Modification of Space Debris Trajectories through Lasers: Dependence of Thermal and Impulse Coupling on Material and Surface Properties

Abstract

:1. Introduction

2. Experiment

2.1. nhelix Laser Facility

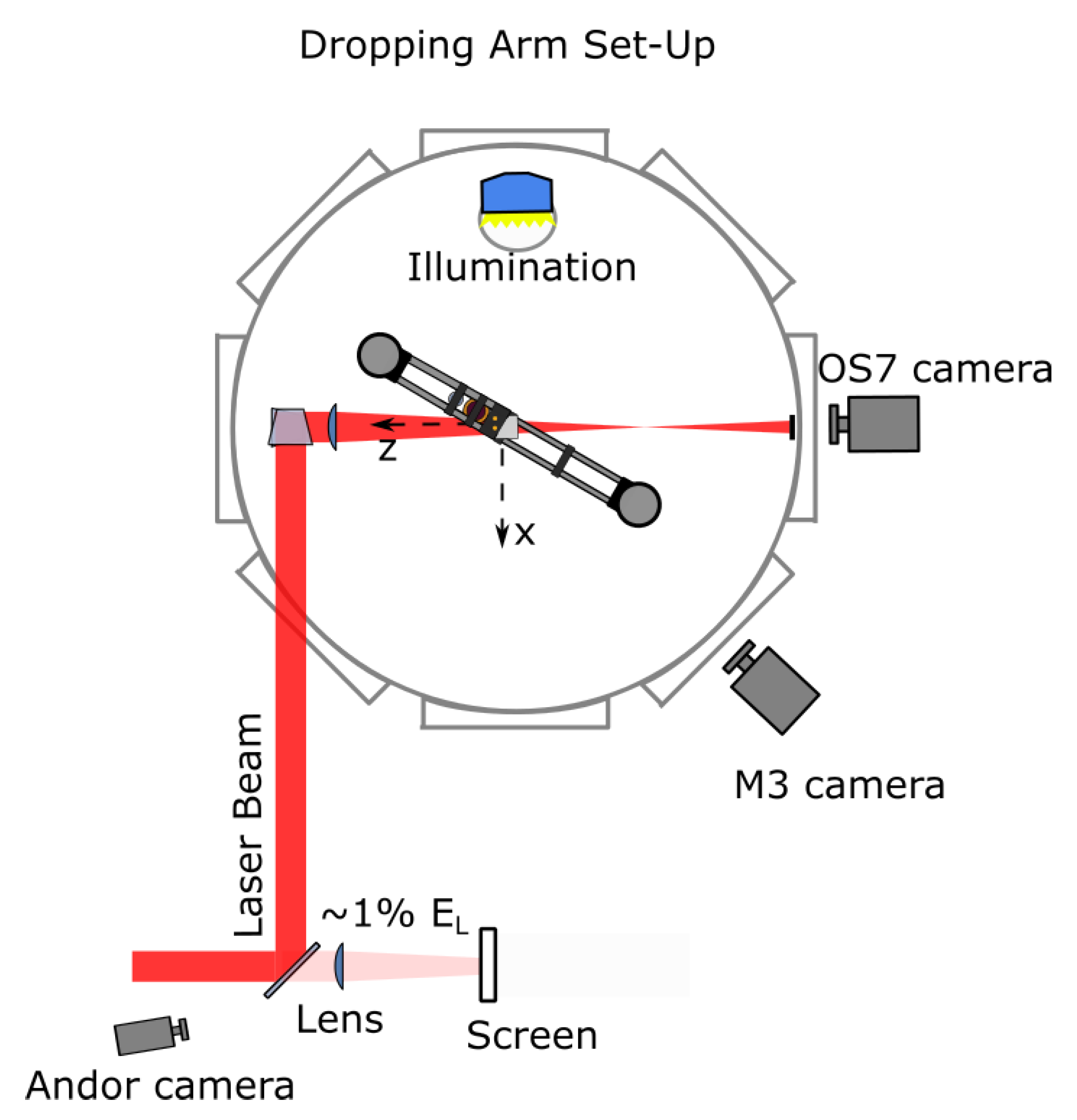

2.2. Experimental Setup

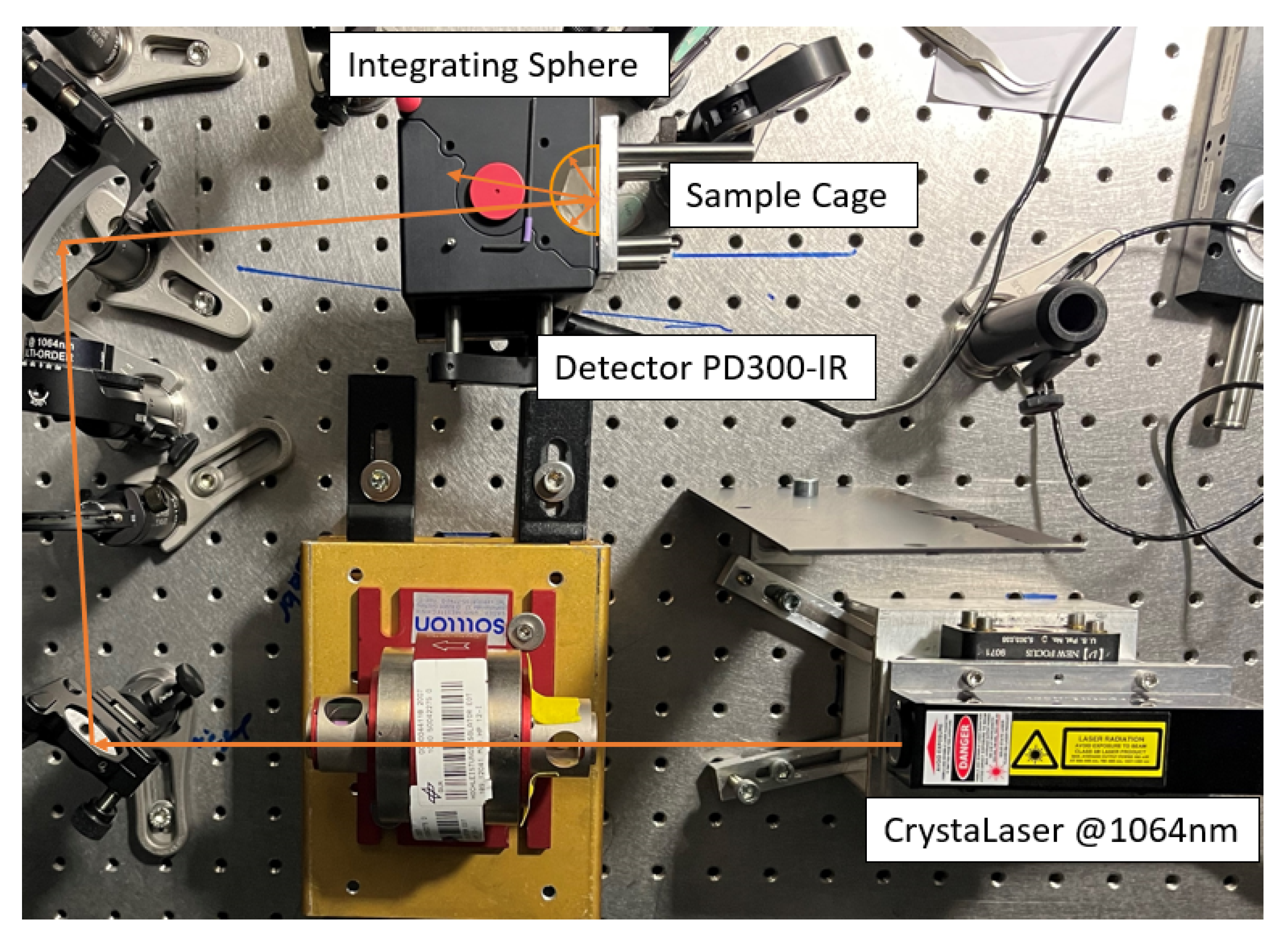

2.3. Hemispherical Reflection of the Samples

3. Experimental Methods

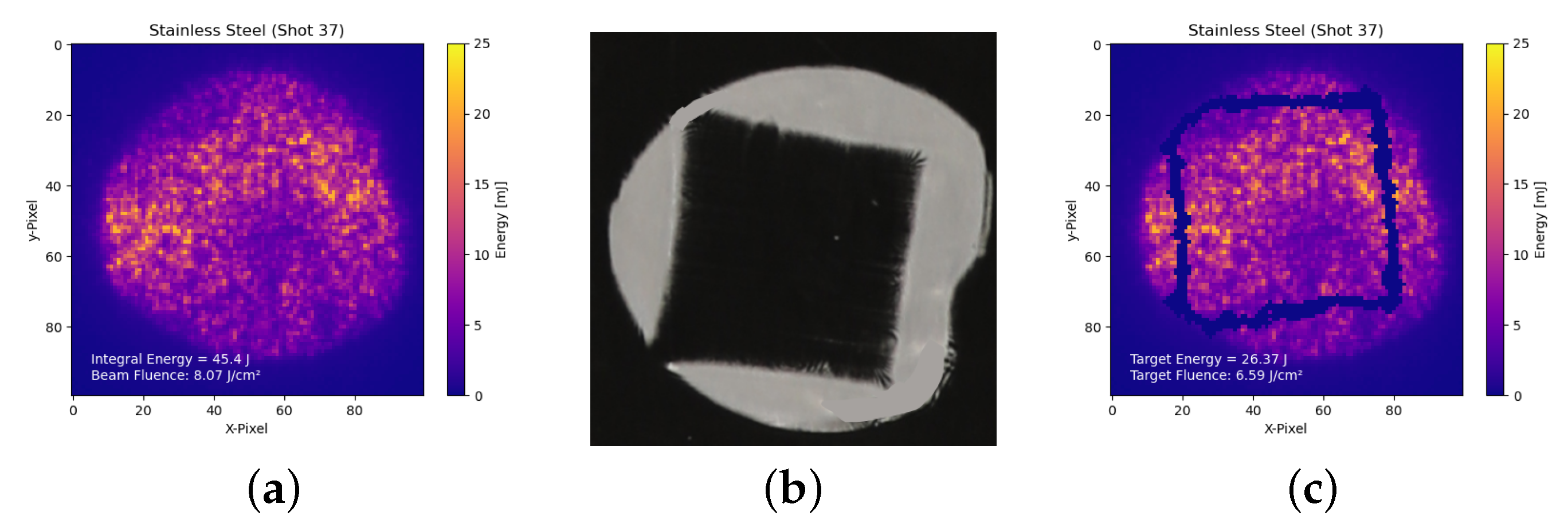

3.1. Fluence Estimation

3.2. Motion Tracking

3.3. Thermal Coupling

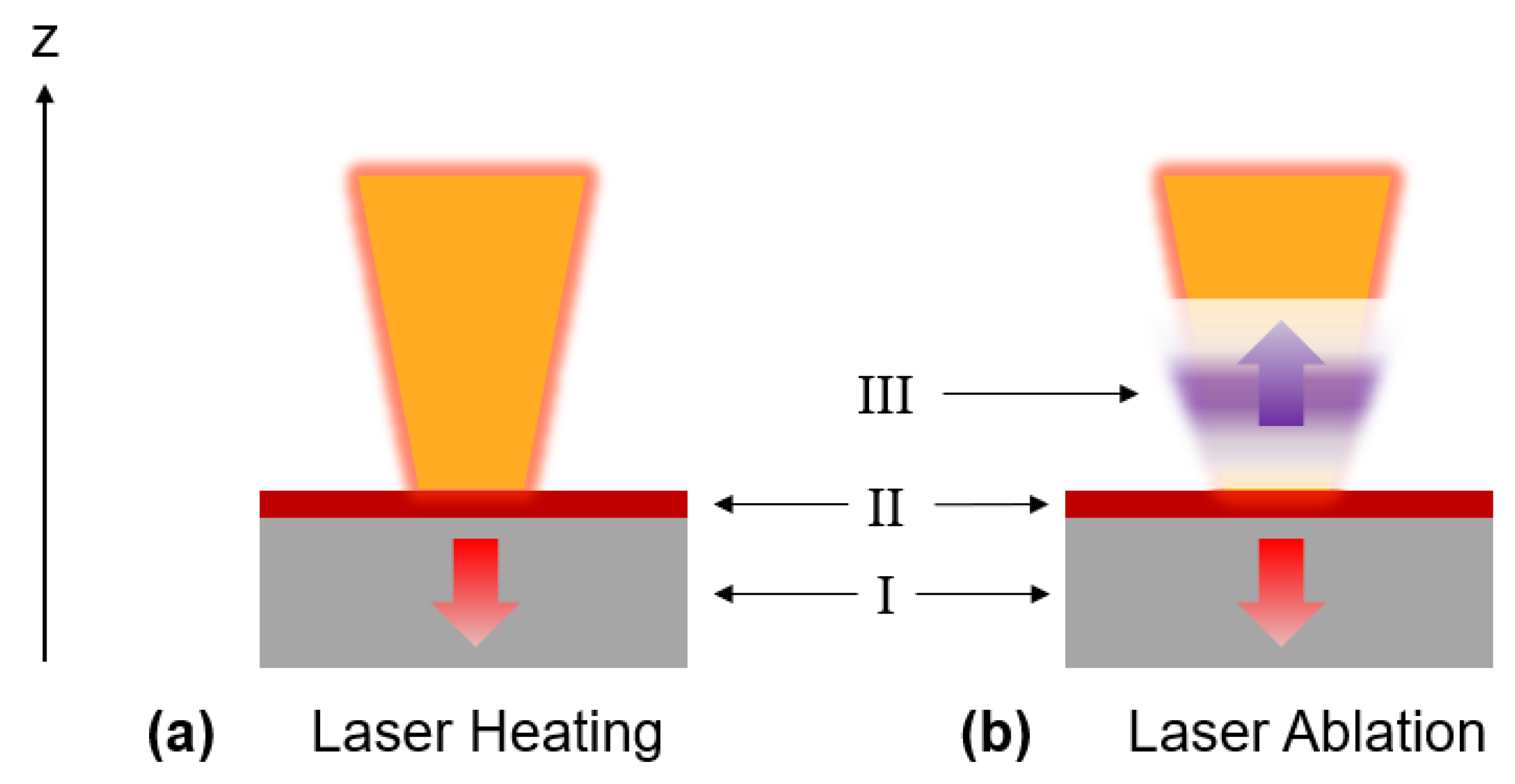

3.4. Ablation Behavior

4. Simulations

4.1. Finite-Element Method (FEM) Simulation

4.2. FEM Configuration

4.3. Post-Processing and Validation

5. Results

5.1. Ablation Behavior

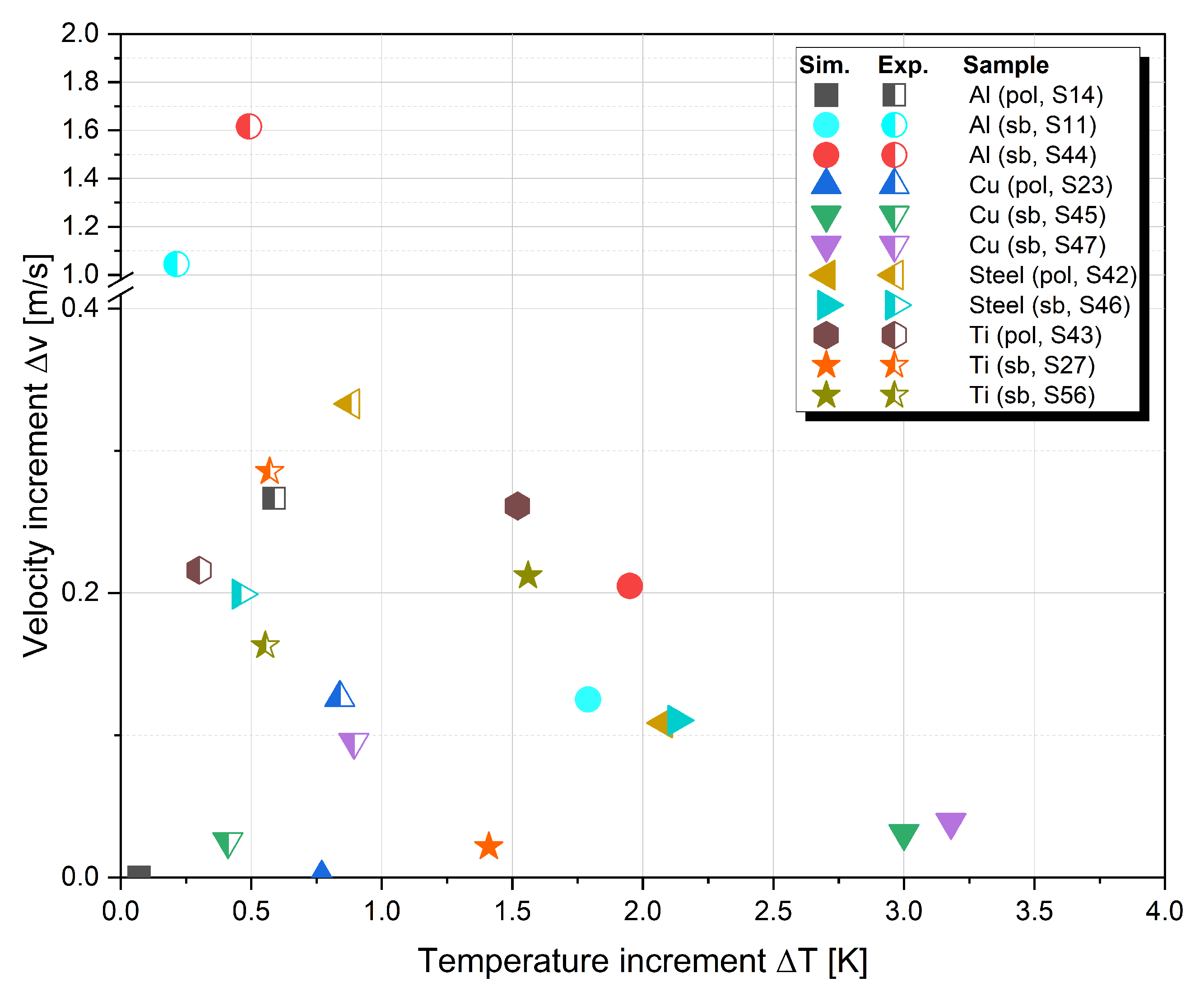

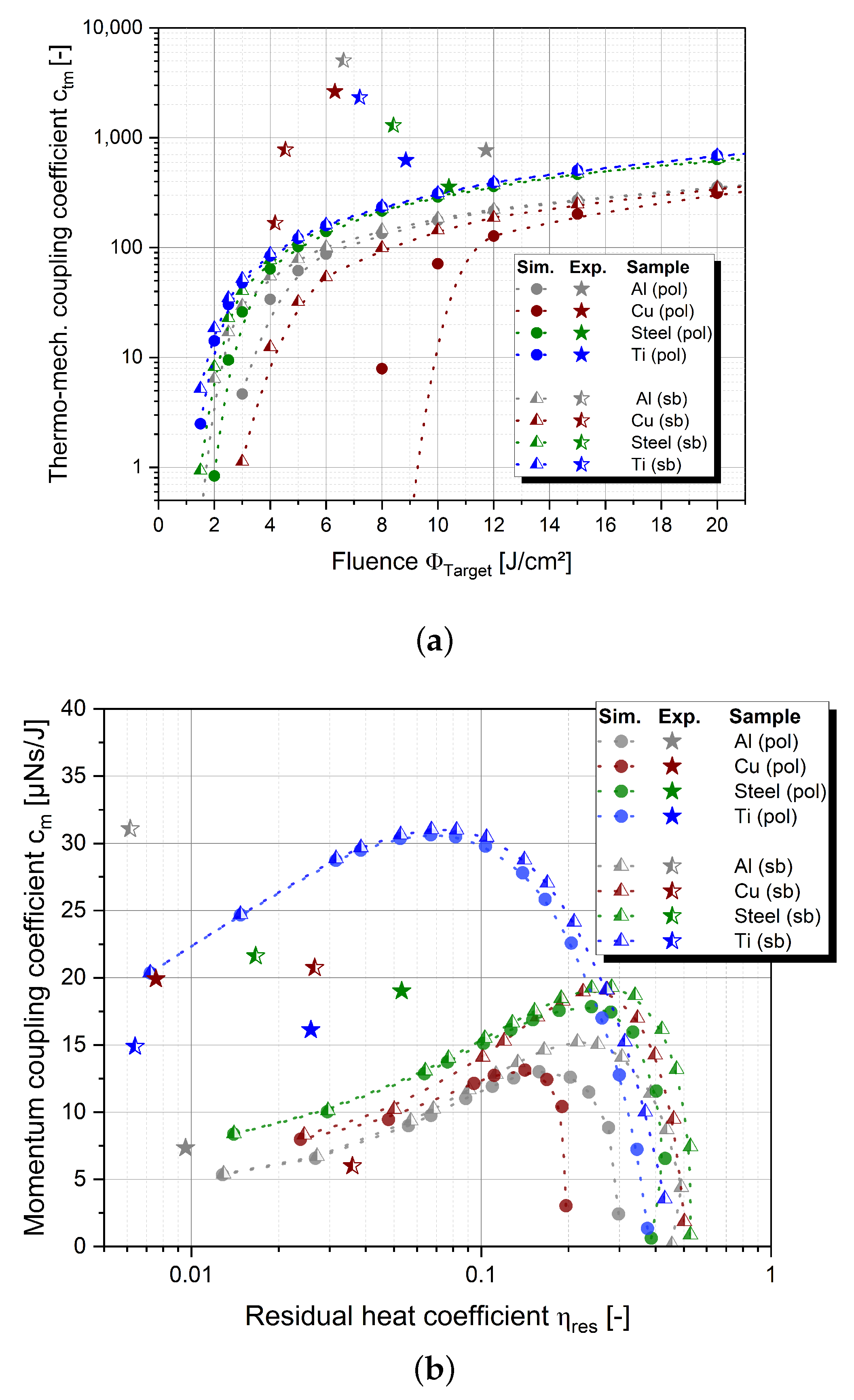

5.2. Laser-Induced Momentum and Heat

5.3. Comparison with Simulations

5.4. Thermo-Mechanical Coupling Coefficient

6. Discussion

7. Conclusions

8. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DLR | German Aerospace Center |

| LEO | Low Earth Orbit |

| GSI | Gesellschaft für Schwerionenforschung |

| nhelix | Nanosecond High Energy Laser for Heavy Ion Experiments |

| GPS | Global Positioning System |

| NASA | National Aviation and Space Agency |

| ESA | European Space Agency |

| BNC | Bayonet Neill Concelman, coaxial cable connector |

| ND | Neutral Density |

| COG | Center of Gravity |

| GUI | Graphical User Interface |

| WLIM | White Light Interferometer |

| FEM | Finite-Element Method |

| Al | Aluminum |

| Fe/Steel/AISI304 | Iron/Stainless Steel |

| n.a. | Not Available |

| EMCCD | Electron Multiplying Charged-Coupled Device |

| ROI | Region of Interest |

| pol | Polished |

| sb | Sandblasted |

| NIF | National Ignition Facility |

| LMJ | Laser Mégajoule |

Appendix A. Equipment

Appendix A.1. Schematic Set-Up

Appendix A.2. Andor iXon Ultra

Appendix A.3. High-Speed Cameras

Appendix A.4. Sartorius CPA225D

| Titanium | PTFE | Polyimide | |

|---|---|---|---|

| Average mass [g] | 1.447919 | 0.727215 | 0.029277 |

| Stand. dev. [g] | 5.4 | 1.2 | 6.4 |

| Error [g] | 1.7 | 3.8 | 2.0 |

Appendix A.5. White Light Interferometer (WLIM) Wyko NT9100

Appendix B. Temperature Dependence of Simulation Parameters

Appendix C. Fit Functions

| Material | Surface | b | c | ||

|---|---|---|---|---|---|

| [J/cm] | [µNs/J] | [-] | [J/cm] | ||

| Al | pol | 2.18 | 0.097 | 0.52 | 2.81 |

| Al | sb | 4.33 | 0.093 | 0.65 | 1.54 |

| Cu | pol | 1.88 | 0.105 | 0.39 | 7.68 |

| Cu | sb | 4.45 | 0.104 | 0.59 | 2.89 |

| Fe | pol | 2.17 | 0.110 | 0.44 | 1.99 |

| Fe | sb | 2.24 | 0.108 | 0.47 | 1.49 |

| Ti | pol | 5.27 | 0.321 | 0.36 | 1.47 |

| Ti | sb | 4.57 | 0.320 | 0.35 | 1.34 |

| Material | Surface | ||||||

|---|---|---|---|---|---|---|---|

| [-] | [] | [] | [] | [] | [] | ||

| Al | pol | 0.040 | −0.045 | 0.015 | −0.567 | 0.075 | 0.0061 |

| Al | sb | 0.180 | −0.037 | 0.054 | −0.577 | 0.149 | 0.0291 |

| Cu | pol | 0.024 | −0.010 | 0.0013 | −0.219 | 0.012 | 0.0003 |

| Cu | sb | 0.257 | 0.049 | 0.0017 | −0.130 | 0.039 | 0.0004 |

| Fe | pol | 0.048 | −0.074 | 0.067 | −0.637 | 0.112 | 0.0344 |

| Fe | sb | −0.049 | 2.417 | 1.364 | 6.140 | −0.282 | 1.0584 |

| Ti | pol | 0.036 | 0.161 | 0.102 | −0.407 | 0.261 | 0.1224 |

| Ti | sb | 0.402 | −0.012 | 0.178 | 0.043 | 0.035 | 0.2141 |

References

- Kessler, D.J.; Cour-Palais, B.G. Collision frequency of artificial satellites: The creation of a debris belt. J. Geophys. Res. Space Phys. 1978, 83, 2637–2646. [Google Scholar] [CrossRef]

- Phipps, C.; Bonnal, C. Laser Ranging and Nudging in Space Debris Traffic Management. Sens. Transducers 2022, 255, 17–23. [Google Scholar]

- Mrusek, B.; Weiland, L. Space Commercialization and the Rise of Constellations: The Resulting Impact on the Kessler Effect. In Proceedings of the 2023 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Hollingham, R. What Would Happen if All Satellites Stopped Working? BBC Future. 10 June 2013. Available online: https://www.bbc.com/future/article/20130609-the-day-without-satellites (accessed on 4 September 2023).

- Colvin, T.J.; Karcz, J.; Wusk, G. Cost and Benefit Analysis of Orbital Debris Remediation; Technical report 10 March 2023; NASA Headquarters, Office of Technology, Policy, and Strategy: Washington, DC, USA, 2023. [Google Scholar]

- Adilov, N.; Braun, V.; Alexander, P.; Cunningham, B. An estimate of expected economic losses from satellite collisions with orbital debris. J. Space Saf. Eng. 2023, 10, 66–69. [Google Scholar] [CrossRef]

- Liou, J.C. An active debris removal parametric study for LEO environment remediation. Adv. Space Res. 2011, 47, 1865–1876. [Google Scholar] [CrossRef]

- ClearSpace1. Available online: https://www.esa.int/Space_Safety/ClearSpace-1 (accessed on 17 March 2023).

- Objects Detected in the Vicinity of ClearSpace-1 Debris Removal Mission Target. 2023. Available online: https://www.esa.int/Space_Safety/Objects_detected_in_the_vicinity_of_ClearSpace-1_debris_removal_mission_target (accessed on 4 September 2023).

- Ben-Larbi, M.K.; Hensel, R.; Atzeni, G.; Arzt, E.; Stoll, E. Orbital debris removal using micropatterned dry adhesives: Review and recent advances. Prog. Aerosp. Sci. 2022, 134, 100850. [Google Scholar] [CrossRef]

- Schall, W.O. Orbital debris removal by laser radiation. Acta Astronaut. 1991, 24, 343–351. [Google Scholar] [CrossRef]

- Shen, S.; Jin, X.; Hao, C. Cleaning space debris with a space-based laser system. Chin. J. Aeronaut. 2014, 27, 805–811. [Google Scholar] [CrossRef]

- Phipps, C.R.; Albrecht, G.; Friedman, H.; Gavel, D.; George, E.V.; Murray, J.; Ho, C.; Priedhorsky, W.; Michaelis, M.M.; Reilly, J.P. ORION: Clearing near-Earth space debris using a 20-kW, 530-nm, Earth-based, repetitively pulsed laser. Laser Part. Beams 1996, 14, 1–44. [Google Scholar] [CrossRef]

- Scharring, S.; Kästel, J. Can the Orbital Debris Disease Be Cured Using Lasers? Aerospace 2023, 10, 633. [Google Scholar] [CrossRef]

- Esmiller, B.; Jacquelard, C.; Eckel, H.A.; Wnuk, E. Space debris removal by ground-based lasers: Main conclusions of the European project CLEANSPACE. Appl. Opt. 2014, 53, I45–I54. [Google Scholar] [CrossRef]

- Scharring, S.; Eisert, L.; Lorbeer, R.A.; Eckel, H.A. Momentum predictability and heat accumulation in laser-based space debris removal. Opt. Eng. 2019, 58, 011004. [Google Scholar] [CrossRef]

- Lorbeer, R.A.; Zwilich, M.; Zabic, M.; Scharring, S.; Eisert, L.; Wilken, J.; Schumacher, D.; Roth, M.; Eckel, H.A. Experimental verification of high energy laser-generated impulse for remote laser control of space debris. Sci. Rep. 2018, 8, 8453. [Google Scholar] [CrossRef] [PubMed]

- Opiela, J.N. A study of the material density distribution of space debris. Adv. Space Res. 2009, 43, 1058–1064. [Google Scholar] [CrossRef]

- Germer, T.A.; Zwinkels, J.C.; Tsai, B.K. (Eds.) Spectrophotometry: Accurate Measurement of Optical Properties of Materials; Elsevier: Amsterdam, The Netherlands, 2014; Volume 46. [Google Scholar]

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef]

- Zwilich, M. 3D-Motion-Tracking for the Aquisition of Free Fall Events in the Ms Range. Bachelor’s Thesis, University of Applied Sciences Münster, Münster, Germany, 2017. (In German). [Google Scholar]

- Beauchemin, S.S.; Barron, J.L. The Computation of Optical Flow. ACM Comput. Surv. 1995, 27, 433–466. [Google Scholar] [CrossRef]

- Sharma, K.K. Development of Motion Trackers for Space Debris Research; Student reseach project; International Space University: Strasbourg, France, 2020. [Google Scholar]

- Seiz, F. Development and Integration of a Wireless Microcontroller for Data Acquisition in Laser Interaction Experiments for Space Debris Removal. Master’s Thesis, University of Stuttgart, Stuttgart, Germany, 2020. [Google Scholar]

- Phipps, C.; Birkan, M.; Bohn, W.; Eckel, H.A.; Horisawa, H.; Lippert, T.; Michaelis, M.; Rezunkov, Y.; Sasoh, A.; Schall, W.; et al. Review: Laser-Ablation Propulsion. J. Propuls. Power 2010, 26, 609–637. [Google Scholar] [CrossRef]

- Klein, E.M. Simulation of Space Debris Heating in Laser-Ablative Orbit Modification Manoeuvers. Master’s Thesis, Technical University Braunschweig, Braunschweig, Germany, 2021. [Google Scholar]

- Ho, C.Y.; Powell, R.W.; Liley, P.E. Thermal Conductivity of the Elements. J. Phys. Chem. Ref. Data 2009, 1, 279–421. [Google Scholar] [CrossRef]

- Simon, N.J.; Drexler, E.S.; Reed, R.P. Properties of Copper and Copper Alloys at Cryogenic Temperatures. Final Report; National Institute of Standards and Technology: Boulder, CO, USA, 1992. [Google Scholar] [CrossRef]

- Military Handbook. MIL-HDBK-5H: Metallic Materials and Elements for Aerospace Vehicle Structures; U.S. Department of Defense: Washington, VA, USA, 1998; Volume 1998, pp. 5–9. [Google Scholar]

- McBride, B.; Gordon, S.; Reno, M. Thermodynamic Data for Fifty Reference Elements; NASA Technical Paper 3287; NASA: Washington, DC, USA, 1993. [Google Scholar]

- Jensen, J.E.; Tuttle, W.A.; Stewart, R.B.; Brechna, H.; Prodell, A.G. Brookhaven National Laboratory Selected Cryogenic Data Notebook: Volume 1, Sections 1–9; Brookhaven National Laboratory: Upton, NY, USA, 1980; Volume V1. [Google Scholar]

- White, G.; Roberts, R. Problems in presenting key values: Linear expansivity of copper. High Temp. High Press. 1980, 12, 3116. [Google Scholar]

- Desai, P.D. Thermodynamic Properties of Iron and Silicon. J. Phys. Chem. Ref. Data 1986, 15, 967–983. [Google Scholar] [CrossRef]

- Nix, F.C.; MacNair, D. The Thermal Expansion of Pure Metals: Copper, Gold, Aluminum, Nickel, and Iron. Phys. Rev. 1941, 60, 597–605. [Google Scholar] [CrossRef]

- Feder, R.; Nowick, A.S. Use of Thermal Expansion Measurements to Detect Lattice Vacancies near the Melting Point of Pure Lead and Aluminum. Phys. Rev. 1958, 109, 1959–1963. [Google Scholar] [CrossRef]

- Gibbons, D.F. Thermal Expansion of Some Crystals with the Diamond Structure. Phys. Rev. 1958, 112, 136–140. [Google Scholar] [CrossRef]

- Kroeger, F., Jr. The Absolute Thermal Expansion of Copper and Aluminum between 5 K and 330 K. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 1974. [Google Scholar] [CrossRef]

- Drotning, W. Thermal expansion of molten tin, lead, and aluminum to 1300/sup 0/K. High Temp. Sci. 1979, 11, 265–276. [Google Scholar]

- Wilson, R., Jr. Density of aluminum at 2450 to 2900 K. High Temp. Sci. 1969, 1, 367–372. [Google Scholar]

- Thornburg, D.; Thall, E.; Brous, J. A Manual of Materials for Microwave Tubes; Wright Air Development Division, Air Research and Development Command, United States Airforce: Dayton, OH, USA, 1961. [Google Scholar]

- Brillo, J.; Egry, I.; Ho, I. Density and Thermal Expansion of Liquid Ag–Cu and Ag–Au Alloys. Int. J. Thermophys. 2006, 27, 494–506. [Google Scholar] [CrossRef]

- Hepworth, M.; Ruud, C. Viscosity and Density of Liquid Copper and Copper Alloys: Final Report; INCRA project: International Copper Research Association: Washington, DC, USA, 1974. [Google Scholar]

- Pstruś, J.; Fima, P. Molar Volume and Surface Tension of Liquid Bi–Cu Alloys. Metall. Mater. Trans. A 2022, 53, 1659–1673. [Google Scholar] [CrossRef]

- Corruccini, R.; Gniewek, J. Thermal Expansion of Technical Solids at Low Temperatures: A Compilation from the Literature; Monograph 29 Series; U.S. Department of Commerce, National Bureau of Standards: Washington, DC, USA, 1961. [Google Scholar]

- Drotning, W. Thermal expansion of iron, cobalt, nickel, and copper at temperatures up to 600 K above melting. High Temp. High Press. 1981, 13, 441–458. [Google Scholar]

- Laquer, H. Low Temperature Thermal Expansion of Various Materials; ADA307613; Defense Technical Information Center: Fort Belvoir, VA, USA, 1952. [Google Scholar]

- Wessing, J.J.; Brillo, J. Density, Molar Volume, and Surface Tension of Liquid Al-Ti. Metall. Mater. Trans. A 2016, 48, 868–882. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, D.; Wu, J.; He, Z.; Deng, X. A thermal model for nanosecond pulsed laser ablation of aluminum. AIP Adv. 2017, 7, 075010. [Google Scholar] [CrossRef]

- Bäuerle, D. Laser Processing and Chemistry, 5th ed.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Balazs, L.; Gijbels, R.; Vertes, A. Expansion of laser-generated plumes near the plasma ignition threshold. Anal. Chem. 1991, 63, 314–320. [Google Scholar] [CrossRef]

- Tsuno, K.; Wada, S.; Ogawa, T.; Ebisuzaki, T.; Fukushima, T.; Hirata, D.; Yamada, J.; Itaya, Y. Impulse measurement of laser induced ablation in a vacuum. Opt. Express 2020, 28, 25723–25729. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Ye, J.; Chang, H.; Zhou, W.; Han, X.; Li, M.; Gao, H. Experimental Research on Characteristics of Impulse Coupling and Plasma Plume Generated by Laser Irradiating Copper Target with Nanosecond Pulsed Laser Propulsion. Aerospace 2023, 10, 544. [Google Scholar] [CrossRef]

- Yu, C.; Zhou, W.; Chang, H.; Chen, Y.; Guo, W. Impulse coupling characteristics of typical metal materials irradiated by nanosecond laser with a millimeter-scale spot size. Infrared Laser Eng. 2021, 50, 20200390. [Google Scholar] [CrossRef]

- WebPlotDigitizer 4.6. Available online: https://apps.automeris.io/wpd/ (accessed on 14 June 2023).

- Phipps, C.R.; Baker, K.L.; Libby, S.B.; Liedahl, D.A.; Olivier, S.S.; Pleasance, L.D.; Rubenchik, A.; Trebes, J.E.; George, E.V.; Marcovici, B.; et al. Removing orbital debris with lasers. Adv. Space Res. 2012, 49, 1283–1300. [Google Scholar] [CrossRef]

- Wnuk, E.; Golebiewska, J.; Jacquelard, C.; Haag, H. Future Orbits of Space Debris after LDR Operation. In Proceedings of the 6th European Conference on Space Debris, Darmstadt, Germany, 22–25 April 2013; Volume 723, p. 70. [Google Scholar]

- Eckel, H.A.; Göge, D.; Zimper, D. Laser-Based Space Debris Removal An Approach for Protecting the Critical Infrastructure Space. Transform. Jt. Air Power J. JAPCC 2016, 22, 75–84. [Google Scholar]

- Haynam, C.; Wegner, P.; Auerbach, J.; Bowers, M.; Dixit, S.; Erbert, G.; Heestand, G.; Henesian, M.; Hermann, M.; Jancaitis, K.; et al. National Ignition Facility laser performance status. Appl. Opt. 2007, 46, 3276–3303. [Google Scholar] [CrossRef]

- CEA—Direction des Applications Militaires. Laser Megajoule: Description de l’Installation LMJ. 2023. Available online: https://www-lmj.cea.fr/lmj-description.html (accessed on 27 October 2023).

- Scharring, S.; Keil, D.; Klein, E.; Lorbeer, R.A.; Schumacher, D.; Roth, M. De-Risking Space Debris Removal: Thermo-Mechanical Integrity of Space Debris Objects under Pulsed Laser Irradiation. In Proceedings of the High-Power Laser Ablation VIII, Santa Fe, NM, USA, 26 February–1 March 2024. submitted. [Google Scholar]

- Patterson, J.D.; Bailey, B.C. Solid State Physics; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar] [CrossRef]

- Ujihara, K. Reflectivity of metals at high temperatures. J. Appl. Phys. 1972, 43, 2376–2383. [Google Scholar] [CrossRef]

- Mathewson, A.; Myers, H. Absolute values of the optical constants of some pure metals. Phys. Scr. 1971, 4, 291. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.W. Optical constants of the noble metals. Phys. Rev. B 1972, 6, 4370. [Google Scholar] [CrossRef]

- Johnson, P.; Christy, R. Optical constants of transition metals: Ti, v, cr, mn, fe, co, ni, and pd. Phys. Rev. B 1974, 9, 5056. [Google Scholar] [CrossRef]

- Palm, K.J.; Murray, J.B.; Narayan, T.C.; Munday, J.N. Dynamic optical properties of metal hydrides. ACS Photonics 2018, 5, 4677–4686. [Google Scholar] [CrossRef]

- Siegel, E. Optical reflectivity of liquid metals at their melting temperatures. Phys. Chem. Liq. 1976, 5, 9–27. [Google Scholar] [CrossRef]

- Allen, C.W. Astrophysical Quantities; Athlone Press: London, UK, 1973. [Google Scholar]

- Phipps, C., Jr.; Turner, T.; Harrison, R.; York, G.; Osborne, W.; Anderson, G.; Corlis, X.; Haynes, L.; Steele, H.; Spicochi, K.; et al. Impulse coupling to targets in vacuum by KrF, HF, and CO2 single-pulse lasers. J. Appl. Phys. 1988, 64, 1083–1096. [Google Scholar] [CrossRef]

| Material | Space Application |

|---|---|

| Aluminum 6082 | General structure material with multiple applications due to light weight and good cost–benefit balance. |

| Copper | Mainly electronic components |

| Stainless Steel AISI304 | Rocket stages |

| Titanium 99% | Structure elements like bolts and screws |

| Shot-No. | Material | m | Ra | v | T | ||

|---|---|---|---|---|---|---|---|

| [J/cm²] | [g] | [nm] | [m/s] | [K] | [K] | ||

| 14 | Aluminum | (11.73) | 1290 | 218.71 | 0.267 | 0.55 | 0.58 |

| 36 | Aluminum | 5.22 | 160 | 163.86 | 0.613 | n.a. | n.a. |

| 19 | Copper | 3.39 | 0 * | 62.64 | 0.158 | n.a. | n.a. |

| 23 | Copper | 6.32 | 21,070 * | 53.36 | 0.126 | 0.80 | 0.84 |

| 39 | Copper | 10.48 | 20 | 83.94 | 0.141 | n.a. | n.a. |

| 37 | Steel | 6.59 | 20 | 115.33 | 0.264 | n.a. | n.a. |

| 42 | Steel | (8.84) | 1920 | 125.97 | 0.333 | 0.84 | 0.88 |

| 18 | Titanium | 2.83 | 50 | 193.09 | 0.316 | n.a. | n.a. |

| 21 | Titanium | 3.85 | 40 | 588.24 | 0.287 | n.a. | n.a. |

| 38 | Titanium | 9.13 | 300 | 344.11 | 1.704 | n.a. | n.a. |

| 43 | Titanium | 8.86 | 430 | 317.53 | 0.216 | 0.28 | 0.30 |

| Shot-No. | Material | m | Ra | v | T | ||

|---|---|---|---|---|---|---|---|

| [J/cm²] | [g] | [nm] | [m/s] | [K] | [K] | ||

| 10 | Aluminum | (10.72) | 500 | n.a. | 0.788 | n.a. | n.a. |

| 11 | Aluminum | 6.63 | 480 | −620 | 1.044 | 0.20 | 0.21 |

| 44 | Aluminum | 12.412 | 790 | −476.67 | 1.616 | 0.46 | 0.49 |

| 22 | Copper | 7.67 | 310 | −65.33 | 0.619 | n.a. | n.a. |

| 24 | Copper | 6.98 | 1090 | −365.33 | 0.419 | n.a. | n.a. |

| 45 | Copper | 4.17 | 850 | −2 | 0.025 | 0.39 | 0.41 |

| 47 | Copper | 4.54 | 620 | −32 | 0.095 | 0.85 | 0.89 |

| 30 | Steel | 2.33 | 360 | +26.63 | 1.734 | n.a. | n.a. |

| 31 | Steel | 9.89 | 480 | +66.63 | 0.475 | n.a. | n.a. |

| 46 | Steel | 8.41 | 30,330 * | −46.7 | 0.199 | 0.44 | 0.46 |

| 25 | Titanium | 2.175 | 200 | −159.97 | 0.047 | n.a. | n.a. |

| 27 | Titanium | 2.023 | 540 | −209.97 | 0.285 | 0.53 | 0.57 |

| 56 | Titanium | 7.205 | 870 | −213.3 | 0.1637 | 0.52 | 0.55 |

| Material | Reference Reflectance | Ablated Sample Reflectance | ||

|---|---|---|---|---|

| Polished | Sandblasted | Polished | Sandblasted | |

| Aluminum | 0.85 | 0.37 | 0.79 | 0.33 |

| Copper | 0.94 | 0.41 | 0.84 | 0.46 |

| Stainless Steel | 0.63 | 0.2 | 0.62 | 0.22 |

| Titanium | 0.67 | 0.19 | 0.54 | 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keil, D.; Scharring, S.; Klein, E.; Lorbeer, R.-A.; Schumacher, D.; Seiz, F.; Sharma, K.K.; Zwilich, M.; Schnörer, L.; Roth, M.; et al. Modification of Space Debris Trajectories through Lasers: Dependence of Thermal and Impulse Coupling on Material and Surface Properties. Aerospace 2023, 10, 947. https://doi.org/10.3390/aerospace10110947

Keil D, Scharring S, Klein E, Lorbeer R-A, Schumacher D, Seiz F, Sharma KK, Zwilich M, Schnörer L, Roth M, et al. Modification of Space Debris Trajectories through Lasers: Dependence of Thermal and Impulse Coupling on Material and Surface Properties. Aerospace. 2023; 10(11):947. https://doi.org/10.3390/aerospace10110947

Chicago/Turabian StyleKeil, Denise, Stefan Scharring, Erik Klein, Raoul-Amadeus Lorbeer, Dennis Schumacher, Frederic Seiz, Kush Kumar Sharma, Michael Zwilich, Lukas Schnörer, Markus Roth, and et al. 2023. "Modification of Space Debris Trajectories through Lasers: Dependence of Thermal and Impulse Coupling on Material and Surface Properties" Aerospace 10, no. 11: 947. https://doi.org/10.3390/aerospace10110947

APA StyleKeil, D., Scharring, S., Klein, E., Lorbeer, R.-A., Schumacher, D., Seiz, F., Sharma, K. K., Zwilich, M., Schnörer, L., Roth, M., Ben-Larbi, M. K., Wiedemann, C., Riede, W., & Dekorsy, T. (2023). Modification of Space Debris Trajectories through Lasers: Dependence of Thermal and Impulse Coupling on Material and Surface Properties. Aerospace, 10(11), 947. https://doi.org/10.3390/aerospace10110947