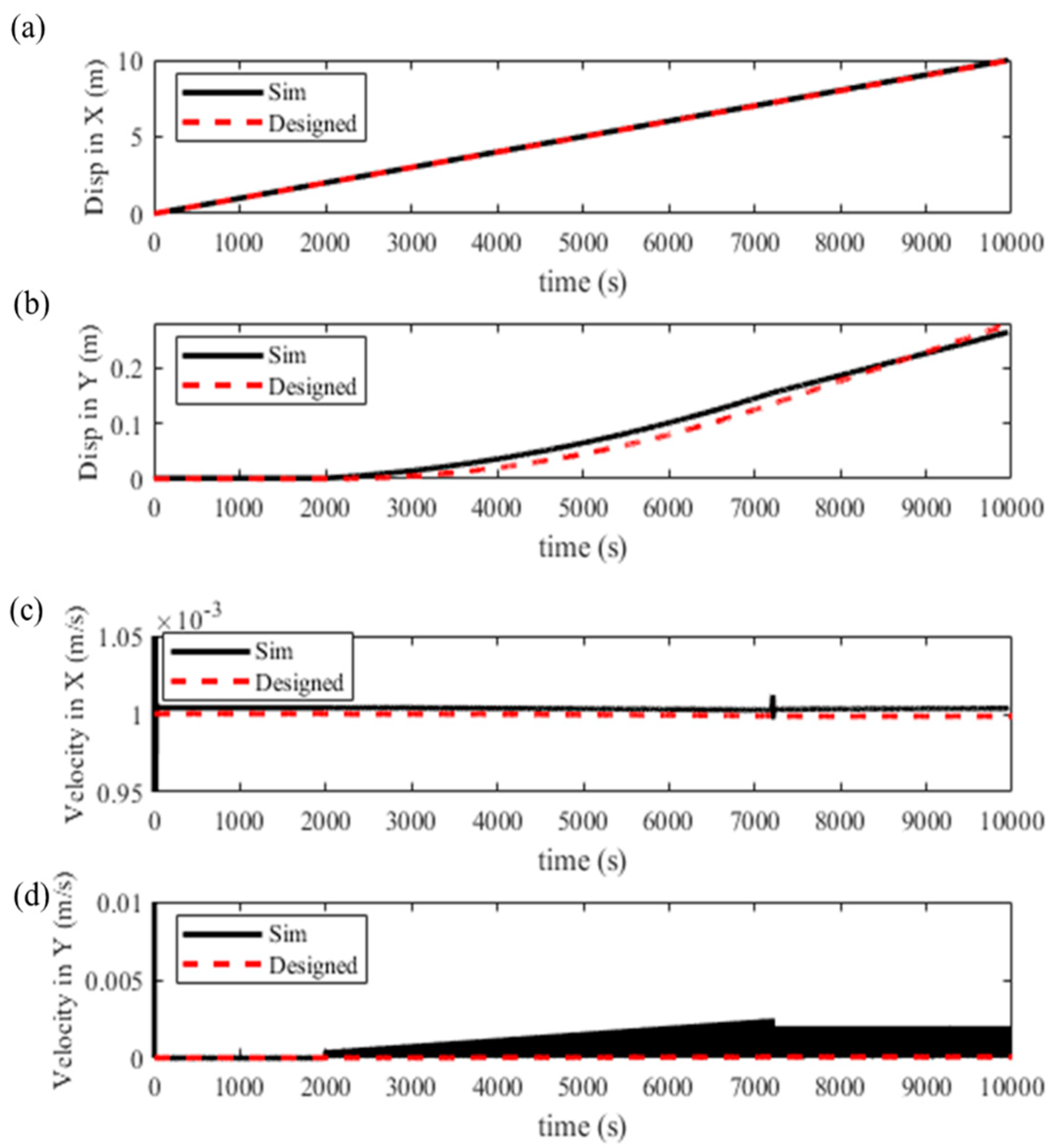

4.2. Trajectory Tracking via PD Control

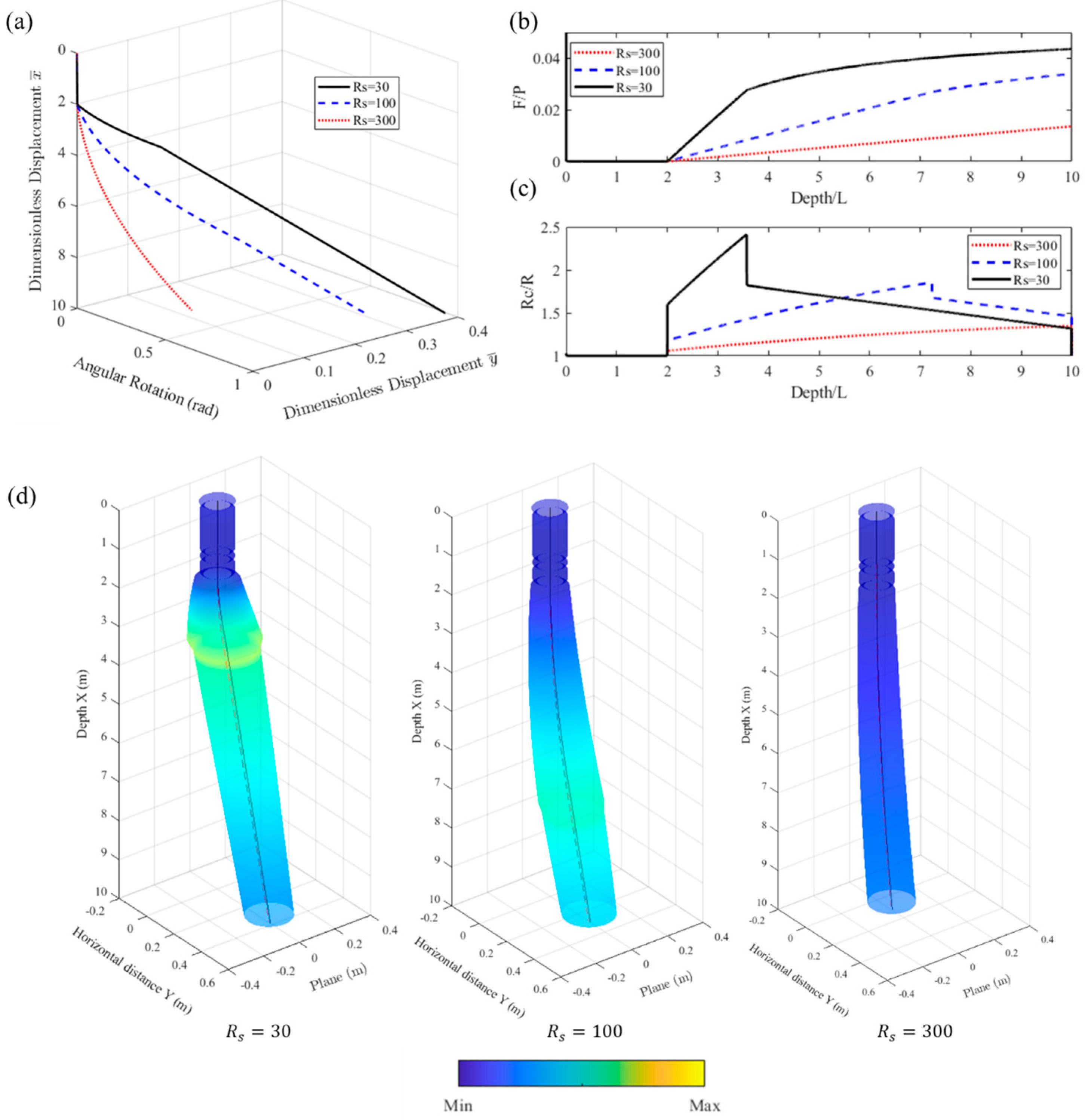

4.3. Parametric Studies on Steerability

4.3.1. Effect of the Curvature of Planned Trajectory

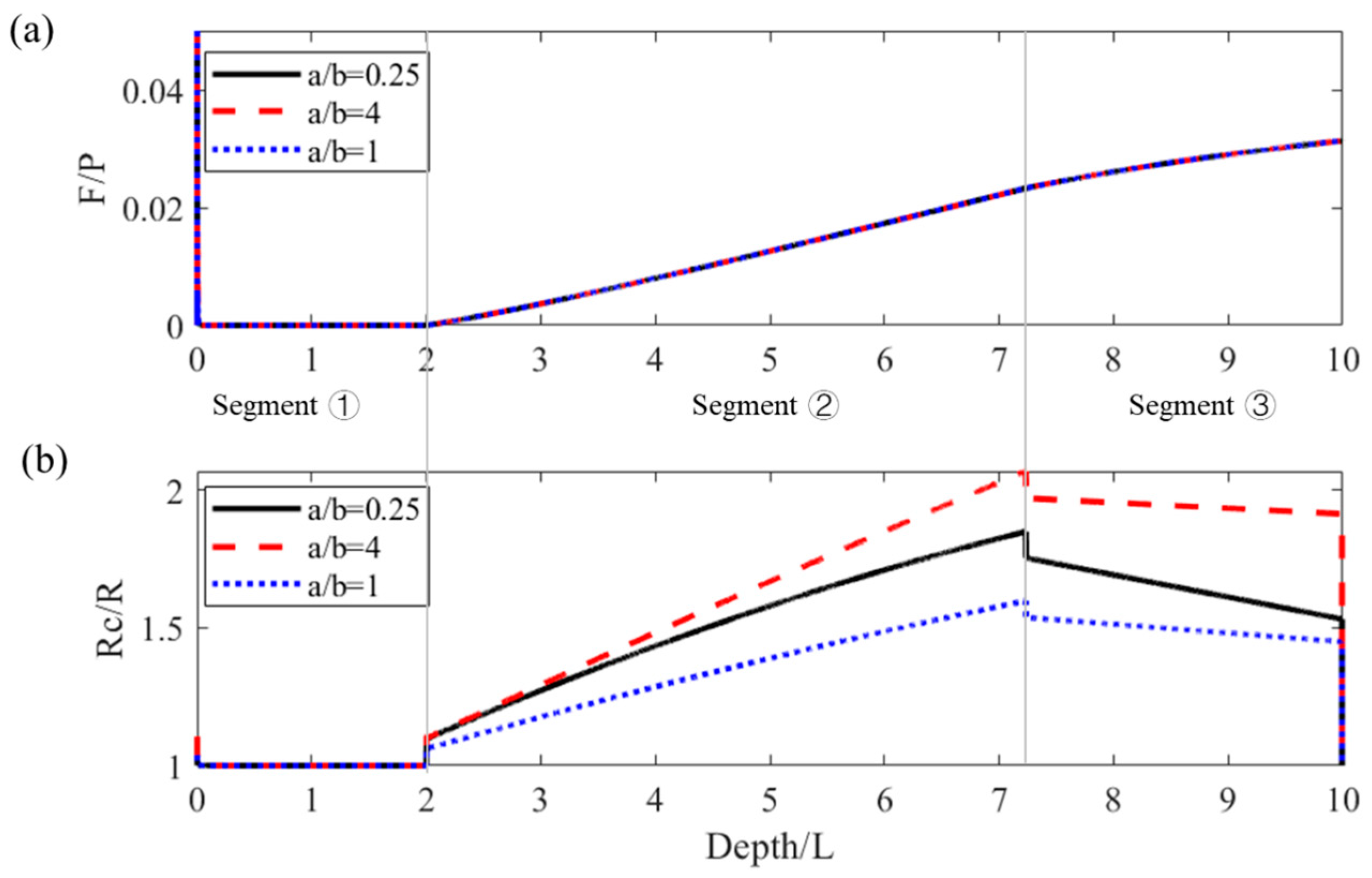

4.3.2. Effect of the Rotation Center in the Robotic Body

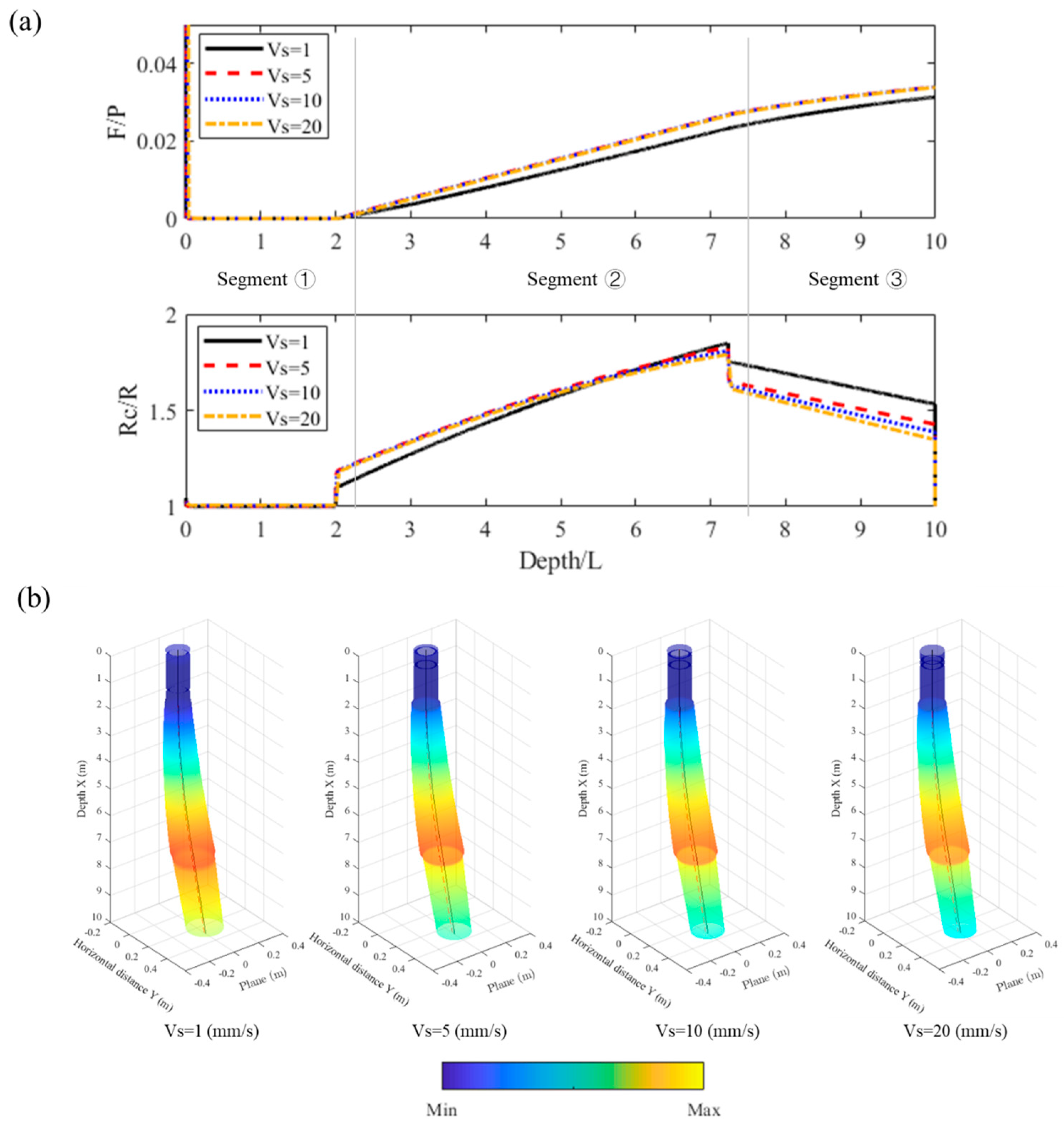

4.3.3. Effect of the Moving Velocity Control

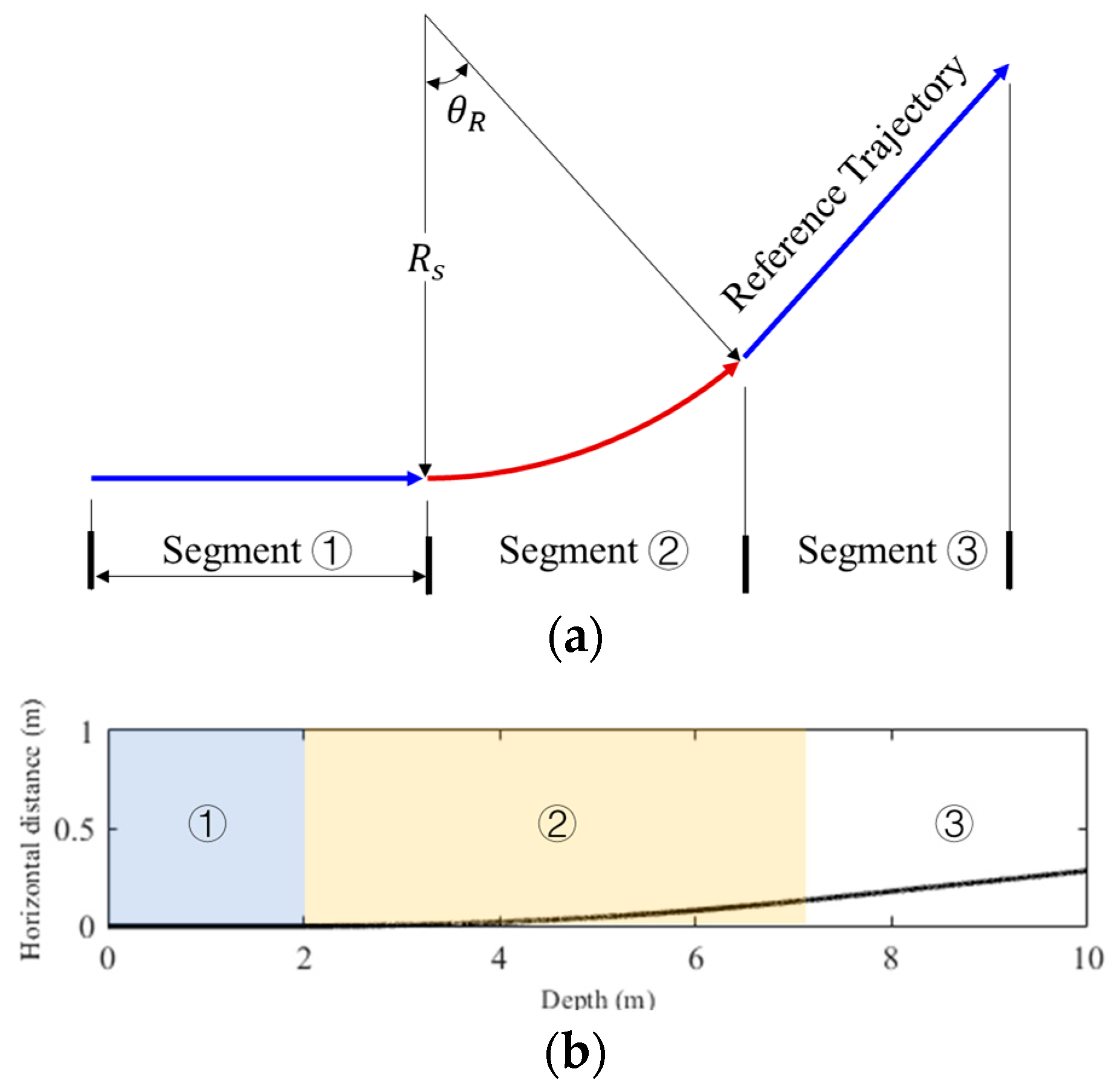

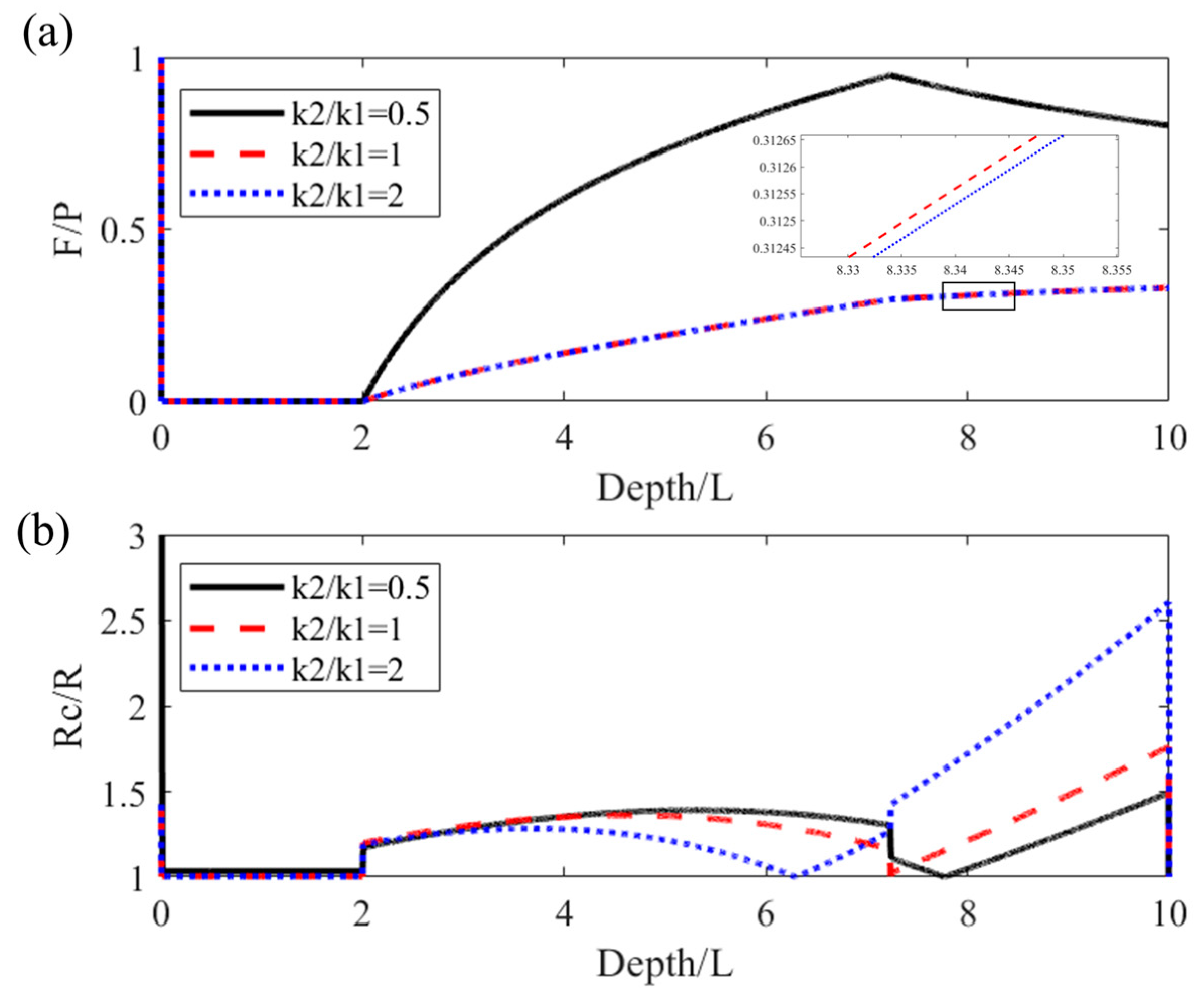

4.4. Directional Drilling in Different Geological Formations

4.4.1. A Layered Formation Model with a Set of Constant Stiffnesses

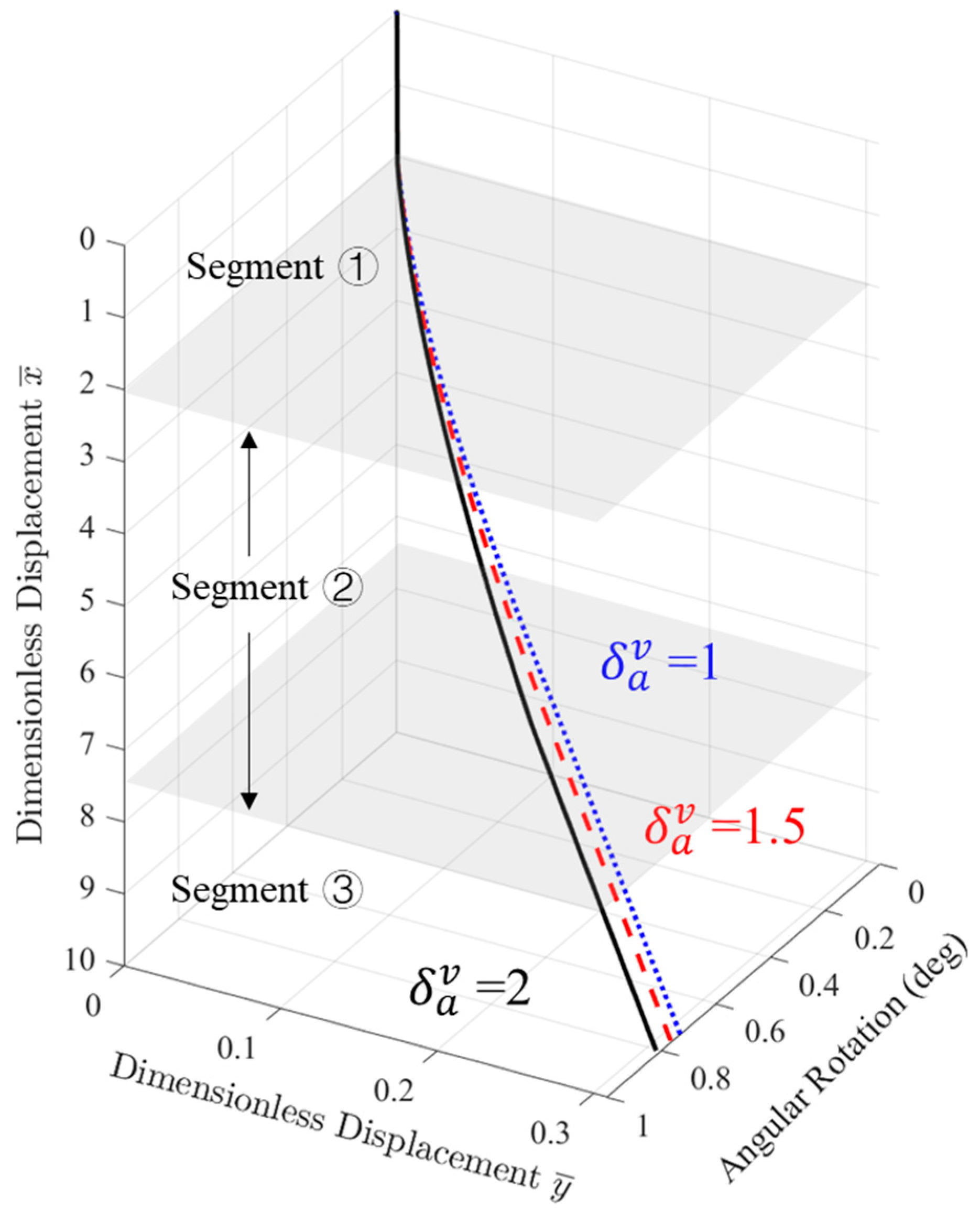

4.4.2. A Formation Model with a Linear Distribution of Stiffness

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aguilar, J.; Zhang, T.; Qian, F.; Kingsbury, M.; McInroe, B.; Mazouchova, N.; Li, C.; Maladen, R.; Gong, C.; Travers, M.; et al. A review on locomotion robophysics: The study of movement at the intersection of robotics, soft matter and dynamical systems. Rep. Prog. Phys. 2016, 79, 110001. [Google Scholar] [CrossRef]

- TZhang, T.; Wang, B.; Wei, H.; Zhang, Y.; Chao, C.; Xu, K.; Ding, X.; Hou, X.; Zhao, Z. Review on planetary regolith-sampling technology. Prog. Aerosp. Sci. 2021, 127, 100760. [Google Scholar] [CrossRef]

- Gorevan, S.P.; Myrick, T.M.; Batting, C.; Mukherjee, S.; Bartlett, P.; Wilson, J. Strategies for future Mars exploration: An infrastructure for the near and longer-term future exploration of the subsurface of Mars. In Proceedings of the 6th International Conference on Mars, Pasadena, CA, USA, 20–25 July 2003; pp. 20–25. Available online: https://ui.adsabs.harvard.edu/abs/2003mars.conf.3196G/abstract (accessed on 1 February 2023).

- Heiken, G.H.; Vaniman, D.T.; French, B.M. Lunar Sourcebook, a User’s Guide to the Moon; Cambridge University Press: Cambridge, UK, 1991; ISBN 9789780521332. [Google Scholar]

- Larose, E.; Khan, A.; Nakamura, Y.; Campillo, M. Lunar subsurface investigated from correlation of seismic noise. Geophys. Res. Lett. 2005, 32, L16201. [Google Scholar] [CrossRef]

- Glass, B.; New, M.; Voytek, M. Future space drilling and sample acquisition: A collaborative industry-government workshop. Icarus 2020, 338, 113378. [Google Scholar] [CrossRef]

- Lopez-Arreguin, A.; Montenegro, S. Towards bio-inspired robots for underground and surface exploration in planetary environments: An overview and novel developments inspired in sand-swimmers. Heliyon 2020, 6, e04148. [Google Scholar] [CrossRef]

- Barenboim, M.; Degani, A. Steerable Burrowing Robot: Design, Modeling and Experiments. In Proceedings of the IEEE International Conference on Robotics and Automation, Paris, France, 31 May–31 August 2020; pp. 829–835. [Google Scholar] [CrossRef]

- Lichtenheldt, R.; Becker, F.; Zimmermann, K. Screw-driven Robot for Locomotion into Sand. In Proceedings of the Ilmenau Scientific Colloquium, Ilmenau, Germany, 11–15 September 2017; pp. 11–15. Available online: https://elib.dlr.de/114033/ (accessed on 1 February 2023).

- Olaf, K.; Marco, S.; Fittock, M.; Georgios, T.; Torben, W.; Lars, W.; Matthias, G.; Jörg, K.; Tilman, S.; Christian, K.; et al. Design details of the HP3 mole onboard the InSight mission. Acta Astronaut. 2019, 164, 152–167. [Google Scholar] [CrossRef]

- Mizushina, A.; Omori, H.; Kitamoto, H.; Nakamura, T.; Osumi, H.; Kubota, T. A discharging mechanism for a lunar subsurface explorer with the peristaltic crawling mechanism. In Proceedings of the International Conference on Recent Advances in Space Technologies, Istanbul, Turkey, 12–14 June 2013; pp. 955–960. [Google Scholar] [CrossRef]

- Zhang, T.N.; Daniel, I.G. The effectiveness of resistive force theory in granular locomotion. Phys. Fluids 2014, 26, 101308. [Google Scholar] [CrossRef]

- Treers, L.K.; Cao, C.; Stuart, H.S. Granular Resistive Force Theory Implementation for Three-Dimensional Trajectories. IEEE Robot. Autom. Lett. 2021, 6, 1887–1894. [Google Scholar] [CrossRef]

- Gorevan, S.P.; Hong, K.Y.; Myrick, T.M.; Bartlett, P.W.; Singh, S.; Stroescu, S. An Inchworm Deep Drilling System for Kilometer Scale Subsurface Exploration of Mars (IDDS). In Proceedings of the Concepts and Approaches for Mars Exploration, Houston, TX, USA, 18–20 July 2000; p. 1. Available online: http://www.lpi.usra.edu/meetings/robomars/ (accessed on 1 February 2023).

- Zhang, W.; Jiang, S.; Tang, D.; Chen, H.; Liang, J. Drilling Load Model of an Inchworm Boring Robot for Lunar Subsurface Exploration. Int. J. Aerosp. Eng. 2017, 2017, 1282791. [Google Scholar] [CrossRef]

- Gouache, T.P.; Gao, Y.; Coste, P.; Gourinat, Y. First experimental investigation of dual-reciprocating drilling in planetary regoliths: Proposition of penetration mechanics. Planet. Space Sci. 2011, 59, 1529–1541. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Zacny, K.; Badescu, M.; Lee, H.J.; Sherrit, S.; Bao, X.Q.; Freeman, D.; Paulsen, G.L.; Beegle, L. Auto-Gopher-2 An Autonomous Wireline Rotary Piezo-Percussive Deep Drilling Mechanism. In Proceedings of the 16th Biennial International Conference on Engineering, Science, Construction, and Operations in Challenging Environments, Cleveland, OH, USA, 9–12 April 2018; pp. 307–316. Available online: http://hdl.handle.net/2014/46258 (accessed on 1 February 2023).

- Bar-Cohen, Y.; Badescu, M.; Sherrit, S.; Bao, X.Q.; Lee, H.J. Auto-Gopher-2 (AG2)-Autonomous Wireline Rotary Piezo-Percussive for Deep Drilling. In Proceedings of the Lunar ISRU 2019-Developing a New Space Economy Through Lunar Resources and Their Utilization, Columbia, MD, USA, 15–17 July 2019; Volume 2152, p. 5104. Available online: https://ui.adsabs.harvard.edu/abs/2019LPICo2152.5104B/abstract (accessed on 1 February 2023).

- Williams, B.J.; Anand, S.V.; Rajagopalan, J.; Saif, M.T.A. A self-propelled biohybrid swimmer at low Reynolds number. Nat. Commun. 2014, 5, 3081. [Google Scholar] [CrossRef]

- Texier, B.D.; Ibarra, A.; Melo, F. Helical Locomotion in a Granular Medium. Phys. Rev. Lett. 2017, 119, 068003. [Google Scholar] [CrossRef]

- Maladen, R.D.; Ding, Y.; Umbanhowar, P.B.; Kamor, A.; Goldman, D.I. Mechanical models of sandfish locomotion reveal principles of high performance subsurface sand-swimming. J. R. Soc. Interface 2011, 8, 1332–1345. [Google Scholar] [CrossRef]

- Kang, W.; Feng, Y.; Liu, C.; Blumenfeld, R. Archimedes’ law explains penetration of solids into granular media. Nat. Commun. 2018, 9, 1101. [Google Scholar] [CrossRef]

- Feng, Y.; Blumenfeld, R.; Liu, C. Support of modified Archimedes’law theory in granular media. Soft Matter 2019, 15, 3008–3017. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Xi, B.; Jiang, M.; Cui, L. 3D DEM analysis of soil excavation test on lunar regolith simulant. Granul. Matter 2021, 23, 1. [Google Scholar] [CrossRef]

- Kawamoto, R.; Andò, E.; Viggiani, G.; Andrade, J.E. All you need is shape: Predicting shear banding in sand with LS-DEM. J. Mech. Phys. Solids 2018, 111, 375–392. [Google Scholar] [CrossRef]

- Khademian, Z.; Kim, E.; Nakagawa, M. Simulation of Lunar Soil with Irregularly Shaped, Crushable Grains: Effects of Grain Shapes on the Mechanical Behaviors. J. Geophys. Res. Planets 2019, 124, 1157–1176. [Google Scholar] [CrossRef]

- Askari, H.; Kamrin, K. Intrusion rheology in grains and other flowable materials. Nat. Mater. 2016, 15, 1274–1279. [Google Scholar] [CrossRef]

- Kamrin, K. Nonlinear elasto-plastic model for dense granular flow. Int. J. Plast. 2010, 26, 167–188. [Google Scholar] [CrossRef]

- Kim, S.; Kamrin, K. Power-Law Scaling in Granular Rheology across Flow Geometries. Phys. Rev. Lett. 2020, 125, 088002. [Google Scholar] [CrossRef]

- Gerolymos, N.; Gazetas, G. Winkler model for lateral response of rigid caisson foundations in linear soil. Soil Dyn. Earthq. Eng. 2006, 26, 347–361. [Google Scholar] [CrossRef]

- De Rosa, M.; Maurizi, M. The influence of concentrated masses and pasternak soil on the free vibrations of euler beams—Exact solution. Journal of Sound and Vibration. J. Sound Vib. 1998, 212, 573–581. [Google Scholar] [CrossRef]

- Richard, T.; Detournay, E.; Fear, M.; Miller, B.; Clayton, R.; Matthews, O. Influence of bit-rock interaction on stick-slip vibrations of PDC bits. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002. [Google Scholar] [CrossRef]

- Detournay, E.; Richard, T.; Shepherd, M. Drilling response of drag bits: Theory and experiment. Int. J. Rock Mech. Min. Sci. 2008, 45, 1347–1360. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, W.; Chávez, J.P.; De Sa, R. Torsional stick-slip vibrations and multistability in drill-strings. Appl. Math. Model. 2019, 76, 545–557. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Guo, X.; Dai, L.; Zhang, C.; Zhu, H. Investigation on axial-lateral-torsion nonlinear coupling vibration model and stick-slip characteristics of drilling string in ultra-HPHT curved wells. Appl. Math. Model. 2022, 107, 182–206. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.; Gosine, R.G.; James, L.A.; De Silva, O.; Mann, G.K.I.; Warrian, P.J. Digital twin for the oil and gas industry: Overview, research trends, opportunities, and challenges. IEEE Access 2020, 8, 104175–104197. [Google Scholar] [CrossRef]

- Bimastianto, P.; Khambete, S.; AlSaadi, H.; Couzigou, E.; Al-Marzouqi, A.; Chevallier, B.; Qadir, A.; Pausin, W.; Laurent, V. Digital Twin Implementation on Current Development Drilling, Benefits and Way Forward. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2020. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, B.; Lin, Y.; Zhu, M.-H.; Song, H.; Dong, Z.; Gao, Y.; Di, K.; Yang, W.; Lin, H.; et al. Lunar regolith and substructure at Chang’E-4 landing site in South Pole–Aitken basin. Nat. Astron. 2021, 5, 25–30. [Google Scholar] [CrossRef]

- Molaro, J.; Byrne, S.; Le, J.-L. Thermally induced stresses in boulders on airless body surfaces, and implications for rock breakdown. Icarus 2017, 294, 247–261. [Google Scholar] [CrossRef]

- Hagermann, A.; Tanaka, S. Ejecta deposit thickness, heat flow, and a critical ambiguity on the Moon. Geophys. Res. Lett. 2006, 33, 1–5. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, Z.; Li, Y.; Zhao, H.F. A Three-Dimensional Path Planning Method of Autonomous Burrowing Robot for Lunar Subsurface Exploration. In Proceedings of the 2021 6th IEEE International Conference on Advanced Robotics and Mechatronics (ICARM), Chongqing, China, 3–5 July 2021; pp. 710–715. [Google Scholar] [CrossRef]

- Li, Y.P.; Huang, L.; Wang, K.; Zhao, H.F. Geometric Reconstruction Method for Predicting Shape of Irregular Rocks under Moon’s Subsurface Using Lunar Penetrating Radar Based on a Deep Learning Algorithm. Electron. Inf. Technol. 2022, 44, 1222–1230. [Google Scholar] [CrossRef]

- Yan, Y.; White, D.J.; Randolph, M.F. Penetration resistance and stiffness factors for hemispherical and toroidal penetrometers in uniform clay. Int. J. Geomech. 2011, 11, 263–275. [Google Scholar] [CrossRef]

- TVromen, T.; Detournay, E.; Nijmeijer, H.; Van De Wouw, N. Dynamics of Drilling Systems with an Antistall Tool: Effect on Rate of Penetration and Mechanical Specific Energy. SPE J. 2019, 24, 1982–1996. [Google Scholar] [CrossRef]

- Yan, Y.; Wiercigroch, M. Dynamics of rotary drilling with non-uniformly distributed blades. Int. J. Mech. Sci. 2019, 160, 270–281. [Google Scholar] [CrossRef]

- Meirovitch, L. Methods of Analytical Dynamics; McGraw-Hill: New York, NY, USA, 1970; ISBN 9780486137599. [Google Scholar]

- Lin, W.; Chávez, J.P.; Liu, Y.; Yang, Y.; Kuang, Y. Stick-slip suppression and speed tuning for a drill-string system via proportional-derivative control. Appl. Math. Model. 2020, 82, 487–502. [Google Scholar] [CrossRef]

- Dai, W.; Yang, J.; Wiercigroch, M. Vibration energy flow transmission in systems with Coulomb friction. Int. J. Mech. Sci. 2022, 214, 106932. [Google Scholar] [CrossRef]

- TAmer, T.S.; Bek, M.A.; Nael, M.S.; Sirwah, M.A.; Arab, A. Stability of the Dynamical Motion of a Damped 3DOF Auto-parametric Pendulum System. J. Vib. Eng. Technol. 2022, 10, 1883–1903. [Google Scholar] [CrossRef]

- Karatzia, X.; Mylonakis, G. Horizontal Stiffness and Damping of Piles in Inhomogeneous Soil. J. Geotech. Geoenvironmental Eng. 2017, 143, 04016113. [Google Scholar] [CrossRef]

- Bradley, H.B. Petroleum Engineering Handbook; Society of Petroleum Engineers: Richardson, TX, USA, 1987; ISBN 97815556301021555630103. [Google Scholar]

- Widisinghe, S.; Sivakugan, N. Vertical Stress Isobars for Trenches and Mine Stopes Containing Granular Backfills. Int. J. Géoméch. 2014, 14, 313–318. [Google Scholar] [CrossRef]

- Ting, C.H.; Sivakugan, N.; Read, W.; Shukla, S.K. Analytical Expression for Vertical Stress within an Inclined Mine Stope with Non-parallel Walls. Geotech. Geol. Eng. 2014, 32, 577–586. [Google Scholar] [CrossRef]

| Names | Symbols | Values | Units (SI) |

|---|---|---|---|

| Mass of motion body | m | 1 | kg |

| Body length | 1 | m | |

| Arm length of lateral thrust, F | lF | 0.8 | m |

| Cross-sectional diameter | 2R | 0.08 | m |

| Ratio of rotational center in length | a/b | 0.25 | / |

| Vertical stiffness | 10 | N/m | |

| Horizontal stiffness | 5 | N/m |

| Names | Symbols | Values | Units (SI) |

|---|---|---|---|

| Mass of motion body | m | 1 | kg |

| Body length | 1 | m | |

| Arm length of lateral thrust, F | lF | 0.8 | m |

| Cross-sectional diameter | 2R | 0.08 | m |

| Ratio of rotational center in length | a/b | 0.25 | / |

| Axial proportional-control factor | 1 × 103 | kg/s2 | |

| Lateral proportional-control factor | 8 × 103 | kg/s2 | |

| Torsional proportional-control factor | 1 × 104 | kg·m2/s2 | |

| Axial derivative-control factor | 100 | kg/s | |

| Lateral derivative-control factor | 100 | kg/s | |

| Torsional derivative-control factor | 1 × 104 | kg·m2/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Z.; Mu, R.; Zhao, H.; Wang, K. Predictive Model of a Mole-Type Burrowing Robot for Lunar Subsurface Exploration. Aerospace 2023, 10, 190. https://doi.org/10.3390/aerospace10020190

Yuan Z, Mu R, Zhao H, Wang K. Predictive Model of a Mole-Type Burrowing Robot for Lunar Subsurface Exploration. Aerospace. 2023; 10(2):190. https://doi.org/10.3390/aerospace10020190

Chicago/Turabian StyleYuan, Zihao, Ruinan Mu, Haifeng Zhao, and Ke Wang. 2023. "Predictive Model of a Mole-Type Burrowing Robot for Lunar Subsurface Exploration" Aerospace 10, no. 2: 190. https://doi.org/10.3390/aerospace10020190

APA StyleYuan, Z., Mu, R., Zhao, H., & Wang, K. (2023). Predictive Model of a Mole-Type Burrowing Robot for Lunar Subsurface Exploration. Aerospace, 10(2), 190. https://doi.org/10.3390/aerospace10020190