Adaptive Kinematic Modelling for Multiobjective Control of a Redundant Surgical Robotic Tool

Abstract

1. Introduction

2. Materials and Method

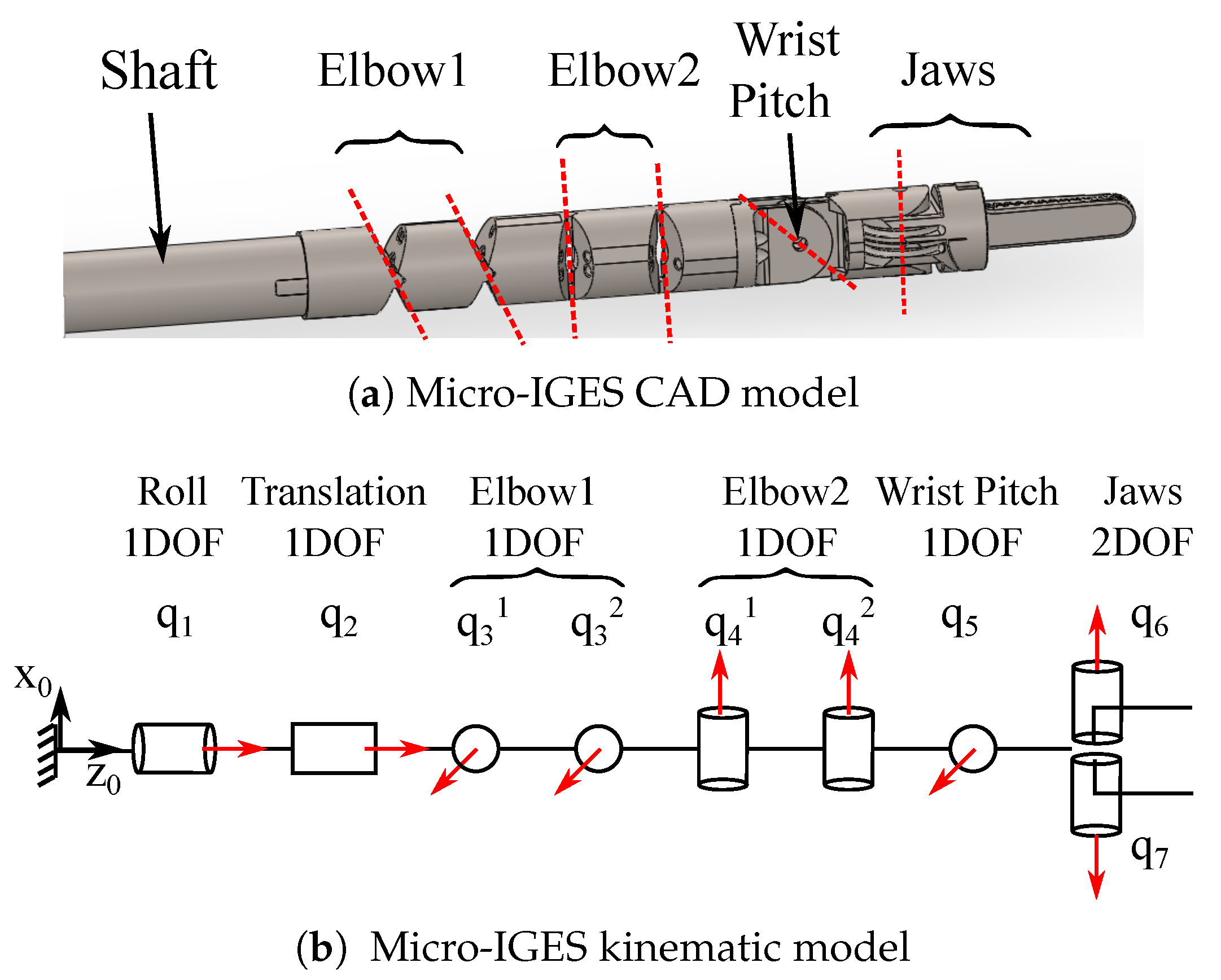

2.1. Robot Kinematic Modelling

2.2. Multiobjective Control

2.3. Adaptive Modelling

| Algorithm 1 Levenberg-Marquardt algorithm for updating the weights of the ANN. |

| function Levenberg-Marquardt() |

| ▹ Initializations |

| getDatasetSize() |

| while do |

| for do |

| ▹ Get inputs and outputs from dataset |

| getData() |

| ▹ Compute network estimates and derivatives |

| getNetEstimates() |

| end for |

| ▹ Compute mean squared error with new weights |

| getMeanSquaredError() |

| if then |

| end if |

| end while |

| return |

| end function |

3. Results

3.1. Robot Modelling

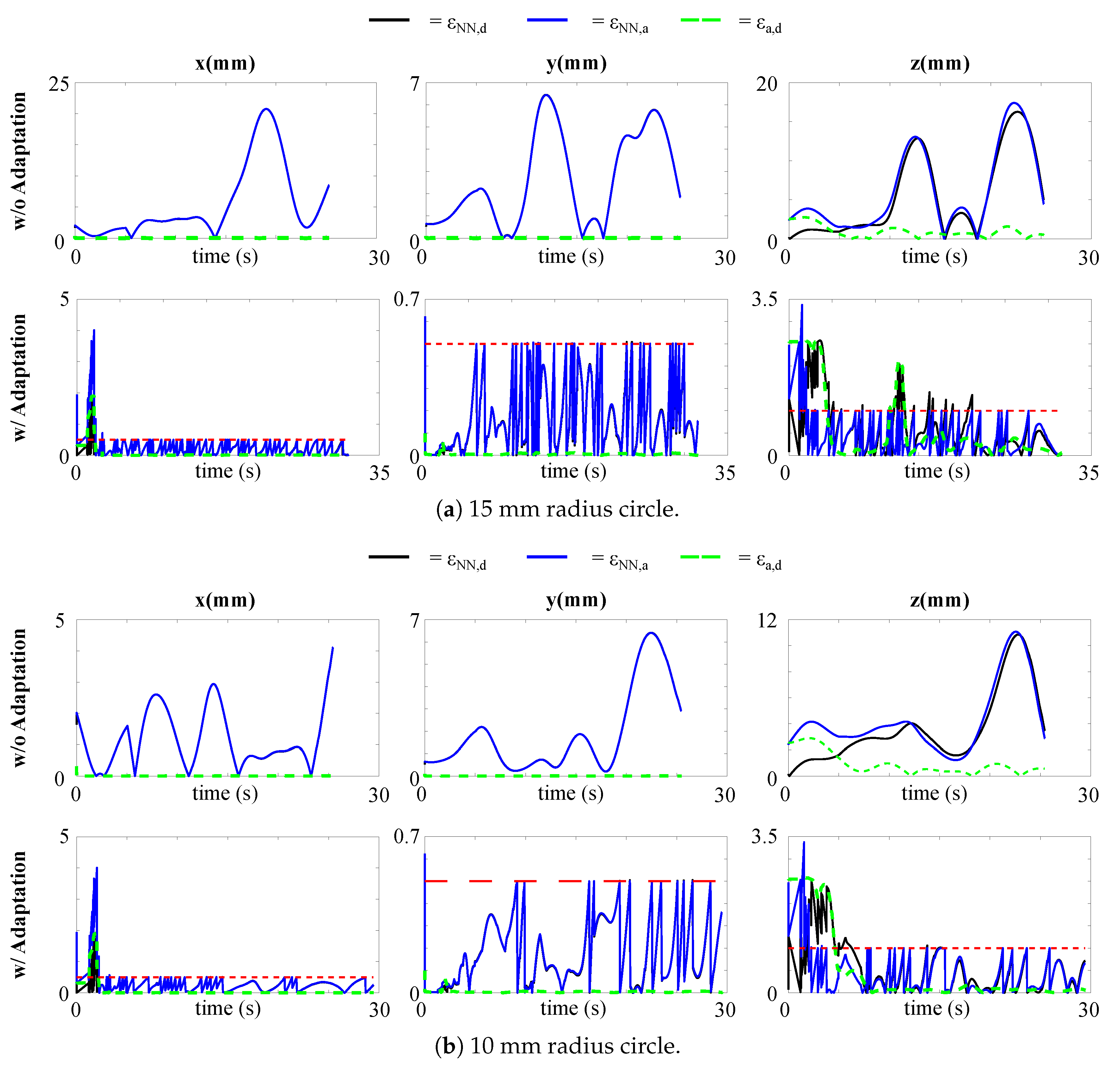

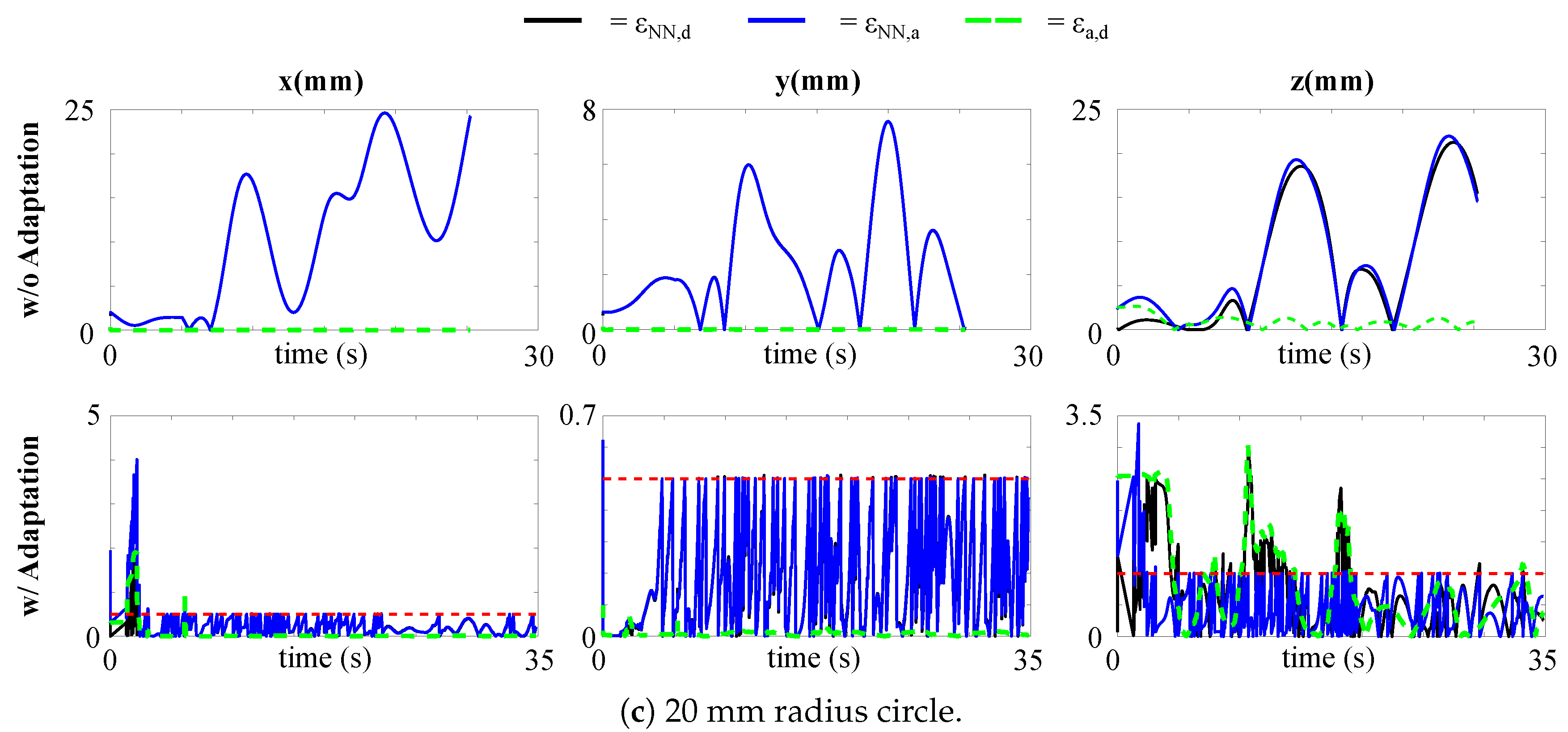

3.2. Autonomous Tracking

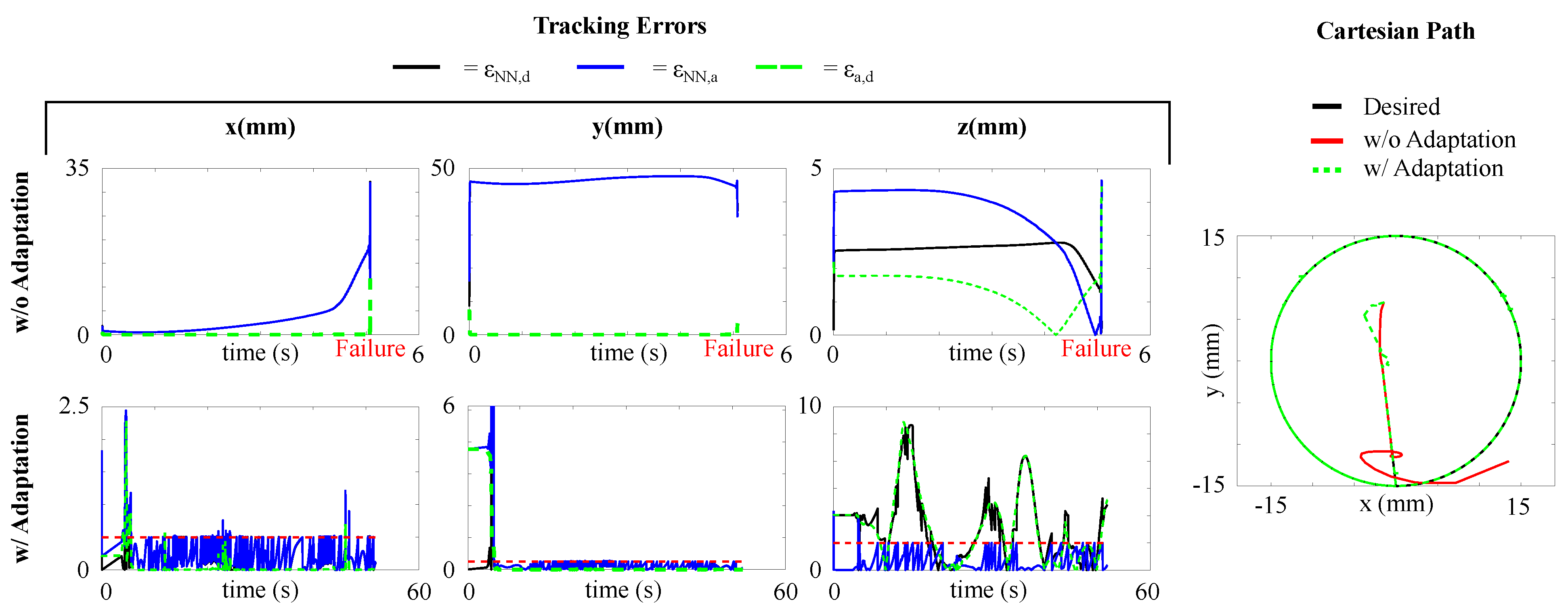

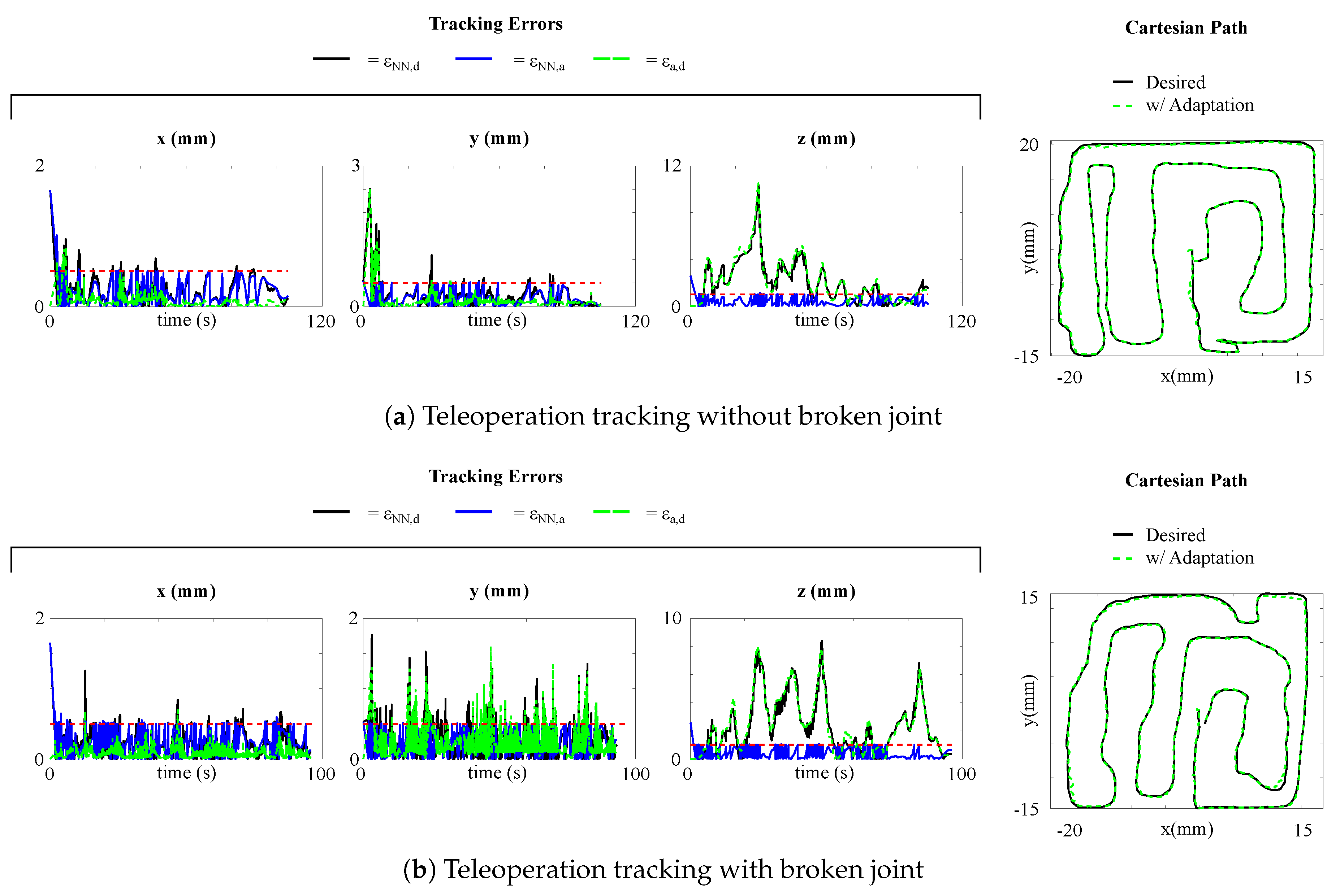

3.3. Teleoperation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yip, M.; Das, N. Robot Autonomy for Surgery. arXiv 2017, arXiv:1707.03080. [Google Scholar]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.W.; Phee, S.J. Nonlinear friction modelling and compensation control of hysteresis phenomena for a pair of tendon-sheath actuated surgical robots. Mech. Syst. Signal Process. 2015, 60, 770–784. [Google Scholar] [CrossRef]

- Ismail, M.; Ikhouane, F.; Rodellar, J. The Hysteresis Bouc-Wen Model, a Survey. Arch. Comput. Methods Eng. 2009, 16, 161–188. [Google Scholar] [CrossRef]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.W.; Yamamoto, T.; Phee, S.J. Hysteresis modeling and position control of tendon-sheath mechanism in flexible endoscopic systems. Mechatronics 2014, 24, 12–22. [Google Scholar] [CrossRef]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.W.S.; Phee, S.J. Performance Control of Tendon-Driven Endoscopic Surgical Robots With Friction and Hysteresis. arXiv 2017, arXiv:1702.02063. [Google Scholar]

- Tjahjowidodo, T.; Zhu, K.; Dailey, W.; Burdet, E.; Campolo, D. Multi-source micro-friction identification for a class of cable-driven robots with passive backbone. Mech. Syst. Signal Process. 2016, 80, 152–165. [Google Scholar] [CrossRef]

- Palli, G.; Borghesan, G.; Melchiorri, C. Modeling, identification, and control of tendon-based actuation systems. IEEE Trans. Robot. 2012, 28, 277–290. [Google Scholar] [CrossRef]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.W.; Phee, S.J. An investigation of friction-based tendon sheath model appropriate for control purposes. Mech. Syst. Signal Process. 2014, 42, 97–114. [Google Scholar] [CrossRef]

- Xu, K.; Simaan, N. Actuation compensation for flexible surgical snake-like robots with redundant remote actuation. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 4148–4154. [Google Scholar] [CrossRef]

- Nguyen-Tuong, D.; Peters, J. Model learning for robot control: A survey. Cogn. Process. 2011, 12, 319–340. [Google Scholar] [CrossRef]

- Reinhart, R.; Shareef, Z.; Steil, J.; Reinhart, R.F.; Shareef, Z.; Steil, J.J. Hybrid Analytical and Data-Driven Modeling for Feed-Forward Robot Control. Sensors 2017, 17, 311. [Google Scholar] [CrossRef]

- Yu, B.; Fernández, J.D.G.; Tan, T. Probabilistic Kinematic Model of a Robotic Catheter for 3D Position Control. Soft Robot. 2019, 6, 184–194. [Google Scholar] [CrossRef] [PubMed]

- Salaün, C.; Padois, V.; Sigaud, O. Control of redundant robots using learned models: An operational space control approach. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 878–885. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Falotico, E.; Cianchetti, M.; Laschi, C. Learning Global Inverse Kinematics Solutions for a Continuum Robot. In CISM International Centre for Mechanical Sciences, Courses and Lectures; Springer International Publishing: Cham, Switzerland, 2016; pp. 47–54. [Google Scholar] [CrossRef]

- Xu, W.; Chen, J.; Lau, H.Y.; Ren, H. Data-driven methods towards learning the highly nonlinear inverse kinematics of tendon-driven surgical manipulators. Int. J. Med Robot. Comput. Assist. Surg. 2017, 13, e1774. [Google Scholar] [CrossRef] [PubMed]

- Yip, M.C.; Sganga, J.A.; Camarillo, D.B. Autonomous Control of Continuum Robot Manipulators for Complex Cardiac Ablation Tasks. J. Med. Robot. Res. 2017, 2, 1750002. [Google Scholar] [CrossRef]

- Kim, C.; Ryu, S.C.; Dupont, P.E. Real-time adaptive kinematic model estimation of concentric tube robots. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–2 October 2015; pp. 3214–3219. [Google Scholar] [CrossRef]

- Zhang, D.; Wei, B. A review on model reference adaptive control of robotic manipulators. Annu. Rev. Control 2017, 43, 188–198. [Google Scholar] [CrossRef]

- Hornik, K. Approximation capabilities of multilayer feedforward networks. Neural Netw. 1991, 4, 251–257. [Google Scholar] [CrossRef]

- Cybenko, G. Approximation by superpositions of a sigmoidal function. Math. Control Signals Syst. 1989, 2, 303–314. [Google Scholar] [CrossRef]

- Bishop, C. Neural Networks Pattern Recognit; Neural Networks for Pattern Recognition: New York, NY, USA, 1995. [Google Scholar]

- Coppelia Robotics. Available online: http://www.coppeliarobotics.com (accessed on 31 July 2014).

- Shang, J.; Leibrandt, K.; Giataganas, P.; Vitiello, V.; Seneci, C.A.; Wisanuvej, P.; Liu, J.; Gras, G.; Clark, J.; Darzi, A.; et al. A Single-Port Robotic System for Transanal Microsurgery—Design and Validation. IEEE Robot. Autom. Lett. 2017, 2, 1510–1517. [Google Scholar] [CrossRef]

- Murray, R.M.; Li, Z.; Sastry, S. A Mathematical Introduction to Robotic Manipulation; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Leibrandt, K.; Wisanuvej, P.; Gras, G.; Shang, J.; Seneci, C.A.; Giataganas, P.; Vitiello, V.; Darzi, A.; Yang, G.Z. Effective Manipulation in Confined Spaces of Highly Articulated Robotic Instruments for Single Access Surgery. IEEE Robot. Autom. Lett. 2017, 2, 1704–1711. [Google Scholar] [CrossRef]

- Cursi, F.; Malzahn, J.; Tsagarakis, N.; Caldwell, G. An online interactive method for guided calibration of multi-dimensional force/torque transducers. In Proceedings of the IEEE/RAS International Conference on Humanoid Robotics, Birmingham, UK, 15–17 November 2017; pp. 398–405. [Google Scholar]

- Hawkins, D.M. Identification of Outliers; Springer: Berlin, Germany, 1980. [Google Scholar]

- Aggarwal, C.C. Outlier Analysis; Springer: Berlin, Germany, 2017. [Google Scholar] [CrossRef]

- Khamis, A.; Ismail, Z.; Haron, K.; Mohammed, A. The Effects of Outliers Data on Neural Network Performance. J. Appl. Sci. 2005, 8, 1394–1398. [Google Scholar]

- Liano, K. Robust error measure for supervised neural network learning with outliers. IEEE Trans. Neural Netw. 1996, 7, 246–250. [Google Scholar] [CrossRef]

- Cursi, F.; Yang, G.Z. A Novel Approach for Outlier Detection and Robust Sensory Data Model Learning. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 4250–4257. [Google Scholar] [CrossRef]

- Sciavicco, L.; Siciliano, B. A Solution Algorithm to the Inverse Kinematic Problem for Redundant Manipulators. IEEE J. Robot. Autom. 1988, 4, 403–410. [Google Scholar] [CrossRef]

- Chiaverini, S.; Oriolo, G.; Walker, I.D. Kinematically Redundant Manipulators. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2008; pp. 245–268. [Google Scholar] [CrossRef]

- Moré, J.J. The Levenberg-Marquardt Algorithm: Implementation and Theory; Springer: Berlin/Heidelberg, Germany, 1978; pp. 105–116. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics; Springer: London, UK, 2009. [Google Scholar] [CrossRef]

| RMSE (mm) | |||

|---|---|---|---|

| Train | Validation | Test | |

| x | 0.040 | 0.040 | 0.040 |

| y | 0.019 | 0.018 | 0.019 |

| z | 0.034 | 0.035 | 0.034 |

| 15 mm Radius | 10 mm Radius | 20 mm Radius | |||||

|---|---|---|---|---|---|---|---|

| w/ Adapt | w/o Adapt | w/ Adapt | w/o Adapt | w/ Adapt | w/ o Adapt | ||

| x | 0.206 | 5.350 | 0.221 | 1.156 | 0.192 | 10.022 | |

| y | 0.182 | 2.648 | 0.192 | 1.870 | 0.194 | 2.471 | |

| z | 0.583 | 5.478 | 0.519 | 3.606 | 0.678 | 7.605 | |

| x | 0.006 | 0.007 | 0.004 | 0.003 | 0.008 | 0.009 | |

| y | 0.006 | 0.006 | 0.004 | 0.004 | 0.008 | 0.008 | |

| z | 0.424 | 0.930 | 0.283 | 0.918 | 0.714 | 0.915 | |

| 15 mm | 10 mm | 20 mm | |

|---|---|---|---|

| x | 42 | 22 | 22 |

| y | 29 | 16 | 16 |

| z | 53 | 27 | 39 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cursi, F.; Mylonas, G.P.; Kormushev, P. Adaptive Kinematic Modelling for Multiobjective Control of a Redundant Surgical Robotic Tool. Robotics 2020, 9, 68. https://doi.org/10.3390/robotics9030068

Cursi F, Mylonas GP, Kormushev P. Adaptive Kinematic Modelling for Multiobjective Control of a Redundant Surgical Robotic Tool. Robotics. 2020; 9(3):68. https://doi.org/10.3390/robotics9030068

Chicago/Turabian StyleCursi, Francesco, George P. Mylonas, and Petar Kormushev. 2020. "Adaptive Kinematic Modelling for Multiobjective Control of a Redundant Surgical Robotic Tool" Robotics 9, no. 3: 68. https://doi.org/10.3390/robotics9030068

APA StyleCursi, F., Mylonas, G. P., & Kormushev, P. (2020). Adaptive Kinematic Modelling for Multiobjective Control of a Redundant Surgical Robotic Tool. Robotics, 9(3), 68. https://doi.org/10.3390/robotics9030068