Prototyping and Validation of MEMS Accelerometers for Structural Health Monitoring—The Case Study of the Pietratagliata Cable-Stayed Bridge

Abstract

1. Introduction, State-of-the-Art and Objectives

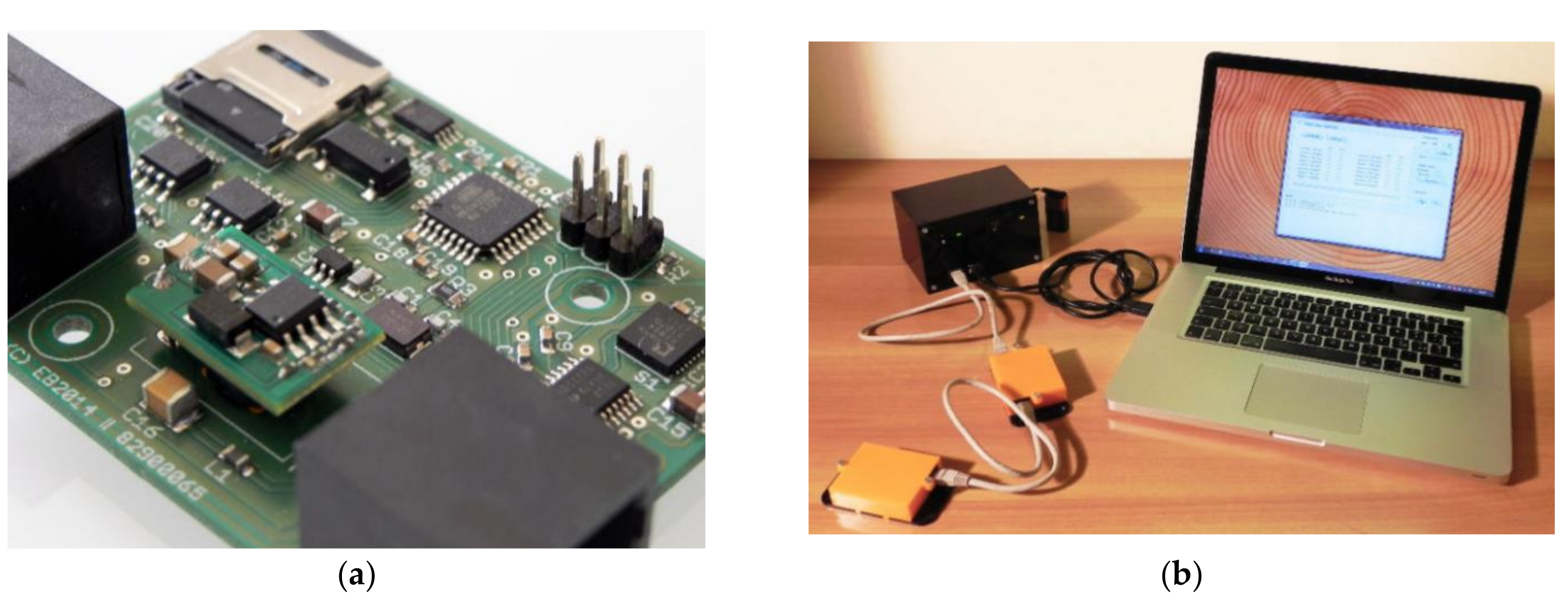

2. Measuring Devices

- (i)

- a logic unit, programmed with the synchronisation and recording routines;

- (ii)

- an accelerometer;

- (iii)

- an Analogue-to-Digital Converter (ADC);

- (iv)

- a micro SD memory card, to store the recorded data;

- (v)

- a real-time clock, to keep the synchronisation between the devices consistent.

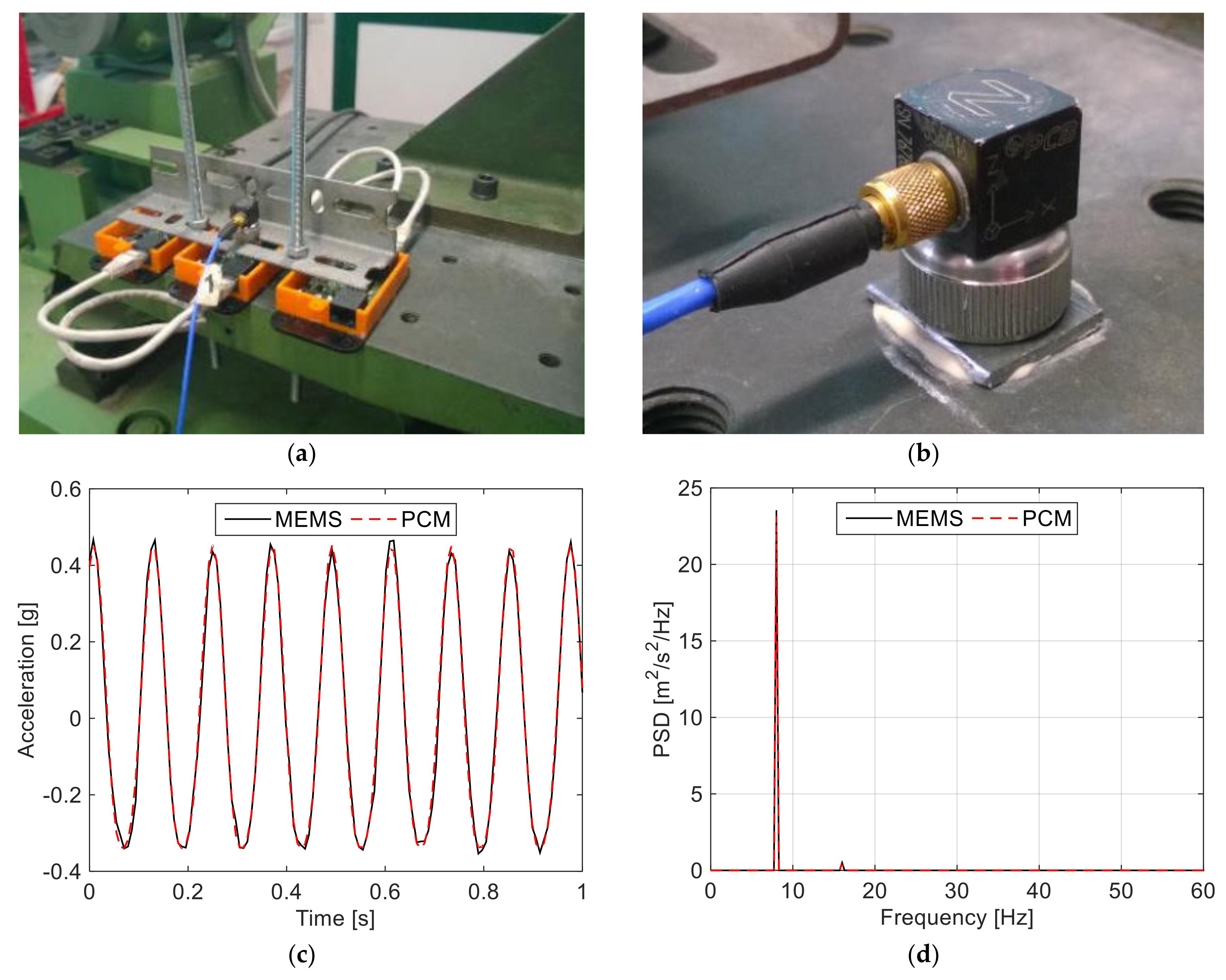

3. Laboratory Testing and Validation

3.1. Shaking Table Testing

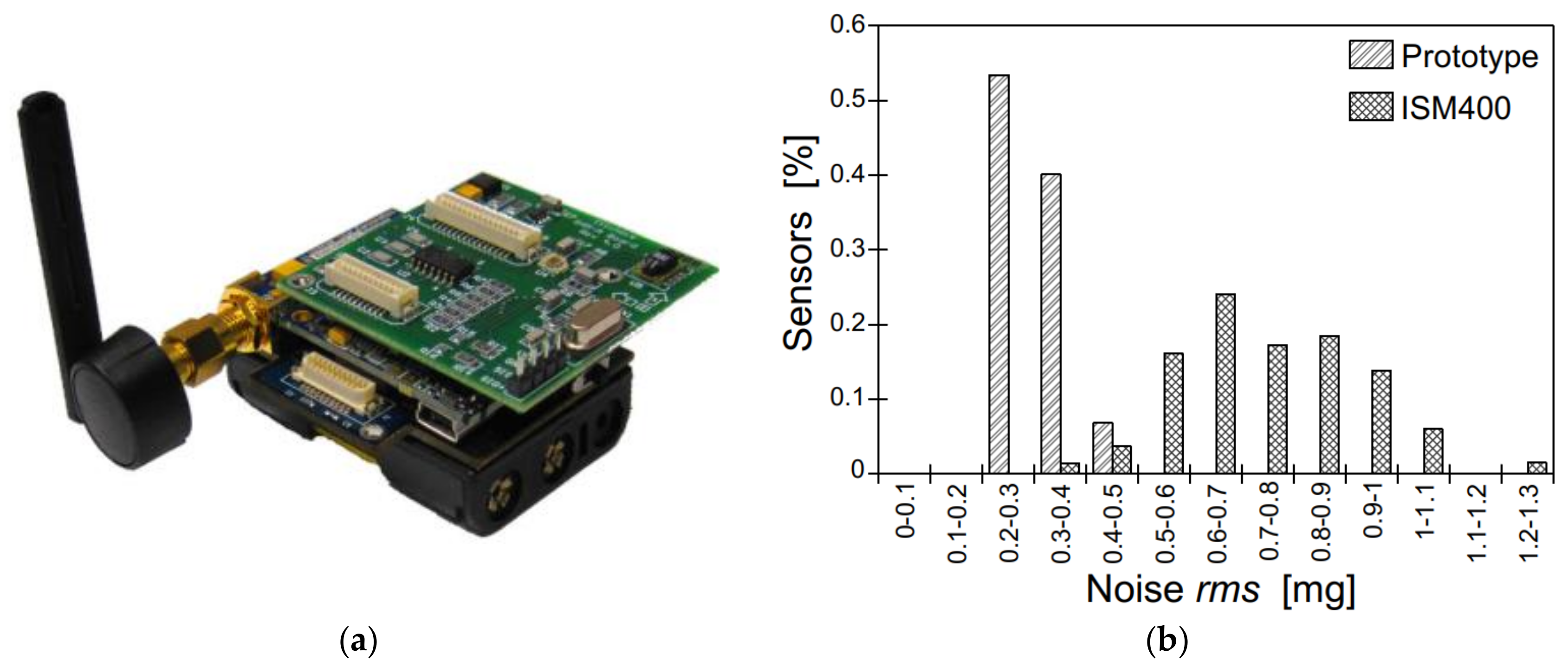

3.2. Noise Level Assessment

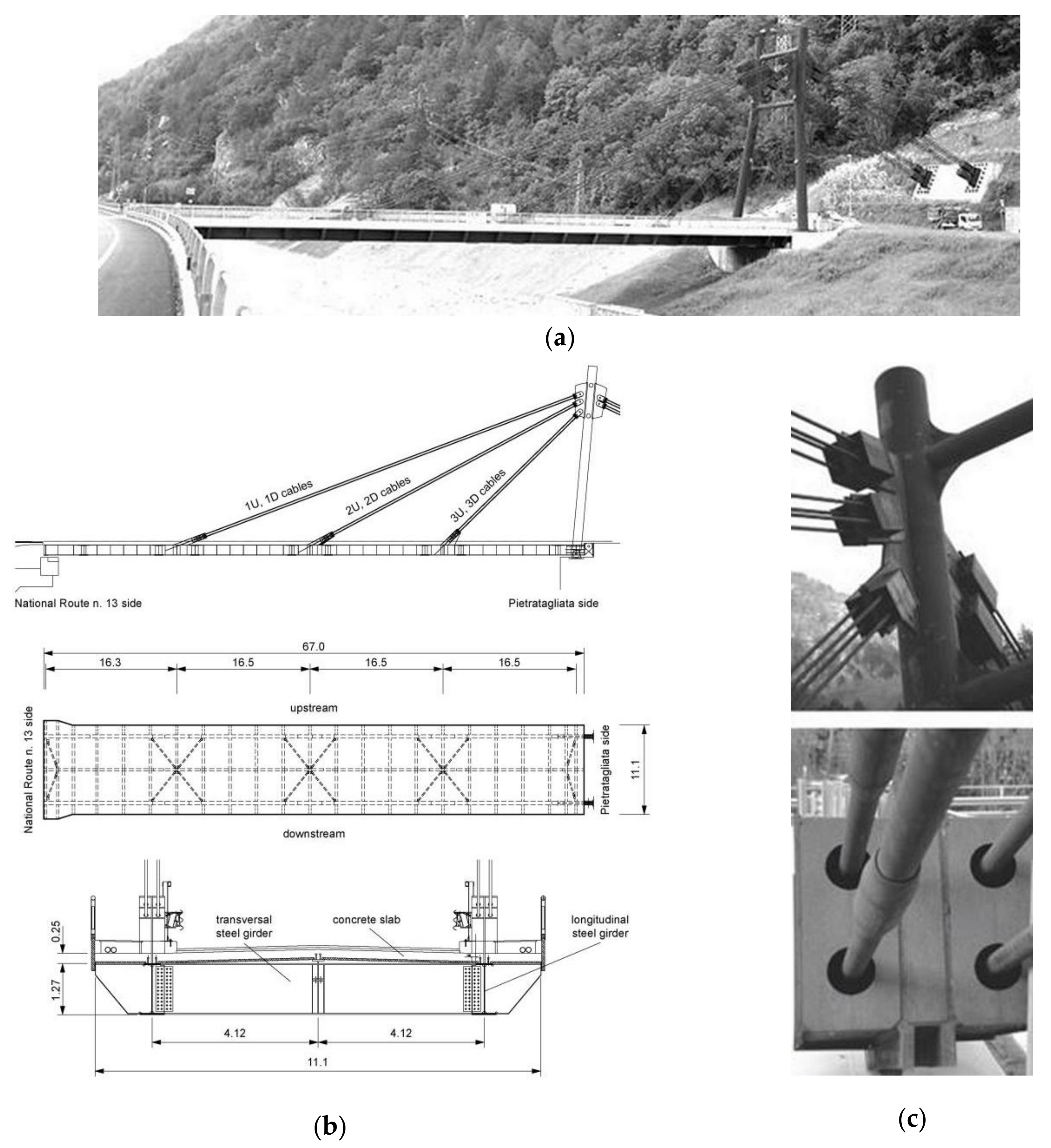

4. Dynamic Identification of the Pietratagliata Cable-Stayed Bridge

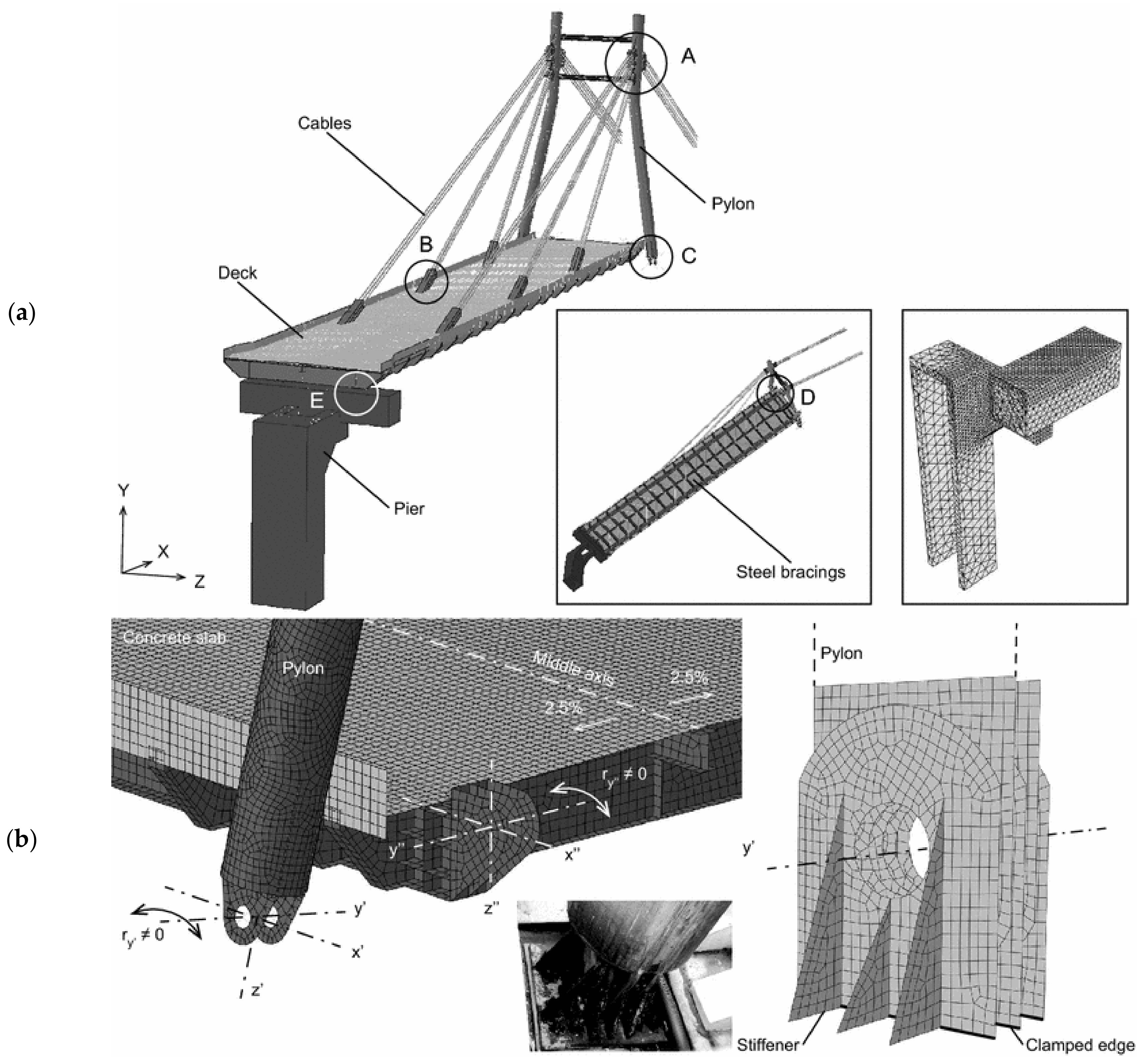

4.1. The Case-Study Bridge

4.2. On-Site Experimental Testing and Dynamic Identification

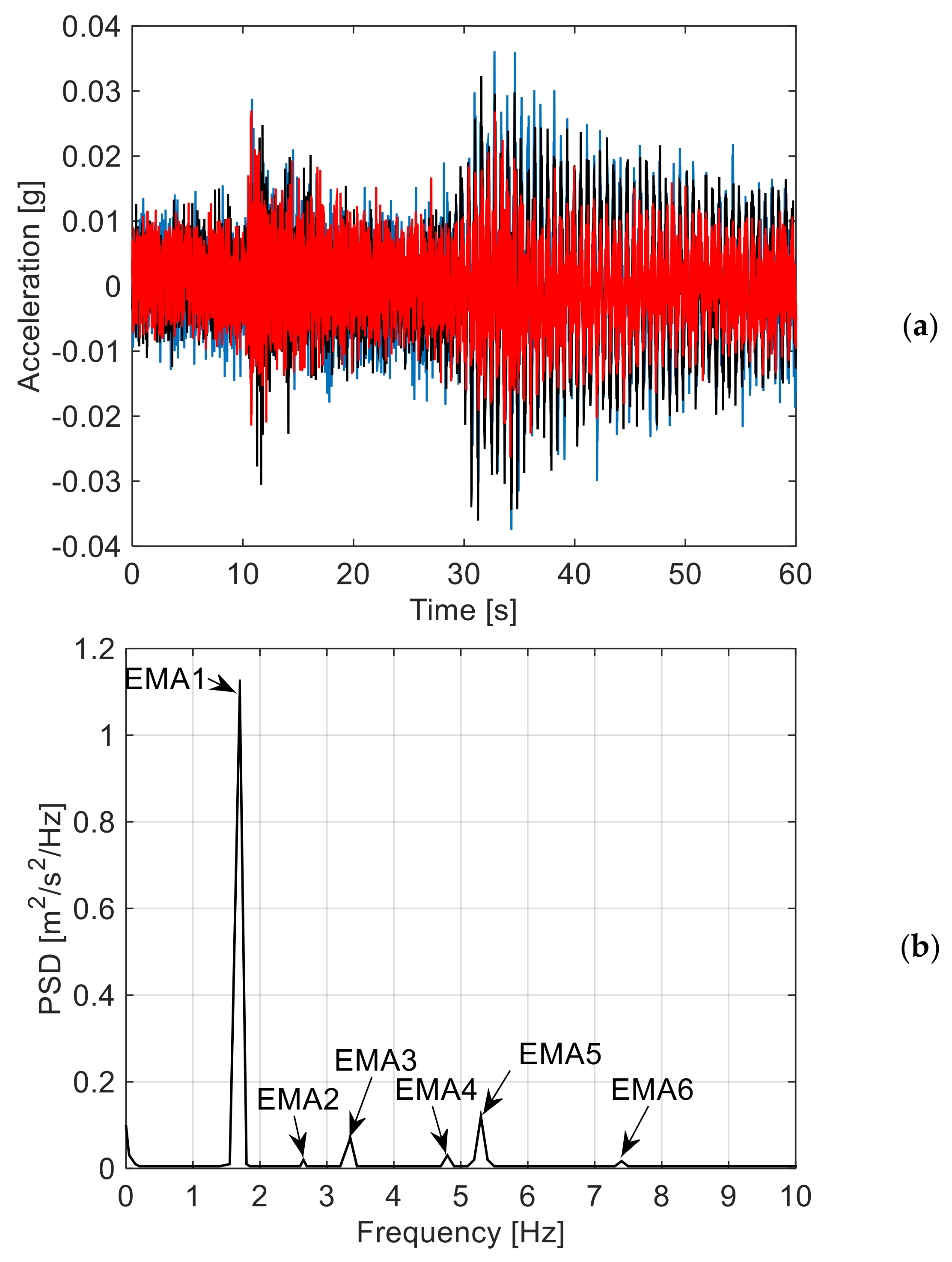

4.2.1. Summary of Past EMA and FEA Predictions

4.2.2. MEMS Experiments: Test Methods and Setup

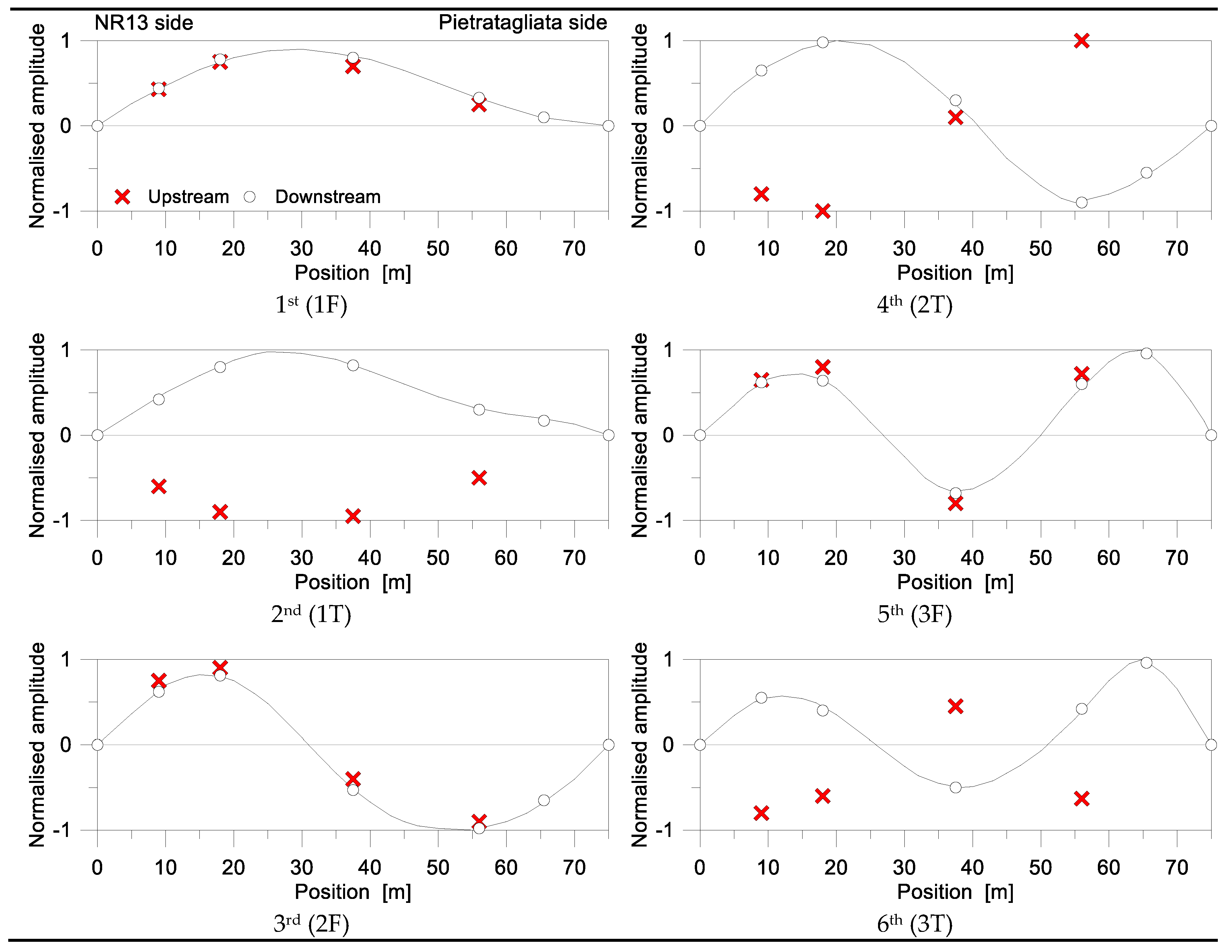

4.2.3. Vibration Modes and Modal Correlation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EN 1991. Eurocode 1: Actions on Structures. European Standard. European Committee for Standardization (CEN): Brussels, Belgium, 2010. Available online: http://www.phd.eng.br/wp-content/uploads/2015/12/en.1991.1.4.2005.pdf (accessed on 27 July 2018).

- Nakano, Y.; Maeda, M.; Kuramoto, H.; Murakami, M. Guideline for post-earthquake damage evaluation and rehabilitation of RC buildings in Japan. In Proceedings of the 13th WCEE World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Xue, Q.; Chen, C.C.; Chen, K.C. Damage loss assessment for the basic earthquake insurance claim of residential RC buildings in Taiwan. J. Build. Apprais. 2011, 6, 213–226. [Google Scholar] [CrossRef]

- Pozzi, M.; Zonta, D.; Trapani, D.; Athanasopoulos, N.; Amditis, A.J.; Bimpas, M.; Garetsos, A.; Stratakos, Y.E.; Ulieru, D. MEMS-based sensors for post-earthquake damage assessment. J. Phys. Conf. Ser. 2011, 305, 012100. [Google Scholar] [CrossRef]

- Menderes, A.; Erener, A.; Sarp, G. Automatic Detection of Damaged Buildings after Earthquake Hazard by Using Remote Sensing and Information Technologies. Procedia Earth Planet. Sci. 2015, 15, 257–262. [Google Scholar] [CrossRef]

- Ubertini, F.; Comanducci, G.; Cavalagli, N. Vibration-based structural health monitoring of a historic bell-tower using output-only measurements and multivariate statistical analysis. Struct. Health Environ 2016, 15, 438–457. [Google Scholar] [CrossRef]

- Di Tommaso, A.; Gentilini, C.; Castellazzi, G. Structural Interpretation of Data from Static and Dynamic Structural Health Monitoring of Monumental Buildings. Key Eng. Mater. 2017, 747, 431–439. [Google Scholar]

- Ramos, L.; Marques, L.; Lourenço, P.; De Roeck, G.; Campos-Costa, A.; Roque, J. Monitoring historical masonry structures with operational modal analysis: Two case studies. Mech. Syst. Sig. Process. 2010, 24, 1291–1305. [Google Scholar] [CrossRef]

- Jouan, B.; Rudolph, J.; Bergholz, S. Structural Health Monitoring Solutions for Power Plants. In Proceedings of the EWSHM—7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014; pp. 623–630. [Google Scholar]

- Lemu, H.G. Assessment and analysis of structural health monitoring techniques for rotating machines. In Proceedings of the 27th International Ocean and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017. [Google Scholar]

- Schubert, F.; Frankenstein, B.; Fröhlich, K.J.; Kuttner, M.; Lamek, B.; Schwenkkros, J.; Kerkhof, K.; Petricevic, R. Structural Health Monitoring of Industrial Piping Systems Based on Guided Elastic Waves. DGZfP 2007, 32, 14–16. Available online: https://pdfs.semanticscholar.org/05e1/ed16583d17c76793c3a65bec592b91ffad15.pdf (accessed on 26 July 2018).

- Giglio, M.; Manes, A.; Sbarufatti, C. MEMS for structural health monitoring in aircraft. In MEMS for Automotive and Aerospace Applications; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2013; pp. 220–244. ISBN 978-0-85709-118-5. [Google Scholar]

- Giurgiutiu, V. Structural Health Monitoring (SHM) of aerospace components. In Polymer Composites in the Aerospace Industry; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2015; pp. 449–507. ISBN 978-0-85709-523-7. [Google Scholar]

- Mecocci, A.; Peruzzi, G.; Pozzebon, A.; Vaccarella, P. Architecture of a hydroelectrically powered wireless sensor node for underground environmental monitoring. IET Wirel. Sens. Syst. 2017, 7, 123–129. [Google Scholar] [CrossRef]

- Bennet, P.; Soga, K.; Wassel, I.; Fidler, P.; Abe, K.; Kobayashi, Y.; Vanicek, M. Wireless sensor network for underground railway applications: Case studies in Prague and London. Smart Struct. Syst. 2010, 6, 619–639. [Google Scholar] [CrossRef]

- Cochran, E.S.; Lawrence, J.F.; Kaiser, A.; Fry, B.; Chung, A.; Christensen, C. Comparison between low-cost and traditional MEMS accelerometers: A case study from the M7.1 Darfield, New Zealand, aftershock deployment. Ann. Geophys. 2011, 54, 728–737. [Google Scholar]

- Evans, J.R.; Allen, R.M.; Chung, A.I.; Cochran, E.S.; Guy, R.; Hellweg, M.; Lawrence, J.F. Performance of Several Low-Cost Accelerometers. Seismol. Res. Lett. 2014, 85, 147–158. [Google Scholar] [CrossRef]

- Cigada, A.; Lurati, M.; Redaelli, M.; Vanali, M. Mechanical performance and metrological characterization of MEMS accelerometers and application in modal analysis. In Proceedings of the IMAC XXV International Modal Analysis Conference, Orlando, FL, USA, 19–22 February 2007; pp. 236–244. [Google Scholar]

- Sun, Z.; Chen, D.; Chen, J.; Deng, T.; Li, G.; Xu, C.; Wang, J. A MEMS based electrochemical seismometer with low cost and wide working bandwidth. Procedia Eng. 2016, 168, 806–809. [Google Scholar] [CrossRef]

- Benevicius, V.; Ostasevicius, V.; Gaidys, R. Identification of capacitive MEMS accelerometer structure parameters for human body dynamics measurements. Sensors 2013, 13, 11184–11195. [Google Scholar] [CrossRef] [PubMed]

- Ciuti, G.; Ricotti, L.; Menciassi, A.; Dario, P. MEMS Sensor Technologies for Human Centred Applications in Healthcare Physical Activities, Safety and Environmental Sensing: A Review on Research Activities in Italy. Sensors 2015, 153, 6441–6468. [Google Scholar] [CrossRef] [PubMed]

- Chaudhury, S.B.; Sengupta, M.; Mukherjee, K. Vibration Monitoring of Rotating Machines Using MEMS Accelerometer. Int. J. Sci. Eng. Res. 2014, 2, J2013358. [Google Scholar]

- Jimenez, S.; Cole, M.O.T.; Keogh, P.S. Vibration sensing in smart machine rotors using internal MEMS accelerometers. J. Sound Vib. 2016, 377, 68–75. [Google Scholar] [CrossRef]

- Pedotti, L.A.S.; Zago, R.M.; Fruett, F. Instrument based on MEMS accelerometer for vibration and unbalance analysis in rotating machines. In Proceedings of the 1st INSCIT—International Symposium on Instrumentation Systems, Circuits and Transducers, Belo Horizonte, Brazil, 29 August–3 September 2016; pp. 25–30. [Google Scholar] [CrossRef]

- Son, J.-D.; Ahn, B.-H.; Ha, J.-M.; Choi, B.-K. An availability of MEMS-based accelerometers and current sensors in machinery fault diagnosis. Measurement 2016, 94, 680–691. [Google Scholar] [CrossRef]

- Bassoli, E.; Vincenzi, L.; Bovo, M.; Mazzotti, C. Dynamic identification of an ancient masonry bell tower using MEMS-based acquisition system. In Proceedings of the 2015 EESMS Workshop on Environmental, Energy and Structural Monitoring Systems, Trento, Italy, 9–10 July 2015. Paper number 15347414. [Google Scholar] [CrossRef]

- Clementi, F.; Pierdicca, A.; Milani, G.; Gazzani, V.; Poiani, M.; Lenci, S. Numerical model upgrading of ancient bell towers monitored with a wired sensor network. In Proceedings of the 10th International Masonry Conference (IMC), Milan, Italy, 9–11 July 2018. [Google Scholar]

- Feng, M.; Fukuda, Y.; Mizuta, M.; Ozer, E. Citizen Sensors for SHM: Use of Accelerometer Data from Smartphones. Sensors 2015, 15, 2980–2998. [Google Scholar] [CrossRef] [PubMed]

- Wargantiwar, N.K.; Barbade, A.S.; Shingade, A.P.; Shire, A.N. Wireless Earthquake Alarm Design based on MEMS Accelerometer. Int. Adv. Res. J. Sci. Eng. Technol. 2017, 4, 128–132. [Google Scholar]

- Kok, R.; Furlong, C.; Putniewicz, R.J. Development of a Wireless MEMS Inertial System for Health Monitoring of Structures. In Materials Research Society Symposium Proceedings; Cambridge University Press: Cambridge, UK, 2003; Volume 785. [Google Scholar] [CrossRef]

- Jung, J.W.; Moon, D.J.; Jung, J.W.; Lee, B.L.; Lee, S.J. A performance test of a 3-axis accelerometer and modal analysis. In Proceedings of the FIG Congress 2014—Engaging the Challenges, Enhancing the Relevance, Kuala Lumpur, Malaysia, 16–21 June 2014. [Google Scholar]

- Rajashri, P.P.; Chaudhari, V.D.; Rane, K.P. ARM based 3-axis seismic data acquisition system using Accelerometer sensor and Graphical User Interface. Int. J. Eng. Res. Gen. Sci. 2015, 3, 833–838. [Google Scholar]

- Beskhyroun, S.; Ma, Q. Low-Cost Accelerometers for Experimental Modal Analysis. In Proceedings of the 15th WCEE—World Conference in Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012; Available online: http://www.iitk.ac.in/nicee/wcee/article/WCEE2012_0771.pdf (accessed on 26 July 2018).

- Spencer, B.F.; Ruiz-Sandoval, M.; Kurata, N. Smart sensing technology for structural health monitoring. In Proceedings of the 13th WCEE—World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Torfs, T.; Sterken, T.; Brebels, S.; Santana, J.; van den Hoven, R.; Spiering, V.; Bertsch, N.; Trapani, D.; Zonta, D. Low Power Wireless Sensor Network for Building Monitoring. IEEE Sensors J. 2013, 13, 909–915. [Google Scholar] [CrossRef]

- Renjan Raj, V.C. Wireless Sensor Network for Building Monitoring. Int. J. Eng. Sci. 2014, 3, 13–18. [Google Scholar]

- Pradeepkumar, N.J.; Ramesh, R.M.; Shalini, K.S.; Sujatha, H.R.; Hemanth Kumar, C.S. Smart System Sensor Network for Building Monitoring. SSRG IJECE 2015, 2, 116–121. [Google Scholar]

- Picozzi, M.C.; Milkereit, C.; Zulfikar, C.; Fleming, K.; Ditommaso, R.; Erdik, M.; Zschau, J.; Fischer, J.; Safak, E.; Ozel, O.; et al. Wireless technologies for the monitoring of strategic infrastructures: An ambient vibration test on the Fatih Sultan Mehmet suspension bridge in Istanbul, Turkey. Bull. Earthq. Eng. 2009, 8, 671–691. [Google Scholar] [CrossRef]

- Domaneschi, M.; Limongelli, M.P.; Martinelli, L. Structural damage localization in a suspension bridge under seismic excitation. In Proceedings of the 15th WCEE Conference—World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Domaneschi, M.; Limongelli, M.P.; Martinelli, L. Interpolation damage detection method on a suspension bridge model: influence of sensors disturbances. Key Eng. Mater. 2013, 569–570, 734–741. [Google Scholar] [CrossRef]

- Dashti, S.; Bray, J.D.; Reilly, J.; Glaser, S.; Bayen, A. iShake: The Reliability of Phones as Seismic Sensors. In Proceedings of the World Conference Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- D’Alessandro, A.; D’Anna, G. Suitability of Low-Cost Three-Axis MEMS Accelerometers in Strong-Motion Seismology: Tests on the LIS331DLH (iPhone) Accelerometer. Bull. Seismol. Soc. Am. 2013, 103, 2906–2913. [Google Scholar] [CrossRef]

- Kong, Q.; Allen, R.M.; Schreier, L.; Kwon, Y.-W. MyShake: A smartphone seismic network for earthquake early warning and beyond. Sci. Adv. 2016, 2. [Google Scholar] [CrossRef] [PubMed]

- Bedon, C.; Dilena, M.; Morassi, A. Ambient vibration testing and structural identification of a cable-stayed bridge. Meccanica 2016, 51, 2777–2796. [Google Scholar] [CrossRef]

- Rice, J.A.; Spencer, B.F. Flexible Smart Sensor Framework for Autonomous Full-Scale Structural Health Monitoring. NSEL Report Series, Report n. NSEL-018, August 2009. Available online: https://core.ac.uk/download/pdf/4822684.pdf (accessed on 1 July 2018).

- Federici, F.; Alesii, R.; Colarieti, A.; Faccio, M.; Graziosi, F.; Gattulli, V.; Potenza, F. Design of Wireless Sensor Nodes for Structural Health Monitoring Applications. Procedia Eng. 2014, 87, 1298–1301. [Google Scholar] [CrossRef]

- Gattulli, V.; Graziosi, F.; Federici, F.; Potenza, F.; Colarieti, A. Structural Health Monitoring of the Basilica S. Maria di Collemaggio. In Proceedings of the 5th International Conference on Structural Engineering, Cape Town, South Africa, 2–4 September 2013. [Google Scholar]

- Antonacci, E.; Ceci, A.; Colarieti, V.; Gattulli, V.; Graziosi, F.; Lepidi, M.; Potenza, F. Dynamic testing and health monitoring via wireless sensor networks in the post-earthquake assessment of structural condition at L’Aquila. In Proceedings of the Eurodyn 2011—8th European Conference on Structural Dynamics, Leuven, Belgium, 4–6 July 2011; pp. 2440–2447. [Google Scholar]

- ISM400—Multimetric Imote2 Sensor Board—Datasheet and User’s Guide. Available online: http://shm.cs.uiuc.edu (accessed on 1 July 2018).

- ABAQUS Computer Software; Simulia: Johnston, RI, USA, 2018.

- SMIT. Available online: http://smit.atlss.lehigh.edu/?page_id=23 (accessed on 1 March 2018).

- Chang, M.; Leonard, R.L.; Pakzad, S.N. SMIT User’s Guide. Release 1.0, 2012. Available online: http://smit.atlss.lehigh.edu/wp-content/uploads/2012/07/SMIT-Users-Guide.pdf (accessed on 26 July 2018).

- Chang, M.; Pakzad, S.N. Observer Kalman Filter Identification for Output-Only Systems Using Interactive Structural Modal Identification Toolsuite. J. Bridge Eng. 2014, 19, 04014002. [Google Scholar] [CrossRef]

- Frizzarin, M.; Feng, M.Q.; Franchetti, P.; Soyoz, S.; Modena, C. Damage detection based on damping analysis of ambient vibration data. Struct. Control Health Monit. 2010, 17, 368–385. [Google Scholar] [CrossRef]

- Turek, M.E.; Bentura, C.E.; Shawwaf, K. Vibration testing of bridge stay cables to obtain damping values. Struct. Dyn. 2011, 3, 331–340. [Google Scholar]

- Gonzalez, A.; Obrien, E.J.; McGetrick, P.J. Identification of damping in a bridge using a moving instrumented vehicle. J. Sound Vib. 2012, 331, 4115–4131. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, Y.; Cao, F.; Zhou, Y.; Wang, S. Statistics and identification of mode-dependent structural damping of cable-supported bridges. In Proceedings of the APCWE-VIII—The 8th Asia-Pacific Conference on Wind Engineering, Chennai, India, 10–13 December 2013. [Google Scholar]

- Bedon, C.; Morassi, A. Dynamic testing and parameter identification of a base-isolated bridge. Eng. Struct. 2014, 60, 85–99. [Google Scholar] [CrossRef]

- Allemang, R.J.; Brown, D.L. A correlation Coefficient for Modal Vector Analysis. In Proceedings of the 1st International Modal Analysis (IMAC) Conference, Orlando, FL, USA, 8–10 November 1982; pp. 110–116. [Google Scholar]

- Allemang, R.J. The Modal Assurance Criterion—Twenty Years of Use and Abuse. Sound Vib. 2003, 37, 14–23. [Google Scholar]

- DDS. FEMtools Computer Software. Customer Support Documentations. Available online: www.femtools.com (accessed on 26 July 2018).

| Accelerometer: Kionix KXR94-2050 | ADC: Texas Instrument ADS1220 | ||

|---|---|---|---|

| Measurement axes | 3 | Type | Sigma-Delta |

| Measurement range | ±2 g | Resolution | 24 bit |

| Sensitivity | 0.66 V/g | Channels | 2 diff./4 single ended |

| Noise density | 45 µg/ | Data rate | 2000 SPS |

| Supply voltage | 3.3 V (typical) | Supply voltage | 3.3 V (typical) |

| Temperature range | from −40 °C to 85 °C | Temperature range | from −40 °C to 125 °C |

| Reference Axis | f (Hz) | ρX,Y | rmsX,Y | ||||

|---|---|---|---|---|---|---|---|

| S#1 | S#2 | S#3 | S#1 | S#2 | S#3 | ||

| Z | 5 | 0.9960 | 0.9950 | 0.9951 | 0.9942 | 0.9983 | 0.9916 |

| 8 | 0.9980 | 0.9971 | 0.9976 | 0.9938 | 0.9971 | 0.9920 | |

| 11 | 0.9989 | 0.9971 | 0.9987 | 0.9930 | 0.9960 | 0.9906 | |

| X | 5 | 0.9797 | 0.9795 | 0.9799 | 0.9652 | 0.9737 | 0.9789 |

| 8 | 0.9607 | 0.9609 | 0.9608 | 0.9615 | 0.9701 | 0.9755 | |

| 11 | 0.9515 | 0.9510 | 0.9519 | 0.9631 | 0.9714 | 0.9714 | |

| Y | 5 | 0.9809 | 0.9809 | 0.9806 | 0.9955 | 0.9959 | 0.9974 |

| 8 | 0.9628 | 0.9621 | 0.9625 | 0.9918 | 0.9924 | 0.9937 | |

| 11 | 0.9535 | 0.9533 | 0.9531 | 0.9888 | 0.9892 | 0.9905 | |

| Vibration Mode | f (Hz) | Δ (%) | ξ (%) | |||

|---|---|---|---|---|---|---|

| n° | Order/Type | MEMS | TEST0 | MEMS | TEST0 | |

| 1 | 1/F | 1.678 | 1.665 | 0.78 | 0.28 | 1.2 ± 0.5 |

| 2 | 1/T | 2.659 | 2.669 | −0.37 | 1.91 | 0.6 ± 0.5 |

| 3 | 2/F | 3.340 | 3.411 | −2.08 | 0.29 | 0.7 ± 0.2 |

| 4 | 2/T | 4.777 | 4.750 | 0.57 | 0.47 | 0.4 ± 0.0 |

| 5 | 3 / F | 5.307 | 5.261 | 0.87 | 0.39 | 0.7 ± 0.2 |

| 6 | 3 / T | 7.353 | 7.336 | 0.23 | 0.78 | 0.9 ± 0.2 |

| MEMS | EMA (MEMS)-to-FEA Modal Correlation | |||||

|---|---|---|---|---|---|---|

| Vibration Mode | MAC (Equation (5)) | fFEA | Δ | |||

| n° | Order/Type | fMEMS (Hz) | (%) | (Hz) | (%) | |

| 1 | 1/F | 1.678 | 99.7 |  | 1.619 | 3.64 |

| 2 | 1/T | 2.659 | 99.1 | 2.691 | −1.19 | |

| 3 | 2/F | 3.340 | 96.8 | 3.238 | 3.15 | |

| 4 | 2/T | 4.777 | 84.4 | 4.718 | 1.25 | |

| 5 | 3/F | 5.307 | 76.1 | 5.296 | 0.21 | |

| 6 | 3/T | 7.353 | 82.9 | 7.372 | −0.26 | |

| Mode # | EMA (MEMS, in Red)-to-FEA (Blue) Modal Correlation | FEA Modal Shape |

|---|---|---|

| 1st (1F) |  |  |

| 2nd (1T) |  |  |

| 3rd (2F) |  |  |

| 4th (2T) |  |  |

| 5th (3F) |  |  |

| 6th (3T) |  |  |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bedon, C.; Bergamo, E.; Izzi, M.; Noè, S. Prototyping and Validation of MEMS Accelerometers for Structural Health Monitoring—The Case Study of the Pietratagliata Cable-Stayed Bridge. J. Sens. Actuator Netw. 2018, 7, 30. https://doi.org/10.3390/jsan7030030

Bedon C, Bergamo E, Izzi M, Noè S. Prototyping and Validation of MEMS Accelerometers for Structural Health Monitoring—The Case Study of the Pietratagliata Cable-Stayed Bridge. Journal of Sensor and Actuator Networks. 2018; 7(3):30. https://doi.org/10.3390/jsan7030030

Chicago/Turabian StyleBedon, Chiara, Enrico Bergamo, Matteo Izzi, and Salvatore Noè. 2018. "Prototyping and Validation of MEMS Accelerometers for Structural Health Monitoring—The Case Study of the Pietratagliata Cable-Stayed Bridge" Journal of Sensor and Actuator Networks 7, no. 3: 30. https://doi.org/10.3390/jsan7030030

APA StyleBedon, C., Bergamo, E., Izzi, M., & Noè, S. (2018). Prototyping and Validation of MEMS Accelerometers for Structural Health Monitoring—The Case Study of the Pietratagliata Cable-Stayed Bridge. Journal of Sensor and Actuator Networks, 7(3), 30. https://doi.org/10.3390/jsan7030030