Enhancing Positional Accuracy of Mechanically Modified Industrial Robots Using Laser Trackers

Abstract

1. Introduction

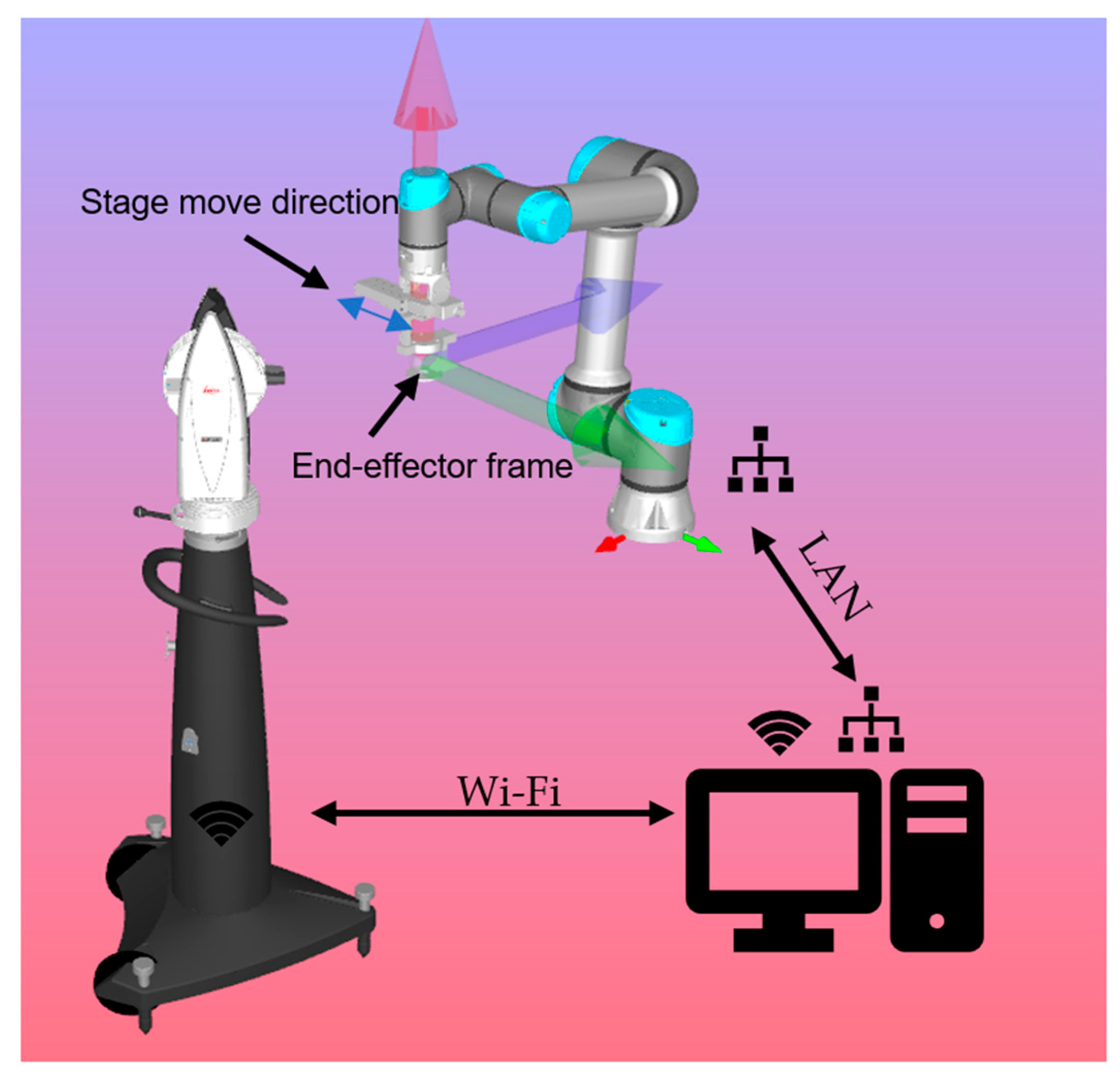

- Integrating a more accurate linear move stage as an active end effector for the industrial robot to enhance its motion resolution;

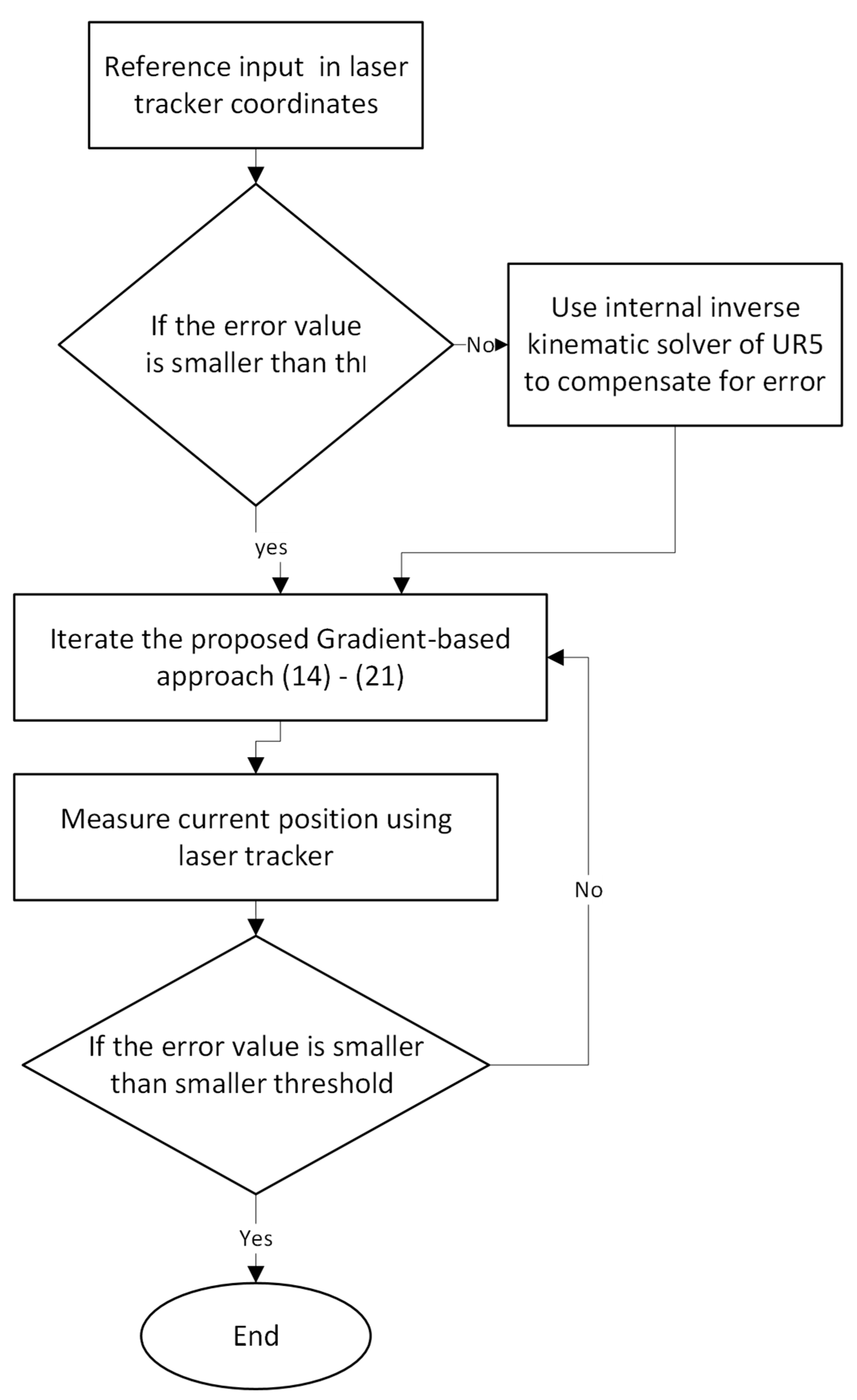

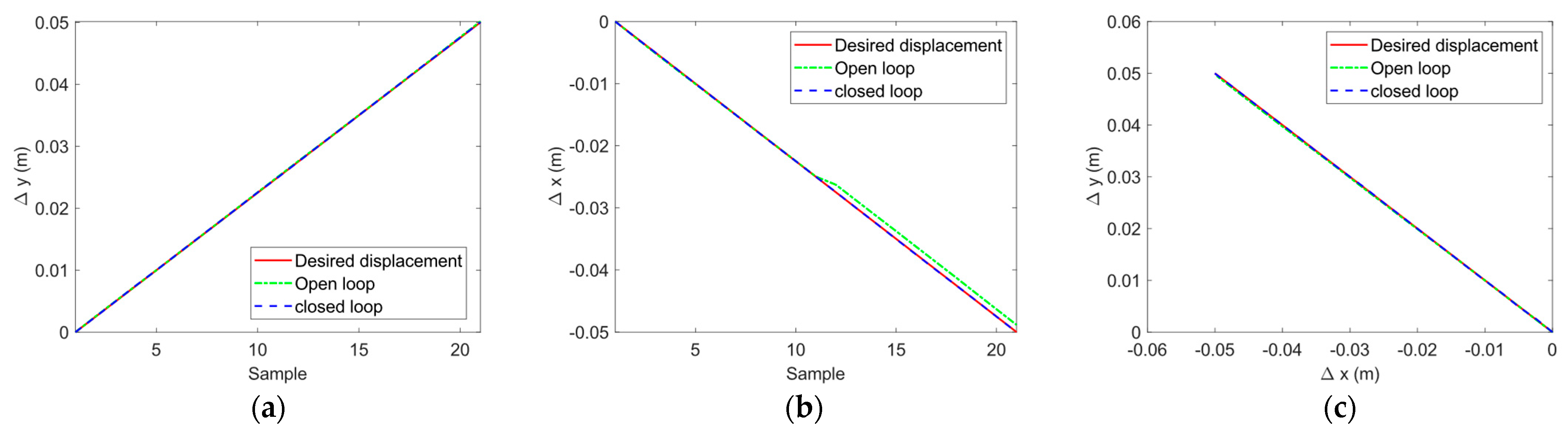

- Employing gradient descent to tune the industrial robot joint angle values and displacement of the linear move stage by using the identified forward kinematics (FK) of the overall system for the calculation of the required partial derivates of the actual position of the end effector with respect to DH parameters of the overall system.

2. Methodology

2.1. Forward Kinematics

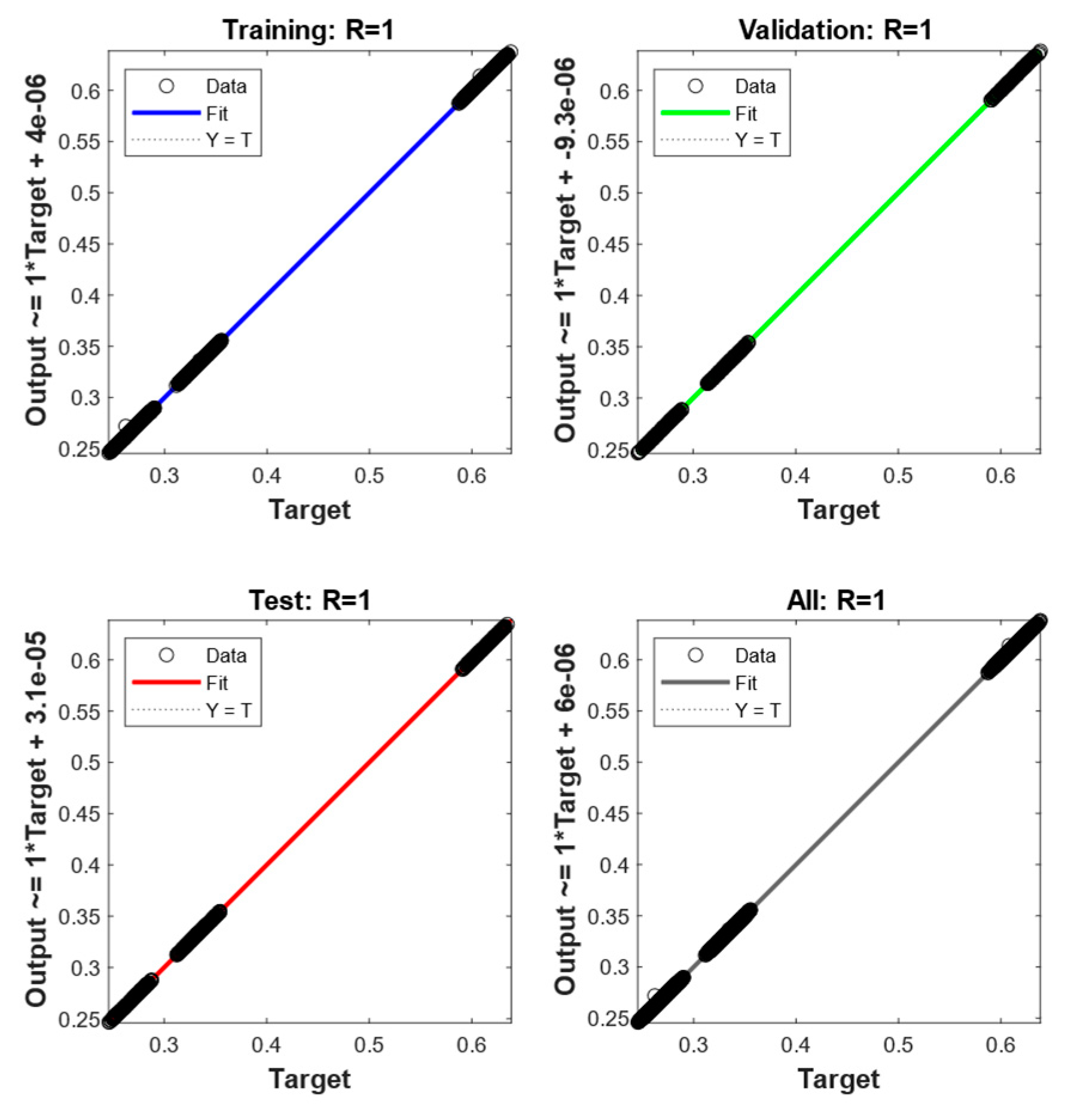

2.2. Computational Forward Kinematics Identification of the Overall System

2.3. Computational Sensitivity Analysis of the Industrial Robot FK

3. System Setup

3.1. Industrial Robot

3.2. Linear Move Stage

3.3. Laser Tracker System

3.4. Overall Connectivity

3.5. Uncertainty Analysis of the Overall System

4. Results

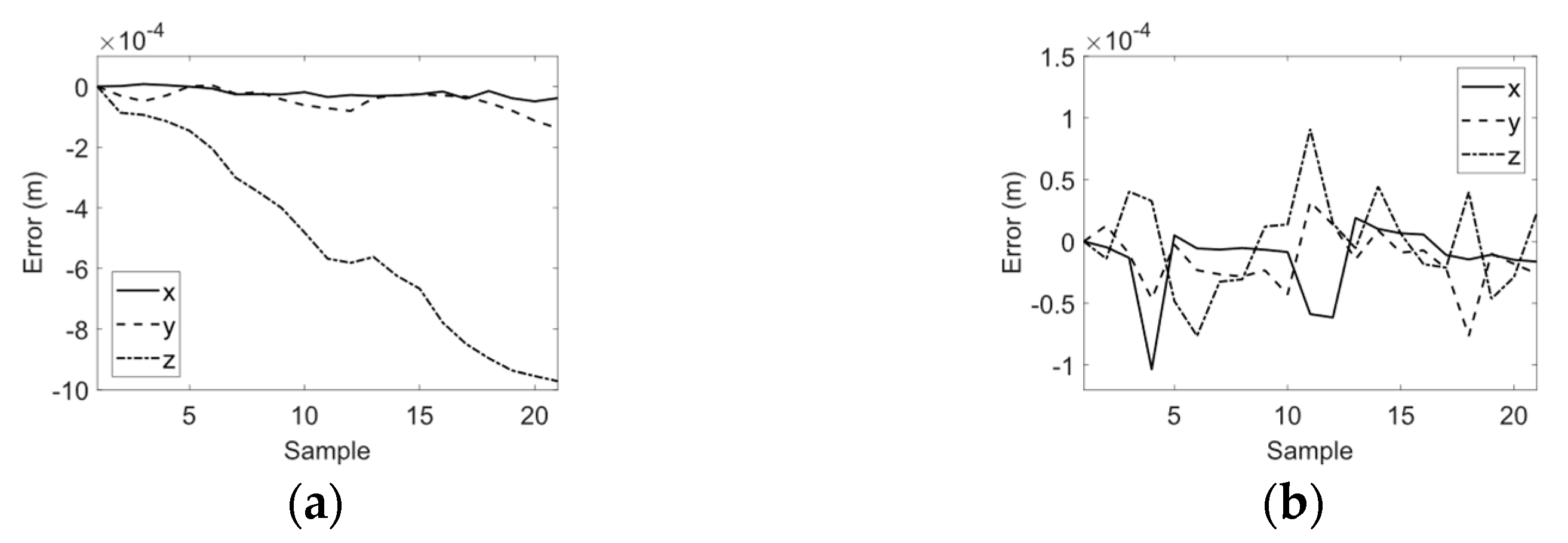

4.1. MLPNN Forward Kinematics Identification of the Overall System

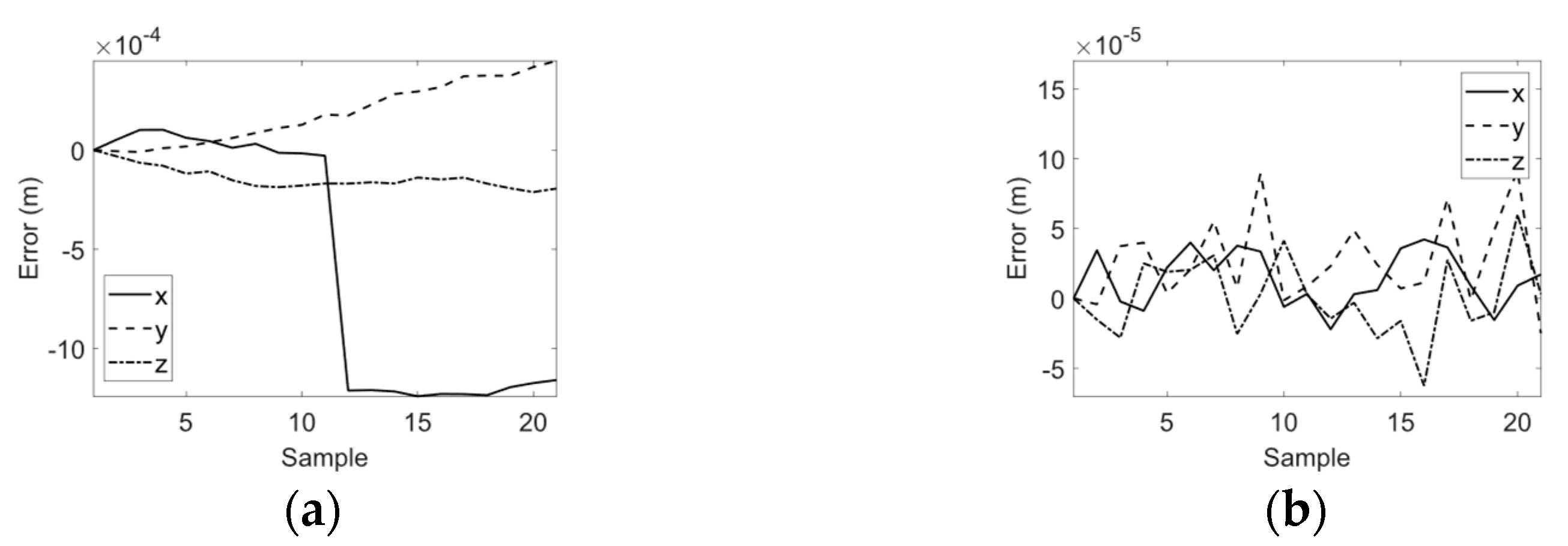

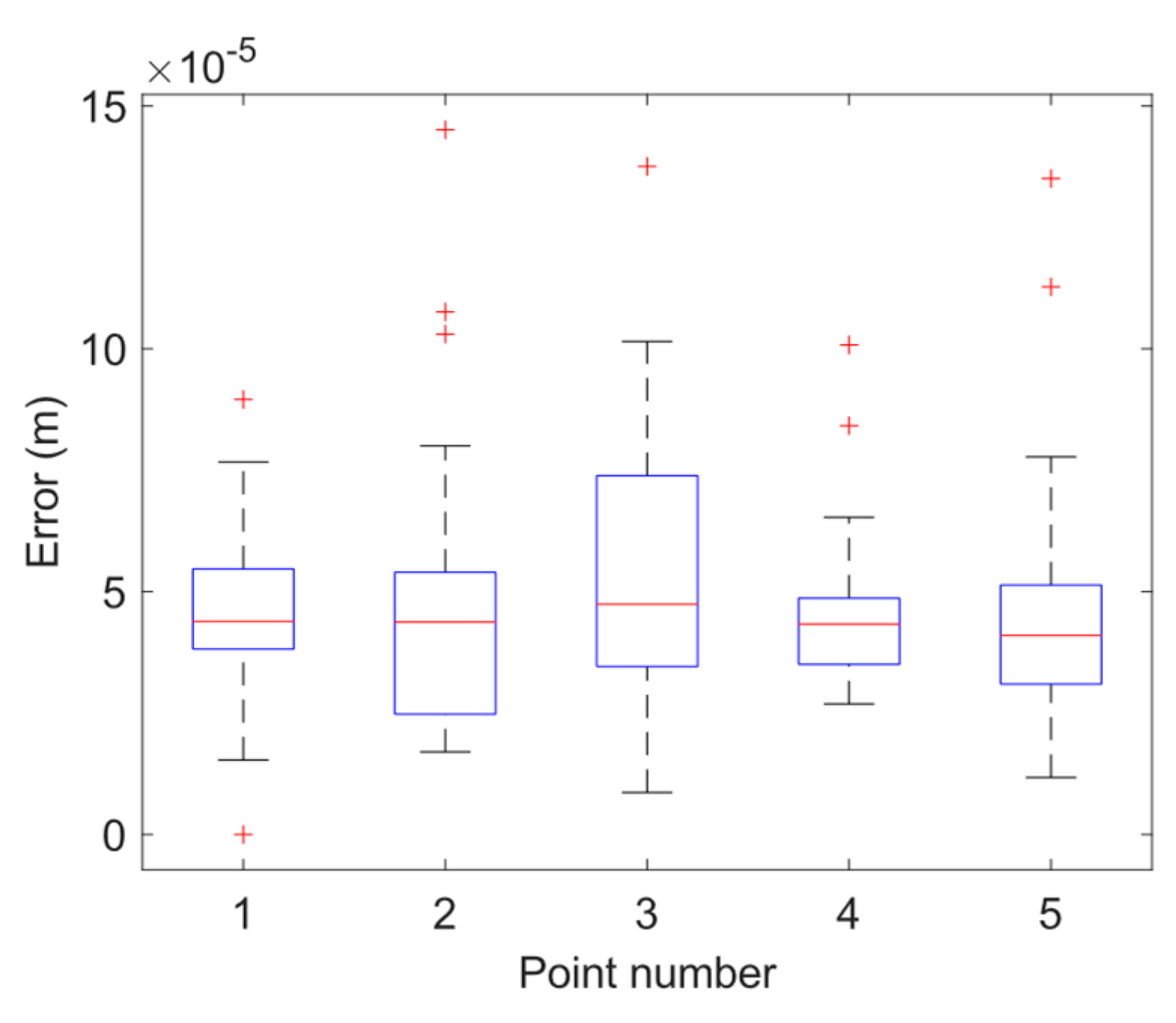

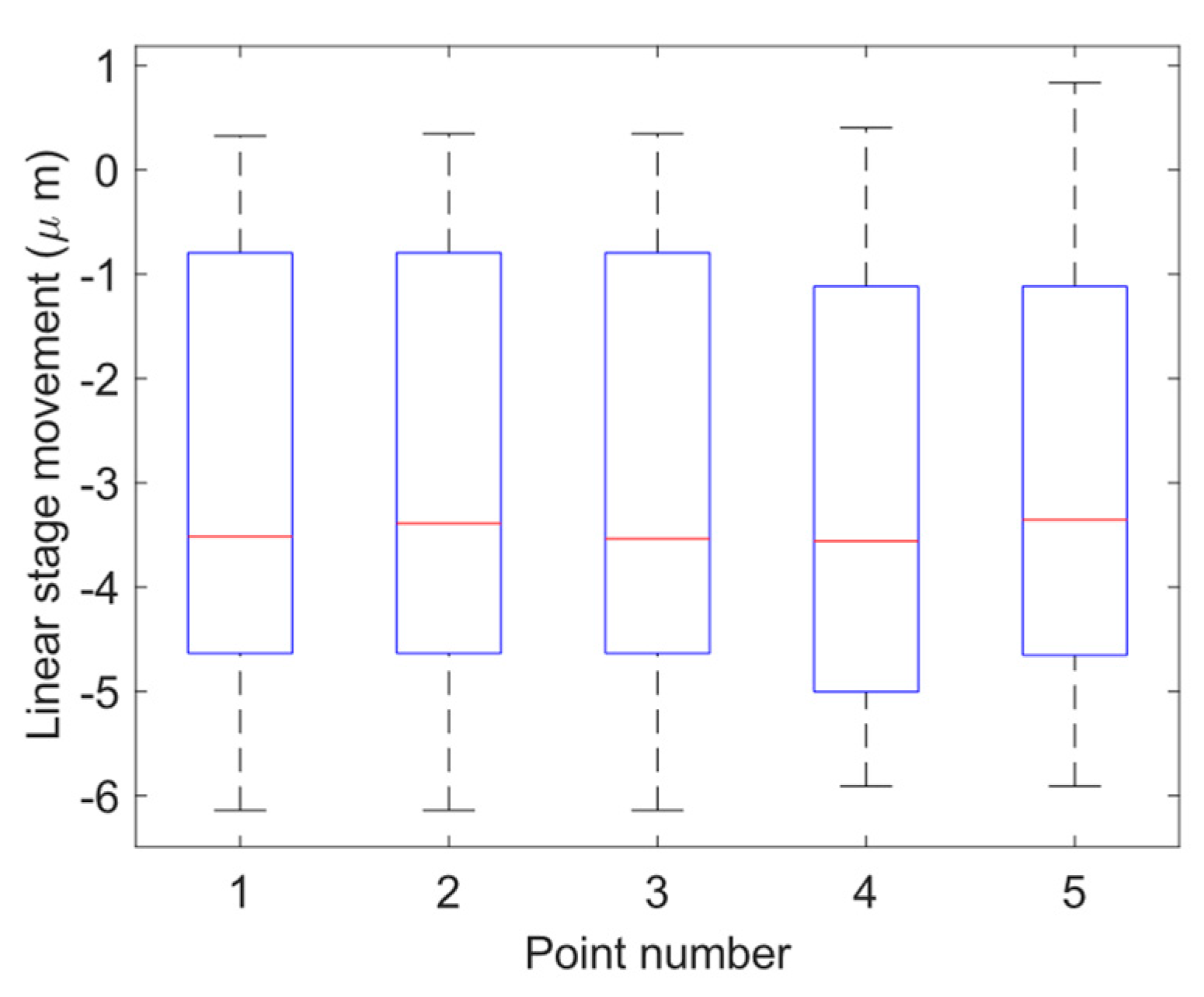

4.2. Precision Positioning of the Robot

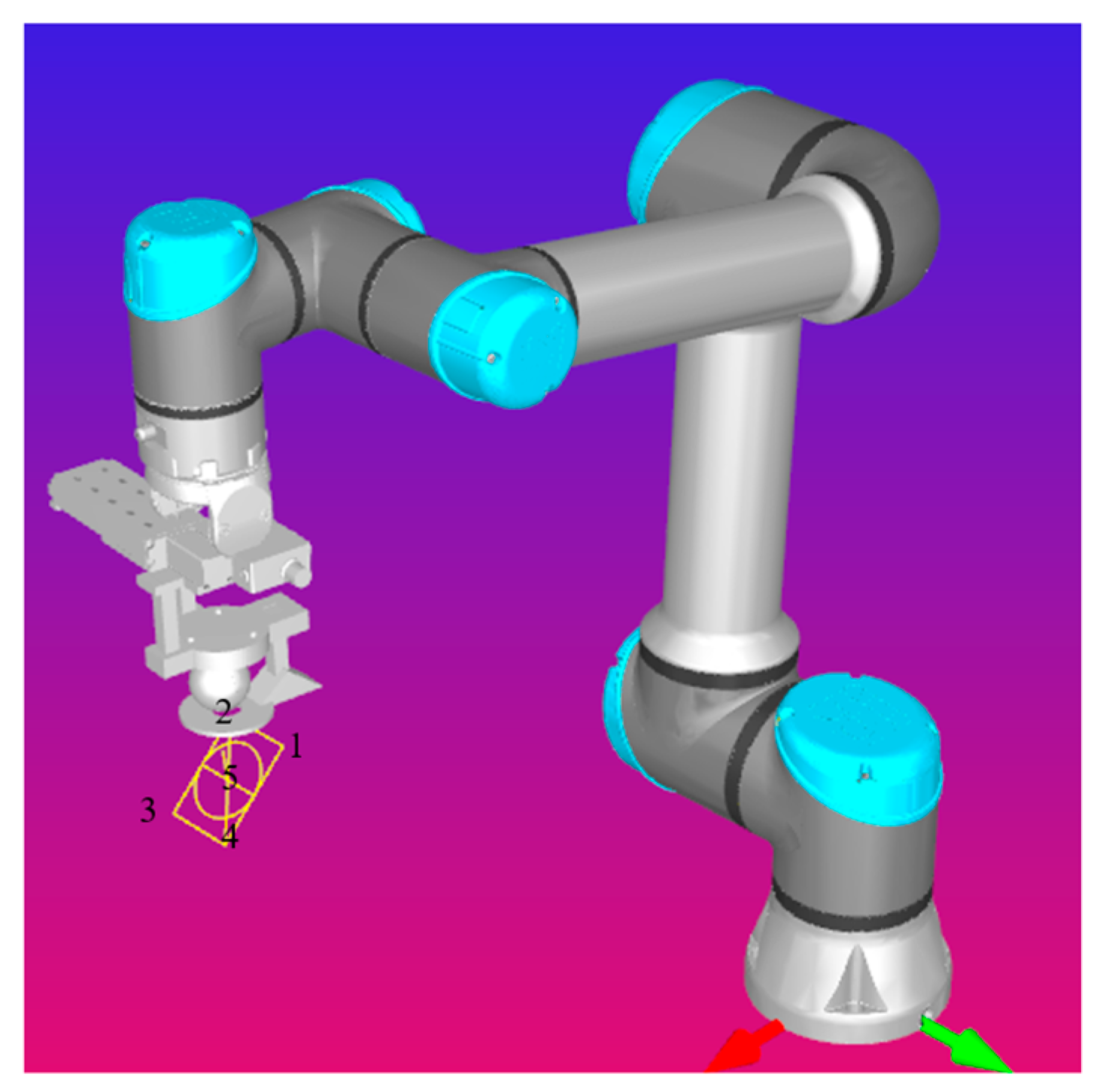

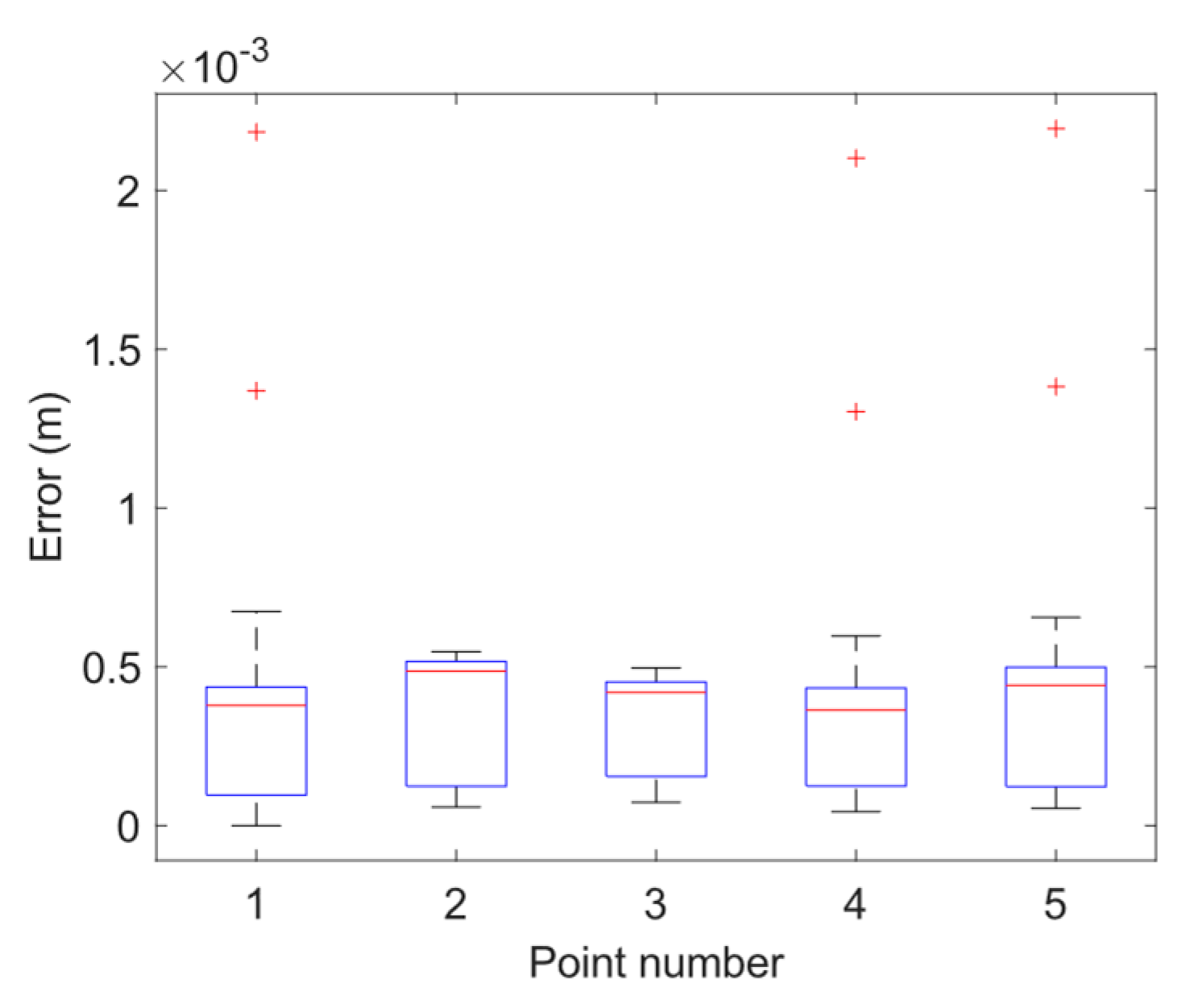

4.3. ISO 9283 Standard

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomas, S.; Rajakumari, R.; George, A.; Kalarikkal, N. Innovative Food Science and Emerging Technologies; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Ansari, R.J.; Karayiannidis, Y. Task-based role adaptation for human-robot cooperative object handling. IEEE Robot. Autom. Lett. 2021, 6, 3592–3598. [Google Scholar]

- Xu, P.; Cheung, C.F.; Wang, C.; Zhao, C. Novel hybrid robot and its processes for precision polishing of freeform surfaces. Precis. Eng. 2020, 64, 53–62. [Google Scholar]

- Yin, Y.; Zheng, P.; Li, C.; Wan, K. Enhancing human-guided robotic assembly: AR-assisted DT for skill-based and low-code programming. J. Manuf. Syst. 2024, 74, 676–689. [Google Scholar]

- Zhang, T.; Peng, F.; Tang, X.; Yan, R.; Deng, R.; Zhao, S. A sparse knowledge embedded configuration optimization method for robotic machining system toward improving machining quality. Robot. Comput. Integr. Manuf. 2024, 90, 102818. [Google Scholar]

- Wahidi, S.I.; Oterkus, S.; Oterkus, E. Robotic welding techniques in marine structures and production processes: A systematic literature review. Mar. Struct. 2024, 95, 103608. [Google Scholar]

- Xu, F.; Zi, B.; Yu, Z.; Zhao, J.; Ding, H. Design and implementation of a 7-DOF cable-driven serial spray-painting robot with motion-decoupling mechanisms. Mech. Mach. Theory 2023, 192, 105549. [Google Scholar]

- Munaro, M.; Antonello, M.; Antonello, M.; Menegatti, E. Continuous mapping of large surfaces with a quality inspection robot. Robot. Auton. Syst. 2022, 156, 104195. [Google Scholar] [CrossRef]

- PChua, Y.; Ilschner, T.; Caldwell, D.G. Robotic manipulation of food products–a review. Ind. Robot. Int. J. 2003, 30, 345–354. [Google Scholar]

- Woo, H.M.; Keasling, J. Measuring the economic efficiency of laboratory automation in biotechnology. Trends Biotechnol. 2024, 42, 1076–1080. [Google Scholar]

- Attanasio, A.; Scaglioni, B.; De Momi, E.; Fiorini, P.; Valdastri, P. Autonomy in surgical robotics. Annu. Rev. Control. Robot. Auton. Syst. 2021, 4, 651–679. [Google Scholar]

- Du, H.; Wang, G.; Wang, L.; Hao, S.; Fang, Z.; Zhou, H. A closed-loop calibration method for serial robots based on position constraints and local area measurement. Precis. Eng. 2024, 89, 121–134. [Google Scholar]

- Khanesar, M.A.; Yan, M.; Isa, M.; Piano, S.; Branson, D.T. Precision Denavit–Hartenberg Parameter Calibration for Industrial Robots Using a Laser Tracker System and Intelligent Optimization Approaches. Sensors 2023, 23, 5368. [Google Scholar] [CrossRef] [PubMed]

- Kluz, R.; Kubit, A.; Trzepiecinski, T. Investigations of temperature-induced errors in positioning of an industrial robot arm. J. Mech. Sci. Technol. 2018, 32, 5421–5432. [Google Scholar]

- Sigron, P.; Aschwanden, I.; Bambach, M. Compensation of Geometric, Backlash, and Thermal Drift Errors Using a Universal Industrial Robot Model. IEEE Trans. Autom. Sci. Eng. 2023, 21, 6615–6627. [Google Scholar]

- Ma, S.; Deng, K.; Lu, Y.; Xu, X. Error compensation method of industrial robots considering non-kinematic and weak rigid base errors. Precis. Eng. 2023, 82, 304–315. [Google Scholar]

- Ueno, Y.; Tachiya, H. Suppressing residual vibration caused in objects carried by robots using a heuristic algorithm. Precis. Eng. 2022, 80, 1–9. [Google Scholar]

- Aoyagi, S.; Kohama, A.; Nakata, Y.; Hayano, Y.; Suzuki, M. Improvement of robot accuracy by calibrating kinematic model using a laser tracking system-compensation of non-geometric errors using neural networks and selection of optimal measuring points using genetic algorithm. In Proceedings of the 2010 IEEE/RSJ International conference on intelligent robots and systems, Taipei, Taiwan, 30 October–5 November 2010; pp. 5660–5665. [Google Scholar]

- Bai, M.; Zhang, M.; Zhang, H.; Li, M.; Zhao, J.; Chen, Z. Calibration method based on models and least-squares support vector regression enhancing robot position accuracy. IEEE 2021, 9, 136060–136070. [Google Scholar]

- Duong, Q.K.; Trang, T.T.; Pham, T.L. Robot Control Using Alternative Trajectories Based on Inverse Errors in the Workspace. J. Robot. 2021, 2021, 1–8. [Google Scholar]

- Nguyen, H.-N.; Zhou, J.; Kang, H.-J. A calibration method for enhancing robot accuracy through integration of an extended Kalman filter algorithm and an artificial neural network. Neurocomputing 2015, 151, 996–1005. [Google Scholar] [CrossRef]

- Cao, S.; Cheng, Q.; Guo, Y.; Zhu, W.; Wang, H.; Ke, Y. Pose error compensation based on joint space division for 6-DOF robot manipulators. Precis. Eng. 2022, 74, 195–204. [Google Scholar]

- Yin, Y.; Gao, D.; Deng, K.; Lu, Y. Vision-based autonomous robots calibration for large-size workspace using ArUco map and single camera systems. Precis. Eng. 2024, 90, 191–204. [Google Scholar]

- Nguyen, H.-N.; Le, P.-N.; Kang, H.-J. A new calibration method for enhancing robot position accuracy by combining a robot model–based identification approach and an artificial neural network–based error compensation technique. Adv. Mech. Eng. 2019, 11, 1687814018822935. [Google Scholar]

- Tao, Y.; Liu, H.; Chen, S.; Lan, J.; Qi, Q.; Xiao, W. An Off-Line Error Compensation Method for Absolute Positioning Accuracy of Industrial Robots Based on Differential Evolution and Deep Belief Networks. Electronics 2023, 12, 3718. [Google Scholar] [CrossRef]

- ISO 9283-1998; Manipulating Industrial Robots Performance Criteria and Related Test Methods. ISO: Geneva, Switzerland, 1998.

- Robodk. 5 March 2025. Available online: https://robodk.com/doc/en/Robot-Validation-ISO9283.html (accessed on 22 March 2025).

- ISO 10218-1:2011; Robot for Industrial Environments—Safety Requirements—Part 1: Robot. Technical Report; International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 10218-2:2011; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 2: Robot Systems and Integration. International Organization for Standardization: Geneva, Switzerland, 2011.

- Kufieta, K. Force Estimation in Robotic Manipulators: Modeling, Simulation and Experiments; Department of Engineering Cybernetics NTNU Norwegian University of Science and Technology: Trondheim, Norway, 2014. [Google Scholar]

- Sun, J.-D.; Cao, G.-Z.; Li, W.-B.; Liang, Y.-X.; Huang, S.-D. Analytical inverse kinematic solution using the DH method for a 6-DOF robot. In Proceedings of the 2017 14th international conference on ubiquitous robots and ambient intelligence (URAI), Jeju, Republic of Korea, 28 June–1 July 2017; pp. 714–716. [Google Scholar]

- Chen, T.; Lin, J.; Wu, D.; Wu, H. Research of calibration method for industrial robot based on error model of position. Appl. Sci. 2021, 11, 1287. [Google Scholar] [CrossRef]

- Pollák, M.; Kočiško, M.; Paulišin, D.; Baron, P. Measurement of unidirectional pose accuracy and repeatability of the collaborative robot UR5. Adv. Mech. Eng. 2020, 12, 1687814020972893. [Google Scholar] [CrossRef]

- Wu, X. Analysis of robot joint rotation error for manufacturing and mechatronics integration. Int. J. Interact. Des. Manuf. IJIDeM 2024, 18, 2503–2516. [Google Scholar]

- Khanesar, M.A.; Piano, S.; Branson, D. Uncertainty analysis of an augmented industrial robot. In Proceedings of the Joint Special Interest Group Meeting between Euspen and ASPE Advancing Precision in Additive Manufacturing, Leuven, Belgium, 19–21 September 2023. [Google Scholar]

- Dusek, J.E.; Triantafyllou, M.S.; Lang, J.H. Piezoresistive foam sensor arrays for marine applications. Sens. Actuators A Phys. 2016, 248, 173–183. [Google Scholar] [CrossRef]

- Castellanos-Ramos, J.; Navas-González, R.; Fernández, I.; Vidal-Verdú, F. Insights into the mechanical behaviour of a layered flexible tactile sensor. Sensors 2015, 15, 25433–25462. [Google Scholar] [CrossRef]

- Arrington, C.B.; Rau, D.A.; Williams, C.B.; Long, T.E. UV-assisted direct ink write printing of fully aromatic Poly (amide imide) s: Elucidating the influence of an acrylic scaffold. Polymer 2021, 212, 123306. [Google Scholar]

| Link | ||||

|---|---|---|---|---|

| 1 | 0 | |||

| 2 | 0 | 0 | ||

| 3 | 0 | 0 | ||

| 4 | 0 | |||

| 5 | 0 | |||

| 6 | 0 | 0 |

| Closed Loop | Open Loop | |||

|---|---|---|---|---|

| Avg. (µm) | Std. (µm) | Avg. (µm) | Std. (µm) | |

| Case I | 47.3 | 31.0 | 506.7 | 681.6 |

| Case II | 47.9 | 26.9 | 468.2 | 321.0 |

| Case III | 55.4 | 35.3 | 576.5 | 288.7 |

| Closed Loop | Open Loop | |||

|---|---|---|---|---|

| Avg. (µm) | Std. (µm) | Avg. (µm) | Std. (µm) | |

| Point 1 | 45.6 | 18.2 | 366.0 | 439.2 |

| Point 2 | 48.4 | 29.9 | 330.3 | 204.2 |

| Point 3 | 54.2 | 25.1 | 307.1 | 159.6 |

| Point 4 | 45.3 | 15.9 | 367.3 | 411.9 |

| Point 5 | 45.0 | 25.8 | 415.9 | 433.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanesar, M.A.; Karaca, A.; Yan, M.; Isa, M.; Piano, S.; Branson, D. Enhancing Positional Accuracy of Mechanically Modified Industrial Robots Using Laser Trackers. Robotics 2025, 14, 42. https://doi.org/10.3390/robotics14040042

Khanesar MA, Karaca A, Yan M, Isa M, Piano S, Branson D. Enhancing Positional Accuracy of Mechanically Modified Industrial Robots Using Laser Trackers. Robotics. 2025; 14(4):42. https://doi.org/10.3390/robotics14040042

Chicago/Turabian StyleKhanesar, Mojtaba A., Aslihan Karaca, Minrui Yan, Mohammed Isa, Samanta Piano, and David Branson. 2025. "Enhancing Positional Accuracy of Mechanically Modified Industrial Robots Using Laser Trackers" Robotics 14, no. 4: 42. https://doi.org/10.3390/robotics14040042

APA StyleKhanesar, M. A., Karaca, A., Yan, M., Isa, M., Piano, S., & Branson, D. (2025). Enhancing Positional Accuracy of Mechanically Modified Industrial Robots Using Laser Trackers. Robotics, 14(4), 42. https://doi.org/10.3390/robotics14040042