Abstract

Ants use their mandibles—effectively a two-finger gripper—for a wide range of grasping activities. Here, we investigate whether mimicking the internal hairs found on ant mandibles can improve performance of a two-finger parallel plate robot gripper. With bin-picking applications in mind, the gripper fingers are long and slim, with interchangeable soft gripping pads that can be hairy or hairless. A total of 2400 video-documented experiments have been conducted, comparing hairless to hairy pads with different hair patterns. Simply by adding hairs, the grasp success rate was increased by at least , and the number of objects that remain securely gripped during manipulation more than doubled. This result not only advances the state of the art in grasping technology, but also provides novel insight into the mechanical role of mandible hairs in ant biology.

1. Introduction

It is increasingly recognized that practical grasping scenarios, such as warehouse automation, require a combination of friction- and suction-based grasping [1,2,3]. Although suction was most successful in the recent Amazon Picking Challenge and has become the most commonly used technology, it is not sufficient on its own for a successful grasping system. For example, cylindrical and parallelepiped objects are better grasped using two-fingered (with custom pads fitted) [4] or three-fingered grippers [5]. In applications, therefore, suction cups are commonly paired with parallel plate grippers [6,7,8,9] (a variation of two-fingered grippers), or other forms of friction grasping [10,11] unless strict assumptions are made about the object shape [12,13,14,15,16,17]. The need for multimodal grippers has led to the development of two- [16,18,19,20,21], three- [22], and four- [23] fingered grippers with suction capability. There is a clear demand for improved fingered grippers, either to support suction in such multimodal systems, or to accomplish the grasping task solo as in Amazon’s Vulcan gripper [24].

Among friction-based grippers, the two-fingered is the most common due to its simplicity, cost effectiveness and ease of control. The parallel plate variation is most convenient for tight space applications such as bin picking, shelf stowing, etc. However, two fingers have limitations in grasping cylindrical objects due to insufficient contact, with three fingers often preferred [25] for better grasp stability despite being more bulky. Attempts to improve/customize parallel plate grippers are numerous. To name only a few, in [26], a scooping-binding variation is developed targeting the food industry, and in [27], the gripper is designed to have a varying width depending on how widely it is opened, in an effort to make the gripper smaller in size. In [28,29], compliant gripping tips are examined to increase the grasp robustness of parallel jaw grippers. These, however, are not suitable for curved surfaces unless the object is very light weight as demonstrated in [27,28], or special v-shaped pads are used [4,30]. We can conclude that any means to improve the performance of two-fingered grippers in grasping cylindrical objects could have significant impact for both friction-based and multimodal grippers, particularly if it is relatively low cost to implement.

Here, we take a novel approach to the problem of improving parallel plate grippers by seeking inspiration from the largest population of two-fingered gripper users, namely the ants. Ants use their mandibles, which consist of two rigid opposed jaws, each hinged and actuated separately (Figure 1), for a huge range of grasping activities, from transporting delicate eggs to dismembering prey. As such, it seems plausible that examination of ant grasping could provide insights to improve the performance of two-finger robot grippers. Despite the recognition that “from the perspective of a roboticist, the variety and refinement of ant manipulation skills can be startling and humbling” [31], there has been very little research work closely studying ants in the context of robotic grasping. In [32] a model gripper is developed inspired by the mandibles of Harpegnathos venator ants in an attempt to replicate its ability to grasp delicate objects in narrow spaces and in [33] the hinge geometry of ant mandibles inspires a design to improve surgical needle holders. Some other insect-inspired gripppers mimick the insect tarsus, either for grasping [34] or to aid in climbing [35,36]. However, these developments are of limited practical use in automation.

Figure 1.

Internal hairs of ant mandibles in Ophthalmopone berthoudi, Ectatomma bruneum, Ectatomma tuberculatum, Rhytidoponera sp., and Paltothyreus tarsatus, respectively, from left to right, adapted with permissionfrom ref. [37]. Copyright 2025 Kamil Stajniak. Circles and lines in left panels highlight tooth-like and cutting structures, respectively.

In this work, we focus on the role of the internal hairs of ant mandibles, shown in Figure 1 for a selection of ant species. These hairs, described in detail in [38], are divided into a set of hair fields at the base of the mandible and “ordinary” sensory hairs along the mandible. Shorter hairs along the internal mandible structure are described as mechanosensory hairs, and have been largely regarded as sensory elements [39] in the biological literature. There is evidence, however, that some ant hairs provide passive mechanical support for items carried by ants. The ammochaetae or psammophores, form a collection of long hairs in the lower head parts of some ant species, and have been shown to play a vital role in supporting water [40] and sand [41] particles, as well as foraged wheat and small seeds [42] grasped by mandibles during transportation. Drawing from these observations, we have developed the parallel plate gripper shown in Figure 2 fitted with hairy pads to evaluate the impact of such hairs on grasp success/robustness as compared to a hairless counterpart. Two performance metrics are used to assess the results, the most conservative of which indicates a performance boost of at least , and up to if the hair configuration is fine-tuned. The contribution of the work presented in this paper is three-fold:

- Extending the capabilities of two-fingered grippers, particularly to make robust grasps of cylindrical objects.

- Enabling slimmer gripper designs for space-constrained grasping tasks, thanks to internal hairs that distribute grasping forces without the added bulk of traditional soft pads.

- Redefining the role of internal hairs of ant mandibles by demonstrating the potential mechanical impact of such hairs in securing a stable grasp.

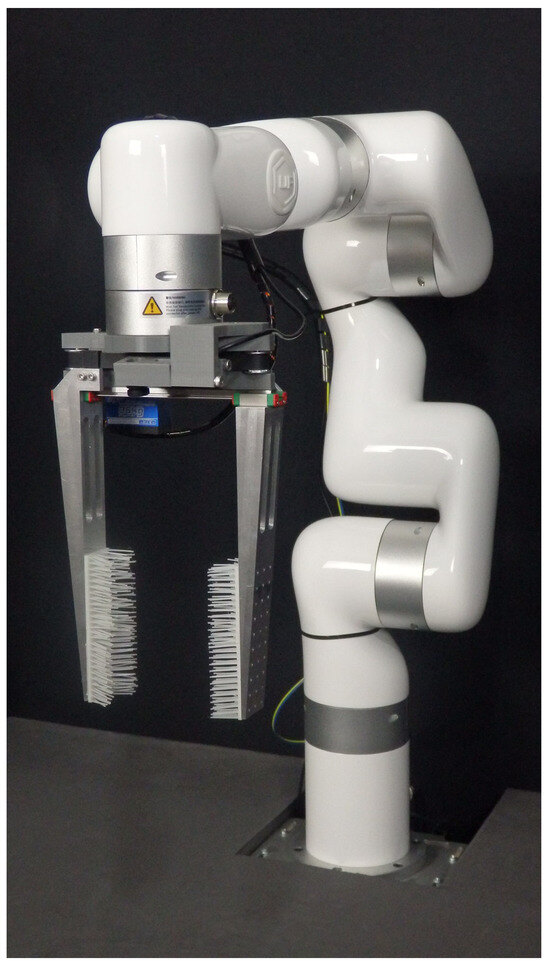

Figure 2.

Ant-inspired gripper “AntGrip” mimicking the mandible’s internal hairs, fitted to robot manipulator.

2. Materials and Methods

A general observation of the ant’s mandible internal structure in Figure 1 reveals three distinctive features. First (highlighted by circles in the left panels of the figure), the mandibles end with irregular protruding tooth-like structures (sometimes appearing sharp) to penetrate/pierce when biting prey or breaking items down into pieces. Second, marked by a white line in the respective panels, are long edges which together with a tooth-tip form an inverted scissor-like structure to perform the cutting process. Third are the internal hairs protruding from both sides of the mandible, seen from the top view in Figure 1. Our hypothesis is that these hairs mechanically support grasped objects and help the ant to achieve stable grasps, especially for irregularly shaped objects that form the majority of ant grasping activities. Note that although the morphology of the mandibles can vary substantially, often adapted to the task performed by a particular ant species or a caste within a species [43,44,45], the internal hairs appear to be a common feature across many species.

In this work, we adopt the use of internal hairs resulting in the CAD design in Figure 3 without imitating other aspects of the ant mandibles, given that our target application differs in some critical ways from the natural domain of ants. Most targets for ant grasps are irregular, rough objects such as food items, whereas warehouse automation usually features smooth surfaces and continuous geometric shapes due to industrial packaging. To this end, while a rotating two-fingered gripper (mandibles) would serve the ant very well due to the necessity of a scissor-like cutting behavior, it would fail to satisfy these robot grasping interests as compared to sliding fingers. In addition, bin/shelf picking/stowing applications require accessing objects from a distance due to tight spaces or a cluttered environment. This, as well as manipulation hardware safety, favors lengthy, slim grippers with inherent or active compliance. These guidelines are used as the main requirements for our application-oriented gripper design, enabling independent evaluation of the impact of internal hairs on grasp success/stability.

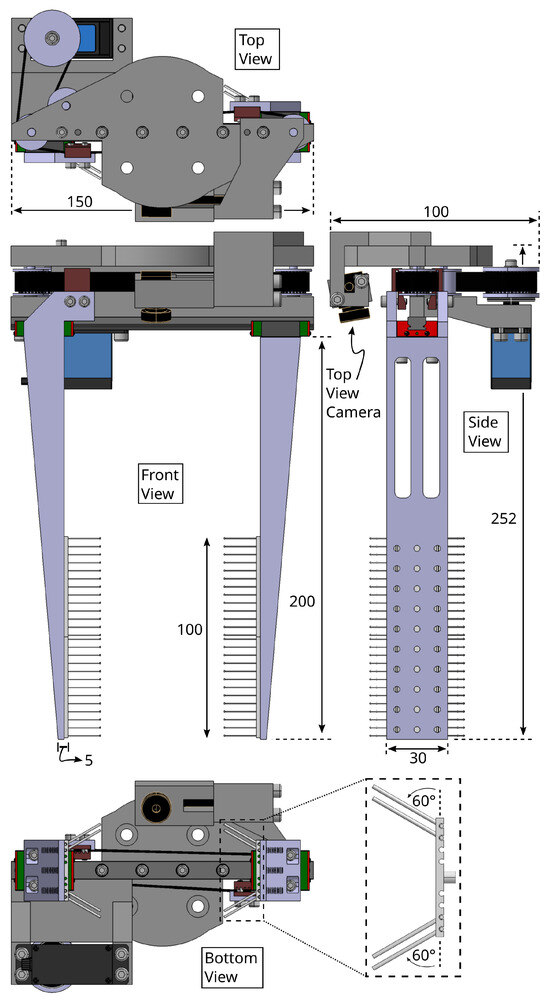

Figure 3.

Ant-inspired gripper “AntGrip” CAD model in front, side, top, and bottom views. Key dimensions are shown in millimeters.

2.1. Ant-Inspired Gripper Design

The CAD model of the designed gripper is shown in Figure 3. The fingers are wedge-shaped to allow them to move in between cluttered objects with minimal disturbance, and are long (200 mm) and thin (5 mm thick fingertip including the hair pad) for the intended space-tight applications. The actuation motor can generate up to 200 N of axial force, whose power is transferred to the fingers via timing belt transmission, with each finger clamped to one side of the belt as depicted in the top view in Figure 3. The GT2 belt used is shown in [46] to withstand at least 600 Newtons of tensile force and introduces a limited amount of passive compliance. Each finger is fixed to a linear bearing/rail system constraining its motion to the gripper’s single degree of freedom (DoF). The minimum and maximum gripper opening is 5 mm and 110 mm, respectively, with positioning accuracy of mm, which is adequate for the target application. A camera is also mounted to the gripper providing a top view. This is used to record/study the interaction of the gripper hairy pads with the object being grasped, and as a means to assess the grasp quality in the experimental results. It could potentially provide feedback information for control regarding grasp stability and object slippage. The gripper has overall dimensions of mm and a total weight of 640 g. It operates in either position or force control mode. The former controls the gripper opening gap, while the latter closes the fingers until the commanded force is achieved, measured via calibrated actuator current. The fingers and pulleys are manufactured from aluminium, the linear bearings and rail from steel, and the remaining parts from polylactic acid (PLA).

Two soft gripping pads are attached to each finger of the gripper and fitted by means of cylindrical pegs on the pad base (insertion side in Figure 4) into corresponding holes in the fingers. This allows for quick replacement of pads while experimenting with different configurations. These pads can include hairs protruding at various angles/densities, or remain hairless. The pad shown in Figure 3 has hairs at an angle of 60° with density pattern designated as (see below). Figure 4 shows the model for the 60° gripping pad base in front, side, and back views, respectively, from left to right, and the two hair patterns used, with either 7 or 13 hairs. Each hair is 20 mm in length.

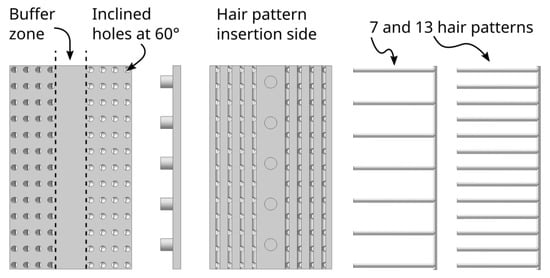

Figure 4.

A 60° gripping pad base (left) and the 2 hair patterns (right) used in this work to construct the hairy pads.

The pad base has a thickness of 2 mm and contains a total of 104 inclined holes, divided equally and symmetrically to the right and left sides of the pad’s buffer (no hair) zone. All, some, or none of these holes can be filled depending on the hair pattern used, and the hole inclination can be varied to alter the angle of the hairs. Figure 5 shows hair density pattern made of 52 hairs, for hair angles from 30 to 75°. To keep the number of tested configurations reasonable, these angles are tested in a first set of experiments to find the (near) optimal hair angle at the lowest hair density we considered sufficient to support cylindrical objects. Subsequently, we test the effects of increasing density for a more limited angle range. Figure 6 shows on the left (for two different angles) a density pattern with 80 hairs, representing a increase in hair density, and on the right, density pattern with 104 hairs, a hair density increase compared to . The gripping pads (both base and hair patterns) are made of thermoplastic polyurethane (TPU), with shore hardness 95A via fused deposition modeling (3D printed). This material strikes a balance between firmness, so that the hairs can support grasped objects and retain their shape, and softness, so that the gripper can move in tight spaces (using minimal finger separation) with the hairs deforming in compliance to allow objects inside the gripper with no disturbance.

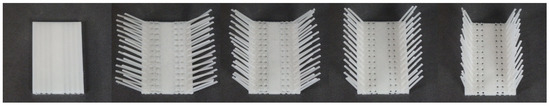

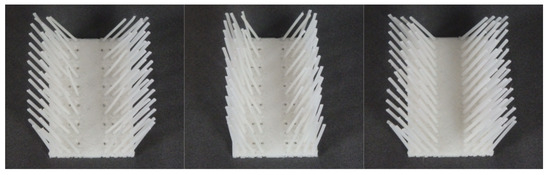

Figure 5.

Gripper pads used in evaluating the impact of hair angle on grasp success/robustness, showing (left to right) the hairless pad and hairy pads at 30°, 45°, 60°, and 75°, all with hair density . These are compared in experiment 1.

Figure 6.

Gripper pads with altered densities: at 60°-, 75°-, and 60°- respectively from left to right. These are compared in experiment 2.

2.2. Stress Analysis

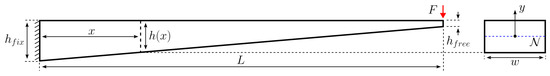

The objective is to build a general gripper platform capable of delivering nominal force/stroke comparable to market counterparts [47,48,49] with the added advantage of long and slim finger design for bin-picking applications. The gripper as such should be capable of delivering a maximum of 200 N force with minimal deflection of the fingers (less than 1 mm at maximum force) and a total stroke of at least 100 mm. For that we have identified the gripper fingers as a critical element of the design for which we perform stress analysis to verify the finger’s deflection under load is within design goals and that such deflection is within the elastic limit of the material used. Also, the analysis below can be used to optimize the design for slimmer fingers in applications featuring less grip force requirement. The schematic diagram of the gripper finger shown in Figure 7 models it as a wedge-shaped cantilever beam of length L under a point load F at its free end.

Figure 7.

Schematic diagram of the wedge cantilever beam representing the gripper finger geometry.

The cross sectional area at any point x along the cantilever length is rectangular in shape with constant width w and varying height ranging from a maximum value of at the fixed end (left most) to a minimum value at the free end of the cantilever (right most). The bending stress at any cross section along the beam is given by [50]:

where is the bending moment computed as the applied force multiplied by the arm length to the cross section, y is the distance from the neutral axis shown in Figure 7 (left) in blue, and is the area moment of inertia of the square section. Since we are interested in the maximum stress value, happening at the outer fiber of the cross section, we can substitute with . The maximum value of stress at a given cross section is as such formulated by:

and the cross section height varies across the wedge length as follows:

with m being the slope of the taper side of the wedge. Substituting by (3) in (2) we get:

For uniform cross section cantilever, the maximum stress is always at the fixed end, however here, such location is unknown, hence we differentiate in (4) with respect to x, and equate to zero and solve for , the critical section location at which the beam is subject to the maximum stress value :

which in turn can be found by substituting from (5) in (4) as:

note that substituting by in (3) will give the beam height at the critical section as:

From (7) we can deduce the condition of validity of these derivations since for a taper, the height at any cross section has to be lower than , the same applies at the critical section:

meaning that the cross section height at the free end must be less than half of that at the fixed end . On the other hand the beam deflection at any point x from the fixed end is given by [50]:

with E being the Young’s modulus of the finger material. For the respective cantilever beam the maximum deflection value is always at the free end, i.e., :

Equations (9) and (4) are used to plot the deflection and stress distributions along the cantilever subject to the maximum load share of a single finger as shown in Figure 8 (top) and Figure 8 (bottom), respectively.

Figure 8.

Deflection distribution along the gripper finger for a point load of 100 N at the free end (top) and the corresponding stress distribution (bottom). The vertical line shows the critical section.

This figure assumes the cost effective Aluminium 6063-T42 alloy as material with GPa and yield strength of 69 MPa, and shape parameters of mm, mm, and mm. Equations (6) and (10) on the other hand are more useful in optimizing the wedge-shaped finger dimensions for a more tailored design for applications with specified maximum force F and finger reach L. In our generic design, the maximum bending stress evaluates to MPa well below the material’s yield strength of 69 MPa at which structural deflections become plastic (permanent deformations) by a safety factor of about . We have opted for such large value since the wedged finger in our design is not completely solid (refer to the finger side view in Figure 3). The maximum deflection mm is also within acceptable limits.

2.3. Experiments and Methodology

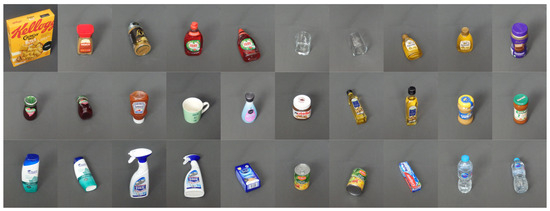

Two sets of experiments have been conducted. The first evaluates the effect of the hair angle on the grasp success at a given hair density as compared to the no-hair performance. The gripper pads used in this experiment are shown in Figure 5. The second experiment explores the effect of varying hair density for the best-performing hair angles, and the gripper pads used are depicted in Figure 6. The developed gripper is fitted to the collaborative robot uFactory xArm6, as shown in Figure 2, capable of manipulating a payload of 5 Kg. Both the robot arm and the gripper are controlled in C++ by sending pose, and position/force commands respectively. In each experiment, the object to be grasped is placed on a fixed mark on the table, representing the centroid point of the gripper workspace projected onto the table plane at the arm home pose.

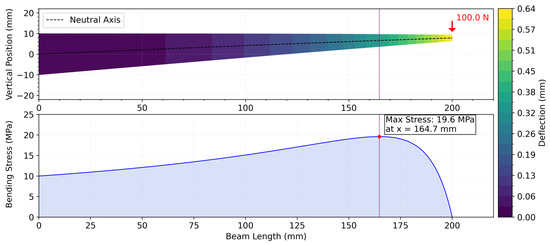

For each gripper pad variation (8 of these are tested here), 30 objects were tested. For each object, 10 grasping attempts were executed. In each of these 10 attempts, the object position is varied about the aforementioned mark by up to mm, simulating potential object localization error. Simultaneously, object orientation about the vertical axis (perpendicular to the table plane) is varied widely across grasping attempts. A total of 2400 grasping trials have been performed, all of which are video-documented (https://rb.gy/vya4om accessed on 27 July 2025). The set of objects used consist of 21 unique objects, of which, 9 objects are tested in two different poses, namely in a lying down or upright pose, making up a total of 30 objects for testing purposes, as shown in Figure 9. In selecting the objects, care was taken to pick half of them to be of cylindrical/circular shape with varying radii, as such objects present a major challenge for parallel plate grippers. This should highlight any contribution of the hairs to improving grasp of such objects. The other half are objects with flat, symmetrical sides, usually easy to grasp by parallel plates, to assess if the added hairs might diminish conventional gripper capabilities.

Figure 9.

Set of objects used to evaluate the proposed gripper.

The objects were otherwise selected to provide variety in texture and deformability. They weigh from 117 to 571 g, with 410 g on average, high enough to excite the object dynamics during the manipulation phase.

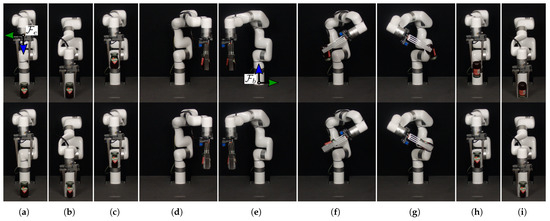

Snapshots of the robot movement sequence in each experiment are presented in Figure 10, comparing the conventional parallel plate gripper (top) to that with hair pads (bottom). Each grasp trial consists of 11 consecutive steps, made up of 9 arm movements and 2 gripper actions, starting with the arm in the home pose (Figure 10a), and the gripper in a predefined opening gap depending on the width of the object to be grasped. The first three steps attempt to grasp and lift the object:

To test the grasp firmness and stability, the arm then manipulates the grasped object into 4 successive poses, designed to excite movement in a direction parallel to the plane of grasp friction simulating a worst case scenario:

The final steps deposit and release the object (assuming it is still grasped):

Figure 10.

Snapshots of the object manipulation steps per experiment, starting with home pose in (a) then grasping (b) and lifting (c), manipulating to test the grasp stability both in linear (d), (e) and rotary (f), (g) movements, followed by stowing (h) and releasing (i). Top is without hairs, while bottom with hairs, producing better grip of the object in poses (f,g).

The arm’s built-in motion profile parameters are set to a maximum velocity, and acceleration of 300 mm/s, and 700 mm/s2 respectively. Let the posevector of the manipulator’s end effector frame expressed in the base frame , shown in Figure 10a (top) and Figure 10e (top) respectively, define the task space coordinates. With bre = [x y z]⊤ being the position vector, and bθe = [α β γ]⊤ denoting a minimal representation of orientation (roll, pitch, yaw RPY variation of Euler angles), the aforementioned poses are given by:

where the position, and orientation values presented in meters, and radians respectively. Note the z coordinate value of ranges from 0.265 m to 0.34 m depending on the height of the object to be grasped.

3. Results

The results of the first set of experiments are provided in Table 1, showing the effect of hair angle at a fixed hair density. If the object slips out of grasp while being lifted or at any other subsequent phase, the trial is deemed a failed grasp. In general, the grasp success rate increases proportionally with the hair angle up to 60°.

Table 1.

Successful grasp trials (out of 10 attempts) for different objects with varying hair angles at fixed hair density . Best performing results designated as quality grasps, shown in bold, defined as those with the ordered pair .

3.1. Evaluation Metrics

To better interpret the results, we classify successful grasps into firm and loose. Once an object is grasped and lifted, if any point of the object is displaced by more than 1 cm (judged by manual inspection of the footage from the top view camera in Figure 3) relative to the gripper during the manipulation phase, the grasp is labelled as loose, otherwise, it is a firm grasp. For each gripper pad variation, the average grasp rate (AGR) is computed as a percentage of the successful grasps () over the total of 300 grasping trials performed. We further define that a quality grasp has occurred (marked as bold in the respective table) for a particular object when, for a total of 10 grasping attempts, all were successful with no more than 2 loose, i.e., satisfying as such the ordered pair:

The hairless pad variation has the lowest AGR value () and the highest number of loose grasps, performing worse than any type of hairy pad. The boost in performance at density ranges from , computed as in case of 45° hair angle, to for the 75° hairs. However, recognising that for many applications, loose grasps would be regarded as failures, we also assess reliability using the quality grasps metric defined above for a more practical relevance. This shows an even more significant improvement in performance. In terms of quality grasps, the performance boost ranges from , computed as in case of 45° hair angle, to for 75° hair angle. Results of the second set of experiments are provided in Table 2, testing the effect of hair density on grasp success.

Table 2.

Successful grasp trials (out of 10 attempts) for different objects with varying hair density.

Since the hair angles of 60° and 75° performed almost equally well in the first set of experiments, these are compared at the higher hair density . The best performing of out of these (by a small margin, the hair angle 60°), is then tested at the higher density . In general, higher hair density resulted in better grasping performance, in particular increasing the number of quality grasps from 19/30 for D1 to 22/30 for D2 and D3. The boost in AGR and in the quality grasps reached and respectively for a 60° protruding hairs at density when compared to the hairless counterpart, reflecting a notable increase in the number of firm grasps across a range of objects.

3.2. Grasp Force Distribution

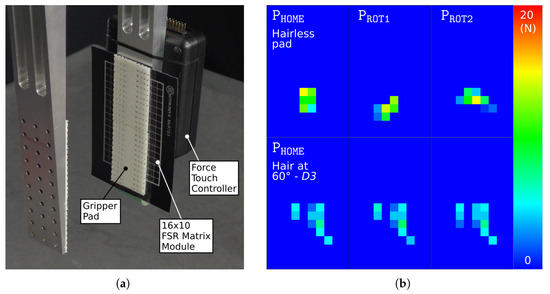

To better explain the improved grasping performance, a measure of the grasp force distribution is essential. To do so, the gripper finger setup is fitted with a force sensing resistor (FSR) matrix [51] as shown in Figure 11a for the hairless pad. Due to the accuracy limitations of the FSR sensors, the objective of such setup is to compare the approximate grasp force distribution in the cases of hairy and hairless pads rather than an accurate force measurements. The result of such comparison is shown in Figure 11b, featuring the jam jar pose1 object, depicted in Figure 10, with the corresponding force distribution heat maps of the hairless and hairy pads to the top and bottom rows respectively. The heat map panels starting from the left, show the force distribution at the experiment poses , , and respectively, these are depicted in Figure 10c,f,g in the same order.

Figure 11.

Hairless gripper-pad fitted with FSR matrix (a), and (b) force distribution for hairless pad (upper row) and hairy pad (lower row) for three robot poses gripping the jam jar pose1 object.

From the results in Figure 11b we can see that, the grasp force is better distributed in the case of the hairy pad, as opposed to larger force over a smaller area for the hairless pad. This essentially means the hairy pad applies lower pressure to the object, which can allow applying higher gripping forces for a more secure grasps. Also, we observe minimal change in the force distribution pattern for the hairy pad, indicating an almost stationary object, a sign of stable grasp. This is not the case with hairless pad, where the force pattern changes dramatically corresponding to an object moving in the gripper.

4. Discussion

Biology has inspired a wide range of robot gripper designs, with recent examples including bird claws [52], bloodworms [53], geckos [54], and many humanoid examples [55], as well as a wide variety of soft robotic end effectors. However it remains an issue that such designs typically introduce substantial complexity in construction, in control, or in both; and often for only limited manipulation improvement or advantage only in specialised scenarios. By considering a biological exemplar that more closely resembles the conventional two finger gripper, i.e., the mandibles of the ant, we have identified that their key function of securing grasped items during transport is aided by their hairy internal construction. This suggested a simple augmentation to a parallel jaw gripper—the addition of hairs—which we have shown here can provide a very significant improvement in handling of common household objects.

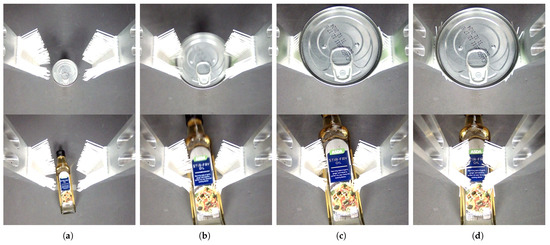

One key advantage of using these internal hairs is the elimination of the typical bulk found in soft grippers and pads, which is usually required to increase contact area with the object. In our design, the hairs deform in compliance to conform to the object during passage as shown in Figure 12b,c for cylindrical (top) and flat (bottom) surfaces, enabling a more compact gripper design—crucial for space-constrained applications. This benefit is clearly illustrated in Figure 12d, where the effective pad thickness reduces back to the base pad level once the grasping force is applied. A video demonstrating this behavior is available online (https://rb.gy/72inpc accessed on 27 July 2025), also clearly showing that the hairs quickly return to their original angles after the object is released.

Figure 12.

Snapshots from the top camera feed showing the hairy pad interaction with the object, starting with initial gripper opening position (a), halfway through the object (b), at final downward position prior to grasping (c) and grasping the object (d).

Each hairy pad underwent at least 400 experimental trials, consistently exhibiting strong shape retention. However, to make definitive conclusions about the long-term durability of these pads would require many thousands of tests, which is beyond the scope of the current paper but a target for future research. We would expect any degradation to be gradual as damage to individual hairs should have little effect, and the low cost and ease of replacement of the pads point towards their practicality for real world deployment.

From Table 1 and Table 2, it is evident that some objects are better grasped with particular hair angles. For example, the objects: mug, and nail polish, were only quality grasped using the hair angle 75°; and the jam jar pose2, ketchup bottle, and oil bottle pose2 for the hair angle 60°. The same conclusion applies to other hair angles in Table 1, where in the particular case of sprayer pose1/2, though never fully grasped, the hair angles 30° and 45° were the best performers. A general conclusion is that, the smaller the radius of curvature of the object’s surface, the larger the hair angle required. This suggests that if a gripper with controllable hair angle, or a pad with several, but fixed hair angles is designed, it might be possible to combine the capabilities reported in Table 1 and Table 2, to produce a quality grasps total of 25 for this particular set of objects. Note that the object nutella bottle enjoys a AGR only with hairy pads, but still produces no quality grasps; and it appears the cases of dishwash liquid pose1, honey bottle pose2, and sprayer pose1/2 require additional friction to the pad/hair combination to be successful. To this end, a direct change in the pad base to a high friction material is expected to greatly enhance the grasping performance. Together with exploring means to achieve multiple hair angles this motivates future work to improve the gripper design.

In hairless pad experiments, during the rotary manipulation phase, objects usually pivot about pad points closer to the finger transmission, which suggests finger bending. Given the lengthy and slim fingers, there will always be some deflection in the gripper structure, especially at the fingers, irrespective of the quality and rigidity of the mechanical components, which can reduce but not eliminate its amplitude. Introducing internal hairs appears to overcome this issue by supporting the grasped object from the sides, increasing the area of contact and by doing so, better distributing the gripper’s applied force on the object surface. The relatively hard material used in this work, TPU, is essential as such to firmly protrude out of the gripper to fill the gaps between the gripper and the object.

Given the level of grasp improvement we have already observed without these optimizations, we are confident that there should be many immediate applications in which AntGrip can improve performance. Looking forward we also plan to explore other aspects of the grasping capabilities of ants, such as their sensing and perceptual processing, for their potential to contribute to robotics.

5. Conclusions

In this work, a novel, ant-inspired gripper is presented. The developed gripper has a parallel plate form, suitable for tight space applications. Experimental evaluation on a pool of objects that are cylindrical in shape shows that adding flexible hairs to the interior of the plates not only improves the grasp success rate by at least , but also the grasp robustness and quality. In addition, this result strongly suggests that the function of the internal hairs of ant mandibles goes beyond sensory feedback and plays an important mechanical role in their grasping ability.

Author Contributions

Conceptualization, M.S.; methodology, M.S.; software, M.S.; validation, M.S.; formal analysis, M.S.; investigation, M.S., B.W.; resources, M.S., B.W.; data curation, M.S.; writing—original draft preparation, M.S.; writing—review and editing, M.S., B.W.; visualization, M.S.; supervision, B.W.; project administration, B.W.; funding acquisition, B.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work is funded by EPSRC under grant agreement EP/V008102/1, “An insect-inspired approach to robotic grasping”.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Correll, N.; Bekris, K.E.; Berenson, D.; Brock, O.; Causo, A.; Hauser, K.; Okada, K.; Rodriguez, A.; Romano, J.M.; Wurman, P.R. Analysis and Observations From the First Amazon Picking Challenge. IEEE Trans. Autom. Sci. Eng. 2018, 15, 172–188. [Google Scholar] [CrossRef]

- Fujita, M.; Domae, Y.; Noda, A.; Ricardez, G.A.G.; Nagatani, T.; Zeng, A.; Song, S.; Rodriguez, A.; Causo, A.; Chen, I.M.; et al. What are the important technologies for bin picking? Technology analysis of robots in competitions based on a set of performance metrics. Adv. Robot. 2020, 34, 560–574. [Google Scholar] [CrossRef]

- Sorour, M.; Elgeneidy, K.; Srinivasan, A.; Hanheide, M.; Neumann, G. Grasping Unknown Objects Based on Gripper Workspace Spheres. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macao, China, 4–8 November 2019; pp. 1541–1547. [Google Scholar] [CrossRef]

- Habibi, M.; Sutera, G.; Guastella, D.C.; Muscato, G. Design and Experimental Validation of a 3D-Printed Two-Finger Gripper with a V-Shaped Profile for Lightweight Waste Collection. Robotics 2025, 14, 87. [Google Scholar] [CrossRef]

- Chen, W.; Zhao, S.; Chow, S.L. Grippers and End-Effectors. In Handbook of Manufacturing Engineering and Technology; Nee, A.Y.C., Ed.; Springer: London, UK, 2015; pp. 2035–2070. [Google Scholar]

- Yu, K.T.; Fazeli, N.; Chavan-Dafle, N.; Taylor, O.; Donlon, E.; Lankenau, G.D.; Rodriguez, A. A Summary of Team MIT’s Approach to the Amazon Picking Challenge 2015. arXiv 2016, arXiv:1604.03639. [Google Scholar]

- Gustavo, R.; El Hafi, L.; von Drigalski, F. Standing on Giant’s Shoulders: Newcomer’s Experience from the Amazon Robotics Challenge 2017. In Advances on Robotic Item Picking: Applications in Warehousing and E-Commerce Fulfillment; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 87–100. [Google Scholar]

- Majumder, A.; Kundu, O.; Dutta, S.; Kumar, S.; Behera, L. Description of IITK-TCS System for ARC 2017. In Advances on Robotic Item Picking: Applications in Warehousing and E-Commerce Fulfillment; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 113–124. [Google Scholar]

- Morrison, D.; Tow, A.W.; McTaggart, M.; Smith, R.; Kelly-Boxall, N.; Wade-McCue, S.; Erskine, J.; Grinover, R.; Gurman, A.; Hunn, T.; et al. Cartman: The low-cost Cartesian Manipulator that won the Amazon Robotics Challenge. arXiv 2017, arXiv:1709.06283. [Google Scholar]

- Fujita, M.; Domae, Y.; Kawanishi, R.; Ricardez, G.A.G.; Kato, K.; Shiratsuchi, K.; Haraguchi, R.; Araki, R.; Fujiyoshi, H.; Akizuki, S.; et al. Bin-picking Robot using a Multi-gripper Switching Strategy based on Object Sparseness. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 1540–1547. [Google Scholar]

- Hernandez, C.; Bharatheesha, M.; Ko, W.; Gaiser, H.; Tan, J.; van Deurzen, K.; de Vries, M.; Van Mil, B.; van Egmond, J.; Burger, R.; et al. Team Delft’s Robot Winner of the Amazon Picking Challenge 2016. In RoboCup 2016: Robot World Cup XX; Behnke, S., Sheh, R., Sarıel, S., Lee, D.D., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 613–624. [Google Scholar]

- Huang, H.; Danielczuk, M.; Kim, C.M.; Fu, L.; Tam, Z.; Ichnowski, J.; Angelova, A.; Ichter, B.; Goldberg, K. Mechanical Search on Shelves using a Novel “Bluction” Tool. In Proceedings of the 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23–27 May 2022; pp. 6158–6164. [Google Scholar]

- Valencia, A.J.; Idrovo, R.M.; Sappa, A.D.; Guingla, D.P.; Ochoa, D. A 3D vision based approach for optimal grasp of vacuum grippers. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and their Application to Mechatronics (ECMSM), Donostia-San Sebastian, Spain, 24–26 May 2017. [Google Scholar]

- Mantriota, G.; Messina, A. Theoretical and experimental study of the performance of flat suction cups in the presence of tangential loads. Mech. Mach. Theory 2011, 46, 607–617. [Google Scholar] [CrossRef]

- Avigal, Y.; Ichnowski, J.; Cao, M.Y.; Goldberg, K. GOMP-ST: Grasp Optimized Motion Planning for Suction Transport. arXiv 2022, arXiv:2203.08359. [Google Scholar] [CrossRef]

- Kang, L.; Seo, J.T.; Kim, S.H.; Kim, W.J.; Yi, B.J. Design and Implementation of a Multi-Function Gripper for Grasping General Objects. Appl. Sci. 2019, 9, 5266. [Google Scholar] [CrossRef]

- Pham, H.; Pham, Q.C. Critically fast pick-and-place with suction cups. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 3045–3051. [Google Scholar]

- Nakamoto, H.; Ohtake, M.; Komoda, K.; Sugahara, A.; Ogawa, A. A Gripper System for Robustly Picking Various Objects Placed Densely by Suction and Pinching. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 6093–6098. [Google Scholar]

- Wade-McCue, S.; Kelly-Boxall, N.; McTaggart, M.; Morrison, D.; Tow, A.W.; Erskine, J.; Grinover, R.; Gurman, A.; Hunn, T.; Lee, D.; et al. Design of a Multi-Modal End-Effector and Grasping System: How Integrated Design helped win the Amazon Robotics Challenge. arXiv 2017, arXiv:1710.01439. [Google Scholar]

- Nechyporenko, N.; Morales, A.; Cervera, E.; del Pobil, A.P. A Practical Approach for Picking Items in an Online Shopping Warehouse. Appl. Sci. 2021, 11, 5805. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, X.; Zhao, J.; Wang, X.; Zhou, W.; Liu, Y. Vision Based Picking System for Automatic Express Package Dispatching. In Proceedings of the 2019 IEEE International Conference on Real-time Computing and Robotics (RCAR), Irkutsk, Russia, 4–9 August 2019; pp. 797–802. [Google Scholar]

- Hasegawa, S.; Wada, K.; Okada, K.; Inaba, M. A Three-Fingered Hand with a Suction Gripping System for Warehouse Automation. J. Robot. Mechatron. 2019, 31, 289–304. [Google Scholar] [CrossRef]

- Vu, Q.; Ronzhin, A. A Model of Four-Finger Gripper with a Built-in Vacuum Suction Nozzle for Harvesting Tomatoes. In Proceedings of the 14th International Conference on Electromechanics and Robotics, Ufa, Russia, 15–18 April 2020; pp. 149–160. [Google Scholar]

- Spectrum, I. Amazon’s Vulcan Robots Now Stow Items Faster Than Humans. Available online: https://spectrum.ieee.org/amazon-stowing-robots? (accessed on 25 July 2025).

- RightHand Robotics Inc. RightPick2. Available online: https://www.righthandrobotics.com/products (accessed on 25 June 2025).

- Wang, Z.; Furuta, H.; Hirai, S.; Kawamura, S. A Scooping-Binding Robotic Gripper for Handling Various Food Products. Front. Robot. AI 2021, 8, 640805. [Google Scholar] [CrossRef]

- Kobayashi, A.; Kinugawa, J.; Arai, S.; Kosuge, K. Design and Development of Compactly Folding Parallel Open-Close Gripper with Wide Stroke. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 4–8 November 2019; pp. 2408–2414. [Google Scholar]

- Guo, M.; Gealy, D.V.; Liang, J.; Mahler, J.; Goncalves, A.; McKinley, S.; Ojea, J.A.; Goldberg, K. Design of parallel-jaw gripper tip surfaces for robust grasping. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 2831–2838. [Google Scholar]

- Harada, K.; Tsuji, T.; Nagata, K.; Yamanobe, N.; Maruyama, K.; Nakamura, A.; Kawai, Y. Grasp planning for parallel grippers with flexibility on its grasping surface. In Proceedings of the 2011 IEEE International Conference on Robotics and Biomimetics, Karon Beach, Thailand, 7–11 December 2011; pp. 1540–1546. [Google Scholar]

- Fan, Y.; Lin, H.C.; Tang, T.; Tomizuka, M. Grasp Planning for Customized Grippers by Iterative Surface Fitting. In Proceedings of the 2018 IEEE 14th International Conference on Automation Science and Engineering (CASE), Munich, Germany, 20–24 August 2018; pp. 28–34. [Google Scholar]

- Mason, M.T. Toward robotic manipulation. Annu. Rev. Control Robot. Auton. Syst. 2018, 1, 1–28. [Google Scholar] [CrossRef]

- Zhang, W.; He, Z.; Sun, Y.; Wu, J.; Wu, Z. A Mathematical Modeling Method Elucidating the Integrated Gripping Performance of Ant Mandibles and Bio-inspired Grippers. J. Bionic Eng. 2020, 17, 732–746. [Google Scholar] [CrossRef]

- B, W.; O, H.; F, V.; T, W.; F, R.; C, E. Understanding the ant’s unique biting system can improve surgical needle holders. Proc. Natl. Acad. Sci. USA 2024, 121, e2201598121. [Google Scholar]

- Winand, J.; Büscher, T.H.; Gorb, S.N. TriTrap: A Robotic Gripper Inspired by Insect Tarsal Chains. Biomimetics 2024, 9, 142. [Google Scholar] [CrossRef] [PubMed]

- Zi, P.; Xu, K.; Tian, Y.; Ding, X. A mechanical adhesive gripper inspired by beetle claw for a rock climbing robot. Mech. Mach. Theory 2023, 181, 105168. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Li, X.; Hou, X.; Zhao, Q.; Meng, Y.; Tian, Y. An Underactuated Adaptive Microspines Gripper for Rough Wall. Biomimetics 2023, 8, 39. [Google Scholar] [CrossRef] [PubMed]

- Stajniak, K. Antonyo Photography. Available online: https://ant-photo.eu/en/ (accessed on 25 July 2025).

- Gronenberg, W.; Tautz, J. The sensory basis for the trap-jaw mechanism in the ant Odontomachus bauri. J. Comp. Physiol. A 1994, 174, 49–60. [Google Scholar] [CrossRef]

- Boublil, B.L.; Diebold, C.A.; Moss, C.F. Mechanosensory Hairs and Hair-like Structures in the Animal Kingdom: Specializations and Shared Functions Serve to Inspire Technology Applications. Sensors 2021, 21, 6375. [Google Scholar] [CrossRef]

- Wheeler, W.M. On Certain Modified Hairs Peculiar to the Ants of Arid Regions. Biol. Bull. 1907, 13, 185–202. [Google Scholar] [CrossRef]

- Spangler, H.G.; Rettenmeyer, C.W. The Function of the Ammochaetae or Psammophores of Harvester Ants, Pogonomyrmex spp. J. Kans. Entomol. Soc. 1966, 39, 739–745. [Google Scholar]

- Porter, S.D.; Jorgensen, C.D. Psammophores: Do Harvester Ants (Hymenoptera: Formicidae) Use These Pouches to Transport Seeds? J. Kans. Entomol. Soc. 1990, 63, 138–149. [Google Scholar]

- Paul, J. Mandible movements in ants. Comp. Biochem. Physiol. Part A Mol. Integr. Physiol. 2001, 131, 7–20. [Google Scholar] [CrossRef] [PubMed]

- Cristian, K.; Marco, A.; Alexandre, C.F.; Evan, E.; Marcio, P. Mandibular morphology, task specialization and bite mechanics in Pheidole ants (Hymenoptera: Formicidae). J. R. Soc. 2021, 18, 20210318. [Google Scholar]

- Gronenberg, W.; Paul, J.; Just, S.; Hölldobler, B. Mandible muscle fibers in ants: Fast or powerful? Cell Tissue Res. 1997, 289, 347–361. [Google Scholar] [CrossRef]

- Wang, B.; Si, Y.; Chadha, C.; Allison, J.T.; Patterson, A.E. Nominal Stiffness of GT-2 Rubber-Fiberglass Timing Belts for Dynamic System Modeling and Design. Robotics 2018, 7, 75. [Google Scholar] [CrossRef]

- Neobotix GmbH. Neobotix Two-Finger-Gripper. Available online: https://www.neobotix-robots.com/products/robot-gripper-1/two-finger-gripper (accessed on 28 July 2025).

- Robotiq Inc. The Robotiq 2-Finger Grippers. Available online: https://robotiq.com/products/adaptive-grippers#Two-Finger-Gripper (accessed on 28 July 2025).

- OnRobot A/S. 2FG7 Parallel Gripper. Available online: https://onrobot.com/en/products/2fg7-finger-gripper (accessed on 28 July 2025).

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 11th ed.; McGraw-Hill: New York, NY, USA, 2015. [Google Scholar]

- Kitronyx Inc. Kitronyx FSR Matrix and Force Controller. Available online: https://www.kitronyx.com/store/?idx=34 (accessed on 28 July 2025).

- Roderick, W.R.T.; Cutkosky, M.R.; Lentink, D. Bird-inspired dynamic grasping and perching in arboreal environments. Sci. Robot. 2021, 6, eabj7562. [Google Scholar] [CrossRef]

- Sui, D.; Zhu, Y.; Zhao, S.; Wang, T.; Agrawal, S.K.; Zhang, H.; Zhao, J. A Bioinspired Soft Swallowing Gripper for Universal Adaptable Grasping. Soft Robot. 2022, 9, 36–56. [Google Scholar] [CrossRef]

- Ruotolo, W.; Brouwer, D.; Cutkosky, M.R. From grasping to manipulation with gecko-inspired adhesives on a multifinger gripper. Sci. Robot. 2021, 6, eabi9773. [Google Scholar] [CrossRef]

- Nguyen, V.P.; Dhyan, S.B.; Mai, V.; Han, B.S.; Chow, W.T. Bioinspiration and Biomimetic Art in Robotic Grippers. Micromachines 2023, 14, 1772. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).