Performance Analysis of Time Series Deep Learning Models for Climate Prediction in Indoor Hydroponic Greenhouses at Different Time Intervals

Abstract

:1. Introduction

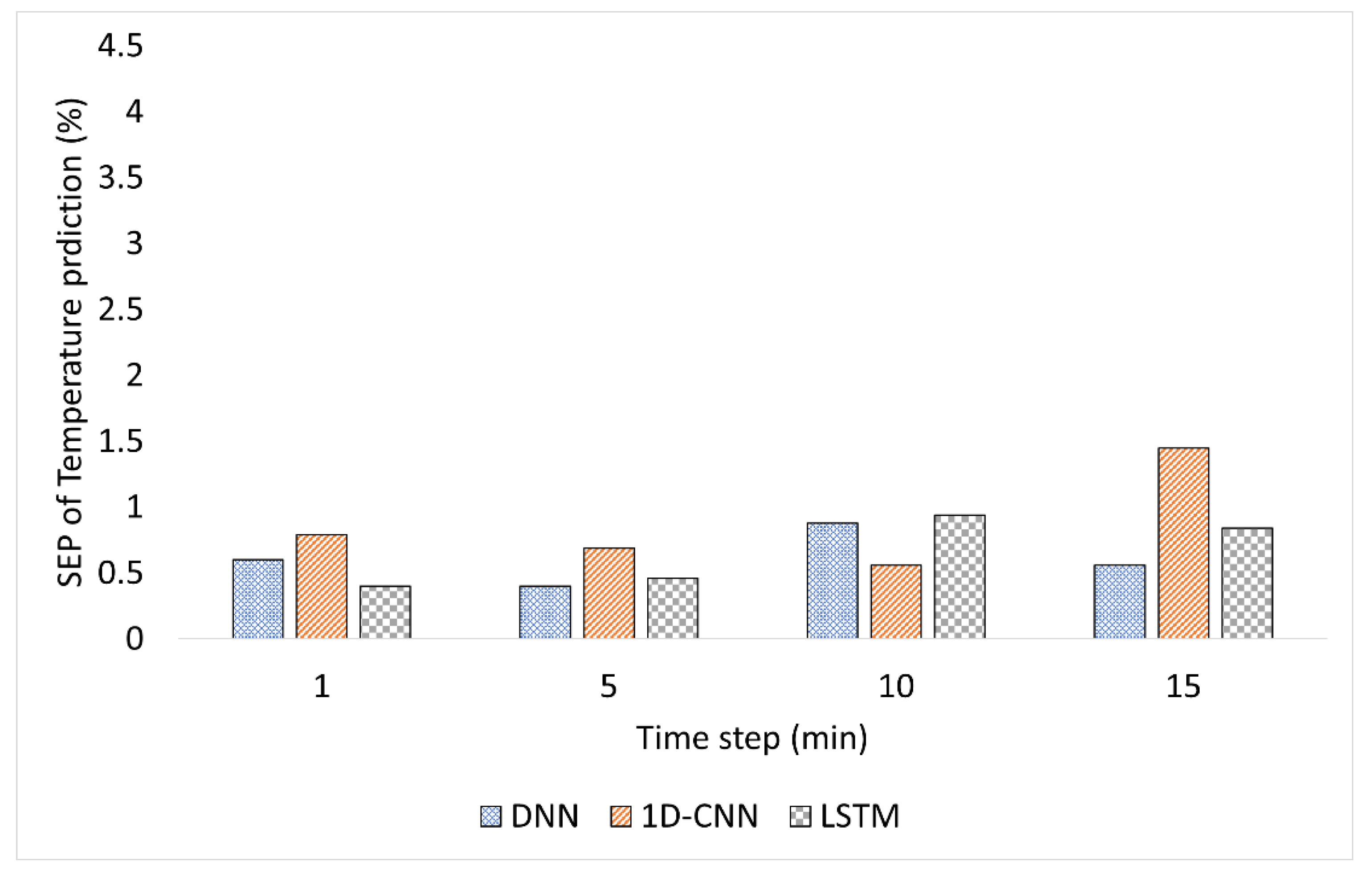

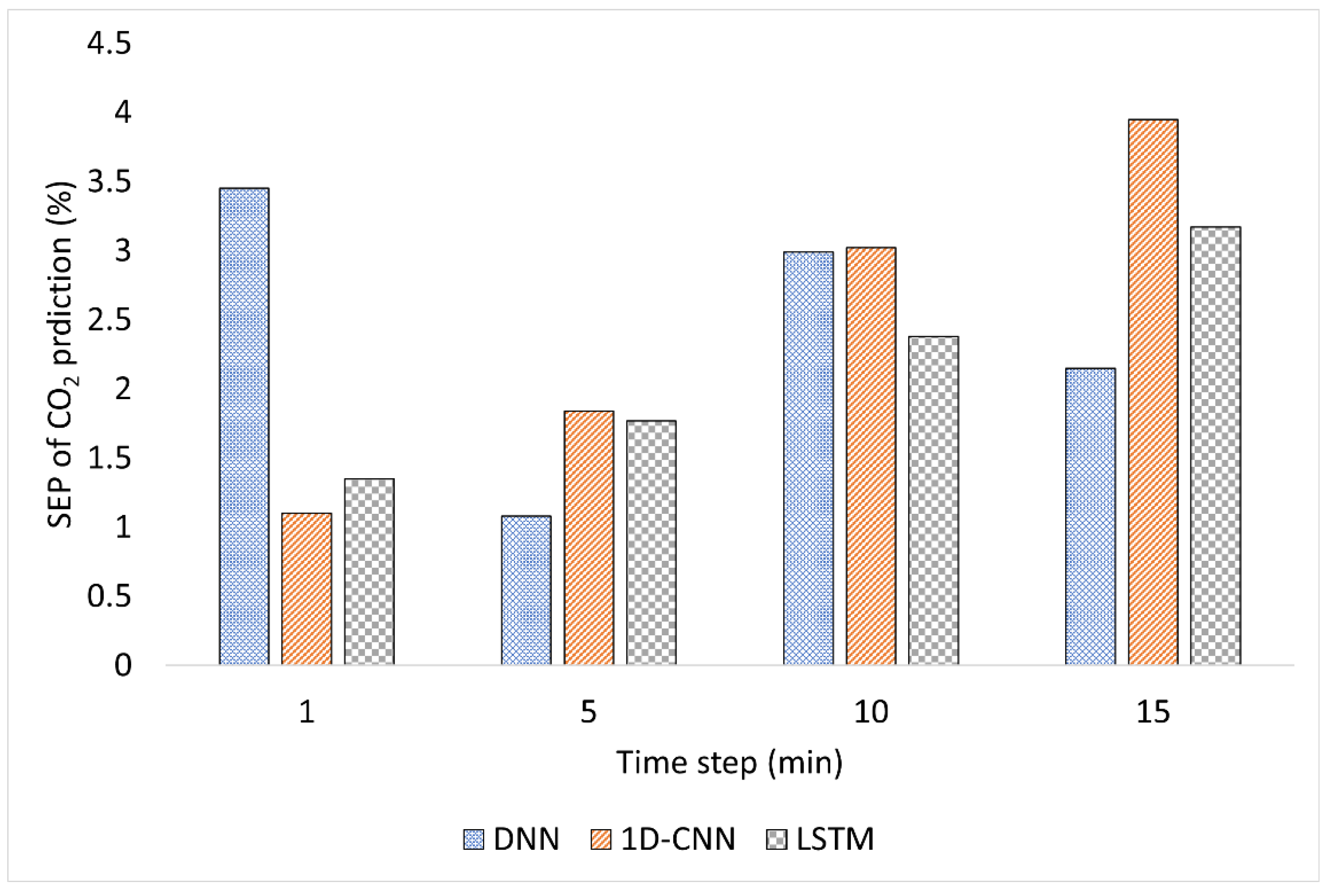

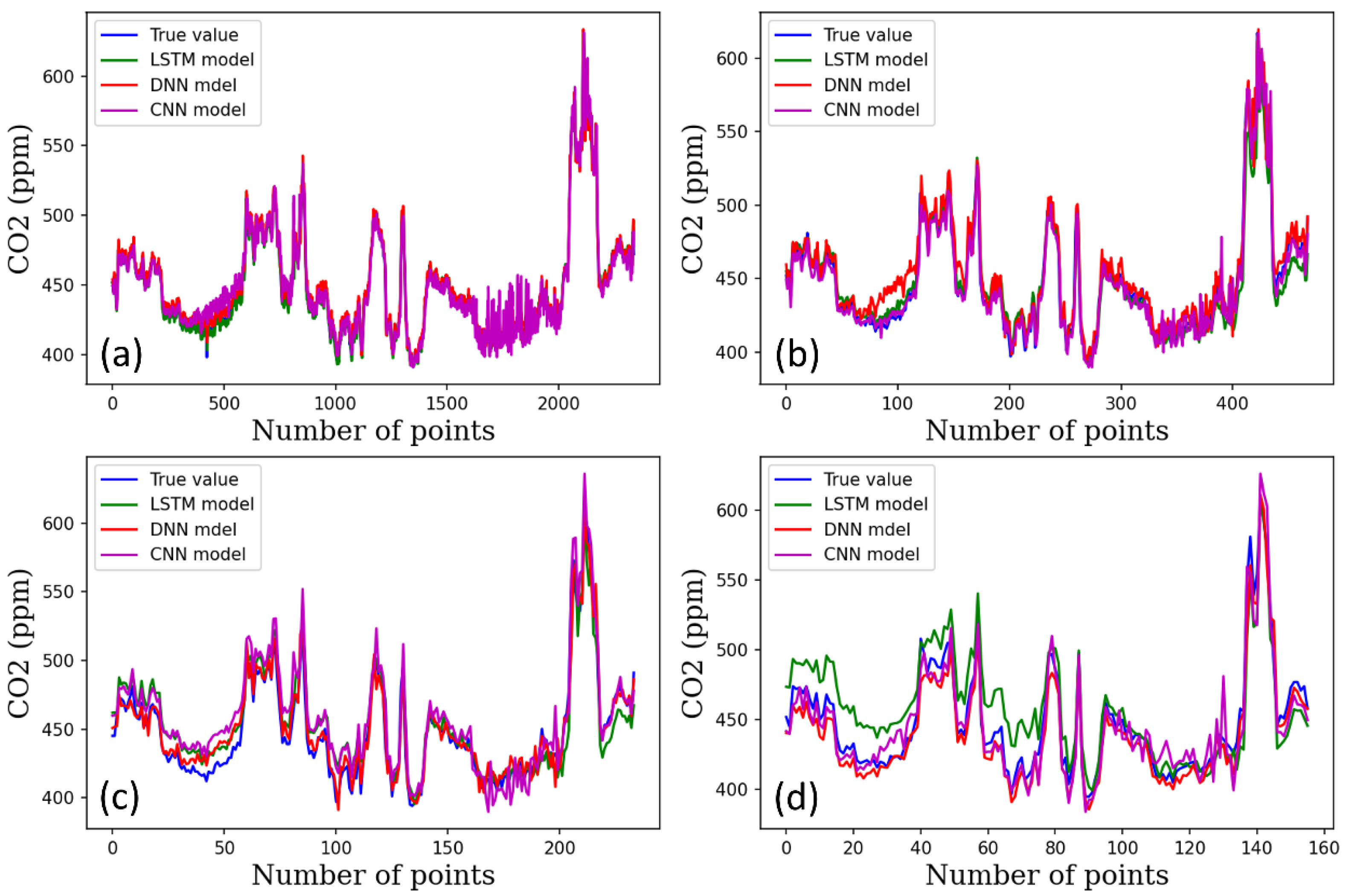

- the LSTM model outperformed the other models in all time intervals in predicting the temperature and humidity, achieving the lowest MAE, RMSE, SEP, and the highest R-squared values;

- the increase in the time interval adversely affects the performance of the models;

- the DNN model performed better than the 1D-CNN model but not as well as the LSTM model;

- the performance of the models varied for different climate variables, with temperature being the easiest to predict and humidity being the most challenging.

2. Related Work

3. Results and Discussion

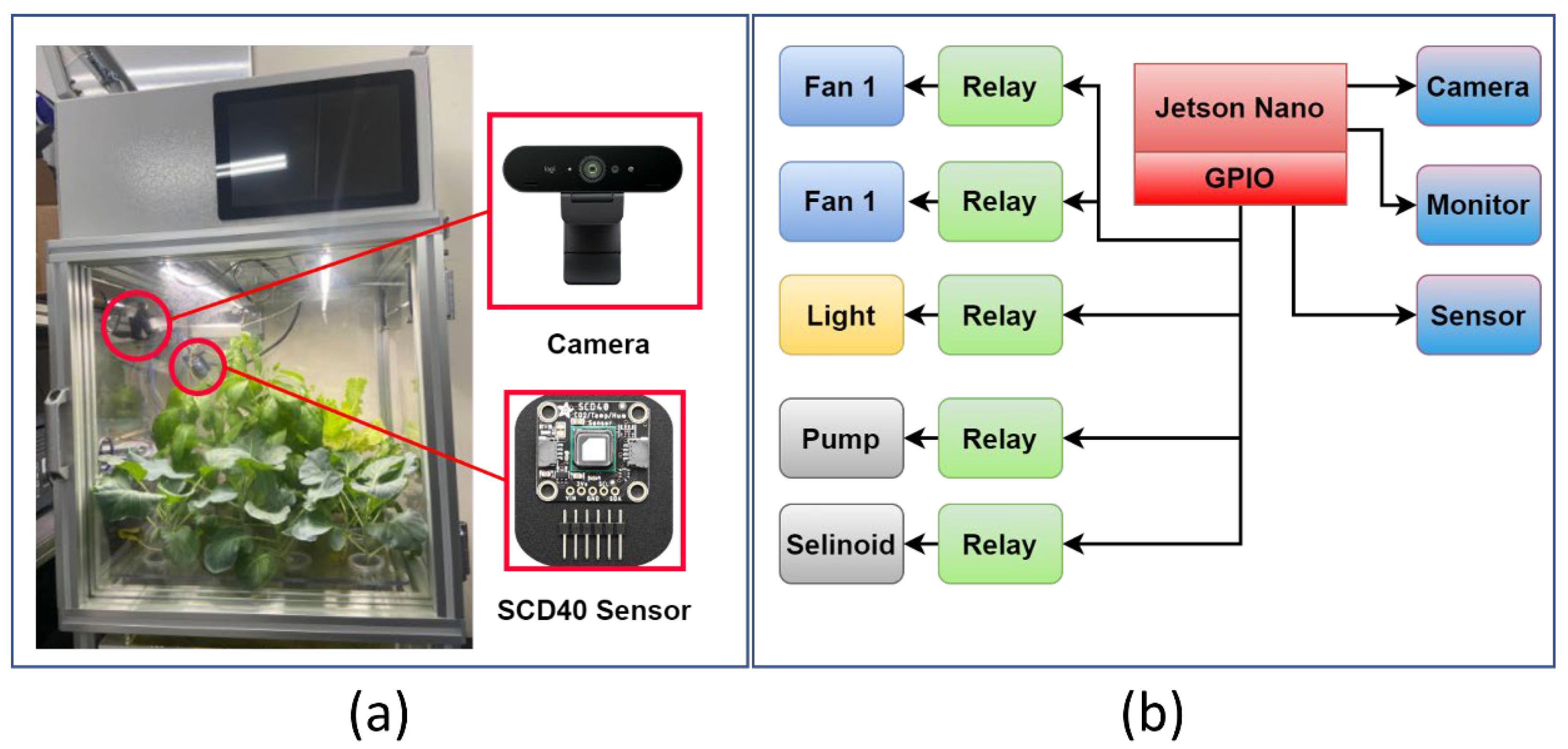

4. Materials and Methods

4.1. Greenhouse Measurements and Dataset

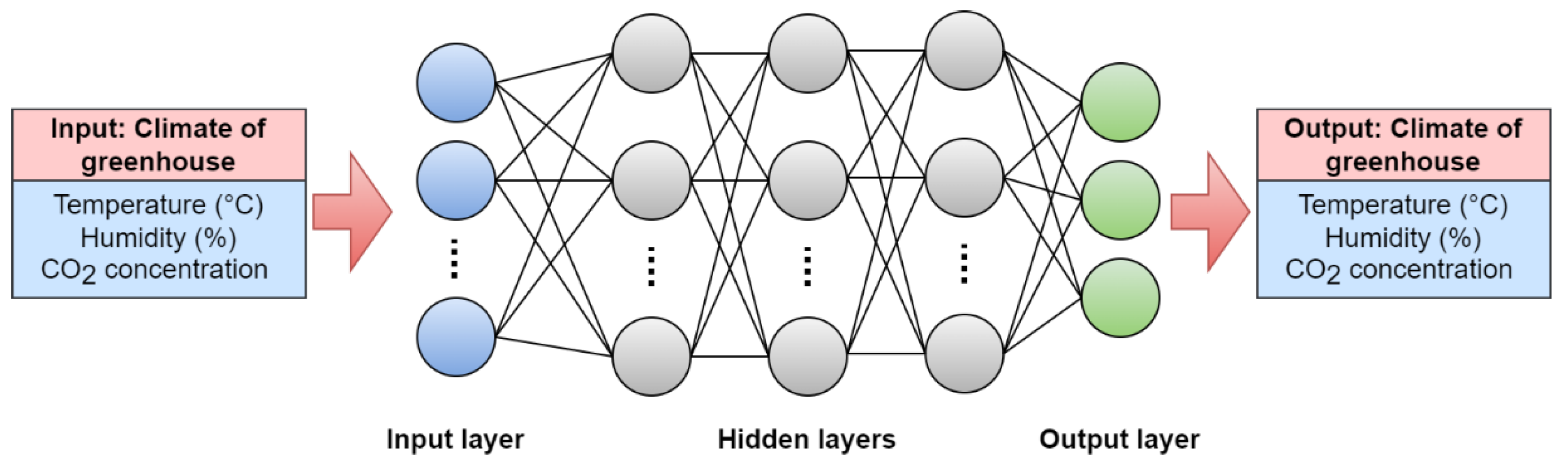

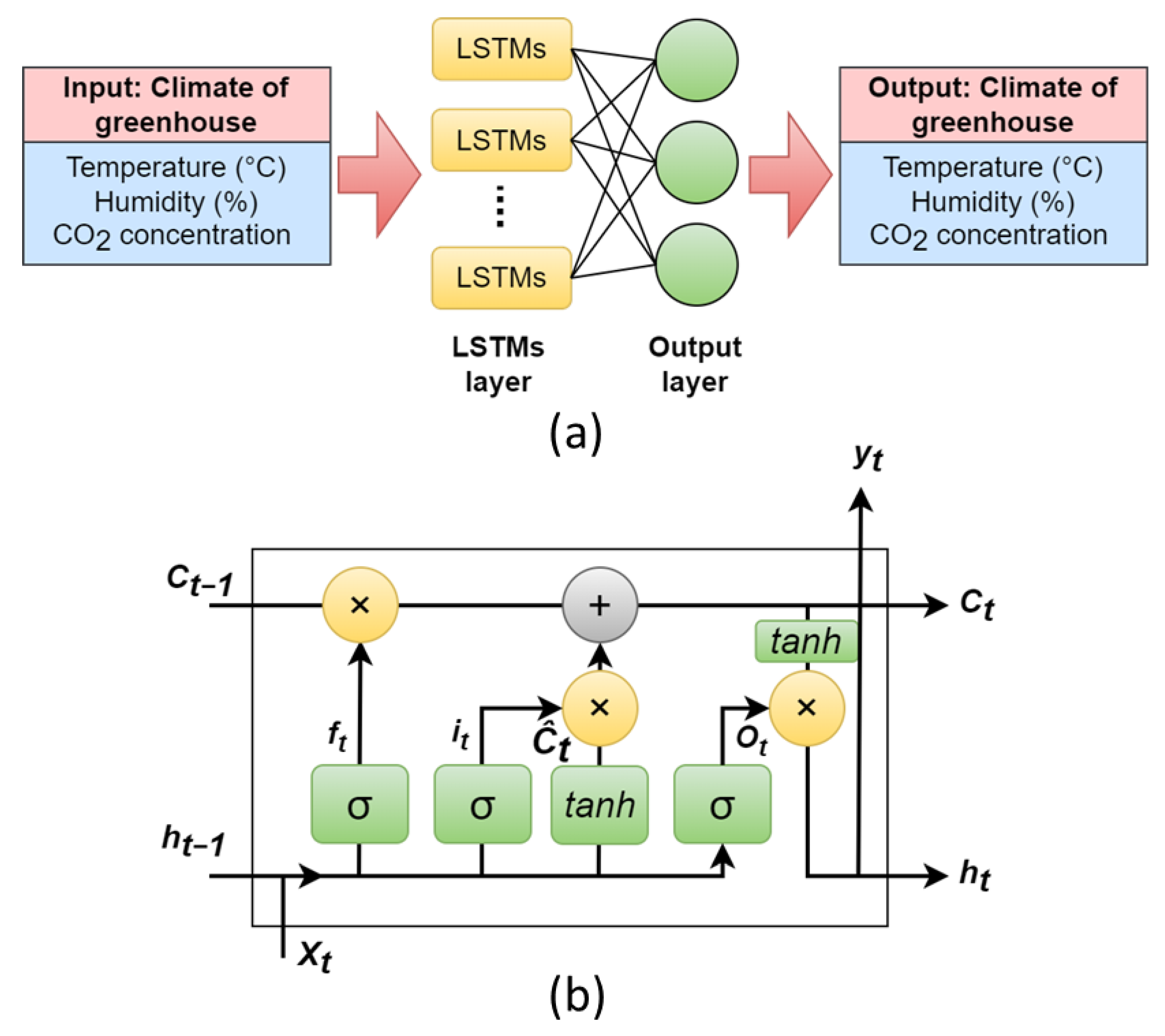

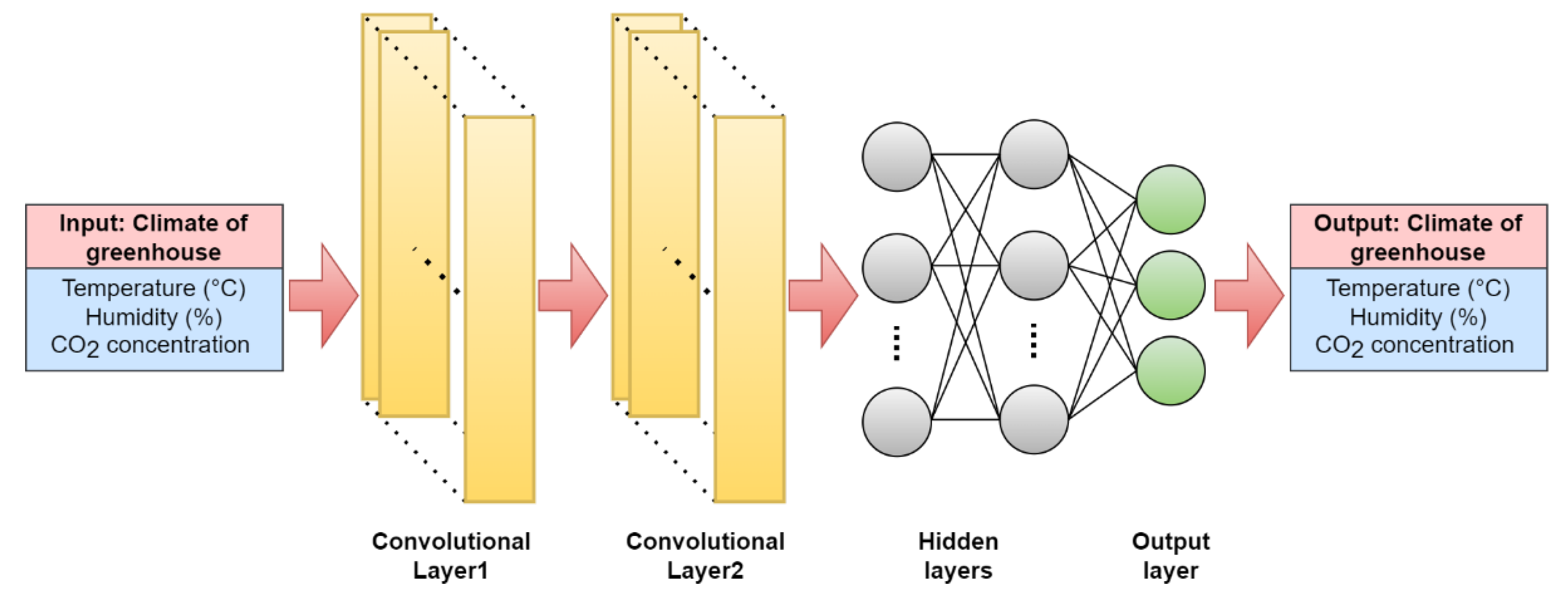

4.2. DL Models for Forecasting Environmental Changes

4.3. Performance Metrics

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Klompenburg, T.; Kassahun, A.; Catal, C. Crop yield prediction using machine learning: A systematic literature review. Comput. Electron. Agric. 2020, 177, 105709. [Google Scholar] [CrossRef]

- Morales-García, J.; Bueno-Crespo, A.; Martínez-España, R.; Cecilia, J.M. Data-driven evaluation of machine learning models for climate control in operational smart greenhouses. J. Ambient. Intell. Smart Environ. 2023, 15, 3–17. [Google Scholar] [CrossRef]

- Sharma, S.; Saxena, A.K.; Bansal, M. Forecasting of GHG (greenhouse gas) Emission using (ARIMA) Data Driven Intelligent Time Series Predicting Approach. In Proceedings of the 7th International Conference on Communication and Electronics Systems ICCES 2022, Coimbatore, India, 22–24 June 2022; pp. 315–322. [Google Scholar] [CrossRef]

- Grimberg, R.; Teitel, M.; Ozer, S.; Levi, A.; Levy, A. Estimation of Greenhouse Tomato Foliage Temperature Using DNN and ML Models. Agriculture 2022, 12, 1034. [Google Scholar] [CrossRef]

- Vanegas-Ayala, S.-C.; Barón-Velandia, J.; Leal-Lara, D.-D. A Systematic Review of Greenhouse Humidity Prediction and Control Models Using Fuzzy Inference Systems. Adv. Hum.-Comput. Interact. 2022, 2022, 8483003. [Google Scholar] [CrossRef]

- Jung, D.-H.; Kim, H.S.; Jhin, C.; Kim, H.-J.; Park, S.H. Time-serial analysis of deep neural network models for prediction of climatic conditions inside a greenhouse. Comput. Electron. Agric. 2020, 173, 105402. [Google Scholar] [CrossRef]

- Gharghory, S.M. Deep Network based on Long Short-Term Memory for Time Series Prediction of Microclimate Data inside the Greenhouse. Int. J. Comput. Intell. Appl. 2020, 19, 2050013. [Google Scholar] [CrossRef]

- Akcan, S.; Kuvvetli, Y.; Kocyigit, H. Time series analysis models for estimation of greenhouse gas emitted by different sectors in Turkey. Hum. Ecol. Risk Assess. Int. J. 2017, 24, 522–533. [Google Scholar] [CrossRef]

- Dariouchy, A.; Aassif, E.; Lekouch, K.; Bouirden, L.; Maze, G. Prediction of the intern parameters tomato greenhouse in a semi-arid area using a time-series model of Deep neural networks. Measurement 2009, 42, 456–463. [Google Scholar] [CrossRef]

- Escamilla-García, A.; Soto-Zarazúa, G.M.; Toledano-Ayala, M.; Rivas-Araiza, E.; Gastélum-Barrios, A. Applications of Deep neural networks in greenhouse technology and overview for smart agriculture development. Appl. Sci. 2020, 10, 3835. [Google Scholar] [CrossRef]

- He, F.; Ma, C. Modeling greenhouse air humidity by means of Deep neural network and principal component analysis. Comput. Electron. Agric. 2010, 71, S19–S23. [Google Scholar] [CrossRef]

- Kamilaris, A.; Prenafeta-Boldú, F.X. Deep learning in agriculture: A survey. Comput. Electron. Agric. 2018, 147, 70–90. [Google Scholar] [CrossRef] [Green Version]

- Jung, D.-H.; Kim, H.-J.; Kim, H.S.; Choi, J.; Kim, J.D.; Park, S.H. Fusion of Spectroscopy and Cobalt Electrochemistry Data for Estimating Phosphate Concentration in Hydroponic Solution. Sensors 2019, 19, 2596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Papaioannou, P.G.; Talmon, R.; Kevrekidis, I.G.; Siettos, C. Nonlinear signal processing using neural networks: Prediction and system modelling. J. Nonlinear Sci. 2022, 32, 083113. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; Lu, H.; Guo, Z. Research and application of a combined model based on variable weight for short term wind speed forecasting. Renew. Energy 2018, 116, 669–684. [Google Scholar] [CrossRef]

- Hu, Y.-L.; Chen, L. A nonlinear hybrid wind speed forecasting model using LSTM network, hysteretic ELM and Differential Evolution algorithm. Energy Convers. Manag. 2018, 173, 123–142. [Google Scholar] [CrossRef]

- Jin, X.; Yu, X.; Wang, X.; Bai, Y.; Su, T.; Kong, J. Prediction for Time Series with CNN and LSTM. Lect. Notes Electr. Eng. 2020, 582, 631–641. [Google Scholar] [CrossRef]

- Tzoumpas, K.; Estrada, A.; Miraglio, P.; Zambelli, P. A Data Filling Methodology for Time Series Based on CNN and (Bi)LSTM Neural Networks. arXiv 2022, arXiv:2204.09994. [Google Scholar]

- Nury, A.H.; Hasan, K.; Bin Alam, J. Comparative study of wavelet-ARIMA and wavelet-ANN models for temperature time series data in northeastern Bangladesh. J. King Saud Univ.-Sci. 2017, 29, 47–61. [Google Scholar] [CrossRef] [Green Version]

- Moon, T.; Ahn, T.I.; Son, J.E. Forecasting root-zone electrical conductivity of nutrient solutions in closed-loop soilless cultures via a recurrent neural network using environmental and cultivation information. Front. Plant Sci. 2018, 9, 1–9. [Google Scholar] [CrossRef] [PubMed]

| DNN-1 | DNN-5 | |||||

|---|---|---|---|---|---|---|

| Temperature | Humidity | CO2 | Temperature | Humidity | CO2 | |

| R2 | 0.98 | 0.96 | 0.81 | 0.99 | 0.95 | 0.97 |

| MAE | 0.005 | 0.02 | 0.01 | 0.004 | 0.02 | 0.003 |

| RMSE | 0.006 | 0.03 | 0.01 | 0.005 | 0.03 | 0.004 |

| SEP (%) | 0.6 | 3.04 | 3.45 | 0.4 | 3.65 | 1.08 |

| DNN-10 | DNN-15 | |||||

| Temperature | Humidity | CO2 | Temperature | Humidity | CO2 | |

| R2 | 0.95 | 0.94 | 0.81 | 0.98 | 0.93 | 0.91 |

| MAE | 0.008 | 0.023 | 0.009 | 0.005 | 0.024 | 0.006 |

| RMSE | 0.009 | 0.031 | 0.011 | 0.006 | 0.035 | 0.007 |

| SEP (%) | 0.88 | 3.8 | 2.99 | 0.56 | 4.22 | 2.15 |

| LSTM-1 | LSTM-5 | |||||

|---|---|---|---|---|---|---|

| Temperature | Humidity | CO2 | Temperature | Humidity | CO2 | |

| R2 | 0.99 | 0.96 | 0.96 | 0.99 | 0.94 | 0.93 |

| MAE | 0.004 | 0.018 | 0.004 | 0.004 | 0.02 | 0.005 |

| RMSE | 0.004 | 0.027 | 0.0045 | 0.005 | 0.032 | 0.006 |

| SEP (%) | 0.4 | 3.09 | 1.35 | 0.46 | 3.54 | 1.77 |

| LSTM-10 | LSTM-15 | |||||

| Temperature | Humidity | CO2 | Temperature | Humidity | CO2 | |

| R2 | 0.95 | 0.94 | 0.89 | 0.96 | 0.93 | 0.81 |

| MAE | 0.008 | 0.022 | 0.007 | 0.007 | 0.024 | 0.009 |

| RMSE | 0.01 | 0.034 | 0.008 | 0.008 | 0.037 | 0.01 |

| SEP (%) | 0.94 | 3.85 | 2.38 | 0.84 | 4.18 | 3.17 |

| 1D-CNN-1 | 1D-CNN-5 | |||||

|---|---|---|---|---|---|---|

| Temperature | Humidity | CO2 | Temperature | Humidity | CO2 | |

| R2 | 0.96 | 0.96 | 0.97 | 0.95 | 0.93 | 0.92 |

| MAE | 0.007 | 0.02 | 0.003 | 0.006 | 0.025 | 0.005 |

| RMSE | 0.008 | 0.03 | 0.004 | 0.009 | 0.035 | 0.007 |

| SEP (%) | 0.79 | 3.46 | 1.1 | 0.69 | 4.2 | 1.84 |

| 1D-CNN-10 | 1D-CNN-15 | |||||

| Temperature | Humidity | CO2 | Temperature | Humidity | CO2 | |

| R2 | 0.97 | 0.95 | 0.74 | 0.88 | 0.94 | 0.74 |

| MAE | 0.005 | 0.02 | 0.009 | 0.013 | 0.024 | 0.011 |

| RMSE | 0.008 | 0.03 | 0.012 | 0.015 | 0.034 | 0.012 |

| SEP (%) | 0.56 | 3.48 | 3.02 | 1.45 | 4.21 | 3.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eraliev, O.; Lee, C.-H. Performance Analysis of Time Series Deep Learning Models for Climate Prediction in Indoor Hydroponic Greenhouses at Different Time Intervals. Plants 2023, 12, 2316. https://doi.org/10.3390/plants12122316

Eraliev O, Lee C-H. Performance Analysis of Time Series Deep Learning Models for Climate Prediction in Indoor Hydroponic Greenhouses at Different Time Intervals. Plants. 2023; 12(12):2316. https://doi.org/10.3390/plants12122316

Chicago/Turabian StyleEraliev, Oybek, and Chul-Hee Lee. 2023. "Performance Analysis of Time Series Deep Learning Models for Climate Prediction in Indoor Hydroponic Greenhouses at Different Time Intervals" Plants 12, no. 12: 2316. https://doi.org/10.3390/plants12122316