Microclimate Characterization of a Low-Tech Greenhouse During a Tomato Crop (Solanum lycopersicum L.) Production Cycle in Chaltura, Imbabura

Abstract

1. Introduction

2. Materials and Methods

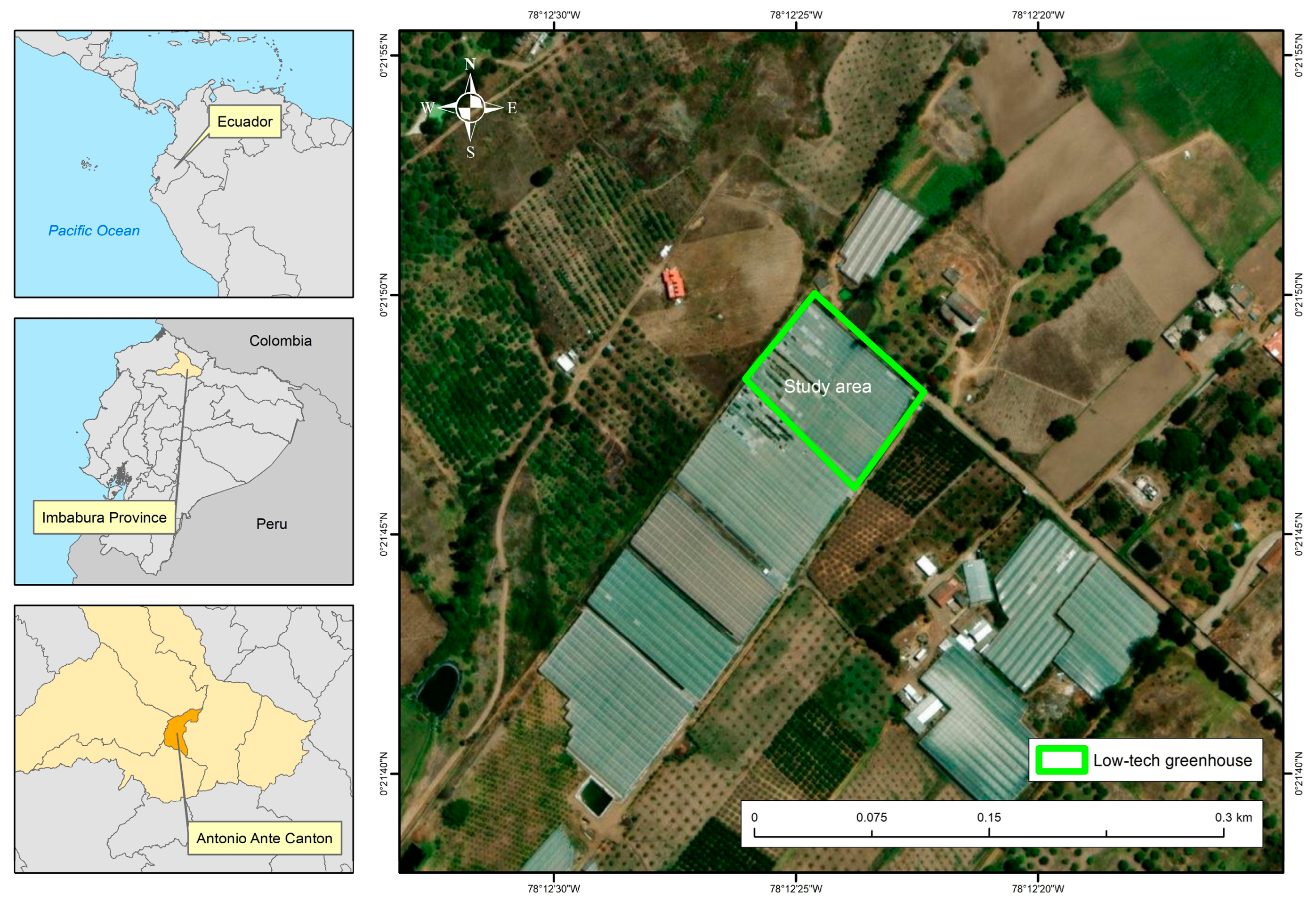

2.1. Study Area Description

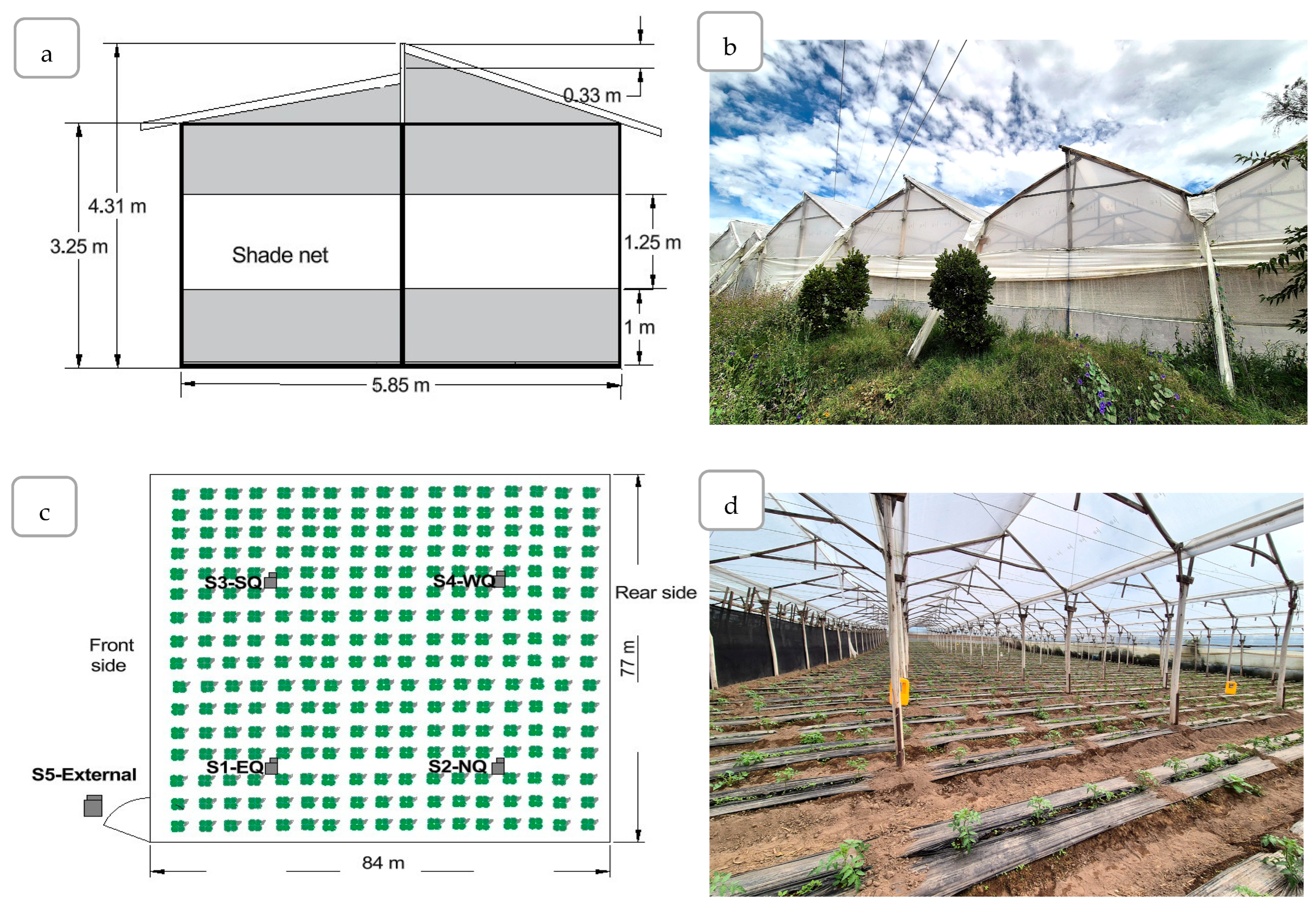

Greenhouse Design Characteristics

2.2. Equipment for Climate Data Recording

2.2.1. Internal Temperature and Relative Humidity Sensors

2.2.2. Weather Station for External Climate Records

2.3. Microclimatic Requirements of Tomato (Solanum lycopersicum L.)

2.4. Agronomic Parameters

2.5. Data Processing and Analysis

2.5.1. Internal Sensors

2.5.2. Weather Station

2.6. Decision Tree-Based Classification of Greenhouse Microclimate

3. Results

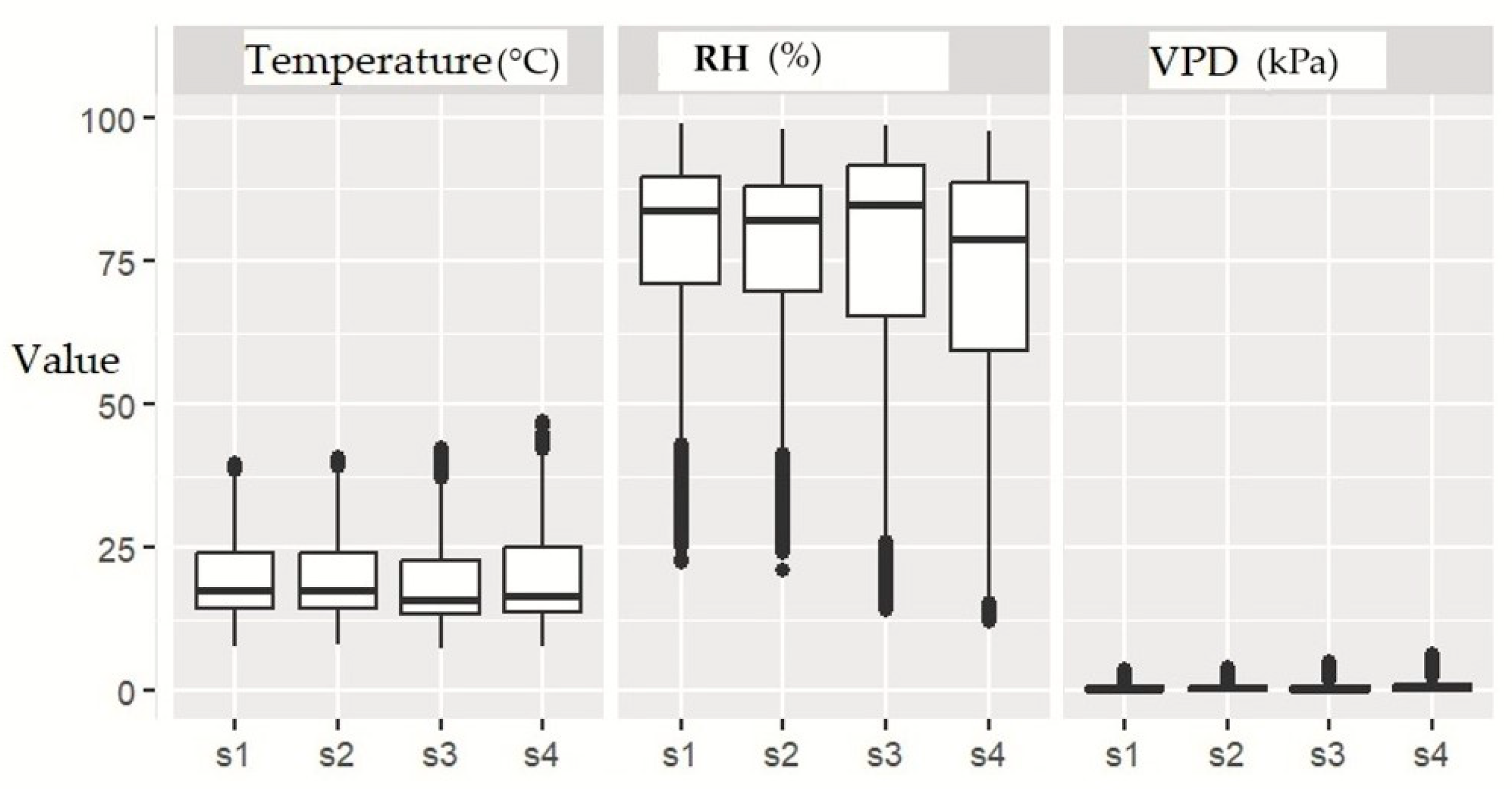

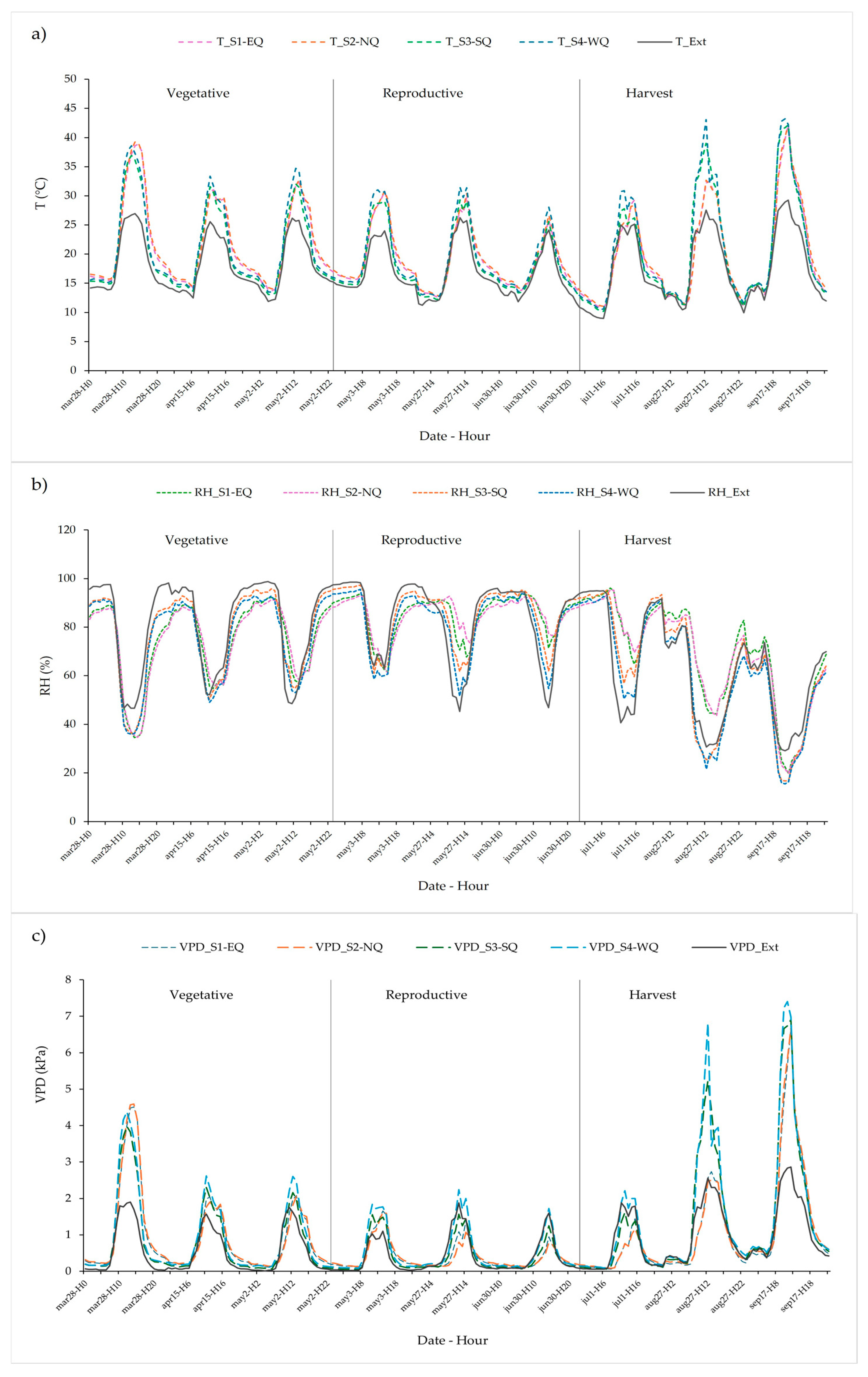

3.1. Microclimatic Characteristics of a Low-Tech Greenhouse in Chaltura, Imbabura

3.2. External Climatic Conditions of the Low-Tech Greenhouse in Chaltura, Imbabura

3.3. Comparison Between Internal and External Conditions

3.4. Microclimate Classification by Phenological Stage and Sensor Quadrant

3.5. Productive and Economic Indicators of Tomato

4. Discussion

5. Conclusions

6. Recommendation

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Feature | Specification |

|---|---|

| Transmission technology | LoRaWAN® |

| Compatible frequencies | CN470, IN865, RU864, EU868, US915, AU915, KR920, AS923 |

| Transmission power | 16 dBm (868 MHz), 20 dBm (915 MHz), 19 dBm (470 MHz) |

| Sensitivity | −137 dBm @ 300 bps |

| Operating modes | OTAA/ABP (Clase A) |

| Temperature range | −30 °C a + 70 °C |

| Temperature accuracy | ±0.3 °C (0–70 °C), ±0.6 °C (−30–0 °C) |

| Temperature resolution | 0.1 °C |

| Relative humidity range | 0–100% HR |

| Relative humidity accuracy | ±3% (10–90% HR), ±5% (<10% o >90% HR) |

| Relative humidity resolution | 0.5% HR |

Appendix B

| Feature | Specification |

|---|---|

| Model | Vantage Vue® |

| Update frequency | Up to every 2.5 s |

| Wireless transmission range | Up to 300 m with spread spectrum technology |

| Data storage capacity | Up to 180 days (depending on logging interval) |

| Sensor compatibility | Integration with over 80 additional sensor types |

| Platform and connectivity | WeatherLink Live (Wi-Fi/Ethernet) |

| Data access | Real-time and historical via app and WeatherLink website |

| Virtual integration | Compatible with Amazon Alexa and Google Assistant |

Appendix C

| Sensor S1-EQ Temperature (T) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 38.7 | 34.7 | 26.5 | 100 |

| Vegetative | Night | 56.9 | 37.6 | 5.5 | 100 |

| Reproductive | Day | 43.9 | 36.0 | 20.1 | 100 |

| Reproductive | Night | 53.3 | 36.3 | 10.4 | 100 |

| Harvest | Day | 26.7 | 43.5 | 29.8 | 100 |

| Harvest | Night | 26.7 | 31.2 | 42.1 | 100 |

| Average | Day | 36.5 | 38.1 | 25.5 | 100 |

| Average | Night | 45.6 | 35.0 | 19.3 | 100 |

| Sensor S1-EQ Relative Humidity (RH) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 41.8 | 23.5 | 34.7 | 100 |

| Vegetative | Night | 5.8 | 9.7 | 84.6 | 100 |

| Reproductive | Day | 56.6 | 20.4 | 23.0 | 100 |

| Reproductive | Night | 1.1 | 13.8 | 85.1 | 100 |

| Harvest | Day | 40.2 | 21.9 | 37.9 | 100 |

| Harvest | Night | 25.9 | 37.5 | 36.6 | 100 |

| Average | Day | 46.2 | 21.9 | 31.9 | 100 |

| Average | Night | 10.9 | 20.3 | 68.7 | 100 |

| Sensor S1-EQ Vapor pressure deficit (VPD) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 21.1 | 34.7 | 44.1 | 100 |

| Vegetative | Night | 8.1 | 23.7 | 68.2 | 100 |

| Reproductive | Day | 43.9 | 23.2 | 32.9 | 100 |

| Reproductive | Night | 2.0 | 12.1 | 85.8 | 100 |

| Harvest | Day | 30.4 | 19.9 | 49.8 | 100 |

| Harvest | Night | 15.4 | 27.2 | 57.4 | 100 |

| Average | Day | 31.8 | 25.9 | 42.3 | 100 |

| Average | Night | 8.5 | 21.0 | 70.5 | 100 |

| Sensor S2-NQ Temperature (T) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 34.5 | 40.1 | 25.4 | 100 |

| Vegetative | Night | 57.6 | 33.9 | 8.5 | 100 |

| Reproductive | Day | 41.6 | 38.8 | 19.6 | 100 |

| Reproductive | Night | 56.9 | 33.2 | 9.9 | 100 |

| Harvest | Day | 24.6 | 45.1 | 30.2 | 100 |

| Harvest | Night | 30.1 | 30.5 | 39.4 | 100 |

| Average | Day | 33.6 | 41.4 | 25.1 | 100 |

| Average | Night | 48.2 | 32.5 | 19.3 | 100 |

| Sensor S2-NQ Relative Humidity (RH) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 43.9 | 23.9 | 32.2 | 100 |

| Vegetative | Night | 9.2 | 13.4 | 77.4 | 100 |

| Reproductive | Day | 42.3 | 27.2 | 30.4 | 100 |

| Reproductive | Night | 0.9 | 17.6 | 81.4 | 100 |

| Harvest | Day | 42.4 | 19.4 | 38.1 | 100 |

| Harvest | Night | 33.8 | 37.8 | 28.4 | 100 |

| Average | Day | 42.9 | 23.5 | 33.6 | 100 |

| Average | Night | 14.6 | 22.9 | 62.4 | 100 |

| Sensor S2-NQ Vapor pressure deficit (VPD) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 16.7 | 27.9 | 55.4 | 100 |

| Vegetative | Night | 11.5 | 30.4 | 58.1 | 100 |

| Reproductive | Day | 43.6 | 17.0 | 39.4 | 100 |

| Reproductive | Night | 2.7 | 15.9 | 81.4 | 100 |

| Harvest | Day | 30.6 | 20.0 | 49.4 | 100 |

| Harvest | Night | 18.8 | 34.3 | 46.9 | 100 |

| Average | Day | 30.3 | 21.6 | 48.1 | 100 |

| Average | Night | 11.0 | 26.9 | 62.1 | 100 |

| Sensor S3-SQ Temperature (T) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 42.0 | 33.3 | 24.6 | 100 |

| Vegetative | Night | 45.4 | 49.8 | 4.8 | 100 |

| Reproductive | Day | 42.0 | 39.3 | 18.7 | 100 |

| Reproductive | Night | 40.1 | 42.9 | 17.0 | 100 |

| Harvest | Day | 25.6 | 44.8 | 29.6 | 100 |

| Harvest | Night | 22.5 | 27.9 | 49.6 | 100 |

| Average | Day | 36.6 | 39.1 | 24.3 | 100 |

| Average | Night | 36.0 | 40.2 | 23.8 | 100 |

| Sensor S3-SQ Relative Humidity (RH) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 38.7 | 26.5 | 34.7 | 100 |

| Vegetative | Night | 3.2 | 2.3 | 94.5 | 100 |

| Reproductive | Day | 67.2 | 13.8 | 19.0 | 100 |

| Reproductive | Night | 0.6 | 4.7 | 94.7 | 100 |

| Harvest | Day | 47.6 | 15.1 | 37.2 | 100 |

| Harvest | Night | 31.0 | 32.4 | 36.6 | 100 |

| Average | Day | 51.2 | 18.5 | 30.3 | 100 |

| Average | Night | 11.6 | 13.2 | 75.2 | 100 |

| Sensor S3-SQ Vapor pressure deficit (VPD) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 18.8 | 37.6 | 43.7 | 100 |

| Vegetative | Night | 2.8 | 5.5 | 91.7 | 100 |

| Reproductive | Day | 37.4 | 32.3 | 30.3 | 100 |

| Reproductive | Night | 0.5 | 3.9 | 95.6 | 100 |

| Harvest | Day | 24.9 | 28.1 | 47.0 | 100 |

| Harvest | Night | 19.0 | 26.4 | 54.6 | 100 |

| Average | Day | 27.0 | 32.7 | 40.3 | 100 |

| Average | Night | 7.4 | 12.0 | 80.6 | 100 |

| Sensor S4-WQ Temperature (T) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 38.0 | 33.8 | 28.2 | 100 |

| Vegetative | Night | 53.9 | 42.9 | 3.2 | 100 |

| Reproductive | Day | 35.1 | 46.5 | 18.4 | 100 |

| Reproductive | Night | 47.2 | 40.7 | 12.1 | 100 |

| Harvest | Day | 16.5 | 46.0 | 37.5 | 100 |

| Harvest | Night | 26.1 | 32.8 | 41.1 | 100 |

| Average | Day | 29.9 | 42.1 | 28.0 | 100 |

| Average | Night | 42.4 | 38.8 | 18.8 | 100 |

| Sensor S4-WQ Relative Humidity (RH) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 35.4 | 31.0 | 33.6 | 100 |

| Vegetative | Night | 3.9 | 4.8 | 91.2 | 100 |

| Reproductive | Day | 66.9 | 18.9 | 14.2 | 100 |

| Reproductive | Night | 2.8 | 13.4 | 83.8 | 100 |

| Harvest | Day | 29.6 | 16.1 | 54.3 | 100 |

| Harvest | Night | 48.2 | 36.0 | 15.8 | 100 |

| Average | Day | 44.0 | 22.0 | 34.0 | 100 |

| Average | Night | 18.3 | 18.1 | 63.6 | 100 |

| Sensor S4-WQ Vapor pressure deficit (VPD) | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 17.4 | 35.4 | 47.2 | 100 |

| Vegetative | Night | 4.1 | 11.8 | 84.1 | 100 |

| Reproductive | Day | 29.2 | 32.5 | 38.3 | 100 |

| Reproductive | Night | 2.0 | 10.1 | 87.9 | 100 |

| Harvest | Day | 14.2 | 23.9 | 61.9 | 100 |

| Harvest | Night | 27.2 | 37.8 | 35.0 | 100 |

| Average | Day | 20.3 | 30.6 | 49.1 | 100 |

| Average | Night | 11.1 | 19.9 | 69.0 | 100 |

References

- Albuja-Illescas, L.M.; Carrión-Burgos, A.M.; Jiménez-Lao, R.; Lao, M.T. Diagnosis of Protected Agriculture in Imbabura—Ecuador, Period 2016–2023. Agronomy 2025, 15, 166. [Google Scholar] [CrossRef]

- Nordey, T.; Basset-Mens, C.; de Bon, H.; Martin, T.; Déletré, E.; Simon, S.; Parrot, L.; Despretz, H.; Huat, J.; Biard, Y.; et al. Protected cultivation of vegetable crops in sub-Saharan Africa: Limits and prospects for smallholders—A review. Agron. Sustain. Dev. 2017, 37, 46. [Google Scholar] [CrossRef]

- Kumar, P.; Khapte, P.S.; Singh, A.; Saxena, A. Optimization of Low-Tech Protected Structure and Irrigation Regime for Cucumber Production under Hot Arid Regions of India. Plants 2024, 13, 146. [Google Scholar] [CrossRef]

- Nordey, T.; Ochieng, J.; Ernest, Z.; Mlowe, N.; Mosha, I.; Fernandes, P. Is vegetable cultivation under low tunnels a profitable alternative to pesticide use? The case of cabbage cultivation in northern Tanzania. Crop Prot. 2020, 134, 105169. [Google Scholar] [CrossRef]

- Omar, S.A. Protected agricultural production in Kuwait. Acta Hortic. 2004, 659, 71–79. [Google Scholar] [CrossRef]

- Lawrence, J.; Simpson, L.; Piggott, A. Protected agriculture: A Climate Change Adaptation for Food and Nutrition Security. In Natural Resources Management: Concepts, Methodologies, Tools, and Applications; IGI Global: Hershey, PA, USA, 2016. [Google Scholar] [CrossRef]

- Kalandarov, P.; Murodova, G. Study on microprocessor control of agricultural greenhouse microclimate. E3S Web Conf. 2024, 497, 03026. [Google Scholar] [CrossRef]

- Riahi, J.; Vergura, S.; Mezghani, D.; Mami, A. Intelligent control of the microclimate of an agricultural greenhouse powered by a supporting PV system. Appl. Sci. 2020, 10, 1350. [Google Scholar] [CrossRef]

- Singh, M.C.; Singh, J.P.; Singh, K.G. Development of a microclimate model for prediction of temperatures inside a naturally ventilated greenhouse under cucumber crop in soilless media. Comput. Electron. Agric. 2018, 154, 305–315. [Google Scholar] [CrossRef]

- Singh, M.C.; Singh, J.P.; Singh, K.G. Mathematical modeling of greenhouse microclimate under vertically trained soilless cropped conditions. Agric. Res. 2022, 11, 482–493. [Google Scholar] [CrossRef]

- Joshi, A.; Saxena, A.; Das, S.K. Effect of Greenhouse Microclimate on Crop Performance. In Protected Cultivation: Structural Design, Crop Management Modeling, and Automation; Apple Academic Press: Palm Bay, FL, USA, 2024. [Google Scholar] [CrossRef]

- Šalagovič, J.; Vanhees, D.; Verboven, P.; Holsteens, K.; Verlinden, B.; Huysmans, M.; van de Poel, B.; Nicolaï, B. Microclimate monitoring in commercial tomato (Solanum lycopersicum L.) greenhouse production and its effect on plant growth, yield and fruit quality. Front. Hortic. 2024, 3, 1425285. [Google Scholar] [CrossRef]

- Reynafarje, X.; Villagrán, E.A.; Bojacá, C.R.; Gil, R.; Schrevens, E. Simulation and validation of the airflow inside a naturally ventilated greenhouse designed for tropical conditions. Acta Hortic. 2020, 1271, 65–72. [Google Scholar] [CrossRef]

- Rojas-Rishor, A.; Flores-Velazquez, J.; Villagran, E.; Aguilar-Rodríguez, C.E. Valuation of climate performance of a low-tech greenhouse in Costa Rica. Processes 2022, 10, 693. [Google Scholar] [CrossRef]

- Villagrán, E.; Flores-Velazquez, J.; Akrami, M.; Bojacá, C. Microclimatic evaluation of five types of Colombian greenhouses using geostatistical techniques. Sensors 2022, 22, 3925. [Google Scholar] [CrossRef]

- Reza, M.N.; Islam, M.N.; Iqbal, M.Z.; Kabir, M.S.N.; Chowdhury, M.; Gulandaz, M.A.; Ali, M.; Jang, M.K.; Chung, S.O. Spatial, temporal, and vertical variability of ambient environmental conditions in Chinese solar greenhouses during winter. Appl. Sci. 2023, 13, 9835. [Google Scholar] [CrossRef]

- Rezvani, S.M.E.; Abyaneh, H.Z.; Shamshiri, R.R.; Balasundram, S.K.; Dworak, V.; Goodarzi, M.; Sultan, M.; Mahns, B. IoT-based sensor data fusion for determining optimality degrees of microclimate parameters in commercial greenhouse production of tomato. Sensors 2020, 20, 6474. [Google Scholar] [CrossRef]

- Koukounaras, A. Advanced greenhouse horticulture: New technologies and cultivation practices. Horticulturae 2021, 7, 1. [Google Scholar] [CrossRef]

- Chemoun, K.; Oubabas, S.; Sadoun, T.; Aoudjit, R.; Gilg, M. An intelligent monitoring system of greenhouse: A belief functions theory-based approach. In Proceedings of the 2023 International Conference on Advances in Electronics, Control and Communication Systems (ICAECCS), Blida, Algeria, 6–7 March 2023. [Google Scholar] [CrossRef]

- Li, A.; Huang, L.; Zhang, T. Field test and analysis of microclimate in naturally ventilated single-sloped greenhouses. Energy Build. 2017, 138, 47–57. [Google Scholar] [CrossRef]

- Bashir, M.K.; Malik, A.U.; Farrukh, M.U.; Hameed, S.; Kamran, M.A.; Ziaf, K. Forecasting tomato production under climate variability in Pakistan. J. Anim. Plant Sci. 2022, 32, 202–207. [Google Scholar] [CrossRef]

- Xu, L.; Meng, F.; Wei, R. Development and verification of tomato crop–environment interaction model in second timescale greenhouse. Trans. Chin. Soc. Agric. Eng. 2021, 37, 215–224. [Google Scholar] [CrossRef]

- Guo, Z.; Feng, L. Multi-step prediction of greenhouse temperature and humidity based on temporal position attention LSTM. Stoch. Environ. Res. Risk Assess. 2024, 38, 4907–4934. [Google Scholar] [CrossRef]

- Laktionov, I.S.; Vovna, O.V.; Kabanets, M.M.; Sheina, H.O.; Getman, I.A. Information model of the computer-integrated technology for wireless monitoring of the state of microclimate of industrial agricultural greenhouses. Instrum. Mes. Métrologie 2021, 20, 305–314. [Google Scholar] [CrossRef]

- Faouzi, D.; Bibi-Triki, N. Modeling, simulation and optimization of agricultural greenhouse microclimate by application of artificial intelligence and/or fuzzy logic. Preprints 2016. [Google Scholar] [CrossRef]

- Ben Ali, R.; Bouadila, S.; Mami, A. Development of a fuzzy logic controller applied to an agricultural greenhouse experimentally validated. Appl. Therm. Eng. 2018, 141, 805–815. [Google Scholar] [CrossRef]

- Perone, C.; Orsino, M.; Catalano, P.; Bianchi, B.; Giametta, F.; La Fianza, G. Microclimatic Monitoring and Analysis in a Hydroponic Greenhouse. In AIIA 2022: Biosystems Engineering Towards the Green Deal—Improving the Resilience of Agriculture, Forestry and Food Systems in the Post-Covid Era; Ferro, V., Giordano, G., Orlando, S., Vallone, M., Cascone, G., Porto, S.M.C., Eds.; Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2023; Volume 337, pp. 893–904. [Google Scholar] [CrossRef]

- Reddy, P.P. Sustainable Crop Protection Under Protected Cultivation; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen–Geiger climate classification. Hydrol. Earth Syst. Sci. 2007, 11, 1633–1644. [Google Scholar] [CrossRef]

- Gobierno Autónomo Descentralizado Parroquial de Chaltura. Plan de Desarrollo y Ordenamiento Territorial de la Parroquia Chaltura 2015–2025. Gobierno Autónomo Descentralizado Provincial de Imbabura. 2015. Available online: https://imbabura.gob.ec/phocadownload/K-Planes-programas/PDOT/Parroquial/PDOT%20CHALTURA%202015.pdf (accessed on 23 June 2025).

- Triana, A.; Llanderal, A.; García-Caparrós, P.; Donoso, M.; Jiménez-Lao, R.; Franco Rodríguez, J.E.; Lao, M.T. Preliminary Mapping of the Spatial Variability in the Microclimate in Tropical Greenhouses: A Pepper Crop Perspective. Agriculture 2024, 14, 1972. [Google Scholar] [CrossRef]

- Bhujel, A.; Basak, J.K.; Khan, F.; Arulmozhi, E.; Jaihuni, M.; Sihalath, T.; Lee, D.; Park, J.; Kim, H.T. Sensor Systems for Greenhouse Microclimate Monitoring and Control: A Review. J. Biosyst. Eng. 2020, 45, 241–259. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Jones, J.W.; Thorp, K.R.; Ahmad, D.; Man, H.C.; Taheri, S. Review of Optimum Temperature, Humidity, and Vapour Pressure Deficit for Microclimate Evaluation and Control in Greenhouse Cultivation of Tomato. Int. Agrophys. 2018, 32, 287–302. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013; Available online: https://www.r-project.org/ (accessed on 7 April 2025).

- Tierney, N. visdat: Visualising Whole Data Frames. J. Open Source Softw. 2017, 2, 355. [Google Scholar] [CrossRef]

- Stekhoven, D.J.; Bühlmann, P. MissForest—Nonparametric Missing Value Imputation Using Random Forest. Bioinformatics 2012, 28, 112–118. [Google Scholar] [CrossRef]

- Noh, H.; Lee, J. The Effect of Vapor Pressure Deficit Regulation on the Growth of Tomato Plants Grown in Different Planting Environments. Appl. Sci. 2022, 12, 3667. [Google Scholar] [CrossRef]

- Bergmeir, C.; Benítez, J.M. On the Use of Cross-Validation for Time Series Predictor Evaluation. Inf. Sci. 2012, 191, 192–213. [Google Scholar] [CrossRef]

- Therneau, T.; Atkinson, B. rpart: Recursive Partitioning and Regression Trees, R Package Version 4.1–15. Available online: https://CRAN.R-project.org/package=rpart (accessed on 7 April 2025).

- Brown, P.; Groves, K.; Jovicich, E. Development of Protected Cropping Systems for Out-of-Season Vegetable Production in the Pacific Islands. Acta Hortic. 2019, 1257, 217–224. [Google Scholar] [CrossRef]

- Singh, M.C.; Sharma, K.K.; Prasad, V. Impact of Ventilation Rate and Its Associated Characteristics on Greenhouse Microclimate and Energy Use. Arab. J. Geosci. 2022, 15, 240. [Google Scholar] [CrossRef]

- Villagrán, E.; Bojacá, C. Study Using a CFD Approach of the Efficiency of a Roof Ventilation Closure System in a Multi-Tunnel Greenhouse for Nighttime Microclimate Optimization. Rev. Ceres 2020, 67, 331–338. [Google Scholar] [CrossRef]

- Villagrán, E.A.; Baeza Romero, E.J.; Bojacá, C.R. Transient CFD Analysis of the Natural Ventilation of Three Types of Greenhouses Used for Agricultural Production in a Tropical Mountain Climate. Biosyst. Eng. 2019, 188, 171–184. [Google Scholar] [CrossRef]

- Munar, E.A.V.; Arias, L.G.; Latorre, D.A.G.; Giraldo, Y.R.; Garzón, I.E.C. Estrategias de Adaptación y Mitigación al Cambio Climático en Sistemas de Producción Agrícola: Un Enfoque desde la Agricultura Protegida y Técnicas de Biotecnología para el Manejo del Cultivo; Corporación Colombiana de Investigación Agropecuaria (AGROSAVIA): Mosquera, Colombia, 2023. [Google Scholar] [CrossRef]

- Mao, Q.; Li, H.; Ji, C.; Peng, Y.; Li, T. Experimental Study of Ambient Temperature and Humidity Distribution in Large Multi-Span Greenhouse Based on Different Crop Heights and Ventilation Conditions. Appl. Therm. Eng. 2024, 248, 123176. [Google Scholar] [CrossRef]

- Kim, H.-K. Evaluating the Ventilation Performance of Single-Span Plastic Greenhouses with Continuous Screened Side Openings. Agronomy 2024, 14, 1447. [Google Scholar] [CrossRef]

- Jung, W.; Kim, H. Evaluation of Heat Stress Levels Inside Greenhouses during Summer in Korea. Int. J. Environ. Res. Public Health 2022, 19, 12497. [Google Scholar] [CrossRef]

- Hou, Y.; Li, A.; Li, Y.; Jin, D.; Tian, Y.; Zhang, D.; Wu, D.; Zhang, L.; Lei, W. Analysis of Microclimate Characteristics in Solar Greenhouses under Natural Ventilation. Build. Simul. 2021, 14, 2165–2179. [Google Scholar] [CrossRef]

- Reuters. “The Climate Is Crazy,” Ecuador Minister Says, Country Faces 12-Hour Power Cuts. Reuters, 23 September 2024. Available online: https://www.reuters.com/business/energy/the-climate-is-crazy-ecuador-minister-says-country-faces-12-hour-power-cuts-2024-09-23 (accessed on 12 August 2025).

- Global Voices. Ecuador Grapples with 14-Hour Blackouts, Climate Change, and Alleged Corruption. Global Voices, 19 November 2024. Available online: https://globalvoices.org/2024/11/19/ecuador-grapples-with-14-hour-blackouts-climate-change-and-alleged-corruption (accessed on 25 August 2025).

- Tridge. Impact of Weather Events on Ecuador’s Agricultural, Productive, and Energy Sectors. Tridge. 2024. Available online: https://www.tridge.com/stories/impact-of-weather-events-on-ecuadors-agricultural-productive-and-energy-sectors (accessed on 25 August 2025).

- Tüzel, Y.; de Zwart, H.F.; Sapounas, A.; Hemming, S.; Stanghellini, C. Improvement of Greenhouse Design and Climate Control in Mediterranean Conditions. J. Food Agric. Environ. 2017, 15, 74–79. [Google Scholar]

- Lyu, X.; Xu, Y.; Wei, M.; Wang, C.; Zhang, G.; Wang, S. Effects of Vent Opening, Wind Speed, and Crop Height on Microenvironment in Three-Span Arched Greenhouse under Natural Ventilation. Comput. Electron. Agric. 2022, 201, 107326. [Google Scholar] [CrossRef]

- Fatnassi, H.; Leyronas, C.; Boulard, T.; Bardin, M.; Nicot, P. Dependence of Greenhouse Tunnel Ventilation on Wind Direction and Crop Height. Biosyst. Eng. 2009, 103, 338–349. [Google Scholar] [CrossRef]

- Tapia, M.; Heinemann, D.; Ballari, D.; Zondervan, E. Spatio-Temporal Characterization of Long-Term Solar Resource Using Spatial Functional Data Analysis: Understanding the Variability and Complementarity of Global Horizontal Irradiance in Ecuador. Renew. Energy 2022, 189, 1297–1314. [Google Scholar] [CrossRef]

- Harel, D.; Fadida, H.; Slepoy, A.; Gantz, S.; Shilo, K. The Effect of Mean Daily Temperature and Relative Humidity on Pollen, Fruit Set and Yield of Tomato Grown in Commercial Protected Cultivation. Agronomy 2014, 4, 167–177. [Google Scholar] [CrossRef]

- Archana, K.A.; Pradeepkumar, T.; John, C.L.; Anitha, P.; Santhoshkumar, A.V.; Vijayaraghavan, R. Screening of Tomato (Solanum lycopersicum L.) Genotypes for Hot-Set Traits. J. Trop. Agric. 2020, 58, 115–123. [Google Scholar]

- Baptista, F.J.; Bailey, B.J.; Meneses, J.F. Effect of Nocturnal Ventilation on the Occurrence of Botrytis cinerea in Mediterranean Unheated Tomato Greenhouses. Crop Prot. 2012, 32, 144–149. [Google Scholar] [CrossRef]

- Elad, Y.; Fogel, M.; Silverman, D.; Biton, S.; Yitzhak, S.; Harari, D.; Adler, U. White Mould of Sweet Basil: Conditions Influencing Its Development in Greenhouses and Cultural Measures for Disease Management. Plant Pathol. 2015, 64, 837–846. [Google Scholar] [CrossRef]

- Jerszurki, D.; Saadon, T.; Zhen, J.; Agam, N.; Tas, E.; Rachmilevitch, S.; Lazarovitch, N. Vertical Microclimate Heterogeneity and Dew Formation in Semi-Closed and Naturally Ventilated Tomato Greenhouses. Sci. Hortic. 2021, 288, 110271. [Google Scholar] [CrossRef]

- Rocha, G.A.O.; Pichimata, M.A.; Villagrán, E. Research on the Microclimate of Protected Agriculture Structures Using Numerical Simulation Tools: A Technical and Bibliometric Analysis as a Contribution to the Sustainability of Under-Cover Cropping in Tropical and Subtropical Countries. Sustainability 2021, 13, 10433. [Google Scholar] [CrossRef]

- Fan, Z.; Li, Y.; Jiang, L.; Wang, L.; Li, T.; Liu, X. Analysis of the Effect of Exhaust Configuration and Shape Parameters of Ventilation Windows on Microclimate in Round Arch Solar Greenhouse. Sustainability 2023, 15, 6432. [Google Scholar] [CrossRef]

- Arbaoui, N.; Tadili, R.; Ihoume, I.; Idrissi, A.; Benchrifa, M.; Krabch, H.; Essalhi, H.; Daoudi, M. Effects of a Solar Heating System on the Microclimate of an Agricultural Greenhouse: Application on Zucchini (Cucurbita pepo). Sol. Energy 2023, 262, 111910. [Google Scholar] [CrossRef]

- Thilakarathne, N.N.; Bakar, M.S.A.; Abas, P.E.; Yassin, H. Towards Making the Fields Talk: A Real-Time Cloud-Enabled IoT Crop Management Platform for Smart Agriculture. Front. Plant Sci. 2023, 13, 1030168. [Google Scholar] [CrossRef] [PubMed]

- Jerca, I.O.; Cîmpeanu, S.M.; Teodorescu, R.I.; Drăghici, E.M.; Nițu, O.A.; Sannan, S.; Arshad, A. A Comprehensive Assessment of the Morphological Development of Inflorescence, Yield Potential, and Growth Attributes of Summer-Grown, Greenhouse Cherry Tomatoes. Agronomy 2024, 14, 556. [Google Scholar] [CrossRef]

- Bowen-Quiroz, C.; Reyna-Bowen, L.; Jaimez, R.; Camacho, O. Arduino-Based Microclimate Monitoring System for Tropical Greenhouse. In Proceedings of the 2023 IEEE 7th Ecuador Technical Chapters Meeting (ECTM), Ambato, Ecuador, 10–13 October 2023. [Google Scholar] [CrossRef]

- Ortiz-Alamilla, A.I.; Neri-Suárez, M.; López-González, J.L.; Vilaboa-Arroniz, J. Análisis de la agricultura protegida y sus impactos socioambientales en tres municipios de la Sierra Nevada de Puebla, México. Religación. Rev. Cienc. Soc. Humanid. 2023, 8, 1–15. [Google Scholar] [CrossRef]

- Brenya, R.; Zhu, J.; Sampene, A.K. Can Agriculture Technology Improve Food Security in Low- and Middle-Income Nations? A Systematic Review. Sustain. Food Technol. 2023, 1, 527–547. [Google Scholar] [CrossRef]

| Phenological Stage | Time of Day | Climatic Variable | Optimal Range | Suboptimal Range | Critical Range |

|---|---|---|---|---|---|

| Vegetative (0–50 DAT *) | Day | T (°C) | 20–28 | 18–19.9 o 28.1–34 | <18 o >34 |

| RH (%) | 55–75 | 50–54 o 76–85 | <50 o >85 | ||

| ** VPD (kPa) | 0.5–1.1 | 0.4–0.49 o 1.2–2.0 | <0.4 o >2.0 | ||

| Night | T (°C) | 15–19 | 12–14.9 o 19.1–20 | <12 o >20 | |

| RH (%) | 50–75 | 45–49 o 76–80 | <45 o >80 | ||

| ** VPD (kPa) | 0.5–0.9 | 0.3–0.49 o 1.0–1.5 | <0.3 o >1.5 | ||

| Reproductive (51–109 DAT *) | Day | T (°C) | 19–26 | 17–18.9 o 26.1–34 | <17 o >34 |

| RH (%) | 50–80 | 45–49 o 81–89 | <45 o >89 | ||

| ** VPD (kPa) | 0.5–1.2 | 0.4–0.49 o 1.3–2.0 | <0.4 o >2.0 | ||

| Night | T (°C) | 15–19 | 13–14.9 o 19.1–20 | <13 o >20 | |

| RH (%) | 50–75 | 45–49 o 76–85 | <45 o >85 | ||

| ** VPD (kPa) | 0.5–0.9 | 0.3–0.49 o 1.0–1.5 | <0.3 o >1.5 | ||

| Harvest (110–190 DAT *) | Day | Temp. (°C) | 19–24 | 17–18.9 o 24.1–34 | <17 o >34 |

| RH (%) | 50–80 | 45–49 o 81–89 | <45 o >89 | ||

| ** VPD (kPa) | 0.5–1.2 | 0.4–0.49 o 1.21–2.0 | <0.4 o >2.0 | ||

| Night | Temp. (°C) | 15–19 | 13–14.9 o 19.1–20 | <13 o >20 | |

| RH (%) | 50–75 | 45–49 o 76–85 | <45 o >85 | ||

| ** VPD (kPa) | 0.5–0.9 | 0.3–0.49 o 1.0–1.5 | <0.3 o >1.5 |

| Phenological Stage | Start Date | End Date | Duration (Days) |

|---|---|---|---|

| Vegetative (0–50 DAT) | 14 March 2024 (* Day 74) | 2 May 2024 (* Day 123) | 50 |

| Reproductive (51–109 DAT) | 3 May 2024 (* Day 124) | 30 June 2024 (* Day 182) | 59 |

| Harvest (110–190 DAT) | 1 July 2024 (* Day 183) | 19 September 2024 (* Day 263) | 81 |

| Total | 190 |

| Phenological Stage | Variable | Sensor | Mean | Min Absolute | Max Absolute | Mean of Min | Mean of Max |

|---|---|---|---|---|---|---|---|

| Vegetative | T (°C) | S1-EQ | 20.3 | 9.8 | 39.8 | 13.7 | 34.1 |

| S2-NQ | 20.7 | 10.1 | 40.8 | 13.9 | 34.8 | ||

| S3-SQ | 19.2 | 9.1 | 38.5 | 12.8 | 32.2 | ||

| S4-WQ | 20.2 | 9.3 | 39.6 | 13.2 | 34.4 | ||

| RH (%) | S1-EQ | 75.0 | 27.0 | 95.0 | 43.2 | 89.8 | |

| S2-NQ | 74.7 | 25.5 | 95.0 | 43.8 | 88.8 | ||

| S3-SQ | 78.1 | 31.0 | 97.0 | 44.9 | 94.1 | ||

| S4-WQ | 75.4 | 29.5 | 96.1 | 42.6 | 92.7 | ||

| VPD (kPa) | S1-EQ | 0.6 | 0.1 | 3.8 | 0.1 | 2.4 | |

| S2-NQ | 0.6 | 0.08 | 4.1 | 0.2 | 2.5 | ||

| S3-SQ | 0.6 | 0.04 | 3.5 | 0.08 | 2.1 | ||

| S4-WQ | 0.6 | 0.06 | 3.7 | 0.1 | 2.4 | ||

| Reproductive | T (°C) | S1-EQ | 18.7 | 11.1 | 33.8 | 13.2 | 29.4 |

| S2-NQ | 19.1 | 11.2 | 35.0 | 13.5 | 30.2 | ||

| S3-SQ | 18.1 | 10.7 | 33.3 | 12.7 | 28.9 | ||

| S4-WQ | 19.7 | 10.9 | 37.2 | 12.9 | 32.5 | ||

| RH (%) | S1-EQ | 84.4 | 53.0 | 98.5 | 63.5 | 94.8 | |

| S2-NQ | 85.3 | 55.5 | 98.0 | 68.5 | 94.8 | ||

| S3-SQ | 84.0 | 44.5 | 98.5 | 57.0 | 95.3 | ||

| S4-WQ | 78.3 | 35.2 | 97.5 | 48.9 | 93.5 | ||

| VPD (kPa) | S1-EQ | 0.3 | 0.03 | 1.7 | 0.07 | 1.2 | |

| S2-NQ | 0.3 | 0.03 | 1.6 | 0.08 | 1.0 | ||

| S3-SQ | 0.4 | 0.02 | 2.1 | 0.06 | 1.4 | ||

| S4-WQ | 0.5 | 0.04 | 2.8 | 0.09 | 1.9 | ||

| Harvest | T (°C) | S1-EQ | 18.9 | 7.9 | 38.0 | 10.9 | 29.2 |

| S2-NQ | 18.8 | 8.2 | 40.3 | 11.3 | 29.3 | ||

| S3-SQ | 17.7 | 7.4 | 42.3 | 10.4 | 31.2 | ||

| S4-WQ | 18.5 | 7.8 | 47.2 | 10.8 | 36.0 | ||

| RH (%) | S1-EQ | 75.8 | 22.5 | 99.0 | 55.9 | 93.4 | |

| S2-NQ | 71.4 | 21.0 | 98.0 | 54.8 | 91.3 | ||

| S3-SQ | 71.9 | 14.0 | 98.2 | 43.1 | 90.7 | ||

| S4-WQ | 65.8 | 12.1 | 94.4 | 31.6 | 85.9 | ||

| VPD (kPa) | S1-EQ | 0.6 | 0.01 | 3.8 | 0.08 | 1.5 | |

| S2-NQ | 0.6 | 0.03 | 4.2 | 0.12 | 1.5 | ||

| S3-SQ | 0.7 | 0.03 | 5.0 | 0.1 | 2.1 | ||

| S4-WQ | 0.8 | 0.08 | 6.5 | 0.2 | 3.2 |

| Df | Sum Sq | Mean Sq | F Value | Pr (>F) | |

|---|---|---|---|---|---|

| One-way ANOVA for temperature | |||||

| Sensor | 3 | 35,981 | 11,994 | 269.3 | <2 × 10−16 *** |

| Residuals | 146,136 | 6,508,741 | 45 | ||

| One-way ANOVA for relative humidity | |||||

| Sensor | 3 | 578,139 | 192,713 | 717.8 | <2 × 10−16 *** |

| Residuals | 146,136 | 39,233,980 | 268 | ||

| One-way ANOVA for vapor pressure deficit | |||||

| Sensor | 3 | 673 | 224.40 | 479.9 | <2 × 10−16 *** |

| Residuals | 146,136 | 65,862 | 0.45 | ||

| Parameter | Criteria | Vegetative (0–50 DAT) | Reproductive (51–109 DAT) | Harvest (110–190 DAT) |

|---|---|---|---|---|

| T (°C) | Mean | 16.54 | 16.27 | 16.23 |

| Min absolute | 9 | 10 | 7 | |

| Max absolute | 26 | 27 | 26 | |

| Mean of Min | 12.6 | 12.42 | 10.80 | |

| Mean of Max | 22.72 | 22.34 | 22.98 | |

| RH (%) | Mean | 77.04 | 79.59 | 64.18 |

| Min absolute | 27 | 29.5 | 18.5 | |

| Max absolute | 99.5 | 99 | 95.5 | |

| Mean of Min | 42.7 | 47.1 | 33.9 | |

| Mean of Max | 92.3 | 96 | 87.4 | |

| Precipitation (L m−2) | Total by phenological stage | 162.5 | 99.3 | 46.3 |

| Wind | Mean_speed (km h−1) | 4.68 | 4.80 | 7.78 |

| Predominant direction | E | E | E | |

| Solar radiation (W m−2) | Mean | 198.2 | 188.8 | 180 |

| Mean_Max | 1168.5 | 1150 | 1145.6 |

| Sensor S1-EQ | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 33.5 | 22.8 | 43.7 | 100 |

| Vegetative | Night | 11.6 | 28.9 | 59.5 | 100 |

| Reproductive | Day | 45.8 | 29.2 | 25 | 100 |

| Reproductive | Night | 1.2 | 14.8 | 84 | 100 |

| Harvest | Day | 28.8 | 27.4 | 43.8 | 100 |

| Harvest | Night | 15.8 | 27.2 | 57.0 | 100 |

| Average | Day | 36.0 | 26.5 | 37.5 | 100 |

| Average | Night | 9.5 | 23.6 | 66.8 | 100 |

| Sensor S2-NQ | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 30.4 | 28.6 | 41.0 | 100 |

| Vegetative | Night | 15.6 | 33.5 | 50.9 | 100 |

| Reproductive | Day | 40.1 | 28.4 | 31.5 | 100 |

| Reproductive | Night | 1.0 | 18.9 | 80.1 | 100 |

| Harvest | Day | 30.6 | 25.1 | 44.3 | 100 |

| Harvest | Night | 18.8 | 35.8 | 45.4 | 100 |

| Average | Day | 33.7 | 27.4 | 38.9 | 100 |

| Average | Night | 11.8 | 29.4 | 58.8 | 100 |

| Sensor S3-SQ | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 48.0 | 21.4 | 30.6 | 100 |

| Vegetative | Night | 1.7 | 6.8 | 91.5 | 100 |

| Reproductive | Day | 43.1 | 35.6 | 21.3 | 100 |

| Reproductive | Night | 0.6 | 5.2 | 94.2 | 100 |

| Harvest | Day | 28.0 | 29.4 | 42.6 | 100 |

| Harvest | Night | 18.0 | 25.4 | 56.6 | 100 |

| Average | Day | 39.7 | 28.8 | 31.5 | 100 |

| Average | Night | 6.8 | 12.5 | 80.8 | 100 |

| Sensor S4-WQ | |||||

| Phenological Stage | Time of Day | Optimal (%) | Suboptimal (%) | Critical (%) | Total (%) |

| Vegetative | Day | 44.4 | 21.9 | 33.7 | 100 |

| Vegetative | Night | 2.6 | 13.4 | 84.0 | 100 |

| Reproductive | Day | 34.7 | 44.1 | 21.2 | 100 |

| Reproductive | Night | 3.0 | 11.9 | 85.1 | 100 |

| Harvest | Day | 15.5 | 26.5 | 58 | 100 |

| Harvest | Night | 26.4 | 37.9 | 35.7 | 100 |

| Average | Day | 31.5 | 30.8 | 37.6 | 100 |

| Average | Night | 10.7 | 21.1 | 68.3 | 100 |

| Category | Weight (kg ha−1) | Share (%) |

|---|---|---|

| First | 37,507.7 | 42.6% |

| Second | 29,591.8 | 33.6% |

| Third | 16,295.6 | 18.5% |

| Fourth | 4607.3 | 5.3% |

| Total | 88,002.5 | 100% |

| Variable | Value (USD ha−1) |

|---|---|

| Total cost | 30,800.9 |

| Gross Income | 44,001.3 |

| Gross profit | 13,200.4 |

| Benefit–cost ratio (B/C) | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albuja-Illescas, L.M.; Gómez-Cabezas, M.; Jácome-Aguirre, G.; Aragón-Suárez, J.P.; Jiménez-Lao, R.; Peña-Fernández, A.; Lao, M.T. Microclimate Characterization of a Low-Tech Greenhouse During a Tomato Crop (Solanum lycopersicum L.) Production Cycle in Chaltura, Imbabura. Plants 2025, 14, 3702. https://doi.org/10.3390/plants14233702

Albuja-Illescas LM, Gómez-Cabezas M, Jácome-Aguirre G, Aragón-Suárez JP, Jiménez-Lao R, Peña-Fernández A, Lao MT. Microclimate Characterization of a Low-Tech Greenhouse During a Tomato Crop (Solanum lycopersicum L.) Production Cycle in Chaltura, Imbabura. Plants. 2025; 14(23):3702. https://doi.org/10.3390/plants14233702

Chicago/Turabian StyleAlbuja-Illescas, Luis Marcelo, Miguel Gómez-Cabezas, Gabriel Jácome-Aguirre, Juan Pablo Aragón-Suárez, Rafael Jiménez-Lao, Araceli Peña-Fernández, and María Teresa Lao. 2025. "Microclimate Characterization of a Low-Tech Greenhouse During a Tomato Crop (Solanum lycopersicum L.) Production Cycle in Chaltura, Imbabura" Plants 14, no. 23: 3702. https://doi.org/10.3390/plants14233702

APA StyleAlbuja-Illescas, L. M., Gómez-Cabezas, M., Jácome-Aguirre, G., Aragón-Suárez, J. P., Jiménez-Lao, R., Peña-Fernández, A., & Lao, M. T. (2025). Microclimate Characterization of a Low-Tech Greenhouse During a Tomato Crop (Solanum lycopersicum L.) Production Cycle in Chaltura, Imbabura. Plants, 14(23), 3702. https://doi.org/10.3390/plants14233702