Extraction of Diterpene-Phytochemicals in Raw and Roasted Coffee Beans and Beverage Preparations and Their Relationship

Abstract

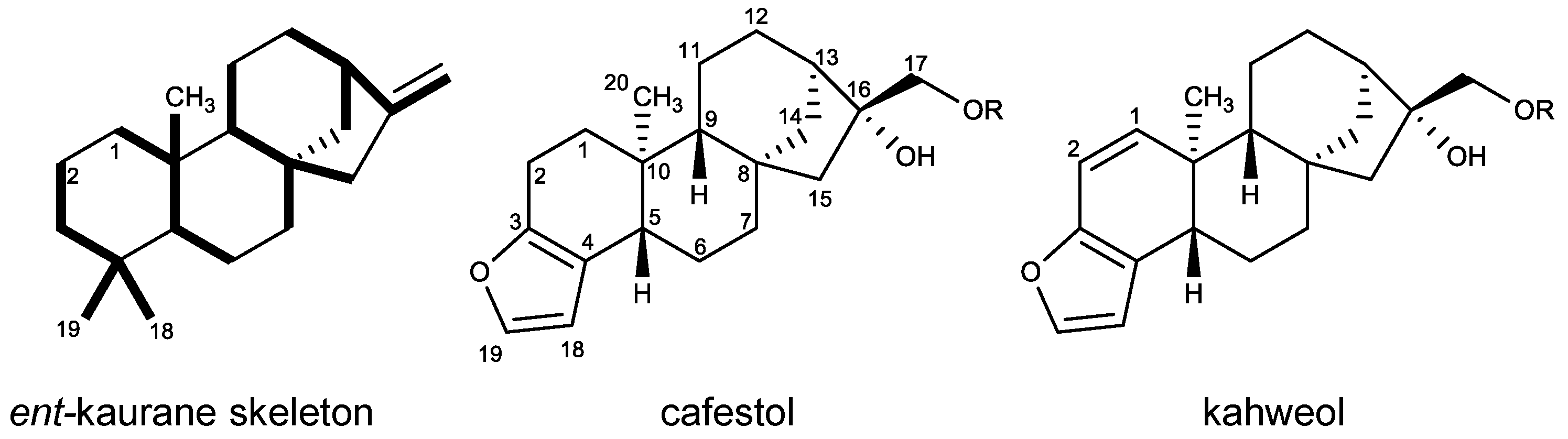

1. Introduction

2. Results and Discussion

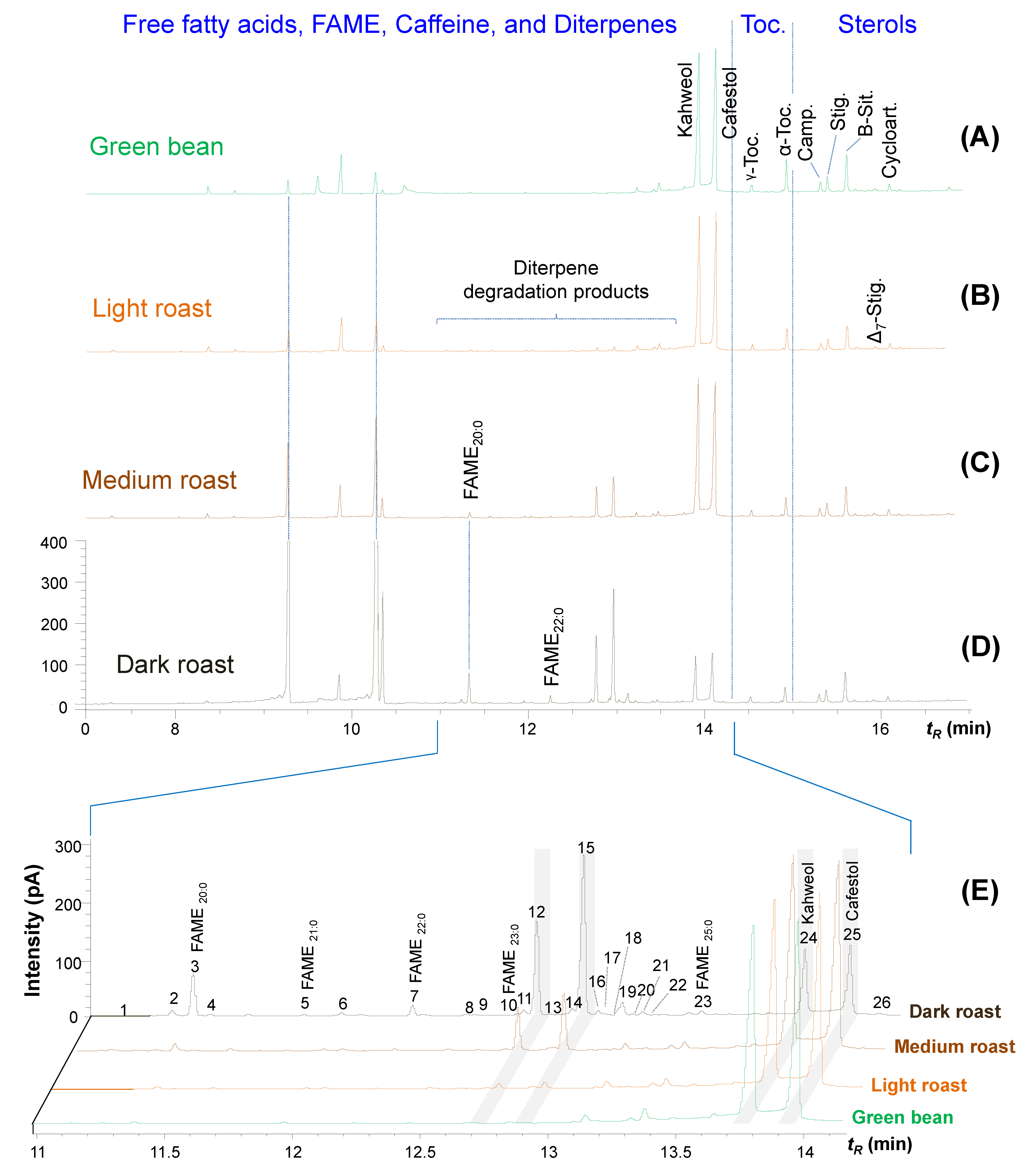

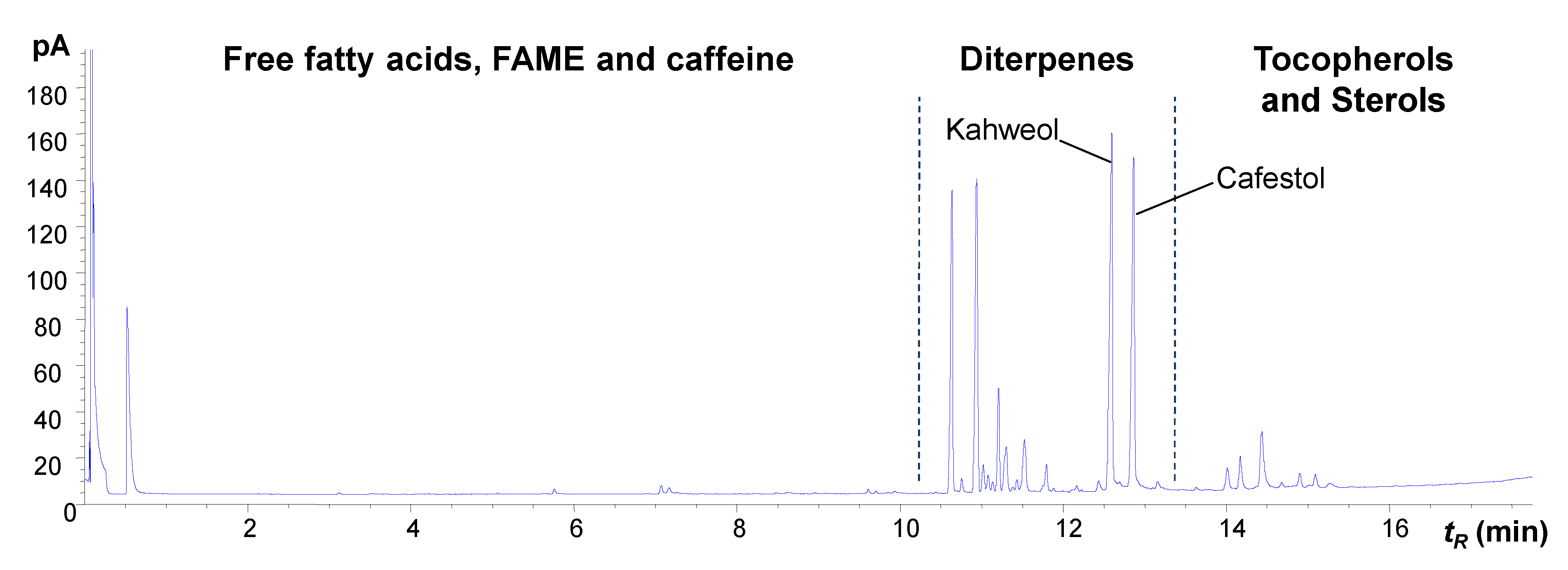

2.1. Diterpene Content in Green and Roasted Coffee Beans

| tR | Name | Molecular Mass | Match/ R. Match | IExp | Present in Coffee Bean | |||

|---|---|---|---|---|---|---|---|---|

| Green | Light | Medium | Dark | |||||

| 9.188 | Palmitic acid, methyl ester | 270 | 947/947 | 1971 | X | X | X | X |

| 9.405 | Ferulic acid, methyl ester | 208 | 955/955 | 2010 | X | X | ||

| 9.524 | Palmitic acid | 256 | 948/953 | 2032 | X | X | X | X |

| 9.767 | Caffeine | 194 | 959/959 | 2077 | X | X | X | X |

| 10.015 | Linoleic acid, methyl ester | 294 | 909/911 | 2123 | X | X | X | X |

| 10.227 | Stearic acid, methyl ester | 298 | 892/898 | 2164 | X | X | X | X |

| 10.528 | Linoleic acid | 280 | 904/936 | 2222 | X | X | X | X |

| 11.025 | Anhydrous cafestol derivate (#1) | 282 | - | 2322 | X | |||

| 11.116 | Eicosenoic acid, methyl ester (#2) | 324 | 957/920 | 2356 | X | |||

| 11.187 | Arachidic acid, methyl ester (#3) | 326 | 779/789 | 2341 | X | X | X | X |

| 11.347 | Anhydrous cafestol derivate (#4) | 282 | - | 2389 | X | |||

| 11.752 | Heneicosanoic acid, methyl ester (#5) | 340 | 778/823 | 2477 | X | |||

| 11.915 | Linolein, 2-mono- (#6) | 354 | 753/825 | 2555 | X | |||

| 12.222 | Behenic acid, methyl ester (#7) | 354 | 938/950 | 2581 | X | X | ||

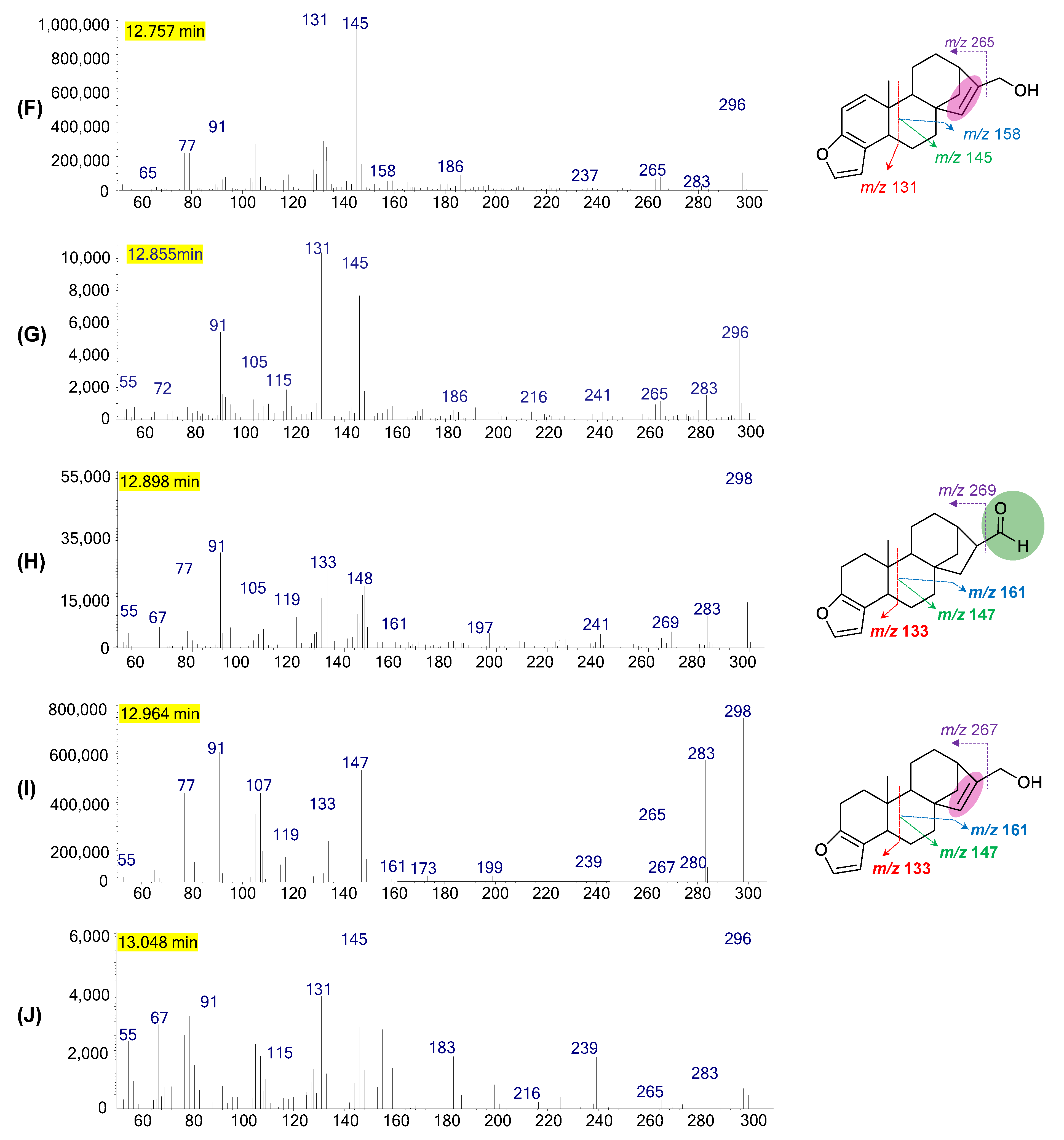

| 12.486 | Kahweal (#8) | 296 | - | 2644 | X | X | X | |

| 12.553 | Dehydro-kahweol derivate (#9) | 296 | - | 2660 | X | X | X | |

| 12.660 | Tricosanoic acid, methyl ester (#10) | 368 | 752/795 | 2694 | X | |||

| 12.697 | Dehydro-kahweol derivate (#11) | 296 | - | 2695 | X | X | X | |

| 12.759 | 15,16-Dehydro-kahweol (#12) | 296 | - | 2710 | X | X | X | |

| 12.855 | Dehydro-kahweol derivate (#13) | 296 | - | 2733 | X | |||

| 12.898 | Cafestal (#14) | 298 | - | 2744 | X | X | X | |

| 12.961 | 15,16-Dehydro-cafestol (#15) | 298 | - | 2759 | X | X | X | |

| 13.018 | Methyl epoxystearate (#16) | 312 | 764/866 | 2772 | X | |||

| 13.048 | Dehydro-kahweol derivate (#17) | 296 | - | 2779 | X | |||

| 13.065 | Kahweol derivative (#18) | 298 | - | 2783 | X | X | ||

| 13.122 | Dehydro-kahweol derivate (#19) | 296 | - | 2797 | X | X | ||

| 13.170 | Cafestol derivative (#20) | 300 | - | 2809 | X | X | X | |

| 13.206 | 16-O-isobutyl-kahweol (#21) | 370 | - | 2818 | X | |||

| 13.382 | 16-O-isobutyl-cafestol (#22) | 372 | - | 2869 | X | |||

| 13.528 | Pentacosanoic acid, methyl ester (#23) | 396 | 825/889 | 2898 | X | X | X | X |

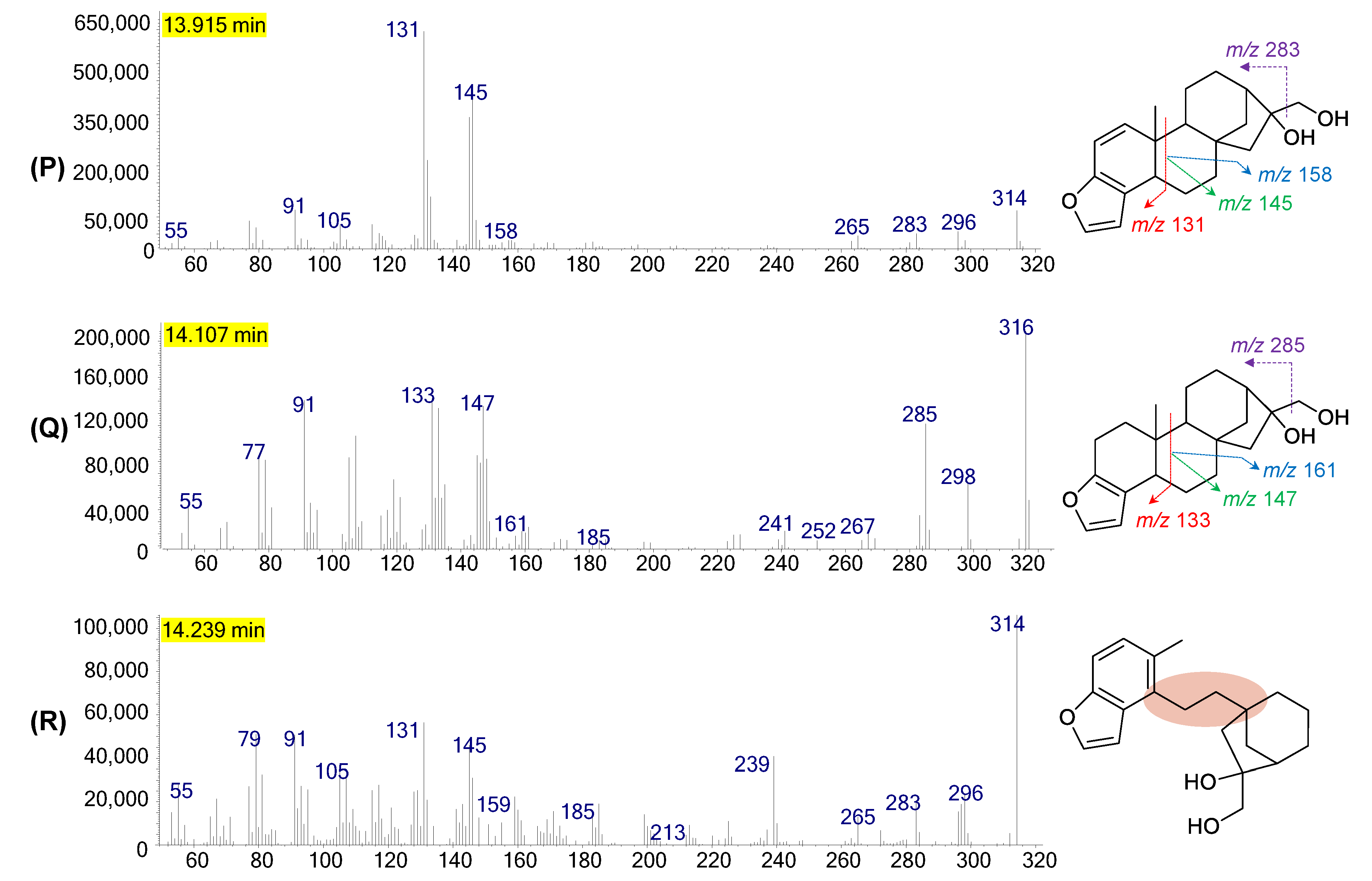

| 13.916 | Kahweol (#24) | 314 | - | 2993 | X | X | X | X |

| 14.105 | Cafestol (#25) | 316 | - | 3044 | X | X | X | X |

| 14.239 | Seco-kahweol (#26) | 314 | - | 3080 | X | |||

| 14.544 | γ-Tocopherol | 416 | 907/914 | 3161 | X | X | X | X |

| 14.894 | α-Tocopherol | 430 | 858/917 | 3258 | X | X | X | X |

| 15.345 | Campesterol | 400 | 898/912 | 3383 | X | X | X | X |

| 15.428 | Stigmasterol | 412 | 902/910 | 3403 | X | X | X | X |

| 15.653 | β-Sitosterol | 414 | 954/957 | 3436 | X | X | X | X |

| 15.757 | 5-Avenasterol | 412 | 788/874 | 3451 | X | X | X | X |

| 15.909 | Stigmast-7-en-3-ol (Δ-7-Stigmastenol) | 414 | 804/855 | 3474 | X | X | X | |

| 15.981 | Cycloartenol | 426 | 916/896 | 3484 | X | X | X | |

| 16.151 | N.I. | - | - | - | X | X | ||

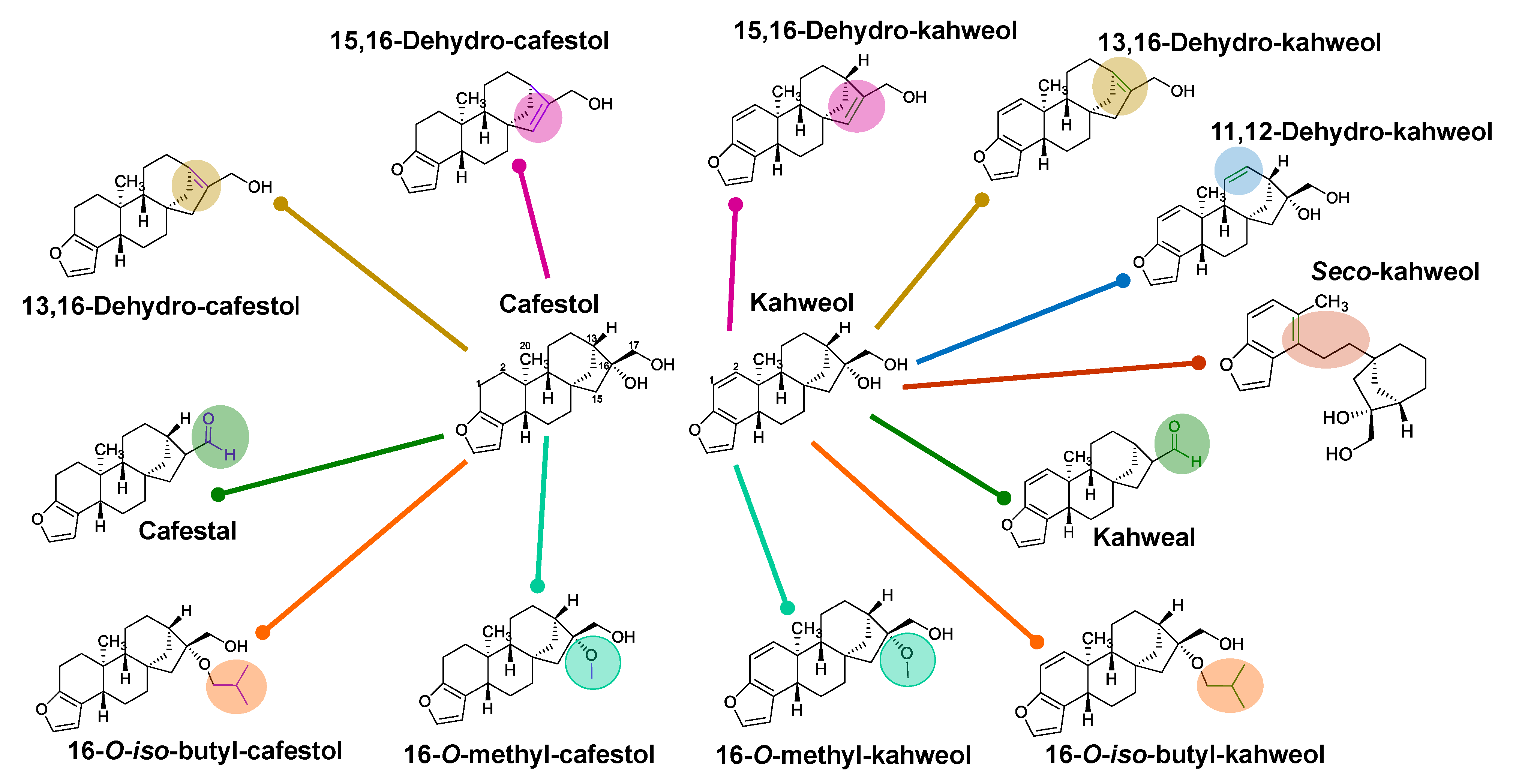

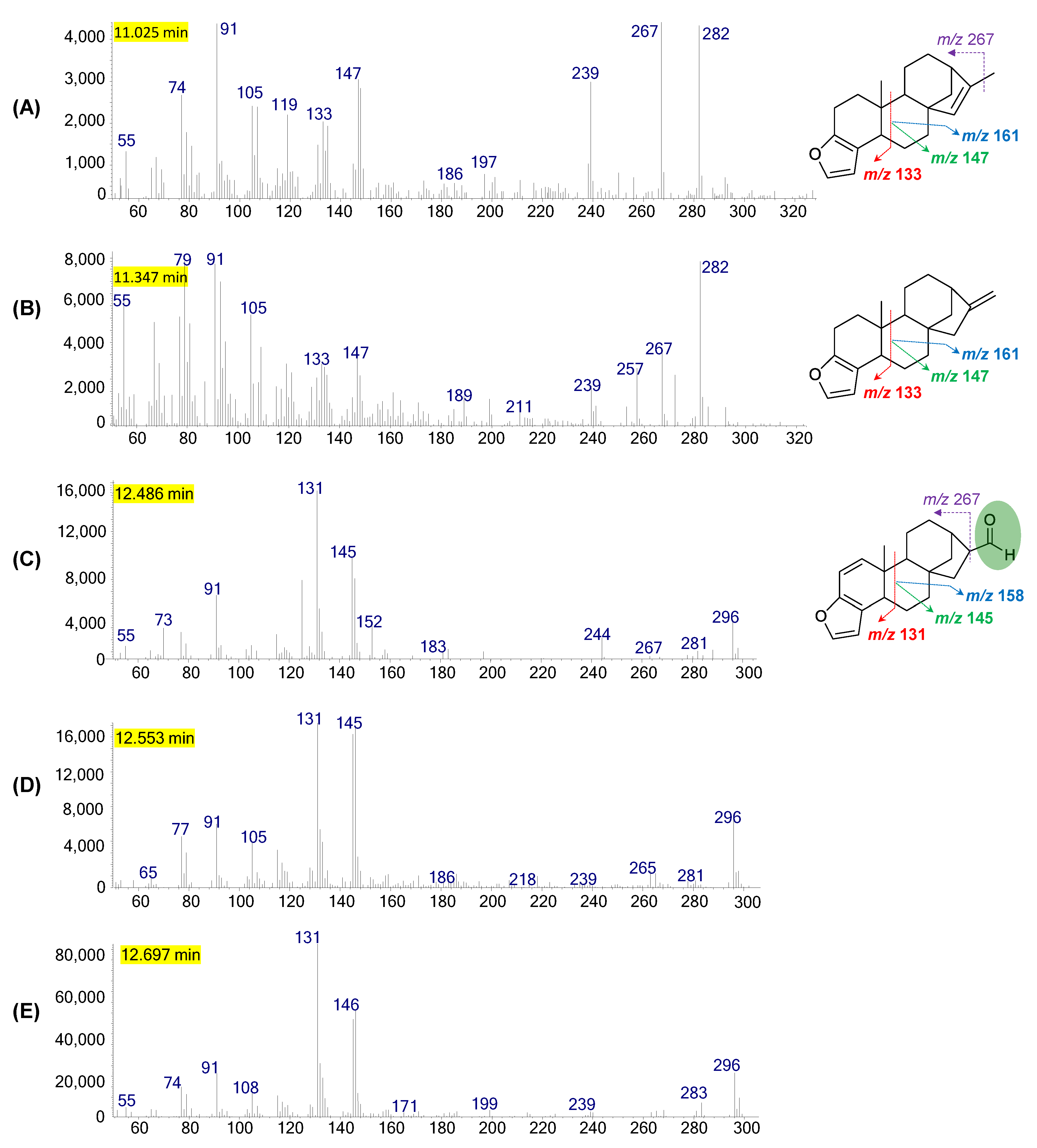

2.2. Identity of C&K Degradation Products

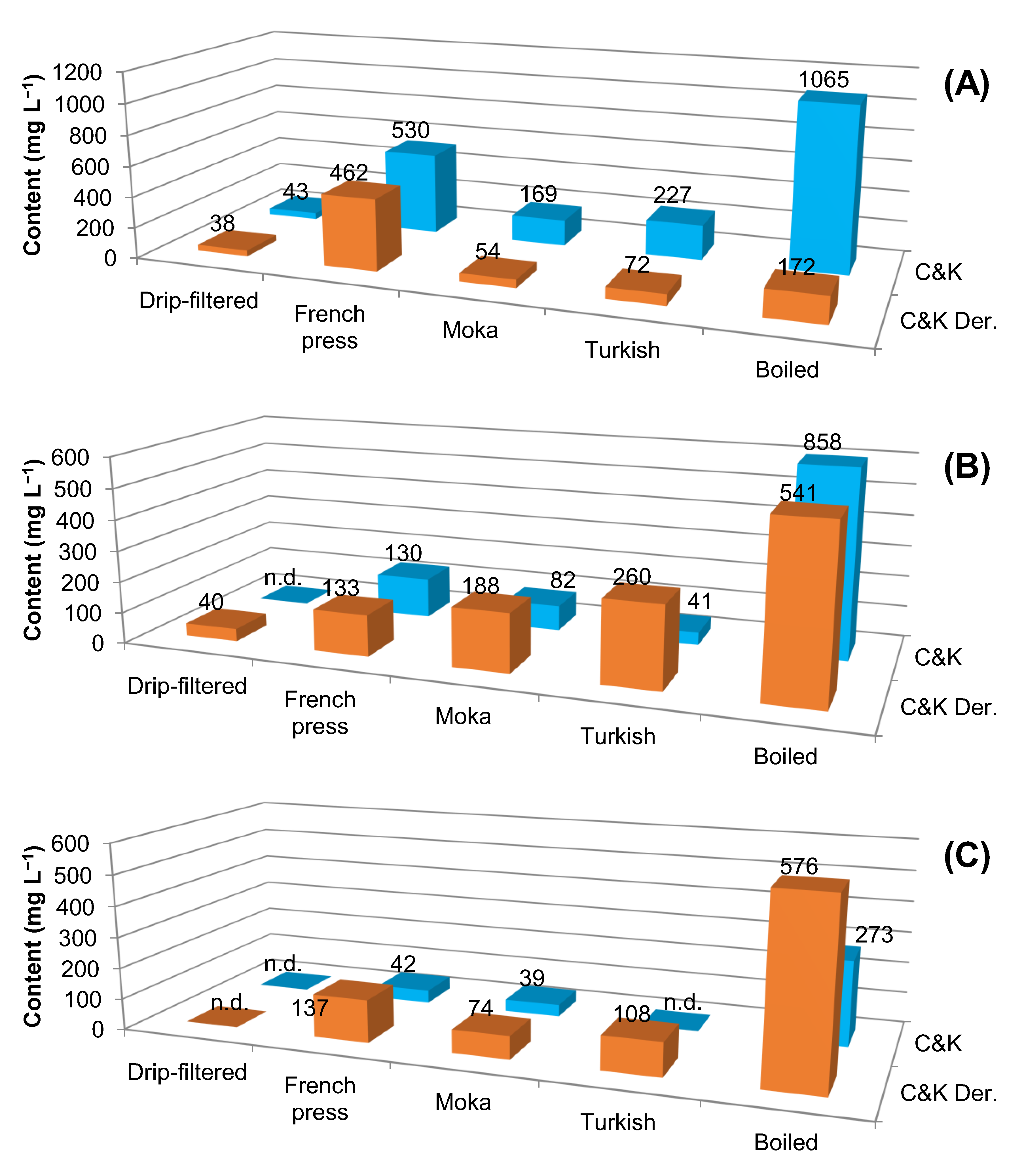

2.3. Diterpene Content in Coffee Beverages Prepared by Different Coffee Makers

3. Materials and Methods

3.1. Standards and Reagents

3.2. Raw and Roasted Coffee Samples

Preparation of Coffee Beverages

- Filtered coffee: The filtered coffee beverage was made in an electric coffee maker (model PH14, Philco) by pouring 150 mL of mineral water into its respective compartment, and 15 g of coffee powder was placed in a filter paper (model 102, 3 Corações, Nova Iguaçu). The coffee maker was turned on, heating the water to a temperature of less than 100 °C, which percolated through the coffee powder on the filter and was collected in a small jar below.

- Boiled Coffee: Boiled coffee was made by placing 15 g of coffee powder in 150 mL of mineral water and boiling for 10 min. Subsequently, the drink was left to rest for 5 min to decant the suspended solids and then collected for analysis.

- Moka (Italian coffee): The bottom compartment of the Moka coffee maker (Bialetti©, six-cup model), also known as an Italian coffee maker, was filled with 150 mL of mineral water, not exceeding the reference level. The coffee powder (15 g) was placed in the funnel without compacting it. The upper part was screwed onto the bottom part, and the coffee maker was placed under heating. When the coffee finished passing under the funnel filled with powder, the coffee maker was removed from the heating and the beverage collect for analysis.

- French Press: 15 g of powder was added to the French press coffee maker (Bialetti©, three-cup model), followed by 150 mL of hot mineral water (90 ± 2 °C). The plunger assembly was placed in the upper part, closing the coffee maker and leaving the drink to infuse for 5 min. After that, the plunger was pushed to the end to complete the extraction.

- Turkish Coffee: 15 g of coffee powder was poured into the cezve—a Turkish coffee pot (Ibrik©, 0.35 L model)—with mineral water (150 mL). The coffee maker was placed under heating. When boiling began and the foam went to the coffee maker’s top, it was removed from heating. The coffee maker heating and its retirement were repeated twice. The beverage was carefully poured into a cup for analysis without transferring the coffee grounds.

3.3. Extraction of Diterpenes in Green and Roasted Coffee Beans

3.4. Extraction of Diterpenes in Coffee Beverages

3.5. GC Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Poisson, L.; Blank, I.; Dunkel, A.; Hofmann, T. The Chemistry of Roasting-Decoding Flavor Formation. In The Craft and Science of Coffee; Folmer, B., Ed.; Academic Press: London, UK, 2017; pp. 273–309. ISBN 9780128035207. [Google Scholar] [CrossRef]

- Farah, A. Coffee: Production, Quality and Chemistry, 1st ed.; Farah, A., Ed.; The Royal Society of Chemistry: London, UK, 2019. [Google Scholar]

- Novaes, F.J.M.; da Silva Junior, A.I.; Kulsing, C.; Nolvachai, Y.; Bizzo, H.R.; de Aquino Neto, F.R.; Rezende, C.M.; Marriott, P.J. New Approaches to Monitor Semi-Volatile Organic Compounds Released during Coffee Roasting Using Flow-through/Active Sampling and Comprehensive Two-Dimensional Gas Chromatography. Food Res. Int. 2019, 119, 349–358. [Google Scholar] [CrossRef] [PubMed]

- Calligaris, S.; Munari, M.; Arrighetti, G.; Barba, L. Insights into the Physicochemical Properties of Coffee Oil. Eur. J. Lipid Sci. Technol. 2009, 111, 1270–1277. [Google Scholar] [CrossRef]

- Pacetti, D.; Lucci, P.; Frega, N.G. Unsaponifiable Matter of Coffee. In Coffee in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: London, UK, 2015; pp. 119–127. ISBN 9780124095175. [Google Scholar] [CrossRef]

- Williamson, K.; Hatzakis, E. NMR Analysis of Roasted Coffee Lipids and Development of a Spent Ground Coffee Application for the Production of Bioplastic Precursors. Food Res. Int. 2019, 119, 683–692. [Google Scholar] [CrossRef]

- Moeenfard, M.; Alves, A. New Trends in Coffee Diterpenes Research from Technological to Health Aspects. Food Res. Int. 2020, 134, 109207. [Google Scholar] [CrossRef]

- Speer, K.; Kölling-Speer, I. The Lipid Fraction of the Coffee Bean. Braz. J. Plant Physiol. 2006, 18, 201–216. [Google Scholar] [CrossRef]

- Novaes, F.J.M.; Itabaiana Junior, I.; Sutili, F.K.; Marriott, P.J.; Bizzo, H.R.; de Aquino Neto, F.R.; de Souza, R.O.M.A.; Rezende, C.M. Lipase-Catalysed Esters Synthesis of Cafestol and Kahweol. Food Chem. 2018, 259, 226–233. [Google Scholar] [CrossRef]

- Lee, K.J.; Jeong, H.G. Protective Effects of Kahweol and Cafestol against Hydrogen Peroxide-Induced Oxidative Stress and DNA Damage. Toxicol. Lett. 2007, 173, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Cárdenas, C.; Quesada, A.R.; Medina, M.Á. Kahweol, a Coffee Diterpene with Anti-Inflammatory Properties; Preedy, V.R., Ed.; Academic Press: London, UK, 2015; pp. 627–633. ISBN 9780124095175. [Google Scholar] [CrossRef]

- Baek, J.H.; Kim, N.J.; Song, J.K.; Chun, K.H. Kahweol Inhibits Lipid Accumulation and Induces Glucose-Uptake through Activation of AMP-Activated Protein Kinase (AMPK). BMB Rep. 2017, 50, 566–571. [Google Scholar] [CrossRef]

- Silva, M.A.E.; Brand, A.L.M.; Novaes, F.J.M.; Rezende, C. Cafestol, Kahweol and Their Acylated Derivatives: Antitumor Potential, Pharmacokinetics, and Chemopreventive Profile. Food Rev. Int. 2022. [Google Scholar] [CrossRef]

- Pereda, M.C.V.; Dieamant, G.C.; Eberlin, S.; Nogueira, C.; Colombi, D.; Di Stasi, L.C.; Queiroz, M.L.S. Effect of Green Coffea Arabica L. Seed Oil on Extracellular Matrix Components and Water-Channel Expression in in Vitro and Ex Vivo Human Skin Models. J. Cosmet. Dermatol. 2009, 8, 56–62. [Google Scholar] [CrossRef]

- Wagemaker, T.A.L.; Silva, S.A.M.; Leonardi, G.R.; Maia Campos, P.M.B.G. Green Coffea Arabica L: Seed Oil Influences the Stability and Protective Effects of Topical Formulations. Ind. Crops Prod. 2015, 63, 34–40. [Google Scholar] [CrossRef]

- Lania, B.G.; Morari, J.; De Souza, A.L.; Da Silva, M.N.; De Almeida, A.R.; Veira-Damiani, G.; Alegre, S.M.; César, C.L.; Velloso, L.A.; Cintra, M.L.; et al. Topical Use and Systemic Action of Green and Roasted Coffee Oils and Ground Oils in a Cutaneous Incision Model in Rats (Rattus Norvegicus Albinus). PLoS ONE 2017, 12, e188779. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, N.A.; Sandini, T.M.; Cornelio-Santiago, H.P.; Martinelli, E.C.L.; Raspantini, L.E.R.; Raspantini, P.C.; Momo, C.; de Oliveira, A.L.; Fukumasu, H. Acute and Subacute (28 Days) Toxicity of Green Coffee Oil Enriched with Diterpenes Cafestol and Kahweol in Rats. Regul. Toxicol. Pharmacol. 2020, 110, 104517. [Google Scholar] [CrossRef] [PubMed]

- Kurzrock, T.; Speer, K. Diterpenes and Diterpene Esters in Coffee. Food Rev. Int. 2001, 17, 433–450. [Google Scholar] [CrossRef]

- Zhu, L.; Luo, J.; Hong, R. Total Synthesis of (±)-Cafestol: A Late-Stage Construction of the Furan Ring Inspired by a Biosynthesis Strategy. Org. Lett. 2014, 16, 2162–2165. [Google Scholar] [CrossRef]

- Kölling-Speer, I.; Strohschneider, S.; Speer, K. Determination of Free Diterpenes in Green and Roasted Coffees. HRC J. High Resolut. Chromatogr. 1999, 22, 43–46. [Google Scholar] [CrossRef]

- Oigman, S.S.; De Souza, R.O.M.A.; Dos Santos Júnior, H.M.; Hovell, A.M.C.; Hamerski, L.; Rezende, C.M. Microwave-Assisted Methanolysis of Green Coffee Oil. Food Chem. 2012, 134, 999–1004. [Google Scholar] [CrossRef]

- Dias, R.C.E.; De Faria, A.F.; Mercadante, A.Z.; Bragagnolo, N.; De Benassi, M.T. Comparison of Extraction Methods for Kahweol and Cafestol Analysis in Roasted Coffee. J. Braz. Chem. Soc. 2013, 24, 492–499. [Google Scholar] [CrossRef]

- Chartier, A.; Beaumesnil, M.; De Oliveira, A.L.; Elfakir, C.; Bostyn, S. Optimization of the Isolation and Quantitation of Kahweol and Cafestol in Green Coffee Oil. Talanta 2013, 117, 102–111. [Google Scholar] [CrossRef]

- Novaes, F.J.M.; Oigman, S.S.; De Souza, R.O.M.A.; Rezende, C.M.; De Aquino Neto, F.R. New Approaches on the Analyses of Thermolabile Coffee Diterpenes by Gas Chromatography and Its Relationship with Cup Quality. Talanta 2015, 139, 159–166. [Google Scholar] [CrossRef]

- Zhang, C.; Linforth, R.; Fisk, I.D. Cafestol Extraction Yield from Different Coffee Brew Mechanisms. Food Res. Int. 2012, 49, 27–31. [Google Scholar] [CrossRef]

- Silva, J.A.; Borges, N.; Santos, A.; Alves, A. Method Validation for Cafestol and Kahweol Quantification in Coffee Brews by HPLC-DAD. Food Anal. Methods 2012, 5, 1404–1410. [Google Scholar] [CrossRef]

- Erny, G.L.; Moeenfard, M.; Alves, A. Liquid Chromatography with Diode Array Detection Combined with Spectral Deconvolution for the Analysis of Some Diterpene Esters in Arabica Coffee Brew. J. Sep. Sci. 2015, 38, 612–620. [Google Scholar] [CrossRef] [PubMed]

- Moeenfard, M.; Silva, J.A.; Borges, N.; Santos, A.; Alves, A. Diterpenes in Espresso Coffee: Impact of Preparation Parameters. Eur. Food Res. Technol. 2015, 240, 763–773. [Google Scholar] [CrossRef]

- Rendón, M.Y.; dos Santos Scholz, M.B.; Bragagnolo, N. Is Cafestol Retained on the Paper Filter in the Preparation of Filter Coffee? Food Res. Int. 2017, 100, 798–803. [Google Scholar] [CrossRef]

- Rendón, M.Y.; dos Santos Scholz, M.B.; Bragagnolo, N. Physical Characteristics of the Paper Filter and Low Cafestol Content Filter Coffee Brews. Food Res. Int. 2018, 108, 280–285. [Google Scholar] [CrossRef]

- Kim, H.G.; Hwang, Y.P.; Jeong, H.G. Kahweol Blocks STAT3 Phosphorylation and Induces Apoptosis in Human Lung Adenocarcinoma A549 Cells. Toxicol. Lett. 2009, 187, 28–34. [Google Scholar] [CrossRef]

- Lee, K.A.; Chae, J.I.; Shim, J.H. Natural Diterpenes from Coffee, Cafestol and Kahweol Induce Apoptosis through Regulation of Specificity Protein 1 Expression in Human Malignant Pleural Mesothelioma. J. Biomed. Sci. 2012, 19, 60. [Google Scholar] [CrossRef]

- Choi, D.W.; Lim, M.S.; Lee, J.W.; Chun, W.; Lee, S.H.; Nam, Y.H.; Park, J.M.; Choi, D.H.; Kang, C.D.; Lee, S.J.; et al. The Cytotoxicity of Kahweol in HT-29 Human Colorectal Cancer Cells Is Mediated by Apoptosis and Suppression of Heat Shock Protein 70 Expression. Biomol. Ther. 2015, 23, 128–133. [Google Scholar] [CrossRef]

- Makino, T.; Izumi, K.; Hiratsuka, K.; Kano, H.; Shimada, T.; Nakano, T.; Kadomoto, S.; Naito, R.; Iwamoto, H.; Yaegashi, H.; et al. Anti-Proliferative and Anti-Migratory Properties of Coffee Diterpenes Kahweol Acetate and Cafestol in Human Renal Cancer Cells. Sci. Rep. 2021, 11, 675. [Google Scholar] [CrossRef]

- Sridevi, V.; Giridhar, P.; Ravishankar, G. A Evaluation of Roasting and Brewing Effect on Antinutritional Diterpenes-Cafestol and Kahweol in Coffee. Glob. J. Med. Res. 2011, 11, 1–7. [Google Scholar]

- Dias, R.C.E.; de Faria-Machado, A.F.; Mercadante, A.Z.; Bragagnolo, N.; Benassi, M.d.T. Roasting Process Affects the Profile of Diterpenes in Coffee. Eur. Food Res. Technol. 2014, 239, 961–970. [Google Scholar] [CrossRef]

- Moeenfard, M.; Erny, G.L.; Alves, A. Variability of Some Diterpene Esters in Coffee Beverages as Influenced by Brewing Procedures. J. Food Sci. Technol. 2016, 53, 3916–3927. [Google Scholar] [CrossRef] [PubMed]

- Novaes, F.J.M.; Bayan, F.C.; Neto, F.R.d.A.; Rezende, C.M. The Occurrence of Cafestol and Kahweol Diterpenes in Different Coffee Brews. Coffee Sci. 2019, 14, 265–280. [Google Scholar] [CrossRef]

- Araújo, J.M.A.; Sandi, D. Extraction of Coffee Diterpenes and Coffee Oil Using Supercritical Carbon Dioxide. Food Chem. 2007, 101, 1087–1094. [Google Scholar] [CrossRef]

- Gloess, A.N.; Yeretzian, C.; Knochenmuss, R.; Groessl, M. On-Line Analysis of Coffee Roasting with Ion Mobility Spectrometry–mass Spectrometry (IMS–MS). Int. J. Mass Spectrom. 2018, 424, 49–57. [Google Scholar] [CrossRef]

- da Rosa, J.S.; Freitas-Silva, O.; Rouws, J.R.C.; Moreira, I.G.d.S.; Novaes, F.J.M.; Azevedo, D.d.A.; Schwab, N.; Godoy, R.L.d.O.; Eberlin, M.N.; de Rezende, C.M. Mass Spectrometry Screening of Arabica Coffee Roasting: A Non-Target and Non-Volatile Approach by EASI-MS and ESI-MS. Food Res. Int. 2016, 89, 967–975. [Google Scholar] [CrossRef]

- Wagemaker, T.A.L.; Carvalho, C.R.L.; Maia, N.B.; Baggio, S.R.; Guerreiro Filho, O. Sun Protection Factor, Content and Composition of Lipid Fraction of Green Coffee Beans. Ind. Crops Prod. 2011, 33, 469–473. [Google Scholar] [CrossRef]

- Wagemaker, T.A.L.; Fernandes, A.S.; Campos, P.M.; Rodrigues, L.M.; Rijo, P. Evaluation of Antioxidant and Antimicrobial Activities of Green Coffee Oil in Cosmetic Formulations. J. Biomed. Biopharm. Res. 2012, 2, 207–214. [Google Scholar] [CrossRef]

- Voytena, A.P.L.; Affonso, R.C.L.; Pitz, H.S.; Ramlov, F.; Alberti, T.; Coelho, D.S.; Pereira, A.; Navarro, B.B.; Fanan, S.; Casagrande, M.; et al. Phytochemical Profile and in Vitro Assessment of the Cytotoxicity of Green and Roasted Coffee Oils (Coffea Arabica L.) and Their Polar Fractions. Rec. Nat. Prod. 2017, 12, 169–174. [Google Scholar] [CrossRef]

- Campanha, F.G.; Dias, R.C.E.; Benassi, M.T. Discrimination of Coffee Species Using Kahweol and Cafestol: Effects of Roasting and of Defects. Coffee Sci. 2010, 5, 87–96. [Google Scholar]

- Kitzberger, C.S.G.; Scholz, M.B.d.S.; Pereira, L.F.P.; Vieira, L.G.E.; Sera, T.; Silva, J.B.G.D.; Benassi, M.d.T. Diterpenes in Green and Roasted Coffee of Coffea Arabica Cultivars Growing in the Same Edapho-Climatic Conditions. J. Food Compos. Anal. 2013, 30, 52–57. [Google Scholar] [CrossRef]

- Guerrero, G.; Suárez, M.; Moreno, G. Chemosystematic Study of Diterpenoids in Green Coffee Beans. In 20th International Colloquium on the Chemistry of Coffee; ASIC: Paris, France, 2005; pp. 292–296. [Google Scholar]

- Fischer, M.; Wohlfahrt, S.; Varga, J.; Saraji-Bozorgzad, M.; Matuschek, G.; Denner, T.; Zimmermann, R. Evolved gas analysis by single photon ionization-mass spectrometry. J. Therm. Anal. Calorim. 2014, 116, 1461–1469. [Google Scholar] [CrossRef]

- Czech, H.; Schepler, C.; Klingbeil, S.; Ehlert, S.; Howell, J.; Zimmermann, R. Resolving Coffee Roasting-Degree Phases Based on the Analysis of Volatile Compounds in the Roasting Off-Gas by Photoionization Time-of-Flight Mass Spectrometry (PI-TOFMS) and Statistical Data Analysis: Toward a PI-TOFMS Roasting Model. J. Agric. Food Chem. 2016, 64, 5223–5231. [Google Scholar] [CrossRef] [PubMed]

- Gross, G.; Jaccaud, E.; Huggett, A.C. Analysis of the Content of the Diterpenes Cafestol and Kahweol in Coffee Brews. Food Chem. Toxicol. 1997, 35, 547–554. [Google Scholar] [CrossRef]

- Del Castillo, M.L.R.; Herraiz, M.; Blanch, G.P. Rapid Analysis of Cholesterol-Elevating Compounds in Coffee Brews by off-Line High-Performance Liquid Chromatography/High-Resolution Gas Chromatography. J. Agric. Food Chem. 1999, 47, 1525–1529. [Google Scholar] [CrossRef]

- Scharnhop, H.; Winterhalter, P. Isolation of Coffee Diterpenes by Means of High-Speed Countercurrent Chromatography. J. Food Compos. Anal. 2009, 22, 233–237. [Google Scholar] [CrossRef]

- Dias, R.C.E.; Campanha, F.G.; Vieira, L.G.E.; Ferreira, L.P.; David, P.O.T.; Marraccini, P.; De Benassi, M.T. Evaluation of Kahweol and Cafestol in Coffee Tissues and Roasted Coffee by a New High-Performance Liquid Chromatography Methodology. J. Agric. Food Chem. 2010, 58, 88–93. [Google Scholar] [CrossRef]

- De Roos, B.; Van Der Weg, G.; Urgert, R.; Van De Bovenkamp, P.; Charrier, A.; Katan, M.B. Levels of Cafestol, Kahweol, and Related Diterpenoids in Wild Species of the Coffee Plant Coffea. J. Agric. Food Chem. 1997, 45, 3065–3069. [Google Scholar] [CrossRef]

- Kamm, W.; Dionisi, F.; Fay, L.B.; Hischenhuber, C.; Schmarr, H.G.; Engel, K.H. Rapid and Simultaneous Analysis of 16-O-Methylcafestol and Sterols as Markers for Assessment of Green Coffee Bean Authenticity by on-Line LC-GC. JAOCS J. Am. Oil Chem. Soc. 2002, 79, 1109–1113. [Google Scholar] [CrossRef]

- Pacetti, D.; Boselli, E.; Balzano, M.; Frega, N.G. Authentication of Italian Espresso Coffee Blends through the GC Peak Ratio between Kahweol and 16-O-Methylcafestol. Food Chem. 2012, 135, 1569–1574. [Google Scholar] [CrossRef] [PubMed]

- De Lucia, M.; Panzella, L.; Melck, D.; Giudicianni, I.; Motta, A.; Napolitano, A.; D’Ischia, M. Differential Reactivity of Purified Bioactive Coffee Furans, Cafestol and Kahweol, with Acidic Nitrite: Product Characterization and Factors Controlling Nitrosation versus Ring-Opening Pathways. Chem. Res. Toxicol. 2009, 22, 1922–1928. [Google Scholar] [CrossRef] [PubMed]

- Tsukui, A.; Santos Júnior, H.M.; Oigman, S.S.; De Souza, R.O.M.A.; Bizzo, H.R.; Rezende, C.M. Microwave-Assisted Extraction of Green Coffee Oil and Quantification of Diterpenes by HPLC. Food Chem. 2014, 164, 266–271. [Google Scholar] [CrossRef] [PubMed]

- Speer, K.; Buchmann, S.; Kölling-Speer, I. Planar Chromatography in Practice TLC Screening for the Detection of Robusta Admixtures to Arabica Coffee. Camag Bibliogr. Serv. 2012, 1–3. Available online: https://www.uni-giessen.de/de/fbz/fb09/institute/ernaehrungswissenschaft/prof/lmw/Publications/CBS109E.pdf (accessed on 12 January 2023).

- Schievano, E.; Finotello, C.; De Angelis, E.; Mammi, S.; Navarini, L. Rapid Authentication of Coffee Blends and Quantification of 16-O-Methylcafestol in Roasted Coffee Beans by Nuclear Magnetic Resonance. J. Agric. Food Chem. 2014, 62, 12309–12314. [Google Scholar] [CrossRef]

- Defernez, M.; Wren, E.; Watson, A.D.; Gunning, Y.; Colquhoun, I.J.; Le Gall, G.; Williamson, D.; Kemsley, E.K. Low-Field 1H NMR Spectroscopy for Distinguishing between Arabica and Robusta Ground Roast Coffees. Food Chem. 2017, 215, 106–113. [Google Scholar] [CrossRef]

- Gunning, Y.; Defernez, M.; Watson, A.D.; Beadman, N.; Colquhoun, I.J.; Le Gall, G.; Philo, M.; Garwood, H.; Williamson, D.; Davis, A.P.; et al. 16-O-Methylcafestol Is Present in Ground Roast Arabica Coffees: Implications for Authenticity Testing. Food Chem. 2018, 248, 52–60. [Google Scholar] [CrossRef]

- Schumann, S.; Gruner, M.; Speer, K. Secokahweol—A New Diterpene Degradation Product in Roasted Coffee. In Proceedings of the 22nd International Conference on Coffee Science, Campinas, Brazil, 14–19 September 2008; pp. 496–499. [Google Scholar]

- Novaes, F.J.M.; Lima, F.A.; Calado, V.; Marriott, P.J.; de Aquino Neto, F.R.; Rezende, C.M. Isolating Valuable Coffee Diterpenes by Using an Inexpensive Procedure. Ind. Crops Prod. 2020, 152, 112494. [Google Scholar] [CrossRef]

- Métodos de Preparo. Available online: https://www.abic.com.br/tudo-de-cafe/metodos-de-preparo/ (accessed on 24 August 2022).

| Sample | Kahweol Derivatives | Cafestol Derivatives | Kahweol | Cafestol | TOTAL |

|---|---|---|---|---|---|

| Green bean | 0.000 | 0.000 | 0.426 | 0.371 | 0.797 |

| Light roast | 0.007 | 0.011 | 0.510 | 0.477 | 1.005 |

| Medium roast | 0.052 | 0.096 | 0.581 | 0.568 | 1.297 |

| Dark roast | 0.173 | 0.265 | 0.143 | 0.159 | 0.740 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novaes, F.J.M.; da Silva, M.A.E.; Silva, D.C.; Aquino Neto, F.R.d.; Rezende, C.M. Extraction of Diterpene-Phytochemicals in Raw and Roasted Coffee Beans and Beverage Preparations and Their Relationship. Plants 2023, 12, 1580. https://doi.org/10.3390/plants12081580

Novaes FJM, da Silva MAE, Silva DC, Aquino Neto FRd, Rezende CM. Extraction of Diterpene-Phytochemicals in Raw and Roasted Coffee Beans and Beverage Preparations and Their Relationship. Plants. 2023; 12(8):1580. https://doi.org/10.3390/plants12081580

Chicago/Turabian StyleNovaes, Fábio Junior Moreira, Maria Alice Esteves da Silva, Diana Cardoso Silva, Francisco Radler de Aquino Neto, and Claudia Moraes Rezende. 2023. "Extraction of Diterpene-Phytochemicals in Raw and Roasted Coffee Beans and Beverage Preparations and Their Relationship" Plants 12, no. 8: 1580. https://doi.org/10.3390/plants12081580

APA StyleNovaes, F. J. M., da Silva, M. A. E., Silva, D. C., Aquino Neto, F. R. d., & Rezende, C. M. (2023). Extraction of Diterpene-Phytochemicals in Raw and Roasted Coffee Beans and Beverage Preparations and Their Relationship. Plants, 12(8), 1580. https://doi.org/10.3390/plants12081580