1. Introduction

Modern technological advancements have led to increased customer demands for designed products. A high level of competition and diverse operating conditions necessitate the development of products with enhanced characteristics, such as high functionality and quality. In such conditions, engineers must design machines that exhibit flexibility and broad applicability. However, the fabrication of prototypes for all potential devices subject to experimental research is constrained by both economic and time-related factors.

Consequently, modeling becomes a crucial stage in both the design of new structures and the modernization of existing ones. Modern CAD systems not only enable the creation of geometric models but also facilitate kinematic, dynamic, and strength analyses. However, integrating control systems into such applications often presents a complex or even unfeasible challenge. For this reason, Matlab, in combination with the Simulink module, is widely used for modeling control systems.

The study in [

1] emphasizes that offline programming (OLP) is an effective method for controlling industrial robots. However, its widespread implementation is hindered by the high cost of commercial OLP systems, which often exceeds the price of the robotic systems themselves. This creates a demand for accessible and efficient OLP solutions based on widely used CAD platforms.

This paper presents the development of the robotic OLP system RobSim, created using SolidWorks Professional 2019 and Microsoft Visual Studio 2010. RobSim is integrated into the SolidWorks environment as an additional tool, providing users with the ability to create, import, and edit objects, as well as conveniently define and modify robot movement trajectories.

In [

2], the authors outline the stages of constructing simulation models developed using SolidWorks and Matlab/Simulink. Examples of simulation models include a laboratory hoist and a forestry crane. These models allow for motion visualization, trajectory tracking, and monitoring of velocity and acceleration at any system point.

In [

3], a computer model of a three-link vertically walking robot is developed in the Matlab environment, illustrating the basic working principles of such robots. The modeling of the vertical walking robot’s movement was conducted using the SimMechanics library in Simulink within the Matlab environment.

Studies [

4,

5,

6] present a methodology for analytically determining internal forces in the links of planar linkage mechanisms and manipulators, considering distributed dynamic loads arising from the self-weight of the links, for both statically determinate and indeterminate structures. Discrete models were developed, and equilibrium equations were derived to establish the relationship between the force vector and the dynamic characteristics of the links. Additionally, algorithms and software codes were created to generate visual plots of dynamic load distribution, transverse and longitudinal forces, and bending moments, with corresponding results provided.

In works [

7,

8], it is assumed that the masses are concentrated at the center of gravity of the manipulator links. The inertia forces and the inertia matrix of the i-th link are determined relative to its center of mass. To illustrate the application of the recursive Newton-Euler equations, a two-link manipulator with rotational kinematic pairs is considered.

In the dynamic analysis of a manipulator, gravitational and inertial forces, as well as moments of inertia, are referenced to the center of mass of each link. However, they can be transferred to the axis of rotation of the link using Steiner’s theorem. When analyzing the dynamics of the entire system, forces and moments are referenced to the axes of rotation of each link. Bringing all forces and moments to the rotation axes allows for the formulation of manipulator dynamics in a convenient form (typically a matrix form) that is directly related to actuators.

In [

9], a method for modeling the dynamics of manipulators with flexible links is presented. This method decomposes the manipulator into components, with the dynamics of these components determined using Newton–Euler equations and linearized based on state vectors. Transfer matrices are developed to establish the system equations, preventing an increase in the size of the dynamic equations when adding joints or beam elements. The method focuses on computing small-scale dynamic equations of components, simplifying the process.

In work [

10], a physically justified approach is presented that accounts for the flexibility of robot links and reducers. The article aims to establish a foundation for modeling flexible robotic structures to enhance accuracy. The elasticity of components is introduced into the discrete-parameter model using pairs of springs and dampers, the number of which is determined by the need to optimize computational costs and simulation time for integrating the model into industrial environments.

In article [

11], two novel arm exoskeletons based on pantograph linkages are introduced, capable of supporting loads of up to 9 kg. The pantograph linkage adapts to the arm’s geometry, ensuring support in any position. Gravity compensation is achieved through shoulder support and a counteracting force behind the back. A passive exoskeleton with a gas spring and an active exoskeleton with a motor are described. The forces generated by the gas spring are analyzed and various mechanism configurations are investigated. The equations governing the pantograph linkage are derived, and the exoskeleton forces are modeled with a comparison to measured values.

Article [

12] presents a method for analyzing the performance of serial robotic manipulators with gravity balancing under dynamic loads. Torque, power, and energy reduction indices are employed to assess performance in both unbalanced and balanced states. The proposed method enables a comprehensive evaluation of the manipulator while considering dynamic effects. As an example, a three-degree-of-freedom manipulator is examined, in which gravity balancing is achieved using a compact module with a geared spring on each link.

Article [

13] introduces an advanced architecture of an internally balanced mechanism based on a four-bar 4R linkage—referred to as the 4R Grand Architecture. The mechanism consists of 24 links and exhibits 26-fold redundant mobility while maintaining mobility with a fixed center of mass. It is demonstrated that all center-of-mass tracking theories for four-bar linkages are contained within this architecture. Additionally, it is shown how new normally constrained two-degree-of-freedom balanced mechanisms can be derived from it by removing specific links.

In article [

14], an approach to designing gravity compensators based on planar four-bar linkages and linear springs is presented. A class of compensators comprising 42 types with high efficiency and kinematic simplicity is developed. The compensators are created by combining four-bar linkages with rotating masses and linear springs, whose parameters are optimized to minimize torque within a specified balancing range.

Work [

15] investigates the influence of manipulator motion on the base posture of a free-floating space robot. When a target is grasped, a closed system is formed, resulting in more complex dynamic interactions. The interaction is analyzed in both open and closed systems.

In manuscript [

16], a mathematical procedure for determining the inertial parameters of maternal manipulators is first described. These parameters are essential for accurate positioning and force control in an electromechanical system designed to assist in surgical operations. The method for determining the mass and center of mass of the manipulator is based on solving static equilibrium equations for rigid bodies. Based on the estimated inertial parameters of the manipulator, the article demonstrates how to determine the force exerted by the manipulator.

Work [

17] examines the effect of time-varying inertial loads on the dynamics of parallel manipulators in joint space, particularly during acceleration and deceleration phases. A comprehensive analysis method based on a two-mass model is proposed.

In work [

18], with the development of parallel manipulators, the issue of inertia matching has become increasingly significant. However, a clear inertia indicator and a method for its reconciliation have not yet been proposed. This study addresses these aspects using the Stewart manipulator as an example.

Work [

19] considers a scenario in which multiple manipulators control a single object. A dynamic model of the system is constructed that explicitly represents the relationship between the object’s dynamics and joint space dynamics, taking into account the object’s dynamics, the dynamics of individual manipulators, and the actuator torques in the joints. Methods are then presented that directly distribute the dynamics of the object and manipulators within the joint space according to criteria based on joint input forces.

In work [

20], a computational methodology for determining the maximum payload capacity of a robotic manipulator with joint elasticity is described, considering constraints related to accuracy and actuator characteristics. The maximum payload achievable by the manipulator along a given trajectory is limited by several factors.

One of the key aspects of manipulator design is ensuring the strength and rigidity of its links throughout the entire operational process. The analysis of the stress–strain state of the links is complicated by the fact that the manipulator is in motion, leading to distributed dynamic loads of a complex nature, which are caused by the mass of the links at each of their cross-sections. These loads vary in magnitude and direction depending on the kinematic characteristics of the links.

Since the manipulator is in motion, it is impossible to determine in advance at which cross-section of a link and at what position the maximum internal force or deformation may occur. Therefore, it is necessary to investigate the stress–strain state of the manipulator over the entire operating cycle.

Moreover, it is crucial to visualize the stress–strain state of all links throughout the complete working cycle so that all types of dynamic loads, internal forces, and deformations are clearly visible across all link cross-sections. This allows the designer to analyze the stress–strain state of each link and make well-founded decisions when calculating the strength and rigidity of the manipulator’s links.

Maple is a powerful mathematical software for symbolic and numerical computations, as well as for engineering modeling. It does not require integration with CAD software or other applications to create computer-based 3D models of manipulators controlled by generalized coordinates. In the Maple environment, three-dimensional manipulator models have been developed with clear visual representations of links, their cross-sections, kinematic pairs, grippers, and loads, which vary in structure and degrees of freedom, ensuring a comprehensive spatial view controlled by generalized coordinates. This environment enables the determination of link positions and orientations, the calculation of all kinematic characteristics required for assessing dynamic loads, and their visualization.

The topic of this study is highly relevant and significant in the field of robotics, particularly in the context of manipulator dynamics and design. The study of dynamic loads on manipulators plays a crucial role in the development of more reliable and efficient robotic systems.

3. Determination of Dynamic Loads Arising in the Cross Sections of the RRRRT Manipulator Links and Construction of Their Visual Diagrams

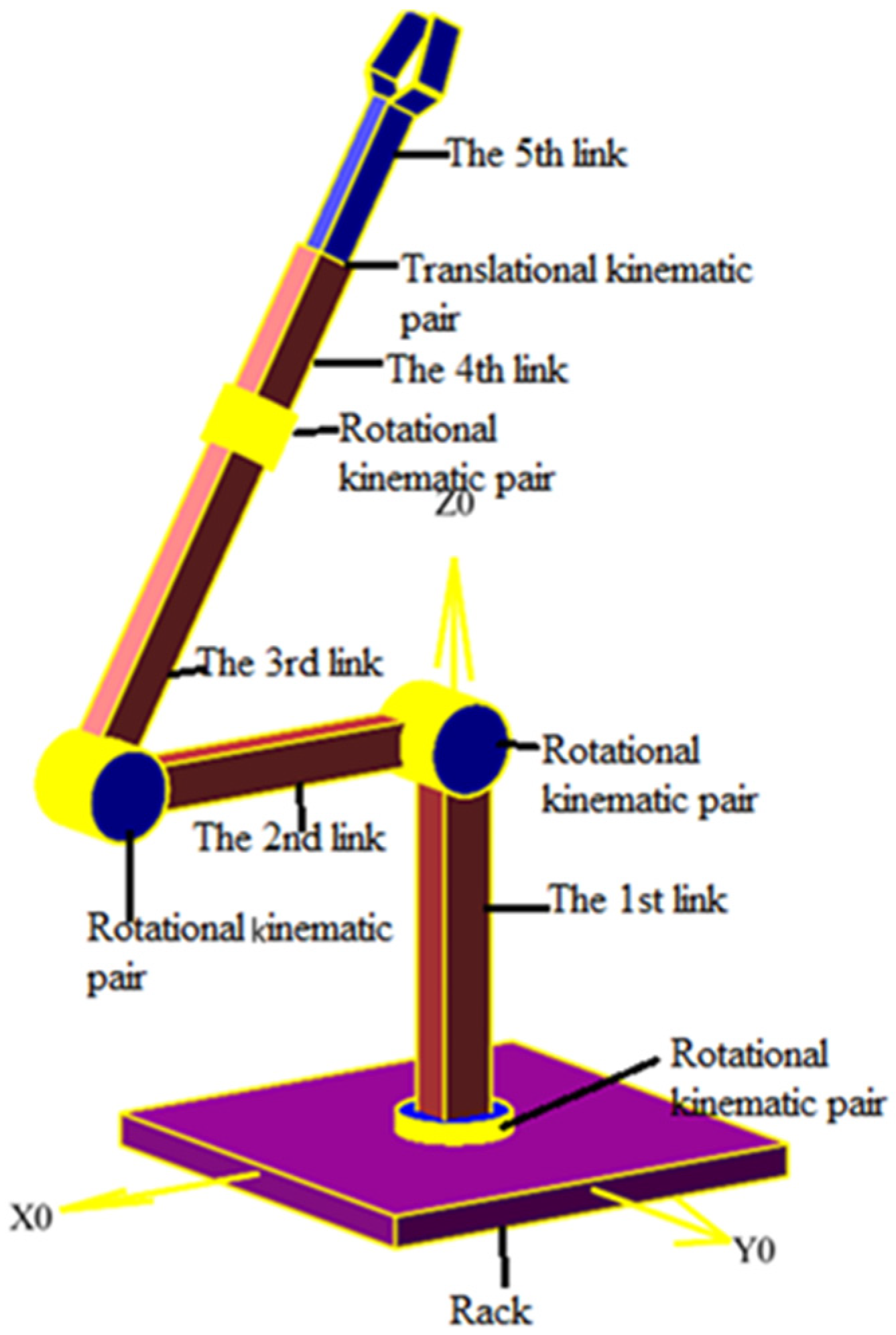

In this study, we examine a 3D model of the RRRRT manipulator (

Figure 2), controlled by generalized coordinates. To obtain numerical values for the kinematic and dynamic characteristics of the manipulator’s links, it is necessary to rigidly associate the links with Denavit–Hartenberg coordinate systems. These coordinate systems must be constructed following the rules of the Denavit–Hartenberg method.

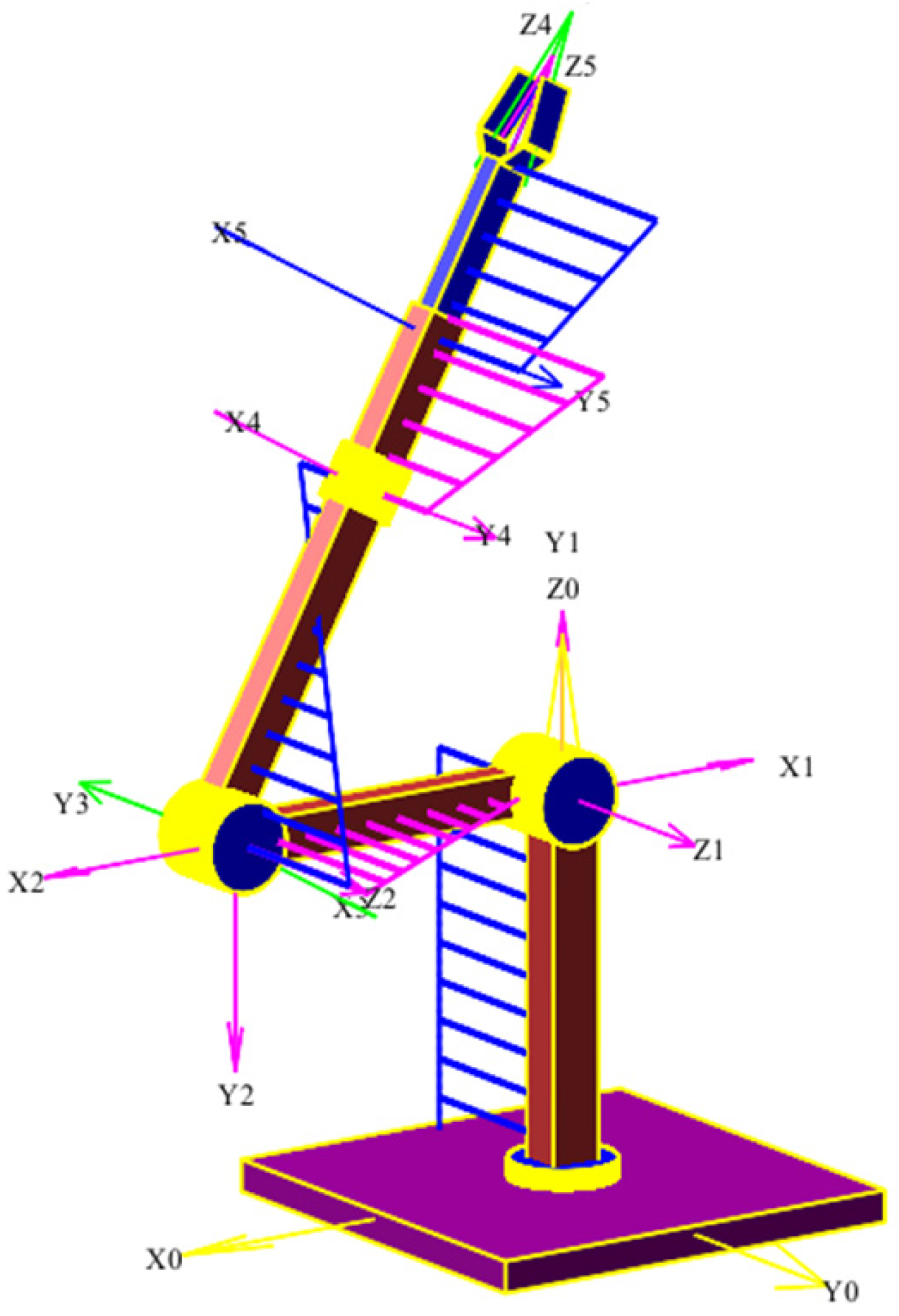

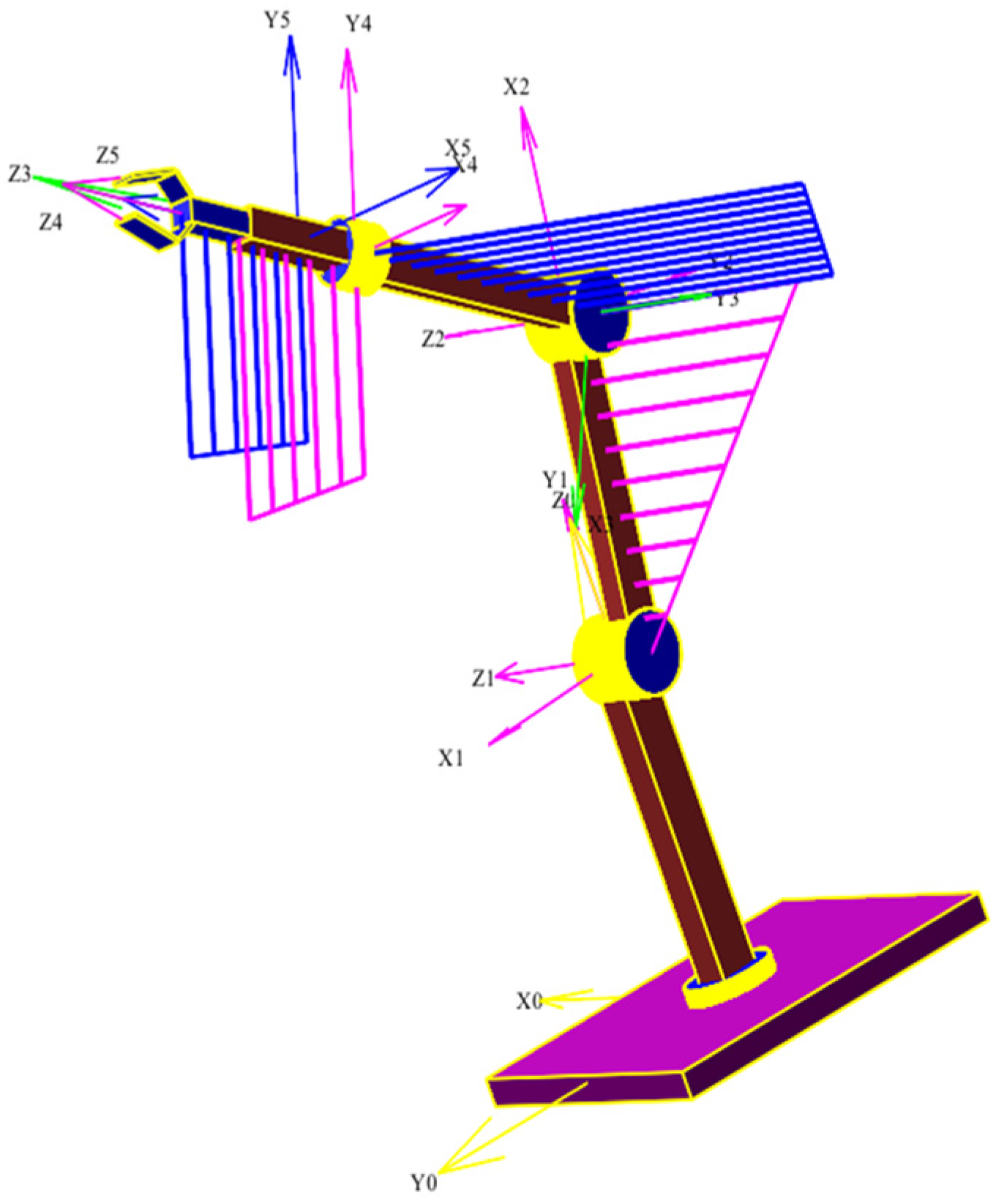

Figure 5 illustrates how the links of the considered manipulator are associated with the Denavit–Hartenberg coordinate systems.

After constructing the Denavit–Hartenberg coordinate system for the RRRRT manipulator, the parameters of these coordinate systems can be determined. These parameters are presented in

Table 1.

The generalized coordinate motion laws of the manipulator are defined as follows: , , , where the unit of time is one second, determined by the relation , where i = 0…36 represents the discrete positions of the manipulator, and k = 36 is the total number of positions; , , ; , , ; , , ; , , .

The cross-sectional areas of the manipulator’s links (unit of measurement m2) are as follows: .

The specific weights of the materials of the manipulator’s links (unit of measurement N/m3) are as follows: .

The cross-sectional dimensions of the manipulator’s links (unit of measurement m) are as follows: ; ; ; ; .

The implementation of the developed algorithms and software enabled the construction of diagrams representing the distribution of dynamic loads across all manipulator links. These diagrams are positioned in mutually perpendicular planes formed by the principal axes of the cross-sections and the longitudinal axes of the manipulator links. The results are presented in

Figure 6,

Figure 7,

Figure 8 and

Figure 9.

The diagram of the longitudinal dynamic load distributed along the Y1 axis of the first link is depicted on the Y1Z1 plane and is colored blue. The direction of the distributed longitudinal dynamic loads in the cross-sections, where the ordinates are oriented opposite to the Z1 axis, is also directed against the Y1 axis. Conversely, the direction of the distributed longitudinal dynamic forces in the cross-sections, where the ordinates are oriented toward the Z1 axis, corresponds to the direction of the Y1 axis.

The diagram of the longitudinal dynamic load distributed along the X2 axis of the second link is presented on the X2Z2 plane in magenta. If the ordinates are directed toward the Z2 axis, the distributed longitudinal dynamic loads in these cross-sections are aligned with the X2 axis. Conversely, if the ordinates are directed opposite to the Z2 axis, the load is oriented in the opposite direction.

The diagram of the longitudinal dynamic load distributed along the Z3 axis of the third link is drawn in blue on the Y3Z3 plane. If the ordinates are directed toward the Y3 axis, the distributed longitudinal dynamic loads in these cross-sections are aligned with the Z3 axis. Conversely, if the ordinates are directed in the opposite direction, the loads will be oriented in the opposite direction.

The diagram of the longitudinal dynamic load distributed along the Z4 axis of the fourth link is presented on the Y4Z4 plane in magenta. If the ordinates are directed toward the Y4 axis, the direction of the distributed longitudinal dynamic loads in these cross-sections will correspond to the Y4 axis. Conversely, if they are directed in the opposite direction, the loads will be oriented accordingly in the opposite direction.

The diagram of the longitudinal dynamic force distributed along the Z5 axis of the fifth link is presented on the Y5Z5 plane in blue. If the ordinates are directed toward the Y5 axis, the direction of the distributed longitudinal dynamic loads in these cross-sections will correspond to the Y5 axis. Conversely, if they are directed in the opposite direction, the loads will be oriented accordingly in the opposite direction.

The diagram of the transverse vertical dynamic load distributed along the X2 axis of the second link is depicted in magenta on the X2Y2 plane. If the ordinates are directed toward the Y2 axis, the distributed transverse vertical dynamic loads in these sections are also oriented toward the Y2 axis. Conversely, if the ordinates are directed in the opposite direction, the distributed transverse vertical dynamic loads will be oriented in the direction opposite to the Y2 axis.

The diagram of the transverse vertical dynamic load distributed along the Z3 axis of the third link is shown in blue on the Y3Z3 plane. If the ordinates are directed toward the Y3 axis, the distributed transverse vertical loads in these sections are aligned with the Y3 axis. Conversely, if they are directed in the opposite direction, the distributed transverse vertical dynamic loads will be oriented against the Y3 axis.

The diagram of the transverse vertical dynamic load distributed along the Z4 axis of the fourth link is presented in magenta on the Y4Z4 plane. If the ordinates are directed toward the Y4 axis, the distributed transverse vertical dynamic loads in these sections are also aligned with the Y4 axis. Conversely, if the ordinates are directed in the opposite direction, the distributed transverse vertical dynamic loads will be oriented against the Y4 axis.

The diagram of the transverse vertical dynamic load distributed along the Z5 axis of the fifth link is depicted in blue on the Y5Z5 plane. If the ordinates are directed toward the Y5 axis, the distributed transverse vertical dynamic loads in these sections are aligned with the Y5 axis. Conversely, if they are directed in the opposite direction, the distributed vertical dynamic loads will be oriented against the Y5 axis.

The diagram of the horizontal dynamic load distributed along the X2 axis of the second link is presented in magenta on the X2Z2 plane. If the constructed ordinates are directed toward the Z2 axis, the intensity of the horizontally distributed dynamic loads in these sections is also directed toward the Z2 axis. Conversely, if the ordinates are directed opposite to the Z2 axis, the intensity of the distributed horizontal dynamic loads is directed against the Z2 axis.

The diagram of the transverse horizontal dynamic load distributed along the Z3 axis of the third link is depicted in blue on the Y3Z3 plane. The ordinates constructed along the Y3 axis indicate the magnitude and direction of the intensity of the distributed horizontal dynamic load in these sections. If the ordinates are directed toward the Y3 axis, the distributed horizontal dynamic loads in these sections are also directed toward the Y3 axis. Conversely, if the ordinates are directed oppositely, the distributed horizontal dynamic loads in these sections are oriented in the opposite direction from the Y3 axis.

The diagram of the transverse horizontal dynamic load distributed along the Z4 axis is represented in magenta on the Y4Z4 plane. If the obtained ordinates are directed toward the Y4 axis, the distributed horizontal dynamic loads in these sections are also directed toward the Y4 axis. Conversely, if they are directed oppositely, the distributed horizontal dynamic loads in these sections are oriented in the opposite direction toward the Y4 axis.

The diagram of the transverse horizontal dynamic load distributed along the Z5 axis is shown in blue on the Y5Z5 plane. If the obtained ordinates are directed toward the Y5 axis, then the distributed horizontal dynamic loads in these sections are also directed toward the Y5 axis. If they are directed oppositely, then the direction of the horizontal dynamic loads in these sections will be opposite to the direction of the Y5 axis.

The diagram of the transverse horizontal dynamic load distributed along the Z5 axis is depicted in blue on the Y5Z5 plane. If the obtained ordinates are directed toward the Y5 axis, the distributed horizontal dynamic loads in these sections are also oriented toward the Y5 axis. Conversely, if they are directed oppositely, the direction of the horizontal dynamic loads in these sections will be opposite to the Y5 axis direction.

The distributed torque moments along the second link are represented in the X2Z2 plane in magenta. The direction and magnitude of the torque moment in this section are indicated by ordinates aligned along the Z2 axis. If the ordinate is directed along Z2, the torque moment in the section induces a counterclockwise rotation about the X2 axis. Conversely, if the ordinate is oriented in the opposite direction, the section rotates clockwise about the X2 axis.

The dynamically distributed torque moments on the third link are represented in the Y3Z3 plane in blue. If the ordinates are directed toward the Y3 axis, the distributed moments in these sections induce a clockwise rotation about the Z3 axis. Conversely, if the ordinates are oriented opposite to the Y3 axis, the distributed dynamic loads cause a counterclockwise rotation of the section about the Z3 axis.

The dynamically distributed torque moments on the fourth link are depicted in the Y4Z4 plane in magenta. If the ordinates are directed towards the Y4 axis, the distributed moments in these sections induce a clockwise rotation about the Z4 axis. Conversely, if the ordinates are oriented in the opposite direction to the Y4 axis, the distributed dynamic loads cause the section to rotate counterclockwise about the Z4 axis.

The dynamically distributed torque moments on the fifth link are represented in the Y5Z5 plane in blue. If the ordinates are directed towards the Y5 axis, the distributed moments in these sections induce a clockwise rotation about the Z5 axis. Conversely, if the ordinates are oriented in the opposite direction to the Y5 axis, the distributed dynamic loads cause the section to rotate counterclockwise about the Z5 axis.