Efficient BEM Modeling of the Heat Transfer in the Turbine Blades of Aero-Parts

Abstract

:1. Introduction

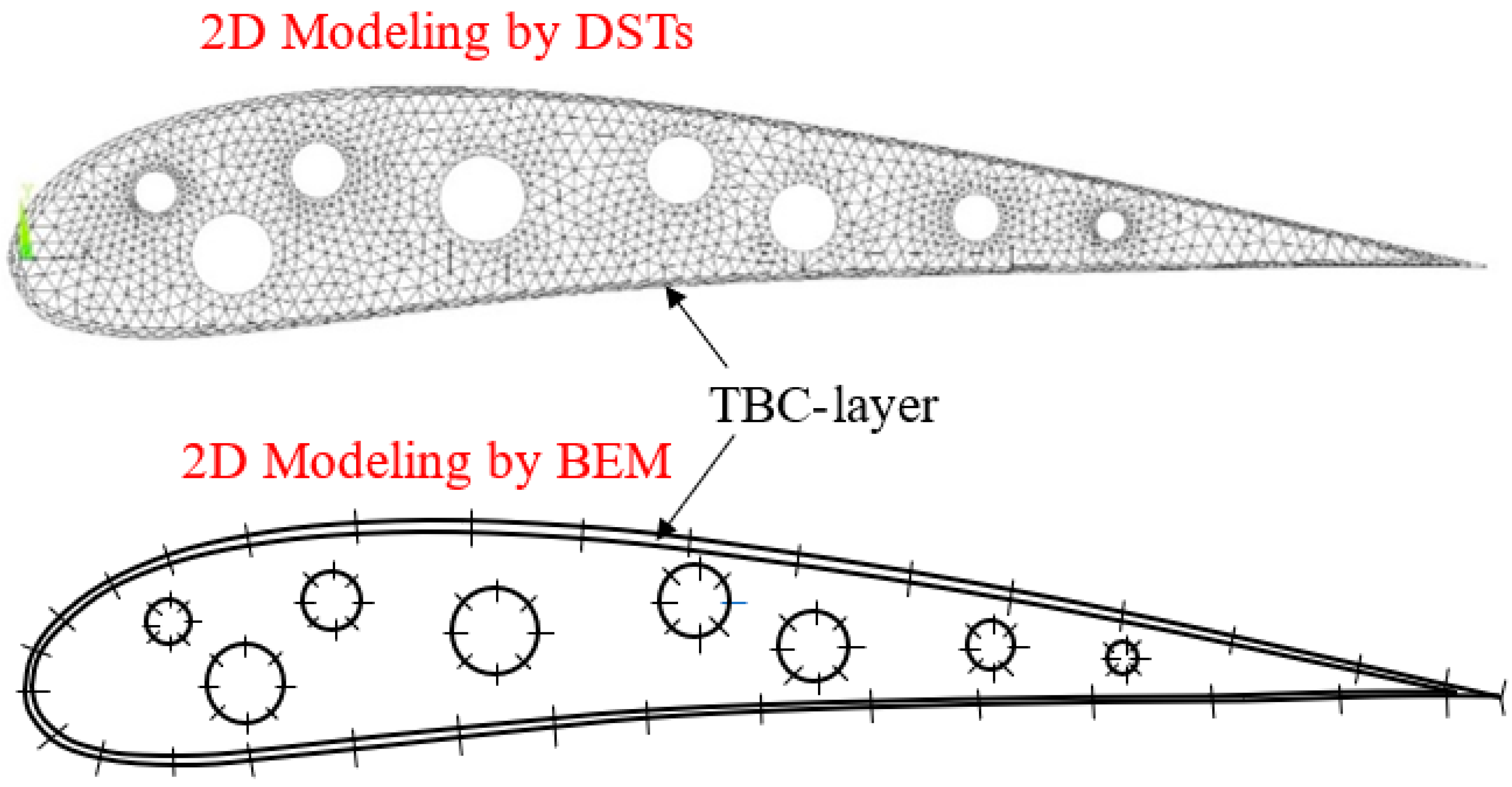

2. Analysis of 3D Anisotropic Heat Conduction

3. Model Simplification of a TBC Blade

3.1. Case (A)

3.2. Case (B)

4. Treatment of Singularity Weakening

5. Numerical Examples

6. Conclusions

- 1.

- In treating multiple thin layers coated on the TBC blade, the BEM may simply impose equivalent boundary conditions to replace the modeling of the thin layers. With such a treatment, significant modeling efforts can be saved and the computation expedited with much better efficiency.

- 2.

- Regardless of the thinness of TBC layers, the CPU time of the BEM simulation will remain unchanged; however, it shall increase exponentially with any decrease in TBC thinness in convectional DSTs.

- 3.

- Having been verified with ANSYS analysis, our examples have shown that the BEM algorithm is capable of analyzing 3D anisotropic heat conduction in a TBC blade by using modeling with very coarse meshes.

- 4.

- The same meshing scheme using coarse meshes is applicable to various turbine blades with very different geometries. In contrast, when employing conventional DSTs, one needs to model each distinctive case with different meshing adaptively. So far, the BEM algorithm developed has not been commercialized for general design, and thus, meshing still requires laborious modeling. Nevertheless, it is very promising that the BEM code will be developed into friendly software capable of providing auto-meshing for general design.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sunden, B.; Xie, G. Gas turbine blade tip heat transfer and cooling: A literature survey. Heat Transf. Eng. 2010, 31, 527–554. [Google Scholar] [CrossRef]

- Camci, C.; Arts, T. Experimental heat transfer investigation around the film-cooled leading edge of a high-pressure gas turbine rotor blade. ASME J. Eng. Power 1985, 107, 1016–1021. [Google Scholar] [CrossRef]

- Li, H.; Kassab, A.J. A coupled FVM/BEM approach to conjugate heat transfer in turbine blades. In Proceedings of the 6th Joint Thermophysics and Heat Transfer Conference, Colorado Springs, CO, USA, 20–23 June 1994. [Google Scholar]

- Iacovides, H.; Raisee, M. Recent progress in the computation of flow and heat transfer in internal cooling passages of turbine blades. Int. J. Heat Fluid Flow 1999, 20, 320–328. [Google Scholar] [CrossRef]

- Vo, D.-T.; Mai, T.D.; Kim, B.; Ryu, J. Numerical study on the influence of coolant temperature, pressure, and thermal barrier coating thickness on heat transfer in high-pressure blades. Int. J. Heat Mass Transf. 2022, 189, 122715. [Google Scholar] [CrossRef]

- Wang, Y.; Wanga, C.; Youa, Y.; Cheng, W.; Dong, M.L.; Zhu, Z.; Liu, J.; Wang, L.; Zhang, X.; Wang, Y. Analysis on thermal stress of optimized functionally graded coatings during thermal shock based on finite element simulation. Mater. Today Commun. 2023, 35, 105699. [Google Scholar] [CrossRef]

- Pu, J.; Zhang, T.; Zhou, W.-l.; Wang, J.-h.; Wu, W.-l. Overall thermal performances of backward film cooling with simulated surface thermal barrier coatings at various walls. Case Stud. Therm. Eng. 2022, 32, 101876. [Google Scholar] [CrossRef]

- Scuderi, L. On the computation of nearly singular integrals in 3D BEM collocation. Int. J. Numer. Methods Eng. 2007, 74, 1733–1770. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Gu, Y.; Chen, J.T. Boundary element analysis of the thermal behaviour in thin-coated cutting tools. Eng. Anal. Bound. Elem. 2010, 34, 775–784. [Google Scholar] [CrossRef]

- Zhou, H.L.; Niu, Z.R.; Cheng, C.Z.; Guan, Z.W. Analytical integral algorithm applied to boundary layer effect and thin body effect in BEM for anisotropic potential problems. Comput. Struct. 2008, 86, 1656–1671. [Google Scholar] [CrossRef]

- Shiah, Y.C.; Hematiyan, M.R.; Chen, Y.H. Regularization of the boundary integrals in the BEM analysis of 3D potential problems. J. Mech. 2013, 29, 385–401. [Google Scholar] [CrossRef]

- Shiah, Y.C.; Chang, R.-Y.; Hematiya, M.R. Three-dimensional analysis of heat conduction in anisotropic composites with thin adhesive/interstitial media by the boundary element method. Eng. Anal. Bound. Elem. 2021, 123, 36–47. [Google Scholar] [CrossRef]

- Chen, X.L.; Liu, Y.J. An advanced 3-D boundary element method for characterizations of composite materials. Eng. Anal. Bound. Elem. 2005, 29, 513–523. [Google Scholar] [CrossRef]

- Qin, X.; Zhang, J.; Xie, G.; Zhou, F.; Li, G. A general algorithm for the numerical evaluation of nearly singular integrals on 3D boundary element. J. Comput. Anal. Appl. 2011, 235, 4174–4186. [Google Scholar] [CrossRef]

- Shiah, Y.C.; Tan, C.L.; Chan, L.-D. Boundary Element Analysis of Thin Anisotropic Structures by the Self-regularization Scheme. CMES-Comp. Model. Eng. Sci. 2015, 109–110, 15–33. [Google Scholar]

- Tuan, N.A.; Shiah, Y.C. BEM Study of 3D Heat Conduction in Multiply Adjoined Anisotropic Media with Quadratic Domain Heat Generation. J. Mech. 2019, 35, 225–231. [Google Scholar] [CrossRef]

- Shiah, Y.-C.; Huang, P.-W.; Hematiyan, M.-R.; Tuan, N.A. Efficient modeling of heat conduction across thin surface coatings on 3D anisotropic substrate. Aerospace 2022, 9, 321. [Google Scholar] [CrossRef]

| Problem I | Problem II | |

|---|---|---|

| Forced Convection (T∞ = 1000 °C) | Top surface of the TBC (ZrO2) | Blade surfaces on top/bottom |

| Dirichlet Condition (T = T0) | T0 = 0 °C Outside surfaces of the substrate (β-Ga2O3) | T0 = −50 °C Blade tip and root surfaces at x3 = 0 and −L |

| Neumann Condition Insulation (q = 0) | Side edges of the top three layers | Tip/root surfaces at x3 = 0 and −L |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsiao, Y.-F.; Shiah, Y.-C. Efficient BEM Modeling of the Heat Transfer in the Turbine Blades of Aero-Parts. Aerospace 2023, 10, 885. https://doi.org/10.3390/aerospace10100885

Hsiao Y-F, Shiah Y-C. Efficient BEM Modeling of the Heat Transfer in the Turbine Blades of Aero-Parts. Aerospace. 2023; 10(10):885. https://doi.org/10.3390/aerospace10100885

Chicago/Turabian StyleHsiao, Yue-Fang, and Yui-Chuin Shiah. 2023. "Efficient BEM Modeling of the Heat Transfer in the Turbine Blades of Aero-Parts" Aerospace 10, no. 10: 885. https://doi.org/10.3390/aerospace10100885

APA StyleHsiao, Y.-F., & Shiah, Y.-C. (2023). Efficient BEM Modeling of the Heat Transfer in the Turbine Blades of Aero-Parts. Aerospace, 10(10), 885. https://doi.org/10.3390/aerospace10100885