Machine Learning Enabled Food Contamination Detection Using RFID and Internet of Things System

Abstract

:1. Introduction

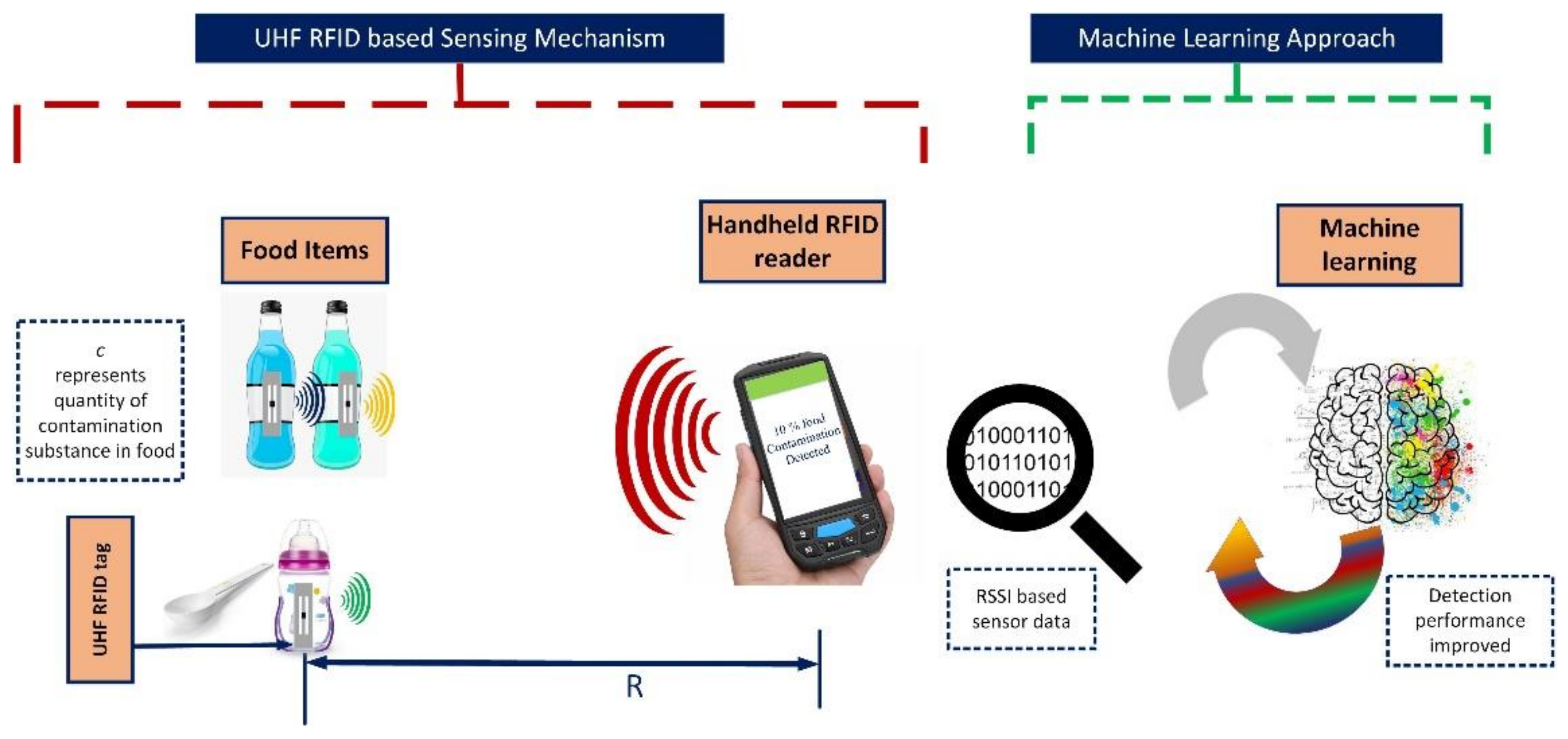

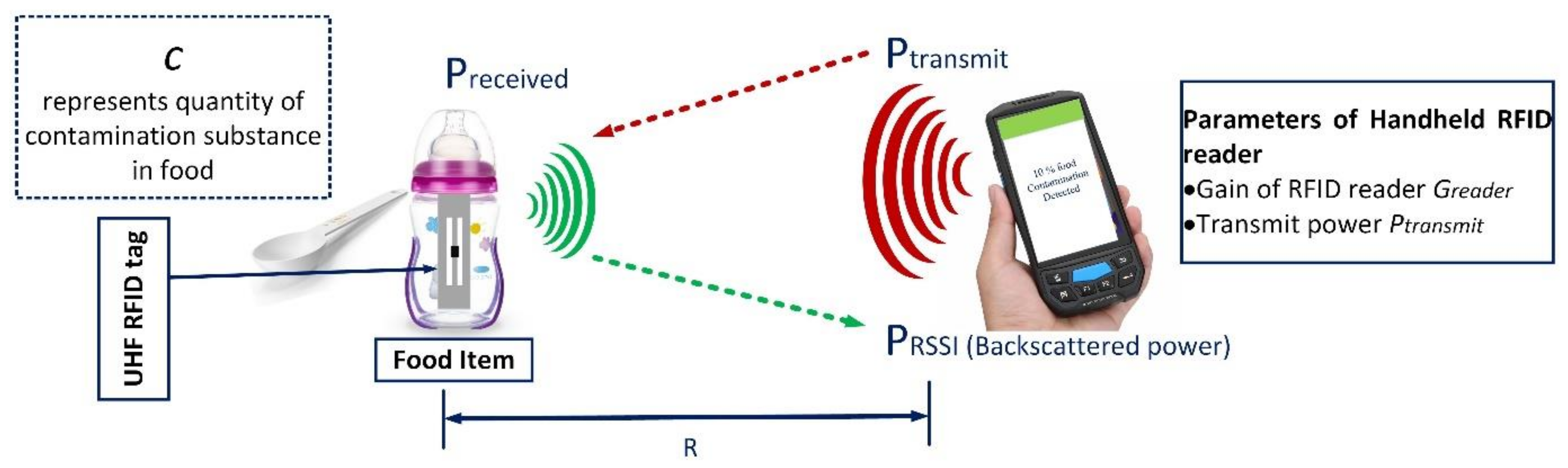

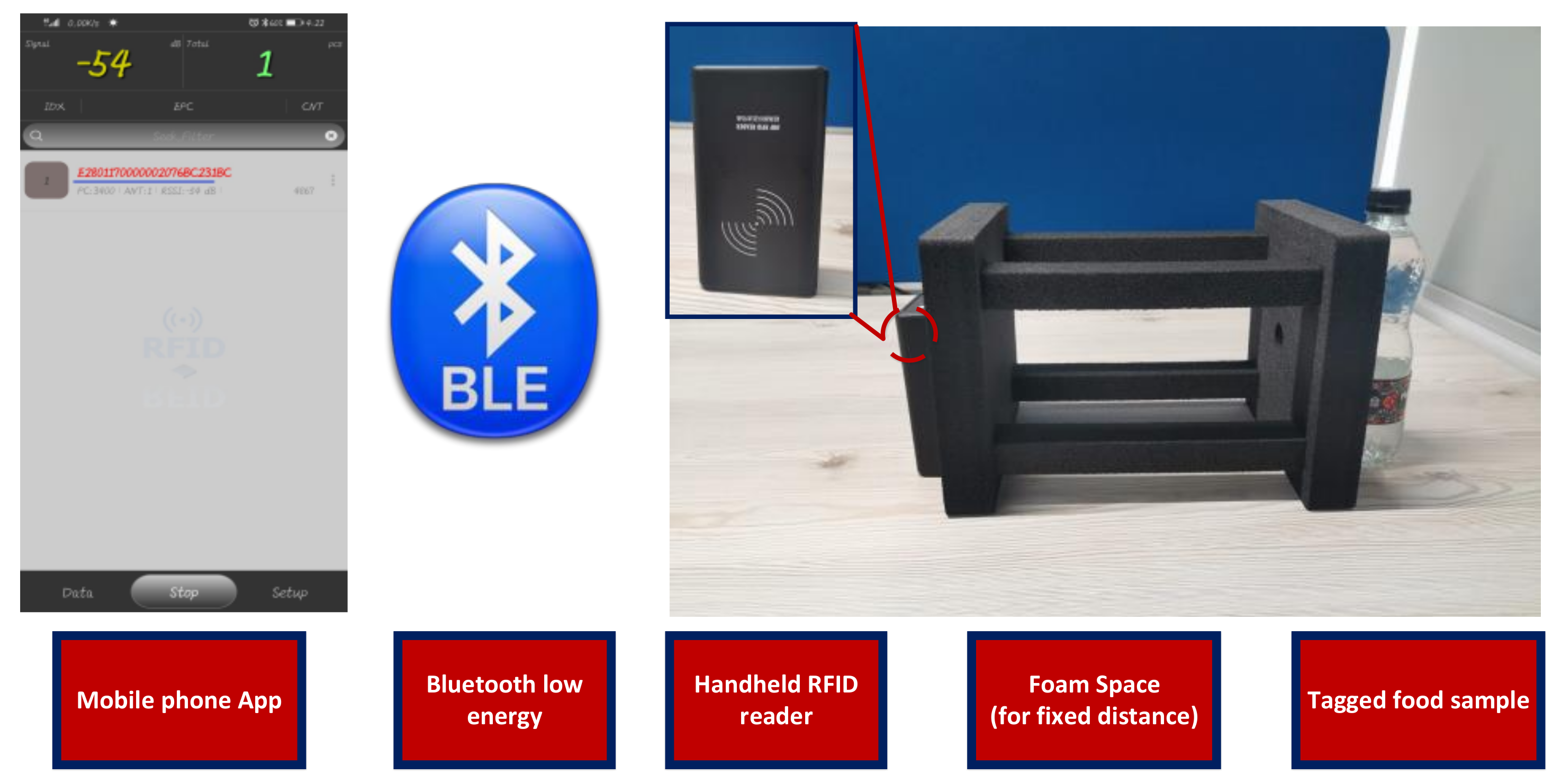

2. Proposed Methodology for Sensing Contamination

3. Experimental Setup

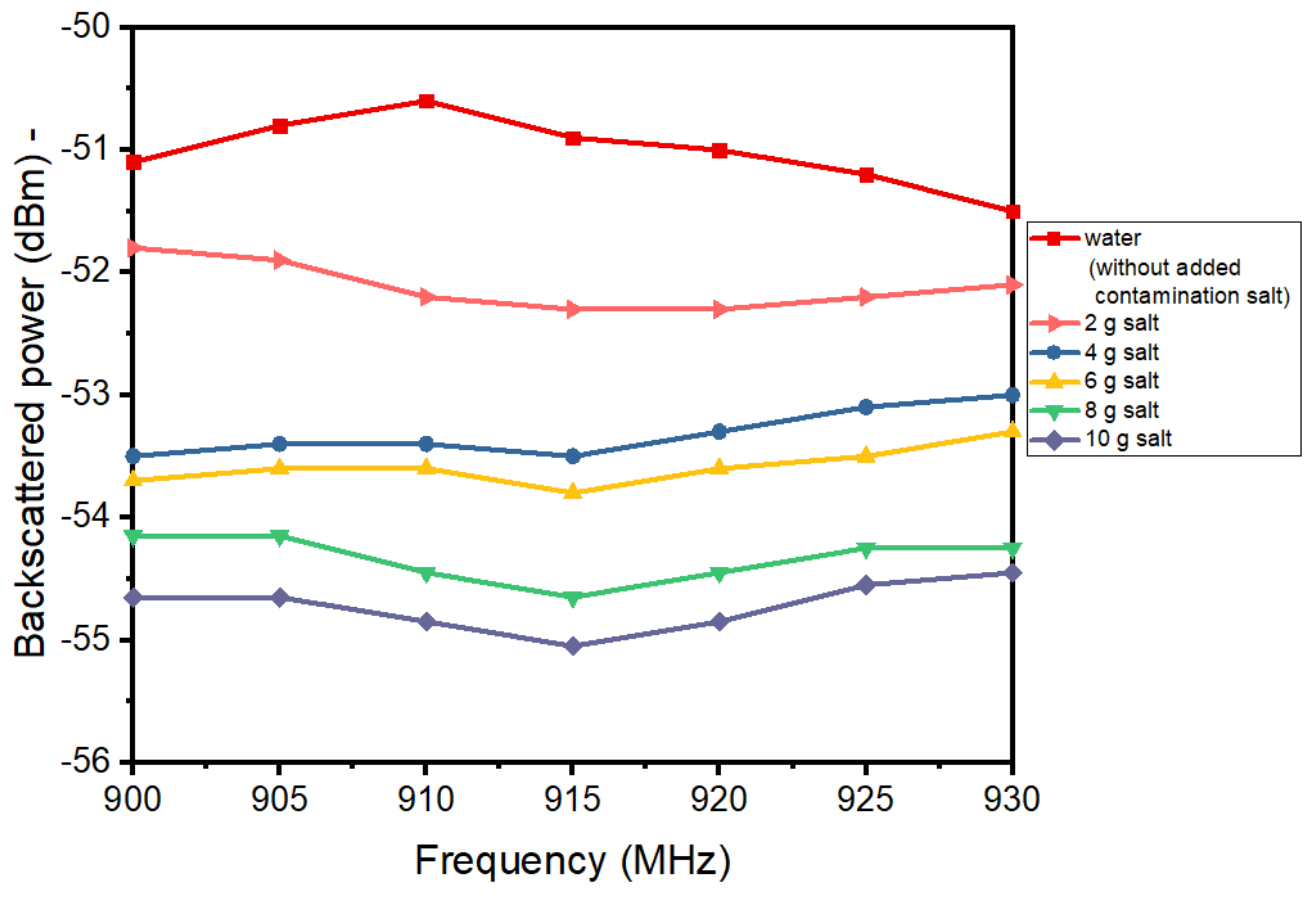

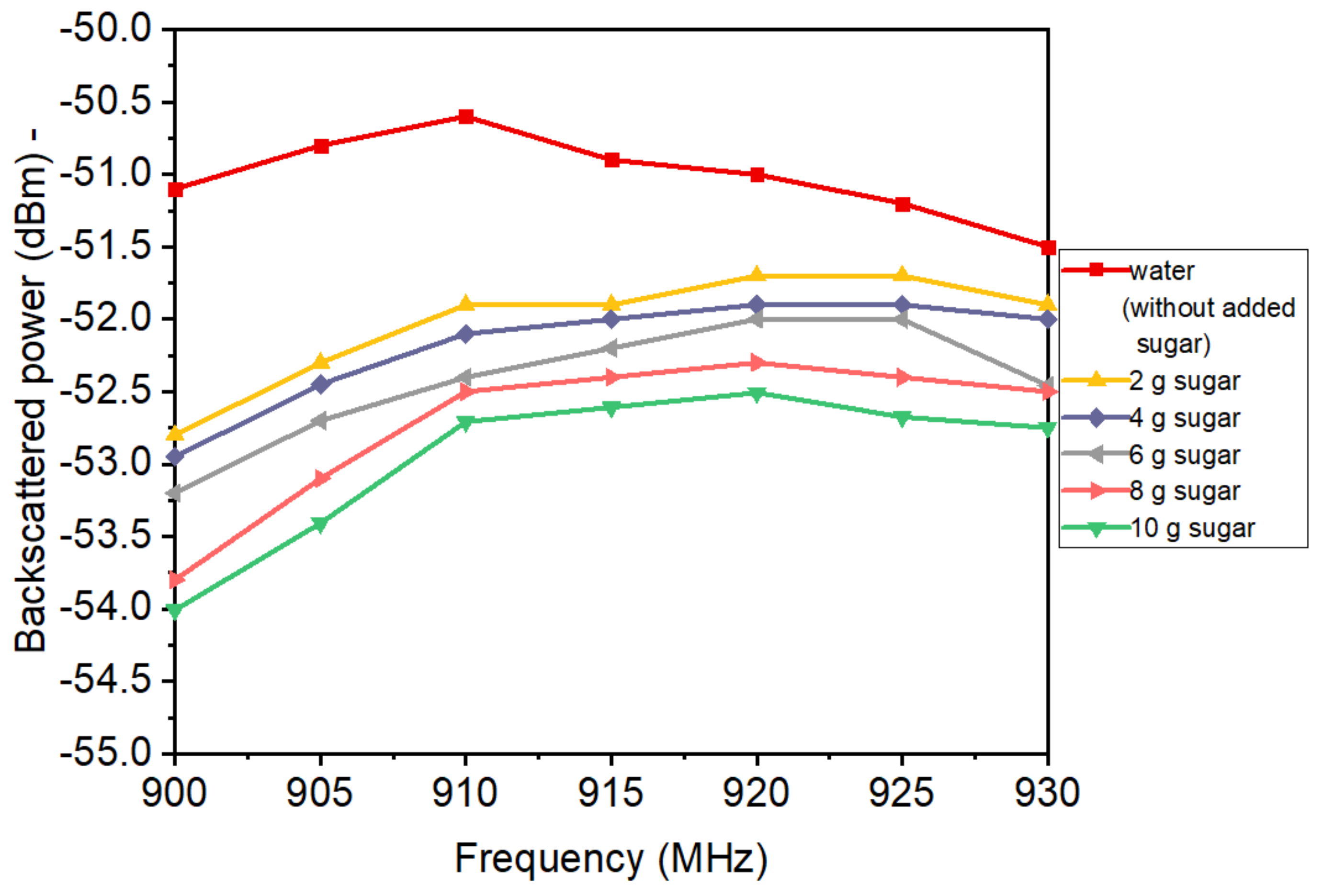

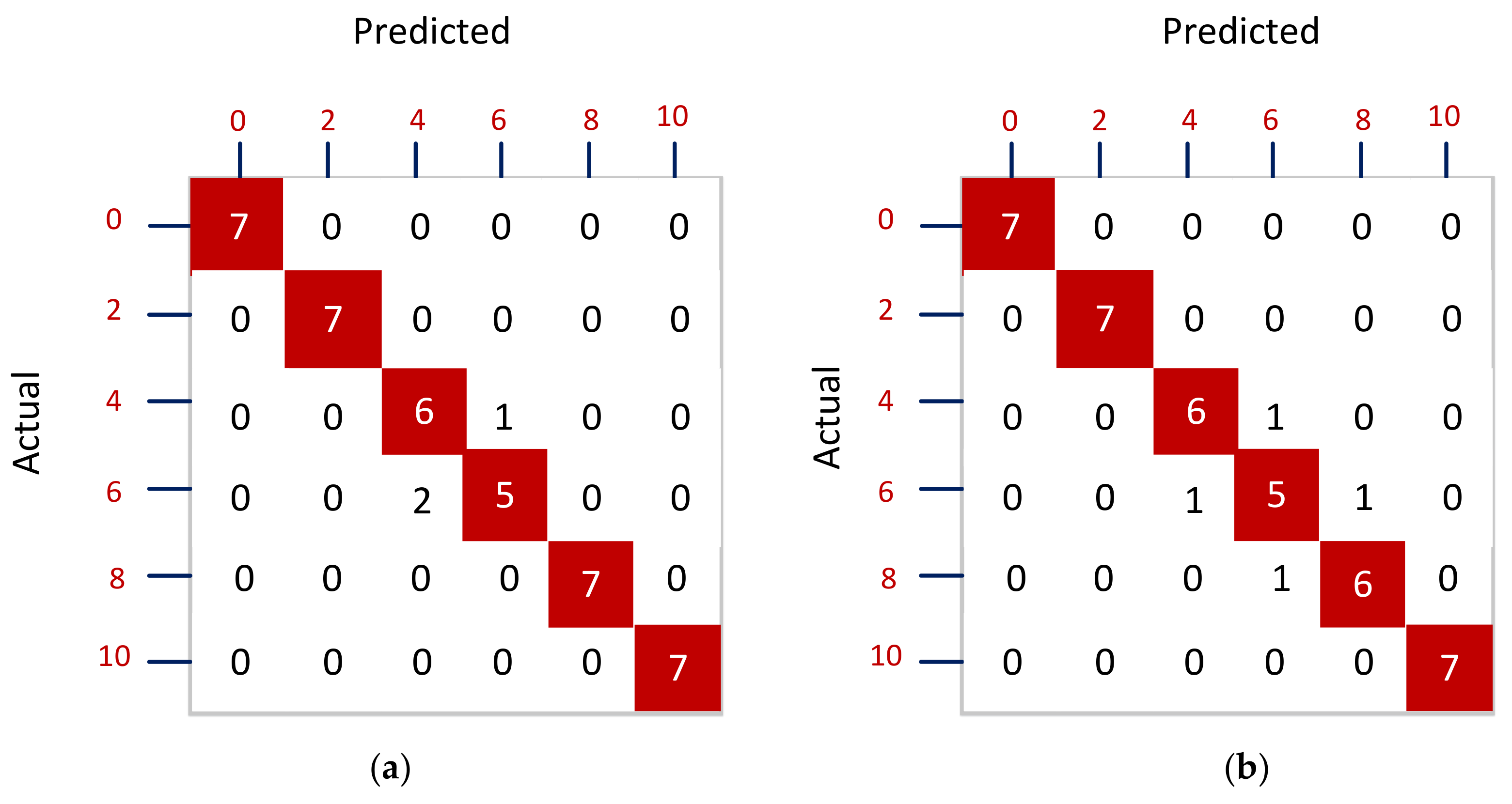

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Osifeko, M.O.; Hancke, G.P.; Abu-Mahfouz, A.M. Artificial intelligence techniques for cognitive sensing in future IoT: State-of-the-Art, potentials, and challenges. J. Sens. Actuator Netw. 2020, 9, 21. [Google Scholar] [CrossRef]

- Sharif, A.; Ouyang, J.; Yang, F.; Chattha, H.T.; Imran, M.A.; Alomainy, A.; Abbasi, Q.H. Low-cost inkjet-printed UHF RFID tag-based system for internet of things applications using characteristic modes. IEEE Internet Things J. 2019, 6, 3962–3975. [Google Scholar] [CrossRef] [Green Version]

- Lai, J.; Luo, C.; Wu, J.; Li, J.; Wang, J.; Chen, J.; Feng, G.; Song, H. TagSort: Accurate Relative Localization Exploring RFID Phase Spectrum Matching for Internet of Things. IEEE Internet Things J. 2020, 7, 389–399. [Google Scholar] [CrossRef]

- Singh, R.; Singh, E.; Nalwa, H.S. Inkjet printed nanomaterial based flexible radio frequency identification (RFID) tag sensors for the internet of nano things. RSC Adv. 2017, 7, 48597–48630. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Hong, Z.; Yu, L. Machine Learning-based Intrusion Detection for IoT Devices in Smart Home. In Proceedings of the 2020 IEEE 16th International Conference on Control & Automation (ICCA), Singapore, 9–11 October 2020; pp. 277–282. [Google Scholar] [CrossRef]

- Kouzayha, N.; Jaber, M.; Dawy, Z. Measurement-Based Signaling Management Strategies for Cellular IoT. IEEE Internet Things J. 2017, 4, 1434–1444. [Google Scholar] [CrossRef]

- Sharif, A.; Kumar, R.; Ouyang, J.; Abbas, H.T.; Alomainy, A.; Arshad, K.; Assaleh, K.; Althuwayb, A.; Imran, M.A.; Abbasi, Q.H. Making assembly line in supply chain robust and secure using UHF RFID. Sci. Rep. 2021, 11, 18041. [Google Scholar] [CrossRef] [PubMed]

- Amendola, G.M.S.; Caccami, M.C.; Caponi, A.; Catarinucci, L.; Cardellini, V.; Di Giampaolo, E.; Manzari, S.; Martinelli, F.; Milici, S.; Occhiuzzi, C. RFID & IoT: A Synergic Pair. IEEE RFID Virtual J. 2015, 1–21. Available online: http://ieeexplore.ieee.org/virtual-journals/rfid/issue/8 (accessed on 6 September 2021).

- Mafamane, R.; Mansour, A.A.; Ouadou, M.; Minaoui, K. FTSMAC: A Multi-Channel Hybrid Reader Collision Avoidance Protocol for RFID Network. J. Sens. Actuator Netw. 2021, 10, 46. [Google Scholar] [CrossRef]

- Khalil, G.; Doss, R.; Chowdhury, M. An Extended Reselling Protocol for Existing Anti-Counterfeiting Schemes. J. Sens. Actuator Netw. 2021, 10, 12. [Google Scholar] [CrossRef]

- Kapun, A.; Adrion, F.; Gallmann, E. Case Study on Recording Pigs’ Daily Activity Patterns with a UHF-RFID System. Agriculture 2020, 10, 542. [Google Scholar] [CrossRef]

- Khalil, G.; Doss, R.; Chowdhury, M. A New Secure RFID Anti-Counterfeiting and Anti-Theft Scheme for Merchandise. J. Sens. Actuator Netw. 2020, 9, 16. [Google Scholar] [CrossRef] [Green Version]

- Kayad, A.; Rainato, R.; Picco, L.; Sartori, L.; Marinello, F. Assessing Topsoil Movement in Rotary Harrowing Process by RFID (Radio-Frequency Identification) Technique. Agriculture 2019, 9, 184. [Google Scholar] [CrossRef] [Green Version]

- Khalil, G.; Doss, R.; Chowdhury, M. A Comparison Survey Study on RFID Based Anti-Counterfeiting Systems. J. Sens. Actuator Netw. 2019, 8, 37. [Google Scholar] [CrossRef] [Green Version]

- Colella, R.; Tarricone, L.; Catarinucci, L. SPARTACUS: Self-Powered Augmented RFID Tag for Autonomous Computing and Ubiquitous Sensing. IEEE Trans. Antennas Propag. 2015, 63, 2272–2281. [Google Scholar] [CrossRef]

- Occhiuzzi, C.; Caizzone, S.; Marrocco, G. Passive UHF RFID antennas for sensing applications: Principles, methods, and classifcations. IEEE Antennas Propag. Mag. 2013, 55, 14–34. [Google Scholar] [CrossRef] [Green Version]

- Manzari, S.; Occhiuzzi, C.; Nawale, S.; Catini, A.; Di Natale, C.; Marrocco, G. Humidity sensing by polymer-loaded UHF RFID antennas. IEEE Sens. J. 2012, 12, 2851–2858. [Google Scholar] [CrossRef] [Green Version]

- Makarovaite, V.; Hillier, A.J.R.; Holder, S.J.; Gourlay, C.W.; Batchelor, J.C. Passive Wireless UHF RFID Antenna Label for Sensing Dielectric Properties of Aqueous and Organic Liquids. IEEE Sens. J. 2019, 19, 4299–4307. [Google Scholar] [CrossRef] [Green Version]

- Perret, E.; Tedjini, S.; Nair, R.S. Design of antennas for UHF RFID tags. Proc. IEEE 2012, 100, 2330–2340. [Google Scholar] [CrossRef]

- Dobkin, D. The RF in RFID: Passive UHF RFID in Practice; Elsevier Inc.: Philadelphia, PA, USA, 2007. [Google Scholar]

- Sharif, A.; Ouyang, J.; Arshad, K.; Imran, M.A.; Abbasi, Q.H. Passive UHF RFID Tag Antennas-Based Sensing for Internet of Things Paradigm. In Backscattering and RF Sensing for Future Wireless Communication; Wiley: New York, NY, USA, 2021; pp. 133–155. [Google Scholar]

- Kamala, K.; Kumar, V.P. Food Products and Food Contamination. In Microbial Contamination and Food Degradation; Academic Press: New York, NY, USA, 2018; pp. 1–19. [Google Scholar] [CrossRef]

- Hassanzadeh, M.K.; Najaran, Z.T.; Nasery, M.; Emami, S.A. Summer Savory (Satureja hortensis L.) Oils. In Essential Oils in Food Preservation, Flavor and Safety; Academic Press: New York, NY, USA, 2016; pp. 757–764. [Google Scholar] [CrossRef]

- Food Safety. Available online: https://www.who.int/news-room/fact-sheets/detail/food-safety (accessed on 13 August 2021).

- Nguyen, D.S.; Phan, G.T.; Pham, T.T.; Le, N.N.; Dang, M.C.; Tedjni, S. A battery free RFID sensor for quality detection of food products. In Proceedings of the Progress In Electromagnetics Research Symposium Proceedings, Stockholm, Sweden, 2–15 August 2013; pp. 583–587. [Google Scholar]

- Tao, X.; Shaik, T.B.; Higgins, N.; Gururajan, R.; Zhou, X. Remote patient monitoring using radio frequency identification (Rfid) technology and machine learning for early detection of suicidal behaviour in mental health facilities. Sensors 2021, 21, 776. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wan, C.Y.; Shah, R.C.; Sample, A.P.; Patel, S.N. IDAct: Towards unobtrusive recognition of user presence and daily activities. Phoenix, AZ, USA, 2–4 April 2019. [Google Scholar] [CrossRef]

- Oguntala, G.A.; Abd-Alhameed, R.A.; Ali, N.T.; Hu, Y.F.; Noras, J.M.; Eya, N.N.; Elfergani, I.; Rodriguez, J. SmartWall: Novel RFID-Enabled Ambient Human Activity Recognition Using Machine Learning for Unobtrusive Health Monitoring. IEEE Access 2019, 7, 68022–68033. [Google Scholar] [CrossRef]

- Ha, U.; Ma, Y.; Zhong, Z.; Hsu, T.M.; Adib, F. Learning food quality and safety from wireless stickers. In Proceedings of the 17th ACM Workshop on Hot Topics in Networks, Redmond, WA, USA, 15–16 November 2018; pp. 106–112. [Google Scholar] [CrossRef]

- Sharif, A.; Ouyang, J.; Raza, A.; Imran, M.A.; Abbasi, Q.H. Inkjet-printed UHF RFID tag based system for salinity and sugar detection. Microw. Opt. Technol. Lett. 2019, 61, 2161–2168. [Google Scholar] [CrossRef]

- Nikitin, P.; Rao, K.V. Theory and measurement of backscattering from RFID tags. IEEE Antennas Propag. Mag. 2006, 48, 212–218. [Google Scholar] [CrossRef]

- Tagformance Pro|Voyantic. Available online: https://voyantic.com/products/tagformance-pro (accessed on 17 August 2021).

- Sohrab, A.P.; Huang, Y.; Hussein, M.N.; Carter, P. A Hybrid UHF RFID Tag Robust to Host Material. IEEE J. Radio Freq. Identif. 2017, 1, 163–169. [Google Scholar] [CrossRef]

- Bluetooth Vs. Bluetooth Low Energy (LE): What’s the Difference? Available online: https://www.link-labs.com/blog/bluetooth-vs-bluetooth-low-energy (accessed on 11 October 2021).

- GS1. EPC/RFID|GS1. 2015. Available online: https://www.gs1.org/standards/epc-rfid (accessed on 11 October 2021).

- Intro to Bluetooth Low Energy|Bluetooth® Technology Website. Available online: https://www.bluetooth.com/bluetooth-resources/intro-to-bluetooth-low-energy/ (accessed on 11 October 2021).

- XGBoost Python Package—Xgboost 1.5.0-dev Documentation. Available online: https://xgboost.readthedocs.io/en/latest/python/index.html (accessed on 17 August 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharif, A.; Abbasi, Q.H.; Arshad, K.; Ansari, S.; Ali, M.Z.; Kaur, J.; Abbas, H.T.; Imran, M.A. Machine Learning Enabled Food Contamination Detection Using RFID and Internet of Things System. J. Sens. Actuator Netw. 2021, 10, 63. https://doi.org/10.3390/jsan10040063

Sharif A, Abbasi QH, Arshad K, Ansari S, Ali MZ, Kaur J, Abbas HT, Imran MA. Machine Learning Enabled Food Contamination Detection Using RFID and Internet of Things System. Journal of Sensor and Actuator Networks. 2021; 10(4):63. https://doi.org/10.3390/jsan10040063

Chicago/Turabian StyleSharif, Abubakar, Qammer H. Abbasi, Kamran Arshad, Shuja Ansari, Muhammad Zulfiqar Ali, Jaspreet Kaur, Hasan T. Abbas, and Muhammad Ali Imran. 2021. "Machine Learning Enabled Food Contamination Detection Using RFID and Internet of Things System" Journal of Sensor and Actuator Networks 10, no. 4: 63. https://doi.org/10.3390/jsan10040063

APA StyleSharif, A., Abbasi, Q. H., Arshad, K., Ansari, S., Ali, M. Z., Kaur, J., Abbas, H. T., & Imran, M. A. (2021). Machine Learning Enabled Food Contamination Detection Using RFID and Internet of Things System. Journal of Sensor and Actuator Networks, 10(4), 63. https://doi.org/10.3390/jsan10040063