A Review on Design, Modeling and Control Technology of Cable-Driven Parallel Robots

Abstract

1. Introduction

2. Mechanical Structure Design of CDPR

2.1. Traditional Structure

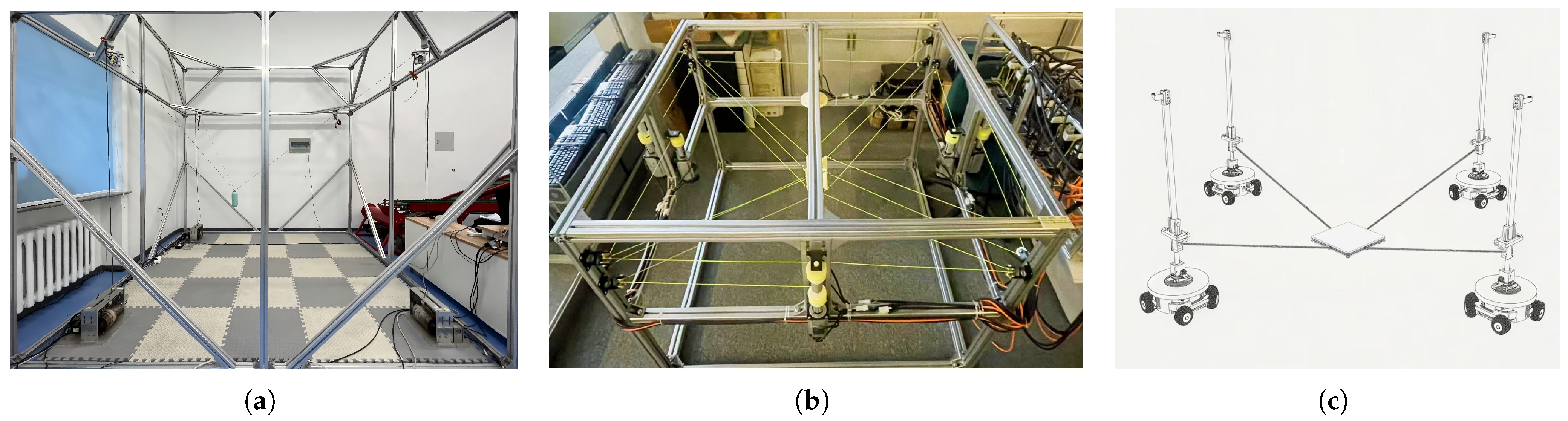

2.2. Reconfigurable Structure

2.3. Special Structure

3. CDPR Modeling Research

3.1. Kinematic and Dynamic Modeling

3.2. Friction Model

3.3. Tension Constraint Model

3.4. Sagging-Cable Model

4. Planning and Control

4.1. Traditional Planning Method

4.2. Traditional Control Method

4.3. Model Predictive Control

4.4. Intelligent Control Method

5. Conclusions and Outlook

- In the field of structural design, the traditional fixed-base structure has a high space occupancy rate and limits the working range of EE, which has prompted many studies to integrate the manipulator configuration with CDPR technology to develop special cable-driven robots mainly used in the field of medical rehabilitation. This type of design not only combines the advantages of traditional rigid robots and traditional CDPRs, but also significantly improves the robot’s environmental adaptability and movement flexibility. However, the inherent flexibility and nonlinear characteristics of the cable make its control system design more difficult and reduce positioning accuracy.The MAS that has emerged in recent years has become an innovative solution to replace the traditional fixed base. This design not only gives CDPR the ability to move autonomously, but also can adapt to diverse and complex environments through dynamic topological structure adjustment. However, the variability of the topological structure changes the tension-feasible domain constraints of the system, resulting in a significant increase in the complexity of control system design. At the same time, due to the lack of base constraints, the system will generate new structural vibration modes and tension distribution constraint problems, bringing new challenges to control system design. Currently, related research is still in its infancy, but this direction has broad research prospects and holds significant academic value and application potential.

- In the mathematical modeling research of CDPRs, dynamic and kinematic modeling has been developed to a relatively complete level, and a large number of papers have deeply explored its tension constraints and workspace characteristics. However, the research on the integration of friction model and catenary model is relatively scarce, and has failed to effectively combine the latest progress in these two fields. In the field of friction research, the Lugre model and the Stribeck model are widely used because of their accurate characterization of friction characteristics. Unfortunately, the current research on CDPRs still generally adopts the outdated Coulomb–viscous friction model, which ignores the nonlinear characteristics (including the stick–slip phenomenon) under low-speed conditions. There is also a lag in the research on the CDPR catenary model. It is worth noting that J. Merlet has filled the gap in this field through a series of studies, and systematically demonstrated the advanced nature of the Irvine model based on singular point analysis and workspace analysis. In summary, although the current research on mathematical modeling of CDPRs has made significant progress, it is still necessary to integrate multidisciplinary cutting-edge results to further improve the accuracy of the model.

- In terms of planning and control, there are currently two main development directions: one is model predictive control, and the other is intelligent control methods. Model predictive control has been a hot topic in the control field in recent years. It has the advantages of multi-variable complex constraint-processing capabilities and dynamic optimization, making it particularly suitable for systems with multiple constraints and multiple nonlinearities such as CDPR. However, the rolling iteration algorithm and multi-step prediction link increase the amount of calculations and are highly dependent on model accuracy. To achieve closed-loop stability, additional terminal constraints need to be designed. Intelligent control methods are emerging control methods that are sought after by researchers for their powerful fitting and learning capabilities. At present, intelligent control researches on CDPR have covered kinematic modeling, error compensation, trajectory-tracking control, etc. [79]. It has good adaptability, fault tolerance and robustness, can handle high-dimensional constraints well, and does not require precise mathematical models. However, the shortcomings of this algorithm are very obvious: lack of a unified stability proof framework, poor interpretability, strong data dependence, lack of real-time performance, and high computational cost. In general, MPC and intelligent control are currently the research focuses in this field and have extremely high research value. Overcoming the shortcomings of these algorithms has therefore become a top priority.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CDPR | Cable-Driven Parallel Robot |

| EE | End-Effector |

| DOF | Degrees of Freedom |

| MAS | Multi-Agent System |

| TDCR | Tendon-Driven Continuum Robot |

| SMC | Sliding-Mode Control |

| MPC | Model Predictive Control |

| PID | Proportional–Integral–Derivative |

| RRT | Rapidly-Exploring Random Tree |

References

- Wijayathunga, L.; Rassau, A.; Chai, D. Challenges and Solutions for Autonomous Ground Robot Scene Understanding and Navigation in Unstructured Outdoor Environments: A Review. Appl. Sci. 2023, 13, 9877. [Google Scholar] [CrossRef]

- Qian, S.; Zi, B.; Shang, W.W.; Xu, Q.S. A review on cable-driven parallel robots. Chin. J. Mech. Eng. 2018, 31, 66. [Google Scholar] [CrossRef]

- Berti, A.; Merlet, J.-P.; Carricato, M. Solving the direct geometrico-static problem of underconstrained cable-driven parallel robots by interval analysis. Int. J. Robot. Res. 2015, 35, 723–739. [Google Scholar] [CrossRef]

- Li, J.; Li, Y. A Survey of Design, Control, and Path Planning of Cable-Driven Parallel Robots. In Proceedings of the 2024 IEEE International Conference on Robotics and Biomimetics (ROBIO), Bangkok, Thailand, 10–14 December 2024; pp. 305–309. [Google Scholar] [CrossRef]

- Ahmadi, S.; Ghaderi, F.; Mohammadi, A.A.; Miandoab, E.M.; Fahim, A. Cable-driven parallel robot control based on a neural network-aided vision system. In Proceedings of the 2023 11th RSI International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 19–21 December 2023; pp. 312–317. [Google Scholar] [CrossRef]

- Shah, M.F.; Hussain, S.; Goecke, R.; Jamwal, P.K. Mechanism design and control of shoulder rehabilitation robots: A review. IEEE Trans. Med. Robot. Bionics 2023, 5, 780–792. [Google Scholar] [CrossRef]

- Xu, P.; Li, J.; Li, S.; Xia, D.; Zeng, Z.; Yang, N.; Xie, L. Design and evaluation of a parallel cable-driven shoulder mechanism with series springs. J. Mech. Robot. 2022, 14, 031012. [Google Scholar] [CrossRef]

- Xiao, F.; Gao, Y.; Wang, Y.; Zhu, Y.; Zhao, J. Design and evaluation of a 7-DOF cable-driven upper limb exoskeleton. J. Mech. Sci. Technol. 2018, 32, 855–864. [Google Scholar] [CrossRef]

- Duan, B. A new design project of the line feed structure for large spherical radio telescope and its nonlinear dynamic analysis. Mechatronics 1999, 9, 53–64. [Google Scholar] [CrossRef]

- Mahdi, S.M.; Abdulkareem, A.I.; Humaidi, A.J.; Mhdawi, A.K.A.; Al-Raweshidy, H. Comprehensive review of control techniques for various mechanisms of parallel robots. IEEE Access 2025, 13, 63381–63416. [Google Scholar] [CrossRef]

- Zarebidoki, M.; Dhupia, J.S.; Xu, W. A Review of Cable-Driven Parallel Robots: Typical Configurations, Analysis Techniques, and Control Methods. IEEE Robot. Autom. Mag. 2022, 29, 89–106. [Google Scholar] [CrossRef]

- Zhang, Z.; Shao, Z.; You, Z.; Tang, X.; Zi, B.; Yang, G.; Gosselin, C.; Caro, S. State-of-the-art on theories and applications of cable-driven parallel robots. Front. Mech. Eng. 2022, 17, 37. [Google Scholar] [CrossRef]

- Xu, J.; Kim, B.G.; Feng, X.; Park, K.S. Online motion planning of mobile cable-driven parallel robots for autonomous navigation in uncertain environments. Complex Intell. Syst. 2024, 10, 397–412. [Google Scholar] [CrossRef]

- Chen, W.; Li, Z.; Cui, X.; Zhang, J.; Bai, S. Mechanical Design and Kinematic Modeling of a Cable-Driven Arm Exoskeleton Incorporating Inaccurate Human Limb Anthropomorphic Parameters. Sensors 2019, 19, 4461. [Google Scholar] [CrossRef] [PubMed]

- Kui, Q.; Li, X.; Lu, Y.; Huan, B.; Xiang, Z.; Tang, F. Hybird Integral Sliding Mode Tracking Control of Cable-Driven Parallel Robots. In Proceedings of the 2024 IEEE 7th International Electrical and Energy Conference (CIEEC), Harbin, China, 10–12 May 2024; pp. 1608–1613. [Google Scholar] [CrossRef]

- Jiang, X.; Barnett, E.; Gosselin, C. Dynamic point-to-point trajectory planning beyond the static workspace for six-dof cable-suspended parallel robots. IEEE Trans. Robot. 2018, 34, 781–793. [Google Scholar] [CrossRef]

- Wang, R.; Li, Y. Jerk-limited online trajectory scaling for cable-driven parallel robots. IEEE Trans. Autom. Sci. Eng. 2025, 22, 11529–11539. [Google Scholar] [CrossRef]

- Hwang, S.W.; Kim, D.H.; Park, J.; Park, J.H. Equilibrium Configuration Analysis and Equilibrium-Based Trajectory Generation Method for Under-Constrained Cable-Driven Parallel Robot. IEEE Access 2022, 10, 112134–112149. [Google Scholar] [CrossRef]

- Li, X.; Kui, Q.; Yao, W.; Wu, L. Robust Parallel Cooperative Control of Cable-Driven Robot System via Adaptive Integral Sliding Mode. IEEE Robot. Autom. Lett. 2025, 10, 5433–5440. [Google Scholar] [CrossRef]

- Khoshkam, S.; Alizadeh, M.; Khosravi, M.A. Stochastic Nonlinear Model Predictive Control of a 3-DoF Suspended Cable-Driven Parallel Robot. In Proceedings of the 2023 11th RSI International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 19–21 December 2023; pp. 695–700. [Google Scholar] [CrossRef]

- Jung, M.-J.; Prak, S.-A.; Kim, C.-S. Workspace Analysis of an Expandable End-Effector for Cable-Driven Parallel Robots. In Proceedings of the 2024 24th International Conference on Control, Automation and Systems (ICCAS), Jeju, Republic of Korea, 29 October–1 November 2024; pp. 1192–1193. [Google Scholar] [CrossRef]

- Bajelani, M.; Khalilpour, S.A.; Hosseini, M.I.; Moosavian, S.A.A.; Taghirad, H.D. Time-Delay Learning-Based Controller for Fully-Constrained Cable-Driven Parallel Robots. In Proceedings of the 2022 8th International Conference on Control, Instrumentation and Automation (ICCIA), Tehran, Iran, 2–3 March 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Kim, J.; Oh, E.; Kim, M.; Kim, E. A Three-Cable Driven Planar Parallel Robot: Closet Set Searching Kinematics and Model Reference Adaptive Control. In Proceedings of the 2021 21st International Conference on Control, Automation and Systems (ICCAS), Jeju, Republic of Korea, 12–15 October 2021; pp. 2254–2256. [Google Scholar] [CrossRef]

- Li, J.; Li, Y. The Structural Design, Kinematics, and Workspace Analysis of a Novel Rod–Cable Hybrid Cable-Driven Parallel Robot. Biomimetics 2025, 10, 4. [Google Scholar] [CrossRef]

- Kim, B.-G.; Shin, D.-Y.; Park, K.-S. Advanced Hybrid Control of Mobile Cable-Driven Parallel Robot with 8-Cables. In Proceedings of the 2024 IEEE 18th International Conference on Advanced Motion Control (AMC), Kyoto, Japan, 28 February–1 March 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Xu, J.; Qian, C.; Park, J.W.; Park, K.S. Adaptive sampling-based moving obstacle avoidance for cable-driven parallel robots. IEEE/ASME Trans. Mechatron. 2022, 27, 4983–4993. [Google Scholar] [CrossRef]

- Mailhot, N.; Abouheaf, M.; Spinello, D. Model-Free Force Control of Cable-Driven Parallel Manipulators for Weight-Shift Aircraft Actuation. IEEE Trans. Instrum. Meas. 2024, 73, 2505108. [Google Scholar] [CrossRef]

- Cui, X.; Chen, W.; Jin, X.; Agrawal, S.K. Design of a 7-DOF Cable-Driven Arm Exoskeleton (CAREX-7) and a Controller for Dexterous Motion Training or Assistance. IEEE/ASME Trans. Mechatron. 2017, 22, 161–172. [Google Scholar] [CrossRef]

- Mao, Y.; Jin, X.; Dutta, G.G.; Scholz, J.; Agrawal, S.K. Human Movement Training with a Cable Driven ARm EXoskeleton (CAREX). IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 84–92. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Lueth, T.C. Optimization of stress distribution in tendon-driven continuum robots using fish-tail-inspired method. IEEE Robot. Autom. Lett. 2022, 7, 3380–3387. [Google Scholar] [CrossRef]

- Peyron, Q.; Burgner-Kahrs, J. Stability analysis of tendon driven continuum robots and application to active softening. IEEE Trans. Robot. 2023, 40, 85–100. [Google Scholar] [CrossRef]

- Shang, W.; Zhang, B.; Zhang, B.; Zhang, F.; Cong, S. Synchronization Control in the Cable Space for Cable-Driven Parallel Robots. IEEE Trans. Ind. Electron. 2019, 66, 4544–4554. [Google Scholar] [CrossRef]

- Li, Y.; Zi, B.; Sun, Z.; Zhao, P. Smooth trajectory planning for a cable driven parallel waist rehabilitation robot based on rehabilitation evaluation factors. Chin. J. Mech. Eng. 2023, 36, 73. [Google Scholar] [CrossRef]

- Zou, Y.; Hu, Y.; Cao, H.; Xu, Y.; Yu, Y.; Lu, W.; Xiong, H. Data-Driven Kinematic Control Scheme for Cable-Driven Parallel Robots Allowing Collisions. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; pp. 5003–5008. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, C.; Yao, W.; Sun, G.; Liu, J.; Wu, L. Deep Reinforcement Learning Control of Fully-Constrained Cable-Driven Parallel Robots. IEEE Trans. Ind. Electron. 2023, 70, 7194–7204. [Google Scholar] [CrossRef]

- Sun, H.; Tang, X.; Cui, Z.; Hou, S. Dynamic response of spatial flexible structures subjected to controllable force based on cable-driven parallel robots. IEEE/ASME Trans. Mechatron. 2020, 25, 2801–2811. [Google Scholar] [CrossRef]

- Peng, Y.; Bu, W. Analysis of reachable workspace for spatial three-cable under-constrained suspended cable-driven parallel robots. J. Mech. Robot. 2024, 13, 061002. [Google Scholar] [CrossRef]

- Kim, M.C.; Choi, H.; Piao, J.; Kim, E.S.; Park, J.O.; Kim, C.S. Remotely manipulated peg-in-hole task conducted by cable-driven parallel robots. IEEE/ASME Trans. Mechatron. 2022, 27, 3953–3963. [Google Scholar] [CrossRef]

- Harandi, M.R.J.; Khalilpour, S.A.; Taghirad, H.D. Adaptive dynamic feedback control of parallel robots with unknown kinematic and dynamic properties. ISA Trans. 2022, 126, 574–584. [Google Scholar] [CrossRef]

- Jia, H.; Shang, W.; Xie, F.; Zhang, B.; Cong, S. Second-order sliding-mode-based synchronization control of cable-driven parallel robots. IEEE/ASME Trans. Mechatron. 2019, 25, 383–394. [Google Scholar] [CrossRef]

- Nguyen, V.; Caverly, R.J. Cable-Driven Parallel Robot Pose Estimation Using Extended Kalman Filtering with Inertial Payload Measurements. IEEE Robot. Autom. Lett. 2021, 6, 3615–3622. [Google Scholar] [CrossRef]

- Wang, R.; Li, S.; Li, Y. A suspended cable-driven parallel robot with articulated reconfigurable moving platform for Schönflies motions. IEEE/ASME Trans. Mechatron. 2022, 27, 5173–5184. [Google Scholar] [CrossRef]

- Harandi, M.R.J.; Hassani, A.; Hosseini, M.I.; Taghirad, H.D. Adaptive position feedback control of parallel robots in the presence of kinematics and dynamics uncertainties. IEEE Trans. Autom. Sci. Eng. 2023, 21, 989–999. [Google Scholar] [CrossRef]

- Voglewede, P.A.; Ebert-Uphoff, I. Application of the antipodal grasp theorem to cable-driven robots. IEEE Trans. Robot. 2005, 21, 713–718. [Google Scholar] [CrossRef]

- Idà, E.; Bruckmann, T.; Carricato, M. Rest-to-rest trajectory planning for underactuated cable-driven parallel robots. IEEE Trans. Robot. 2019, 35, 1338–1351. [Google Scholar] [CrossRef]

- Song, D.; Zhang, L.; Xue, F. Configuration optimization and a tension distribution algorithm for cable-driven parallel robots. IEEE Access 2018, 6, 33928–33940. [Google Scholar] [CrossRef]

- Merlet, J.P. A generic numerical continuation scheme for solving the direct kinematics of cable-driven parallel robot with deformable cables. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 4337–4343. [Google Scholar] [CrossRef]

- Merlet, J.P. Computing cross-sections of the workspace of suspended cable-driven parallel robot with sagging cables having tension limitations. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 5042–5047. [Google Scholar] [CrossRef]

- Merlet, J.P. Singularity of cable-driven parallel robot with sagging cables: Preliminary investigation. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 504–509. [Google Scholar] [CrossRef]

- Briot, S.; Merlet, J.P. Direct kinematic singularities and stability analysis of sagging cable-driven parallel robots. IEEE Trans. Robot. 2023, 39, 2240–2254. [Google Scholar] [CrossRef]

- Baskar, A.; Plecnik, M.; Hauenstein, J.D.; Wampler, C.W. A numerical continuation approach using monodromy to solve the forward kinematics of cable-driven parallel robots with sagging cables. Mech. Mach. Theory 2024, 195, 105609. [Google Scholar] [CrossRef]

- Gosselin, C.; Foucault, S. Experimental determination of the accuracy of a three-DOF cable-suspended parallel robot performing dynamic trajectories. In Cable-Driven Parallel Robots: Proceedings of the Second International Conference on Cable-Driven Parallel Robots; Springer: Cham, Switzerland, 2015; pp. 101–112. [Google Scholar] [CrossRef]

- Lin, D.; Mottola, G. Dynamic Launch Trajectory Planning of a Cable-Suspended Translational Parallel Robot Using Point-to-Point Motions. Machines 2023, 11, 224. [Google Scholar] [CrossRef]

- Dion-Gauvin, P.; Gosselin, C. Beyond-the-static-workspace point-to-point trajectory planning of a 6-DoF cable-suspended mechanism using oscillating SLERP. Mech. Mach. Theory 2022, 174, 104894. [Google Scholar] [CrossRef]

- Jiang, X.; Gosselin, C. Dynamic point-to-point trajectory planning of a three-DOF cable-suspended parallel robot. IEEE Trans. Robot. 2016, 32, 1550–1557. [Google Scholar] [CrossRef]

- Mottola, G.; Gosselin, C.; Carricato, M. Dynamically feasible motions of a class of purely-translational cable-suspended parallel robots. Mech. Mach. Theory 2019, 132, 193–206. [Google Scholar] [CrossRef]

- Zhang, B.; Shang, W.; Cong, S. Optimal RRT* planning and synchronous control of cable-driven parallel robots. In Proceedings of the 2018 3rd International Conference on Advanced Robotics and Mechatronics (ICARM), Singapore, 18–20 July 2018; pp. 95–100. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, B.; Shang, W.; Zhang, F.; Cong, S. Constrained path planning for reconfiguration of cable-driven parallel robots. IEEE/ASME Trans. Mechatron. 2023, 28, 2352–2363. [Google Scholar] [CrossRef]

- Xu, J.; Kim, B.G.; Park, K.S. A collaborative path planning method for mobile cable-driven parallel robots in a constrained environment with considering kinematic stability. Complex Intell. Syst. 2023, 9, 4857–4868. [Google Scholar] [CrossRef]

- Mishra, U.A.; Métillon, M.; Caro, S. Kinematic stability based afg-rrt path planning for cable-driven parallel robots. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 6963–6969. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, B.; Shang, W.; Cong, S. Optimal reconfiguration planning of a 3-dof point-mass cable-driven parallel robot. IEEE Trans. Ind. Electron. 2023, 71, 2672–2682. [Google Scholar] [CrossRef]

- Merlet, J.P. Simulation of discrete-time controlled cable-driven parallel robots on a trajectory. IEEE Trans. Robot. 2017, 33, 675–688. [Google Scholar] [CrossRef]

- Guagliumi, L.; Berti, A.; Monti, E.; Fabritius, M.; Martin, C.; Carricato, M. Force-Sensor-Free Implementation of a Hybrid Position–Force Control for Overconstrained Cable-Driven Parallel Robots. Robotics 2024, 13, 25. [Google Scholar] [CrossRef]

- García-Vanegas, A.; García-Bonilla, M.J.; Forero, M.G.; Castillo-García, F.J.; Gonzalez-Rodriguez, A. AgroCableBot: Reconfigurable Cable-Driven Parallel Robot for Greenhouse or Urban Farming Automation. Robotics 2023, 12, 165. [Google Scholar] [CrossRef]

- Koszulinski, A.; Ennaiem, F.; Sandoval, J.; Romdhane, L.; Laribi, M.A. Optimal Design and Experimental Validation of a Cable-Driven Parallel Robot for Movement Training of the Head–Neck Joint. Robotics 2023, 12, 18. [Google Scholar] [CrossRef]

- de Rijk, R.; Rushton, M.; Khajepour, A. Out-of-plane vibration control of a planar cable-driven parallel robot. IEEE/ASME Trans. Mechatron. 2018, 23, 1684–1692. [Google Scholar] [CrossRef]

- Xiang, S.; Gao, H.; Liu, Z.; Gosselin, C. Dynamic transition trajectory planning of three-DOF cable-suspended parallel robots via linear time-varying MPC. Mech. Mach. Theory 2020, 146, 103715. [Google Scholar] [CrossRef]

- Bettega, J.; Piva, G.; Richiedei, D.; Trevisani, A. Model predictive control for path tracking in cable driven parallel robots with flexible cables: Collocated vs. noncollocated control. Multibody Syst. Dyn. 2023, 58, 47–81. [Google Scholar] [CrossRef]

- Qin, Y.; Chen, Q. A cascaded dynamic obstacle avoidance strategy for cable-driven continuum robots based on kinematics and dynamics. Nonlinear Dyn. 2025, 113, 13415–13435. [Google Scholar] [CrossRef]

- Cao, Y.; Li, T.; Hao, L.Y. Lyapunov-based model predictive control for shipboard boom cranes under input saturation. IEEE Trans. Autom. Sci. Eng. 2022, 20, 2011–2021. [Google Scholar] [CrossRef]

- Zhang, X.; Diao, S.; Yang, T.; Fang, Y.; Sun, N. LSTM-NN-Enhanced Tracking Control for PAM-Driven Parallel Robot Systems with Guaranteed Performance. IEEE Trans. Circuits Syst. I Regul. Pap. 2025, 72, 3556–3569. [Google Scholar] [CrossRef]

- Oghabi, E.; Moghaddam, R.K.; Kobravi, H.R. Adaptive interval type-2 fuzzy neural network nonsingular fast terminal sliding mode control for cable-driven parallel robots. Eng. Appl. Artif. Intell. 2024, 136, 108963. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, H.; Qian, Y. Reinforcement learning strategy-based adaptive tracking control for underactuated dual ship-mounted cranes: Theoretical design and hardware experiments. IEEE Trans. Ind. Electron. 2024, 72, 5408–5417. [Google Scholar] [CrossRef]

- Idà, E.; Briot, S.; Carricato, M. Natural oscillations of underactuated cable-driven parallel robots. IEEE Access 2021, 9, 71660–71672. [Google Scholar] [CrossRef]

- Cheah, S.K.; Hayes, A.; Caverly, R.J. Adaptive passivity-based pose tracking control of cable-driven parallel robots for multiple attitude parameterizations. IEEE Trans. Control Syst. Technol. 2023, 32, 202–213. [Google Scholar] [CrossRef]

- Villalba-Aguilera, E.; Blesa, J.; Ponsa, P. Model-Based Predictive Control for Position and Orientation Tracking in a Multilayer Architecture for a Three-Wheeled Omnidirectional Mobile Robot. Robotics 2025, 14, 72. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, B. Utilizing Reinforcement Learning to Drive Redundant Constrained Cable-Driven Robots with Unknown Parameters. Machines 2024, 12, 372. [Google Scholar] [CrossRef]

- Xiong, H.; Ma, T.; Zhang, L.; Diao, X. Comparison of end-to-end and hybrid deep reinforcement learning strategies for controlling cable-driven parallel robots. Neurocomputing 2020, 377, 73–84. [Google Scholar] [CrossRef]

- Zhang, Z.; Meng, Q.; Cui, Z.; Yao, M.; Shao, Z.; Tao, B. Machine Learning Applications in Parallel Robots: A Brief Review. Machines 2025, 13, 565. [Google Scholar] [CrossRef]

| Type | Features | References |

|---|---|---|

| Underconstrained CDPRs | The number of cables is less than or equal to DOF of EE | [15,18,19,20] |

| Fully-Constrained CDPRs | The number of cables is more than DOF of EE | [17,21,22,23,24] |

| Base Type | Features | References |

|---|---|---|

| Autonomous Cars | Ground Mobility, Flexibility, Great Load Capacity and Intelligence | [13,25,26] |

| Drones | Flexibility, Rapid Deployment, Scalability, Adaptability and Intelligence | [27] |

| Type | Method | Reference | |

|---|---|---|---|

| Traditional Planing Method | Dynamic Programming | Specific Frequency Selection Algorithm & Parameter Recursive Optimization | [16,52,53,54] |

| Fifth-order polynomial & three-dimensional trigonometric function analysis trajectory | [54,55,56] | ||

| Improved RRT* Method | Mixed Potential Field Functions & Manifold Tangent Space Theory & Adaptive Sampling | [57,58,59,60] | |

| Collaborative Optimization of Tree Topology & Dynamic Maintenance | [2,13,26] | ||

| Energy Optimization Planning | Continuous Space Optimization & Competitive Particle Swarm Optimization | [61] | |

| Online Zoom Trajectory | Path Speed Breakdown & Forward-Looking Adjustments | [17] | |

| Equilibrium Planning | Balanced Configuration Analysis & Input Shaping Technology | [18] | |

| Traditional Control Method | Improved PID Control | High Gain Parameter & Nonlinear Feedforward Compensation | [42,62,63,64,65] |

| Sliding-Mode Control | Mixed Integral SMC | [15,19] | |

| Adaptive Integral SMC & Ring Topology | [19] | ||

| Multiple Input and Multiple Output SMC | [66] | ||

| Dynamic Inverse Control | Combined with Time Delay Learning Method | [22] | |

| Compound Control | Admittance Control & Dual-Mode Motion Strategy | [38] | |

| Model Predictive Control | Standard MPC | Time Domain Iterative Optimization | [17,67,68] |

| Robust MPC | Probabilistic Constraints& Unscented Kalman Filter | [20] | |

| Super-Helical Sliding-Mode Observer& Recursive Integral Terminal SMC | [69] | ||

| Lyapunov Function | [70] | ||

| Intelligent Control | Neural Networks | Learning Algorithms | [34] |

| Long Short-Term Memory Neural Network | [71] | ||

| Fuzzy Control | Interval Type-2 Fuzzy Neural Network& Non-singular Terminal SMC | [72] | |

| Deep Reinforcement Learning | DRL & PID control | [36] | |

| DRL & Lyapunov Function | [35,41] | ||

| Multi-agent DRL | [73] | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Li, J.; Li, Y. A Review on Design, Modeling and Control Technology of Cable-Driven Parallel Robots. Robotics 2025, 14, 116. https://doi.org/10.3390/robotics14090116

Wang R, Li J, Li Y. A Review on Design, Modeling and Control Technology of Cable-Driven Parallel Robots. Robotics. 2025; 14(9):116. https://doi.org/10.3390/robotics14090116

Chicago/Turabian StyleWang, Runze, Jinrun Li, and Yangmin Li. 2025. "A Review on Design, Modeling and Control Technology of Cable-Driven Parallel Robots" Robotics 14, no. 9: 116. https://doi.org/10.3390/robotics14090116

APA StyleWang, R., Li, J., & Li, Y. (2025). A Review on Design, Modeling and Control Technology of Cable-Driven Parallel Robots. Robotics, 14(9), 116. https://doi.org/10.3390/robotics14090116