Displacement Analysis and Design of a (2–RRU)–URR Parallel Mechanism Performing 2R1T Output Motion for Thumb Rehabilitation

Abstract

1. Introduction

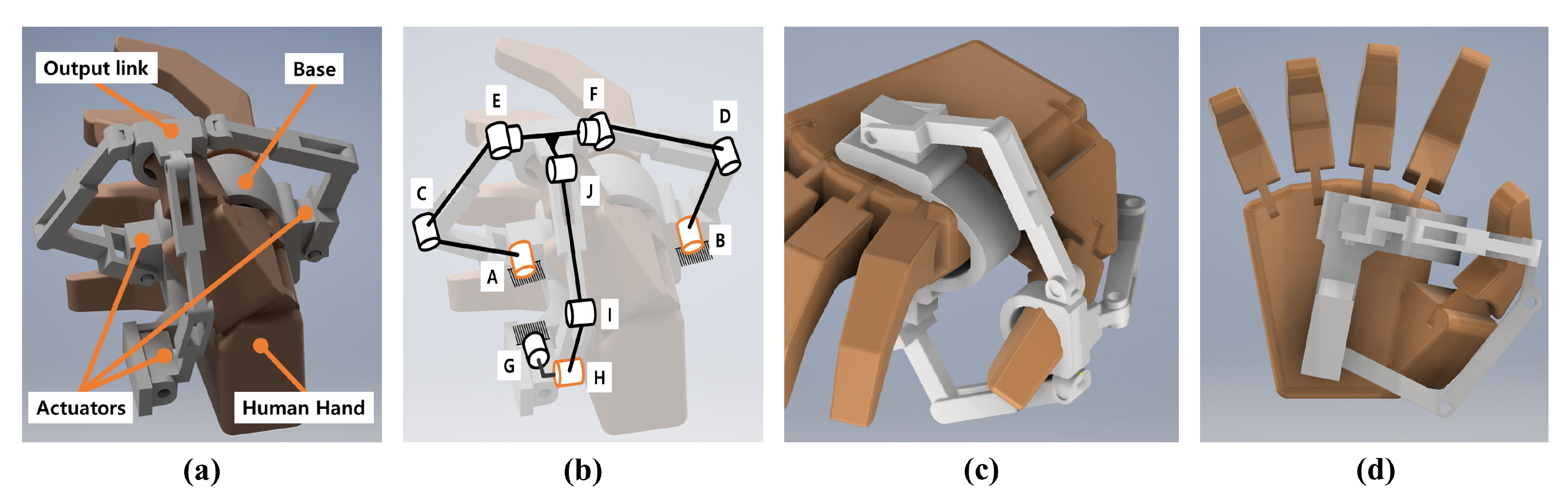

2. (2-RRU)-URR Mechanism and Its Mobility

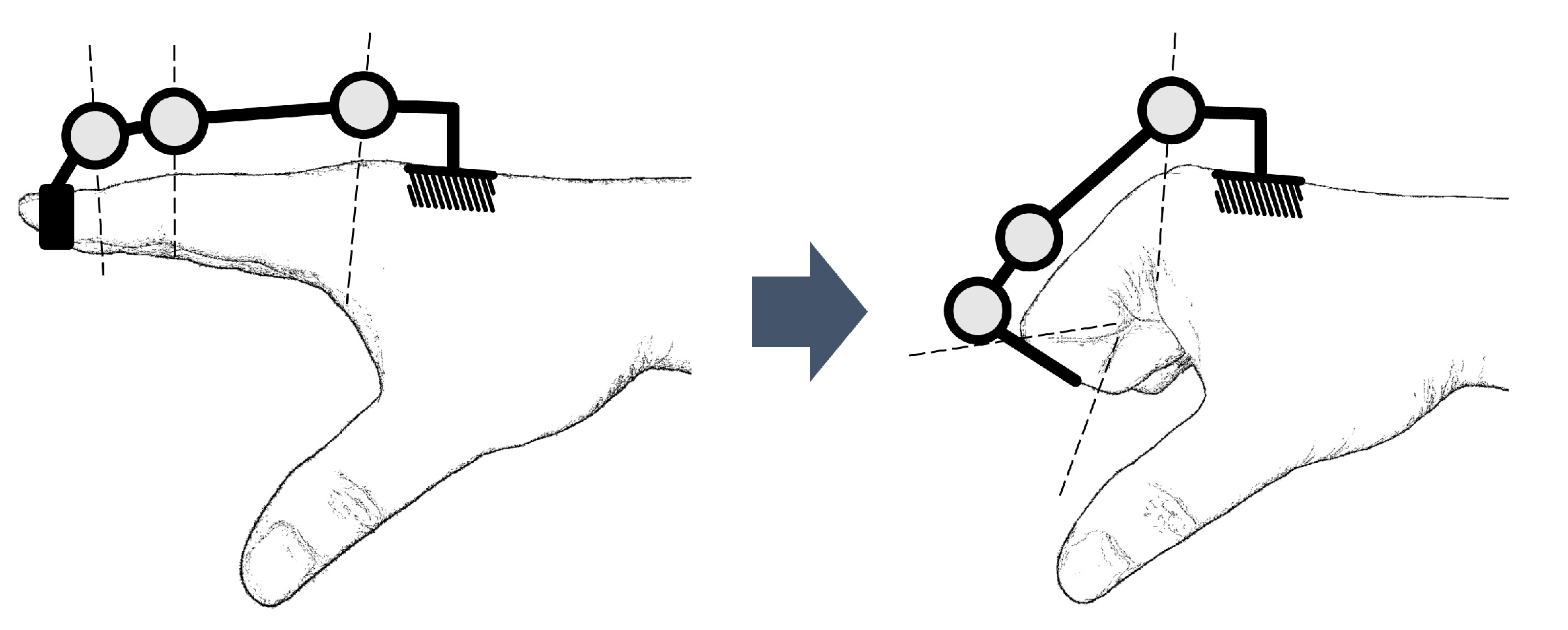

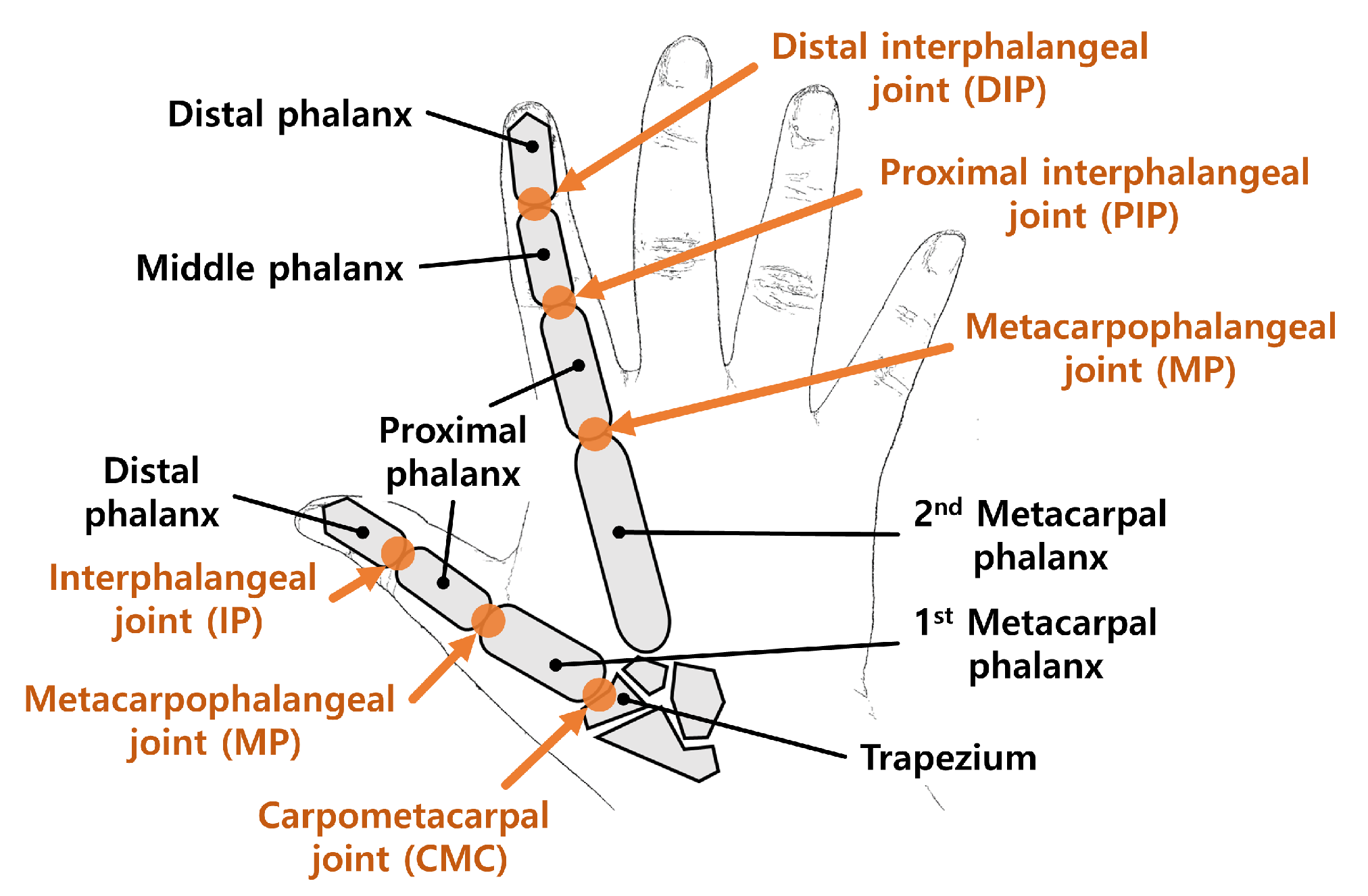

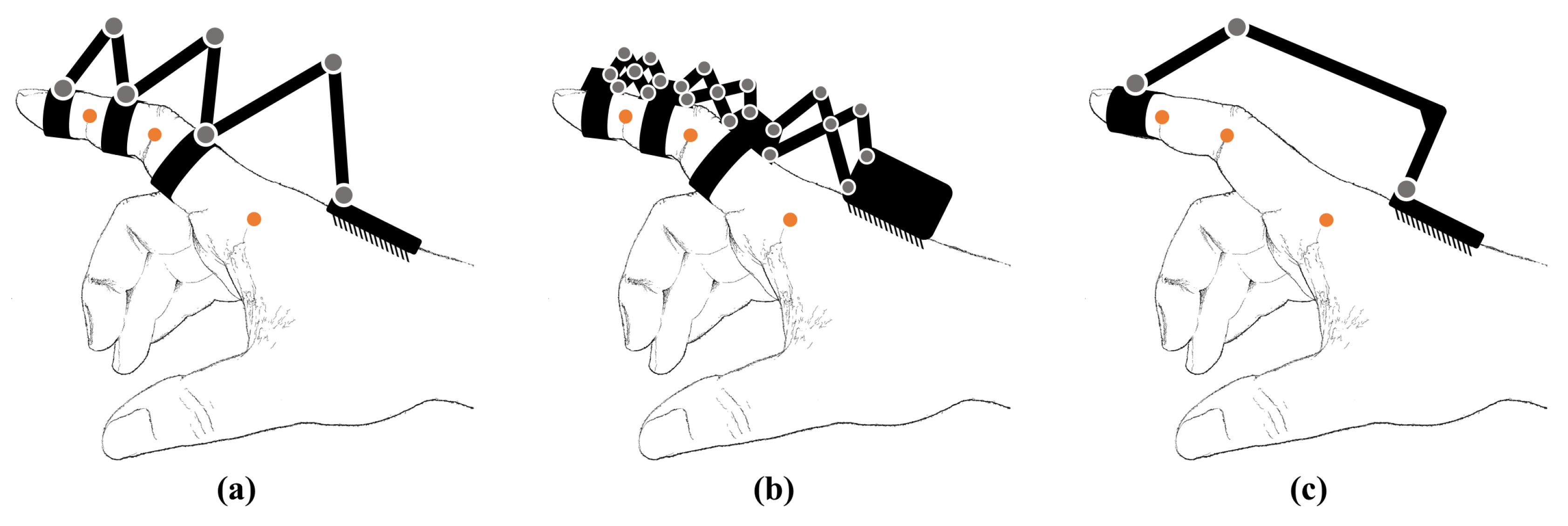

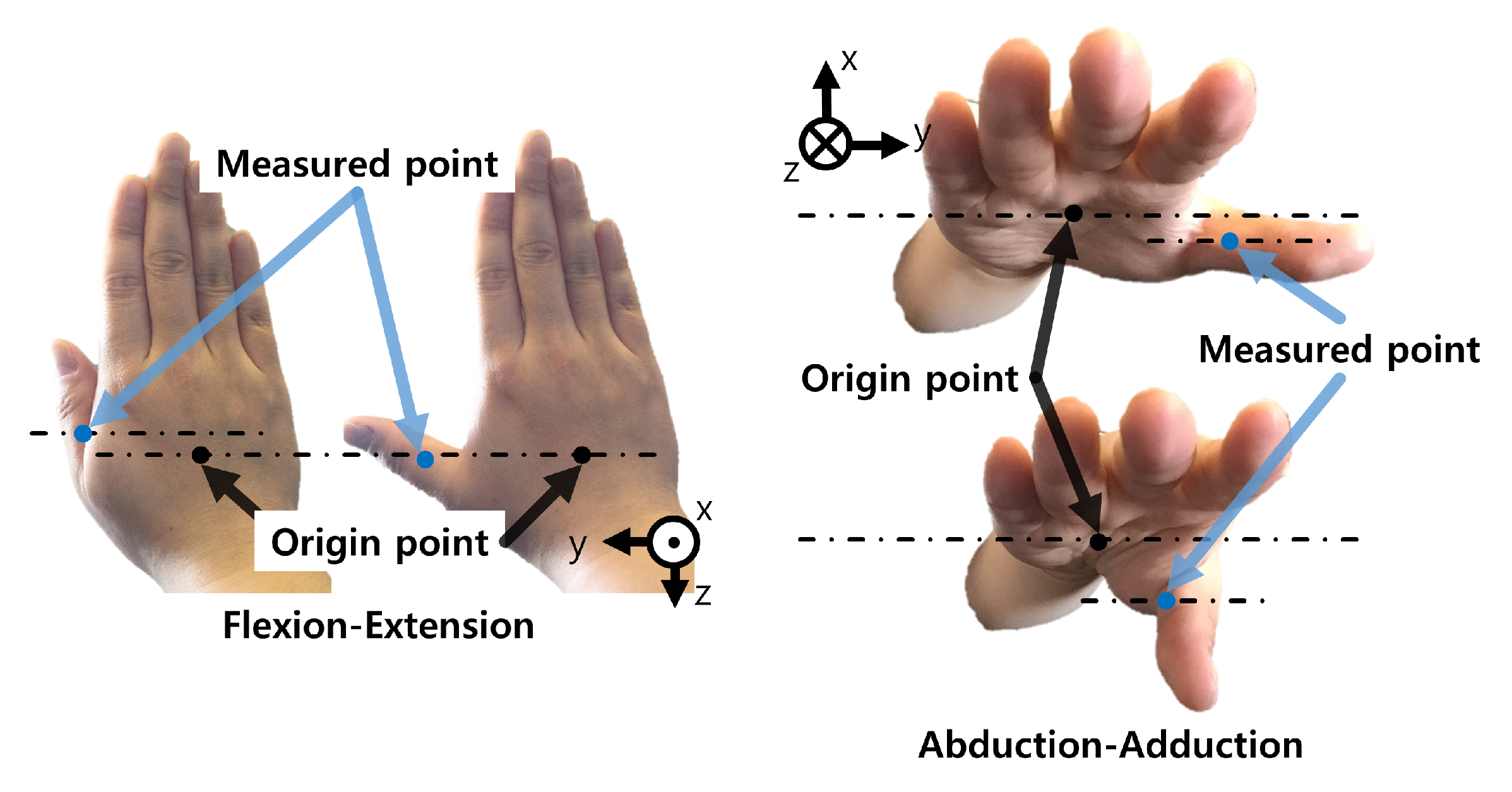

2.1. Mechanism Configuration

2.2. Mobility Analysis

2.3. Overall Jacobian Matrix

3. Displacement Analysis

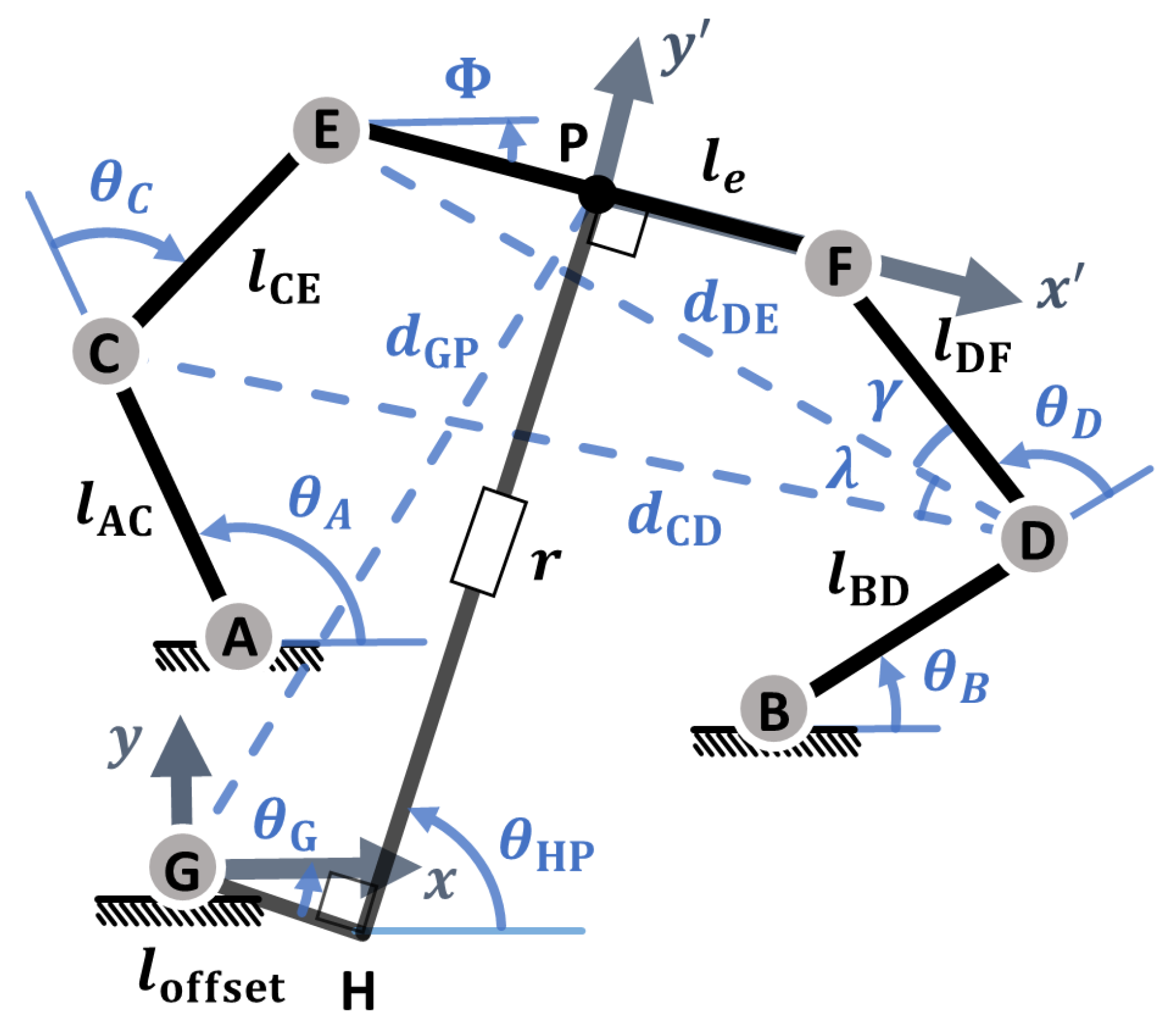

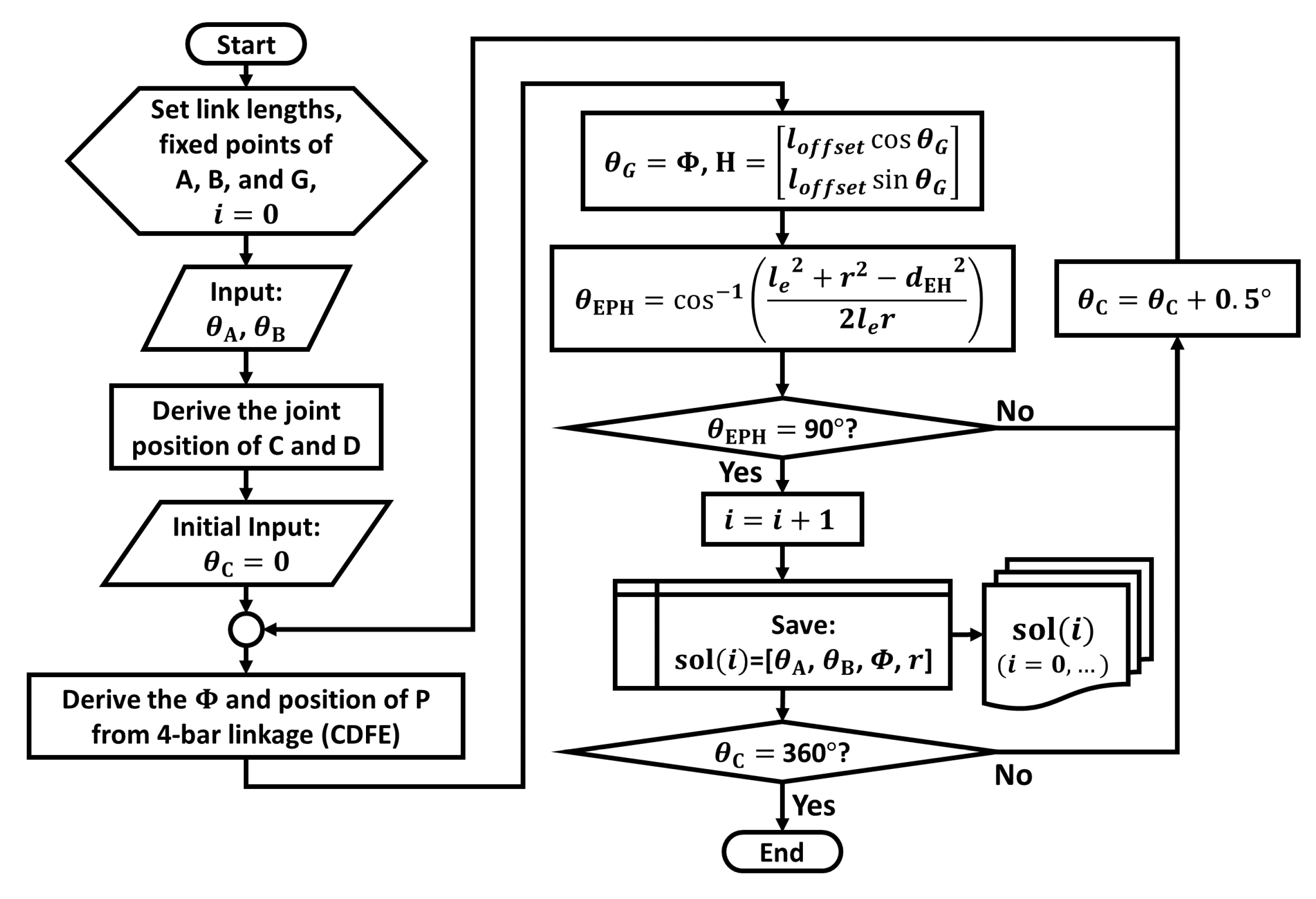

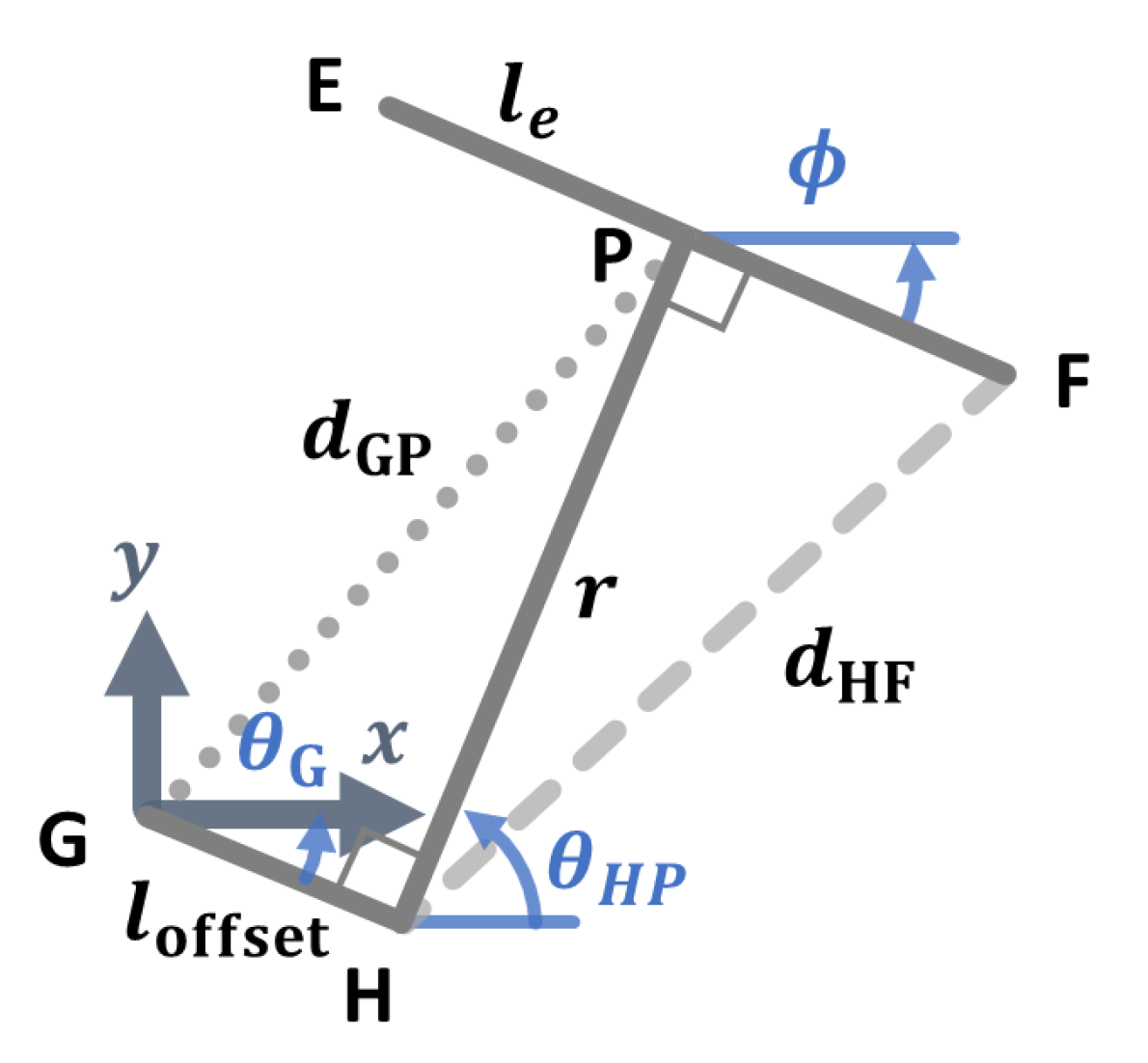

3.1. Forward Displacement Analysis of Planar Motion Generator

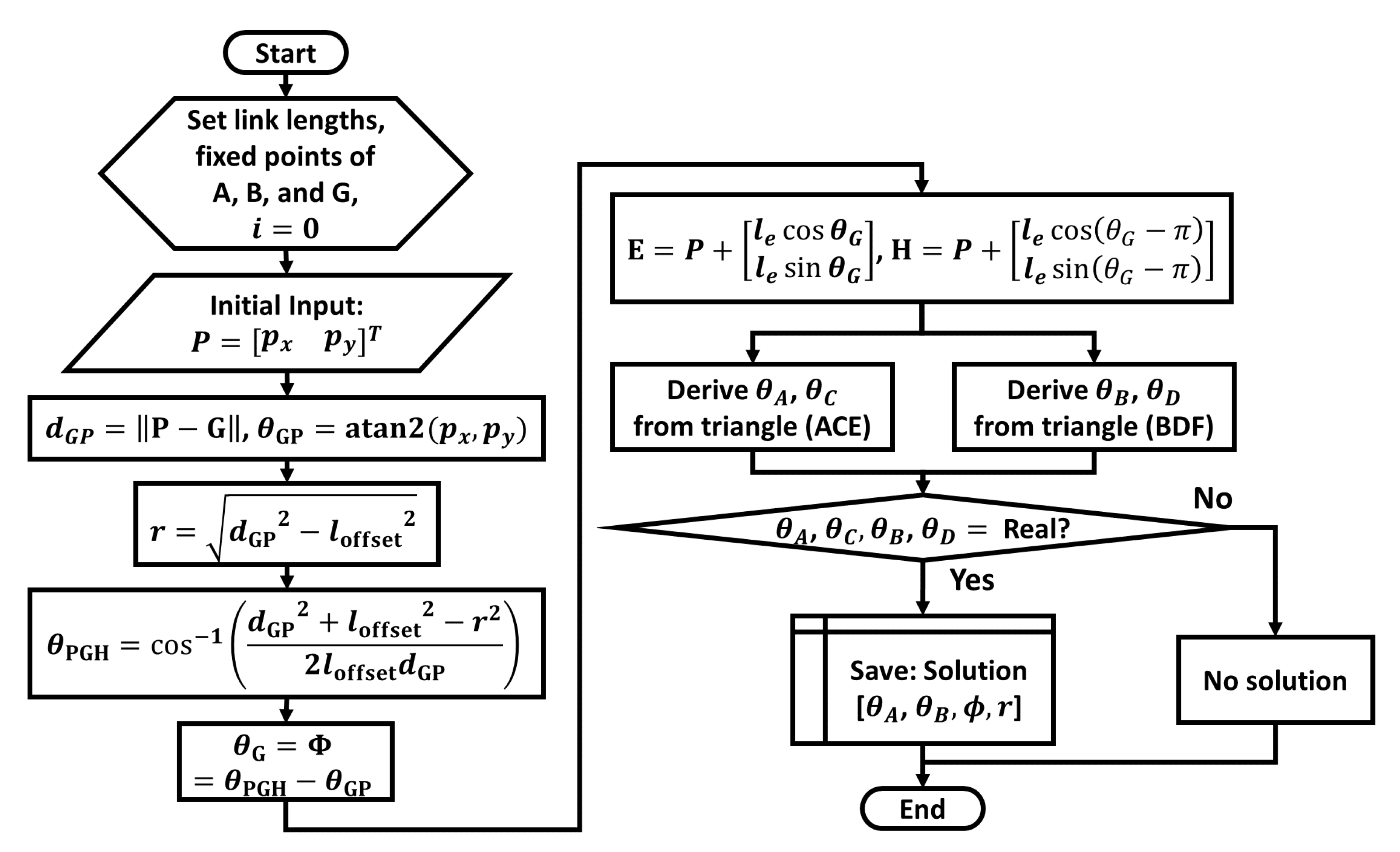

3.2. Inverse Kinematics of Planar Motion Generator

3.3. Forward and Inverse Kinematics of Orientation Generator

4. Kinematic Performance Analysis

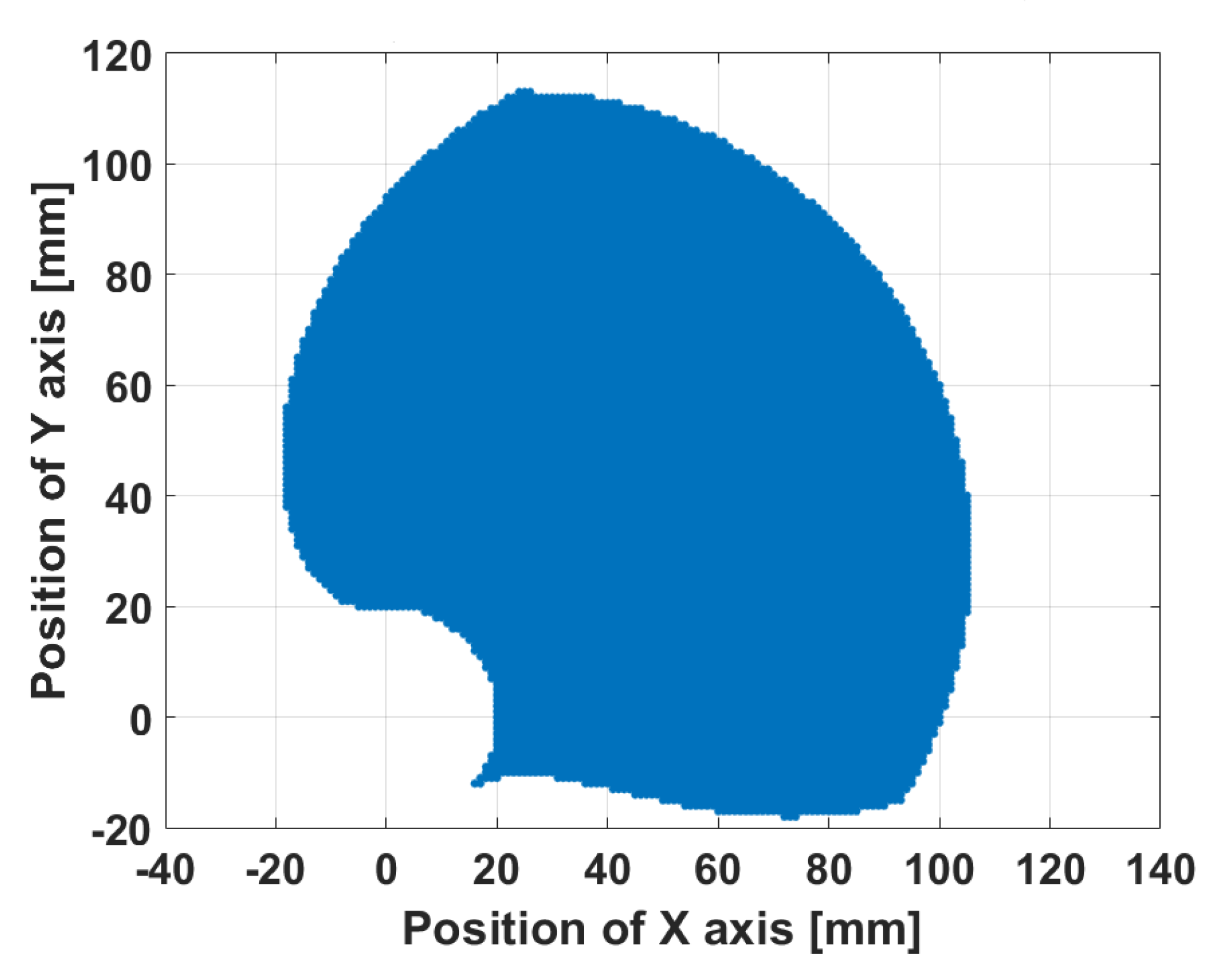

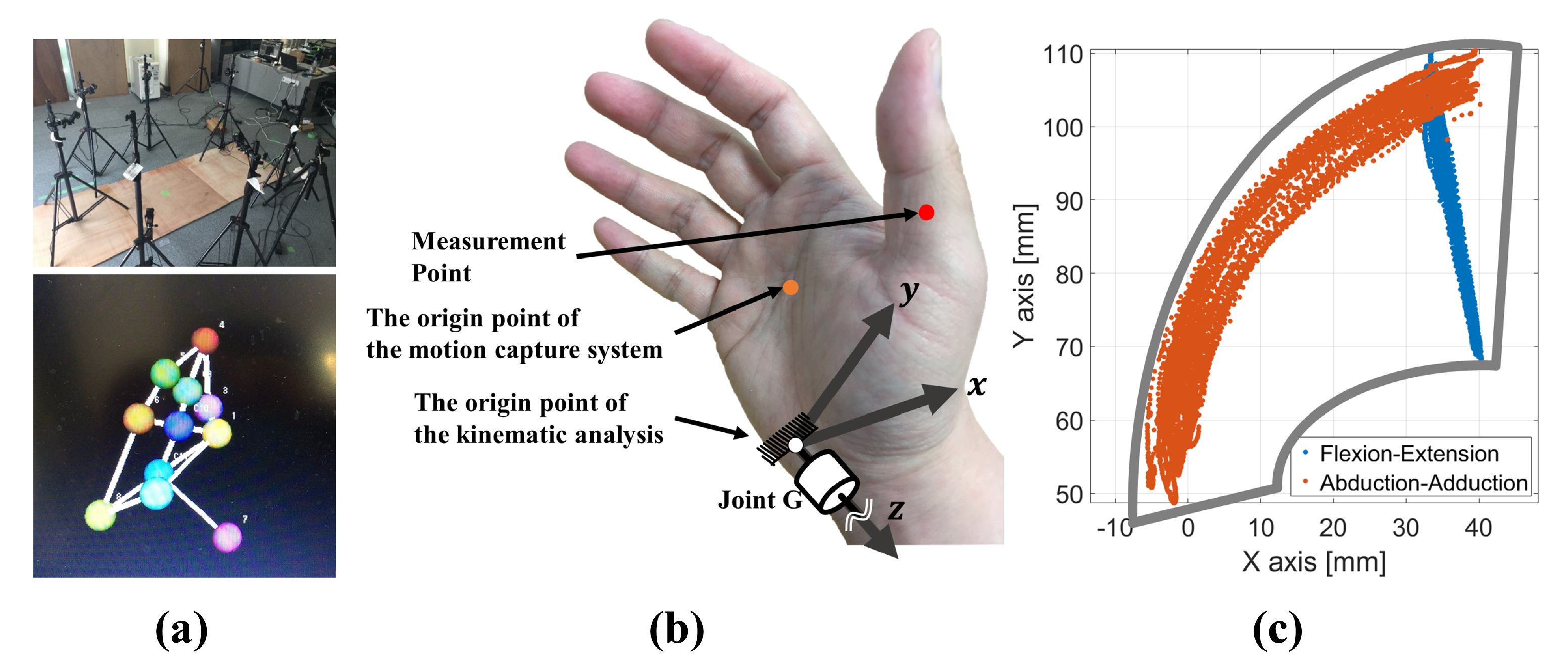

4.1. Reachable Workspace of Planar Motion Generator

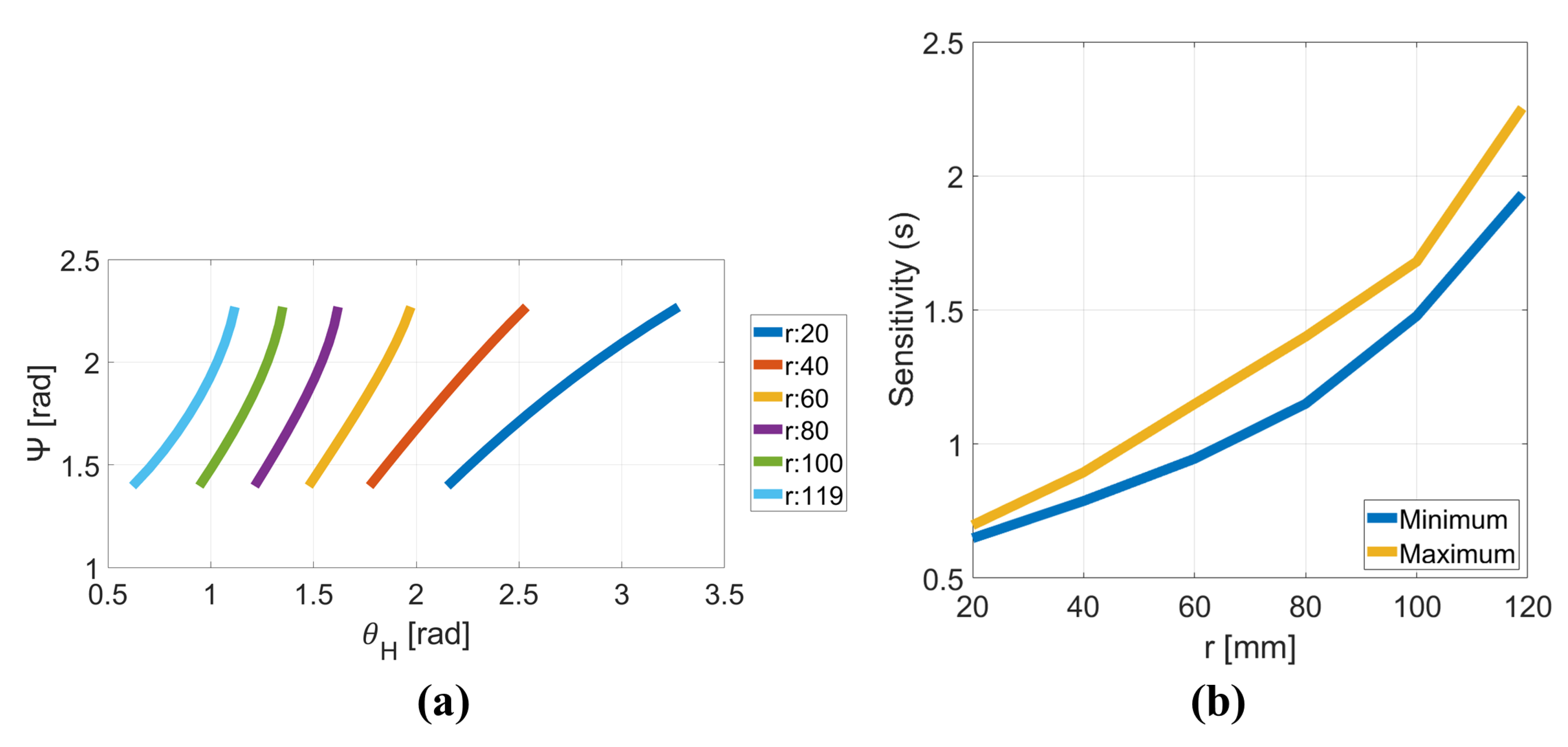

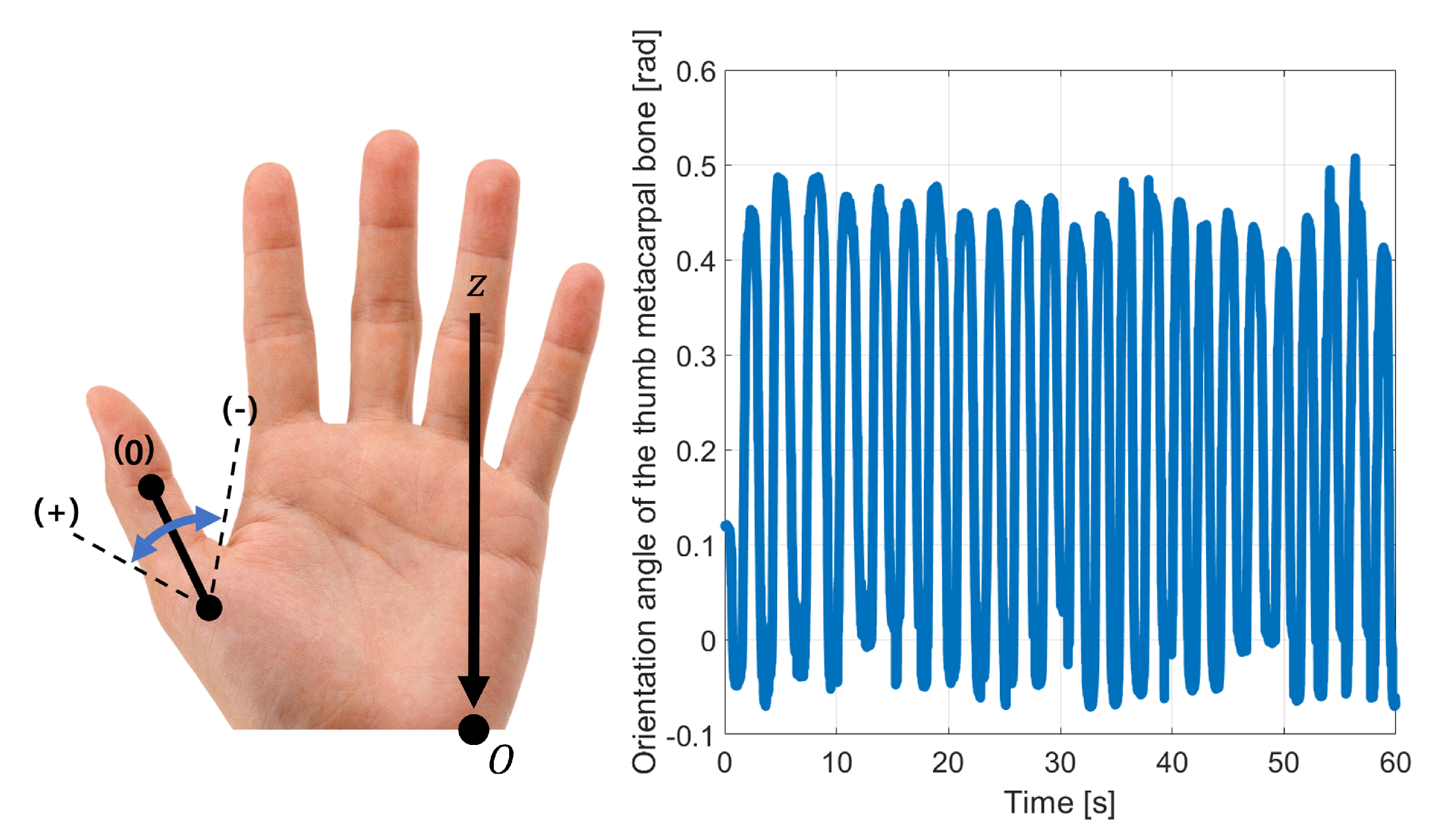

4.2. Rotational Capability and Sensitivity of Orientation Generator

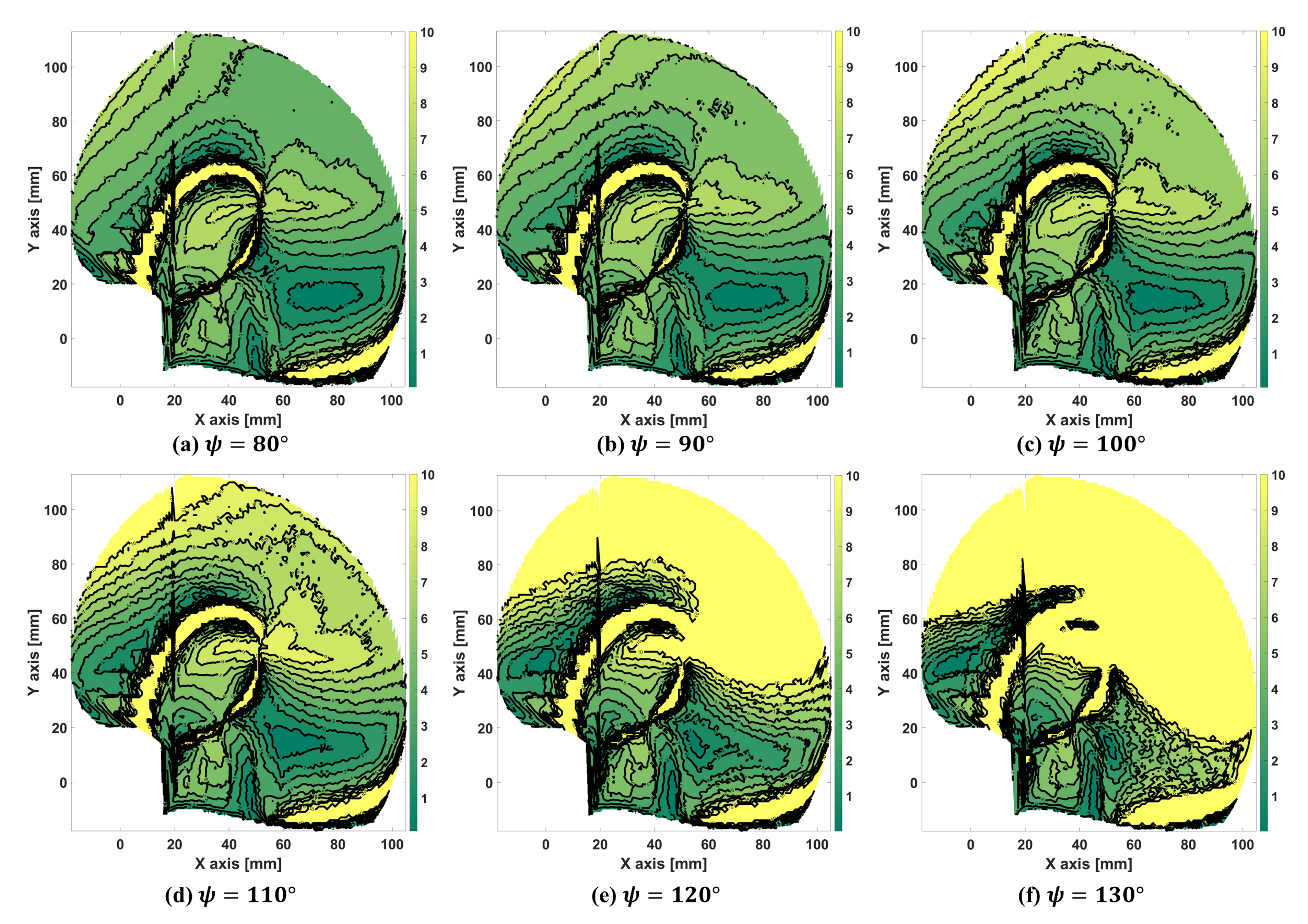

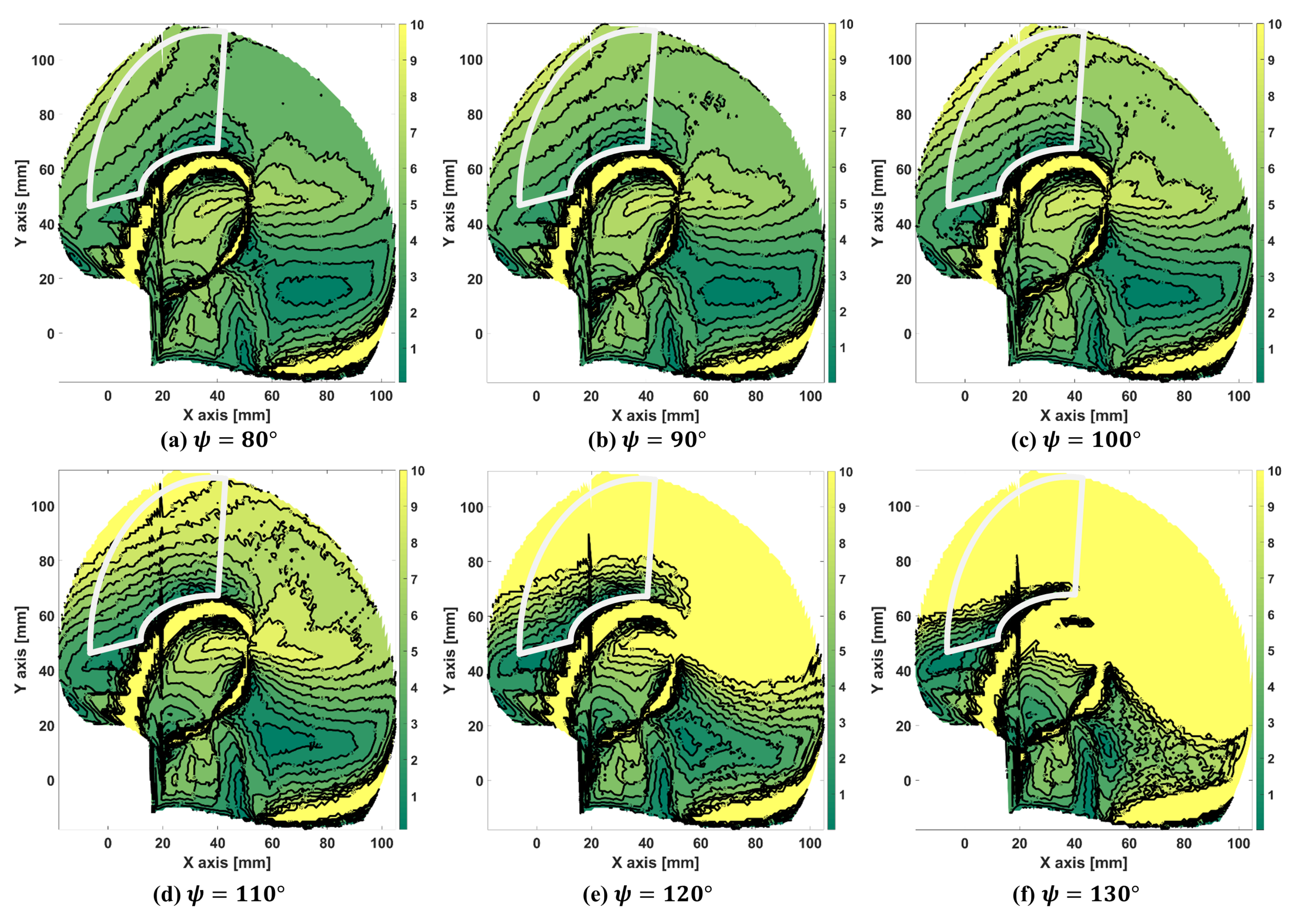

4.3. Effective Workspace with the Torque Difference

- The target user is expected as the paralyzed patient who got the botulinum toxin injection.

- The maximum torque of the proposed mechanism is 6 Nm.

- The target workspace is set as the same workspace of the healthy persons’ one.

- If the magnitude of D is equal to or less than a threshold, the point is considered to be inside the effective workspace. In the following example, we used 6 Nm as the threshold value.

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| D | Difference between maximum torque and minimum torque of | r | Distance between O and P | |

| d | Distance between two joints | Screw vector of joint k (k = A,..., J) | ||

| F | External Load to output link | Screw axis of joint k (k = A,..., J) | ||

| Forces of external loads | Constraint wrenches of chain (i = 1,..., 3 / j = 1, 2) | |||

| Moments of external loads | Independent constraint wrenches (n = 1,..., 3) | |||

| Degrees of freedom of the joints (i = 1, 2) | Force components of | |||

| i | Number of the chains | Moment components of | ||

| J | the number of the joints | Actuated wrenches of each chain | ||

| Overall Jacobian matrix | Force components of | |||

| Actuation Jacobian matrix | Moment components of | |||

| Constraint Jacobian matrix | Angle of joint (k = A,..., J) or Angle in the triangle of three points ( is angle B from triangle ABC) | |||

| L | the number of the links | Input velocity of the actuation joints | ||

| l | Link length of two joints | Vectors of actuation torque | ||

| Link length of offset | Vectors of constraint torque | |||

| O | Origin point in O- coordinate | Orientation angle in plane | ||

| P | Position vector of output point | Orientation angle in plane | ||

| position value of P in x axis | Three-dimensional zero vector | |||

| position value of P in y axis | ||||

References

- Neumann, D.A. Kinesiology of The Musculoskeletal System: Foundations for Rehabilitation; Elsevier Health Sciences: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Galvin, R.; Murphy, B.; Cusack, T.; Stokes, E. The impact of increased duration of exercise therapy on functional recovery following stroke—What is the evidence? Top. Stroke Rehabil. 2008, 15, 365–377. [Google Scholar] [CrossRef]

- Lee, J.; Kim, B.R. Role of Intensity and Repetition in Rehabilitation Therapy. Brain Neurorehabilit. 2012, 5, 6–11. [Google Scholar] [CrossRef]

- Kwakkel, G.; van Peppen, R.; Wagenaar, R.C.; Wood Dauphinee, S.; Richards, C.; Ashburn, A.; Miller, K.; Lincoln, N.; Partridge, C.; Wellwood, I.; et al. Effects of augmented exercise therapy time after stroke: A meta-analysis. Stroke 2004, 35, 2529–2539. [Google Scholar] [CrossRef] [PubMed]

- WHO. World Health Statistics 2008; World Health Organization: Geneva, Switzerland, 2008. [Google Scholar]

- Bernhardt, J.; Dewey, H.; Thrift, A.; Donnan, G. Inactive and alone: Physical activity within the first 14 days of acute stroke unit care. Stroke 2004, 35, 1005–1009. [Google Scholar] [CrossRef] [PubMed]

- Taub, E.; Miller, N.E.; Novack, T.A.; Cook, E.W.; Fleming, W.C.; Nepomuceno, C.S.; Connell, J.S.; Crago, J. Technique to improve chronic motor deficit after stroke. Arch. Phys. Med. Rehabil. 1993, 74, 347–354. [Google Scholar]

- Loureiro, R.C.; Harwin, W.S.; Nagai, K.; Johnson, M. Advances in upper limb stroke rehabilitation: A technology push. Med. Biol. Eng. Comput. 2011, 49, 1103. [Google Scholar] [CrossRef] [PubMed]

- Yue, Z.; Zhang, X.; Wang, J. Hand rehabilitation robotics on poststroke motor recovery. Behav. Neurol. 2017. [Google Scholar] [CrossRef]

- Sheng, B.; Zhang, Y.; Meng, W.; Deng, C.; Xie, S. Bilateral robots for upper-limb stroke rehabilitation: State of the art and future prospects. Med. Eng. Phys. 2016, 38, 587–606. [Google Scholar] [CrossRef]

- Endo, T.; Tanimura, S.; Kawasaki, H. Development of tool-type devices for a multifingered haptic interface robot. IEEE Trans. Robot. 2012, 29, 68–81. [Google Scholar] [CrossRef]

- Lambercy, O.; Dovat, L.; Gassert, R.; Burdet, E.; Teo, C.L.; Milner, T. A haptic knob for rehabilitation of hand function. IEEE Trans. Neural Syst. Rehabil. Eng. 2007, 15, 356–366. [Google Scholar] [CrossRef]

- Takahashi, C.D.; Der-Yeghiaian, L.; Le, V.; Cramer, S.C. A robotic device for hand motor therapy after stroke. In Proceedings of the 9th International Conference on Rehabilitation Robotics, ICORR 2005, Chicago, IL, USA, 28 June–1 July 2005; pp. 17–20. [Google Scholar] [CrossRef]

- Dovat, L.; Lambercy, O.; Gassert, R.; Maeder, T.; Milner, T.; Leong, T.C.; Burdet, E. HandCARE: A cable-actuated rehabilitation system to train hand function after stroke. IEEE Trans. Neural Syst. Rehabil. Eng. 2008, 16, 582–591. [Google Scholar] [CrossRef] [PubMed]

- Ueki, S.; Kawasaki, H.; Ito, S.; Nishimoto, Y.; Abe, M.; Aoki, T.; Ishigure, Y.; Ojika, T.; Mouri, T. Development of a hand-assist robot with multi-degrees-of-freedom for rehabilitation therapy. IEEE/ASME Trans. Mechatron. 2010, 17, 136–146. [Google Scholar] [CrossRef]

- Wege, A.; Hommel, G. Development and control of a hand exoskeleton for rehabilitation of hand injuries. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 3046–3051. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Zhang, Y.; Wang, S. Design of an exoskeleton for index finger rehabilitation. In Proceedings of the 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 3–6 September 2009; pp. 5957–5960. [Google Scholar] [CrossRef]

- Shields, B.L.; Main, J.A.; Peterson, S.W.; Strauss, A.M. An anthropomorphic hand exoskeleton to prevent astronaut hand fatigue during extravehicular activities. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 1997, 27, 668–673. [Google Scholar] [CrossRef]

- Fontana, M.; Dettori, A.; Salsedo, F.; Bergamasco, M. Mechanical design of a novel hand exoskeleton for accurate force displaying. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 1704–1709. [Google Scholar] [CrossRef]

- Nakagawara, S.; Kajimoto, H.; Kawakami, N.; Tachi, S.; Kawabuchi, I. An encounter-type multi-fingered master hand using circuitous joints. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; pp. 2667–2672. [Google Scholar] [CrossRef]

- Iqbal, J.; Ahmad, O.; Malik, A. HEXOSYS II-towards realization of light mass robotics for the hand. In Proceedings of the 2011 IEEE 14th International Multitopic Conference, Karachi, Pakistan, 22–24 December 2011; pp. 115–119. [Google Scholar] [CrossRef]

- Stergiopoulos, P.; Fuchs, P.; Laurgeau, C. Design of a 2-finger hand exoskeleton for VR grasping simulation. In Proceedings of the EuroHaptics 2003, Dublin, Ireland, 6–8 July 2003; pp. 80–93. [Google Scholar]

- Garcia-Hernandez, N.; Sarakoglou, I.; Tsagarakis, N.; Caldwell, D. Under-actuated hand exoskeleton with novel kinematics for potential use in rehabilitation. In Proceedings of the EuroHaptics 2014, Versailles, France, 24–27 June 2014; pp. 24–27. [Google Scholar]

- Aubin, P.M.; Sallum, H.; Walsh, C.; Stirling, L.; Correia, A. A pediatric robotic thumb exoskeleton for at-home rehabilitation: The Isolated Orthosis for Thumb Actuation (IOTA). In Proceedings of the 2013 IEEE 13th International Conference on Rehabilitation Robotics (ICORR), Seattle, WA, USA, 24–26 June 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Leonardis, D.; Barsotti, M.; Loconsole, C.; Solazzi, M.; Troncossi, M.; Mazzotti, C.; Castelli, V.P.; Procopio, C.; Lamola, G.; Chisari, C.; et al. An EMG-controlled robotic hand exoskeleton for bilateral rehabilitation. IEEE Trans. Haptics 2015, 8, 140–151. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Mikami, Y.; Watanabe, K.; Sankai, Y. Five-fingered assistive hand with mechanical compliance of human finger. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 718–724. [Google Scholar] [CrossRef]

- Bouzit, M.; Burdea, G.; Popescu, G.; Boian, R. The Rutgers Master II-new design force-feedback glove. IEEE/ASME Trans. Mechatron. 2002, 7, 256–263. [Google Scholar] [CrossRef]

- Lambercy, O.; Schröder, D.; Zwicker, S.; Gassert, R. Design of a thumb exoskeleton for hand rehabilitation. In Proceedings of the 7th International Convention on Rehabilitation Engineering and Assistive Technology, Gyeonggi-do, Korea, 29–31 August 2013; No. 41. pp. 1–4. [Google Scholar]

- Wang, F.; Shastri, M.; Jones, C.L.; Gupta, V.; Osswald, C.; Kang, X.; Kamper, D.G.; Sarkar, N. Design and control of an actuated thumb exoskeleton for hand rehabilitation following stroke. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 3688–3693. [Google Scholar] [CrossRef]

- Agarwal, P.; Yun, Y.; Fox, J.; Madden, K.; Deshpande, A.D. Design, control, and testing of a thumb exoskeleton with series elastic actuation. Int. J. Robot. Res. 2017, 36, 355–375. [Google Scholar] [CrossRef]

- Choi, W.h.; Takeda, Y. Kinematic Analysis of (2-RRU)-URR Parallel Mechanism Performing 2R1T Output Motion. In IFToMM International Symposium on Robotics and Mechatronics; Springer: Berlin/Heidelberg, Germany, 2019; pp. 114–124. [Google Scholar] [CrossRef]

- Stewart, D. A platform with six degrees of freedom. Proc. Inst. Mech. Eng. 1965, 180, 371–386. [Google Scholar] [CrossRef]

- Clavel, R. A fast robot with parallel geometry. In Proceedings of the International Symposium on Industrial Robot, Lausanne, Switzerland, 26–28 April 1988; pp. 91–100. [Google Scholar]

- Gosselin, C.M.; Hamel, J.F. The agile eye: A high-performance three-degree-of-freedom camera-orienting device. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; pp. 781–786. [Google Scholar] [CrossRef]

- Liu, X.J.; Tang, X.; Wang, J. HANA: A novel spatial parallel manipulator with one rotational and two translational degrees of freedom. Robotica 2005, 23, 257–270. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.J. Analysis of a novel cylindrical 3-DoF parallel robot. Robot. Auton. Syst. 2003, 42, 31–46. [Google Scholar] [CrossRef]

- Joshi, S.A.; Tsai, L.W. Jacobian analysis of limited-DOF parallel manipulators. J. Mech. Des. 2002, 124, 254–258. [Google Scholar] [CrossRef]

- Batmanabane, M.; Malathi, S. Movements at the carpometacarpal and metacarpophalangeal joints of the hand and their effect on the dimensions of the articular ends of the metacarpal bones. Anat. Rec. 1985, 213, 102–110. [Google Scholar] [CrossRef] [PubMed]

- Cooney, W.P.; Lucca, M.J.; Chao, E.; Linscheid, R. The kinesiology of the thumb trapeziometacarpal joint. J. Bone Joint Surg. Am. 1981, 63, 1371–1381. [Google Scholar] [CrossRef] [PubMed]

- Ro, T.; Ota, T.; Saito, T.; Oikawa, O. Spasticity and Range of Motion Over Time in Stroke Patients Who Received Multiple-Dose Botulinum Toxin Therapy. J. Stroke Cerebrovasc. Dis. 2020, 29, 104481. [Google Scholar] [CrossRef]

- Flowers, K.R.; LaStayo, P. Effect of total end range time on improving passive range of motion. J. Hand Ther. 1994, 7, 150–157. [Google Scholar] [CrossRef]

- Haruhisa, K.; Hiroki, K.; Satoshi, I.; Yutaka, N.; Hiroyuki, H.; Hirohumi, S. Hand Rehabilitation Support System. Trans. Jpn. Soc. Mech. Eng. C 2006, 72, 2568–2573. [Google Scholar] [CrossRef]

- Masia, L.; Krebs, H.I.; Cappa, P.; Hogan, N. Design and characterization of hand module for whole-arm rehabilitation following stroke. IEEE/ASME Trans. Mechatron. 2007, 12, 399–407. [Google Scholar] [CrossRef]

- Neumann, D.A.; Bielefeld, T. The carpometacarpal joint of the thumb: Stability, deformity, and therapeutic intervention. J. Orthop. Sports Phys. Ther. 2003, 33, 386–399. [Google Scholar] [CrossRef]

- Smutz, W.P.; Kongsayreepong, A.; Hughes, R.E.; Niebur, G.; Cooney, W.P.; An, K.N. Mechanical advantage of the thumb muscles. J. Biomech. 1998, 31, 565–570. [Google Scholar] [CrossRef]

- Liu, Y.C.; Takeda, Y. Kineto-Static Analysis of a Wrist Rehabilitation Robot with Compliance and Passive Joints for Joint Misalignment Compensation. Machines 2020, 8, 23. [Google Scholar] [CrossRef]

| Position of Joints [mm] | Length of Links [mm] | ||||

|---|---|---|---|---|---|

| A(x, y, z) | (16, 36, 0) | 26 | 45 | ||

| B(x, y, z) | (74, 36, 0) | , , , | 40 | 8.5 | |

| O(x, y, z) | (0, 0, 0) | , | 70 | 20 | |

| Parameter | Given Values [mm] |

|---|---|

| −100 ∼ 100 Interval: 0.1 mm | |

| −100 ∼ 100 Interval: 0.1 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, W.-h.; Takeda, Y. Displacement Analysis and Design of a (2–RRU)–URR Parallel Mechanism Performing 2R1T Output Motion for Thumb Rehabilitation. Robotics 2020, 9, 67. https://doi.org/10.3390/robotics9030067

Choi W-h, Takeda Y. Displacement Analysis and Design of a (2–RRU)–URR Parallel Mechanism Performing 2R1T Output Motion for Thumb Rehabilitation. Robotics. 2020; 9(3):67. https://doi.org/10.3390/robotics9030067

Chicago/Turabian StyleChoi, Woo-hyeok, and Yukio Takeda. 2020. "Displacement Analysis and Design of a (2–RRU)–URR Parallel Mechanism Performing 2R1T Output Motion for Thumb Rehabilitation" Robotics 9, no. 3: 67. https://doi.org/10.3390/robotics9030067

APA StyleChoi, W.-h., & Takeda, Y. (2020). Displacement Analysis and Design of a (2–RRU)–URR Parallel Mechanism Performing 2R1T Output Motion for Thumb Rehabilitation. Robotics, 9(3), 67. https://doi.org/10.3390/robotics9030067