4.2. Assessing Various WtE Technologiess in Terms of Effectiveness and Appropriateness for Use in Bahrain

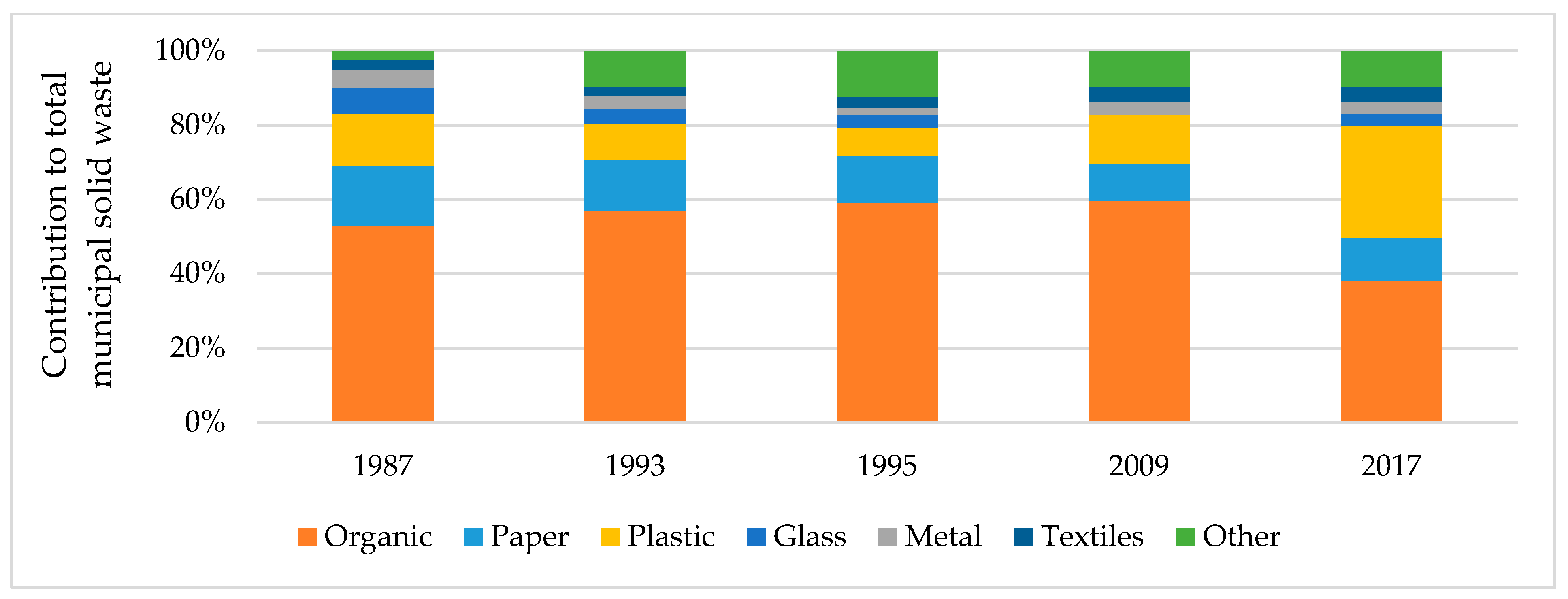

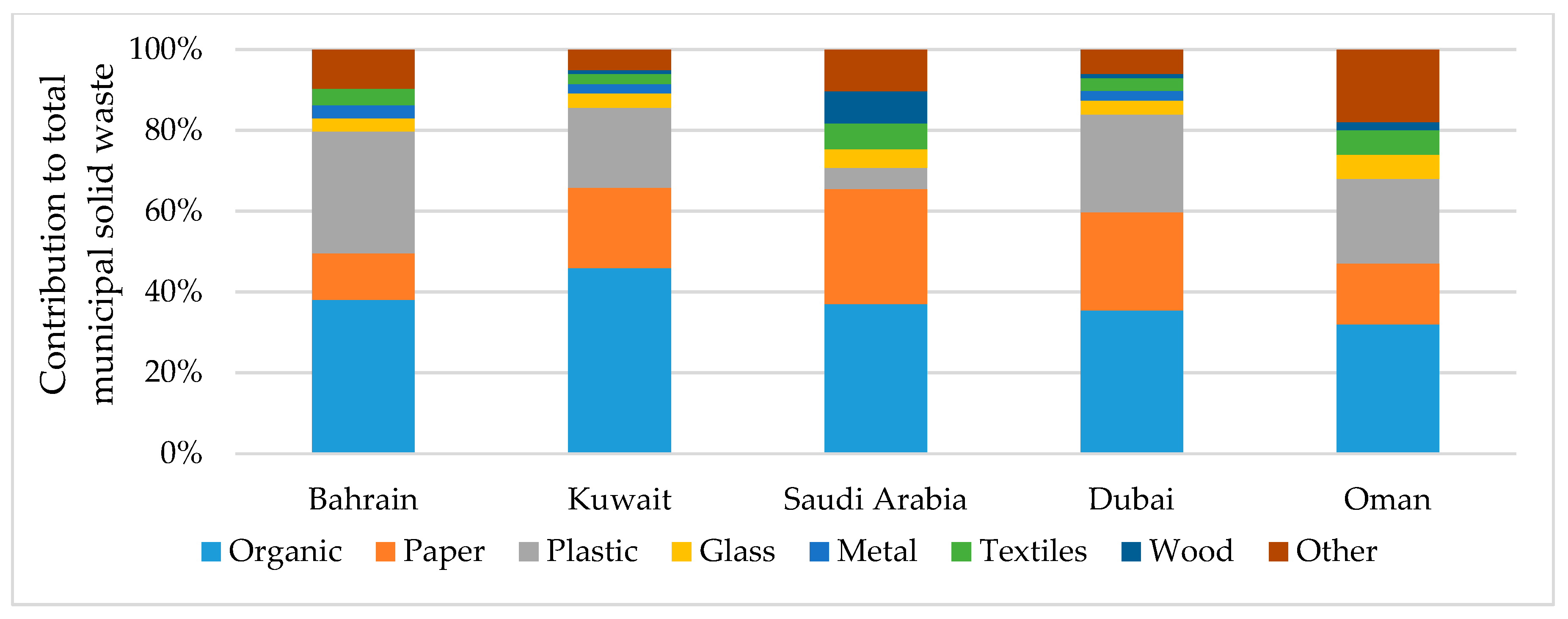

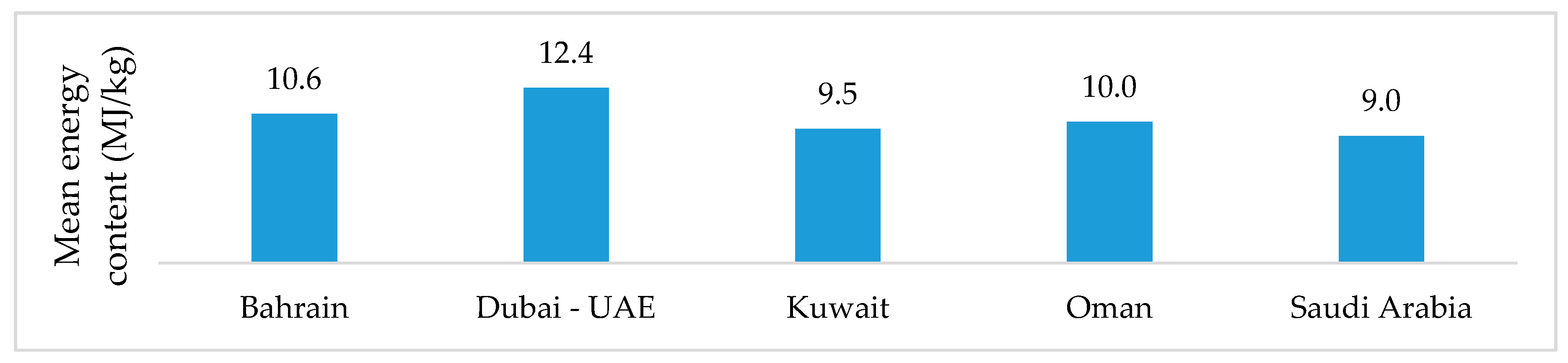

The calculated energy content of MSW in Bahrain was ~10.6 MJ/kg, which is almost similar to the energy contents of MSW in other GCC countries (

Figure 12).

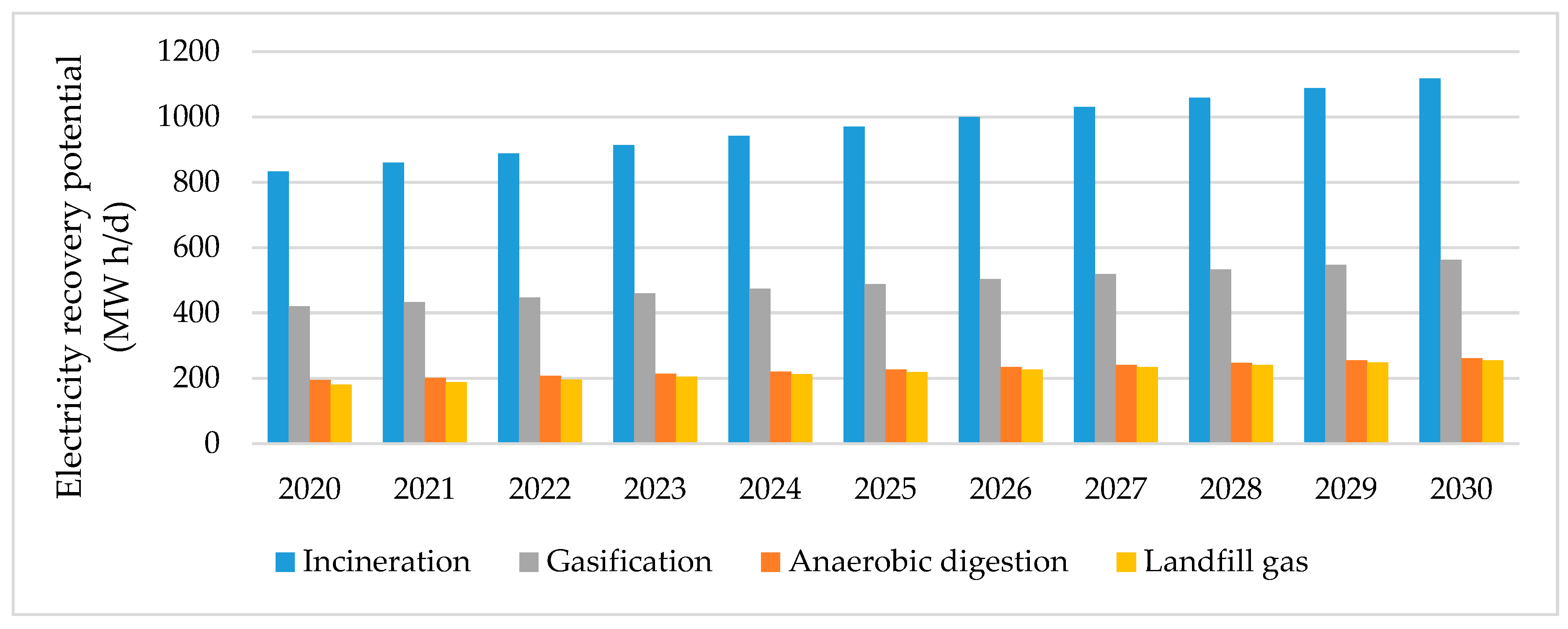

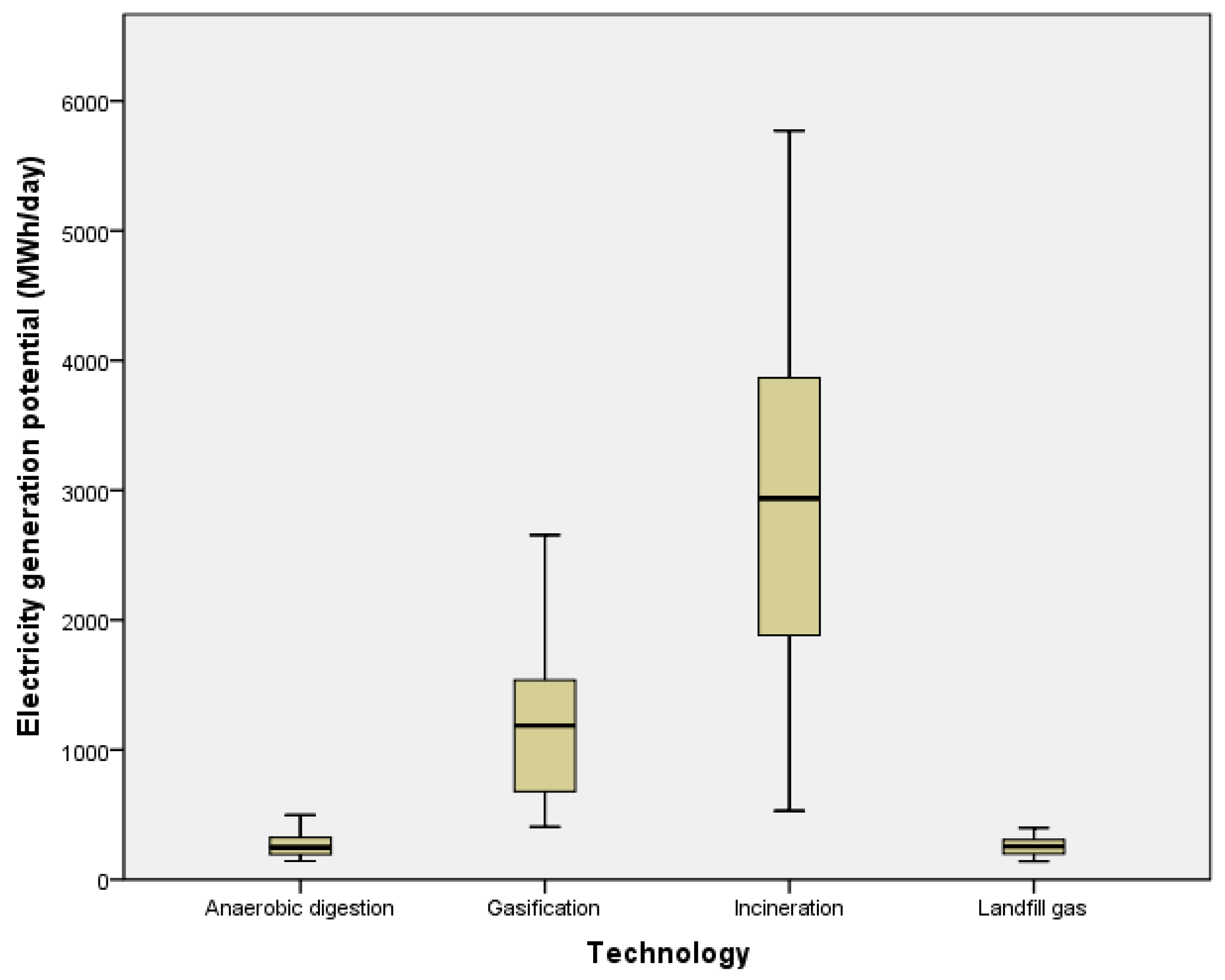

Incineration was found to have the highest electricity generation potential, followed by gasification, AD, and landfill gas recovery (

Figure 13). The predicted electricity generation potential for incineration in 2030 was ~1120 MWh/day. The predicted electricity generation potential for landfill gas recovery in 2030 was only ~255 MWh/day. These results roughly indicate the amount of electricity that could be generated from MSW but would otherwise be wasted. The sensitivity analyses indicated that incineration would give the most variable electricity generation potential, implying that changing the amount of waste produced per capita, MSW DOC, waste characteristics, or process efficiency would markedly affect the amount of electricity generated, potentially making the amount generated as low as the amount that could be generated using other WtE technologies (

Figure 14). These data are rough estimates of the potential electricity generation values in use by decision-makers comparing the benefits and costs of CO

2e mitigation measures for different sectors. The generation of electricity from MSW contributes to climate change mitigation through the elimination of landfill gas and replacing fossil fuel-fired power plants [

79].

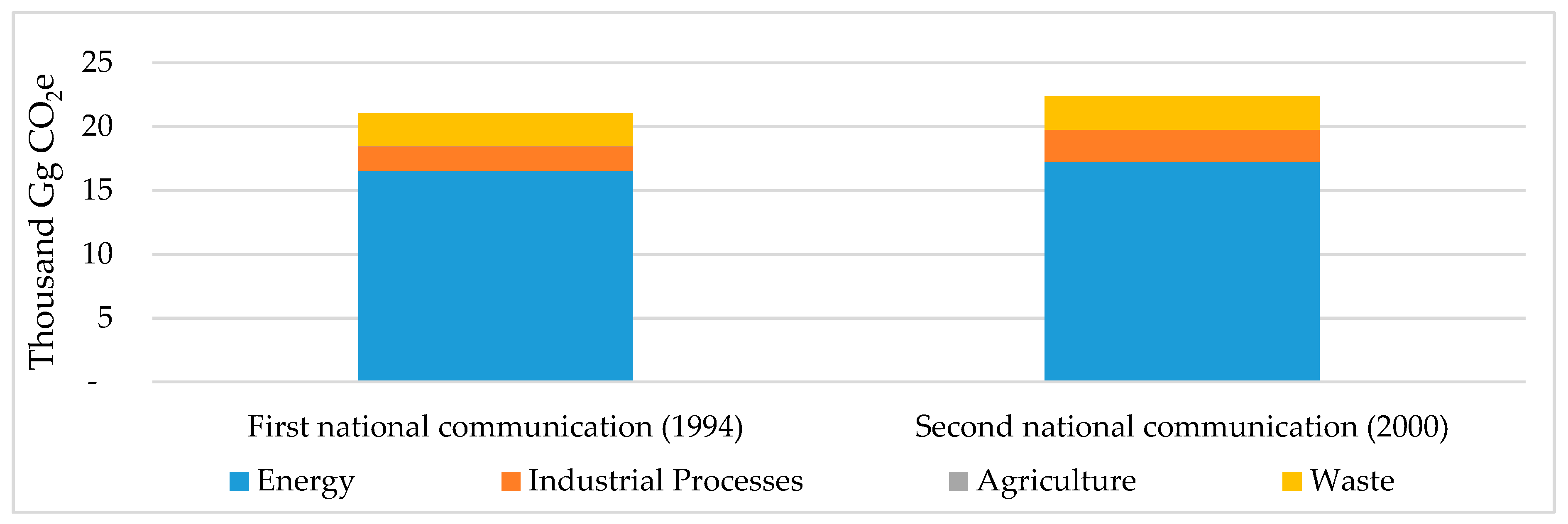

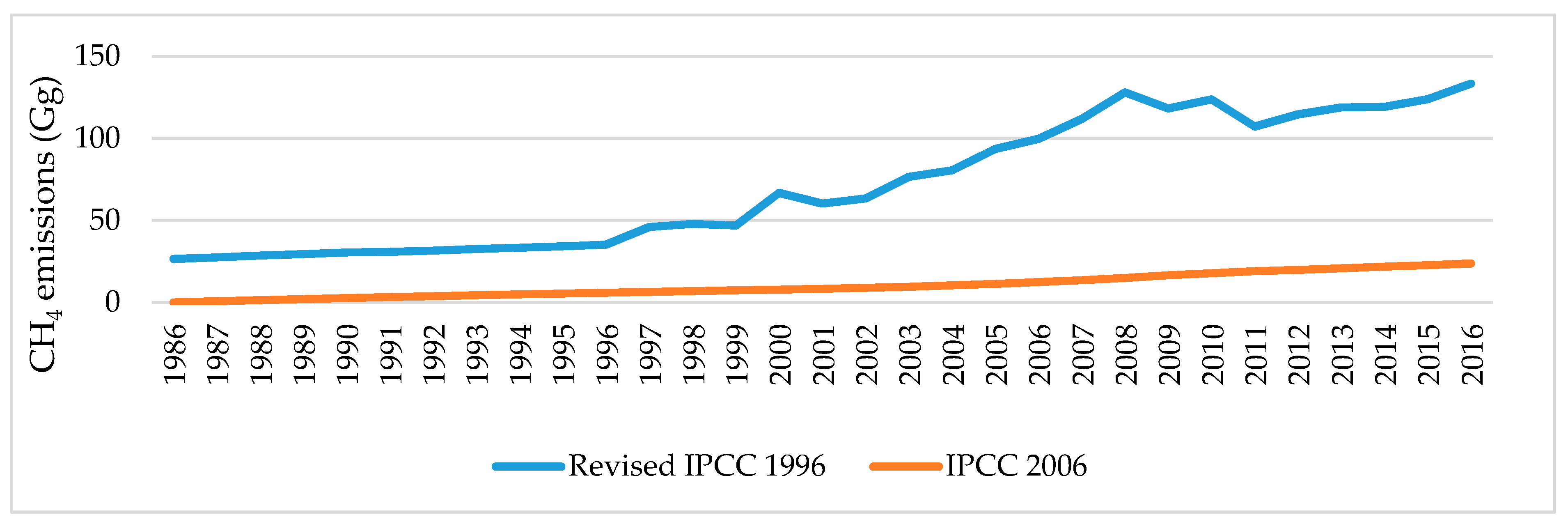

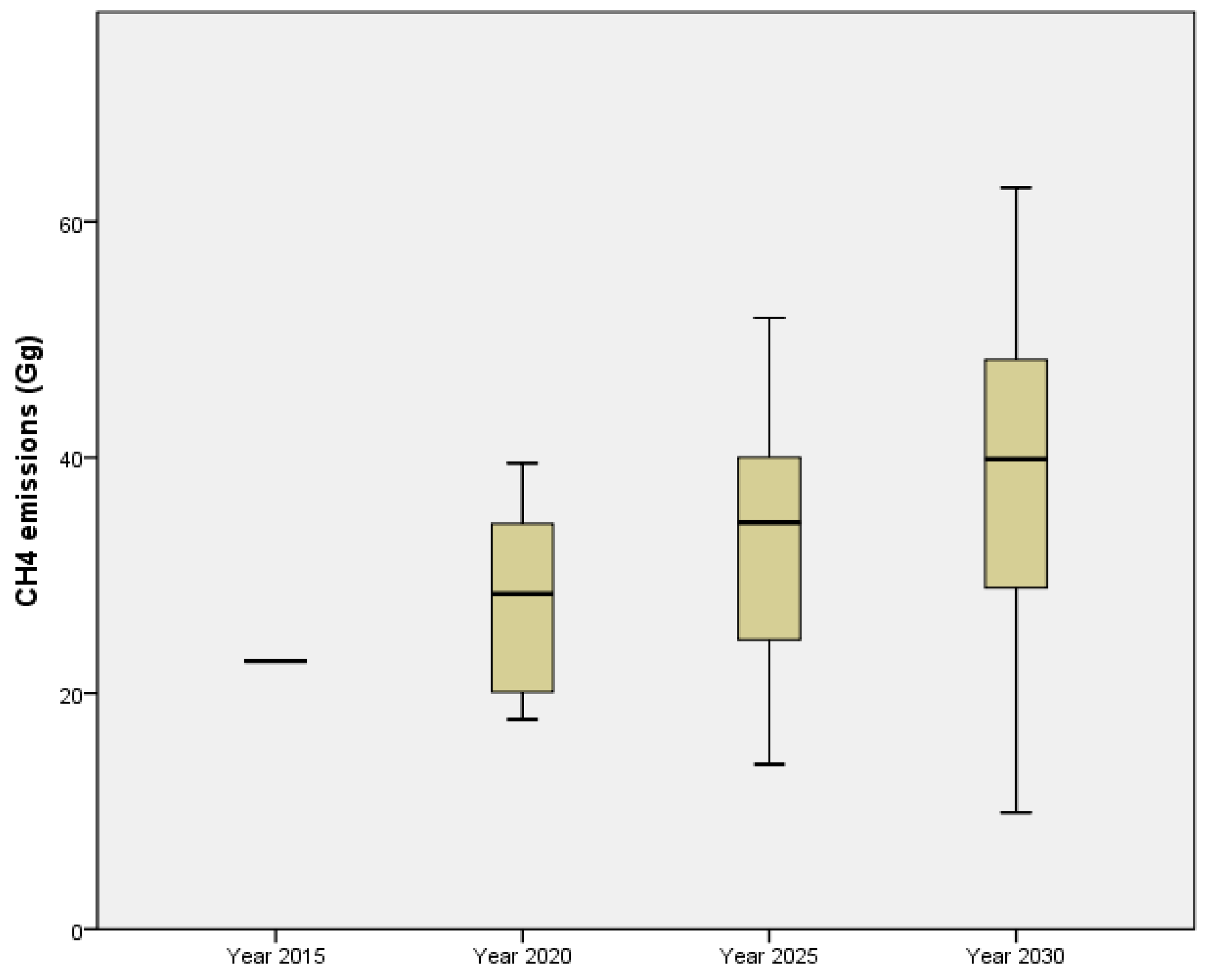

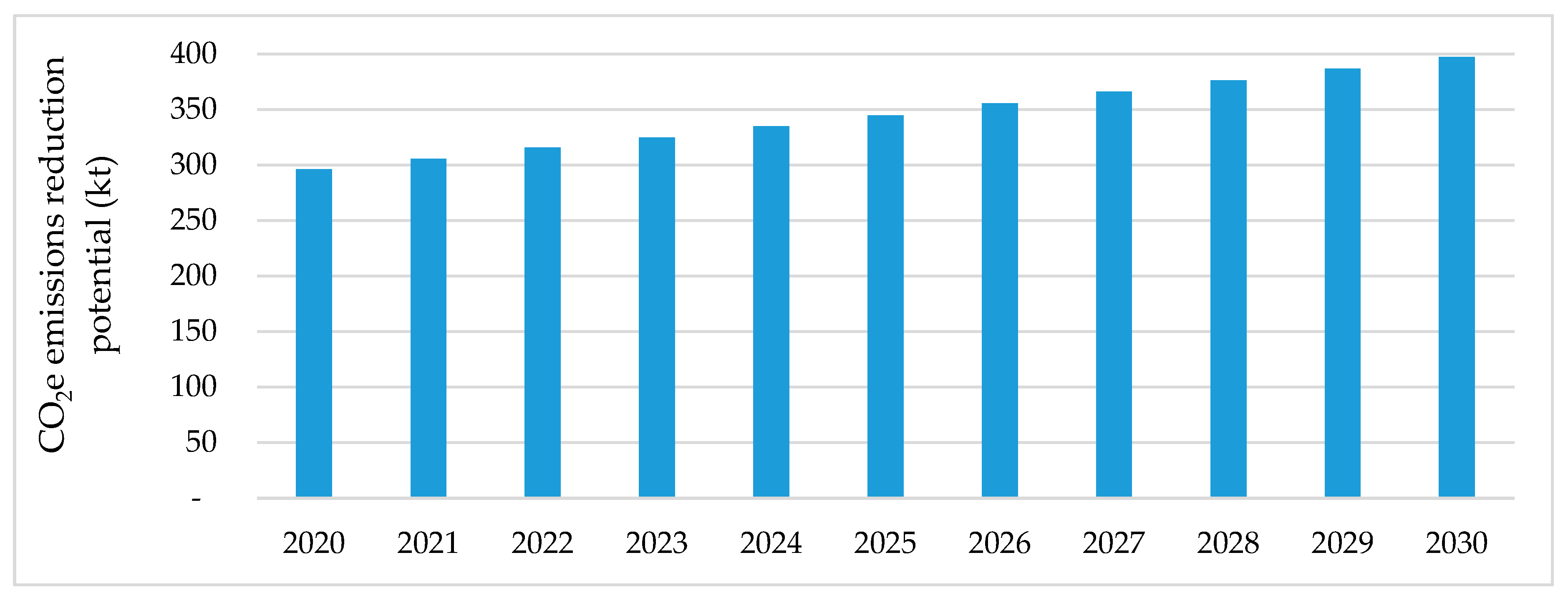

Adopting WtE technologies could contribute to a 400-kt CO

2e emissions reduction from MSW in Bahrain in 2030 (

Figure 15). The best WtE technology in terms of climate change mitigation is AD, with a potential for emissions reduction ranging between 0.2 and 0.41 t CO

2e per tonne of MSW [

6,

70].

Incineration has the highest capital, operating, and maintenance costs, and gasification the next highest (

Table 4). The total annual costs, including capital, operating, and maintenance costs, for the different WtE technologies were found to be 2–330 USD/t of MSW (

Table 4). Potential revenues from the electricity generated would decrease the total cost by 3–47 USD/t of MSW (

Table 4). Recovering landfill gas could be profitable, but the capital costs of incineration (in particular) and gasification would remain relatively high, indicating that funding would be required for such projects.

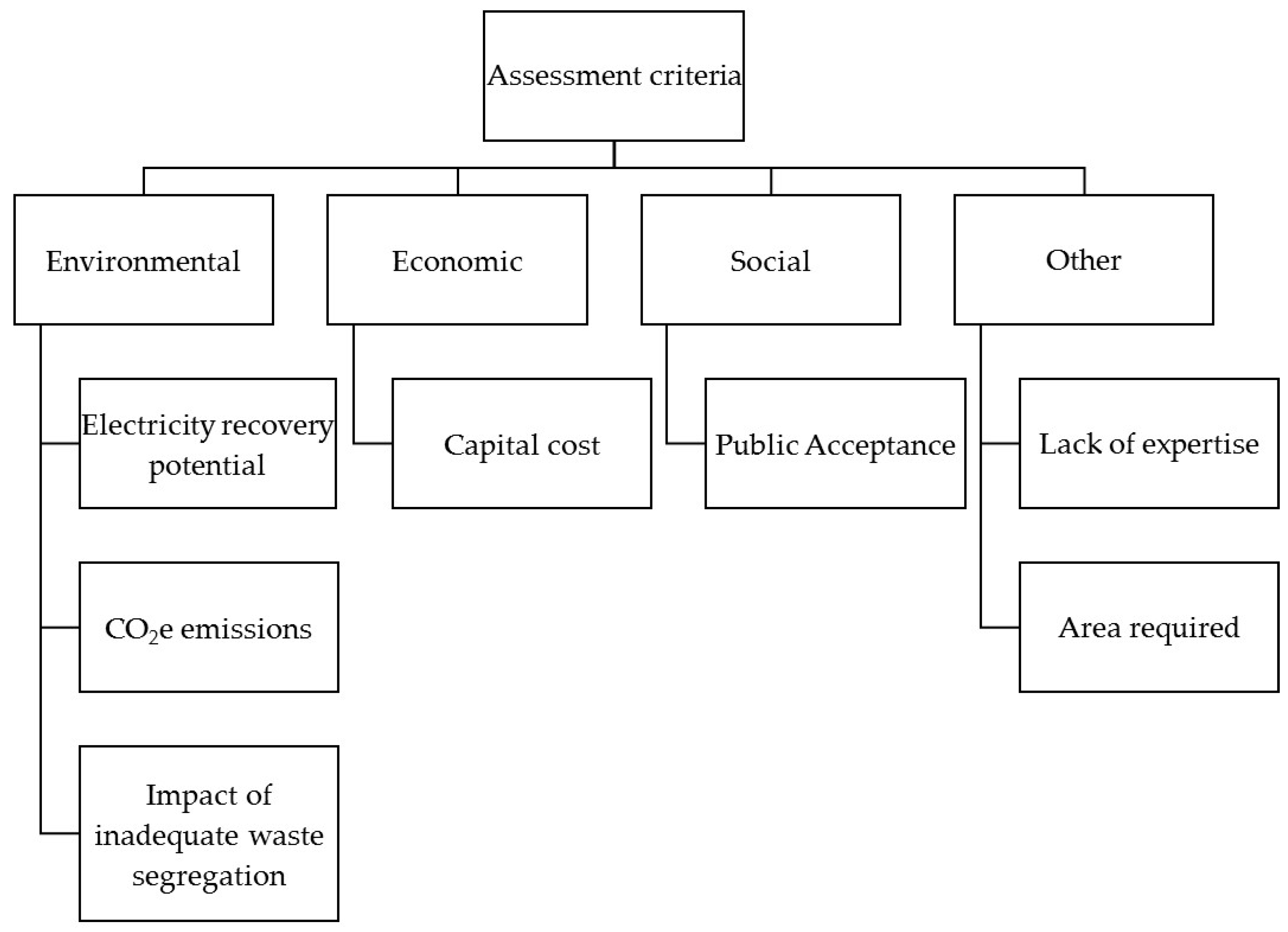

Four MCA models were built using the linear additive model and a simple MCA matrix method. These models differed in the assessment criteria and criteria weights (see

Section 3.2). The amounts of energy recovered, costs, and performances of the different WtE technologies based on selected assessment criteria were aggregated in the four MCA models. The first MCA model indicated that AD was the most appropriate WtE technology, with incineration and landfill gas recovery next and gasification the least appropriate (

Table 5). AD had high scores for most criteria but requires waste to be segregated and biogas to be treated before use. In contrast, incineration does not require waste to be segregated but does require a constant and stable supply of waste with a high calorific value (

Table 1). The second MCA model, using criteria weightings derived from Reference [

38], gave almost the same ranking order for the WtE technologies (Equations (13) and (14)). Equation (13) is an example equation for solving the second multiple criteria analysis model. The results of the second multiple criteria analysis model for the use of waste-to-energy technologies in Bahrain are presented in Equation (14).

The third and fourth MCA models were based on Reference [

14], in which a system for selecting WtE technologies for use in developing and emerging countries using 12 criteria was presented. The ranking orders were different from the ranking orders for the first two models. Recovering landfill gas was ranked top, then AD and incineration, and finally gasification (

Table 6). These results appeared to be reasonable because WtE technologies have not previously been used in Bahrain, so starting with the cheapest option (even though it has a relatively low energy recovery potential) would be sensible now or in the near future once the national waste management strategy has been fully implemented. The results of the four MCA models were aggregated, and the Friedman nonparametric test suggested that there were no statistically significant differences in the ranking orders for the WtE technologies. AD and landfill gas recovery were ranked highest, then incineration, and finally gasification (

Table 7). These results were consistent with the results of previous studies for Saudi Arabia and Oman, for which AD was also ranked top [

38,

43].

Comparing the WtE technologies by performing MCAs allowed for several quantitative and qualitative assessment criteria to be taken into consideration. The assessment criteria selected strongly affected the ranking order. Ensuring that all of the relevant criteria were selected was therefore important to assessing the performances, strengths, and weaknesses of WtE technologies. However, selecting the most appropriate WtE technology is not easy, because it is important to minimize negative impacts on the environment [

38].

There are several challenges to the use of WtE in Bahrain. The first is the energy content and composition of MSW. Waste with a high moisture content, e.g., food waste, can negatively affect incineration and gasification by causing the energy recovery potential to be low [

21,

22,

71]. MSW with a lower heating value (LHV) of less than 3.15 MJ/kg can give very low electricity generation efficiencies for incinerators (mean 22%), and some of the electricity generated will be consumed by certain processes within an incinerator. This means that if most paper and plastic waste in Bahrain is recycled, the electricity generation potential of MSW could be low [

82]. This is because plastic waste and paper waste are good fuels for WtE incinerators [

14,

21]. This means that all waste recycling plans must be considered before deciding whether MSW should be incinerated.

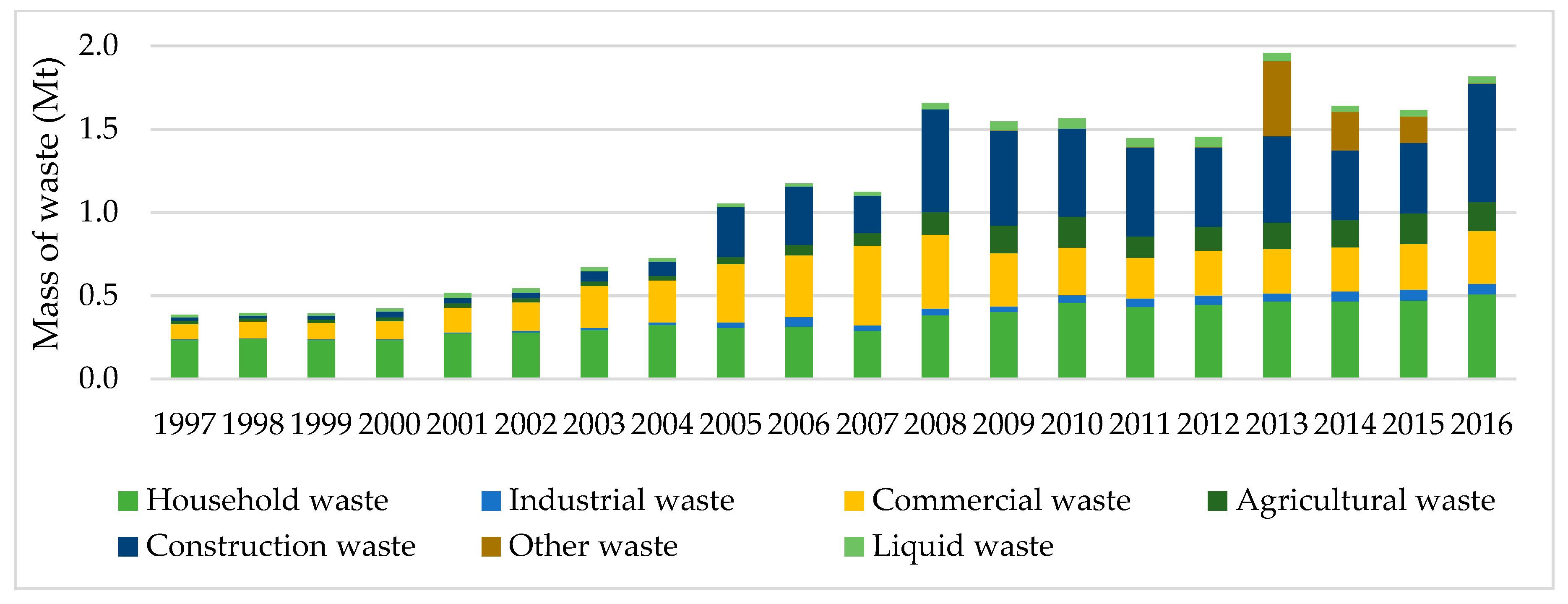

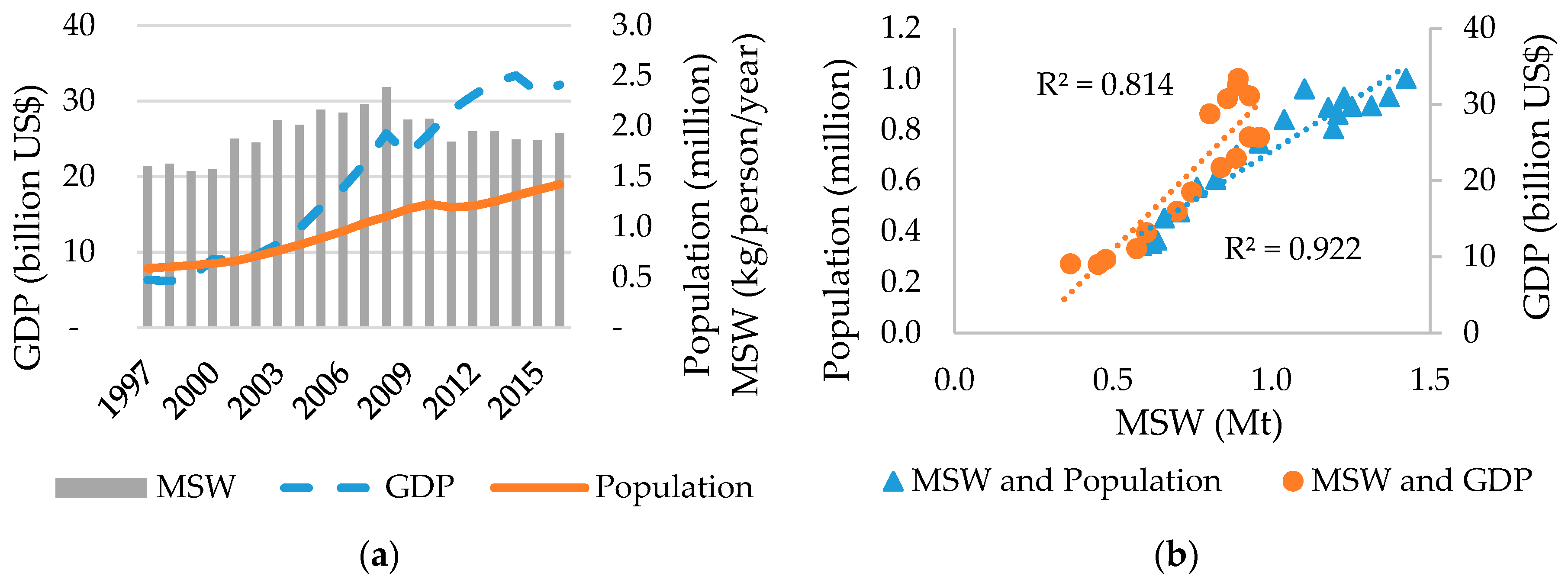

The second challenge is related to waste production being stable enough to ensure energy can be recovered effectively. Waste production stability is perceived to be a barrier in many countries [

71]. There is an alarming trend in Bahrain. The total amount of waste produced in the Capital Governorate decreased by 23% in the first quarter of 2019. This could have been caused by waste awareness campaigns or the implementation of a new value-added tariff. This decrease in MSW production will affect the cost effectiveness and energy recovery potential of WtE technologies. Other factors could also affect the waste production stability. For example, campaigns to distribute food waste and campaigns to decrease plastic use could affect MSW production stability. All future campaigns and changes in reuse and recycling activities must be considered when planning the use of WtE technologies in Bahrain.

Another potential challenge is controlling air pollution and ensuring that toxic flue gases (e.g., polychlorinated dibenzo-

p-dioxins and dibenzofurans) are removed [

22,

71]. This is not an issue in the EU because of strict laws and the use of advanced technologies. Polychlorinated dibenzo-

p-dioxin, dibenzofuran, and particulate matter (PM

10) emissions during WtE incineration are minimal in the EU in both absolute terms and in terms of the contributions of such emissions to total emissions [

83]. Although flue gas emissions for the best available technologies are low, they are close to flue gas emissions limits in the EU [

17]. Complying with strict emissions limits increases construction costs [

83]. Emissions during incineration are not controlled effectively in many developing countries because of the high costs involved [

7].

The cost of investing in WtE technologies is relatively high compared to the costs involved in conventional and renewable energy sources. WtE technologies have been estimated to cost 1700–2000 USD/kW to install, whereas natural gas combined cycle systems cost 450–1500 USD/kW to install, photovoltaic systems are 900–1500 USD/kW to install, and onshore wind turbines are 1100–1500 USD/kW to install [

84]. The capital cost may be perceived to be an obstacle in Bahrain, particularly because a “fiscal balance program” has been implemented for 2019–2022. The annual budget for projects was 530 × 10

6 USD in the recently approved state budget for the fiscal years 2019–2020. Previously published capital costs have ranged from 6 × 10

6 to 207 × 10

6 USD (

Table 4), but the actual costs for similar projects in other GCC countries have been much higher (

Table 2) and have been close to or higher than the annual budget for projects in Bahrain. Establishing similar projects in Bahrain in this period will therefore need to be strongly justified, if such a project is to be financed by the government, to ensure that the three pillars of sustainable development (society, economy, and environment) are considered.

There are two main justifications for financing WtE projects in Bahrain: to contribute to achieving the renewable energy targets of 5% by 2025 and 10% by 2035 or to decrease CO2e emissions. The capital costs of other types of renewable energy in Bahrain range from 11 × 106 USD for offshore wind to 115 × 106 USD for solar energy. WtE technologies cost considerably more. The electricity generation potentials for WtE technologies in Bahrain are very sensitive to several factors, making it difficult to guarantee the generation of large amounts of electricity. WtE incinerators have the highest electricity generation potential, but the capacity of WtE incinerators would be ~100 MW, which is only 14% of the renewable energy goal, and the cost would be higher than, for example, solar energy. In terms of using WtE technologies to decrease CO2e emissions, the share the waste sector could contribute to decreasing total national emissions will be relatively low, making it logical to target emissions from other sectors.

One last justification for using WtE technologies could be valid. This is decreasing the area required for landfills if current economic, social, and environmental conditions are assumed to be valid in the future. Bahrain has limited areas available for landfills, so it would be wise to decrease the area required for MSW. However, there may be other ways of achieving this, such as by exporting MSW to neighboring countries with WtE plants but insufficient MSW. Nonetheless, there are several international funding opportunities for developing WtE plants, including the “Green Climate Fund” and the “Nationally Appropriate Mitigation Actions (NAMA) facility” [

73].

Despite the challenges, it is imperative to ensure public participation throughout a WtE project to ensure success [

17]. Public approval must be obtained before construction of a WtE plant because of environmental concerns. Public objections to WtE plants have caused many projects around the world to be terminated or delayed [

45].

The challenges to establishing WtE plants (described above) have been addressed in many studies performed worldwide. In general, WtE technologies are supported in many developing countries, but there is a growing trend against incineration in some developed countries. For example, some nongovernmental organizations in the EU have argued that incineration closes the material loop and does not encourage recycling. The European Commission has suggested that the waste hierarchy should be used as a guideline and that an incineration plant should not be constructed unless there is a guaranteed feedstock for the lifetime of the plant, taking recycling obligations into consideration. On the other hand, some people perceive waste to be a source of renewable energy that can help countries meet their renewable energy goals [

85].

The findings of this paper suggest several policy implications for Bahrain, as follows:

Although the national waste strategy suggests that Estidama is responsible for data collection, it is imperative to provide data and indicators related to waste in Bahrain. Such data are not only missing in Bahrain but also in some other countries in the GCC [

40];

Set targets for waste recycling and WtE and ensure collaboration with stakeholders;

Ensure consistency in waste-relevant policies among different stakeholders;

Encourage the reduction, reuse, and recycling of waste before disposal, which contributes to climate change mitigation;

Emphasize the need to adopt a participatory approach to waste management in Bahrain.

It is recommended for Bahrain and perhaps for other areas with similar circumstances that an understanding of how the fiscal balance program influences the quantity and characteristics of MSW be gained before decisions about establishing WtE plants are made. It is recommended that Bahrain wait until 2021 to make such decisions because WtE plants in other GCC countries will start operating at that time. This will allow the performances of those plants to be assessed and the energy recovery potentials in the ex ante assessments to be compared to the actual electricity production values in ex post assessments.